Abstract

The wear rate of diamond wire saw plays a vital role in the performance of sawing process. Predicting the sawing performance is very important in the production’s cost estimation and planning of the dimension stone quarries. In this research, an adaptive neuro-fuzzy inference system (ANFIS) is applied to estimate the wear rate of diamond wire saw under uncertain processes; hence, indirect prediction in ANFIS is carried out using subtractive clustering method (SCM) and fuzzy c-means clustering method based on four effective rock properties, such as Shore hardness, Schimazek’s F-abrasivity, uniaxial compressive strength and Young modulus. For this purpose, 38 rock samples were selected to test the proposed model from Turkey quarries. The results of indirect prediction indicated that the best performed model was related to ANFIS-SCM with highly acceptable degrees of accuracy 0.998 and 0.59 for R2 of the train and test data sets, respectively. In addition, group method of data handling type of neural network is used to assess the factors influencing the wear rate of the diamond wire saw. A sensitivity analysis was performed on the laboratory test results of studied rocks using three methods. In comparison to the existing models, the estimated results showed that a satisfactory performance could be obtained using the proposed ANFIS-subtractive clustering method.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Nowadays, diamond wire cutting (DWC) in dimension Stone industry (plan and quarry) has an excessive significance in spite of its economic and technological problems. The wear rate of the diamond wire does not affect so much operating costs when marbles or limestones are extracted. It is worth mentioning that the consumption of DW plays a key role in abrasive stones such as granites. This is very important for optimization and other technological studies related to the DWC (Careddu and Marras 2015).

In DWC method, after the complete preparation for production, the vertical and horizontal holes perpendicular to each other are drilled on blocks. Diamond wire is threaded through these holes and mounted around the drive wheel of the cutting machine. Then, it is rotated with the drive wheel’s movement. Tension and rotation forces required for cutting are provided by the movement of a diamond wire-cutting machine away from the cut surface on the rail. Water is applied with spin direction of the wire as a coolant and as a means of removing the particles (Özçelik and Bayram 2004). A schematic figure of DWC layout is shown in Fig. 1.

Schematic presentation of a diamond wire-cutting layout (Özçelik et al. 2002)

Up to now, the performance evaluation of diamond wire cutting has been well studied in the literature. Some of these studies have been done on sawability of dimension stone and some relationships have been presented among rock properties and cutting rate, wear rate and energy consumption. The performance of the diamond wire saw in the hard rocks’ cutting process was studied by Ciccu et al. (1998). The wear rate of diamond beads in the cutting process of different dimension stone types was investigated by Özçelik et al. (2002) using the regression analyses. The effect of dimension stone properties on the diamond wire saw’s performance such as the diamond wire cutting rate and wear were studied by Agus et al. (2003) using a multiple regression approach. The diamond wire cutting process was studied by Özçelik (2005) to obtain the optimum working conditions of cutting machines in the marble industry. The influence of operating parameters on the performance of diamond wire in cutting of granite was studied by Cai et al. The results showed that the peripheral speed of the diamond wire is important for tool life and energy consumption (Cai et al. 2007). The production rate of the diamond wire saw was investigated by Ataei et al. (2012) using the statistical analysis. The performance of diamond wire saw with respect to texture characteristics of carbonate rock was studied by Ghaysari et al. (2012). The production rate of diamond wire saws was predicted by Sadegheslam et al. (2013) using the multiple nonlinear regression analysis and artificial neural network. The granite sawing using the diamond wire saw was studied by Careddu and Cai (2014). This study focused on the diamond wire technology. The difference between multi-wires and older technologies was discussed in terms of their both economic and environmental issues. The effect of cutting wire tension on the production rate of diamond wire in the cutting of travertine was studied by Almasi et al. (2015). The harmony search algorithm was used by Mikaeil et al. (2016) for evaluating the performance of the diamond wire. The diamond wire saw in basalt quarries was studied by Careddu et al. This study provided a technical, economic and environmental assessment of the diamond wire used in the quarrying basalt (Careddu et al. 2017).

Artificial intelligence (AI) techniques have been the most appropriate scientific tools to deal with imprecision and vagueness of human knowledge, complex phenomena and systems for assessment of different types of industrial, political, engineering, social and environmental problems in recent decades (Berry et al. 1989; Bortolussi et al. 1990; Rad et al. 2012; Fattahi 2016; Haghshenas et al. 2016a, b; Salemi et al. 2017; Aryafar et al. 2018; Mikaeil et al. 2018a, b). Recently, aside from traditional methods and empirical equations available, the use of these approaches have been used successfully for modeling and prediction in field of rock mechanics. Hence, this research presents three AI techniques, namely ANFIS-SCM, ANFIS-FCM, GMDH-type neural network to predict the performance of sawing process through cutting operations. The major advantages of these methods are their capability of tolerate imprecision, simulation of uncertainty systems and vague data. Adaptive ANFIS and GMDH type of neural networks are used as other statistical tools. Several effective rock properties such as Shore hardness, Schimazek’s F-abrasivity, uniaxial compressive strength and Young modulus are used as input data and wear on beads is considered as an output to the prediction of the diamond wire cutting’s performance. The root mean square error (RMSE), the mean square error (MSE) and the squared correlation coefficient (R2) of the train and test data are considered to assess ANFIS and GMDH-type neural network models. In fact, this study is aimed to investigate the application and efficiency of the artificial intelligence to evaluate the performance of diamond beads through cutting operations. This paper is organized as follows. In Sect. 2, ANFIS, SCM, FCM are described. In Sect. 3, GMDH is explained. The study areas and laboratory studies are presented in Sect. 4. The application of ANFIS-based SCM and FCM are discussed in Sect. 5. Section 6 describes the application of GMDH-type artificial neural networks (ANN) and sensitive analysis with ANFIS model. In Sect. 7, conclusions and recommendations for future studies are presented.

2 Adaptive Network-Based Fuzzy Inference System (ANFIS)

One of the most common Neuro-fuzzy systems performed for Sugeno fuzzy system in a neural structure is ANFIS model. The typical mathematical tools such as differential equations are not appropriate and efficient for modeling complex and uncertain systems. ANFIS model proposed in 1993 is a combined complex form of ANN and FIS (Jang 1993; Kasabov 2001). ANFIS model is an appropriate model for predicting complex conditions and problems under uncertainty due to the learning power of ANN model on the one hand, and application of logic and formation of rule base and fuzzy data on the other hand, and is capable of modeling qualitative aspects of human knowledge and reasoning processes very accurately without using the quantitative analysis (Kasabov et al. 2013; Kecman 2001). In fact, the structure of adaptive network includes a set of connected nodes which are directly interconnected, where each node is considered as a processing unit. In ANFIS model as an adaptive model of this structure, there is no limitation on the functions of nodes, except that they must be differentiable section by section. In terms of effectiveness, the Neuro-fuzzy network corresponds to the fuzzy inference system (FIS).

ANFIS model has a high capability in modeling and mapping input–output data. The structure of ANFIS model includes 5 layers based on Fig. 2 which is defined as follows:

The first layer: in each node i in this layer, using the membership functions (MFs), each node produces the membership belonging to each of the appropriate fuzzy sets based on Eq. (1).

where Ql,i is the membership degree of the fuzzy set and \(\mu\) is the membership function. In these equations, x and y are the inputs of node i, and Ai and Bi are linguistic labels relating to this node.

The second layer: Each node in this layer is formed by a node called II which its output is the multiplication of all input signals based on Eq. (2). In this layer, each output node indicates the firing strength of a rule. In fact, in this layer, operator “AND” was used.

The third layer: In this layer, each node is named with N fixed label which in ith node, the ratio of ith rule’s firing strength is calculated based on Eq. (3) for all rules’ firing strength.

where \(\bar{W}_{i}\) is the output of this layer and is called normalized firing strengths.

The fourth layer: Each node i in this layer is matched with functions’ node based on Eq. (4). In Eq. (4), \(\bar{W}_{i}\) is the output of the third layer and is called normalized firing strengths. pi, qi and ri are parameters of this node which are considered as inductive parameters of the fuzzy model section.

The fifth layer: This layer is only one node with label \(\sum\) which calculates all outputs from the total input signals based on Eq. (5). Therefore, in this layer, obtained fuzzy results are calculated based on defuzzifier rules in the form of non-fuzzy output.

Neuro-fuzzy model makes it possible for fuzzy systems to use adaptive back propagation training algorithm in parameters training topics. In this method, using error gradient descend algorithm, the error rate is distributed toward inputs and parameters are corrected. This training method is exactly like the error back propagation method used in artificial neural networks. In fact, in artificial neural networks, this method is known as error back propagation method.

2.1 Subtractive Clustering Method (SCM)

SCM was first introduced by Chiu (1994). This technique is one of the most efficient methods for determining the number of clusters and initial position of clusters’ centers. In the subtractive clustering technique, each sample point is considered as a potential cluster center. The cluster center of all data was determined using SCM. Then, automatic membership functions, rule base and the location of MF within dimensions were generated using the numbers of subtractive centers.

At the beginning of SCM process, a set of data points \(\left\{ {x_{1} ,x_{2} ,x_{3} , \ldots ,x_{n} } \right\}\) is considered in the m-dimensional space. Then, each data point such as \(x_{i}\) is considered as the center of cluster for this set and a density measure is determined for that \(x_{i}\) based on Eq. (6).

where \(D_{i}\) is the density measure for \(x_{i}\)·\({\text{r}}_{\text{a}}\) indicates a neighborhood radius as a positive constant for each data point under study. In addition, a data point with a high density in the neighborhood radius has many neighboring data points in this domain (radius). Data points outside the domain of \({\text{r}}_{\text{a}}\) radius do not have any high and indirect effect on the determination of the density amount, but they impose a low impact on the amount of density. In the next step, the first center of cluster from among data points reaches a data point with the highest amount of density, and \(x_{c1}\) and \(D_{c1}\) are determined as the center and amount of density in the first cluster, respectively (Jang et al. 1997). Then, the density of other \(x_{i}\) is calculated based on Eq. (7).

where \({\text{r}}_{\text{b}}\) indicates a positive constant defining a neighborhood which includes measurable reductions in the density measure.

Then, the amount of density for the next data point is calculated and \(x_{c2}\) is determined and the process of algorithm is corrected and updated until the required number of clusters is obtained.

2.2 Fuzzy C-Means (FCM) Clustering Technique

One of the unsupervised learning methods is clustering, through which data are divided into clusters with the most familiar members. Therefore, FCM clustering method was proposed by Bezdak using the fuzzy logic and membership degree concept based on the generalization and extension of Hard C-mean (HCM) method (Bezdek et al. 1984). This clustering technique is one of the most efficient clustering methods for the optimal management of a system. Fuzzy clustering technique has different applications, including risk management of mechanized tunnels based on the evaluation of geological units (Haghshenas et al. 2016a, b), investigation of the effects of freezing on the resistance of stones (Mikaeil et al. 2016) and evaluation of Cretaceous stones (Rad et al. 2014).

The beginning of algorithm for determining the number of clusters (\(c\)) is between larger than or equal to 2 and smaller than or equal to \(n\) (number of samples). Then, by determining \(m^{\prime}\) index as the weighting factor for the amount of fuzziness in the clustering process, the clustering process is started. \(U^{\left( 0 \right)}\) is guessed as initial partition matrix and each step or replication of this algorithm is determined by r value. Then, the center of clusters \(\left\{ {V_{i}^{\left( r \right)} } \right\}\) per replication is calculated and the partitioned matrix for rth replication is updated as \(\tilde{U}^{\left( r \right)}\). The process is defined based on Eqs. (8) to (12).

where \(\mu_{ik}^{{\left( {r + 1} \right)}}\) indicates the membership degree of kth data in ith cluster for \(r + 1\) replication of algorithm. \(d_{ik}\) is the Euclidean distance (distance function) between the center of ith cluster and kth data and can be ordered in the form of vector (Bezdek et al. 1984; Das and Basudhar 2009).

In the last step, the result obtained from clustering or in other words, the accuracy of algorithm \(\varepsilon_{L}\) is evaluated. If Eq. (13) is satisfied, the result of clustering achieved an appropriate optimization. Under this condition, the computations can be stopped. Otherwise, the computation process returns to the previous steps and this ring will continue up to an acceptable level of algorithm’s accuracy for optimization.

3 Group Method of Data Handling (GMDH)-Type Neural Networks

GMDH was proposed by Ivakhnenko as an algorithm based on the neural network for solving complex and imprecise problems (Ivakhnenko 1968). GMDH algorithm can directly determine and obtain information about the objective function through sampling data. This algorithm is a self-organized and unilateral neural network formed by several layers and neurons. In fact, GMDG-type neural network includes a set of neurons which is resulted from combining different pairs of a quadratic polynomial (Ivakhnenko 1971; Sheikholeslami et al. 2014; Bagheri-Esfe and Safikhani 2016). By combining quadratic polynomials resulted from all neurons, the algorithm produces an approximate function (proper mapping) with output for a set of inputs such as \(x = \left\{ {x_{i1} ,x_{i2} ,x_{i3} , \ldots ,x_{im} } \right\}\) with the minimum possible error compared to output y based on Eq. (14).

The general form of GMDH basic neural network’s mapping for input data based on output data can be obtained according to Eq. (15). It is also called Ivakhnenko polynomial.

where m is the number of data for values \(x_{1} ,x_{2} ,x_{3} , \ldots ,x_{m}\) for an output such as y. GMDH-type neural networks is very efficient for systems’ modeling, prediction, optimization and identification of non-linear patterns (Ivakhnenko and Ivakhnenko 1995).

4 Study Areas and Laboratory Studies

This study investigated 38 different kinds of dimension stones by laboratory and field studies. In field studies, the wear rate of beads is measured, while laboratory tests provided us physical and mechanical characteristics of rocks. Block cutting was performed on three different rock types consisting of ten limestone, thirteen marble and fifteen andesite samples. At least three cutting operations were performed for each rock type on-site, and their averages were taken and recorded as a representative on-site measurement. Location map of the investigated marble quarry areas under consideration is shown in Fig. 3.

In this study, the wear values of diamond bead were measured after a series of cutting tests in each studied rock type using a digital micrometer. At the end of the cutting test, the diameters of selected beads were measured two times at points A–AI, B–BI, C–CI, D–DI and E–EI, as shown in Fig. 4. The average of the differences between the diameter values before and after the cutting operation gave the average wear amount on the diamond beads. The wear rate of each diamond bead was calculated from these average wears. The characteristics of studied rocks including Shore hardness, Schimazek’s F-abrasivity, uniaxial compressive strength and Young modulus and wear rate of beads are given in Table 1. These data sets of rock properties are used for training and testing the constructing models.

5 Prediction of Wear Rate Using ANFIS Models

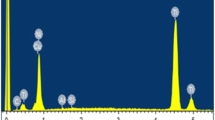

Wear rate is one of the most important factors affecting diamond wire saw machine performance. Hence; in order to predict wear rate in saw machine, first the datasets in Table 1 are provided as input and output data and then pseudo codes of ANFIS modeling based on subtractive clustering method and Fuzzy c-means clustering are written for computing in MATLAB software. Then, after the preparation of the pseudo-code of ANFIS algorithms in MATLAB, the algorithms’ control parameters are adjusted in order to have a desired prediction and optimization, including Maximum Epoch = 300, Initial step size = 0.1 and 0.5 for ANFIS-SCM and ANFIS-FCM, respectively. MFs type and output MFs are considered as Gaussian and linear for two modelings. The data set consisted of 38 different kinds of dimension stones by laboratory and field studies that use the 80% of the dataset for training and remaining (20%) of it for testing as random selection. In Modelings, after the initial analysis, some limitations should be considered which include Max epoch and Initial step size equal to 100 and 0.5, respectively. After running of the program, once the computing has reached to the max epoch, the calculations are stopped. Figures 5 and 6 show the membership functions (MFs) of input data (Rock properties) for ANFIS-SCM and ANFIS-FCM models, respectively.

Two scenarios are designed in order to predict the wear rate in performance of sawing machine. The comparison results of the predicted wear rate versus measured values for train and test data are depicted in Figs. 7 and 8.

In comparison to the existing values of the wear rate, prediction of results for train and test data show that a satisfactory performance is obtained using the proposed ANFIS-SCM model. A similar pattern was repeated for ANFIS-FCM modeling with an appropriate trend for train data, but this trend isn’t agreeable for test data compared to ANFIS-SCM model.

Accordingly, modelings of ANFIS-SCM and ANFIS-FCM for predicting wear rate summarized the results in Table 2. After assessment of the results, R2 for train and test data in ANFIS-SCM has higher values than another models. Furthermore, there was this superiority for other results.

6 Prediction of Wear Rate Using GMDH-Type Neural Network Models

In this work, assessment and prediction were performed using the train and test data employed in the GMDH type of neural network models. After several analyses, the most appropriate control parameters were obtained. The considered control parameters in the prediction are the maximum number of neurons of 12 in a layer, maximum number of 5 layers and iteration number of 300. Figure 9 shows the comparison between predicted wear rate using GMDH type of neural network models for train and test data and measured wear rate from laboratory tests that is calculated and obtained using pseudo code in MATLAB software.

The R2 is calculated and drawn for train and test data in Fig. 10. Furthermore, the results of evaluation and prediction of train and test data are shown in Table 3 and are compared with the results of ANFIS-SCM model.

The results presented here show that ANFIS-SCM technique is superior to GMDH-type neural network based on values of the R2, RMSE, MSE and SD for train and test data.

In this study, the ANFIS-SCM, ANFIS-FCM and GMDH type of ANNs were used for estimating the wear rate and then those modelings were compared according to their capability and the highest accuracy. A comparison was conducted between results of laboratory and prediction of the wear rate. Finally, after performing calculations and comparisons, the priority of using wear rate predicting based on soft computing techniques and laboratory is as follows: ANFIS-SCM > ANFIS-FCM > GMDH-type neural network.

7 Conclusion

This paper presented the application of three intelligent models using GMDH-type ANNs and adaptive neuro-fuzzy inference system based on the subtractive clustering method and Fuzzy c-means clustering approach to predict the wear rate for the diamond wire saw machine performance from database of 38 different varieties of dimension stones from Turkey mines. Artificial intelligence techniques have been successfully used to estimate the performance of sawing machine based on the cutting operations. As evidenced from the results obtained, it can be concluded that ANFIS-SCM is a reliable modeling approach for forecasting the wear rate. The reasonable correlation with a coefficient higher than 0.998 and 0.59 and appropriate RMSE: 1.3863e−04 and 0.0043 for train and test data indicates the validity of the observed system. Hence, ANFIS-SCM technique can be effectively used for prediction and found to be more efficient than ANFIS-FCM and GMDH type of neural networks. Also, ANFIS-FCM is superior to GMDH-type neural networks. Future studies are focused on comparing the methods presented here with other soft computing approaches. Prediction of the wear rate can also be assessed with Grey Wolf Optimizer (GWO), Self-Organizer Map (SOM), neural networks based on Particle Swarm Optimization (PSO) and Imperialist Competitive Algorithm (ICA), Tabu search algorithm, Ant Colony algorithm, etc.

References

Agus M, Bortolussi A, Careddu N, Ciccu R, Grosso B, Massacci G (2003) Influence of stone properties on diamond wire performance. In: Fourth international conference on computer applications in the minerals industries (CAMI 2003)

Almasi SN, Bagherpour R, Mikaeil R, Khademian A (2015) Influence of cutting wire tension on travertine cutting rate. In: 24th international mining congress and exhibition of turkey, pp 1096–1102

Aryafar A, Mikaeil R, Doulati Ardejani F, Shaffiee Haghshenas S, Jafarpour A (2018) Application of non-linear regression and soft computing techniques for modeling process of pollutant adsorption from industrial wastewaters. J Min Environ. https://doi.org/10.1016/j.measurement.2018.03.056

Ataei M, Mikaiel R, Sereshki F, Ghaysari N (2012) Predicting the production rate of diamond wire saw using statistical analysis. Arab J Geosci 5(6):1289–1295. https://doi.org/10.1007/s12517-010-0278-z

Bagheri-Esfe H, Safikhani H (2016) Modeling of deviation angle and performance losses in wet steam turbines using GMDH-type neural networks. Neural Comput Appl. https://doi.org/10.1007/s00521-016-2389-2

Berry P, Bortolussi A, Ciccu R, Manca PP, Massacci G (1989) Optimum use of diamond wire equipment in stone quarrying. In: APCOM 89, pp 351–365. SME/TMS AIME

Bezdek JC, Ehrlich R, Full W (1984) FCM: the fuzzy c-means clustering algorithm. Comput Geosci 10(2):191–203. https://doi.org/10.1016/0098-3004(84)90020-7

Bortolussi A, Ciccu R, Manca PP, Massacci G (1990) Simulation and optimization of rock cutting with diamond wire. In: Proceedings 22nd APCOM, Berlin, 1990, vol III, pp 163–176

Cai O, Careddu N, Mereu M, Mulas I (2007) The influence of operating parameters on the total productivity of diamond wire in cutting granite. Ind Diamond Rev 67(3):25–32

Careddu N, Cai O (2014) Granite sawing by diamond wire: from Madrigali “bicycle” to modern multi-wires. DIAMANTE 79:33–50

Careddu N, Marras G (2015) Marble processing for future uses of CaCO3-microfine dust: a study on wearing out of tools and consumable materials in stoneworking factories. Miner Process Extr Metall Rev 36(3):183–191

Careddu N, Perra ES, Masala O (2017) Diamond wire sawing in ornamental basalt quarries: technical, economic and environmental considerations. Bull Eng Geol Env. https://doi.org/10.1007/s10064-017-1112-6

Chiu SL (1994) Fuzzy model identification based on cluster estimation. J Intell Fuzzy Syst 2(3):267–278. https://doi.org/10.3233/IFS-1994-2306

Ciccu R, Manca P, Massacci G (1990) Simulation and optimization of rock cutting with diamond wire. In: APCOM ‘90, 22nd international symposium, vol 3, pp 163–176. ISBN: 3798313741

Ciccu R, Agus M, Bortolussi A, Massacci G, Careddu N (1998) Diamond wire sawing of hard rocks. In: Superabrasives and CVD diamond, theory and applications, pp 365–377

Das SK, Basudhar PK (2009) Utilization of self-organizing map and fuzzy clustering for site characterization using piezocone data. Comput Geotech 36(1):241–248. https://doi.org/10.1016/j.compgeo.2008.02.005

Fattahi H (2016) Prediction of slope stability using adaptive neuro-fuzzy inference system based on clustering methods. J Min Environ. https://doi.org/10.22044/jme.2016.637

Ghaysari N, Ataei M, Sereshki F, Mikaiel R (2012) Prediction of performance of diamond wire saw with respect to texture characteristics of rock. Arch Min Sci 57(4):887–900. https://doi.org/10.2478/v10267-012-0058-6

Haghshenas SS, Haghshenas SS, Barmal M, Farzan N (2016a) Utilization of soft computing for risk assessment of a tunneling project using geological units. Civil Eng J 2(7):358–364

Haghshenas SS, Neshaei MAL, Pourkazem P, Haghshenas SS (2016b) The risk assessment of dam construction projects using fuzzy TOPSIS (Case Study: Alavian Earth Dam). Civil Eng J 2(4):158–167

Ivakhnenko AG (1968) The group method of data handling-a rival of the method of stochastic approximation. Sov Autom Control 13(3):43–55

Ivakhnenko AG (1971) Polynomial theory of complex systems. IEEE Trans Syst Man Cybern 4:364–378. https://doi.org/10.1109/TSMC.1971.4308320

Ivakhnenko AG, Ivakhnenko GA (1995) The review of problems solvable by algorithms of the group method of data handling (GMDH). Pattern Recognit Image Anal C/C Raspoznavaniye Obrazov I Analiz Izobrazhenii 5:527–535

Jang JS (1993) ANFIS: adaptive-network-based fuzzy inference system. IEEE Trans Syst Man Cybern 23(3):665–685

Jang JSR, Sun CT, Mizutani E (1997) Neuro-fuzzy and soft computing; a computational approach to learning and machine intelligence. ISBN-13: 978-0132610667

Kasabov N (2001) Evolving fuzzy neural networks for supervised/unsupervised online knowledge-based learning. IEEE Trans Syst Man Cybern Part B (Cybern) 31(6):902–918. https://doi.org/10.1109/3477.969494

Kasabov N, Dhoble K, Nuntalid N, Indiveri G (2013) Dynamic evolving spiking neural networks for on-line spatio-and spectro-temporal pattern recognition. Neural Netw 41:188–201. https://doi.org/10.1016/j.neunet.2012.11.014

Kecman V (2001) Learning and soft computing: support vector machines, neural networks, and fuzzy logic models. MIT press, USA

Mikaeil R, Ozcelick Y, Ataei M, Haghshenas SS (2016) Application of harmony search algorithm to evaluate the performance of diamond wire Saw. J Min Environ. https://doi.org/10.22044/jme.2016.723

Mikaeil R, Haghshenas SS, Haghshenas SS, Ataei M (2018a) Performance prediction of circular saw machine using imperialist competitive algorithm and fuzzy clustering technique. Neural Comput Appl 29(6):283–292. https://doi.org/10.1007/s00521-016-2557-4

Mikaeil R, Haghshenas SS, Hoseinie SH (2018b) Rock penetrability classification using artificial bee colony (ABC) algorithm and self-organizing map. Geotech Geol Eng 36(2):1309–1318. https://doi.org/10.1007/s10706-017-0394-6

Özçelik Y (2005) Optimum working conditions of diamond wire cutting machines in the marble industry. Ind Diamond Rev 1:58–64

Özçelik Y, Bayram F (2004) Optical investigations of bead wear in diamond wire cutting. IDR Ind Diam Rev 3:60–65

Özçelik Y, Kulaksız S, Çetin MC (2002) Assessment of the wear of diamond beads in the cutting of different rock types by the ridge regression. J Mater Process Technol 127(3):392–400. https://doi.org/10.1016/S0924-0136(02)00429-6

Rad MY, Haghshenas SS, Kanafi PR, Haghshenas SS (2012) Analysis of protection of body slope in the Rockfill reservoir dams on the basis of fuzzy logic. In: IJCCI, 367–373

Rad MY, Haghshenas SS, Haghshenas SS (2014) Mechanostratigraphy of cretaceous rocks by fuzzy logic in East Arak, Iran. In: Proceedings of 4th international workshop on computer science and engineering Dubai, pp 45–51

Sadegheslam G, Mikaeil R, Rooki R, Ghadernejad S, Ataei M (2013) Predicting the production rate of diamond wire saws using multiple nonlinear regression analysis. Geosyst Eng 16(4):275–285. https://doi.org/10.1080/12269328.2013.856276

Salemi A, Mikaeil R, Haghshenas SS (2017) Integration of finite difference method and genetic algorithm to seismic analysis of circular shallow tunnels (Case study: Tabriz urban railway tunnels). KSCE J Civil Eng. https://doi.org/10.1007/s12205-017-2039-y

Sheikholeslami M, Sheykholeslami FB, Khoshhal S, Mola-Abasia H, Ganji DD, Rokni HB (2014) Effect of magnetic field on Cu–water nanofluid heat transfer using GMDH-type neural network. Neural Comput Appl 25(1):171–178. https://doi.org/10.1007/s00521-013-1459-y

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mikaeil, R., Haghshenas, S.S., Ozcelik, Y. et al. Performance Evaluation of Adaptive Neuro-Fuzzy Inference System and Group Method of Data Handling-Type Neural Network for Estimating Wear Rate of Diamond Wire Saw. Geotech Geol Eng 36, 3779–3791 (2018). https://doi.org/10.1007/s10706-018-0571-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-018-0571-2