Abstract

Drying dissipative structural patterns formed in the course of drying colloidal crystals of silica spheres (110 nm in diameter) in water, methyl alcohol, ethyl alcohol, 1-propyl alcohol, diethyl ether, and in the mixtures of ethyl alcohol with the other solvents above have been studied on a cover glass. The macroscopic broad rings were formed in the outside edges of the dried film for all the solvents examined. Furthermore, much distinct broad rings appeared in the inner area when the solvents were ethyl alcohol, methyl alcohol, and their mixtures. Profiles of the thickness of the dried films were sensitive to the organic solvents and explained well with changes in the surface tensions, boiling points, and viscosities of the solvents. The macroscopic and microscopic spoke-like crack patterns formed. The drying area (or the drying time) increased (or decreased) as the surface tension of the solvent decreased. However, the absolute values of these drying parameters are determined also by the boiling points of the solvents. Importance of the fundamental properties of the solvents is supported in addition to the characteristics of colloidal particles in the drying dissipative pattern formation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Generally speaking, most structural patterns in nature form via self-organization accompanied with the dissipation of free energy and in the non-equilibrium state. Among several factors in the free energy dissipation of aqueous colloidal suspensions, evaporation of water molecules at the air–water interface and the gravitational convection are very important. To understand the mechanisms of the dissipative self-organization of the simple model systems instead of much complex nature itself, the authors have studied the convectional, sedimentation, and drying dissipative patterns of colloidal suspensions as systematically as possible.

Drying dissipative patterns have been studied for suspensions and solutions of many kinds of colloidal particles [1–14], linear-type polyelectrolytes [15], water-soluble non-ionic polymers [16, 17], biopolymers [18], ionic and non-ionic detergents [9, 19, 20], and gels [21] mainly on a cover glass. The macroscopic broad ring patterns of the hill, accumulated with spheres in the outside edges, always formed. For the nonspherical particles, the round hill was formed in the center area in addition to the broad ring. Macroscopic spoke-like cracks or fine hills, including flickering spoke-like ones, were also observed for many solutes. The convection of water and the solute molecules at different rates under gravity and the translational and rotational Brownian movement of the latter were important for the macroscopic pattern formation. Furthermore, beautiful fractal patterns such as branch-like, arc-like, block-like, star-like, cross-like, and string-like ones were observed in the microscopic scale. These microscopic drying patterns were reflected from the shape, size, and flexibility of the solute molecules themselves. Microscopic patterns also supported importance of the electrostatic and the hydrophobic interactions between solutes and/or between the solutes and substrate in the course of the solidification. One of the important findings in our experiments was that the primitive vague patterns were formed already in the concentrated suspension state before dryness, and they grew toward fine structures in the course of solidification.

Quite recently, the sedimentation dissipative patterns have been studied in the course of drying suspensions of colloidal silica spheres and green tea in a glass dish, a watch glass, and others [22–25]. The broad ring patterns also formed within several 10 min in suspension state by the convectional flow of water and the colloidal particles. An important finding in this study was that the sedimentary particles were suspended above the substrate and always moved by the external fields, including convectional flow and the sedimentation of the particles by the gravity.

The convectional dissipative structures were studied for the Chinese black ink and the 100% ethanol suspensions of colloidal silica spheres in our laboratory [10, 26]. The existence of the small circle-like convection cells, proposed by Terada et al. [27–29], for the first time, was supported. Vigorous cell convectional flow was observed for the suspensions with the naked eyes, and the patterns changed dynamically with time.

In this work, drying dissipative patterns of colloidal crystals of silica spheres (110 nm in diameter) in the organic solvents and the binary mixtures of the two solvents, including water, have been studied in the macroscopic and microscopic scales.

Experimental

Materials

CS91 silica spheres in ethanol were kindly donated by Catalysts and Chemicals Ind. (Tokyo). Diameter, standard deviation from the mean diameter, and polydispersity index of the spheres were 110, 4.5, and 0.041, respectively. The sphere suspensions were carefully treated on the molecular sieves granules [code 3A 1/8, Wako Chemicals (Osaka)] and a mixed bed of cation- and anion-exchange resins [Bio-Rad, AG501-X8(D), 20-50 mesh] in the organic solvents for more than 10 years before use, as newly produced silica spheres always released a considerable amount of alkali ions from the porous sphere surfaces for a long time. Molecular sieves were used for dehydration from the stock suspension. Methyl alcohol (guaranteed grade), ethyl alcohol (guaranteed grade), 1-propyl alcohol (for amino acid analysis), and diethyl ether (guaranteed grade) were purchased from Wako Pure Chemicals. Methyl alcohol, ethyl alcohol, and 1-propyl alcohol were further treated with the mixtures of ion-exchange resins and the granules of molecular sieves more than 5 years before use for the experiments to delete ionic impurities and water molecules thoroughly as possible from the solvents. Diethyl ether was used without further treatment. Water used for the sample preparation and rinsing glasswares was purified by a Milli-Q reagent grade system (Milli-RO5 plus and Milli-Q plus, Millipore, Bedford, MA, USA). Sphere concentrations were always 0.02 in volume fraction.

Observation of the dissipative structures

One to 10 μl of the sample suspension of CS91 spheres was put carefully and gently onto a microcover glass (30 × 30 mm, thickness no. 1, 0.12, to 0.17 mm, Matsunami Glass, Kishiwada, Osaka) set in a glass dish (60 mm in diameter, 15 mm in depth, Petri, Tokyo). The cover glasses were used without further rinse treatment. The contact angle for the pure water was 31 ± 0.5° from the drop profiles of water on the unrinsed cover glass. Extrapolation to the zero amount of water was made from the measurements at the several amount of water. A micropipet (Multi-pet Plus 4981, Eppendorf, UK) was used for the dropping. Observation of the drying patterns was made for the suspensions set on a desk until dried up completely in a room air-conditioned at 25 °C. The humidity of the room air of the laboratory was between 50–65%, which was not regulated.

Observation of the drying patterns was made for the film formed after the solutions were dried up completely on a cover glass. Microscopic dissipative structures were observed on a laser 3D profile microscope (type VK-8500, Keyence), a digital HD microscope (type VH-7000 Keyence, Osaka), and a videotape recorder (WV-ST1, Sony). Microscopic structures were also observed with a metallurgical microscope (PME-3, Olympus, Tokyo). Macroscopic close-up pictures were also taken on a Canon EOS 55 camera with macro-lens (EF50 mm, f = 2.5) and a life-size converter EF.

Results and discussion

Drying dissipative patterns of CS91 spheres in 100% ethyl alcohol on a cover glass

Figure 1 shows the drying dissipative patterns of CS91 spheres in 100% ethyl alcohol on a cover glass. Amount of the liquid (v) ranged from 1 μl (a) to 10 μl (e). All dried films were bluish with the iridescent Bragg diffraction of light by the crystal-like array of the colloidal spheres in the film. The drying area was insensitive to the amount of liquid within the range between 1 and 10 μl. This insensitivity is due to the experimental fact that the contact angle of the liquid on a cover glass increases as the amount of liquid increases in general. The most reliable value of the contact angle is therefore determined by the extrapolation of the angles at zero amount of liquid. Clearly, distinct broad ring patterns with the spoke-like cracks were observed at the inner area of the films in addition to the broad rings at the outer edges of the films. The thickness distribution of the drying film at v = 10 μl is shown by solid circles in Fig. 8 and demonstrates the existence of the inner broad ring clearly. These inner broad rings were observed in ethyl alcohol, for the first time, in this work. The silica spheres were almost vacant in the central area, which has been quite often observed in aqueous media. A main cause for the broad ring formation is due to the convection flow of ethyl alcohol and the silica spheres in the different rates, where the rate of the latter will be slower than that of the former under gravity. Especially, flow of the spheres from the center area toward the outside edges in the lower layer of the liquid, which was observed on a digital HD microscope directly from the movement of the very rarely occurring aggregates of the colloidal particles of Chinese black ink in water, is important [10]. Clearly, the convectional flow is enhanced by the evaporation of ethyl alcohol at the liquid surface, resulting to lowering of the suspension temperature in the upper region of the suspension. When the colloidal spheres reach the edge wall of the dish at the outside region of the liquid, a part of the spheres will turn upward and go back to the center region. However, many large and heavy spheres may drop downward on the cell bottom close to the outside cell wall, where the effective horizontal flow of the spheres may stop temporarily. This process must be followed by the broad ring accumulation of the spheres near the round outside edges. It should be noted here that the broad rings were also observed in Fig. 1, but appearance of the main broad rings in the inner area is quite characteristic in ethyl alcohol media. It should be mentioned in this paper that an example of the thickness profile of the dried film from 100% ethyl alcohol suspension as a function of the distance from the center is shown by solid circles in Fig. 8.

As will be described later, quite similar broad rings in the inner area also appeared in methyl alcohol. Boiling points, surface tensions, and viscosities of methyl alcohol and ethyl alcohol are 65 °C, 23 dyn/cm (at 20 °C) and 0.61 cP (at 20 °C) and 78 °C, 22 dyn/cm and 1.2 cP, respectively. These values of methyl alcohol and ethyl alcohol are low, very low, and low or slightly high compared with those of water, respectively (100 °C, 73 dyn/cm and 1.0 cP). These parameters of boiling point, surface tension, and solvent viscosity play a very important role for the strength of vaporization, shape of liquid on a cover glass, and shape of liquid and rate of convectional flows of the solvent and the particles, respectively. Most plausible explanation of the inner broad ring formation proposed by the authors at present is as follows. The liquid thickness of the outer area in the extended initial liquid is thin because the surface tensions of alcohol are very low and the shape of drop profile will be like mountain having wide skirts with small slope. Then, the outer regions should evaporate fast compared with the inner rather thick liquid area and must be dried up first. Thus, the low broad rings in the outside edges will be formed by the convectional flow of the solvent and the spheres only in the outer regions of the liquid drop. Most of the liquid will remain in the central area, and they will form typical broad rings after the outside regions were dried up. The rather high viscosities of the alcohols should also contribute to the formation of drop profile composed of the thick liquid layer in the central area and the widely spread thin liquid skirts in the outside area. It should be noted here that diethyl ether is also very low in the surface tension, but its viscosity is substantially low. Then, the initial liquid drop must be thin anywhere including the central area and wide in shape. It should be mentioned here that inclusion of water molecules from air surrounding the cell into the sample liquid drop in 100% ethyl alcohol and the dynamic change in the component of water and ethyl alcohol by the Marangoni convection must be also important.

It should be noted here that the broad ring formation in the dried film has been observed so often for most of the solutions and suspensions examined by our group [7–15, 17–26] and further by other researchers [1–6]. Recently, microgravity experiments were made for the observation of the drying dissipative patterns of deionized suspension of colloidal silica spheres [30]. Surprisingly, the broad ring patterns did not disappear even in microgravity. This supports strongly that both the gravitational and the Marangoni convections contribute to the broad ring formation on earth, and the latter is still important in microgravity. We should note here that the broad ring patterns, which were generally observed for all drying patterns of suspensions and solutions on a cover glass including the present paper, were formed already in the process of convectional flow of water and solutes in suspension state in a glass dish, in a polystyrene dish [22], in a watch glass [23], and even in a deep bowl [25].

Figure 2 shows the extended patterns of Fig. 1e at different locations from the center (1) to the outside edge (7) of the dried film. Very fine spoke-like crack patterns are observed clearly, which is due to the traces of the convectional flows of ethyl alcohol and CS91 spheres.

Drying dissipative patterns of CS91 spheres in the mixtures of ethyl alcohol with water, diethyl ether, methyl alcohol, and 1-propyl alcohol on a cover glass

The patterns of Fig. 3 shows the drying patterns in purely ethyl alcohol (Fig. 3a), purely water (Fig. 3e), and the mixtures between them (Fig. 3b,c, and d). Clearly, these figures show the continuous change of the patterns from the significant broad rings in the inner region for 100% ethyl alcohol toward the broad rings only in the outside edge for water. Furthermore, the drying area decreased as the content of water increased. These pattern changes are explained nicely with the increase in surface tension and then change in the initial shapes of the liquid drop on a cover glass from the mountain with a wide thin skirt in the outside area toward the mountain with the sharp slope in the outside as the content of water increases. It should be noted that the spoke-like cracks always appeared in the broad ring area irrespective of the contents of the two solvents.

Figure 3a,f,g, and h shows the drying patterns of ethyl alcohol and its mixtures with diethyl ether. Clearly, the drying area increased substantially by the addition of diethyl ether, which is quite consistent with the sharp decrease in the surface tension of the mixture by the addition of diethyl ether. Broad rings at the outside edges always appeared irrespective of the content of diethyl ether. However, the heights of the rings were quite low in these mixtures, as is clearly shown in Fig. 8 (shown by crosses). Figure 8 also shows that the dried films formed from ethyl alcohol + diethyl ether mixtures were thin and flat except the broad rings in the outside edges. Thin and flat drying patterns support the idea that the initial shape of the liquid is flat and thin, and further very fast evaporation takes place in the course of dryness, as all the parameters of boiling point, surface tension, and viscosity of diethyl ether are lowest among five kinds of the solvents examined in this work.

Figure 4a–d shows the macroscopic drying patterns in 100% ethyl alcohol and the mixtures with methyl alcohol. The overall patters and the drying areas were quite similar irrespective of the mixing ratio. The difference in the values of boiling point and surface tension is not so much between ethyl alcohol and methyl alcohol. The viscosity of the former is about twice that of the latter; however, this difference in viscosity seems not affecting the patterns so much. Thickness profiles of the dried film were also quite similar to each other among ethyl alcohol, methyl alcohol, and their mixtures (compare the solid circles and open triangles in Fig. 8).

Figure 4e,f, and g is the drying patterns of the mixtures of ethyl alcohol and 1-propyl alcohol. The drying area decreased slightly as content of 1-propyl alcohol increased, which is explained nicely with a slight increase in the surface tension of 1-propyl alcohol (24 dyn/cm) compared with that of ethyl alcohol (22 dyn/cm). Interestingly, the broad rings in the inner area shifted toward outside edges continuously when content of 1-propyl alcohol increased, as is also clearly shown in Fig. 8 (compare the solid circles, solid diamonds, and open squares). These changes in the patterns are explained nicely with the fact that the surface tension and viscosity of 1-propyl alcohol are larger than those of ethyl alcohol, i.e., these parameters are favorable for shrinking of the liquid area and thickening of the initial liquid layer in the outside area.

Figures 5 and 6 show the microscopic patterns of the dried films formed from 1:1 and 1:3 mixtures of ethyl alcohol and 1-propyl alcohol, respectively, where the extended pictures were taken from the central area [from 1 to the right-hand side edge (7 and 6, respectively] on a metallurgical microscope. Very fine spoke-like crack patterns were observed. It should be noted here that the length of the cracks and the inter-crack distance changed as a function of the distance from the center of the film. It should be noted further that the microscopic patterns were very similar among 100% ethyl alcohol (Fig. 2), 1:1 mixture of ethyl alcohol and 1-propyl alcohol (Fig. 5), and 1:3 mixture (see Fig. 6).

Drying time (T), pattern area (S), and thickness of drying film (d)

Figure 7a shows the drying times (T) as a function of fractions (x) of water (open circles), diethyl ether (crosses), methyl alcohol (open triangles), and 1-propyl alcohol (open squares) in the binary mixtures, respectively. Increase, sharp decrease, insensitivity, and insensitivity of T were observed by the increase in the contents of water, diethyl ether, methyl alcohol, and 1-propyl alcohol, respectively. Interestingly, decrease, sharp increase, insensitivity, and slight decrease were observed for the drying area (S) by the addition of these organic solvents, respectively, although the graph showing these were omitted but will be deduced from Figs. 3 and 4. Clearly, T values decreased as S values increased when the same amount of liquids was dried up on a cover glass. However, the absolute values of T will be determined also by the boiling points of the organic solvents, and T will decrease as the boiling point decreases.

Drying time (T) of CS91 sphere as a function of mixing ratio (x) (a) and drying area (S) (b) at 25 °C. ϕ = 0.02; a v = 10 μl, open circle EtOH + H2O, times symbol EtOH + Et2O, open triangle EtOH + MeOH, open square EtOH + PrOH; b v = 1, 2, 5, 7, 10, open circle [EtOH]/[H2O] = 1:3, times symbol [EtOH] + [Et2O] = 1:3, open triangle [EtOH] + [MeOH] = 1:3, open square [EtOH] + [PrOH] = 1:3, filled circle EtOH

Figure 7b shows the relationship between T and S values, when the amount of the liquid ranged from 1 to 10 μl. Clearly, T and S increased as the added amounts of the organic solvent increased. Furthermore, T increased proportionally as S increased. The slopes of the T vs S plots increased sharply as the boiling points of the secondary solvents decreased, where the primary solvent is ethyl alcohol in the mixtures.

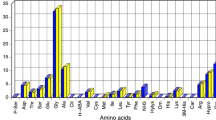

Figure 8 shows the thickness distribution of the drying films (d) as a function of r/r 0, where r and r 0 are the distance from the center of a dried film and the radius of the same film. The broad ring patterns were observed in the inner regions of the films from 100% ethyl alcohol and also from 100% methyl alcohol. The peak positions of the broad rings shifted toward the outside area, when the content of 1-propyl alcohol increased. The reasons for these changes were discussed above already.

Thickness of the drying film (d) of CS91 spheres as a function of normalized distance from center (r/r o) at 25 °C. ϕ = 0.02, v = 10 μl. Open circle [EtOH]/[H2O] = 1:3; times symbol [EtOH] + [Et2O] = 1:3; open triangle [EtOH] + [MeOH] = 1:3; open square [EtOH] + [PrOH] = 1:3; filled circle EtOH; filled diamond [EtOH] + [PrOH] = 1:1

In summary, the macroscopic and microscopic drying patterns were observed for the colloidal silica spheres (110 nm in diameter) in ethyl alcohol and the mixed solvents of ethyl alcohol with water, ethyl ether, methyl alcohol, and 1-propyl alcohol. The broad rings always formed in the outside edges of the dried film, although their peak heights depended on the kind of organic solvents. Distinguished broad rings of colloidal silica spheres in the inner area of the film were observed in ethyl alcohol and mixture solvents with methyl alcohol in addition to the broad rings at the outside edge. Peaks of the inner broad rings in ethyl alcohol shifted outward, as the content of 1-propyl alcohol increased and almost disappeared in the presence of the excess amount of the latter. The fine spoke-like crack patterns were observed for all the suspensions in the organic solvents examined. These dissipative patterns, drying time, and drying area were quite sensitive to the boiling points, surface tension, and viscosity of the organic solvents.

References

Vanderhoff JW (1973) J Polymer Sci Symp 41:155

Nicolis G, Prigogine I (1977) Self-organization in non-equilibrium systems. Wiley, New York

Ohara PC, Heath JR, Gelbart WM (1997) Angew Chem 109:1120

Maenosono S, Dushkin CD, Saita S, Yamaguchi Y (1999) Langmuir 15:957

Nikoobakht B, Wang ZL, El-Sayed MA (2000) J Phys Chem 104:8635

Ung T, Litz-Marzan LM, Mulvaney P (2001) J Phys Chem B 105:3441

Okubo T, Okuda S, Kimura H (2002) Colloid Polymer Sci 280:454

Okubo T, Kimura K, Kimura H (2002) Colloid Polymer Sci 280:1001

Okubo T, Kanayama S, Kimura K (2004) Colloid Polymer Sci 282:486

Okubo T, Kimura H, Kimura T, Hayakawa F, Shibata T, Kimura K (2005) Colloid Polymer Sci 283:1

Okubo T, Yamada T, Kimura K, Tsuchida A (2005) Colloid Polymer Sci 283:1007

Yamaguchi T, Kimura K, Tsuchida A, Okubo T, Matsumoto M (2005) Colloid Polymer Sci 283:1123

Okubo T, Nozawa M, Tsuchida A (2006) Colloid Polymer Sci 285:827–832

Okubo T, Kimura K, Tsuchida A (2007) Colloids Surf (in press). DOI 10.1016/j.colsufb.2006.10.012

Okubo T, Kanayama S, Ogawa H, Hibino M, Kimura K (2004) Colloid Polymer Sci 282:230

Shimomura M, Sawadaishi T (2001) Curr Opin Coll Interf Sci 6:11

Okubo T, Yamada T, Kimura K, Tsuchida A (2006) Colloid Polymer Sci 284:396

Okubo T, Onoshima D, Tsuchida A (2007) Colloid Polymer Sci (in press). DOI 10.1007/s00396-007-1645-5

Kimura K, Kanayama S, Tsuchida A, Okubo T (2005) Colloid Polymer Sci 283:898

Okubo T, Shinoda C, Kimura K, Tsuchida A (2005) Langmuir 21:9889

Okubo T, Itoh E, Tsuchida A, Kokufuta E (2006) Colloid Polymer Sci 285:339–349

Okubo T (2006) Colloid Polymer Sci 284:1395

Okubo T (2006) Colloid Polymer Sci 284:1191

Okubo T (2006) Colloid Polymer Sci 285:331

Okubo T, Okamoto J, Tsuchida A (2007) Colloid Polymer Sci (in press)

Okubo T (2006) Colloid Polymer Sci 285:225

Terada T, Yamamoto R, Watanabe T (1934) Proc Imper Acad Tokyo 10:10

Terada T, Yamamoto R, Watanabe T (1934) Sci Paper Inst Phys Chem Res Jpn 27:75

Terada T, Yamamoto R (1935) Proc Imper Acad Tokyo 11:214

Tsuchida A, Okubo T (2003) Sen’I Gakkaishi 59:264

Acknowledgments

Financial supports from the Ministry of Education, Culture, Sports, Science and Technology, Japan and Japan Society for the Promotion of Science are greatly acknowledged for Grants-in-Aid for Exploratory Research (17655046) and Scientific Research (B; 16350124 and 18350057), respectively. Catalysts and Chemicals is thanked deeply for providing the colloidal silica sphere in ethyl alcohol and methyl alcohol.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Okubo, T., Nakagawa, N. & Tsuchida, A. Drying dissipative patterns of colloidal crystals of silica spheres in organic solvents. Colloid Polym Sci 285, 1247–1255 (2007). https://doi.org/10.1007/s00396-007-1678-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-007-1678-9