Abstract

The comparison between two series of optimal remediation designs using deterministic and stochastic approaches showed a number of converging features. Limited sampling measurements in a supposed contaminated aquifer formed the hydraulic conductivity field and the initial concentration distribution used in the optimization process. The deterministic and stochastic approaches employed a single simulation–optimization method and a multiple realization approach, respectively. For both approaches, the optimization model made use of a genetic algorithm. In the deterministic approach, the total cost, extraction rate, and the number of wells used increase when the design must satisfy the intensified concentration constraint. Growing the stack size in the stochastic approach also brings about same effects. In particular, the change in the selection frequency of the used extraction wells, with increasing stack size, for the stochastic approach can indicate the locations of required additional wells in the deterministic approach due to the intensified constraints. These converging features between the two approaches reveal that a deterministic optimization approach with controlled constraints is achievable enough to design reliable remediation strategies, and the results of a stochastic optimization approach are readily available to real contaminated sites.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In many studies undertaken to optimize groundwater management, it is widely recognized that the scarcity of information about the hydrogeological setting or contaminant distribution is the main factor leading to uncertainty in the resultant optimal strategy. It makes a stochastic approach more appropriate for the amelioration of subsurface problems working within the constraints of limited measurements. A stochastic approach to optimization is mainly employed in order to consider the uncertainty arising from incomplete information given by limited point measurements (Freeze and Gorelick 1999; Mayer et al. 2002). The spatial distribution of randomly generated realizations of hydraulic parameters and the contaminant plume, using limited point measurements, are contained in an optimization process. Results generally show the distribution of design factors and their reliability.

Based on the Monte Carlo method, various stochastic optimization methods have been developed and investigated (Gorelick 1983; Freeze and Gorelick 1999; Mayer et al. 2002). In particular, a simulation–optimization method with random realizations generated by geostatistical simulation under a stochastic distribution for an uncertain parameter has often been suggested because of its flexibility in relation to complex groundwater management problems. Wagner and Gorelick (1989) used a stochastic simulation–optimization model, known as the multiple realization approach, for the remediation design of a contaminated aquifer having uncertain hydraulic conductivity. Aly and Peralta (1999) presented the same approach with an artificial neural network and genetic algorithm to solve remediation problems arising from uncertain aquifer parameters, and to show the trade-off between remediation design factors and reliability. Feyen and Goelick (2004) introduced a multiple realization approach for a reliable groundwater management system in hydroecologically uncertain and sensitive areas.

Although the multiple realization approach has some merits in its solutions to uncertain groundwater environmental problems, the stochastic optimization approach generally requires enormous computational resources, such as computing time or memory (Freeze and Gorelick 1999; Baú and Mayer 2006). In order to improve computational efficiency, several methods have been suggested. In the chance-constrained technique, the obtained optimal design satisfies the stochastic constraints with a predetermined probability distribution, which represents the uncertainty of aquifer parameters. It mostly accounts for the uncertainty in the optimal design factors or identifies optimal pumping and sampling strategies in groundwater remediation using a decision framework (Wagner and Gorelick 1987; Sawyer and Lin 1998; Wagner 1999). The objective function in robust optimization techniques can often be divided into two components: deterministic and stochastic parts. The deterministic part is fixed for all given realizations, and the stochastic or probabilistic part is variable due to the uncertain conditions of realizations. Through this variation in the stochastic part because of the uncertain conditions, the trade-off between the penalty factor within the stochastic part and the uncertainty of aquifer parameters can be controlled (Watkins Jr. and McKinney 1997; Pinder et al. 2001).

Some studies on the optimization of remediation designs took an interest in the relationship between the deterministic and stochastic behaviors. Freeze and Gorelick (1999) showed the convergence between the results of deterministic and stochastic optimizations using decision analysis with a safety factor. This study showed that the reliability of the deterministic optimization was almost the same as that of stochastic optimization using the Monte Carlo analysis with similar pumping rates.

The objective of this study is to compare the results of remediation designs using a pump and treat method for two optimization approaches: deterministic and stochastic. From the limited data from the contaminated aquifer, the interpolation technique produced the deterministic domain and the geostatistical simulation technique generated random realizations for the uncertain hydraulic conductivity field. The deterministic approach found the optimal remediation designs in the deterministic interpolated domain under several controlled constraints. A multiple realization approach performed a search for optimal remediation designs using a stochastic approach with a variable stack size, which means the number of generated realizations imported in the optimization process. From the results, we compared the designs of the two approaches and discussed the converging features between them.

2 Materials and methods

2.1 Contaminated aquifer domain

Supposed to be the “true” environment, we generated a contaminated aquifer domain. It is a two-dimensional unconfined aquifer system of 800 × 610 m (Fig. 1). Constant head boundaries are set on the left and right ends, but no flow boundaries are placed on the upper or lower sides of the aquifer domain. Figure 1 also shows 15 candidate extraction wells used in optimizing the remediation design as well as the assumed “true” hydraulic conductivity field and “true” initial contaminant distribution.

The mean and standard deviation of the hydraulic conductivity in the true field are 10−4 and 100.33 m/s in common logarithm under log-normal distribution, respectively. The semivariogram, which represents the spatial continuity for hydraulic conductivities in common logarithm, was assumed as followings:

where h (m) is the lag distance. Other parameters used in groundwater flow and contaminant transport simulations are in Table 1.

2.2 Interpolated domain by limited measurements

It is impossible to gain the entire information about contaminated aquifers because the measurements can only be obtained at a few limited points, not over the whole domain. In order to reflect that situation, 40 sampling points provided the measurements of hydraulic conductivity and contaminant concentration from the true domain (Fig. 2). These data played a main role in characterizing the contaminated aquifer and optimizing remediation design using a pump and treat method. Ordinary kriging (Goovaerts 1997) with the same spatial correlation as Eq. (1) made the interpolated hydraulic conductivity field. In the case of contaminant distribution, the concentration values are biased to very small value: more than 85% of all measured concentration values are less than 1.0 mg/L (Fig. 3). It can lead to a considerable degradation of the estimated value and its variance if general interpolation methods, such as ordinary kriging, are used (Reed et al. 2004). In order to minimize such a significant degradation of the estimated values, quantile kriging method built the initial concentration distribution (Goovaerts 1997; Juang et al. 2001; Reed et al. 2004).

Sampling locations and interpolated domains by measurements for hydraulic conductivity, K, and contaminant concentration on the area where is surrounded by dotted lines in Fig. 1 (circle: sampling location; contour lines represent same concentration levels in Fig. 1; dotted line means 1.0 mg/L of the “true” contaminant distribution)

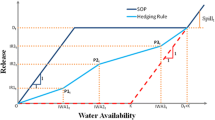

2.3 Objective function in optimization process

The objective function in this study implied the minimization of the total cost of remediation. For the purpose of this study, the simplified objective function with a single time period is given by

subject to

where a op, a we, and a pe are the unit cost of the operation, capital cost for extraction well and treatment facility construction, and penalty, respectively (cost unit); Q i is the pumping volume at the ith extraction well (m3) as a function of q i and t; q i is the pumping rate of the ith extraction well (m3/day); t is the pumping duration (day); N well is the number of extraction wells used in the remediation process; ω is the weighting factor for the penalty value (dimensionless); q mini and q maxi are the minimum and maximum values of q i; I is the number of candidate extraction wells; C max, t max, and s max are the maximum values of concentration (mg/L), time (day), and drawdown (m) at the end of the remediation process, respectively; C * is the constraint value of the concentration for the remediation system (mg/L); t * and s * are the limit values of the time (day) and drawdown (m) for the remediation system, respectively; and \( C^{{\max }}_{{{\text{comp}}}} \) and \( C^{{\text{*}}}_{{{\text{comp}}}} \) are the maximum and constraint concentrations at the compliance line (Fig. 1). The base condition of C * is fixed as 1.0 mg/L. The values for q mini , q maxi , t *, and s * were set to 0.0 m/day, 200.0 m/day, 1,095 days, and 4.0 m, respectively. C *comp is set to 1.0 mg/L. If the candidate design does not meet this compliance constraint, its total cost greatly increases by assigning a penalty cost. It makes the candidate design have the minimum fitness in this optimization problem. a op represents the lumped unit cost for extraction, treatment, and disposal of the groundwater, which are proportional to the total pumping volume. a we is the unit cost for extraction well construction.

The weighting factor, ω, was set as the degree of violation of constraint components needed to search for the optimum quickly (Chan Hilton and Culver 2000). In this study, ω is a function of C max, C *, t max, t *, s max, and s *, and is defined as

where a c, a t, and a s are the weighting coefficients for violations by concentration, time, and drawdown constraint, respectively. These are changeable, and can be changed to obtain an optimal remediation design for a certain case, in which one of them may be a more important factor than the others. In this study, the importance of each constraint was taken to be the same, and then these coefficients were set to one. The penalty value, a pe, was sufficiently large to seek the feasible design.

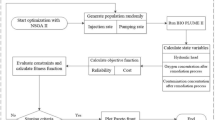

2.4 Single simulation–optimization method in a deterministic approach

The simulation–optimization method found an effective remediation design using the pump and treat method by optimizing the number, locations, and rates of the extraction wells. The simulation–optimization method uses two models independently; simulation and optimization models. The simulation model solves groundwater flow and contaminant transport equations and the optimization model determines the decision variables by using state variables from the simulation model and an inherent optimizing algorithm. In this study, the decision variables are the rates and locations of extraction wells, and the state variables are the values of drawdown and contaminant concentration. These two models run repeatedly until a suitable optimal remediation design is found or a stopping criterion is met. As a simulation model and an optimization model are independent of each other, a simulation–optimization method has the advantage of flexible application to complex groundwater flow and contaminant transport problems, though considerable computing resources are required (Wagner 1995; Wang and Zheng 1997; Zheng and Wang 2002; Feyen and Goelick 2004, 2005; Ko et al. 2005; Guan and Aral 2005; Ren and Minsker 2005).

For a comparison with the stochastic approach, a deterministic approach found optimal remediation designs. The interpolated domain in Fig. 2 shows the initial conditions of a contaminated aquifer system. The concentration constraint, C *, was first set to its base condition (1.0 mg/L). To enhance the reliability of the remediation designs, the simulation–optimization method found the optimal solutions by controlling the concentration constraints.

In this study, MODFLOW (Harbaugh and McDonald 1996) and MT3DMS (Zheng and Wang 1999) solved groundwater flow and contaminant transport equations as the simulation models. The optimization model searched the optimal solutions by a genetic algorithm (GA). As a GA can find the global or near-global optimum for optimization problems with mathematically complex objective functions and constraints such as non-convex problems, there are many studies using a GA to optimize problems about groundwater remediation and management (Goldberg 1989; Huang and Mayer 1997; Ren and Minsker 2005). Selection using a roulette wheel method with elitism (Goldberg 1989), crossover, and mutation operators all played a part in the GA process. The probabilities of crossover and mutation are 0.6–0.7 and 0.05–0.10, respectively. The details of the GA process in this study can be found in Ko et al. (2005).

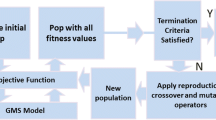

2.5 Stochastic approach using multiple realizations

Taking into consideration the uncertainty of hydraulic conditions in optimizing remediation design, a multiple realization approach, one of the stochastic optimization methods, searched for reliable designs. The multiple realization approach can establish the optimal remediation strategy, by multiple implementations of a simulation–optimization method (Wagner and Gorelick 1989; Morgan et al. 1993; Feyen and Goelick 2004). In the multiple realization approach, the optimization process handles a certain number of generated realizations and a simulation–optimization method operates on each of these realizations. If 100 realizations of the hydraulic conductivity field are supposed, a simulation–optimization method is involved in all 100 realizations. This plays the role of establishing100 constraint conditions in the optimization process for each candidate design. If the candidate design has the maximum fitness value of the given objective function in all realizations, it becomes an optimal remediation design. In this study, Eq. (2) calculated the values of the objective function for each realization, as in the case of the deterministic approach. The candidate design has its final fitness value in the multiple realization approach by summing up the values of the objective functions for each realization.

3 Results of deterministic and stochastic approach for remediation designs

3.1 Deterministic case

The deterministic approach sought the optimal remediation designs for the interpolated domain using a single simulation–optimization method. The optimization process found the base design under the base condition (C * = 1.0 mg/L) and the constraint-controlled designs under the intensified concentration constraints (C * = 0.2–0.8 mg/L) in order to consider an effective and reliable remediation design (Table 2). All of the optimal designs satisfy the constraints for drawdown, time, and the concentration given in Eqs. (2)–(5). The cost means the relative value based on the unit extraction volume, and the values of a op and a we are determined using the reference of USEPA (1999).

For the base concentration constraint condition, the optimal design selected P8 and P13 as the extraction wells. The extraction rate of P13 is more than that of P8 in regards to the effectiveness of remediation and the regulation of the compliance line. When C * intensifies, the extraction rate of P8 increases and P7 becomes the additional extraction well (C * = 0.2 mg/L). This is because the rapid removal of groundwater from a highly contaminated zone must meet the intensified constraints under the same limitations regarding clean-up time and the maximum extraction rate of each well. The increase in the number of extraction wells and the total extraction volume, due to the increased extraction rate, raises the remediation cost (Table 2).

3.2 Stochastic case

The multiple realization approach found the stochastic optimal remediation designs for stack sizes of 1, 2, 5, 10, 20, 30, 40, and 50. The geostatistical simulation, such as simulation annealing (Olea 1999), generated the conditional random realizations of hydraulic conductivity by measurements at 40 sampling locations in Fig. 2 and the spatial correlation of Eq. (1). The multiple realization approach used these realizations. If the stack size grows, the required number of the extraction wells and extraction rates increases (Fig. 4). There are relatively high increments of about 10–20% in the averages of the total extraction rate, number of wells used, and cost when the stack size is from one to ten. These large increments start to disappear when the stack size is more than 10.

The averages of the total extraction rates for each stack size are between 346.6 and 521.7 m3/day, and show very small increments when they are over 500 m3/day (Fig. 4b). The average of the number of used extraction wells also increases from 2.12 to 3.00 (Fig. 4c). These variations in averages of the total extraction rate and the number of used extraction wells constitute a change in the total cost according to stack size (Fig. 4a).

However, determining the locations of the selected extraction wells is not simple. According to the selection frequency of extraction wells in Fig. 4c, P7 and P8 are major extraction wells for all stack sizes. In particular, almost all optimal remediation designs choose these wells when the stack size is over 5. P13 and P9 compete with each other in relation to the position of the additional extraction well. Although some fluctuation exists, P13 is more frequently selected as the stack size rises. This means that the locations of P7 and P8 are indispensable, and that of P13 may be more optimal than that of P9.

The result of the stochastic approach reveals that P13 and P9 can be expected to be the additional extraction wells for more reliable remediation designs. For a practical remediation strategy requiring definite design factors, the remediation design including P13 will be more appropriate than P9 for the given contaminated aquifer as P13 was selected more frequently as an additional well. The design using P9 as an additional extraction well may be the next best strategy if the previous design using P13 does not accomplish the expected level of contaminant removal or concentration decrease. This is a very important feature because the limited sampling measurements or monitoring can cause uncertainties in the hydraulic conductivity and contaminant concentration, and can result in unexpected events during the operation of the obtained optimal remediation design.

In respect of the extraction rate of each well when they are involved in each of the optimal designs, the rates of two major extraction wells (P7 and P8) increase and approximate to certain values (Fig. 4c). However, the average rates of P9 and P13 decrease when the stack size is from 1 to 5. The optimal remediation design obtained is very sensitive to the hydraulic conductivity field and initial contaminant distribution. In particular, it can have a considerable influence on the average value of the extraction rates of involved wells when the stack size is less than five. When the stack size is one, using P9 or P13 can be more effective than using the major two wells at the same time because the design must meet the given constraints in its own realization only. However, when the stack size becomes two, the obtained optimal remediation designs must satisfy the constraints in two random realizations simultaneously. It may happen that the optimal location of an extraction well in one realization is not effective in another realization. It may then be more effective to increase the extraction rates of the major two wells instead of P9 or P13 in order to satisfy the constraints of all realizations, though a greater total extraction rate is required. In that case, the average rates of P9 and P13 when two wells are involved in each of the optimal designs will decrease because the two major wells play a main role in contaminant removal. P9 and P13 have a minor task, such as the observance of the compliance constraints. This tendency also continues when the stack size reaches to five.

When the stack size is more than five, the average extraction rates of P9 and P13, when they participated in the each optimal design are used, increase like the major wells. The rate of P9 is lower than that of P13, which becomes almost the same as one of the major wells (P7), for all stack sizes. It results from the initial condition of the contaminant distribution and existence of the compliance line (Fig. 1). The asymmetric distribution of the contaminant makes it more optimal to increase the extraction rate of P13 rather than P9.

The number of stacks also has an influence on the reliability of the obtained optimal remediation designs (Fig. 5). Thousand random hydraulic conductivity fields generated by the limited data and the same spatial correlation as Eq. (1) provided the evaluation of the reliability for the obtained optimal remediation designs. The reliability directly represents whether the design can satisfy the remediation goals or not, by applying the designs to the generated fields. If the stack size becomes lager, the reliability increases. In a small stack size, the optimal design may be available only over a small part of the generated realizations. As the stack size increases, the generated realizations appropriate for the obtained remediation designs also grow. So, the designs obtained in the larger stack size are more reliable because the optimal remediation design can cover a wider uncertainty in hydraulic conductivity caused by the larger stack size.

4 Converging features of the two approaches by controlling constraint intensity and stack size

In the two optimization approaches, it is clear that both the intensified control of concentration constraints and increasing the number of involved realizations have the same influence on the obtained optimal remediation design (Fig. 6). As the concentration constraint becomes more intensified, or the stack size gets larger, the cost, extraction rates, and the number of required extraction wells all increase. In particular, stack sizes of two and ten in the multiple realization approach and with the intensified concentration constraint of C * = 0.4 and 0.2 mg/L, respectively, obtain similar results.

The optimal remediation cost in the deterministic approach shows considerable increase at C * = 0.2 mg/L (Fig. 6a). The main factors in such a large increment are the addition of extraction wells and increased extraction rates. The extraction rates in both approaches, however, demonstrate a steady increment. This large increase results from the additional extraction well (P7) in the deterministic approach at C * = 0.2 mg/L. In the stochastic approach, the average values of the number of involved extraction wells changes relatively slowly, so there is no rapid increase in cost (Fig. 4).

The additional extraction wells, selected for a more reliable remediation design, are also similar in both approaches. In the stochastic approach, the selection frequencies of P7 and P13 are almost the same when the stack size is one. As the stack size increases to 50, then the selection frequency of P7 reaches one, and the required number of extraction wells becomes three. This tendency is also represented in the deterministic approach. At C * = 0.2 mg/L, P7 is selected by the additional required well. Both approaches show converging features in the number and location of extraction wells when the stack size is 50 and the controlled concentration constraint is 0.2 mg/L. That is, an additional well in the deterministic approach can be expected by the selection frequency of each well in the stochastic approach.

With an evaluation of the reliability for the obtained optimal remediation designs, Fig. 6c shows the similar tendency between two approaches. Thousand randomly generated hydraulic conductivity fields using the same method as the case of the stochastic approach evaluated the reliability of the deterministic optimal remediation designs. The two optimization approaches, which are using deterministic interpolated conditions with controlled constraints and using a multiple realization approach, which takes the uncertainty in the control of the stack size into consideration, show similar results when the intensity of constraint enlarges and the stack size increases. It reveals that an intensified constraint and an increased stack size with the base constraint have the same effects on the reliability of the optimal remediation designs because the increment of the stack size means a wider uncertainty in hydraulic conductivity must be taken into consideration. It also definitely demonstrates that the intensity of constraints can control the reliability of the remediation design in the deterministic approach.

5 Summary and conclusions

Both the deterministic and stochastic approaches using a single simulation–optimization method and a multiple realization approach, respectively, found reliable optimal remediation designs. For a comparison of the results, the two approaches controlled the concentration constraint and the stack size, respectively. The optimal remediation designs obtained show the converging features of the deterministic and stochastic approaches in contaminated aquifer remediation design using a pump and treat method. Intensified constraints in the deterministic approach, and a great stack size in the stochastic approach, have the same effect on the total required cost, total extraction rate, well locations, and the number of used extraction wells: the cost, extraction rate, and the number of wells increase, and the well locations are almost the same.

From the results in this study, the deterministic approach with controlled constraints can lead to the same effects as a stochastic approach with the controlled uncertainty considered in the optimization process. It reveals that controlling the constraint levels in the deterministic optimization approach can be an effective way of adjusting the reliability of the obtained optimal remediation designs, and is readily available for saving various computing resources like memory or calculating time. The similar results of the two approaches for the design factors may give us some clues, but this study did not show the definite quantitative relationship between two approaches. More studies about this relationship are required, and we leave it to further study.

In respect of its simultaneous consideration of the uncertainty and reliability of an optimized remediation design, however, the stochastic approach still has strong merits. The stochastic approach can propose rough ranges for the extraction rates, clean-up time, and candidate well locations. The definite values for practical optimal remediation design factors, such as the number and locations of the extraction wells, can be obtained by the deterministic approach. In practical design strategy, both approaches can help in the production of more effective and efficient remediation designs.

References

Aly AH, Peralta RC (1999) Optimal design of aquifer cleanup systems under uncertainty using a neural network and a genetic algorithm. Water Resour Res 35:2523–2532

Baú DA, Mayer AS (2006) Stochastic management of pump-and-treat strategies using surrogate functions. Adv Water Resour 29:1901–1917

Chan Hilton AB, Culver TB (2000) Constraint handling for genetic algorithms in optimal remediation design. J Water Resour Plann Manage 126:128–137

Feyen L, Goelick SM (2004) Reliable groundwater management in hydroecologically sensitive areas. Water Resour Res 40:W07408. doi:10.1029/2003WR003003

Feyen L, Goelick SM (2005) Framework to evaluate the worth of hydraulic conductivity data for optimal groundwater resources management in ecologically sensitive areas. Water Resour Res 41:W03019. doi:10.1029/2003WR002901

Freeze RA, Gorelick SM (1999) Convergence of stochastic optimization and decision analysis in the engineering design of aquifer remediation. Ground Water 37:934–954

Goldberg DE (1989) Genetic algorithms in search, optimization, and machine learning. Addison-Wesley, Reading

Goovaerts P (1997) Geostatistics for natural resources evaluation. Oxford University Press, New York

Gorelick SM (1983) A review of distributed parameter ground water management modeling method. Water Resour Res 19:305–319

Guan J, Aral MM (2005) Remediation system design with multiple uncertain parameters using fuzzy sets and genetic algorithm. J Hydrolog Eng 10:386–394

Harbaugh AW, McDonald MG (1996) User’s documentation for MODFLOW-96, an update to the US Geological Survey modular finite–difference ground-water flow model, US Geological Survey Open-File Report 96-485, US Geological Survey, Virginia

Huang C, Mayer AS (1997) Pump-and-treat optimization using well locations and pumping rates as decision variables. Water Resour Res 33:1001–1012

Juang K-W, Lee D-Y, Ellsworth TR (2001) Using rank-order geostatistics for spatial interpolation of highly skewed data. J Environ Qualit 30:894–903

Ko NY, Lee KK, Hyun Y (2005) Optimal groundwater remediation design of a pump and treat system considering clean-up time. Geosci J 9:23–31

Mayer AS, Kelley CT, Miller CT (2002) Optimal design for problems involving flow and transport phenomena in saturated subsurface system. Adv Water Resour 25:1233–1256

Morgan DR, Eheart JW, Valocchi AJ (1993) Aquifer remediation design under uncertainty using a new chance constrained programming technique. Water Resour Res 29:551–561

Olea RA (1999) Geostatistics for engineers and earth scientists. Kluwer Academic Publishers, Massachusetts

Pinder GF, Ricciardi K, Karatzas GP, Wobber F, Roesler G (2001) Least-cost groundwater remediation using uncertain hydrogeological information (final report). US Department of Energy, Washington

Reed PM, Ellsworth TR, Minsker BS (2004) Spatial interpolation methods for non-stationary plume data. Ground Water 42:190–202

Ren X, Minsker B (2005) Which groundwater remediation objective is better: a realistic one or simple one? J Water Res Plann Manage 131:351–361

Sawyer CS, Lin Y-F (1998) Mixed-integer chance-constrained models for ground-water remediation. J Water Res Plann Manage 124:285–294

US Environmental Protection Agency (1999) Groundwater cleanup: overview of operating experience at 28 sites. Office of Solid Waste and Emergency Response, Washington

Wagner BJ (1995) Recent advances in simulation-optimization groundwater management modeling. Review of geophysics US national report to international union of geodesy and geophysics 1991–1994:1021–1028

Wagner BJ (1999) Evaluating data worth for ground-water management under uncertainty. J Water Resour Plann Manage 125:281–288

Wagner BJ, Gorelick SM (1987) Optimal groundwater quality management under parameter uncertainty. Water Resour Res 23:1162–1174

Wagner BJ, Gorelick SM (1989) Reliable aquifer remediation in the presence of spatially variable hydraulic conductivity: from data to design. Water Resour Res 25:2211–2225

Wang M, Zheng C (1997) Optimal remediation policy selection under general condition. Ground Water 35:757–764

Watkins Jr DW, McKinney DC (1997) Finding robust solutions to water resources problems. J Water Resour Plann Manage 123:49–58

Zheng C, Wang PP (1999) MT3DMS: a modular three-dimensional multispecies transport model for simulation of advection, dispersion, and chemical reactions of contaminants in groundwater systems: Documentation and User’s Guide, US Army Engineer Research and Development Center Contract Report SERDP-99-1, Mississippi

Zheng C, Wang PP (2002) A field demonstration of the simulation optimization approach for remediation system design. Ground Water 40:258–265

Acknowledgments

This study was supported by Advanced Environmental Biotechnology Research Center (AEBRC) at POSTECH. Sustainable Water Resources Research Center of 21st Century Frontier Research Program (# 3-4-3), and partly by Korea Energy Management Corporation (KEMCO) through KIGAM.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ko, NY., Lee, KK. Convergence of deterministic and stochastic approaches in optimal remediation design of a contaminated aquifer. Stoch Environ Res Risk Assess 23, 309–318 (2009). https://doi.org/10.1007/s00477-008-0216-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00477-008-0216-8