Abstract

We demonstrated a 1.9-μm-pumped high-efficiency single-longitudinal-mode Ho:YAG laser with intra-cavity etalons for the first time. By inserting the F–P etalons into the laser cavity, single-longitudinal-mode Ho:YAG lasing was achieved at a wavelength of 2081.2 nm. The maximum single-longitudinal-mode output power of 309 mW was obtained with absorbed pump power of 4.97 W, corresponding to a slope efficiency of 12.77 %. The oscillating wavelength can be tuned (from 2077 to 2081 nm), and single-longitudinal-mode laser is achieved at each wavelength. The M 2 factors of the single-longitudinal-mode Ho:YAG laser in the x and y directions were 1.18 and 1.2, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The interest in single-longitudinal-mode (SLM) laser operating in the eye-safe spectral region near 2 μm is acknowledged for various applications such as Doppler radar wind sensing, differential absorption lidar, high-resolution spectroscopy and so on [1–3]. It is important for the seed laser of lidar with low thermal load, wavelength tunable, frequency stability and compact size [4]. Several techniques have been used to obtain SLM lasers, such as microchip laser, twisted-mode cavity, unidirectional ring cavity, coupled cavity and intra-cavity Fabry–Perot (F–P) etalons [5–9]. The intra-cavity etalon method is a common way to obtain SLM laser for its simple structure. Henderson and Hale reported a diode-pumped continuous-wave SLM Tm, Ho:YAG laser by inserting double etalons into the cavity, and the maximum output power of 58 mW was achieved [10]. In 2005, a 113 mW SLM Tm, Ho:YLF laser with two etalons was demonstrated [11]. Wu et al. [12] reported a diode-pumped Tm:YAG laser with single frequency output power of 75 mW. In 2014, a Tm, Ho:LLF laser with double etalons operating at 2064.4 nm was demonstrated by Zhang et al. [13].

Direct laser pumping (using 1.9-μm radiation) of the Ho laser offers several advantages: low quantum defect, elimination of energy transfer (no sensitizer ions used), reduced up-conversion losses (linearity of gain vs absorbed pump intensity), high short-pulse extraction efficiency and reduced sensitivity of gain versus temperature [14]. Resonantly pumped Ho lasers based on YAG [15, 16], YLF [17] and YAP [18] host material have been extensively investigated for the generation of 2-μm laser. Among them, the Ho:YAG crystal is an attractive laser material due to a combination of good thermo-mechanical properties and favorable spectroscopic properties.

In this study, we reported a SLM Ho:YAG laser pumped by 1.9-μm laser. By using three F–P etalons, the maximum SLM output power of 309 mW at 2081.2 nm was obtained. By tuning the angle of the etalons, the oscillating wavelength could be changed from 2077 to 2081 nm. And at each wavelength, the SLM laser was achieved. To our knowledge, this is the first time for Ho:YAG laser employing F–P etalons to obtain SLM operation.

2 Experimental setup

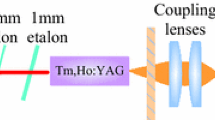

Figure 1 shows our experimental setup. An L-shaped plano-concave resonator is employed to make the system simple and compact with a physical cavity length of 103 mm. The resonator consisted of two plane mirrors and one curved mirror. M1 was a flat mirror coated for high transmission at the pump wavelength and high reflectivity at the laser wavelength. The M2 was a 45º flat dichroic mirror with a high transmission at the pump wavelength and high reflectivity at the laser wavelength. M3, which was the output coupler of the laser, was coated with 90 % reflectivity at the laser wavelength with a 200 mm radius of curvature. Three F–P etalons (0.1 mm, 1 mm thickness for YAG without coating and 6 mm thickness for quartz coating with 10 % reflectivity at 2 μm) were inserted in the cavity to select the wavelength of the Ho:YAG laser. A 0.8 at % Ho3+ doping concentration Ho:YAG crystal with a dimension of Φ4 × 25 mm was employed as the gain medium. Both end faces of the Ho:YAG crystal are anti-reflection (AR) coated at the pump and laser wavelengths. The Ho:YAG crystal was wrapped in indium foil and mounted in a cooper heat sink which held at a temperature of 15 °C by a thermoelectric cooler (TEC). The Ho:YAG crystal is pumped by a 1908 nm Tm:YLF laser with a maximum power of 20 W. By using a focused lens with the focal length of 150 mm, the pump beam was focused into the Ho:YAG crystal with a diameter of 268 μm. Although M1, M2 and the Ho:YAG crystal are coated for high transmission at the pump wavelength, some pump light still be reflected to the Tm:YLF laser. This will affect the stability of Tm:YLF laser. As the pump source of SLM laser, the stability is important. In order to weaken the disturbance of the reflective light to Tm:YLF laser, we have added a half-wave plate, a quarter-wave plate and a TFP (thin film polarizer) to pump system. The output of Tm:YLF laser is p-polarized, then changed to s-polarized after passing through the half-wave plate. The TFP is high transmission for p-polarized component and high reflection for s-polarized component at 1908 nm. Passing though the quarter-wave plate, the s-polarized laser changed to circularly polarized. When the reflective light passed through the quarter-wave plate again, the laser changed to p-polarized and transmitted through the TFP instead of reflecting to Tm:YLF laser.

3 Experimental results and discussion

In the first experiment, we measured the output spectra of the Ho:YAG laser for free running (etalons were not inserted in the cavity). The spectral output of the free running Ho:YAG laser was recorded by a spectrum analyzer (WA-650, EXFO) combined with a wavemeter (WA-1500, EXFO). The output laser spectrum of the free running Ho:YAG laser is shown in Fig. 2. The output laser wavelength centralized at 2122 nm. To investigate the longitudinal mode of the free running Ho:YAG laser, we have measured the spectra of the laser by a scanning F–P interferometer with a free spectral range of 3.75 GHz. Figure 3 shows a typical output signal from the scanning F–P interferometer. When we removed the quarter-wave plate, some 1.9-μm reflective pump laser provided by Ho:YAG laser resonator was transmitting to Tm:YLF laser directly. At this moment, the stability of pump source was affected and the longitudinal mode of Ho:YAG output laser was in a state of chaos as seen in Fig. 3a. Then, we added the quarter-wave plate in order to weak the disturbance of reflective light to pump source, and the stabilization of longitudinal mode of Ho:YAG laser has much improved as seen in Fig. 3b. The free running Ho:YAG laser typically ran on multi-longitudinal modes.

In order to achieve SLM operation of the Ho:YAG laser, three F–P etalons with thickness of 0.1 , 1 and 6 mm were inserted into the resonator. For the F–P etalons in the cavity, the laser can oscillate with lower loss when the maximum transmissions of these F–P etalons are superposed. When regulating the angle of the F–P etalons carefully, the transmission peak of the F–P etalons could be adjusted consistently with the Ho:YAG gain curve, and then the laser can obtain the SLM operation. Figure 4 shows the output spectrum of the Ho:YAG laser with single wavelength. The emission line was located at 2081.2 nm. Compared to free running operation, the oscillating wavelength of Ho:YAG laser shifts a large range from 2122 to 2081 nm. That is because of the different loss and gain experienced by 2122 and 2081 nm laser, respectively. The 2081 nm laser suffered from more re-absorption loss, but having larger emission cross-section than 2122 nm. For free running, the Ho:YAG laser dominated by re-absorption loss, and the wavelength of output laser centers on 2122 nm. The intra-cavity etalons increased the round trip loss of laser cavity, and the laser mainly overcomes the round trip loss to obtain oscillating. So the 2081 nm laser could get enough gain to oscillate. Figure 5 shows the output signal from the scanning F–P interferometer as the laser running on SLM operation. As can be seen in Fig. 5, no other modes were observed in the scanning F–P spectrum, and the laser operated on a SLM.

The output power of the Ho:YAG laser with multi-mode and SLM was investigated. Fig 6a shows the multi-mode and SLM operation laser output power as a function of the incident pump power. Under the incident pump power of 6.14 W available from the Tm:YLF laser, up to 309 mW SLM output at 2081.2 nm was obtained, corresponding to a slope efficiency of 10.04 %. For multi-mode operation, the maximum output power and slope efficiency were 1.44 W and 32.54 %, respectively. We have measured the pump power losses before the Ho:YAG crystal and the unabsorbed pump power. The pump power losses were measured to be 227 mW as the incident pump power of 6.14 W. The unabsorbed pump power in multi-mode and SLM regime under the incident pump power of 6.14 W was 573 mW and 938 mW, respectively. Figure 6b shows the measured output power of the Ho:YAG laser with multi-mode and SLM versus the absorbed pump power. In the multi-mode, the output power of 1.44 W was achieved with an absorbed pump power of 5.34 W, and the fitted threshold absorbed pump power was about 1.65 W, corresponding to a slope efficiency of 37.25 %. For the maximum SLM output power of 309 mW, the absorbed pump power was 4.97 W, and the fitted threshold absorbed pump power was about 2.68 W, corresponding to a slope efficiency of 12.77 %. The lower efficiency and higher threshold of the single-longitudinal-mode Ho:YAG laser can possibly be attributed to the large loss leading by the F–P etalons.

As shown in Fig. 7, the wavelength of the SLM Ho:YAG laser could be tuned a range from 2077.2 to 2081.2 nm by regulating the angle of the F–P etalons. As can be seen from Fig. 8, Ho:YAG crystal has four main emission peaks at 2.08, 2.09 and 2.12 μm [19]. The emission cross-section of 2.09 μm is much higher than that of 2.08 μm. In experiment, we failed to achieve SLM laser at 2.09 μm, possibly due to the larger emission cross-section leading to a higher gain in cavity. The loss introduced by the F–P etalons was insufficient to make the Ho:YAG laser running on SLM operation. Table 1 shows the output power with different wavelength under same pump power. The output power variation of different wavelength is according to the different loss and gain of modes oscillating in laser cavity.

Emission cross-section of Ho:YAG at 2000–2200 nm [19]

The wavelength stability of the Ho:YAG laser is shown in Fig. 9. The average wavelength of SLM Ho:YAG laser is 2081.2 nm. The standard deviation of the wavelength measured is 4 pm. Fig 10 shows the power stability of the SLM of Ho:YAG laser at highest power level which measured by a Coherent Power Meter 0310B12R with a resolution limited to 0.1 mW. The average output power is 309 Mw, and the standard deviation of the output power measured is ±1.7 mW.

The propagation characteristics of the SLM Ho:YAG laser beam at the maximum output power level were investigated. As shown in Fig. 11, the beam profile was taken by Spiricon Pyrocam I pyroelectric camera. In addition, we measured the output beam quality of SLM Ho:YAG laser by measuring the beam radius with a knife-edge technique at several positions through a waist formed by a lens. The data were fitted by least squares analysis to standard mix-mode Gaussian beam propagation equations to determine the beam quality or M 2 parameter. The M 2 factors in the x and y directions were 1.18 and 1.2, respectively.

4 Conclusions

In summary, we presented a SLM Ho:YAG laser at a wavelength of 2081.2 nm with the F–P etalons. The maximum SLM output power of 309 mW was obtained under absorbed pump power of 4.97 W, corresponding to a slope efficiency of 12.77 %. The beam quality factor of M 2 at the maximum SLM output power was measured to be 1.18 and 1.2 for x and y directions, respectively. The CW SLM Ho:YAG laser operating in the 2-μm spectral region could be used as the seed laser source of coherent Doppler lidar.

References

G.J. Koch, J.Y. Beyon, B.W. Barnes, M. Petros, J. Yu, F. Amzajerdian, M.J. Kavaya, U.N. Singh, Opt. Eng. 46, 116201 (2007)

F. Gibert, D. Edouart, C. Cénac, F. Le Mounier, Appl. Phys. B 116, 967 (2014)

I. Galli, S. Bartalini, P. Cancio, F. Cappelli, G. Giusfredi, D. Mazzotti, N. Akikusa, M. Yamanishi, P. De Natale, Opt. Lett. 39, 5050 (2014)

T.Y. Dai, Y.L. Ju, X.M. Duan, W. Liu, B.Q. Yao, Y.Z. Wang, Appl. Phys. B 111, 89 (2013)

Z.Y. You, Y. Wang, J.L. Xu, Z.J. Zhu, J.F. Li, H.Y. Wang, C.T. Tu, Opt. Lett. 40, 3846 (2015)

C. Gao, R. Wang, Z. Lin, M. Gao, L. Zhu, Y. Zheng, Y. Zhang, Appl. Phys. B 107, 67 (2012)

L. Wang, C.Q. Gao, M.W. Gao, Y. Li, Opt. Express 21, 9541 (2013)

C.T. Wu, Y.L. Ju, Z.G. Wang, Y.F. Li, H.Y. Ma, Y.Z. Wang, Laser Phys. Lett. 5, 510 (2008)

B.Q. Yao, F. Chen, C.H. Zhang, Q. Wang, C.T. Wu, X.M. Duan, Opt. Lett. 36, 1554 (2011)

S.W. Henderson, C.P. Hale, Appl. Opt. 29, 1716 (1990)

X.L. Zhang, Y.L. Ju, Y.Z. Wang, Opt. Express 13, 4056 (2005)

C.T. Wu, Y.L. Ju, Z.G. Wang, Q. Wang, C.W. Song, Y.Z. Wang, Laser Phys. Lett. 5, 793 (2008)

X.L. Zhang, S. Zhang, N.N. Xiao, J.H. Cui, J.Q. Zhao, L. Li, Appl. Opt. 53, 1488 (2014)

P.A. Budni, C.R. Ibach, S.D. Setzler, E.J. Gustafson, R.T. Castro, E.P. Chicklis, Opt. Lett. 28, 1016 (2003)

J. Kwiatkowski, J.K. Jabczynski, W. Zendzian, L. Gorajek, M. Kaskow, Appl. Phys. B 114, 395 (2014)

T.Y. Dai, Y.L. Ju, B.Q. Yao, Y.J. Shen, W. Wang, Y.Z. Wang, Laser Phys. Lett. 9, 716 (2012)

H. Fonnum, E. Lippert, M.W. Haakestal, Opt. Lett. 38, 1884 (2013)

B.Q. Yao, X.M. Duan, L.L. Zheng, Y.L. Ju, Y.Z. Wang, G.J. Zhao, Q. Dong, Opt. Express 16, 14668 (2008)

Database laser of NASA, Emission cross-section of Ho:YAG, http://www.mennerat.fr/gab/References/DatabaseLasers/spectra/hoyag.htm

Acknowledgments

This work was supported by National Natural Science Foundation of China (Nos. 61308009, 61405047), China Postdoctoral Science Foundation funded project (Numbers 2013M540288 and 2015M570290), Fundamental Research funds for the Central Universities Grant (Numbers HIT.NSRIF.2014044 and HIT. NSRIF.2015042) and Science Fund for Outstanding Youths of Heilongjiang Province (JQ201310), Heilongjiang Postdoctoral Science Foundation Funded Project (LBH-Z14085).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ju, Y.L., Liu, W., Yao, B.Q. et al. Resonantly pumped single-longitudinal-mode Ho:YAG laser. Appl. Phys. B 122, 5 (2016). https://doi.org/10.1007/s00340-015-6291-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00340-015-6291-x