Abstract

This paper reports on the development of the tunable diode laser absorption spectroscopy sensor near 4350 cm−1 (2298 nm) for measurements of CO and H2O mole fractions and soot volume fraction under gasification conditions. Due to careful selection of the molecular transitions [CO (υ″ = 0 → υ′ = 2) R34–R36 and H2O at 4349.337 cm−1], a very weak (negligible) sensitivity of the measured species mole fractions to the temperature distribution inside the high-temperature zone (1000 K < T < 1900 K) of the gasification process is achieved. The selected transitions are covered by the tuning range of single diode laser. The CO and H2O concentrations measured in flat flames generally agree better than 10 % with the results of 1-D flame simulations. Calibration-free absorption measurements of studied species in the reactor core of atmospheric pilot-scale entrained-flow gasifier operated at 0.1 MW power are reported. Soot concentration is determined from the measured broadband transmittance. The estimated uncertainties in the reactor core CO and H2O measurements are 15 and 20 %, respectively. The reactor core average path CO mole fractions are in quantitative agreement with the µGC CO concentrations sampled at the gasifier output.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Continuously stringent regulations regarding the pollutant emission together with the depletion of easily accessible fossil fuel resources have forced the developers of high-temperature energy conversion (such as combustion or gasification) equipment to look for alternative fuels and new (or moderated) technologies. Entrained-flow gasification of biomass is one of many possible ways to manufacture high-quality syngas for motor fuel synthesis. Due to the complexity of the gasification process and the lack of experience with many biomass fuels, fast and reliable in-furnace measurements of the important parameters of the process such as temperature, gas species and soot concentrations are of importance for reaching the optimal process operation. The measured data can also be used to identify the actual state of gasification and to detect anomalous operation.

The laser-based absorption techniques, in particular TDLAS and WMS (wavelength modulation spectroscopy) as was demonstrated by a number of researchers, see [1, 2] and references therein, are capable of providing accurate and sensitive diagnostics of many gases in combustion environment. In practical (pilot-scale and industrial) combustion devices, the tunable diode lasers found its application primarily for emission diagnostics of the exhaust gases in order to cope with pollutant regulations. One important property of any type of absorption measurements is that they integrate signals over the whole path of the laser beam. This property is quite often considered as a drawback in the studies of the processes where the local information is required. However, in the practical systems this feature can be considered as an advantage, since the average signal characterizes the overall process completeness and efficiency. In recent years, also the suitability of the TDLAS- and WMS-based sensors for high-temperature measurements in the reactor core has been confirmed. Ebert et al. [3] developed a laser-based absorption spectrometer using two separate near IR diode lasers for the simultaneous in situ detection of water vapor and oxygen within the combustion chamber of an industrial incinerator. The real-time measurement of O2 and CO concentration levels was described in a 300 ton/day incinerator furnace [4] and in post-combustion chamber of 3.5 MWth hazardous waste incinerator [5]. Teichert et al. [6] reported simultaneous in situ measurement of CO, H2O and gas temperatures in a full-sized coal-fired power plant by near-infrared diode lasers.

The sensors based on tunable diode lasers have been also applied in the high-temperature reaction zones of gasification processes. The measurements in the gasification environment are characteristically complicated by the presence of particulates considerably reducing the transmission of the laser beam and elevated pressure of the process, leading to broadening of the absorption lines. We could find only a handful of papers describing the application of the TDLAS- and WMS-based sensors for high-temperature measurements in the reactor core of the practical gasification process. Lackner et al. [7] deployed two tunable diode lasers for quantitative diagnostics of CO, CH4 and H2O in the core of laboratory-scale fluidized bed combustor. Ortwein et al. [8] developed a tunable diode laser absorption spectrometer for calibration-free, absolute in situ HCl detection with minimized cross-sensitivity to CO2 and H2O. The spectrometer was applied to in situ measurements in a pilot-scale entrained-flow gasification process (T = 1130 °C, P = 1 atm, L = 28 cm). Recently, the group of Dr. R. Hanson (Stanford University) [9, 10] reported the first diode laser absorption measurements for gas temperature and species concentrations in a pilot-scale, high-pressure, entrained-flow, oxygen-blown, slagging coal gasifier with pressures up to 18 atm and temperatures to 1800 K in the reactor. The measurements were taken at three locations (1) reactor core (temperature in the range 1300–1800 K), (2) the exit of the reactor (600–1000 K) and (3) in the gasifier product stream (320–400 K). In the reactor core, the temperature measurements were reported by using three pairs of H2O transitions at near 1.4 µm. The same group published in situ measurement of pressurized syngas H2O, CH4 and CO2 concentrations in the gasifier product stream [9, 11]. To permit quantitative measurements, the collision-broadening coefficients of the selected transitions were determined for collisions with possible syngas components, namely CO, CO2, CH4, H2O, N2 and H2. Sample measurements were taken for each species in gas cells at room temperature and pressures up to 20 atm. A very recent publication by the group reports the similar measurements at temperatures up to 600 K [12].

As can be noticed from the above-mentioned works, the application of TDLAS and WMS sensors for characterizing the high-temperature reaction zones of the pilot-scale and industrial combustion and especially gasification processes is still quite a new field with many research areas required considerable attention. These areas include measurements of new species, detection at elevated pressures, improving uncertainties of the measurements, usage of single laser for multispecies detection, application to the devices with restricted optical accesses.

The aim of this study is to develop a technique for accurate real-time in-furnace monitoring of CO, H2O and soot under pilot-scale (and industrial) gasification conditions. Here we report, to our knowledge for the first time, on the development and application of a TDLAS sensor based on single laser for the detection of the above-mentioned parameters in the reactor core of pilot-scale gasification process (T > 1000 K). The novelty of the work is (1) the diagnostics of the average path CO, H2O mole fraction and soot concentration in the reactor core of the pilot-scale gasifier using a single diode laser, (2) the application of the CO and H2O lines at 4350 cm−1 for diagnostics (absorption via the selected transitions has a very modest temperature dependence in the temperature range of the gasifier), which practically eliminates the uncertainties related to the inhomogeneous distribution of the species and temperature inside the gasifier. The experiments were performed both in well-defined flat flames and in a pilot-scale atmospheric air-blown entrained-flow gasifier located at SP ETC in Piteå, Sweden. Powder from peat was used as fuel during the experiments. The experimental data in the flat flames are compared with those predicted using detailed chemical mechanism; the in-furnace measurements are compared with micro-(µ)GC data sampled at the gasifier exit.

2 Approach

2.1 Data Reduction

In the absorption measurement taken in a media where the temperature and concentration of the species can vary along the laser beam path, a signal, I S, measured by a detector installed after the media can be written as in [13]

where I 0 is the intensity of initial light, k(v) is the absorption coefficient of the component being detected at frequency v, I BG is the background radiation, L is the absorption path length, L = l 2 − l 1. Tr(t) is temporal fluctuations of the broadband overall transmission caused in general by such factors as broadband absorption and light scattering by particles. The absorption coefficient can be expressed as

where S ik is the spectral line intensity for the transition from the initial level i to the level k, f is the normalized absorption line function,\(\mathop \smallint \limits_{ - \infty }^{\infty } f(\nu ){\text{d}}\nu = 1,\) T is the temperature and N is the molecular number density; summation over all allowed transitions ik in the considered spectral interval is assumed. In the case of a gas, N is related to the species mole fraction X M through:

where P is the pressure and k B is the Boltzmann constant. Rewriting Eq. (1) in terms of the absorption, A, and using Eqs. (2) and (3), we arrive at the following expression:

Determination of the species mole fraction at some arbitrary location X M(l 0) requires the temperature distribution and relative profile of the studied species mole fraction along the beam path [14]. The required information can be obtained in laboratory flames, but is hardly accessible in pilot- and industrial-scale equipment. Instead, the average path mole fraction

is often used. Provided that the S ik /T term is a weak function of temperature along the laser path for the selected transition(s), it can be taken outside the integral in Eq. (4). The frequency integration of the left and right parts over some well-separated selected transition(s) yields then:

The above procedure provides the calibration-free determination of \(\tilde{X}_{\text{M}}\) from the measured values if Tr(t) and I BG(t) are experimentally determined (see the discussion below) and the S ik /T ratio in the studied medium is known. In the given approach, calculation of the absorption line function is not needed. Another approach includes fitting the experimental spectrum Eq. (4) using the known spectroscopic parameters; the weak temperature dependence of the S ik /T and f terms is assumed. The approach is especially useful for deriving the multiple-species concentrations with overlapping transitions from the measured spectra; it might also be useful for evaluating the average temperature. In this work, we use both approaches (integration and fitting) for deriving CO and H2O average path mole fractions. To determine the species concentrations, a computer code was written that calculates the theoretical absorption spectrum. The spectral simulations were performed using the molecular parameters tabulated in HITRAN 2012 [15] and HITEMP 2010 [16] databases. The molecular absorption line function was simulated/fitted using the Voigt profile [17] calculated by algorithm suggested by Humlíček [18]. Taken into account that the collisional broadened line width of the molecules (required for calculation of the Voigt profile) for the studied conditions are unknown, we fitted these parameters in this work.

2.2 Selection Procedure

The aim of the work was a sensor capable of accurate determination of the key parameters in the gasification process. The intention was to use a single diode laser for deriving more than one species and soot concentration from the measured spectra. Since the major species of interest was CO, the spectral region near 4350 cm−1 (2.3 µm) containing strong CO transitions was selected for analysis. The region also contains a considerable number of H2O and CH4 transitions.

A major criterion for the selection of the spectral interval was the weak temperature dependence of the S/T term for CO transition(s). Based on the spectral simulation performed using the molecular parameters tabulated in HITRAN 2012 and HITEMP 2010, the region near 4350 cm−1 was selected as potentially attractive for the gasification measurements. Figure 1 shows the calculated absorption spectrum of CO, H2O and CH4 molecules from 4348.8 cm−1 to 4352 cm−1 (HITRAN 2012, T = 1250 K, L = 50 cm). The figure also contains the experimental transmittance spectrum measured inside the entrained-flow gasifier, see Sect. 3.1 for detailed description of the data treatment procedure, during the peat gasification. The temperature measured by an in-furnace thermocouple located close to the laser beam was around 1300 K.

The selected interval contains three CO R34–R36 (υ″ = 0 → υ′ = 2) lines, the CO R36 line is well isolated, the CO R35 transition overlaps with small neighboring CH4 lines, and the CO R34 line overlaps with H2O line \((\upsilon_{1}^{{\prime \prime }} ,\upsilon_{2}^{{\prime \prime }} ,\upsilon_{3}^{{\prime \prime }} ,j^{{\prime \prime }} ,k_{a}^{{\prime \prime }} ,k_{c}^{{\prime \prime }} \to \upsilon_{1}^{{\prime }} ,\upsilon_{2}^{{\prime }} ,\upsilon_{3}^{{\prime }} ,j^{{\prime }} ,k_{a}^{{\prime }} ,k_{c}^{{\prime }} )\) [000(13 2 11) → 001(14 4 10)] near 4349.337 cm−1. Analysis of the simulations reveals that the sum of all CH4 line intensities forming the CH4 feature in the vicinity of the CO R35 line is about 3 % from the line intensity of the R35 CO transition at the concentration level reported, see also discussion in Sect. 4.2. The contribution decreases at higher temperatures. The spectrum has also an isolated CH4 feature near 4349.2 cm−1, which might be useful for its concentration evaluation. Turning to the experimental spectrum, we note a good accord with the simulations regarding the position of the CO, H2O and CH4 transitions.

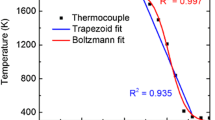

The normalized temperature dependences of the S/T term for the CO R35 line and the H2O line near 4349.337 cm−1 are shown in Fig. 2. The figure shows that in the temperature range from 1100 to 1900 K the S/T term for the CO R35 line changes by <10 %. The term has a maximum value around 1500 K; at temperatures below 1100 K, the term decreases rapidly. We note that the neighboring CO lines have similar T dependence due to closeness of their initial energy levels. The temperature dependence of the H2O S/T term has maximum near 1100 K and changes by <20 % in the temperature range from 900 to 1500 K. The S/T value decreases rapidly at temperatures below 900 K; at temperatures above 1100 K, it reduces steadily with the rate ~12 % per 200 K. We conclude that the selected lines have a very modest temperature dependence in the temperature range expected in our entrained-flow gasification experiments, approximately 1100–1900 K. The CH4 feature near 4349.2 cm−1 consists mainly from the transitions from low initial energy levels and has very strong temperature dependence in the gasifier temperature range, which makes the assumption leading to Eq. (5) invalid. Considering that, we decided not to attempt the quantification of CH4 here.

3 Experimental

3.1 Laser system

After the line selection procedure, the Cheetah laser system (Sacher Lasertechnik) consisting of a controller unit (PILOT PC-500) and external laser head was chosen to generate the cw laser beam with an output power of ~3 mW at wavelength near 4350 cm−1 with the line width of 1.5 MHz. Figure 3 shows the basic schematic of the experimental setup used for CO, H2O and soot absorption measurements in flat flames and gasification experiments. The laser wavelength was tuned over a range of up to ~4 cm−1 in 1.1 or 11 ms by modulation of the driving current by the triangular shaped voltage at constant diode temperature (23.5 °C). The voltage was produced by the function generator (BK Precision 4011A) and applied to the controller. The initial part of the voltage ramp was selected to be somewhat below the generation threshold. This allowed us to measure the background radiation required for evaluation of the quantitative data at the time of the scan. The collimated radiation from the laser was directed through the studied object (flat flame or entrained-flow reactor). The power of the sample beam was measured by the InGaAs amplified detector PDA10 (Thorlabs). The detector signal and output voltage from the controller were sampled at 1 MHz by the digital oscilloscope (ME-UM202, Melihaus) and processed by a PC. The 1.1 and 11 ms spectra were saved every 0.1 and 0.5 s, respectively. The total number of the scans in one series of measurements was 100 or 1000. For all gasification and most of the flat flame measurements, each scan in a series was treated separately. In addition, for each of the gasification conditions studied, a number (up to 80) of scans were recorded continuously. An air-spaced (L = 7 cm) Fabry–Perot interferometer was used for frequency calibration.

For all experiments reported here, the magnitude of the background radiation varied by less than few percent on scan-to-scan basis. We further note that the magnitude of the transmitted (laser) signal was sufficiently large in comparison with the background one to limit corresponding estimated uncertainty in concentration measurements to few percent for all gasification conditions studied. The overall transmission was deduced by taking a ratio of signals measured by a detector installed after the gasifier during the gasification and when only air entered the gasifier. The signals were firstly corrected for corresponding backgrounds. The spectral region selected in the given work (see Fig. 1) contains well-resolved spectroscopic features permitting us accurate determination of broadband transmission signal from the measured spectra. The overall transmittance was determined as an average of transmittance from a number of spectral intervals (within the selected wavelength region) containing no apparent spectral features. We note that for these spectral intervals the contribution from the neighboring molecular transitions amounts to the absorption below ~3 × 10−3, calculated using HITRAN databases. It is ~2 orders of magnitude lower than minimal broadband absorption observed during the gasification experiments. We also evaluated the influence of the wings of the strong H2O lines located the range from 3500 to 4300 cm−1 to the selected for diagnostic interval. It appeared that their contribution is below 3 × 10−5 (absorption). The tuning of the laser over the selected wavelength region was sufficiently fast to ensure the constancy of the transmission and the background signals.

3.2 Flat flame burner and entrained-flow gasifier setups

The methane/air flames studied in this work were stabilized on a 6-cm McKenna products water-cooled sinter burner. The McKenna burner used in the experiments has central open jet with outer diameter of 1 cm [19]. The flow rates of methane and air were measured by calibrated Bronkhorst mass flow controllers. The equivalence ratio was calculated from the measured flows. A wide range of flame temperatures was achieved by varying the exit velocity of the fuel–air mixture at constant equivalence ratio, thus varying the heat transfer to the burner [20]. To minimize the variation of the absorption path length with the exit gas flow a 60-mm-circular plate of thick stainless steel was placed approximately 21 mm above the burner. The experimental profiles were compared with the predictions of one-dimensional flame calculations using GRI-Mech 3.0 chemical mechanism [21] and the PREMIX code from the CHEMKIN II [22] package.

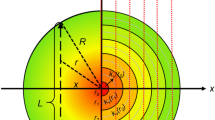

The pilot-scale atmospheric entrained-flow gasifier, see Fig. 4, is cylindrically shaped with an inner diameter of 500 mm and the height about 4 meters. The outer shell is made of steel protected by 200 mm of refractory and insulation materials. The gasifier is equipped with thermocouples at eight levels both inside the refractory and in combination with ceramic covers in the actual gas flow. Optical access is possible at four different levels as well as from the top and bottom. A constant flow of N2 was supplied to the glass windows to prevent their fouling. The diameter of tubes/openings from the reactor to the windows for optical access was 2 cm. The value of the N2 flow, 2 l/m, was selected (based on the sensitivity of the TDLAS measured concentrations to the N2 flow rate) in such a way to minimize the mixing of the cold N2 with the hot gases outside the inner diameter of the reactor. The absorption measurements taken at the constant gasification condition showed very modest decrease in the measured quantities, <7 %, with an increase in the N2 flow from 0.5 to 4 l/m. The data suggest that the penetration of the N2 gas into the gasifier core is modest for the flow range applied, and the effective path length of our laser measurements is close to that of the inner diameter of the gasifier (50 cm).

The gasifier was run air-blown with powder from peat as a fuel. The particle size distribution of the peat powder and its chemical compositions are given in Table 1. All experiments are performed at P = 1 atm. The power was constrained to ~100 kWth during the whole set of operational points; by controlling the burner air flow, the equivalence ratio was changed. The fuel was pneumatically feed from the feed hopper entering the gasifier centrally in the top mounted burner. The burner used in campaign was completely axial forming a jet type of flame. After the gasifier, the syngas is combusted in a boiler by addition of heated air before evacuation through the flue gas stack. Before the boiler, the syngas is sampled and analyzed by a µGC (micro-gas chromatograph Varian 490 GC with molecular sieve 5A and PoraPlot U columns). An additional gas stream, see Fig. 4, was sampled just outside the exit of the gasifier to determine the concentration and size distributions of soot in the syngas by an electrical low pressure impactor (ELPI) produced by Dekati.

3.3 Evaluation of soot concentration

Provided that the broadband reduction in the signal inside the gasifier is caused predominantly by the soot absorption and assuming that soot particles are isotropic spheres, the quantitation of the soot is possible using the following relation from the measured transmittance

where f v is the soot volume fraction, λ is the wavelength, E(m) is the absorption function, m is the complex refractive index of the soot particles. It was reported by Simonsson et al. [23] that for mature soot the absorption function is constant in the wavelength interval 685–1064 nm. Our recent soot absorption measurements taken using visible (635 nm) and IR (1400 nm and 2300 nm) lasers point also out on the very modest variation of the absorption function, within 20 %, for the mature soot for the wavelengths used. The measurements were taken in a number of C2H4/O2/N2 sooty flat flames at the equivalence ratios similar to those used during our gasification experiments, and the aerodynamic mean diameters of the soot particles measured by ELPI in the flat flames (up to 200 nm) and the exit of the gasifier (100–160 nm) were similar. In this work, we used E(m) value 0.35 (following the publication [23]) to quantify the soot concentration. We recognize that the optical property of soot formed in the pilot-scale gasifier might still be somewhat different from that formed in the laboratory-scale ethylene flames due to formation of metal containing nano-carbon particles [24] from the ash forming elements in the fuel. However, at the moment we have no available data allowing us to quantify the difference, see also the discussion in Sect. 4.2.

4 Results and Discussion

4.1 Flat flame measurements

At first, we demonstrate the application of two, described above, procedures (integration and fitting) for deriving CO and H2O concentrations from absorption spectra measured in the well-defined one-dimensional fuel-rich methane–air flames. The measurements were taken at a height of 5 mm above the burner surface in the burner-stabilized flames at fuel equivalence ratios φ = 1.2 and 1.3. The selected flames have a sizable CO and H2O equilibrium concentrations, which, as detailed flame calculation demonstrates, are reached within 2 mm from the burner surface. Furthermore, the equilibrium CO and H2O concentrations are weak function of the flame temperature at a given equivalence ratio. For example, the CO mole fraction varies from 5.6 to 6 % in the temperature range from 1700 to 2000 K at φ = 1.3. The laser beam did not pass above the center of the burner, but was radially shifted by ~15 mm. The projection of the laser beam to the burner surface equaled to 5.1 cm, and this distance was taken as the absorption path length in the calculations/fittings. We used the predicted flame temperatures for the evaluation of the measured concentrations.

Figure 5a–d shows examples of the measured, calculated and fitted spectral features selected for the quantitative diagnostics of H2O and CO molecules. Figure 5a shows the measured transmittance and calculated absorption (using HITEMP 2010) spectra near the R35 CO transition. The experimental spectrum is measured in methane–air flame at φ = 1.3 at the flow rate of the cold gases 16 l/m. The calculated spectrum was simulated using the following concentrations and temperature [H2O] = 18.1 %, [CO] = 5.8 % and T = 1881 K obtained from 1-D flame simulations, see above. The spectra were calculated in the wavenumber range from 4345 to 4355 cm−1 with a step of 0.005 cm−1. The figure shows both molecular absorption spectra of H2O and CO and their sum. The HITEMP calculations reveal that even at that relatively high flame temperature, the R35 CO transition is practically free from any sizeable interference with H2O lines. The calculations show that the sum of all H2O line intensities in the spectral interval from 4350.5 to 4350.9 cm−1 is <2 % from the line intensity of the R35 CO transition for T = 1881 K. The value gets lower with the decrease in temperature. Further, we performed the spectral integration of the experimental absorption spectrum (see Fig. 5b) and received the value of 5.3 % as the flame CO concentration [using Eq. (6)]. The difference between the calculated equilibrium CO concentration and the obtained value is about 10 %, which we consider as a very good agreement. Important source of the uncertainties in the integration method is the finite extent of the absorption profile. To estimate the effect of the finite extent of the absorption profile for CO concentration, we simulated the molecular spectrum of a single R35 CO transition ([CO] = 5.9 % and T = 1881 K). The simulations continued over the spectral interval with a width of 200 cm−1; the middle of the interval was centered on the peak values of the transition; all other transitions in the interval were not included in the calculations. The absorption integrated over the interval extended ±100 cm−1 from the line center resulted in the CO concentration equal to the nominal CO concentration, but the value calculated over ±0.15 cm−1 interval (typically used for the treatment of the experimental spectra) was about 10 % lower. While performing these spectral simulations, we calculated collisional broadened line widths via the following relation

where γ M and γ air are self- and air-broadened line widths for molecule M, n is the temperature dependence coefficient. Self- and air-broadened line widths are tabulated in the HITEMP databases. At the flame and especially gasification conditions, the composition of the perturbing gas deviates significantly from that of the air. To account for the effect of the finite extent of the absorption profile on the concentration, we decided to spectrally fit the measured absorption spectra using the tabulated line intensity of the CO R35 transition (reported with uncertainty better than 5 %). The fitted parameters were the background, the CO concentration and the combustion products mixture broadened line width. Figure 5b includes the fitted spectrum; the fitted concentration is 5.76 %, and the fitted background is shown in the figure as a green line. The collisional CO line width calculated using the fitted data is about 30 % bigger than one calculated using the air-broadened line width for the CO R35 transition tabulated in the database. The result is perhaps not unexpected since H2O molecule is generally more efficient quencher than air. Below, reporting the CO concentration evaluated from the CO R35 transition, we will provide the fitted data. The spectral integration provided the values approximately 10 % lower than the fitted data for all studied gasification and flame environment (the difference was never more than 15 %).

Measured, calculated and fitted spectral features selected for the quantitative diagnostics of H2O and CO molecules. The measurements were taken in flat CH4/Air flames at φ = 1.3 at 16 l/m (a, b) and 10 l/m (c, d). a Measured transmittance spectrum and the CO and H2O absorption spectra calculated using HITEMP 2010. b Fitted and experimental absorption spectra. c Measured transmittance spectrum and the CO and H2O absorption spectra calculated using HITEMP 2010 and HITRAN 2012. d Fitted and experimental absorption spectra. The green horizontal line in c and d shows the fitted background, see text for more details

Figure 5c shows the measured transmittance and calculated absorption (using HITRAN 2012 and HITEMP 2010) spectra near R34 CO transition. The measurements are taken in methane–air flame at φ = 1.3 at the flow rate of the cold gases 10 l/m. The calculated spectra were simulated using the following concentrations and temperature [H2O] = 18.1 %, [CO] = 5.6 % and T = 1812 K. The HITRAN 2012 database, apart from the H2O spectral line near 4349.337 cm−1, includes a number of high-temperature H2O transitions in the selected spectral region, however, none of which appeared to be of any sizable influence on the selected CO and H2O transitions. The HITEMP 2010 database includes a large number of high-level H2O lines contributing to the spectral feature. Apart from two transitions at 4349.301 and 4349.316 cm−1, the line intensities of these transitions are below than 1 % of the H2O spectral line near 4349.337 cm−1. The sum of two H2O line intensities is <8 % from the line intensity of the H2O line near 4349.337 cm−1 for the given temperature (the value reduces to <3 % for T = 1500 K). In the temperature range from 1500 to 2000 K, the line intensity of H2O transition at 4349.316 cm−1 is about five times larger than that at 4349.301 cm−1. We note that HITRAN 2012 and HITEMP 2010 databases report the same molecular parameters for the H2O transition at 4349.337 cm−1. Considering above and taking into account the large uncertainties in the molecular parameters of the high-level H2O lines (the line intensities, for example, are known with uncertainties 20 % and worse) and their relatively small contribution to the overall spectral feature, we decided to fit the experimental spectra using two methods. In the first method, we use two molecular transitions tabulated in HITRAN 2012 database (the R34 CO transition and the H2O spectral line near 4349.337 cm−1) for fitting. In the second, we add to these two transitions the H2O spectral line at 4349.316 cm−1 from HITEMP database. Figure 5d shows the measured and fitted (method 1) absorption spectra; the fitted background is included in the figure as a green line. The fitted CO and H2O concentrations were 6.1 and 17.5 %, respectively, within 10 % from the corresponding equilibrium concentrations. The fitted CO and H2O concentrations (method 2) were 6.1 and 16.4 %. The difference between the H2O concentrations fitted using two methods is approximately 6 %. We deduced the similar difference for other flames studied here. Considering relatively small difference between the concentrations evaluated using two methods, we selected the method 1 for representation of the flame and gasification results.

Figure 6 shows the ratio of the calculated to measured H2O (a) and CO (b) concentrations 5 mm above the burner surface as a function of the flow rate of the cold gases. Figure 6b shows the experimental CO concentrations derived as explained above using the fitting routines for the R34 and R35 lines. The spectral feature near 4349.4 cm−1 was used to fit simultaneously the H2O and CO concentrations. The line intensity of the H2O transition at 4349.337 cm−1 is known with uncertainty better than 10 %. Figure 6a includes also the calculated temperatures at a 5 mm distance from the burner. The ratios are reported for the temperature range from 1770 to 1960 K. The CO ratios are within approximately 10 % from unity for the flow rates from 8 to 30 l/m for all CO lines studied. We also derived the CO concentration via fitting of the CO R36 line (not reported in Fig. 6b), and the received values were within 10 % from the corresponding equilibrium values. The H2O ratio is also within approximately 10 % from the unity and slightly increases with the decrease in flow rate. We attribute the behavior to the presence of the unaccounted high-temperature lines. In general, the evaluated CO and H2O concentrations are in quantitative agreement with calculations. For the studied flat flames, the overall calculated uncertainty in the CO measurements is 10 % and that for H2O is 15 %.

4.2 Measurements in the gasifier

Having tested the experimental procedures for deriving the species mole fractions in well-defined conditions, we attempted in situ TDLAS measurements inside the gasifier. Figure 7 shows the average path CO and H2O mole fractions (a) and the transmittance and the average path soot concentration (b) measured as a function of time during the peat gasification. The vertical lines in the figure mark the time when the air equivalence ratio β = 1/φ was changed. Every symbol in the figure represents the average of 100 or 1000 scans (each scan in a series was treated separately), and the duration of the scans were 1.1 or 11 ms, as explained in Sect. 3.1. The measured CO concentration was evaluated for the R35 and R34 lines, the former using the integration and fitting routines and the latter via the fitting routine. The concentrations reported in Fig. 7a were evaluated using the fitting routine, see the previous section. The average H2O and CO mole fractions are reported at β = 0.7, 0.5 and 0.35. For deriving the concentrations, we used the process temperature measured by the thermocouple inserted in the actual gas flow at the level closest to the laser level, see Fig. 4. The process temperature is included in Fig. 7a. The temperature measured by the thermocouple located at the same level inside the refractory was approximately 150 K lower during the whole measurement domain. Since the sensitivity of the selected molecular transitions to the temperature is very mild within expected temperature variations inside the gasifier, see Fig. 2, we do not expect any considerable influence of this parameter on the measured concentrations.

Figure 7a shows that two measured CO profiles (R35 and R34 lines) agree excellently with each other being within 5 % in the measurement domain. The CO data demonstrate clear dependence on β, and the CO mole fraction enhances with the decrease in air equivalence ratio. The reactor core TDL CO measurements are well correlated with the soot concentration measurements (Fig. 7b and discussion below) exhibiting the qualitatively similar dependence on β. The average path H2O mole fraction reduces with the decrease in air equivalence ratio . Figure 7a also includes the µGC dry CO concentrations, the comparison of the TDL and µGC CO data reveals that the µGC data lie above the corresponding TDL measurements; however, the difference between two profiles is generally within 10 %. We note here that the conversion of the TDL CO data into an equivalent dry basis (using measured TDL H2O concentration) would make the agreement even better. We report that CH4 concentrations measured by µGC were below 1 % for the conditions studied in this work and the ratio of the µGC CO to the µGC CH4 concentration was always below 15. Taking into account that the measured spectra do not suggest the presence of (sizably) larger than measured by µGC CH4 concentration, we believe that the reported CO R35 concentration is affected by the neighboring CH4 transitions by <2 %, see also Sect. 2.2. We estimated the overall uncertainty of our CO measurements on the level of 15 % and the H2O measurements 20 %.

Turning now to the soot concentration and transmittance measurements, we note that the data reported in Fig. 7b are shown for four air equivalence ratios. We report additionally the data at β = 1.2; the gasifier operates in the combustion mode at this equivalence ratio. The figure shows that ~90 % of the laser light is transmitted at β = 1.2. Since, no soot should be formed at these conditions; we think that the attenuation of the laser intensity might be caused by the fly ashes, see Table 1. We would like to emphasize here that when applying the sensor to the gasification of fuels containing significantly lower percent of ashes, we did not detect any noticeable losses of the laser intensity at β = 1.2. The values of soot shown in Fig. 7b were calculated using Eq. (7), and the possible contribution from the ashes to the laser light attenuation was unaccounted and amounts to ~0.06 ppm.

Rather unexpected degree of the agreement between the TDL and µGC CO data, apart from providing an additional confidence in our data, treatment procedure suggests that at the TDL location the CO concentration reached (or being very close to) its stationary value for all gasification conditions studied. The observation is further supported by analysis of single-scan data. We report that practically all measured single-scan spectra were not visually disturbed. The circumstance means that at the TDL measurement location there were no fast disturbances in our gasification system. We do also expect that the unburned fuel concentration at the measurement location was very low.

To illustrate the scan-to-scan variation of the TDL measured parameters, we plot in Fig. 8 the CO and H2O mole fractions and the soot concentration measured over 100 consequent scans. The duration of each scan was 11 ms. The CO mole fractions are presented for two selected for diagnostic transitions. The scans were performed during the peat gasification at β = 0.5, and the corresponding averaged values of the concentrations are shown in Fig. 7 at time 13:38. The data are plotted as a function of time, and the time difference between two scans is 0.5 s. The variation in the CO mole fractions and the soot concentration are very well correlated with each other. The standard deviation of these parameters is around 6 % and that of H2O mole fraction is around 17 %. Since the evaluation of the CO mole fraction and soot concentration, in principle, is decoupled from each other, we are inclined to think that the variation is related to the actual change in the equivalence ratio of the gasification process due to the biomass flow variation. We observed similar variations of the concentrations at other equivalence ratios studied. We note that the soot concentration evaluated from the scans measured continuously shows only very modest scan-to-scan variation on the level of few percent. Figure 9 shows the single-scan experimental and fitted absorption spectra of the spectral features at 4350.7 cm−1 (a) and 4349.4 cm−1 (b). The fitted concentrations are shown in Fig. 8 at time 0.5 s. Defining the detectable limit as the mole fraction giving an absorption of the same magnitude as the noise, we estimated (from Fig. 9) the single-scan detectable limit of ~1000 ppm for CO and ~3000 ppm for H2O for the current setup. Improvement in the detectable limit requires the increase in transmitted signal to background radiation ratio.

We also compared the fitted CO and H2O collisional broadened line widths with those calculated using the data tabulated in the HITRAN databases via Eq. (8). At the gasification conditions, the composition of the perturbing gas deviates significantly from that of the air, so the purpose of the exercise was to evaluate the effect of the environment on the spectroscopic parameters determining the line width. It appeared that for all gasification conditions studied in this work, the obtained H2O collisional broadened line widths were within 10 % from those calculated using Eq. (8). The fitted collisional CO line widths were bigger than the calculated ones, and the difference increased from 15 to 22 % with the decrease in β. The drawn comparison suggests that there is no significant effect of the environment (syngas or air) on the collisional line width of the selected H2O line and for the CO lines, the effect is noticeable.

5 Conclusions

The TDLAS sensor near 4350 cm−1 (2.3 µm) is developed for measurements of the CO and H2O mole fractions and the soot volume fraction under gasification conditions. The sensor was tested in flat flames; comparison of the measured CO and H2O concentrations with the results of 1-D computation made using detailed chemistry of GRI-Mech 3.0 shows a very good agreement, generally better than 10 %. In situ tunable laser diode direct absorption measurements of the average path CO, H2O mole fractions and soot volume fraction inside pilot-scale atmospheric-pressure air-blown entrained-flow gasifier are reported. The estimated uncertainties in the reactor core CO and H2O measurements are 15 and 20 %, respectively. The reactor core TDL CO and soot measurements are well correlated with the changes in equivalence ratio; the CO and soot concentrations increase with the decrease in air equivalence ratio. The TDL CO measurements are in quantitative agreement with the CO µGC measurements taken at the gasifier output.

References

K. Kohse-Höinghaus, R.S. Barlow, M. Aldén, J. Wolfrum, Proc. Combust. Inst. 30, 89 (2005)

M.A. Bolshov, Y.A. Kuritsyn, Y.V. Romanovskii, Spectrochim. Acta Part B At. Spectrosc. 106, 45 (2015)

V. Ebert, J. Fitzer, I. Gerstenberg, K.-U. Pleban, H. Pitz, J. Wolfrum, M. Jochem, J. Martin, Symp. Combust. 27, 1301 (1998)

Y. Deguchi, M. Noda, M. Abe, Proc. Combust. Inst. 29, 147 (2002)

V. Ebert, H. Teichert, P. Strauch, T. Kolb, H. Seifert, J. Wolfrum, G. Nathan, F. Winter, Proc. Combust. Inst. 30(1), 1611 (2005)

H. Teichert, T. Fernholz, V. Ebert, Appl. Opt. 42, 2043 (2003)

M. Lackner, G. Totschnig, G. Loeffler, H. Hofbauer, F. Winter, Therm. Sci. 6, 13 (2002)

P. Ortwein, W. Woiwode, S. Fleck, M. Eberhard, T. Kolb, S. Wagner, M. Gisi, V. Ebert, Exp. Fluids 49, 961 (2010)

K. Sun, R. Sur, X. Chao, J.B. Jeffries, R.K. Hanson, R.J. Pummill, K.J. Whitty, Proc. Combust. Inst. 34, 3593 (2013)

R. Sur, K. Sun, J.B. Jeffries, R.K. Hanson, R.J. Pummill, T. Waind, D.R. Wagner, K.J. Whitty, Appl. Phys. B Lasers Opt. 116, 33 (2014)

K. Sun, R. Sur, J.B. Jeffries, R.K. Hanson, T. Clark, J. Anthony, in 8th US National Combustion Meeting. Paper No. 070DI-0313 (2013)

R. Sur, K. Sun, J.B. Jeffries, J.G. Socha, R.K. Hanson, Fuel 150, 102 (2015)

E. Schlosser, J. Wolfrum, L. Hildebrandt, H. Seifert, B. Oser, V. Ebert, Appl. Phys. B Lasers Opt. 75, 237 (2002)

A.V. Sepman, V.M. van Essen, V.V. Toro, A.V. Mokhov, H.B. Levinsky, in Proceedings of the European Combustion Meeting. Paper No. 65 (2005)

L.S. Rothman, I.E. Gordon, Y. Babikov, A. Barbe, D. Chris Benner, P.F. Bernath, M. Birk, L. Bizzocchi, V. Boudon, L.R. Brown, A. Campargue, K. Chance, E.A. Cohen, L.H. Coudert, V.M. Devi, B.J. Drouin, A. Fayt, J.M. Flaud, R.R. Gamache, J.J. Harrison, J.M. Hartmann, C. Hill, J.T. Hodges, D. Jacquemart, A. Jolly, J. Lamouroux, R.J. Le Roy, G. Li, D.A. Long, O.M. Lyulin, C.J. Mackie, S.T. Massie, S. Mikhailenko, H.S.P. Müller, O.V. Naumenko, A.V. Nikitin, J. Orphal, V. Perevalov, A. Perrin, E.R. Polovtseva, C. Richard, M.A.H. Smith, E. Starikova, K. Sung, S. Tashkun, J. Tennyson, G.C. Toon, V.G. Tyuterev, G. Wagner, J. Quant. Spectrosc. Radiat. Transf. 130, 4 (2013)

L.S. Rothman, I.E. Gordon, R.J. Barber, H. Dothe, R.R. Gamache, A. Goldman, J. Quant. Spectrosc. Radiat. Transf. 111, 2139 (2010)

I.I. Sobelman, L.A. Vainshtein, E.A. Yukov, Excitation of Atoms and Broadening of Spectral Lines (Springer, Berlin, 1995)

J. Humlíček, J. Quant. Spectrosc. Radiat. Transf. 21, 309 (1979)

R. Whiddon, B. Zhou, J. Borggren, M. Aldén, Z.S. Li, Rev. Sci. Instrum. 86, 093107 (2015)

A. Sepman, A.V. Mokhov, H.B. Levinsky, Proc. Combust. Inst. 29, 2187 (2003)

G.P. Smith, D.M. Golden, M. Frenklach, N.W. Moriarty, B. Eiteneer, M. Goldenberg. http://www.me.berkeley.edu/gri_mech/

R. Kee, F. Rupley, J. Miller, Report No. 89-8009 (1989)

J. Simonsson, N.-E. Olofsson, S. Török, P.-E. Bengtsson, H. Bladh, Appl. Phys. B 119, 657 (2015)

H. Wiinikka, F. Weiland, E. Pettersson, O. Öhrman, P. Carlsson, J. Stjernberg, Combust. Flame 161, 1923 (2014)

Acknowledgments

This work has been performed within the platform for entrained-flow gasification (Bio4Gasification) in the Swedish Centre for Gasification financed by the Swedish Energy Agency and the member companies.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sepman, A., Ögren, Y., Gullberg, M. et al. Development of TDLAS sensor for diagnostics of CO, H2O and soot concentrations in reactor core of pilot-scale gasifier. Appl. Phys. B 122, 29 (2016). https://doi.org/10.1007/s00340-016-6319-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-016-6319-x