Abstract

Redox-active polytriarylamine with hydroxyl groups is a useful material for optoelectronic applications, especially in the solution-processable multilayer devices. A novel regiocontrolled triarylamine-based polymer, poly(di-5-naphthyl-2-ol)phenylamine, with 2-naphthol units was synthesized via oxidative coupling polymerization. Polymerization in tetrahydrofuran using a Cu-amine complex oxidant under O2 atmosphere produced polymers with number-averaged molecular weights as high as 11,300 g mol−1. The structure of the polymer was characterized by 1H and 13C NMR spectroscopy, showing that the oxidative coupling polymerization occurred at the outer ortho position of the 2-naphthols, preserving the hydroxyl groups. The polymer exhibited good solubility in polar aprotic solvents, with a high thermal stability of 446 °C that corresponded to 5% weight loss. The UV–vis absorption of the polymer was similar to that of DNPA, indicating that the kinked-structured polymer hindered the formation of charge-transfer complexes. These results suggest promising applications of the developed polymer in optoelectronic devices.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Aromatic polymers, including polyphenylene, polyaniline, polypyrrole, and polythiophene, have attracted significant interest due to their optoelectrical, thermal, and mechanical properties [1,2,3,4]. Typically, two polymerization methods are used in the synthesis of aromatic polymers: The first is a transition metal-catalyzed coupling polymerization of aryl dihalides [5,6,7], and the other involves oxidative coupling polymerization via electrochemical or chemical methods [8,9,10,11]. While the former strategy requires auxiliary functional groups for polymerization, such as dihalides, oxidative coupling polymerization can form carbon–carbon bonds from simple monomer structures [12]. Therefore, oxidative coupling polymerization provides a more practical route for the synthesis of aromatic polymers.

Hydroxyl-modified aromatic polymers have been applied for primer coating [13, 14], positive-type photosensitive polymer [15,16,17,18], and semiconductor manufacturing as both protection and insulation layers [19,20,21]. The reactive hydroxyl groups allow simple functionalization of the polymer, facilitating their usefulness for several applications [22,23,24,25,26]. However, oxidative coupling of phenolic hydroxyl groups generally involves C–O bond formation [27,28,29]. Therefore, a naphthol alternative has been used for oxidative coupling polymerization. Particularly, oxidative coupling of 2-naphthol using a catalytic amount of a Cu-amine complex showed good regioselectivity with excellent yields [30] suitable for polymer synthesis with a regioregular structure and preservation of its hydroxyl groups. Successful synthesis of hydroxyl-modified regioregular aromatic polymers has been reported, and extensive applications have been demonstrated [31,32,33,34,35].

The electron-rich and redox-active properties of triarylamine derivatives are useful for optoelectronic devices [36,37,38]. In addition, their bulky and propeller-shaped structure provides a porous aromatic framework for mesoporous materials with a high surface area that is suitable for use in proton membranes [39,40,41,42]. Triarylamine derivatives in polymers have advantages in terms of mechanical properties and easy processability compared to monomeric and oligomeric analogues [43,44,45]; especially, the oxidative coupling polymerization of triarylamine derivatives provides a straightforward method for preparing polymeric triarylamine and has been used for the successful synthesis of triarylamine polymers [46].

Herein, we report the synthesis of regiocontrolled poly(di-5-naphthyl-2-ol)phenylamine (PDNPA) by oxidative coupling polymerization of the triarylamine monomer containing two naphthol units. A novel triarylamine monomer was prepared by replacing phenyl rings with 2-naphthol units. Introduction of the naphthalene rings can lead to steric repulsion, which is advantageous in preventing a close packing of polymer chains due to its large dihedral angle and suppressing the formation of charge-transfer complex [47]. In addition, the hydroxyl group on naphthalene ring imparts a good adhesion and site that can introduce cross-linkable group for multilayer optoelectronic devices [48,49,50]. The synthesized polymer has BINOL structures in the main chain as a result of the oxidative coupling reaction of 2-napthol and can also be used as a soluble polymer-supported BINOL for various catalytic applications [51,52,53,54,55].

Experimental

Materials

Tris(dibenzylideneacetone)dipalladium(0) [Pd2(dba)3], tri-tert-butylphosphine [(tBu)3P], sodium tert-butoxide (NaOtBu), toluene, anhydrous tetrahydrofuran (THF, 99.9%), anhydrous N,N-dimethylformamide (DMF, 99.8%), tetramethylenediamine (TMEDA) tetrabutylammonium tetrafluoroborate (Bu4NBF4), and anhydrous acetonitrile (99.8%) were purchased from Sigma-Aldrich. Aniline, methyl iodide (MeI), di-μ-hydroxo-bis[(N,N,N′.N′-tetramethylethylenediamine)copper(II)] chloride [CuCl(OH)TMEDA], and potassium carbonate (K2CO3) were purchased from TCI. Hydrobromic acid (HBr, 48% solution), acetic acid (99%), and sodium bicarbonate (NaHCO3) were purchased from Junsei. Ethyl acetate (EA, 99%), hexane (95%), and magnesium sulfate (MgSO4) were purchased from Daejung. 5-Iodo-2-naphthol was prepared according to a previously described method [56].

Material characterization

The 1H and 13C NMR spectra of the synthesized materials were recorded using a Bruker Fourier Transform AC 400 (400 MHz) spectrometer. Chemical shifts were expressed in parts per million (ppm) with reference to the residual peaks of DMSO for 1H (2.49 ppm) and 13C (39.52 ppm). Mass spectra were obtained using a microTOF-Q, and elemental analysis was recorded using a FLASH 200 series instrument. Polymer molecular weights and distributions were measured via size exclusion chromatography (SEC). The SEC traces were obtained using a Viscotek TDA302 instrument equipped with a RI detector and packing column (three PLgel 10 μm MIXED-B) using tetrahydrofuran (THF) as the eluent at 35 °C. The number and weight average molecular weights of the polymers were calculated relative to linear polystyrene standards. Thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC) were conducted using TA Instruments TGA Q500 and DSC Q100 instruments, respectively. The TGA and DSC measurements were performed under a nitrogen atmosphere at a heating rate of 10 °C min−1. The Tg values were determined from the second heating scan of the DSC thermograms after cooling to 0 °C from 200 °C. Wide-angle X-ray diffraction (WAXD) pattern was obtained with a Rigaku D/MAX-2500 X-ray diffractometer. Cu K alpha (1.5418 Å) was used as a light source. UV–vis spectra were measured on a JASCO V-530 spectrometer. The electrochemical experiments were performed using a CH instrument CHI 617B potentiostat equipped with a three-electrode system. Pt wire was used as the counter electrode, silver/silver nitrate (Ag/AgNO3) as the reference electrode, and a 2-mm-diameter platinum disk as the working electrode.

Preparation of 6-(2-methoxy)-1-iodonaphthalene (1) 5-Iodo-2-naphthol (8.65 g, 32.03 mmol), anhydrous K2CO3 (22.110 g, 160 mmol), and MeI (22.71 g, 160 mmol) were dissolved in anhydrous DMF (100 mL). The solution was then heated at 70 °C and stirred for 16 h under a nitrogen atmosphere. The reaction mixture was subsequently poured into water and extracted with ethyl acetate. The organic layer was successively washed with water and dried over anhydrous MgSO4. The solvent was evaporated, and the remaining residue was purified via column chromatography on silica gel with ethyl acetate/hexane (1/4, v/v) as the eluent to yield an orange viscous liquid (9.01 g, 99%). 1H and 13C NMR spectra are shown in Figs. S1, S2.

1H NMR (DMSO-d6, 400 MHz, ppm): 7.94 (dd, 1H, J = 7.2, 1.2 Hz), 7.89 (d, 1H, J = 7.6 Hz), 7.87 (d, 1H, J = 6.8 Hz), 7.35 (1H, d, J = 2.4 Hz), 7.28 (dd, 1H, J = 9.2 Hz), 7.20 (1H, t, J = 8 Hz), 3.89 (3H, s). 13C NMR (DMSO-d6, 100 MHz, ppm): 157.75, 134.96, 134.84, 132.88, 129.06, 127.91, 127.66, 120.36, 106.69, 99.15, 55.44.

Preparation of di(1-(6-(2-methoxy)naphthyl))phenylamine (2) The synthesis of compound 2 was performed based on a similar procedure that was described previously [57]. To a two-necked round-bottomed flask (RBF) equipped with a reflux condenser, 1 (8.93 g, 31.43 mmol), aniline (1.32 g, 14.19 mmol), Pd2(dba)3 (0.288 g, 0.31 mmol), (tBu)3P (0.25 g, 1.24 mmol), NaOtBu (4.23 g, 44 mmol), and anhydrous toluene (80 mL) were added and stirred at 90 °C for 24 h under a nitrogen atmosphere. The mixture was poured into water and extracted with ethyl acetate. After drying over anhydrous MgSO4, the solvent was evaporated. The residue was purified via column chromatography on silica gel with dichloromethane/hexane (1/1, v/v) as the eluent to yield a white solid (4.017 g, 86%). 1H and 13C NMR spectra are shown in Figs. S3, S4.

1H NMR (DMSO-d6, 400 MHz, ppm): 7.80 (2H, d, J = 9.2 Hz), 7.67 (2H, d, J = 8.4 Hz), 7.37 (4H, m), 7.12 (2H, t, J = 8 Hz), 7.04 (2H, dd, J = 9.2, 2.8 Hz), 6.96 (2H, dd, J = 7.4, 1.2 Hz), 6.84 (1H, t, J = 7.2 Hz), 6.56 (2H, dd, J = 8.6, 1.2 Hz), 3.85 (6H, s). 13C NMR (DMSO-d6, 100 MHz, ppm): 157.25, 149.96, 144.17, 136.28, 129.04, 126.83, 125.09, 124.70, 124.55, 122.15, 120.60, 119.75, 118.68, 106.84, 55.16. Anal. Calcd. for C28H23NO2: C, 82.94; H, 5.72; N, 3.45; O, 7.89. Found: C, 83.01; H, 5.70; N, 2.90. ESI–MS: m/z 406.17 for [M + H]+ (Calcd for [M]: m/z 405.17).

Preparation of di(1-(6-(2-hydroxy)naphthyl))phenylamine (DNPA) To an RBF equipped with a reflux condenser, 2 (5.51 g, 13.59 mmol), HBr (17.1 mL, 48% solution), and acetic acid (70 mL) were added and stirred at 130 °C for 12 h. The mixture was subsequently poured into water and extracted with ethyl acetate. The organic layer was repeatedly washed with a basic solution (0.1 M NaHCO3 aqueous solution). After drying over anhydrous MgSO4, the solvent was removed under pressure. The residue was purified via column chromatography on silica gel with ethyl acetate/hexane (1/1, v/v) as the eluent. The resulting product was dissolved in toluene and precipitated in heptane to yield a gray solid (3.95 g, 77%).

1H NMR (DMSO-d6, 400 MHz, ppm): 9.79 (2H, s), 7.78 (2H, d, J = 9.2 Hz), 7.53 (2H, d, J = 8.4 Hz), 7.28 (2H, t, J = 8 Hz), 7.17 (2H, d, J = 2.4 Hz), 7.09 (2H, t, J = 7.8 Hz), 6.95 (2H, dd, J = 9.2, 2.4 Hz), 6.90 (2H, dd, J = 7.4, 1.2 Hz), 6.80 (1H, t, J = 7.2 Hz), 6.54 (2H, dd, J = 8.6, 1.2 Hz). 13C NMR (DMSO-d6, 100 MHz, ppm): 155.42, 150.08, 144.22, 136.57, 128.96, 126.54, 125.31, 124.04, 123.97, 121.43, 120.30, 119.54, 118.82, 109.43. Anal. Calcd. for C26H19NO2: C, 82.74; H, 5.07; N, 3.71; O, 8.48. Found: C, 81.75; H, 5.18; N, 3.02. ESI–MS: m/z 378.14 for [M + H]+ (Calcd for [M]: m/z 377.14).

Polymerization

PDNPA (run 8) To an RBF, DNPA (0.132 g, 0.35 mmol), CuCl(OH)TMEDA (8.13 mg, 0.0175 mmol), and THF (1 mL) were added and stirred at 30 °C under oxygen. After polymerization for 16 h, the reaction mixture was poured into methanol containing a small amount of hydrochloric acid and subsequently filtered. The precipitate was washed in a Soxhlet apparatus with methanol and collected with THF, which was then condensed and precipitated in methanol. The final product was obtained after drying in vacuo at 60 °C, yielding a green powder (0.104 g, 78.6%).

Results and discussion

Synthesis of DNPA The synthetic routes for DNPA are shown in Scheme 1. The hydroxyl groups of 5-iodo-2-naphthol were protected before the palladium-catalyzed amination reaction. Compound 1 was reacted with 0.45 equiv. of aniline, and after deprotection of the methyl protecting groups, DNPA was afforded. DNPA was purified via column chromatography followed by reprecipitation of the toluene solution into heptane to yield a pale brown powder. The chemical structure of DNPA was verified by 1H-NMR and C-H correlated spectroscopy (COSY). Figure 1 shows the 1H-NMR spectrum of the prepared DNPA, consisting multiplets at 6.54–7.78 ppm and a broad peak at 9.79 ppm, which were assigned to the aromatic and hydroxyl protons, respectively. Figure 2 shows the C-H COSY spectrum for aromatic region of DNPA with corresponding peak assignments.

Cyclic voltammogram The oxidative coupling reaction includes a radical coupling step, in which the radical species generated by one-electron oxidation are involved in the coupling process [58]. Therefore, it is important to measure the oxidation–reduction potentials of DNPA to select the proper oxidant. The oxidation potential of the first one-electron transfer from DNPA was estimated using cyclic voltammetry (CV) with Bu4NBF4 (0.1 M in acetonitrile) at a scan rate of 50 mV s−1 under a nitrogen atmosphere. It should be noted that the effect of TMEDA on the oxidation of DNPA was confirmed by comparing the oxidation and onset potentials of DNPA, TMEDA, and DNPA + TMEDA mixed solution. As shown in Fig. 3, first electrochemical oxidation peaks of DNPA and TMEDA were measured at 0.590 and 0.330 V, respectively, and the onset potentials of DNPA and TMEDA were 0.488 and 0.160 V, respectively. For the DNPA + TMEDA mixture (Fig. 3, red line), it is clear that a new oxidation peak and onset potential appeared at 0.068 and − 0.024 V, respectively, which were observed only in the mixed solution. The cyclovoltametric results indicate that DNPA can be affected by TMEDA, and its electrochemical oxidation shifted to a lower oxidation potential (even lower than the TMEDA oxidation potential). According to these results, CuCl(OH)TMEDA was selected as the oxidant for use in the oxidative coupling polymerization of DNPA.

Polymer synthesis and thermal properties The polymerization of DNPA was performed in the presence of CuCl(OH)TMEDA (5 mol% per monomer fed) in THF at 30 °C (Scheme 2), and the results are summarized in Table 1. After polymerization, the resulting polymers were purified by repeated precipitation with methanol containing a small amount of HCl and Soxhlet extraction with methanol to remove any remaining catalyst. With increasing reaction time, the molecular weights of polymers increased. The polymers obtained from run 1–8 were soluble in THF, but run 9 contained approximately 25% insoluble polymer. The polymer was soluble in polar organic solvents such as THF, DMF, and DMSO at room temperature (20 °C) but was only partly soluble even under heating in chloroform, methylene chloride, and acetone.

As shown in Scheme 3, the mechanism of oxidative coupling reaction could be explained by the redox process accompanying a single electron transfer between 2-naphthalate and Cu(II) ion [10]. The resulting 2-naphthoxy radical is stabilized by delocalization, and carbon–carbon coupling reaction is occurred on C−1 position with the highest electron spin density. The monomers undergo successive oxidation and coupling reaction giving the high molecular weight polymer. During polymerization, the Cu(II) is recovered by oxidation of the Cu(I) under oxygen.

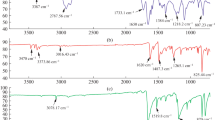

The structure of PDNPA (run 8) was determined by NMR spectroscopy. The 1H NMR spectrum of PDNPA hardly showed clear peak splitting (Fig. 4) due to the restricted conformations induced by the repulsion between bulky naphthalene rings. Consequently, the structure of PDNPA was estimated using 13C NMR and distortionless enhancement by polarization transfer (DEPT) spectroscopy. The aromatic region of the 13C and DEPT45 spectra and assignment of DNPA are described in Fig. 5. After oxidative polymerization, the outer ortho position (C-10 peak) of the 2-naphthols of DNPA shifted down field and subsequently disappeared in the DEPT45 spectrum. This clearly indicated that coupling occurred selectively at the C-10 position. For better assignment, 13C NMR and DEPT45 analysis of the low molecular weight polymer (run 4) was also conducted (Fig. S5). Unlike the high molecular weight polymer, it showed a sharp spectrum and provided useful information for analysis of the polymer structure.

The thermal properties of PDNPA were investigated with TGA and DSC. PDNPA showed good thermal stability, with a polymer weight loss of < 5% at 446 °C (Td5) under a nitrogen atmosphere. In addition, PDNPA exhibited high char yields of 73% at 800 °C. In the derivative thermogravimetry (DTG) curve, the major degradation peak appeared at 687 °C and the second degradation peak appeared at 438 °C (Fig. 6). The DSC trace exhibited no endothermic peaks or baseline shift indicating a melting point or glass transition, respectively. The crystalline structure of the polymer film was further studied with the WAXD. The polymer film was prepared by spin coating the polymer solution (THF) on a silicon wafer. As shown in Fig. 7, the WAXD pattern of polymer indicated that the polymer was amorphous.

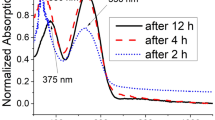

UV–vis absorption properties The normalized UV–vis absorption spectra of DNPA and PDNPA in THF are shown in Fig. 8. DNPA and PDNPA showed maximum absorptions at 344 and 356 nm, respectively. The UV–vis absorption onset of DNPA (381 nm) and PDNPA (388 nm) was similar, indicating a small extension of π-conjugation in PDNPA. This suggests that the steric repulsion of the naphthalene rings induced a large dihedral angle between neighboring naphthalene rings. In addition, this kinked structure may prevent interchain interactions between polymer chains, hindering the formation of charge-transfer complexes, which results in reduced electroluminescence efficiency and an additional emission band in the long wavelength region when applied in optoelectronic devices [59, 60]. The optical band gap of PDNPA, as calculated from the onset absorption, was 3.19 eV.

Conclusions

Regiocontrolled PDNPA was prepared via oxidative coupling polymerization of DNPA using CuCl(OH)TMEDA as an oxidant. By increasing the polymerization time, the polymer molecular weight increased, but an insoluble portion was formed at times exceeding 16 h. The structure of PDNPA was characterized by 1H and 13C NMR spectroscopy, indicating that the polymerization reaction selectively occurred at the outer ortho C-10 position of the 2-naphthol groups, leaving the hydroxyls unreacted. PDNPA exhibited good solubility in polar organic solvents and showed a high thermal stability of Td5 at 446 °C. Similar onset absorptions of DNPA and PDNPA in their UV–vis spectra revealed that the regioregularly kinked polymer structure prevented interchain interactions of the polymer chains. The hydroxyl groups of PDNPA allow for further modification for various purposes. In particular, this novel polymer could be applied in hole-transporting materials for solution-processable multilayer OLEDs through the introduction of cross-linkable groups.

References

Habaue S, Seko T, Okamoto Y (2003) Copper(I)-catalyzed asymmetric oxidative coupling polymerization of 2,3-dihydroxynaphthalene using bisoxazoline ligands. Macromolecules 36:2604–2608. https://doi.org/10.1021/ma021797c

Feast WJ, Tsibouklis J, Pouwer KL, Groenendaal L, Meijer EW (1996) Synthesis, processing and material properties of conjugated polymers. Polymer 37:5017–5047. https://doi.org/10.1016/0032-3861(96)00439-9

Berresheim AJ, Müller M, Müllen K (1999) Polyphenylene nanostructures. Chem Rev 99:1747–1786. https://doi.org/10.1021/cr970073+

Martin RE, Diederich F (1999) Linear monodisperse π-conjugated oligomers: model compounds for polymers and more. Angew Chem Int Ed Engl 38:1350–1377. https://doi.org/10.1002/(SICI)1521-3773(19990517)38:10%3c1350:AID-ANIE1350%3e3.0.CO;2-6

Hartwig JF (1998) Transition metal catalyzed synthesis of arylamines and aryl ethers from aryl halides and triflates: scope and mechanism. Angew Chem Int Ed Engl 37:2046–2067. https://doi.org/10.1002/(SICI)1521-3773(19980817)37:15%3c2046:AID-ANIE2046%3e3.0.CO;2-L

Ley SV, Thomas AW (2003) Modern synthetic methods for copper-mediated C(aryl)-O, C(aryl)-N, and C(aryl)-S Bond formation. Angew Chem Int Ed Engl 42:5400–5449. https://doi.org/10.1002/anie.200300594

Goodson FE, Hauck SI, Hartwig JF (1999) Palladium-catalyzed synthesis of pure, regiodefined polymeric triarylamines. J Am Chem Soc 121:7527–7539. https://doi.org/10.1021/ja990632p

Kranz C, Wohlschläger H, Schmidt H-L, Schuhmann W (1998) Controlled electrochemical preparation of amperometric biosensors based on conducting polymer multilayers. Electroanalysis 10:546–552. https://doi.org/10.1002/(SICI)1521-4109(199807)10:8%3c546:AID-ELAN546%3e3.0.CO;2-%23

Finkbeiner H, Hay AS, Blanchard HS, Endres GF (1966) Polymerization by oxidative coupling. The function of copper in the oxidation of 2,6-dimethylphenol. J Org Chem 31:549–555. https://doi.org/10.1021/jo01340a048

Amou S, Takeuchi K, Asai M, Niizeki K, Okada T, Seino M, Haba O, Ueda M (1999) Synthesis of regiocontrolled polymer having 2-naphthol unit by CuCl-amine catalyzed oxidative coupling polymerization. J Polym Sci A Polym Chem 37:3702–3709. https://doi.org/10.1002/(SICI)1099-0518(19991001)37:19%3c3702:AID-POLA6%3e3.0.CO;2-A

H Higashimura, S Kobayashi (2002) Oxidative polymerization. In: Encyclopedia of polymer science and technology. Wiley, Hoboken (2002). https://doi.org/10.1002/0471440264.pst226

Klussmann M, Sureshkumar D (2011) Catalytic oxidative coupling reactions for the formation of carbon–carbon bonds without carbon–metal intermediates. Synthesis 2011:353–369. https://doi.org/10.1055/s-0030-1258303

Meneguzzi A, Ferreira CA, Pham MC, Delamar M, Lacaze PC (1999) Electrochemical synthesis and characterization of poly (5-amino-1-naphthol) on mild steel electrodes for corrosion protection. Electrochim Acta 44(12):2149–2156. https://doi.org/10.1016/S0013-4686(98)00323-5

Rubinger CPL, Moreira RL, Cury LA, Fontes GN, Neves BRA, Meneguzzi A, Ferreira CA (2006) Langmuir–Blodgett and Langmuir–Schaefer films of poly(5-amino-1-naphthol) conjugated polymer. Appl Surf Sci 253:543–548. https://doi.org/10.1016/j.apsusc.2005.12.096

Hayase R, Kihara N, Oyasato N, Matake S, Oba M (1994) Positive photosensitive polyimides using polyamic acid esters with phenol moieties. J Appl Polym Sci 51:1971–1978. https://doi.org/10.1002/app.1994.070511113

Tsuchiya K, Shibasaki Y, Suzuki M, Ueda M (2004) Three-component, negative-type, alkaline-developable, thermally stable, and photosensitive polymer based on poly(2,6-dihydroxy-1,5-naphthalene), a crosslinker, and a photoacid generator. J Polym Sci A Polym Chem 42:2235–2240. https://doi.org/10.1002/pola.20122

Tsuchiya K, Shibasaki Y, Ueda M (2004) A positive type alkaline developable thermally stable and photosensitive polymer based on partially O-methylated poly(2,6-dihydroxy-1,5-naphthylene), an acidolytic de-cross-linker, and a photoacid generator. Polymer 45:6873–6878. https://doi.org/10.1016/j.polymer.2004.08.011

Sasada Y, Shibasaki Y, Suzuki M, Ueda M (2002) New positive-type photosensitive polymer based on poly(2,6-dihydroxy-1,5-naphthylene) and diazonaphthoquinone. J Polym Sci A Polym Chem 40:393–398. https://doi.org/10.1002/pola.10117

Mochizuki A, Ueda M (2001) Recent development in photosensitive polyimide (PSPI). J Photopol Sci Technol 14:677–687. https://doi.org/10.2494/photopolymer.14.677

Ebara K, Shibasaki Y, Ueda M (2002) New synthetic route for photosensitive poly(benzoxazole). J Polym Sci A Polym Chem 40:3399–3405. https://doi.org/10.1002/pola.10432

Ebara K, Shibasaki Y, Ueda M (2003) Photosensitive poly(benzoxazole) based on precursor from diphenyl isophthalate and bis(o-aminophenol). Polymer 44:333–339. https://doi.org/10.1016/S0032-3861(02)00784-X

Bhattacharya A, Misra BN (2004) Grafting: a versatile means to modify polymers: techniques, factors and applications. Prog Polym Sci 29:767–814. https://doi.org/10.1016/j.progpolymsci.2004.05.002

Vöge A, Deimede VA, Kallitsis JK (2012) Side chain crosslinking of aromatic polyethers for high temperature polymer electrolyte membrane fuel cell applications. J Polym Sci A Polym Chem 50:207–216. https://doi.org/10.1002/pola.25006

Jungermann S, Riegel N, Müller D, Meerholz K, Nuyken O (2006) Novel photo-cross-linkable hole-transporting polymers: synthesis, characterization, and application in organic light emitting diodes. Macromolecules 39:8911–8919. https://doi.org/10.1021/ma060844o

Zuniga CA, Barlow S, Marder SR (2011) Approaches to solution-processed multilayer organic light-emitting diodes based on cross-linking. Chem Mater 23:658–681. https://doi.org/10.1021/cm102401k

Kim H-C, Kim J-S, Baek S, Ree M (2006) Functional polythiophene bearing hydroxyethyl groups and their derivatives. Macromol Res 14:173–178. https://doi.org/10.1007/BF03218505

Hay AS, Blanchard HS, Endres GF, Eustance JW (1959) Polymerization by oxidative coupling. J Am Chem Soc 81:6335–6336. https://doi.org/10.1021/ja01532a062

Sasada Y, Shibasaki Y, Suzuki M, Ueda M (2003) Convenient synthesis of poly(2,6-dihydroxy-1,5-naphthylene) by Cu(II)-amine catalyzed oxidative coupling polymerization. Polymer 44:355–360. https://doi.org/10.1016/S0032-3861(02)00687-0

Gao J, Zhong SH, Zingaro RA (2004) The oxidative coupling polymerization of 2,6-dimethylphenol catalyzed by a μ-OCH3-bridged dicopper(II) Complex catalyst. J Mol Catal A 207:15–20. https://doi.org/10.1016/S1381-1169(03)00463-1

Noji M, Nakajima M, Koga K (1994) A new catalytic system for aerobic oxidative coupling of 2-naphthol derivatives by the use of CuCl-amine complex: a practical synthesis of binaphthol derivatives. Tetrahedron Lett 35:7983–7984. https://doi.org/10.1016/0040-4039(94)80028-6

Habaue S, Seko T, Okamoto Y (2002) Asymmetric oxidative coupling polymerization of optically active tetrahydroxybinaphthalene derivative. Macromolecules 35:2437–2439. https://doi.org/10.1021/ma011828o

Habaue S, Ajiro H, Yoshii Y, Hirasa T (2004) Asymmetric oxidative coupling polymerization affording polynaphthylene with 1,1′-bi-2-naphthol units. J Polym Sci A Polym Chem 42:4528–4534. https://doi.org/10.1002/pola.20363

Habaue S, Muraoka R, Aikawa A, Murakami S, Higashimura H (2005) Oxidative coupling polymerization of 2,3-dihydroxynaphthalene with dinuclear-type copper(II) catalyst. J Polym Sci A Polym Chem 43:1635–1640. https://doi.org/10.1002/pola.20637

Yan P, Temma T, Habaue S (2008) Lewis-acid-assisted highly selective oxidative cross-coupling polymerization with copper catalysts. Polym J 40:710–715. https://doi.org/10.1295/polymj.PJ2008052

Matsumoto K, Shibasaki Y, Ando S, Ueda M (2006) Synthesis of novel poly[(1,3-adamantyl)bis(2-naphthol)] with low dielectric constant. Polymer 47:3043–3048. https://doi.org/10.1016/j.polymer.2006.02.084

Thelakkat M (2002) Star-shaped, dendrimeric and polymeric triarylamines as photoconductors and hole transport materials for electro-optical applications. Macromol Mater Eng 287:442–461. https://doi.org/10.1002/1439-2054(20020701)287:7%3c442:AID-MAME442%3e3.0.CO;2-H

Shirota Y (2005) Photo- and electroactive amorphous molecular materials—molecular design, syntheses, reactions, properties, and applications. J Mater Chem 15:75–93. https://doi.org/10.1039/B413819H

Shirota Y, Kageyama H (2007) Charge carrier transporting molecular materials and their applications in devices. Chem Rev 107:953–1010. https://doi.org/10.1021/cr050143+

Choi JK, Cho K, Yoon T-H (2010) Synthesis and characterization of polyimides from triphenylamine-based diamine monomers with thiophene or trifluoromethyl side group. Synth Met 160:1938–1944. https://doi.org/10.1016/j.synthmet.2010.07.013

Wang Z, Zhang B, Yu H, Li G, Bao Y (2011) Synthetic control of network topology and pore structure in microporous polyimides based on triangular triphenylbenzene and triphenylamine units. Soft Matter 7:5723–5730. https://doi.org/10.1039/C1SM05315A

Li G, Wang Z (2013) Microporous polyimides with uniform pores for adsorption and separation of CO2 gas and organic vapors. Macromolecules 46:3058–3066. https://doi.org/10.1021/ma400496q

Zhang F, Li N, Cui Z, Zhang S, Li S (2008) Novel acid–base polyimides synthesized from binaphthalene dianhydrie and triphenylamine-containing diamine as proton exchange membranes. J Membr Sci 314:24–32. https://doi.org/10.1016/j.memsci.2008.01.032

Son JM, Mori T, Ogino K, Sato H, Ito Y (1999) Synthesis of polymers having a hole transporting ability by condensation polymerization of N, N′-diphenyl-N, N′-bis(4-methylphenyl)-(1,1′-biphenyl)-4,4′-diamine and aldehydes. Macromolecules 32:4849–4854. https://doi.org/10.1021/ma990040r

Lu J, Hlil AR, Hay AS, Maindron T, Dodelet J-P, Lam J, D’Iorio M (2000) Synthesis of poly(arylene ether)s containing hole-transport moieties from an isocyanate masked bisphenol. J Polym Sci A Polym Chem 38:2740–2748. https://doi.org/10.1002/1099-0518(20000801)38:15%3c2740:AID-POLA140%3e3.0.CO;2-R

Lee MS, Kim SY (2005) Synthesis of poly(arylene ether)s containing triphenylamine units via nitro displacement reaction. Macromolecules 38:5844–5845. https://doi.org/10.1021/ma048170+

Lin H-Y, Liou G-S (2009) Poly(triphenylamine)s derived from oxidative coupling reaction: substituent effects on the polymerization, electrochemical, and electro-optical properties. J Polym Sci A Polym Chem 47:285–294. https://doi.org/10.1002/pola.23155

Nomura M, Shibasaki Y, Ueda M, Tugita K, Ichikawa M, Taniguchi Y (2004) Synthesis and properties of poly[di(1-naphthyl)-4-tolylamine] as a hole transport material. Macromolecules 37:1204–1210. https://doi.org/10.1021/ma0355709

Getautis V, Daskeviciene M, Gaidelis V, Jankauskas V (2005) New branched hydrazones as hole transporting materials. J Photoch Photobio A Chem 175:39–44. https://doi.org/10.1016/j.jphotochem.2005.04.032

Ho S, Liu S, Chen Y, So F (2015) Review of recent progress in multilayer solution-processed organic light-emitting diodes. J Photon Energy 5:057611. https://doi.org/10.1117/1.JPE.5.057611

Kahle F-J, Saller C, Köhler A, Strohriegl P (2017) Crosslinked semiconductor polymers for photovoltaic applications. Adv Energy Mat 7:1700306. https://doi.org/10.1002/aenm.201700306

Jayaprakash D, Sasai H (2001) Synthesis and catalytic applications of soluble polymer-supported BINOL. Tetrahedron Asymmetry 12:2589–2595. https://doi.org/10.1016/S0957-4166(01)00443-8

Liu D, Ouyang K, Yang N (2016) Preparation of several BINOL-based polymeric ligands for the enantioselective addition of triethylaluminum to aromatic aldehydes. Tetrahedron 72:1018–1023. https://doi.org/10.1016/j.tet.2015.12.076

Schmidt J, Kundu DS, Blechert S, Thomas A (2014) Tuning porosity and activity of microporous polymer network organocatalysts by co-polymerisation. Chem Commun 50:3347–3349. https://doi.org/10.1039/c3cc49220f

Monterde C, Navarro R, Iglesias M, Sánchez F (2019) Admantyl-BINOL as platform for chiral porous polymer aromatic frameworks. Multiple applications as recyclable catalysts. J Catal 337:609–618. https://doi.org/10.1016/j.jcat.2019.07059

Altava B, Burguete MI, Verdugo EG, Luis SV (2018) Chiral catalysts immobilized on achiral polymers: effect of the polymer support on the performance of the catalyst. Chem Soc Rev 47:2722–2771. https://doi.org/10.1039/ccs00734e

Snyckers F, Zollinger H (1970) Stereochemistry of the σ-complex intermediate in sterically hindered electrophilic aromatic substitutions. Helv Chim Acta 53:1294–1305. https://doi.org/10.1002/hlca.19700530606

Lee J, Cha H, Kong H, Seo M, Heo J, Jung IH, Kim J, Shim H-K, Park CE, Kim SY (2014) Synthesis of triarylamine-based alternating copolymers for polymeric solar cell. Polymer 55:4837–4845. https://doi.org/10.1016/j.polymer.2014.08.018

Grzybowski M, Skonieczny K, Butenschön H, Gryko DT (2013) Comparison of oxidative aromatic coupling and the scholl reaction. Angew Chem Int Ed Engl 52:9900–9930. https://doi.org/10.1002/anie.201210238

Cornil J, Heeger AJ, Bredas JL (1997) Effects of intermolecular interactions on the lowest excited state in luminescent conjugated polymers and oligomers. Chem Phys Lett 272:463–470. https://doi.org/10.1016/S0009-2614(97)00573-3

Marsitzky D, Scott JC, Chen J-P, Lee VY, Miller RD, Setayesh S, Müllen K (2001) Poly-2,8-(indenofluorene-co-anthracene)—a colorfast blue-light-emitting random copolymer. Adv Mater 13:1096–1099. https://doi.org/10.1002/1521-4095(200107)13:14%3c1096:AID-ADMA1096%3e3.0.CO;2-I

Acknowledgements

This work was supported by Korea Institute of Energy Technology Evaluation and Planning (KETEP) Grant funded by the Korea government (MOTIE) (20191510301070, Development dissolved boron removal system contained in effluent of discharged from liquid radioactive waste treatment system).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Lee, J., Park, J., Choi, H. et al. Synthesis of regiocontrolled triarylamine-based polymer with a naphthol unit. Polym. Bull. 78, 965–979 (2021). https://doi.org/10.1007/s00289-020-03146-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03146-y