Abstract

Superabsorbent hydrogels of chitosan-g-polyacrylamide with N,N′-methylene-bis-acrylamide as a crosslinker were prepared via UV irradiation in the absence of photoinitiator under homogeneous conditions. The product was characterized by Fourier transform infrared spectroscopy, differential scanning calorimetry, and scanning electron microscopy to confirm the formation of hydrogels. The transparent hydrogels have been observed to exhibit as much as 2987% swelling in acidic solution. In addition, the hydrogel which hydrolyzed for 6 h (0.24 × 103 min) can have a water uptake of 106 times its weight (5300% swelling for 0.5 g hydrogel). The effect of several variables such as time, temperature, pH, acrylamide/chitosan ratio, crosslinker amount, and different media was explored. Finally, the prepared hydrogel have been used in adsorption of Zn(II) ions from water with high removal efficiency (0.636 meq g−1 or 20.8 mg g−1) at pH = 7. The experimental data of the adsorption equilibrium from Zn(II) solution fit well with the pseudo-second-order model.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Superabsorbent hydrogels are three-dimensional hydrophilic polymers that absorb large amounts of water and swell to form a solid gel structure while maintaining the physical structure without dissolving. Superabsorbent hydrogels are held together by the crosslinks of covalent bonds or ionic and/or secondary forces, such as hydrogen bonds or hydrophobic interactions which improve the wet strength of hydrogels [1]. Because of the presence of certain functional groups as well as polymer chains with carboxylic acid, amine, hydroxyl, amide, and sulfonic acid groups, hydrogels are often sensitive to the conditions of the surrounding environment and are referred to as “intelligent materials” [2]. For example, the water uptake of these materials may be sensitive to temperature [3], pH [4], or to the ionic strength [5] of the swelling solutions. These smart hydrogels are mainly used in the fields of medicine, pharmacy, and biotechnology, with applications as artificial tissues and organ implants, biomedical separation systems, controlled release systems, drug release [6, 7], absorbent sanitary goods, agriculture, and horticulture products to improve the water retention capability of soil [8], waste water treatment, and hygienic products [7]. Alternatively, interpenetrating networks (IPN) are a combination of two or more polymers which one or all of them synthesized or cross-linked independently in network form [9]. The networks are held by topological bonds essentially without covalent bonds [10]. Cross-linked polymers exhibiting high equilibrium swelling in water or aqueous solutions can be based exclusively on macromolecules with a high hydrophilicity and flexibility, which are often a function of the polyelectrolytic nature of the chains [11].

Recently, there has been considerable interest in the preparation of superabsorbent materials by the common synthesis route of free radical cross-linking copolymerization of hydrophilic non-ionic monomers such as acrylic acid [12], acrylamide [2, 13, 14], acrylic acid-co-acrylamide [15], acrylic acid/acrylamide/2-acrylamido-2-methyl-1-propanesulfonicacid [7], hydroxylethyl methacrylate [16], methacrylic acid [17], and vinyl alcohol [18] onto natural materials including chitosan, cellulose, starch and sodium alginate, and carrageenan. Chitosan is a high molecular weight polysaccharide that mostly consists of β-(1→4)-2-deoxy-2-amino-d-glucopyranose units, but also has of β-(1→4)-2-deoxy-2-acetamido-d-glucopyranose as a minor constituent. Chitosan is a basic polymer with amine side groups and is of great interest with its wide application. Chitosan and its derivatives especially hydrogel forms care widely applied in the treatment of water due to the free amino groups for adsorption of heavy metals such as cadmium, lead, copper, nickel, zinc, and chromium which are not biodegradable and tend to accumulate in living organisms, leading to several types of diseases and disturbances [19]. Chitosan has exhibited Zn(II) ions sorption capacities around 0.2 meq g−1at pH 7.0 [20]. But because of its solubilization in acid media and a decrease in the rate of the adsorption process, several methods have been used to modify natural chitosan either physically or chemically [21]. For instance, chitosan-g-polyacrylamide hydrogel which synthesized under microwave irradiation showed around 0.3 meq g−1 adsorption for Zn(II) ions at pH = 7 [20].

The objective of this study is the easy synthesis of chitosan-g-polyacrylamide semi-IPN superabsorbent hydrogel through UV irradiation in the absence of any photoinitiator or catalyst (the superabsorbent hydrogel is free from any impurities), higher amount of swelling compared with the other methods such as gamma radiation synthesized of chitosan-g-poly(Acrylic acid-co-Acrylamide) copolymer hydrogels which has 800% swelling in the absence of acrylic acid [22] and the priority of this superabsorbent hydrogel in adsorption of Zn(II) ions in comparison with previous methods as mentioned above [20].

Experimental

Materials

Medium molecular weight chitosan (4 × 105) with 200 mPa s viscosity was used as the base in a grafting experiment. The chitosan sample (Aldrich) with an 85% degree of deacetylation value (as reported by the manufacturer), accompanied by acrylamide (Aldrich), was dried in the oven at 60 °C overnight. N,N′-methylene-bis-acrylamide (Aldrich), Ethylenediaminetetraacetic acid (EDTA) (Sigma), zinc sulfate (Mreck), sodium hydroxide (Aldrich), sodium chloride (Analar), sodium hydroxide (Aldrich), sodium hydrogen carbonate (Analar), sodium hydrogen orthophosphate (Analar), potassium chloride (Sigma Aldrich), potassium phosphate monobasic (Aldrich), potassium hydrogen phthalate (Analar), magnesium sulfate (Analar), calcium chloride (Aldrich), acetic acid 100% (Riedel-de Haen), and hydrochloric acid 37% (Riedel-de Haen) were used as received.

Preparation of (chitosan-g-polyacrylamide) superabsorbent hydrogel

First, chitosan solution was prepared with 1 g chitosan powder dissolved in 60 mL acetic acid aqueous solution (2%). The preparation of the semi-IPN hydrogel of chitosan/acrylamide was performed in a quartz tube (10 cm long and 1 cm internal diameter) by adding 3.3 g chitosan solution (1.66 w/v in acetic acid), 0.002 g of N,N′-methylene-bis-acrylamide as a crosslinker and acrylamide (0.45 g) dissolved in 3 mL distilled water. Then, the homogenous mixture was exposed to UV lamps (Luzchem Photoreactor, Luzchem Research Inc., Canada) with 7670 μW/cm2 power (in UVA region, 350 nm) for 24 h at 20 °C and the air atmospheric conditions. The distance between the reaction mixture and the light source was kept constant at 15 cm. Thereafter, the superabsorbent hydrogel of the chitosan-g-polyacrylamide product in the form of rods (about 6 cm length) was immersed in 100 mL of water at room temperature overnight with replacement of water, then immersed in Soxhlet extractor for 2 days, and finally dried at 80 °C until it reached a constant weight, extensively with the suitable solvent system for 48 h (2.88 × 103 min). They were all dried at 60 °C to constant weight.

For hydrolyzation of the products, dried hydrogel was kept in 50 mL of sodium hydroxide solution (1 N) for 2 h (0.12 × 103 min) and 6 h (0.24 × 103 min) at room temperature. It was then washed with water several times.

Swelling of the superabsorbent hydrogel

The water absorbency of hydrogel was examined by immersing 0.5 g of hydrogel in 50 mL of distilled water at 20 °C for a day until the swelling equilibrium was achieved. The hydrogel’s mass increase allowed the calculation of the swelling percentage by using the following equation:

where W s and W d are the weights of the swollen gel and the dried sample, respectively. The effect of variable conditions such as time, acrylamide/chitosan ratio, crosslinking content, as well as pH and temperature on the swelling behavior was also examined. When studying one factor, the other variable conditions were kept constant. For instance, the influence of acrylamide/chitosan ratio on swelling was calculated using 3.3 g chitosan solution (1.66 w/v in acetic acid) and 0.002 g N,N′-methylene-bis-acrylamide with different amount of acrylamide dissolved in 3 mL water and irradiated for 24 h (1.44 × 103 min). Then, different dried products were immersed in 50 mL neutral water for water uptake at room temperature for a day. Furthermore, the water absorbency of 0.5 g semi-IPN superabsorbent hydrogel in 50 mL of different media [water, NaCl (1.5 mol/L) and Hanks solution] simulated their swelling behavior in the fluid system of the human body for a day. The Hank’s solution is prepared by using different types of salt such as sodium chloride (0.8 g), potassium chloride (0.4 g), sodium hydrogen carbonate (0.35 g), potassium phosphate monobasic (0.06 g), magnesium sulfate (0.246 g), calcium chloride (0.144 g), and sodium hydrogen orthophosphate (0.0358 g) in 100 mL of water [16].

Sorption of Zn(II) ion on the superabsorbent hydrogel

The Zn(II) ions adsorption capacity of the hydrogel was determined by using the batch equilibrium method. The hydrogel (0.1 g) was suspended in 15 mL non-buffered water with continues shaken for 4 h (0.24 × 103 min). After the stirring proceeded, 50 mL of aqueous solution of 1 mM Zn(II) ions (65.38 mg/L Zn(II) ion) was added to the hydrogel. The mixture was stirred at 20 °C for specific period of time and then filtered. The amount of adsorbed Zn(II) ions was calculated by difference between the initial and final concentration of Zn(II) ions by using the titration method with 0.01 mol/L EDTA and Erichrome Black-T as indicator. The Zn(II) loaded hydrogel was washed twice with 2 mol/L hydrochloric acid followed by distilled water several times to remove adsorbed Zn(II) ions.

Also, in order to approximate efficiency of Zn(II) ions adsorption by chitosan-g-polyacrylamide semi-IPN superabsorbent hydrogel kinetics adsorption tests were performed. However, the aqueous sample were taken at time intervals and the concentration of Zn(II) were similarly measured. The Zn(II) uptake at any time, q t (mg/g) was calculated by following equation:

where q t is the amount of the Zn(II) adsorbed on the hydrogel, V is the sample volume (L), W is the weight of hydrogel used (g), C 0 and C t (mg/L) are the initial concentration and the final concentration of Zn(II) ion adsorbed at time t (min), respectively.

Results and discussion

Characterization of the superabsorbent hydrogel

The chitosan-g-polyacrylamide superabsorbent semi-IPN hydrogel was produced according to the procedure above. Photographs of 0.5 g of hydrogel formed as it is (after irradiation), in the swollen state (after immersing in 50 mL of water for a day), and dried state (after drying in oven at 80 °C for a day) as well as its transparency are depicted in Fig. 1a–d.

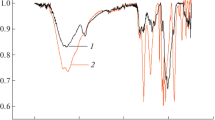

Fourier Transform Infrared (FTIR) analysis

The synthesis of chitosan-g-polyacrylamide semi-IPN superabsorbent hydrogels was confirmed by comparing its FTIR spectrum with the spectrum of chitosan (Fig. 2a, b). The chitosan spectrum shows the characteristic absorption bands at 1655 cm−1 (amide) and 1597 cm−1 (amine). These two peaks have a minor shift and are sharper in the hydrogel spectrum, which is reconfirmed by a peak at 3206 cm−1 (amide). Moreover, the C–H and O–H bending vibrations are observed in the 1300–1400 cm−1 with a sharp peak at 1383 cm−1. However, this sharp peak is related to the O–H group like two very sharp peaks at 1159 and 1082 cm−1 (alcoholic and etheric C–O stretching vibrations, respectively), which are not present in the hydrogel spectrum. This implies that the hydroxyl group of chitosan is the preferred site for the reaction with the crosslinker and the grafting of acrylamide due to lower steric hindrance of the primary hydroxyl group.

Differential scanning calorimetry (DSC) analysis

DSC thermograms of (a) chitosan and (b) chitosan-g-polyacrylamide semi-IPN superabsorbent hydrogel are presented in Fig. 3. The endothermic peak present in DSC thermograms of chitosan at 100.5 °C is due to the loss of water contained in the chitosan backbone which is bound to the structure via unsubstituted free –OH and –NH2 groups of chitosan. This endothermic peak which represents melting temperature (T m) for semi-IPN hydrogel is shifted to a higher temperature (240.10 °C) due to the presence of more free amide groups in the structure of networks (Scheme 1). In addition, chain scission and the destruction of the crosslinked network can enhance the evaporation temperature of hydrogels.

Scanning electron microscopy (SEM) analysis

SEM analysis studied the change in surface morphology of the semi-IPN superabsorbent hydrogel compared with chitosan. As can be seen in Fig. 4a, b, the chitosan has smooth surface whereas the superabsorbent hydrogel exhibits a coarse surface. This distinguished change in the surface of hydrogel is suitable for the penetration of water into the polymeric network, and can improve water absorbency of corresponding superabsorbent.

Schematic illustration for hydrogel formation

The superabsorbent semi-IPN hydrogel was synthesized by the reaction of chitosan, acrylamide and N,N′-methylene-bisacrylamide as the crosslinker. Owing to the absence of any initiator, the hydrogel is free from any impurities. This completely transparent hydrogel has a large swelling percentage that is illustrated below. Scheme 1 shows all possible reactions leading to the formation of the semi-IPN hydrogel. Chitosan chains in the presence of N,N′-methylene-bisacrylamide can be crosslinked. In addition, under irradiation of UV rays polyacrylamide is grafted onto chitosan and then crosslinked together. In relation to the result of FTIR spectroscopy, the –OH group of chitosan is the preferred site of the reaction with the crosslinker and acrylamide, respectively. Furthermore, the polyacrylamide chains as a result of the reaction with the bifunctional crosslinker. Hence, a mixture of crosslinked and uncrosslinked chitosan, chitosan-g-polyacrylamide, and polyacrylamide are formed.

Swelling behavior

Effect of time on swelling percentage

As shown in Fig. 5, the swelling percentage first increased and then reached a plateau. The equilibrium swelling percentage of 2514.2% was achieved after immersing the semi-IPN hydrogel in water for 1.92 × 103 min. Hence, this may be attributed to the hydrophilicity of the polyacrylamide chains involved and the higher capacity in the structure of chitosan-g-polyacrylamide to hold water. Therefore, the osmotic pressure difference between the gels and the solution can reduce by enhancing polymer–solute interactions. As a result, the rate of sorption from aqueous solutions will increase. However, further increases in time cause balance in osmotic pressure and the swelling therefore will remain constant. Furthermore, hydrolyzation of hydrogel for 2 h (0.12 × 103) and 6 h (0.36 × 103 min) revealed a similar trend (a sharp increase followed by leveling off), but the rate of swelling is more than non-hydrolyzed hydrogel whereas maximum swelling was 3460 and 5300%, respectively. This is attributed to the breakage of the crosslink bonds during hydrolysis which results in lowering the crosslinking density and can be further facilitates water ingress.

Effect of time on the swelling percentage of hydrogel before hydrolysis (filled square), after 0.12 × 103 min of hydrolysis (filled triangle) and after 0.36 × 103 min hydrolysis (filled circle) [3.3 g chitosan solution (1.66 w/v in acetic acid), 0.45 g acrylamide (2 mol/L), 0.002 g N,N′-methylene-bisacrylamide, at 20 °C]

Effect of acrylamide/chitosan ratio on swelling percentage

The swelling behavior of superabsorbent hydrogels was studied at different acrylamide/chitosan ratios. As seen in Fig. 6, the swelling percentage increases with an increase in acrylamide, reaching the maximum value of swelling capacity (2987.2%). This is probably due to a greater availability of the monomer molecules in the vicinity of the chitosan and higher molecular collisions. A further increase in acrylamide concentration compared with chitosan lead to a decrease in the swelling capacity. The swelling decrease at higher acrylamide/chitosan ratios can be attributed to the formation of homopolymer, followed by an increase in viscosity that hinders the movement of free radicals and monomer molecules.

Effect of the acrylamide/chitosan ratio on the swelling percentage of hydrogel (filled triangle) [3.3 g chitosan solution (1.66 w/v in acetic acid), 3 mL water, 0.002 g N,N′-methylene-bisacrylamide, at 20 °C, for 1.44 × 103 min], and the effect of crosslinker amounts on the swelling percentage of hydrogel (filled circle) [3.3 g chitosan solution (1.66 w/v in acetic acid), 0.45 g acrylamide (2 mol/L), at 20 °C, 1.44 × 103 min]

Effect of crosslinker amounts on swelling percentage

To study the influence of the crosslinker on the swelling parameters, the swelling performed at six different crosslinking amounts ranging from 0.002 to 0.016 g. As shown in Fig. 6, the water absorbency of hydrogel decreased as the crosslinker amount was increased, and maximum absorbency was achieved at 0.002 g of N,N′-methylene-bis-acrylamide. In the presence of greater crosslinker density, branching of acrylamide and chitosan chain increased through the generation of an additional network, which leads to a lower amount of space in the chains for water preservation by hydrogels during swelling. A similar trend was reported by Wang et al. [23] in the preparation of superabsorbent hydrogels based on sodium alginate-g-poly(sodium acrylate) and polyvinylpyrrolidone.

Effect of pH on swelling percentage

Figure 7 shows the pH responsive swelling of the superabsorbent hydrogels. The effect of pH on the swelling capacity was examined in buffer solutions in the pH range of 1–10. A maximum swelling of 3150% was achieved under basic conditions (pH = 8). Under acidic conditions, the amide groups of acrylamide converted to carboxyl groups (COO−). Therefore, the hydrogel composed of chitosan as cationic (NH3 +) and acrylic acid as anionic (COO−) polyelectrolyte [12]. However, under acidic conditions at pH = 2 the cationic character of hydrogel (NH3 +) predominates. Therefore, the NH3 +–NH3 + electrostatic repulsion increases the osmotic pressure inside the gel relative to the solution. The gel reaches equilibrium of osmotic pressure by swelling. However, in very acidic condition (pH = 1) the presence of chloride ion (Cl−) prevented from NH3 +-NH3 + electrostatic repulsion [2]. As a result, the swelling decreased. When the pH increased above 2, the hydrogel contains NH3 + and COO− ions without dominance which resulted in higher ionic strength and a lower difference in osmotic pressure between the gel and the media. Therefore, the swelling percentage was reduced. But, at pH = 8 the swelling percentage increased probably due to the predominance of the anionic character of the hydrogel (COO−).

Effect of pH on the swelling percentage of hydrogel (filled triangle) [3.3 g chitosan solution (1.66 w/v in acetic acid), 0.45 g acrylamide (2 mol/L), 0.002 g N,N′-methylene-bisacrylamide, at 20 °C, for 1.44 × 103 min], and the effect of temperature on the swelling percentage of hydrogel (filled circle) [3.3 g chitosan solution (1.66 w/v in acetic acid), 0.45 g acrylamide (2 mol/L), 0.002 g N,N′-methylene-bisacrylamide, 0.18 × 103 min]

Effect of temperature on swelling percentage

The dependence of the swelling capacity of hydrogels on temperature is illustrated in Fig. 7. By increasing the temperature for 3 h (0.18 × 103 min) while keeping the gel under water the water absorbing capacity increased and the maximum swelling percentage (871.2%) was achieved at 65 °C. Any further increase in the temperature leads to a decrease in gel content. This behavior originates from the greater activation of backbone radicals and opens up the network structure, thereby increasing water accessibility. Beyond the optimum temperature, radical centers and crosslink formation of the hydrogel further increased, causing swelling loss [24].

Effect of different media on swelling percentage

The effect of time in different swelling media; water, Hank’s solution, and saline solution on the swelling of the superabsorbent hydrogels were considered. As shown in Fig. 8, the swelling percentage of hydrogels in water is more than the swelling percentage in saline or Hank’s solution. This well-known phenomenon can be attributed to the decrease in osmotic pressure between internal and external network solutions in the presence of salt and therefore, the swelling percentage is reduced. In addition, because NaCl is the main component of Hank’s solution, the swelling behavior of the hydrogel in salt and Hank’s solution is comparable. A similar observation has been reported by Kim et al. [16] in the case of hydrogels based on chitosan and poly (hydroxylethyl methacrylate).

Effect of time in different swelling media, water (filled circle), Hank’s solution (filled triangle), and salt solution (filled square) on the swelling percentage of hydrogel, [3.3 g chitosan solution (1.66 w/v in acetic acid), 0.45 g acrylamide (2 mol/L), 0.002 g N,N′-methylene-bisacrylamide, at 20 °C]

Zn(II) ions uptake on semi-IPN hydrogel

As mentioned in above, the adsorption capacity of Zn(II) ions (q t ) with hydrogel was investigated by a batch equilibration technique as a function of contact time. Figure 9 shows adsorption of Zn(II) ions with hydrogel during 35 h (2.10 × 103 min). The Zn(II) ions uptake increased rapidly and after 24 h (1.44 × 103 min) it slightly reached to plateau. It can be due to increased number of vacant sites available at the initial stage during swelling process. As mentioned above, the maximum swelling capacity of hydrogel was achieved after 32 h (1.92 × 103 min) immersing hydrogel under water, and also at this stage the adsorption of Zn(II) ions will be the highest amount (20.8 mg g−1) Subsequently, with gradual decrease in the available adsorption site, the slower adsorption would be obtained. The effect of reaction condition on Zn(II) ions adsorption will be considered in next study.

Adsorption kinetic studies

While the kinetic of adsorption is one of the most important factors for finding the efficiency of adsorption, the two kinetic models including pseudo-first-order and pseudo-second-order will be considered. These two models are given in Eqs. 3 and 4, respectively.

where the t is the time (min), q e, q t , and q 2e are the amounts of Zn(II) ions adsorbed onto hydrogel at equilibrium, at time t, and the maximum adsorption capacity (mg/g), respectively. Also, k 1 and k 2 are the adsorption rate constant of pseudo-first-order (1/min) and pseudo-second-order (g/mg/min) (Figs. 10, 11).

As can be seen in Fig. 11, the adsorption kinetic data of the Zn(II) ion adsorption on chitosan-g-polyacrylamide superabsorbent hydrogel are well represented by pseudo-second-order model where linear plot of \( \frac{t}{{q_{t} }} \) versus t was obtained with the correlation coefficient (R 2) being 0.993 and the rate constant was 4.25 × 104. The output of these models was listed in Table 1. Moreover, with comparing theoretical equilibrium adsorption capacity to experimental value (20.8 mg g−1) in both models and observing the agreement between these two values in just the pseudo-second order it can be easily concluded that adsorption of Zn(II) ions by chitosan-g-polyacrylamide semi-IPN hydrogel is the best fitted into the pseudo-second order. It should be mentioned that these models are based on the adsorption capacity and they support validity of studies. Therefore, the adsorption mechanism will remain uncertain.

Conclusion

A semi-interpenetrating polymer network (semi-IPN) superabsorbent hydrogel with crosslinked chitosan, acrylamide, and chitosan-g-acrylamide in the absence of any initiator was synthesized. Swelling capacity of the hydrogels was found to be affected by the acrylamide/chitosan ratio, crosslinker amount, and the type of media solution, which included salt solution and Hank’s solution. The water uptake of the hydrogel revealed sensitivity to temperature and pH. Furthermore, the swelling capacity of hydrogel was affected by hydrolyzation of grafted product and was highly dependent on the time of hydrolysis. Therefore, the maximum swelling percentage, 5300% was observed for hydrolyzed hydrogels after 2.4 × 103 min suspending under water. This smart gel with valuable properties such as high swelling percentage, pH, and media sensitivity can be applied in industry especially in water treatment. This hydrogel show 20.8 mg g−1 (0.636 meq g−1) Zn(II) ions uptake capacities from water. The Zn(II) ions adsorption kinetic followed the mechanism of pseudo-second-order model. The effect of reaction conditions on uptake capacity and also the regeneration of hydrogel after first uptake will be investigated in the next studies.

References

Pourjavadi A, Mahdavinia GR (2006) Superabsorbency, pH-sensitivity and swelling kinetics of partially hydrolyzed chitosan-g-poly(acrylamide) hydrogels. Turk J Chem 30:595–608

Qu X, Wirsen A, Albertsson AC (2000) Novel pH-sensitive chitosan hydrogels: swelling behavior and states of water. Polymer 41:4589–4598

Pagonis K, Bokias G (2007) Temperature- and solvent-sensitive hydrogels based on N-isopropylacrylamide and N,N-dimethylacrylamide. Polym Bull 58:289–294

Tang QM, Wu JH, Lin JM (2008) A multifunctional hydrogel with high conductivity, pH-responsive, thermo-responsive and release properties from polyacrylate/polyaniline hybrid. Carbohydr Polym 73:315–321

Firestone BA, Siegel RA (1988) Dynamic pH-dependent swelling properties of a hydrophobic poly-electrolyte gel. Polym Commun 29:204–208

Rao KSVK, Ha CS (2009) pH Sensitive hydrogels based on acryl amides and their swelling and diffusion characteristics with drug delivery behavior. Polym Bull 62:167–181

Bao Y, Ma JZ, Li N (2011) Synthesis and swelling behaviors of sodium carboxymethyl cellulose-g-poly(AA-co-AM-co-AMPS)/MMT superabsorbent hydrogel. Carbohydr Polym 84:76–82

Abedi-Koupai J, Sohrab F, Swarbrick G (2008) Evaluation of hydrogel application on soil water retention characteristics. J Plant Nutr 31:317–331

Al-Kahtani AA, Sherigara BS (2009) Controlled release of theophylline through semi-interpenetrating network microspheres of chitosan-(dextran-g-acrylamide). J Mater Sci 20:1437–1445

Rokhade AP, Patil SA, Aminabhavi TM (2007) Synthesis and characterization of semi-interpenetrating polymer network microspheres of acrylamide grafted dextran and chitosan for controlled release of acyclovir. Carbohydr Polym 67:605–613

Kim SJ, Shin SR, Kim NG, Kim SI (2005) Swelling behavior of semi-interpenetrating polymer network hydrogels based on chitosan and poly(acryl amide). J Macromol Sci Pure Appl Chem A42:1073–1083

Yazdani-Pedram M, Retuert J, Quijada R (2000) Hydrogels based on modified chitosan, 1—Synthesis and swelling behavior of poly(acrylic acid) grafted chitosan. Macromol Chem Phys 201:923–930

Mahdavinia GR, Pourjavadi A, Zohuriaan-Mehr MJ (2008) Synthesis and properties of highly swelling PAAm/chitosan semi-IPN hydrogels. Macromol Symp 274:171–176

Wu JH, Lin JM, Zhou M, Wei CR (2000) Synthesis and properties of starch-graft-polyacrylamide/clay superabsorbent composite. Macromol Rapid Commun 21:1032–1034

Mahdavinia GR, Pourjavadi A, Hosseinzadeh H, Zohuriaan MJ (2004) Modified chitosan 4. Superabsorbent hydrogels from poly(acrylic acid-co-acrylamide) grafted chitosan with salt- and pH-responsiveness properties. Eur Polym J 40:1399–1407

Kim SJ, Shin SR, Shin DI, Kim IY, Kim SI (2005) Synthesis and characteristics of semi-interpenetrating polymer network hydrogels based on chitosan and poly (hydroxyethyl methacrylate). J Appl Polym Sci 96:86–92

Chen SL, Liu MZ, Jin SP, Chen Y (2005) Synthesis and swelling properties of pH-sensitive hydrogels based on chitosan and poly (methacrylic acid) semi-interpenetrating polymer network. J Appl Polym Sci 98:1720–1726

Wang T, Gunasekaran S (2006) State of water in chitosan-PVA hydrogel. J Appl Polym Sci 101:3227–3232

Holt MS (2000) Sources of Chemical Contaminants and Routesin to the Fresh water Environment. Food Chem Toxicol 38:21–27

Singh V, Tiwari A, Tripathi DN, Sanghi R (2006) Microwave enhanced synthesis of chitosan-graft-polyacrylamide. Polymer 47:254–260

Barros FCF, Sousa FW, Cavalcante RM, Carvalho TV, Dias FS, Queiroz DC, Vasconcellos LCG, Nascimento RF (2008) Removal of copper, nickel and zinc ions from aqueous solution by chitosan-8-hydroxyquinoline beads. Clean 36:292–298

Abou Taleb FM (2008) Radiation synthesis of polyampholytic and reversible ph-responsive hydrogel and its application as drug delivery system. Polym Bull 61:341–351

Wang W, Wang A (2010) Synthesis and swelling properties of pH-sensitive semi-IPN superabsorbent hydrogels based on sodium alginate-g-poly(sodium acrylate) and polyvinylpyrrolidone. Carbohydr Polym 80:1028–1036

Lim DW, Whang HS, Yoon KJ, Ko SW (2001) Synthesis and absorbency of a superabsorbent from sodium starch sulfate-g-polyacrylonitrile. J Appl Polym Sci 79:1423–1430

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saber-Samandari, S., Gazi, M. & Yilmaz, E. UV-induced synthesis of chitosan-g-polyacrylamide semi-IPN superabsorbent hydrogels. Polym. Bull. 68, 1623–1639 (2012). https://doi.org/10.1007/s00289-011-0643-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-011-0643-4