Abstract

Nontraditional manufacturing processes (NTMPs) bring the processing capabilities such as machining high strength and hard materials with desired accuracies and surface finish to the manufacturing companies. Therefore, there has been a significant increase in the use and number of NTMPs. Hence, choosing a particular NTMP for a specific application turns out to be a complex decision-making problem, which involves conflicting qualitative and quantitative ranking criteria. In recent NTMP ranking literature, it is noted that fuzzy approaches are better suited for handling uncertainties and incomplete information that exist within the NTMP ranking environment. This paper introduces such a fuzzy approach using the hesitant fuzzy preference selection index (PSI) method for the assessment of the criteria weights and the hesitant fuzzy correlation coefficient principle for ranking and recommending the most appropriate NTMP for a specific application. The proposed methodology and its efficiency in dealing with incomplete information under the fuzzy decision-making environment are explored with a case study. As a result of the study, the proposed model preferred the electron beam machining (EBM) as the most suitable nontraditional manufacturing process. On the other hand, triangular fuzzy TOPSIS methods offered the electrochemical machining (ECM) as the best choice among the alternatives. The differences among the ranking decisions are also analyzed in the paper. It can be concluded from the authors’ various applications of the proposed hesitant fuzzy PSI method that it is extremely effective in representing fuzzy decision-making environments in NTMP ranking decisions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

This study proposes a fuzzy ranking model based on the hesitant fuzzy set theory for ranking and selection of the most appropriate NTMP among the alternatives for a given manufacturing application. Hesitant fuzzy set theory can deal the most extreme uncertainty and vagueness level that exists in a decision-making environment (Torra and Narukawa 2009; Liao et al. 2020; Naz and Akram 2019; Lalotra and Singh 2020). In the proposed application of the hesitant fuzzy model, the weights of ranking criteria are determined first, and then the alternatives are ranked. The highest ranked NTMP is recommended for the specified machining application.

Traditional and nontraditional manufacturing processes (NTMP) are both in use in today’s manufacturing industries. Roy et al. (2014) provide the reasoning for the selection of the nontraditional over traditional machining processes as

‘…with the growing applications of hard and difficult-to-machine materials with high precision and surface finish in turbine, aviation, tool and die making industries. Traditional machining involves direct interaction of tool and work-piece. As such, this technique cannot be utilized to machining of difficult-to-cut materials, since hardness becomes the limiting factor. Moreover, the traditional machining processes involve chip formation so their accuracy and surface finish get deteriorated. Therefore, the option left with is nontraditional machining (NTM) process. Thus, NTM processes turn out to be extremely useful for such applications as there is no direct contact of tool and the work-piece...’

Most of the nontraditional manufacturing processes will produce parts with small heat-affected zones and clean edges with fewer burns (Nestic et al., 2019). Moreover, NTMPs can machine high strength and brittle materials and generate complicated, impracticable, or inaccessible shapes in a cost-effective way (Jain, 2009). As a result, over the last four decades, there has been a significant increase in the number of NTMPs and machines sold. Today, NTMPs with different capabilities and specifications are available for a wide range of manufacturing applications. More than 30 different nontraditional manufacturing processes are reported by Jain (2009) and Davim (2013).

In the literature, nontraditional manufacturing processes are recommended in situations where traditional machining processes are unsatisfactory or uneconomical. Examples of such situations include ‘(1) Work-piece material is too hard, strong, or tough; (2) Work-piece is too flexible to resist cutting forces or too difficult to clamp; (3) Part shape is very complex with internal or external profiles or small holes; (4) Requirements for surface finish and tolerances are very high; and (5) Temperature rise or residual stresses are undesirable or unacceptable.’Footnote 1

The specifications of the nontraditional manufacturing machines can take a wide range of values. Therefore, it is not possible to evaluate widely distributed values with currently popular fuzzy numbers. Each fuzzy number type requires determination of a membership function. For example, a triangular fuzzy number is specified with only three values namely, lower, middle, and upper values and straight lines between lower and middle values and between middle and upper values. Using the same fuzzy number type for all different specifications relevant to the NTMP ranking environment may lead to incorrect NTMP ranking results. On the other hand, hesitant fuzzy number type proposed in this study does not have a strict membership function and is adaptable to specific characteristics for each specification. The authors are not aware of any application of NTMP ranking model based on hesitant fuzzy numbers in the literature. The model developed in this paper contributes the NTMP ranking literature by using hesitant fuzzy numbers in its ranking model especially where high levels of uncertainties and differences exist in representing and comparisons among the NTMP specifications. In the developed model, preference selection index (PSI) method and the hesitant fuzzy correlation coefficient principle are used for the assessment of the specifications’ hesitant fuzzy membership functional expressions and NTMP ranking process, respectively. The main contributions of the presented study can be summarized as follows:

-

Applicability of the integrated fuzzy approach using the hesitant fuzzy preference selection index (PSI) method and the hesitant fuzzy correlation coefficient principle for NTMP ranking decisions is shown.

-

The application results of the proposed model exhibited excellent performance against crisp, triangular and intuitionistic fuzzy multi-criteria decision-making (MCDM) models.

-

A well-structured case study has been proposed in detail basis on the nontraditional manufacturing process ranking problem.

-

Concerning the case study proposed in this paper, a critical review of existing NTMP fuzzy MCDM ranking models has been presented.

-

The comparisons of the proposed and existing fuzzy NTMP ranking models are provided within the case study.

The remaining of this paper is organized as follows: Sect. 2 briefly reviews the relevant NTMP ranking literature. Section 3 illustrates the application of the proposed hesitant fuzzy NTMP ranking model. In Sect. 4, the proposed model is compared with other NTMP ranking models and conclusions are presented.

2 Literature review

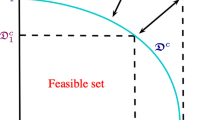

In the last few decades, the field of NMTP ranking attracts the attention of researchers, since the emerging need for newly introduced materials feeds the development of newer manufacturing techniques. These new and advanced processes make use of certain properties of such materials. This working principle makes them the most appropriate for some applications and at the same time, puts some limitations on their use. Therefore, with the consideration of productivity and economic aspects of them, the ranking of the most suitable NTMP consists of a complex decision-making problem, and researchers have generally applied distinct decision-making models according to the examined situations. Yurdakul and Çoğun, (2003) simultaneously applied two multi-criteria decision-making (MCDM) methods; analytic hierarchy process (AHP) and technique for order preference by similarity to ideal solution (TOPSIS), to determine the suitable NTMPs and make a ranking among the feasible set, for a specific manufacturing application. The compatibility of the shape feature of the working material and the process capabilities of feasible NTMPs was used in the ranking phase of the proposed model. Chakraborty and Dey (2006, 2007) developed expert systems with graphical user interfaces, designed with MATLAB GUI, for NTMP ranking under constrained material and manufacturing conditions. Edison et al. (2008) developed a web-based expert system for identification of the suitable NMTPs. This tool enables transparent information propagation and the establishment of a consensus among the differently geographically located process engineers. In the same year, Chakladar and Chakraborty (2008) presented an MCDM based expert system, consisting of AHP and TOPSIS, which considers any number of quantitative and qualitative criteria. The performance of the model was explored with different materials coupled with distinct operational requirements. Another digraph-based expert system, which can deal with qualitative as well as quantitative data, was also proposed by Chakladar et al. (2009). The proposed system identifies and considers different evaluation criteria and their interrelations for a given NTMP ranking problem. Sugumaran et al. (2010) developed a feed forward multi-user perceptron structure, ‘Neuralyst,’ for ranking of the optimal NTMP capable of generating the desired product features. Chakraborty (2011) applied multi-objective optimization based on ratio analysis (MOORA) method in a real-time manufacturing environment, by selecting the most appropriate NTMP for a given work material and shape feature combination. In another study, a well-structured two-phase decision model was proposed by Sadhu and Chakraborty (2011). The model consisted of data envelopment analysis (DEA) for the identification of the most efficient NTMPs and a MCDM approach to rank the efficient alternatives. A hybrid preference ranking organization method for enrichment evaluation (PROMETHEE) and geometrical analysis for interactive aid (GAIA) method was used to solve the NMTP ranking problem by Karande and Chakraborty (2012). Chatterjee and Chakraborty (2013a, 2013b) investigated the applicability and efficiency of two decision-making tools: ORESTE (the abbreviation for the French propositional phrase organization, rangement et synthèse de donnés relationnelles) and evaluation of mixed data (EVAMIX) method. Both methods had different advantages; ORESTE did not require any precise information about criteria weights or formulation of any preference function, and EVAMIX minimized the chance of loss of information. Prasad and Chakraborty (2014) developed a decision-making model that was enhanced with a graphical user interface and visual decision aids to automate the NTMP ranking procedure. The proposed model was integrated with the QFD technique to correlate customers’ requirements (product characteristics) with technical requirements (process capabilities). An almost unexplored MCDM method, operational competitiveness ratings analysis (OCRA) method was introduced by Madić et al. (2015). In that work, the computational procedure of the OCRA method has been demonstrated and its applicability was scrutinized while solving various case studies.

Furthermore, in the literature, Chakraborty et al. (2019) proposed a design of experiment (DoE) based TOPSIS model to select the optimal parametric mixes for different NTM processes. Gürgen et al. (2019) investigated different turning operations (conventional, ultrasonic-assisted, and hot ultrasonic-assisted operations) of Ti6Al4V alloy using the TOPSIS and VIKOR methods via experimental design principles. Shastri et al. (2020) demonstrated real-world applications of variations of cohort and multi-cohort intelligent CI algorithms in the nontraditional manufacturing processes area by solving nonlinear, non-separable, and multimodal problems.

In recent years, the use of fuzzy numbers instead of exact or crisp numbers is promoted by many researchers, because of the limitations of crisp decision-making approaches in handling the uncertainties that exist in personal judgments. In the literature, fuzzy set theory was first proposed by Zadeh (1965) to overcome the limits of classical set theory by assigning a membership degree ranging between 0 and 1 to a given element. The mathematics related to fuzzy set theory is still in progress with proposed extensions in the literature (Atanassov 1999; Torra and Narukawa 2009; Zimmermann 2010).

There are various fuzzy NTMP ranking models available in the literature. Temuçin et al. (2013), Temuçin et al. (2014)) conducted a comparative study applying TOPSIS, fuzzy TOPSIS, ELECTRE I, and PROMETHEE II methods to rank the alternative NTMPs for cutting operation of carbon structural steel. Roy et al. (2014) employed fuzzy AHP and QFD methods to calculate the relative ranking scores of various NTMPs. Khandekar and Chakraborty (2016) developed an approach based on fuzzy axiomatic design (FAD) principles for the ranking of proper NTMPs for various manufacturing applications. In another study performed by Yurdakul and İç (2019), they demonstrated the advantages of including fuzziness in NTMP ranking decisions in applications of fuzzy AHP and fuzzy TOPSIS approaches together. Finally, Yurdakul et al. (2020) proposed intuitionistic and triangular fuzzy NTMP ranking models and compared their ranking results with the crisp ranking model. Their comparisons show that there are statistically significant differences among all three ranking models’ NTMP ranking results.

The authors’ literature search indicates that a hesitant fuzzy NTMP ranking model despite its compatibility in expressing people's hesitancy is not available in the literature. This paper aims to fill this gap by developing a complete hesitant fuzzy NTMP ranking model. A first step in development of such a model is dealing with incomplete and vague evaluation information by applying the hesitant fuzzy PSI method (Maniya and Bhatt 2010). The hesitant fuzzy PSI method is used as an objective weighting method to overcome incomplete information related to the evaluation criteria in this paper. Then, the hesitant fuzzy correlation coefficient is utilized between each alternative and positive ideal alternative to rank the alternative NTMPs.

3 Implementation of the proposed hesitant fuzzy NTMP ranking model

The concepts and operational laws for hesitant fuzzy sets are provided in ‘Appendix 1.’ On the other hand, the developed implementation steps of the proposed model are made available in ‘Appendix 2.’ In this section, the application of the proposed model is illustrated with an example. In a specific NTMP application, the NTMPS that satisfy technical requirements of the specific application are accepted as feasible (alternative) and they are ranked using the developed hesitant fuzzy model.

In the illustrative example, the alternative NMTPs are electrochemical manufacturing (ECM), electrical discharge manufacturing (EDM), electron beam manufacturing (EBM), and laser beam manufacturing (LBM). Six ranking criteria are tolerance (\({C}_{1})\), surface finish (\({C}_{2})\), surface damage (\({C}_{3})\), hole diameter (\({C}_{4})\), width of cut (\({C}_{5})\) and depth/diameter ratio (for cylindrical holes) and depth/width ratio (for blind cavity) (\({C}_{6})\). \({C}_{1}\),\({C}_{3}\),\({C}_{4}\), \({C}_{5}\), and \({C}_{6}\) are cost-type criteria, and \({C}_{2}\) is a benefit-type criterion. Hence, the proposed hesitant fuzzy NTMP ranking model given in ‘Appendix 2’ is applied step by step as follows.

Step 1 Determine the measurement intervals for each alternative NTMP.

The decision maker provides the lower and upper limits that constitute the range of values that the specified criteria can take for each process regarding the requirements of the application. The measurements intervals are constructed accordingly and are given in Table 1.

Step 2 Generate random numbers to construct the set of possible measurement values for each alternative NTMP.

According to the sensitivity of the variability of the criterion values, the decision maker determines \(k\) value for each criterion. A high \(k\) value is interpreted as a high degree of sensitivity for the corresponding criterion. The decision maker sets multiple \(k\) values as 2, 3, 3, 1, 2, and 2, respectively, for each criterion. Random numbers are generated based on the uniform distribution and are given in Table 2.

Step 3 Construct the hesitant fuzzy decision matrix.

The corresponding triangular fuzzy numbers with left and right limit values and the most preferable value corresponding to each criterion are provided in Table 3. Then, using the related triangular membership functions and the measurements values in Table 2, as it is indicated in the remark the hesitant fuzzy decision matrix \(\tilde{R }\) is constructed. \(\tilde{R }\) is given in Table 4.

Step 4 Construct the normalized hesitant fuzzy decision matrix.

As mentioned, \({C}_{1}\),\({C}_{3}\),\({C}_{4}\), \({C}_{5}\), and \({C}_{6}\) are cost-type criteria, and \({C}_{2}\) is a benefit-type criterion. Hence, the normalized hesitant fuzzy decision matrix is constructed and is given in Table 5.

Step 5 Determine the preference variation value for each criterion.

Preference variation value, \({PV}_{j}\), for each criterion is calculated by using either Hamming distance or Euclidean distance which are derived from Eq. (7) in ‘Appendix 1.’ The distance expresses the deviation from the mean, \(\overline{{h }_{j}}\). The mean is found for each criterion separately, regarding all membership degrees using Eq. (18) in ‘Appendix 2.’ \({PV}_{j}\) values, which are calculated with distance measures, are given in Table 6.

Step 6 Determine the overall weight of each criterion.

The weight of each criterion is calculated considering either Eq. (19) or Eq. (20) (see ‘Appendix 2’) depending on the selected distance measure. The ranking criteria weights are given in Table 7.

Step 7 Construct the weighted hesitant fuzzy decision matrix.

The weighted hesitant fuzzy decision matrix,\({\tilde{R }}_{w}\) is obtained for each weight vector. As a demonstration, Hamming weighted hesitant fuzzy decision matrix is introduced in Table 8.

Note that the same procedure is followed to find the Euclidean weighted hesitant fuzzy decision matrix.

Step 8 Calculate the correlation coefficient between each alternative and the ideal alternative.

The correlation coefficient between each alternative and the ideal alternative \({A}^{*}\) is calculated by using either measure in Eq. (8) or Eq. (9) (see ‘Appendix 1’). In Table 9, the two correlation coefficients are given for Hamming weighted alternatives. Same calculations are also done with Euclidean weighted hesitant fuzzy decision matrix.

Step 9 Rank the alternatives in accordance with the values of correlation coefficients.

Correlation coefficients are ranged in decreasing order and a complete ranking is obtained. The most suitable manufacturing process is selected to be the one with the highest correlation coefficient. The results are shown in Table 10. According to the results in Table 10, the alternatives are ranked as follows: \({A}_{3}\succ {A}_{1}\succ {A}_{4}\succ {A}_{2}\) and the most suitable manufacturing alternative is \({A}_{3}(EBM)\).

4 Discussion and conclusions

The ranking results of the proposed hesitant fuzzy model and the ones of the crisp model (Yurdakul and Coğun 2003), triangular fuzzy TOPSIS models available in Chang 1996 and Chen and Hwang 1992 and intuitionistic fuzzy TOPSIS model (Yurdakul et al. 2020) are compared Rank the alternatives in accordance with the values of correlation coefficients.by analyzing the differences among their rankings. The differences in the rankings of alternative NTMPs are provided in Table 11 and Fig. 1. It can be observed from Table 11 and Fig. 1 that not only the ranking order but also the recommended NTMP change when the hesitant fuzzy model is applied. The analysis also shows that the ranking results in terms of the scores and order differ significantly for all five ranking models.

It can be concluded that when the uncertainty level in decision makers’ preferences and decisions increases, the hesitant fuzzy ranking model provides a more thorough representation of the decision environment by comparing the ranges for the criteria (Table 12 and Fig. 2). Each number within the range is considered at the same importance level. On the other hand, other crisp and fuzzy NTMP ranking approaches models the fuzziness with specific numbers. For example, the triangular fuzzy NTMP approach assigns lower, middle, and upper values for each criterion and represents the fuzziness using these three values. The middle value of the triangular fuzzy number is considered as the most likely value to occur. The importance level decreases with movement closer to the upper or lower value. Assigning the same importance level within a range provides a more complete representation of uncertainties for relative importance values and prevents loss of comparison data within the decision environment. The proposed model is a better model to capture and reflect the process parameter differences in the hesitant fuzzy environment in the appropriate nontraditional manufacturing process selection studies.

Availability of data and material

Not applicable.

Code availability

Not applicable.

References

Atanassov KT (1999) Intuitionistic fuzzy sets. Intuitionistic fuzzy sets. Physica, Heidelberg, pp 1–137

Chakladar ND, Chakraborty S (2008) A combined TOPSIS-AHP-method-based approach for non-traditional manufacturing processes selection. Proceedings of the Institution of Mechanical Engineers, Part b: Journal of Engineering Manufacture 222(12):1613–1623. https://doi.org/10.1243/09544054JEM1238

Chakladar ND, Das R, Chakraborty S (2009) A digraph-based expert system for non-traditional manufacturing processes selection. Int J Adv Manuf Technol 43(3–4):226–237. https://doi.org/10.1007/s00170-008-1713-0

Chakrabarti S, Mitra S, Bhattacharyya B (2007) Development of a management information system as knowledge base model for manufacturing process characterization. Int J Adv Manuf Technol 34(11–12):1088–1097. https://doi.org/10.1007/s00170-006-0673-5

Chakraborty S, Dey S (2006) Design of an analytic-hierarchy-process-based expert system for non-traditional manufacturing process selection. Int J Adv Manuf Technol 31(5–6):490–500. https://doi.org/10.1007/s00170-005-0216-5

Chakraborty S, Dey S (2007) QFD-based expert system for non-traditional manufacturing processes selection. Expert Systems with Applications, 32:1208–1217. Available at: https://www.sciencedirect.com/science/article/pii/S0957417406000960 (Accessed: 2 October 2019).

Chakraborty S (2011) Applications of the MOORA method for decision making in manufacturing environment. Int J Adv Manuf Technol 54(9–12):1155–1166. https://doi.org/10.1007/s00170-010-2972-0

Chakraborty S, Chatterjee P, Das PP (2019) A DoE–TOPSIS method-based meta-model for parametric optimization of non-traditional machining processes. J Model Manag 14(2):430–455

Chang DY (1996) Applications of the extent analysis method on fuzzy AHP. Eur J Oper Res 95(3):649–655

Chatterjee P, Chakraborty S (2013a) ‘Advanced manufacturing systems selection using ORESTE method. International Journal of Advanced Operations Management 5(4):337. https://doi.org/10.1504/ijaom.2013.058896

Chatterjee P, Chakraborty S (2013b) Nontraditional manufacturing processes selection using evaluation of mixed data method. Int J Adv Manuf Technol 68(5–8):1613–1626. https://doi.org/10.1007/s00170-013-4958-1

Chen SY, Lu CC (2015) Assessing the competitiveness of insurance corporations using fuzzy correlation analysis and improved fuzzy modified TOPSIS. Expert Syst 32(3):392–404

Chen S-J, Hwang C-L (1992) Fuzzy multiple attribute decision making. Springer, Berlin

Davim JP (2013) Nontraditional machining processes. Manufacturing process selection handbook. Springer, London, pp 205–226

Edison Chandrasselan R, Jehadeesan R, Raajenthiren M (2008) Web-based knowledge base system for selection of non-traditional manufacturing processes. Malays J Comput Sci 21(1):45–56

Garmendia L, del Campo RG, Recasens J (2017) Partial orderings for hesitant fuzzy sets. Int J Approximate Reasoning 84:159–167

Gürgen S, Çakır FH, Sofuoğlu MA et al (2019) Multi-criteria decision-making analysis of different non-traditional machining operations of Ti6Al4V. Soft Comput 23:5259–5272. https://doi.org/10.1007/s00500-019-03959-8

Jain VK (2009) Advanced machining processes. Allied publishers, Chennai

Karande P, Chakraborty S (2012) A Fuzzy-MOORA approach for ERP system selection. Decision Science Letters 1:11–22. https://doi.org/10.5267/j.dsl.2012.07.001

Khandekar AV, Chakraborty S (2016) Application of fuzzy axiomatic design principles for selection of non-traditional manufacturing processes. Int J Adv Manuf Technol 83(1–4):529–543. https://doi.org/10.1007/s00170-015-7608-y

Liao H, Gou X, Xu Z, Zeng XJ, Herrera F (2020) Hesitancy degree-based correlation measures for hesitant fuzzy linguistic term sets and their applications in multiple criteria decision making. Inf Sci 508:275–292

Liao H, Xu Z, Zeng XJ (2014) Distance and similarity measures for hesitant fuzzy linguistic term sets and their application in multi-criteria decision making. Inf Sci 271:125–142

Lalotra S, Singh S (2020) Knowledge measure of hesitant fuzzy set and its application in multi-attribute decision-making. Comp Appl Math 39:86

Madić M, Petković D, Radovanović M (2015) Selection of non-conventional manufacturing processes using the OCRA method. Serbian Journal of Management 10(1):61–73. https://doi.org/10.5937/sjm10-6802

Maniya K, Bhatt MG (2010) A selection of material using a novel type decision-making method: Preference selection index method. Mater Des 31(4):1785–1789

Nestic S, Lampón JF, Aleksic A, Cabanelas P, Tadic D (2019) Ranking manufacturing processes from the quality management perspective in the automotive industry. Expert Syst 36(6):e12451

Naz S, Akram M (2019) Novel decision-making approach based on hesitant fuzzy sets and graph theory. Comp Appl Math 38:7

Prasad K, Chakraborty S (2014) A decision-making model for non-traditional manufacturing processes selection. Decision Science Letters 3(4):467–478. https://doi.org/10.5267/j.dsl.2014.7.002

Qian M, Wang Y, Xu W, Deng H (2019) An improved TOPSIS approach for the competitiveness analysis of provincial information resource industries in China. Expert Syst 36:e12407

Roy MK, Ray A, Pradhan BB (2014) ‘Non-traditional manufacturing process selection using integrated fuzzy AHP and QFD techniques: a customer perspective. Production and Manufacturing Research 2(1):530–549. https://doi.org/10.1080/21693277.2014.938276

Sadhu A, Chakraborty S (2011) Non-traditional manufacturing processes selection using data envelopment analysis (DEA). Expert Syst Appl, 38(7):8770–8781. Available at: https://www.sciencedirect.com/science/article/pii/S0957417411001084 (Accessed: 3 October 2019).

Shastri AS, Nargundkar A, Kulkarni AJ et al (2020) Multi-cohort intelligence algorithm for solving advanced manufacturing process problems. Neural Comput & Applic 32:15055–15075. https://doi.org/10.1007/s00521-020-04858-y

Sugumaran V, Muralidharan V, Bharath Kumar Hegde RTC (2010) ‘Intelligent process selection for NTM—a neural network approach. Int J Indust Eng Res Development, 1(1):87–96. Available at: http://www.academia.edu/download/32192013/INTELLIGENT_PROCESS_SELECTION_FOR_NTM_-_A_NEURAL_NETWORK_APPROACH.pdf (Accessed: 3 October 2019).

Temuçin T et al (2013) A fuzzy based decision support model for non-traditional manufacturing process selection. Tech Gaz 20:787–793

Temuçin T et al (2014) A fuzzy based decision model for nontraditional manufacturing process selection. Int J Adv Manuf Technol 70(9–12):2275–2282. https://doi.org/10.1007/s00170-013-5474-z

Torra V (2010) Hesitant fuzzy sets. Int J Intell Syst 25:529–539

Torra V, Narukawa Y (2009) ‘On hesitant fuzzy sets and decision. In: 2009 IEEE International Conference on Fuzzy Systems, August pp 1378–1382.

Wang JQ, Wu JT, Wang J, Zhang HY, Chen XH (2016) Multi-criteria decision-making methods based on the Hausdorff distance of hesitant fuzzy linguistic numbers. Soft Comput 20(4):1621–1633

Yurdakul M, Iç YT (2019) Comparison of Fuzzy and Crisp Versions of an AHP and TOPSIS Model for Nontraditional Manufacturing Process Ranking Decision. J Adv Manufacturing Syst 18(2):167–192. https://doi.org/10.1142/S029686719500094

Yurdakul M, Iç YT, Atalay KD (2020) Development of an intuitionistic fuzzy ranking model for nontraditional machining processes. Soft Comput 24:10095–10110

Yurdakul M, Çoğun C (2003) Development of a multi-attribute selection procedure for non-traditional manufacturing processes. Proceedings of the Institution of Mechanical Engineers, Part b: Journal of Engineering Manufacture 217(7):993–1009. https://doi.org/10.1243/09544050360686851

Xia M, Xu Z (2011) Hesitant fuzzy information aggregation in decision making. Int J Approximate Reasoning 52(3):395–407

Xu Z, Xia M (2011) On distance and correlation measures of hesitant fuzzy information. Int J Intell Syst 26(5):410–425

Zadeh LA (1965) Fuzzy sets. Inform Control 8(3):338–353

Zimmermann HJ (2010) Fuzzy set theory. Wiley Interdisciplinary Reviews: Computational Statistics 2(3):317–332

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants performed by any of the authors.

Informed consent

Informed consent was obtained from all individual participants included in the study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendices

Appendix 1: Basic concepts and operational laws for hesitant fuzzy sets

Definition 1.

(Torra and Narukawa 2009; Naz and Akram 2019; Lalotra and Singh 2020; Xia and Xu 2011; Garmendia et al. 2017) A hesitant fuzzy set (HFS) on the reference set \(X\) is defined in terms of a function \(A\) that returns a subset of \(\left[ {0,1} \right]\) when it is applied to \( X\).

where \( h\left( x \right)\) is a set of different values in \(\left[ {0,1} \right]\), expressing the possible membership degree of an element \(x \in X\) to \(A\). For convenience, Xu and Xia (2011) called \(h\left( x \right) = \left\{ {\mu_{1} , \mu_{2} , \ldots , \mu_{l} } \right\}\) a hesitant fuzzy element (HFE), which denotes a basic component of the HFS with \(\mu_{i}\) \(\left( {i = 1,2, \ldots , l} \right)\) being the possible membership degrees of an element \(x\) to a given set. The complement of \(A\) is defined as \( A^{c} = \left\{ {\left\langle {x, h^{c} \left( x \right)} \right\rangle |x \in X} \right\}\), where \( h^{c} = \mathop \cup \limits_{\mu \in h} \left\{ {1 - \mu } \right\}\).

Definition 2.

(Torra 2010; Xu and Xia 2011; Liao et al. 2020) Let \( h\), \(h_{1}\) and \(h_{2}\) be three HFEs, then the following relations and operations are defined:

In the following works, Liao et al. (2014) gave the generalized form of operation in Eq. (2). Let \(h_{p} \left( {p = 1,2,. . ., r} \right) \) be a collection of HFEs, and then the generalized operation is defined as in Eq. (4).

It should be noted that the number of values, denoted by \( l_{{h_{p} }}\), may be different from HFE to HFE. Then, based on the above operational law, they also proved the following.

(Liao et al. 2014) Let \(h_{1}\) and \(h_{2}\) be two HFEs, and \(l_{{h_{1} }}\) and \(l_{{h_{2} }}\) denote the number of values in \(h_{1}\) and \(h_{2}\), respectively. The number of values in the sum of \(h_{1}\) and \( h_{2}\), denoted by \( l_{{h_{1} \oplus h_{2} }}\), is calculated according to Eq. (5).

When there are \(r\) different HFEs, it still holds. The number of values in the sum of \( r\) HFEs, denoted by \( l_{{ \oplus_{p = 1}^{r} h_{p} }}\), is calculated based on Eq. (6).

Definition 3.

The existing distance measures are all defined under a strict assumption that the compared HFEs are of equal length. If the two HFEs are not the same length, the one which has fewer elements, should be extended accordingly to either optimistic or pessimistic extension approach. However, the preferred extension technique directly affects the comparison result. Therefore, to overcome this limitation a new distance measure is introduced. Let \(h_{1}\) and \(h_{2}\) be two HFEs, the generalized hesitant fuzzy Hausdorff distance measure (Wang et al. 2016) is given in Eq. (7).

If \(\lambda = 1\), then Eq. (7) is reduced to the hesitant fuzzy Hamming–Hausdorff distance and if \(\lambda = 2\), then Eq. (7) is reduced to the hesitant fuzzy Euclidean–Hausdorff distance. Throughout the work, Hamming distance and Euclidean distance are referred to measures introduced in above.

Definition 4.

Correlation is an indicator which measures how well two variables move together in a linear fashion, and correlation coefficient is a tool to express this relationship. Therefore, the correlation coefficient has been integrated into different circumstances. Xia and Xu (2011) introduced several correlation coefficients of HFEs, under the assumption that they all are of the same length. However, some of these measures are not suitable when there is only one element in HFEs. Considering the limitations, Chen and Lu (2015) defined the correlation coefficients of HFSs given in Eqs. (8) and (9). Let B and C be two HFSs, then

where \(h_{B}^{\tau \left( j \right)} \left( {x_{i} } \right)\) and \(h_{C}^{\tau \left( j \right)} \left( {x_{i} } \right)\) are the \(j^{th}\) largest values in \(h_{B} \left( {x_{i} } \right)\) and \(h_{C} \left( {x_{i} } \right)\).

Appendix 2: Hesitant fuzzy correlation integrated preference selection index method

In this section, the proposed hesitant fuzzy correlation integrated preference selection index (PSI) method is introduced. The algorithm consists of two major steps: evaluation criteria weighting via the hesitant fuzzy PSI and ranking of alternatives depending on the correlation coefficients.

Before introducing the integrated evaluation method, some definitions are given about a random number generation procedure which is used at the very beginning of the method. In addition, a brief review of the triangular fuzzy numbers is provided.

Definition 1.

When there is a lack of measurement; hence, incomplete information, the following approach can be considered with tight intervals to generate near measurement results. Let \(x_{ij}\) be continuous variables which are measurable, and \(\max x_{ij}\) and \(\min x_{ij}\) be the maximum and minimum values that \(x_{ij}\) can attain, respectively. \(M_{ij}\) is defined as a set of numbers being elements of the interval \(I_{ij} = \left[ {\min x_{ij} , \max x_{ij} } \right]\). In order to create an appropriate \(M_{ij}\), \(k\) many numbers are randomly generated between the minimum and the maximum according to uniform distribution.

Example 1.1.

Let \(I_{ij} = \left[ {0.50, 1.30} \right]\) be an interval expressing all possible values that a measurable quantity can take and \(k\) be 2. Then, 2 random numbers are generated respecting the boundary values. The set \(M_{ij}\) is shown as in Eq. (10).

Definition 2.

\(\tilde{A} = \left( {\min x_{ij} , x_{ij}^{*} , \max x_{ij} } \right)\) is a triangular fuzzy number. The membership function of \(\tilde{A}\) is given in Eq. (11).

The membership degrees of the elements of a set \(M_{ij}\) are calculated by using triangular membership function in Eq. (11). The intermediate value of the corresponding triangular fuzzy number (Eq. 10) is estimated to be 0.90 and the membership function is written as in Eq. (12).

The membership degree of each element of \(M_{ij}\) is obtained as \(\mu_{{\tilde{A}}} \left( {0.50} \right) = \mu_{{\tilde{A}}} \left( {1.30} \right) = 0\), \(\mu_{{\tilde{A}}} \left( {0.79} \right) = 0.73\) and \(\mu_{{\tilde{A}}} \left( {0.99} \right) = 0.78\).

Application steps of the hesitant fuzzy model for an MCDM problem with \(m\) alternatives \(A_{i} \left( {i = 1,2, \ldots , m} \right)\) and \(n\) criteria \( C_{j} \left( {j = 1,2, \ldots , n} \right)\) is provided below:

Step 1 Determine the measurement intervals for each alternative.

Measurement intervals, denoted by \(I_{ij}\), are defined as the interval of reals including possible minimum (\(\min x_{ij}\)) and maximum (\(\max x_{ij} )\) values that a measurable quantity can take. Then, the data is provided in a matrix, as shown in Eq. (13).

where \(I_{ij} = \left[ {\min x_{ij} ,\max x_{ij} } \right].\)

Step 2 Generate random numbers to construct the set of possible measurement values for each alternative.

According to the sensitivity of the variability of the criterion value, the decision maker determines how many values should be generated within the range. In other words, the \(k\) value is declared by the decision maker. Hence, \(k\) many random numbers are generated based on the uniform distribution, and the set \(M_{ij}\) is constituted for each alternative under each criterion.

Step 3. Construct the hesitant fuzzy decision matrix.

Considering each of the \(k_{j}\) many values in the set \(M_{ij}\), the set of possible membership degrees, \(h_{ij}\) is calculated using the membership function given in Eq. (12). \(h_{ij} = \left\{ {\mu_{ij}^{1} , \mu_{ij}^{2} , \ldots , \mu_{ij}^{{k_{j} }} } \right\}\) is an HFE, expressing \(k_{j}\) different membership degrees assigned to the \(i{th}\) alternative for the \(j{th}\) criterion. The hesitant fuzzy decision matrix, shown in Eq. (14) also, denoted by \( \tilde{R}\), is constructed by HFEs,\(h_{ij} \left( {i = 1, 2, ..., m;j = 1, 2, . .., n} \right)\)

Step 4 Construct the normalized hesitant fuzzy decision matrix.

The normalized hesitant fuzzy decision matrix, denoted by \( \tilde{R}_{N}\), is shown in Eq. (15).

where \({h_{ij}}_{N} = \left\{ {\begin{array}{*{20}c} {h_{ij} , \;{\text{if}} j {\text{is a}} \,{\text{benefit{-}type criterion}}} \\ {h_{ij}^{c} ,\; {\text{if}} \,j \,{\text{is a cost{-}type criterion}}} \\ \end{array} } \right.\).

\(h_{ij}^{c}\) indicates the complement of the corresponding HFE and is calculated according to Definition 1 in Section 2. It should be noted that it is assumed that a criterion is either a benefit criterion or a cost criterion and none of the criteria excludes the classification.

Step 5 Determine the preference variation value for each criterion.

Preference variation value, \(PV_{j}\), for each criterion is determined by using Eq. (16) or Eq. (17). These equations are derived from distance measures introduced in Definition 3, in Section 2.

In Eqs. (16) and (17), \(\overline{{h_{j} }}\) is the average HFE which is calculated by using the summation and the product operators introduced in Eqs. (2) and (3), respectively.

\(\left( {k_{j} } \right)^{m}\) indicates the length of the HFE found by the summation of \(m\) many HFEs, \(\oplus_{i = 1}^{m} {h_{ij}}_{N}\) and it is calculated according to Eq. (6) in Section 2.

Step 6 Determine the overall weight of each criterion.

The overall weight, \(w_{j}\), is calculated according to Eq. (19) or Eq. (20) depending on selected distance measure. Weights should satisfy the following two: \( w_{j} \left[ {0,1} \right], j = 1, 2, ..., n\), and \(\mathop \sum \nolimits_{j = 1}^{n} w_{j} = 1\).

\((\varphi_{j} )_{{{\text{Hamming}}}}\) and \((\varphi_{j} )_{{{\text{Euclidean}}}}\) are the deviation in preference value of each criterion and are calculated with Eqs. (21) and (22), respectively.

Step 7 Construct the weighted hesitant fuzzy decision matrix.

The weighted hesitant fuzzy decision matrix is denoted by \(\tilde{R}_{w}\) and depicted in Eq. (23). Each element of \(\tilde{R}_{w}\) is calculated by using Eq. (3).

Step 8 Calculate the correlation coefficient between each alternative and the ideal alternative.

The correlation coefficient between each alternative \(A_{i}\) and the ideal alternative \(A^{*}\), \(Corr_{i}\), is calculated by using measures in Eqs. (8) and (9). \(A^{*}\) is selected to be as in Eq. (24) since the maximum value of a membership degree can attain is 1.

Step 9 Rank the alternatives in accordance with the values of correlation coefficients.

All alternatives are sorted in decreasing order according to correlation coefficient values, and hence a complete ranking is obtained. The larger the value of correlation coefficient, the higher the priority of alternative is \( A_{i}\).

Rights and permissions

About this article

Cite this article

Atalay, K.D., İç, Y.T., Keçeci, B. et al. Development of a new hesitant fuzzy ranking model for NTMP ranking problem. Soft Comput 25, 14537–14548 (2021). https://doi.org/10.1007/s00500-021-06372-2

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00500-021-06372-2