Abstract

This paper builds an integrated optimization model for the laminated plate to suppress the structural frequency response in a given frequency band, where the objective is to minimize the dynamic compliance of the structure excited by an external sinusoidal mechanical load with given amplitude and frequency range. The dynamic response analysis of the laminated structure is performed via a finite element model based on the first-order shear deformation theory. Therein, the Heaviside penalization of the discrete material optimization method and the solid isotropic material with penalization scheme are separately employed to optimize the fiber orientation and the layout of the damping material. Meanwhile, mode reduction method and a decoupled sensitivity analysis are incorporated for efficient frequency and sensitivity analysis to reduce the heavy computational burden from many frequency steps in each iteration, a large number of freedom degrees and plenty of design variables as well as maintain high accuracy. And the method of moving asymptotes is used to solve the optimization problem. And three numerical examples including the efficiency and accuracy demonstration, single load and multi-load case with separate and integrated optimization are presented to verify the validity and advantage of the proposed model.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Recently, the vibration suppression of structures has become gradually a hot research topic attracting much attention. Efficient reduction of the vibration level is significant in engineering structures as many engineering structures are served in dynamic environments and the excessive vibration could have detrimental effects on structural performances.

Topology optimization is regarded as a powerful tool for innovative design to achieve the above goal. And various researches have been done in the dynamic topology optimization field to suppressing structural vibration such as the eigenvalue optimization [1, 2], the dynamic response in frequency domain like the average input power of the excitation [3], the vibration level difference, and the vibrational power flow [4, 5], the dynamic compliance [6], and the vibration magnitude at a point, along a line or in a domain of the structure [7].

Besides, in the field of combination of vibration control and topology optimization, vibration responses of structures can be reduced by optimizing the damping materials layout [8], the layout of embedding intelligent materials [9], the integrated layout of the host structure layer, and intelligent material layer [10] as well as adding the hybrid damping through intelligent constrained layer treatments [11]. Particularly, for the damping material, Zheng et al. [12] studied the optimal layout of Passive Constrained Layer Damping (PCLD) on a shell structure to minimize vibration energy with the Genetic Algorithm (GA). Takezawa et al. [13] used complex dynamic compliance as the objective function to reduce resonance response. Yamamoto et al. [14] proposed to maximize the modal loss factors through only real eigenvalue on the thin panel. Yun and Youn [15] studied the topology optimization of damping layers in the time domain. Madeira et al. [16] proposed a multi-objective method to optimize the laminated sandwich structures for minimizing the weight and maximizing the modal loss factors.

The above-mentioned studies concentrate on either the improvement of the damping properties or maximum of the Eigenfrequency or optimization in a single operating frequency. Only a few studies investigate the optimization in a broad frequency range [17,18,19]. Broadband dynamic optimization is also important since many structures always service in a broadband dynamic environment. Additionally, these studies seldom consider the optimization of the other parts of the structure, especially for the other parts with anisotropic material like fiber, which relates to the stiffness of the structure and therefore influences the structure vibration. Even the fiber orientation design is considered, each fiber layer is related to one angle [16]. This cannot fully achieve the potential of the fiber material.

For the optimal design of the fiber material, it can be divided into constant-stiffness and variable-stiffness optimization. The constant-stiffness optimization aims to determine the optimum stacking sequence and fiber angles for different requirements such as bending deflection [20] and natural frequency [21, 22]. For the variable-stiffness optimization, the development of the automated manufacturing techniques [23,24,25] has paved the way for tailoring fiber angles favorably and help to achieve the optimized design for the variable-stiffness laminate. And one of the effective methods to optimize the local fiber orientation is the discrete material optimization (DMO) technique [26]. And it has shown its effectiveness in solving both static and dynamic problems like transducers design [27], Eigenfrequency optimization [28] and minimum sound radiation [29]. What’s more, there are numerous methods to optimize composite structures, e.g., the shape functions with penalization (SFP) [30], bi-value coding parameterization (BCP) [31], the Heaviside-based DMO (HPDMO) [32].

To suppress the structural vibration more efficiently, this work builds an integrated optimization model for the laminated structure to minimize the dynamic compliance in a broad frequency range, where the local fiber angle in each fiber layer and the layout of the damping material are simultaneously optimized. And mode reduction method and a decoupled sensitivity analysis are incorporated for efficient frequency and sensitivity analysis to reduce the heavy computational burdens from hundreds of frequency steps in each iteration, many freedom degrees and plenty of design variables. Besides, the separation optimization for the damping material and the fiber material is also done in the numerical examples to show the advantage of the integrated model.

2 Formulation of optimization methodology

2.1 Vibration analysis of laminated plate

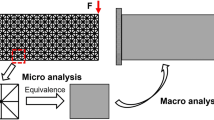

A finite element model is used to compute the dynamic response of the laminated plate as shown in Fig. 1. The nodal displacement \({\mathbf{u}}^{e}\) is represented by

where \(u_{1} ,u_{2} ,u_{3} ,\theta_{1} {\kern 1pt}\) and \(\theta_{2}\) are the three translational and two rotational degrees of freedom.

Then the dynamic equation is represented as

where \({\mathbf{\ddot{u}}}(t)\) and \({\mathbf{u}}(t)\) are, respectively, the acceleration and displacement vector at time t; M is the global mass matrix; Kis the global stiffness matrix and because of the existence of the hysteretic damping material core it is composed of a real part and imaginary part (the imaginary part describes the damping properties of the structure), i.e.,\({\mathbf{K}} = {\mathbf{K}}_{R} + j{\mathbf{K}}_{I}\) and \(j = \sqrt { - 1}\) is the complex unit.

When the harmonic excitation \({\mathbf{f}}(t) = {\mathbf{F}}e^{j\omega t}\) is applied, the structural displacement can be described as \({\mathbf{u}} = {\mathbf{U}}e^{j\omega t}\), the dynamic equation can be rewritten as

where U is the complex amplitude.

The finite element model for this laminated plate is based on the first-order shear deformation theory (FSDT) and selective integration is used to avoid shear locking [33]. Then the element stiffness matrix can be expressed as

where \(\Omega^{e}\) denotes the element domain, B is the strain displacement matrix. The elasticity matrix c can be defined as

where the sub-matrices A, B, and D are defined as

where \((Q_{st} )^{l}\) denotes the element constitutive matrix of the lth layer; and \(z_{l}\) denotes the distance between the lth layer and mid-surface.

2.2 Discrete material optimization method

For the fiber layer, though employing the HPDMO technique, the element constitutive matrix in the ith finite element for the lth layer can be expressed as a weighted sum of the matrices of the candidate materials:

where \({\mathbf{Q}}_{m}\) and \(\xi_{m,i}^{l}\) are the constitutive matrix and the weighting function of the mth candidate material in the ith element, respectively. \(n^{l}\) is the number of candidate materials in the lth layer.

Similarly, the element mass density in the ith finite element for the lth layer can be also expressed as

where \(\rho_{m}\) is the mass density of the mth candidate material.

The sum of weighting functions of candidate materials in each layer is enforced to unit which can be expressed as [32, 34]

where

where \(\overline{x}_{m,i}^{l} = e^{{ - \beta_{1} (1 - x_{m,i}^{l} )}} - (1 - x_{m,i}^{l} )e^{{ - \beta_{1} }}\), \(x_{m,i}^{l}\) represents the relative density of the mth candidate material for the lth layer and ith element; and \(\beta_{1}\) is the nonlinear penalty parameter. Figure 2 shows the curve of the nonlinear function \(\overline{x}_{m,i}^{l} = e^{{ - \beta_{1} (1 - x_{m,i}^{l} )}} - (1 - x_{m,i}^{l} )e^{{ - \beta_{1} }}\) with different penalty parameters \(\beta_{1}\). The penalty of the nonlinear function significantly increases with the increase of the penalty parameter \(\beta_{1}\), which helps to drive the density after the penalty to 0 or 1 and ultimately prevents the design from falling into the difficulties of cross-fiber selection.

2.3 Solid isotropic material with penalization

For the damping layer, the solid isotropic material with penalization (SIMP) is employed [2]. The design domain has meshed into \(N\) elements and each element is assigned a design variable to represent the selection of the damping material. It can be represented as

where \({\mathbf{D}}_{i}\) is the effective constitutive matrix of the damping material on the ith element; \({\mathbf{D}}_{1}\) and \({\mathbf{D}}_{2}\) are the constitutive matrixes for the damping material and the foam material, respectively;\(\rho_{1}\) and \(\rho_{2}\) are the mass density of two candidate materials, respectively;\(\tilde{x}_{i}^{d}\) denotes the relative physical density of the damping material in the ith finite element;\(p_{1}\) is the penalty factor.

For the damping material, the complex modulus representation is used [14], i.e., \(E_{{}}^{*} = E_{{}}^{^{\prime}} + jE_{{}}^{^{\prime\prime}}\); \(E_{{}}^{^{\prime}}\) represents the storage modulus and the imaginary part \(E_{{}}^{^{\prime\prime}}\) represents the loss modulus and \(j = \sqrt { - 1}\) is the complex unit.

The candidate materials are shown in Fig. 3. For the fiber layers, eight fiber candidate materials oriented at \([0^{^\circ } , \pm 22.5^{^\circ } , \pm 45^{^\circ } , \pm 67.5^{^\circ } ,90^{^\circ } ]\) are used. The black and the white separately denote the damping material and the foam in the damping layer.

Besides, to obtain a clear black-and-white 0/1 result, the modified threshold Heaviside projection method is adopted [18]. And it is stated as

where \(x_{\min }^{d}\) is the low bound corresponding to the original design variable \(x_{i}^{d}\); \(x_{{{\text{th}}}}^{d}\) is the projection threshold value; when \(\beta_{2} \to + \infty\), Eq. (15) projects \(x_{i}^{d}\) below \(x_{{{\text{th}}}}^{d}\) to \(x_{\min }^{d}\) and above \(x_{th}^{d}\) to 1.

2.4 Optimization formulation

Based on the above description, the integrated optimization model is formulated as

where \(J_{d} = \int_{{\omega_{l} }}^{{\omega_{u} }} {J\left( {\omega ,x_{i}^{d} ,x_{m,i}^{l} } \right)} {\text{d}}\omega\) is taken as the objective function;\(\omega_{l}\) and \(\omega_{u}\) are the lower and upper bound of the frequency interval, respectively;\({\mathbf{S}} = - \omega^{2} {\mathbf{M}} + {\mathbf{K}}\); V is the maximum allowable volume fraction for the damping material;\(v_{i}^{{}}\) is the volume of the ith finite element; \({\mathbf{x}}_{{}}^{d}\) and \({\mathbf{x}}_{m}^{l}\) are the original design variable vector.

Here, the dynamic compliance definition provided by Ma et al. [35] is adopted:

The harmonic response curve presents a very sharp jump around the resonant natural frequency. If the frequency interval includes the resonant natural frequency, a significant effort should be made to produce convergence. Here, the Gauss–Legendre integration is adopted to calculate the objective function because it needs few integration points while maintaining high accuracy, and it can be described as follows:

where \(\gamma_{k}\) is the weight factor for the kth Gaussian point, and \(\mu_{k}\) is the Gaussian point in the range [− 1, 1], \(N_{f}\) is the number of Gaussian points.

If the frequency interval includes the Eigenfrequency, Eq. (17) can also be rewritten as

where \(\omega_{i} (i = 1,2, \ldots ,p_{2} )\) is the ith Eigenfrequency, \(p_{2}\) is the number of the Eigenfrequency in the whole frequency interval \(\left[ {\omega_{l} ,\omega_{u} } \right]\).\(\left[ {\omega_{i} ,\omega_{i + 1} } \right]\) is the fine frequency subinterval. Each item in Eq. (19) can be calculated by Eq. (18). And It is suggested that 136 integration points between two adjacent resonant frequencies are required to maintain the high accuracy [17, 18].

2.5 Mode reduction method

From Eqs. (16) and (18), the computational cost is very high because Eq. (3) needs to be solved in every Gaussian integration point. Further, a large number of degrees of freedom in the finite element model also increase the computational cost. To reduce the computational cost and maintain the high accuracy for the evaluation of the objective function, the modal reduction method is employed.

In modal space, Eq. (3) can be described as

where \({\mathbf{\varphi }}\) is the system eigenvector matrix, \(\omega_{{q_{3} }}\) is the \(q_{3}\)th natural frequency; \(\ddot{y}_{{q_{3} }} (t)\) and \(y_{{q_{3} }} (t)\) are the mode acceleration and mode displacement at time t in the mode space, respectively.

The modal displacement method (MDM) approximates the displacement–response by a linear combination of the set of vibration modes with the first n lower mode orders:

And the mode acceleration method (MAM) remedies the MDM approximation by employing a pseudo-static solution [36]:

where the following well-known fact is used:

For the harmonic excitation \({\mathbf{f}}(t) = {\mathbf{F}}e^{j\omega t}\), the displacement–response amplitude by MDM and MAM can, respectively, be stated as

where \(Y_{{q_{3} }} = \frac{{{\mathbf{\varphi }}_{{q_{3} }}^{T} {\mathbf{F}}}}{{\omega_{{q_{3} }}^{2} - \omega^{2} }}\); \(\omega\) is the excitation frequency. No matter how many integration points in Eq. (18) are used, for the MAM \({\mathbf{K}}^{ - 1} {\mathbf{f}}\) only needs to be solved only once and \(\sum\nolimits_{{q_{3} = 1}}^{n} {{\mathbf{\varphi }}_{{q_{3} }} \left( {Y_{{q_{3} }} - \frac{{{\mathbf{\varphi }}_{{q_{3} }}^{T} {\mathbf{F}}}}{{\omega_{{q_{3} }}^{2} }}} \right)}\) is calculated in the modal space by Eq. (19). Thus, the computation cost is very low.

2.6 Evaluation of convergence measure

For the weight \(\xi_{m,i}^{l}\) in HPDMO, it is regarded as converged if the inequality is satisfied:

where \(\varepsilon\) is a tolerance value.

Then a total convergence measure is defined to evaluate the fiber convergence for HPDMO:

Additionally, a convergence criterion is given to describe the changes of the objective function along with the iteration process:

where \(\varepsilon_{0}\) is the allowed convergence tolerance and is given as 0.01; \(p_{3}\) is the number of the continuous several iterative steps; z denotes the current iterative step. And the final convergence condition is the allowed convergence tolerance \(\varepsilon_{0}\) is satisfied.

3 Sensitivity analysis

3.1 Adjoint sensitivity analysis

The adjoint variable method is used to conduct the sensitivity analysis [18] and it can be stated as

where \({\overline{\mathbf{S}}}\) and \({\overline{\mathbf{F}}}\) represent the conjugate dynamic stiffness and the conjugate force amplitude, respectively;\({{\varvec{\uplambda}}}_{1}\) and \({{\varvec{\uplambda}}}_{2}\) are the Lagrangian multiplier vectors, respectively;

By differentiating the Lagrangian equation \(\phi_{L}\), the following equations are obtained:

Here, \(\alpha\) is a general form of design variable (\(\alpha { = }x_{m,i}^{l} {\kern 1pt} {\kern 1pt} {\kern 1pt} or{\kern 1pt} {\kern 1pt} x_{i}^{d}\)).

Comparing the conjugate of Eq. (31) with Eq. (32), \({{\varvec{\uplambda}}}_{1} { = }{\overline{\mathbf{\lambda }}}_{2}\). Therefore, the following equation can be obtained:

The sensitivity of the mass and stiffness matrix concerning the design variable \(\tilde{x}_{i}^{d}\) can be expressed as

where

Here, to circumvent the checkerboard pattern, the sensitivity filter [37] is used and can be described as

where \(N_{e}\) is the set of elements for which the center-to-center distance to element e is smaller than the filter radius.\(w\left( {r_{ek} } \right)\) can be expressed as

Besides, the sensitivity of the mass and stiffness matrix concerning the design variable \(x_{m,i}^{l}\) can be expressed as

where

3.2 Decoupled sensitivity for fiber layer design variables

The direct method (DM) for the sensitivity analysis is stated as follows:

From Eq. (45), the sensitivity of the objective function concerning the design variables \({\mathbf{x}}_{m}^{l}\) in one fiber layer needs to be calculated \(N_{f} \times N \times n^{l}\) times in each iteration process. For multiple fiber layers, \(N_{f} \times N \times n^{l} \times l_{f}\) (\(l_{f}\) is the number of the fiber layers) loops are required.

Refer to the research [18], a decoupled method for the sensitivity analysis of the fiber layer design variables is proposed. And it can be written as

In Eq. (46), the terms \(\sum\nolimits_{k = 1}^{{N_{f} }} {\gamma_{k} (\omega_{u} - \omega_{l} )( - \omega_{k}^{2} {\mathbf{u}}_{i,k} {{\varvec{\uplambda}}}_{i,k}^{T} )}\) and \(\sum\nolimits_{i = 1}^{{N_{f} }} {\gamma_{k} (\omega_{u} - \omega_{l} )({\mathbf{u}}_{i,k} {{\varvec{\uplambda}}}_{i,k}^{T} )}\) are first computed and stored in matrices. Then the obtained matrices are used in the item \({\text{trace}}\left( {\sum\nolimits_{q = 1}^{{n^{l} }} * } \right)\). Thus, the sensitivity of the objective function for the design variables \({\mathbf{x}}_{m}^{l}\) in one fiber layer is only calculated \(N_{f} \times N{ + }N \times n^{l}\) times in each iteration process. Thus, the decoupled method (DE) can efficiently reduce the computational cost.

To solve the presented optimization model, the MMA method [38] is adopted. The optimization iteration process is represented in Fig. 4.

4 Numerical examples

In this section, a couple of numerical examples are employed to verify the validity of the proposed optimization method. As shown in Fig. 1, in all numerical examples, a five-layer laminated plate subjected to a harmonic mechanical load with a prescribed frequency interval and a real amplitude \(100N\) at the central point of the top of the plate is investigated. The layers are numbered from bottom to top (i.e., 1–5). The length, width and total thickness of the plate are 1 m, 0.5 m and 1 mm (each layer has the same thickness), respectively. All four plate edges are clamped. The plate is meshed by 800 (40 × 20) four-node Mindlin laminated plate elements. The material prosperities are shown in Table 1. The candidate materials used in the first, second, fourth and fifth layers are carbon fiber reinforced epoxy oriented at \(\left[ {\begin{array}{*{20}c} {0^{^\circ } } & { \pm 22.5^{^\circ } } & { \pm 45^{^\circ } } & { \pm 67.5^{^\circ } } & {90^{^\circ } } \\ \end{array} } \right]\). In the initial design, all the design variables for the fiber layers are set as 0.5, which means all the candidate materials have the same contribution to the constitutive matrix of the initial design in the fiber layers. For the damping layer, the initial values for all the design variables are set as the volume fraction of phase material 1. Due to the symmetry of the plate along the thickness direction, the fiber in each element of the first and the fifth layers, the second and the fourth layers have the same angles.

The initial and maximum values for \(\beta_{1}\) and \(\beta_{2}\) are set as 1 and 200, respectively. Along with the iteration process, if the maximum change of the objective function is less than 0.01 or every 50 iteration steps, \(\beta \, (\beta_{1} \;{\text{or}}\;\beta_{2} )\) is set as \(\beta = 2\beta\). And \(p_{1}\) in Eq. (13) is set as 3. \(x_{{{\text{th}}}}^{d}\) in Eq. (15) is set as 0.5. And both \(x_{\min }^{d}\) and \(x_{\min }^{l}\) in Eq. (16) are set as 0.001. \(\varepsilon\) in Eq. (26) is set as 0.95 and it means at least 95% of the elements are converged. \(\varepsilon_{0}\) and \(p_{3}\) in Eq. (28) are, respectively, set as 0.01 and 10.

4.1 Efficiency and accuracy demonstration

Before conducting optimization, the efficiency and accuracy comparison of different methods (i.e., all freedom degrees method (FM), MDM, and MAM) for the initial design condition are carried out. The volume fraction for phase material 1 in the damping layer is set as 0.7. The first several natural frequencies of the laminated plate are \(151.3\;{\text{Hz}}\), \(195.5\;{\text{Hz}}\), \({\kern 1pt} 275.1\;{\text{Hz}}\), \({\kern 1pt} 390.1\;{\text{Hz}}\), \({\kern 1pt} 396.4\;{\text{Hz}}\), \({\kern 1pt} 438.7\;{\text{Hz}}\), \({\kern 1pt} 512\;{\text{Hz}}\), \({\kern 1pt} 539.7\;{\text{Hz}}\) and \({\kern 1pt} 618.5\;{\text{Hz}}\). The load position and orientation are shown in Fig. 1. The displacement–response curve at the load position is shown in Fig. 5. The whole process is done on a computer with Intel(R)-Core(TM) i5-2520 M CPU@2.50 GHz.

According to the displacement–response curve shown in Fig. 5 and the calculated natural frequencies, in such a load condition, in the frequency interval [0, 600] Hz, the first (\(151.3\;{\text{Hz}}\)), third (\({\kern 1pt} 275.1\;{\text{Hz}}\)) and eighth (\({\kern 1pt} 539.7\;{\text{Hz}}\)) order modes are excited. The second (\(195.5\;{\text{Hz}}\)), fourth (\({\kern 1pt} 390.1\;{\text{Hz}}\)), fifth (\({\kern 1pt} 396.4\;{\text{Hz}}\)), sixth (\({\kern 1pt} 438.7\;{\text{Hz}}\)) and seventh (\({\kern 1pt} 512\;{\text{Hz}}\)) modes are not excited this is mainly because the load is applied on the non-zero vertical displacement point of these corresponding mode shapes. Thus, these excitation modes may dominantly influence the optimized result. Further, compared with the full degree freedom method, the more modes are used, the higher accuracy is achieved in the MAM while the MDM has lower accuracy. To attain high accuracy and low computational cost, the MAM is adopted in the following numerical examples and the mode orders are set as 30 as it can provide enough accuracy.

Besides, the accuracy and CPU time for the sensitivity analysis by the direct method and the decoupled method are also presented. And the MAM is used to calculate the displacement–response. The results are, respectively, shown in Fig. 6 and Table 2. From Fig. 6 and Table 2, the decoupled method can provide effective and high-accuracy sensitivity analysis results. Even if more frequency steps are used in large frequency intervals, the computational time is still much lower than the direct sensitivity method.

4.2 Single-load case

In this numerical example, several frequency intervals including \([0,10]\;Hz\), \([0,100]\;Hz\), \([0,200]\;Hz\), \([0,300]Hz\), \([0,400]\;Hz\) and \([0,600]\;Hz\) in Fig. 7 are employed to verify the effectiveness of the proposed method. The frequency intervals \([0,10]\;Hz\) and \([0,100]\;Hz\) are less than the first natural frequency. And frequency interval \([0,200]\;Hz\) includes the first two natural frequencies. The frequency intervals \([0,300]\;Hz\), \([0,400]\;Hz\) and \([0,600]\;Hz\) include the first three, five and eight natural frequencies, respectively. The allowed maximum volume fraction for phase material 1 in the damping layer is set as 0.7. The load position and orientation are shown in Fig. 1. In the frequency interval \([0,600]\;Hz\), three symmetric eigenmodes are excited as shown in Fig. 8.

In this section, integrated and separate optimization are both investigated. In the following tables, the abbreviation C represents only the damping core is optimized; the abbreviation L represents only fiber layers are optimized; the abbreviation C + L represents the damping core and the fiber layers are simultaneously optimized. In the final optimized results, blue lines are the fibers in converged elements and red lines are the fibers in elements without convergence. The optimized results for the objective function, the convergence measurement of the fiber layer and the iteration process are, respectively, shown in Table 3 and from Figs. 9, 10, 11 and 12. In these figures, fiber ply angles (blue lines) in most of the elements are converged, only very few (red lines) fiber angles are non-converged.

From Table 3, all convergence measures for fiber layers are more than 90%. It clearly shows that at low-frequency intervals \([0,10]\;Hz\) and \([0,100]\;Hz\), when damping materials are only optimized, the relative decrease of the objective function is very small. However, only fiber angles are optimized or the integrated optimization is conducted, the relative decrease of the objective function is significantly apparent. Compared with the optimized results in Figs.9a, b, 10a, b as well as Fig. 13a, b, although the layout of the damping material is different for three cases, the fiber angles for layer 1 in three cases are very similar. The same phenomenon can be seen for layer 2. Obviously, for these two cases ([0, 10] Hz and [0, 100] Hz), the stiffness of the fiber layers is more important on the final value of the objective function while the damping material has almost no effect. This is mainly because in low-frequency interval, according to the dynamic equation the optimization is more similar to the static optimization as the stiffness K has dominant influence while the item \({ - }\omega^{2} {\mathbf{M}}\) has less effect. However, in the high-frequency interval, according to the dynamic equation, the items \({ - }\omega^{2} {\mathbf{M}}\) and K both significantly influence the final optimized result.

However, when the frequency interval includes the natural frequencies, the relative decrease of the objective function is different from that corresponding to the low-frequency bandgap. The optimized results for the damping core are slightly different on the layout boundary of the damping material in these four frequency intervals while are different those from the low frequencies. For these four high-frequency intervals, the fiber angles are significantly different near the middle part of the plate. In such a condition, separately optimizing the damping core or the fiber layers will slightly reduce the objective function value, but the simultaneous optimization will significantly decrease the objective function, i.e., the integrated optimization can obtain the best performance.

Besides, the displacement–response curves are presented in Fig. 13. Apparently, for the [0, 10] Hz the resonant peaks after optimization slightly decrease while for the [0, 100] Hz, the resonant peaks after integrated optimization increase. For frequency band [0, 200] Hz, only optimizing the fiber layers decreases the first natural frequency while the integrated optimization increases the first natural frequency. For high-frequency band gaps, i.e. [0, 300] Hz, [0, 400] Hz and [0, 600] Hz, only optimizing the fiber layers also apparently decreases the first natural frequency while the integrated optimization hardly changes the first natural frequency. When the damping core is only optimized, it is clear that the first several order natural frequencies almost does not change and the resonant peaks slightly decrease. For the integrated optimized results from [0, 300] Hz and [0, 400] Hz, the second and third resonant peaks become larger while for [0 600]Hz, all three resonant peaks decrease.

4.3 Multi-load cases

In this numerical example, the frequency intervals used in the above example are still employed to verify the effectiveness and robustness of the proposed method. The load position and orientation are shown in Fig. 14. In the frequency interval \([0,600]\;Hz\), for the multi-load case 1, there are three same mode shapes excited as shown in Fig. 8. The applied load can excite these three symmetric eigenmodes so that these three modes may have a significant influence on the optimized results. For the multi-load case 2, in the frequency interval \([0,600]\;Hz\), there are two mode shapes excited as shown in Fig. 15. They are the second (\(195.5\;{\text{Hz}}\)) and the fourth (\({\kern 1pt} 390.1\;{\text{Hz}}\)) mode shape as shown in Fig. 16. From these mode shapes, it is clear that the applied load excites the nodal points of these three anti-symmetric Eigenmodes so these three modes may significantly influence the final optimized results. The model acceleration method is used to calculate the structural displacement–response and all the other parameters are the same as the above numerical example. The optimized results for the objective function, the convergence measurement of the fiber layer, the iteration process are, respectively, shown in Tables 4 and 5 and from Figs. 17, 18, 19, 20, 21, 22, 23 and 24.

For the multi-load case 1, from Table 4 all the convergence measures for fiber layers are still more than 90%. At low-frequency intervals, the optimization of damping materials has little effect on the relative decrease of objective function while separately optimizing fiber angles or the integrated optimization are conducted, an apparent change is obtained on the relative decrease of the objective function. By comparing the optimized results in Figs. 17a, b, 18a, b as well as Fig. 20a, b, the layout of the damping material is also different from the single load case although the same mode shapes are excited in these two load cases. The optimized fiber angles for layer 1 and layer 2 in three cases are very similar and different from the results of the single load situation. In these two low-frequency intervals, the damping material has also almost no effect on the value of the final objective function.

However, for the frequency interval exceeding the first natural frequency, the relative decrease of the objective function for separately optimizing the damping core or the fiber layers and the integrated optimization is different from the low-frequency bandgap. This is mainly because the optimization of damping material core layout mainly changes the structural damping property while optimizing the fiber orientation, the stiffness of the structure is changed. In such conditions, separate optimization will slightly reduce the objective function value while the integrated optimization has the best performance in the three methods.

When the multi-load case 2 is applied to the structure, the optimized results for separate and integrated optimization are all very different from the situations for single load and the multi-load case 1. This is because in this applied load condition the excited mode shapes differ from the first two load conditions and it significantly influences the structural vibration level. It is worth pointing out that in the case of [0, 200] Hz for multi-load case 2, the damping material volume fraction is 70% but from the iteration process, less damping material is needed. This means that in such conditions, more damping material use will not apparently improve or even worsen the objective value although the use of more damping material is allowed.

The displacement–response curves in the frequency domain are presented from Figs. 25 and 26. For multi-load case 1, when the low-frequency band does not include the first frequency interval, all the optimized results will drive the first natural frequency far from its original value and the first resonant peak even increases in these situations. However, for the high-frequency intervals ([0, 200] Hz, [0, 300] Hz and [0, 400] Hz), the first natural frequency slightly decreases after optimization while for the optimized results from [0 600] Hz, the integrated optimization also increases the first natural frequency while only the third resonant peak reduces and the first two resonant peaks even slightly increase. For the multi-load case 2, the integrated optimized results from all frequency gaps all increase the first natural frequency. This means the optimized design broads the structural serving frequency range under low-frequency condition. For all frequency intervals, it is hard to conclude the resonant peaks will decrease after optimization. Because the objective function is to minimize the dynamic compliance in a given frequency range and sometimes it cannot efficiently restrict the resonant peak value.

5 Conclusions

This paper develops an integrated optimization model for the laminated structure with the damping material core and fiber layers. And some conclusions can be drawn as follows:

-

1.

A decoupled sensitivity analysis method for the discrete material optimization is built. And the incorporation of the mode acceleration method and the decoupled sensitivity analysis can efficiently reduce the computational cost and simultaneously maintain the high accuracy by comparing with the model displacement method and direct sensitivity analysis method.

-

2.

In the single load and multi-load cases, for the fiber layer optimization, the adopted Heaviside penalization of discrete material optimization can obtain high converged results. In low-frequency intervals, the stiffness dominates the optimized results so that the optimization for fiber angles significantly influences the final decrease of the objective while the layout of damping material has a negligible effect. However, in high-frequency intervals, both the optimization of fiber material and the damping material significantly influence the final decrease of the objective. For all frequency intervals, the optimized layout of the damping material mainly influences the resonant peaks and has almost no effect on the change of natural frequencies.

-

3.

For high-frequency intervals, the applied load condition influences the final optimized results because they excite different dominant mode shapes. Even the same mode shapes are excited under single load and multi-load case 1, the optimized results are also influenced by the load position.

-

4.

The proposed optimization model is effective and robust for different frequency intervals and different load conditions. And the integrated optimization model can obtain the best performance by comparing with the separate optimization cases.

References

Olhoff N (1977) Maximizing higher order Eigenfrequencies of beams with constraints on the design geometry. Mech Base Des Struct Mach 5(2):107–134

Du J, Olhoff N (2007) Topological design of freely vibrating continuum structures for maximum values of simple and multiple eigenfrequencies and frequency gaps. Struct Multidiscip Optim 34(2):91–110

Jog CS (2002) Topology design of structures subjected to periodic loading. J Sound Vib 253(3):687–709

Sun HL, Chen HB, Zhang K, Zhang PQ (2008) Research on performance indices of vibration isolation system. Appl Acoust 69(9):789–795

Wang J, Mak CM (2013) An indicator for the assessment of isolation performance of transient vibration. J Vib Control 19(16):2459–2468

Olhoff N, Du J (2014). In: Rozvany G, Lewiński T (eds) Topological design for minimum dynamic compliance of structures under forced vibration. Topology optimization in structural and continuum mechanics. Springer, Heidelberg

Sigmund O, Jensen JS (2003) Systematic design of photonic band-gap materials and structures by topology optimization. Philos Trans 361(1806):1001–1019

Lall A, Asnani N, Nakra B (2020) Vibration and damping analysis of rectangular plate with partially covered constrained viscoelastic layer. J Vib Acoust Stress Reliab 109(3):241–247

Xu B, Ou JP, Jiang JS (2013) Integrated optimization of structural topology and control for piezoelectric smart plate based on genetic algorithm. Finite Elem Anal Des 64:1–12

Kang Z, Tong L (2008) Integrated optimization of material layout and control voltage for piezoelectric laminated plates. J Intell Mater Syst Struct 19(8):889–904

Shen I (1994) Hybrid damping through intelligent constrained layer treatments. J Vib Acoust 116(3):341–349

Ling Z, Ronglu X, Yi W, El-Sabbagh A (2011) Topology optimization of constrained layer damping on plates using method of moving asymptote (MMA) approach. Shock Vib 18:221–244

Takezawa A, Daifuku M, Nakano Y et al (2016) Topology optimization of damping material for reducing resonance response based on complex dynamic compliance. J Sound Vib 365:230–243

Yamamoto T, Yamada T, Izui K, Nishiwaki S (2015) Topology optimization of free-layer damping material on a thin panel for maximizing modal loss factors expressed by only real eigenvalues. J Sound Vib 358:84–96

Yun KS, Youn SK (2018) Topology optimization of viscoelastic damping layers for attenuating transient response of shell structures. Finite Elem Anal Des 141:154–165

Madeira JFA, Ara’ujo AL, Mota Soares CM, Mota Soares AC, Ferreira AJM (2015) Multiobjective design of viscoelastic laminated composite sandwich panels. Compos Pt B Eng 77:391–401

Liu H, Zhang W, Gao T (2015) A comparative study of dynamic analysis methods for structural topology optimization under harmonic force excitations. Struct Multidiscip Optim 51(6):1321–1333

Zhao J, Yoon H, Youn BD (2019) An efficient concurrent topology optimization approach for frequency response problems. Comput Methods Appl Mech Eng 347:700–734

Yoon GH (2010) Structural topology optimization for frequency response problem using model reduction schemes. Comput Methods Appl Mech Eng 199:1744–1763

Sharma N, Lalepalli AK, Hirwani CK, Das A, Panda SK, Topal U, Dede T (2021) Optimal deflection and stacking sequence prediction of curved composite structure using hybrid (FEM and soft computing) technique. Eng Comput 37:477–487

Das A, Hirwani CK, Panda SK, Topal U, Dede T (2018) Prediction and analysis of optimal frequency of layered composite structure using higher-order fem and soft computing techniques. Steel Compos Struct 29(6):745–754

Anil KL, Panda SK, Sharma N, Hirwani CK, Topal U (2020) Optimal fiber volume fraction prediction of layered composite using frequency constraints—a hybrid FEM approach. Comput Concr 25(4):303–310

Denkena B, Schmidt C, Weber P (2016) Automated fiber placement head for manufacturing of innovative aerospace stiffening structures. Proc Manuf 6:96–104

Kim BC, Weaver PM, Potter K (2014) Manufacturing characteristics of the continuous tow shearing method for manufacturing of variable angle tow composites. Compos Part A Appl Sci Manuf 61:141–151

Uhlig K, Bittrich L, Spickenheuer A, Almeida JHS Jr (2019) Waviness and fiber volume content analysis in continuous carbon fiber reinforced plastics made by tailored fiber placement. Compos Struct 222:110910

Stegmann J, Lund E (2005) Discrete material optimization of general composite shell structures. Int J Numer Methods Eng 62(14):2009–2027

Kiyono CY, Silva ECN, Reddy JN (2012) Design of laminated piezocomposite shell transducers with arbitrary fiber orientation using topology optimization approach. Int J Numer Methods Eng 90(12):1452–1484

Lund E, Stegmann J (2006) Eigenfrequency and buckling optimization of laminated composite shell structures using discrete material optimization. IUTAM symposium on topological design optimization of structures, machines and materials. Springer, Dordrecht

Niu B, Olhoff N, Lund E, Cheng G (2010) Discrete material optimization of vibrating laminated composite plates for minimum sound radiation. Int J Solids Struct 47(16):2097–2114

Bruyneel M (2011) SFP—a new parameterization based on shape functions for optimal material selection: application to conventional composite plies. Struct Multidiscip Optim 43(1):17–27

Gao T, Zhang WH, Duysinx P (2013) Simultaneous design of structural layout and discrete fiber orientation using bi-value coding parameterization and volume constraint. Struct Multidiscip Optim 48(6):1075–1088

Duan Z, Yan J, Zhao G (2015) Integrated optimization of the material and structure of composites based on the Heaviside penalization of discrete material model. Struct Multidiscip Optim 51(3):721–732

Reddy JN (2004) Mechanics of laminated composite plates and shells: theory and analysis. CRC Press, Boca Raton

Niu B, Shan Y, Lund E (2019) Discrete material optimization of vibrating composite plate and attached piezoelectric fiber composite patch. Struct Multidiscip Optim 60:1759–1782

Ma ZD, Kikuchi N, Hagiwara I (1993) Structural topology and shape optimization for a frequency response problem. Comput Mech 13(3):157–174

Zhao J, Wang C (2016) Dynamic response topology optimization in the time domain using model reduction method. Struct Multidiscip Optim 53:101–114

Huang X, Zhou S, Sun G et al (2015) Topology optimization for microstructures of viscoelastic composite materials. Comput Methods Appl Mech Eng 283:503–516

Svanberg K (2002) A class of globally convergent optimization methods based on conservative convex separable approximations. SIAM J Optim 12:555–573

Funding

This work was supported by the National Natural Science Foundation of China (11872311) and the Natural Science Basic Research Plan in Shaanxi Province of China (2020JM085).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared no potential conflicts of interest with respect to the research, authorship, and publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ding, H., Xu, B., Duan, Z. et al. Optimal design of laminated plate for minimizing frequency response based on discrete material model and mode reduction method. Engineering with Computers 38 (Suppl 4), 2919–2951 (2022). https://doi.org/10.1007/s00366-021-01428-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-021-01428-1