Abstract

Encapsulation of inorganic nanoparticles (as a core) by polymers (as a shell) is one of the interesting research subjects that lead to the synthesis of nanocomposite. These materials include properties of not only the organic polymer (e.g. optical properties, toughness, processability, flexibility, etc.) but also the inorganic nanoparticles (e.g. mechanical strength, thermal stability, etc.). Some of the applied preparative methods are dry-spray, dispersion, suspension, emulsion and miniemulsion polymerization techniques. Here, miniemulsion polymerization technique was used in order to obtain white-color nanocomposite latex particles containing nano-alumina (40–47 nm) encapsulated by copoly [styrene (St)–methyl methacrylate (MMA)] under high-shear ultrasonic irradiation. At first, bare nano-alumina was encapsulated with the copolymer to obtain latex particles. In another attempt and in order to investigate the effect of compatiblizing system, alumina nanoparticles were coated with oleic acid in order to form modified alumina core. Then miniemulsion polymerization was performed in the minidroplets including modified alumina, St and MMA for obtaining core/shell nanocomposite particles. The progress of encapsulation polymerization was followed by different instrumental techniques such as FT-IR spectra, thermal gravimetric analysis, dynamic light scattering, induced-coupled plasma, TEM and SEM.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Several patents [1, 2] and papers [3] deal with the encapsulation of colloidal metals, sol–gel type inorganic oxides particles (SiO2, TiO2) [4] and other inorganic pigments to give organic–inorganic hybrid dispersions, where the polymer shell is built in situ by means of conventional emulsion [5–8], miniemulsion [9–15] and related dispersed-phase polymerization processes.

Encapsulation of inorganic nanoparticles as a core by polymers as a shell forms core/shell structures containing not only polymer properties but also inorganic nanoparticle properties. Extensive research has been reported involving various inorganic particles, such as, calcium carbonate, silica, titanium dioxide [16–21], carbon black [22] and magnetite [4, 23] with either micrometer or nanometer sizes.

Alumina nanoparticles are of much interest because of their high hardness, high strength, and good wear resistance [24]. They have widely been used as fillers for polymers for improvement of the mechanical, tribological, barrier, and conductive properties [25–27].

Duguet et al. [28] have reported encapsulation of spherical submicron size alumina particles through suspension polymerization. Guo and coworkers [29] have also reported encapsulation of needle-shaped nanosize alumina with polystyrene (PS) through emulsion polymerization. It seems that spheres are easier to be encapsulated than needles due to easier stabilization by the reaction medium.

Conventional miniemulsions are aqueous dispersions of relatively stable dispersed minidroplets with a size less than 500 nm. They are prepared at high shears in a system containing oil, water, a surfactant and a highly water-insoluble compound (hydrophobe) to suppress Ostwald ripening of the droplets [30]. The polymerization of such miniemulsions extends the possibilities of widely applied emulsion polymerization and provides advantages with respect to incorporation of hydrophobic compounds and composition of the oil phase [31].

On the other hand, ultrasonic cavitations can generate local high temperature and high pressure and a very rigorous environment for chemical reaction [32]. Under these rigorous conditions, radicals can be generated due to the decomposition of water, monomer, surfactant, or rupture of polymer chains to initiate the polymerization of monomer [33].

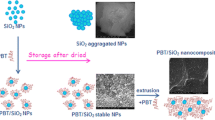

Duguet et al. [28] applied 3-methacryloxy propyl trimethoxy silane (MPTMS) as a reactive coupling agent to chemical modification of alumina particles surface. Ding et al. [34] used oleic acid as a functionalized monomer because the C=C bonds of oleic acid can be copolymerized with styrene (St) monomer. They reported that oleic acid could bond to the silica surface through hydrogen bonding. Surface-modified silica nanoparticles were then used in the encapsulation polymerization process. St monomer added to fully dispersed silica particles modified by oleic acid as seeds, was copolymerized with the oleic acid via in situ emulsion polymerization, in the presence of an initiator. We have also used silica-modified nanoparticles with oleic acid through miniemulsion polymerization reaction for obtaining nanocomposite particles with core/shell morphology and the role of oleic acid as a compatiblizing agent was investigated too [16].

In this study, encapsulation of alumina nanoparticles with copoly [St–methyl methacrylate (MMA)] was performed for preparation of spherical nanosize alumina/copoly (St–MMA) nanocomposite particles by miniemulsion polymerization under ultrasonic irradiation. Also, alumina nanoparticles were coated with oleic acid to obtain modified alumina and then they were incorporated into the miniemulsion polymerization in order to obtain core/shell particles with copoly (St–MMA) as the shell and nano-alumina or modified nano-alumina as the core.

Experimental

Materials

Styrene with 20 ppm inhibitor from Merck Chemical Co. (analytical grade) was washed with 5 wt% aqueous sodium hydroxide to remove the inhibitor, dried over calcium chloride and stored at 0 °C. MMA, oleic acid, span80, hexadecane (HD) and benzoyl peroxide (BPO) from Merck Chemical Co., sodium dodecyl sulfate (SDS) and nano-Al2O3 particles with size of 40–47 nm from Aldrich were used without further purification.

Apparatus

Fourier transform infrared (FT-IR) spectra of the samples in KBr pellets were recorded on a FT-IR BRUKER-IFS 48 spectrophotometer (Germany). Thermal gravimetric analyses (TGA) were recorded on a STA-PL instrument (England). The essential operations were carried out according to the manufacture’s instructions. The samples were weighed on a Shimadzu LIBRORE AEU-210 analytical electrobalance to a precision of 0.0001 g for this analysis. SEMATECH light scattering (France) with 633 nm wavelength was used to obtain size of the nanoparticles through dynamic laser light scattering (DLS). The morphology of alumina nanoparticles and formation of the copoly (St/MMA) shell layer around the nano-alumina particles were investigated by transmission electron microscopy (TEM) on a ZEISS 902A (Germany). The samples were diluted up to 20 times and dropped on a copper grid and dried. The morphology of samples was also characterized by scanning electron microscopy (SEM) on a XL30 instrument from Philips Company (Netherland). The equipment employed to generate ultrasonic irradiation was a SONOPLUS Ultrasonic homogenizer, HF-GM 2200 from BANDELIN electronic GmbH & Co, KG (Germany) with a frequency of 20 ± 0.5 kHz and a titanium probe MS-73 with diameter of 3 mm. In some steps, material dispersions were prepared in a Julabo Labortechnik GMBH D-733 Seelbatch (Germany) ultrasound bath with frequency of 35 kHz. Induced coupled plasma-optical emission spectroscopy (ICP-OES) analyses were recorded on an ICP-OES CCD, Vista-Pro model, from Varian Company (Italy).

Pretreatment of nano-alumina with oleic acid (m-Al2O3)

Alumina (1 g), oleic acid (1 ml) and 50 ml distilled water were added into the sonochemical reaction vessel. Ultrasonic irradiation was carried out with the probe of ultrasonic horn immersed directly into the mixture for 5 min. The aqueous ammonia (5 ml, 25 wt%) was added to the above mixture, irradiated with ultrasonic for 5 min and stirred with magnetic stirrer for 2 h. The mixture was demulsified by adding HCl (20 wt%) dropwise. The liquid phase was decanted. Redispersion of the white residue in methanol (95%) was achieved by ultrasonic bath. After 5 min, modified nano-alumina was precipitated, separated and dried at 50 °C for 10 h. The amount of adsorbed oleic acid onto the surface of alumina nanoparticles was 7.5 wt% relative to the total amount of obtained product.

Miniemulsion polymerization

Typical procedure for encapsulation of nano-alumina

The process to obtain nanocomposite latexes was as follows: typically, the mixture of nano-alumina (0.69 g), St (7.7 ml) and MMA (7.2 ml) (molar ratio of 1:1 for monomers) with 2.2 ml HD and 0.5 ml span 80 were added into the sonochemical reaction vessel and mixed by ultrasonic irradiation for 5 min just before use. Then a solution of 0.29 g SDS in definite amount of distilled water (62 ml) was introduced and sonicated for 10 min. After miniemulsion was formed, the above mixture with 0.27 g BPO (initiator) was moved into a 500 ml round bottomed reactor equipped with a mechanical stirrer and condenser, under nitrogen atmosphere to prevent probable inhibition. The reaction temperature was set at 70 °C and stirring rate was fixed at 300 rpm in the whole process. Sampling was carried out every 1 h along the progress of reaction (it was completed after 10 h) and each sample was inhibited with 1 ml solution of hydroquinone/methanol (1% W/V). Samples were dried at room temperature and used to obtain the conversion amount.

Typical procedure for encapsulation of modified nano-alumina

The mentioned procedure in above section (3-4-1) was also applied for preparation of latexes containing modified nano-alumina (m-nano Al2O3).

The detailed recipe (Tables 1, 2) summarizes two series of encapsulation experiments.

Results and discussion

In order to obtain successful encapsulation process, it was necessary to achieve good particles dispersion in the monomers phase and obtaining stable minidroplets of monomers containing inorganic nanoparticles. The stabilization system contained Span80 and SDS as surfactants and HD as hydrophobic agent. In other attempt and in order to investigate the effect of modifiers of nanoparticles, nano-alumina particles were coated with oleic acid to change their hydrophilic characteristic into the hydrophobic ones. With the aid of ultrasonic irradiation, minidroplets were provided and by adding initiator (BPO) into the reactor, polymerization reaction of comonomers was initiated and continued until completion.

Preparation of modified nano-alumina

Adsorption of oleic acid onto the surface of alumina nanoparticles through electrostatic interaction and hydrogen bonding formation was confirmed by FT-IR spectroscopy. FT-IR spectrum of pure alumina, oleic acid and coated alumina with oleic acid (m-nano Al2O3) has been given in Fig. 1. The comparison between FT-IR spectra of alumina and m-nano Al2O3 reveals the presence of oleic acid characteristic peaks in the pretreated alumina spectra. Before taking FT-IR spectra, the m-nano Al2O3 powder was dispersed in methanol (95%) by using ultrasonic bath and then filtered off and dried at 50 °C for 10 h. This ensured us about disappearance of any non-adsorbed oleic acid from the surface of alumina nanoparticles. The presence of peak at 1,708 cm−1 (C=O bond) and the stretching C–H bonds at 3,000–3,200 cm−1 confirms the adsorption of oleic acid onto the alumina nanoparticles.

Also the amount of adsorbed oleic acid onto the surface of alumina nanoparticles was determined by TGA (Fig. 2). 7.5% weight loss at up to 650 °C reveals the total amount of oleic acid in obtained product at this step.

Determination of alumina content

TGA thermograms were used to determine the amount of nano-alumina encapsulated in the copolymer. For providing samples, latexes were coagulated with few droplets of concentrated sulfuric acid. The coagulum was filtered off and washed three times with plenty of distilled water in order to remove the adsorbed surfactant and sulfuric acid. Then the samples were dried at 60 °C for an overnight. This procedure has the advantage of separation of freely dispersed alumina in the latex from the encapsulated ones. So, the residual weight percent after disappearance of the organic polymer at 650 °C could be considered as the encapsulated alumina nanoparticles. In order to exclude the probability of formation of non-volatile oxidative degradation products that causes some uncertainties in our calculations, TGA analysis were carried out under N2 atmosphere.

The results of corrected weight percent of remained alumina and ultimate percent of encapsulated alumina in the polymeric phase have been listed in Table 3. It is notable that TGA analysis of the blank sample was recorded in order to find out ash content of the copolymer at 650 °C. This ash content was subtracted from those obtained for other samples in order to determine the alumina content with less uncertainty.

It could be observed that the encapsulation of most of the NanoAl2O3 has been done successfully for modified samples and also for non-coated alumina in SMA-1 and SMA-2 samples. Some coagulation was observed at the bottom of reactor vessel for SMA-3 and SMA-4. On the other hand, this coagulation was not observed for the modified nano-alumina particles in which the presence of oleic acid helps in formation of better and more stable dispersion of alumina nanoparticles in the aqueous phase.

Through ICP analysis, the amount of non-encapsulated alumina (freely dispersed alumina in the continuous phase) during miniemlusion polymerization was measured. This could give us a good estimate of the encapsulated alumina indirectly. Preparation of the samples was performed by coagulation of the latex with concentrated sulfuric acid. The remaining serum was used as the source for injection into the ICP. As shown in Table 4, the amount of free alumina in the serum phase is not very significant and this could ensure us about the progress of miniemulsion polymerization on the surface of alumina nanoparticles. It was found that the amount of non-encapsulated alumina for the samples containing modified alumina was less than that of bare alumina.

The added alumina could be found in three different zones: (a) in the coagulated mass because of the aggregation process; (b) as freely dispersed particles, which have not been encountered in the polymeric particles in the miniemulsion polymerization (obtained from ICP) and (c) as encapsulated particles by the newly formed copolymer (obtained from TGA). The difference between total added alumina and the obtained data from TGA and ICP analysis could give a reasonable estimation of entrapped alumina in the coagulum (Table 5). The experimental results show that for both types of the above samples, the percentage of encapsulation decreases with increasing alumina content. This would be concluded that most of the modified nano-alumina is encapsulated and their presence in the coagulum is negligible. But for the bare alumina, the amount of nano-alumina in the coagulum is moderate and increases with its amount in the feed.

Determination of size and morphology of the obtained nanoparticles

Dynamic laser light scattering analysis was used in order to determine mean particles size in the latex. As shown in Table 6, the increase in nanocomposite particle sizes relative to the primary alumina particles (40–47 nm) represents the reason of polymeric shell formation on the inorganic cores. This illustrates that the polymerization reaction have certainly progressed in the presence and on the surface of alumina nanoparticles. Another important result is the role of alumina as seed or primary nanoparticles and the polymerization conditions do not allow nanocomposite particles to grow up too much. In fact, obtaining such nanoparticles is the result of miniemulsion polymerization condition that controls the growth and size of particles.

The growth of particle diameter in the presence of modified alumina was due to the aggregation of primary m-nano Al2O3 nanoparticles, which was related to the presence of oleic acid. Oleic acid was not able to stabilize each particle separately through steric effects in the polymerization condition and consequently, they tended to aggregate to the larger ones. Therefore, these aggregates become the core for adsorption of monomer and polymerization reaction to reach to core–shell nanocomposite particles and dispersion stability with semi-spherical particles.

The morphology of the above nanocomposite particles was examined by TEM and SEM too. SEM analysis reveals the formation of spherical shape of the core/shell nanoparticles with smooth outer surface (Fig. 3).TEM micrographs show dark nano-alumina cores and light polymeric shells around each core (Fig. 4).

Conclusion

Alumina particles with nanometric size were encapsulated by copoly (St/MMA) via miniemulsion polymerization process. Polar interactions between the surfactant used to stabilize nano-alumina particles within the comonomer mixture and produce stable miniemulsion. Ultrasonic irradiation has an excellent dispersion effect on the modified alumina with oleic acid in the aqueous media containing surfactants relative to the bare nano-alumina. The stable copoly (St/MMA)/alumina nanocomposite latexes with high monomer conversion and medium solid content were prepared through ultrasonic assisted miniemulsion polymerization in the presence of alumina. The obtained nanocomposite particles were analyzed by different techniques such as DLS, SEM and TEM in order to prove the morphology and size of the particles. Also the probability of presence of primary dispersed nano-alumina in different zones was determined through TGA and ICP measurements.

References

Solc NH (1983) Colloidal size of hydrophobic polymers particulate having discrete particles. US Patent 4421660

Martin RW (1986) Method of encapsulating finely divided solid particles. US Patent 4608401

Yang J, Park S-B, Yoon H-G, Huh Y-M, Haam S (2006) Preparation of poly ε-caprolactone nanoparticles containing magnetite for magnetic drug carrier. Int J Pharm 324:185–190

Viala P, Bourgeat-Lami E, Guyot A, Legrand P, Lefebvre D (2002) Pigment encapsulation by emulsion polymerization, redespersible in water. Macromol Symp 187:651–662

Lee DC, Jang LW (1996) Preparation and characterization of PMMA-clay hybrid composite by emulsion polymerization. J Appl Polym Sci 61:1117–1122

Reculusa S, Poncet-Legrand C, Ravaine S, Mingotaud C, Duguet E, Bourgeat-Lami E (2002) Syntheses of raspberry like silica/polystyrene materials. Chem Mater 14:2354–2359

Jianmin Z, Jungang G, Xiuguo S (2007) Preparation and characterization of TiO2/Poly(St-co-MAA) core/shell composite particles. Iranian Polym J 16:1

Yu R, Hong-Zheng C, Han-Ying L, Mang W (2005) Encapsulation of titanium dioxide particles by polystyrene via radical polymerization. Colloids Surf A Physicochem Eng Aspects 253:193–197

Erdem B, Sudol ED, Dimonie VL, El-Aasser MS (2000) Encapsulation of inorganic particle via miniemulsion polymerization. Macromol Symp 155:181–195

Antonietti M, Landfester K (2002) Polyreactions in miniemulsions. Prog Polym Sci 27:689–756

Juan Z, Shengwen Z, Xiaoguang Q, Xiaoqin L, Limin W (2005) Synthesis of SiO2/poly(styrene-co-butyl acrylate) nanocomposite microspheres via miniemulsion polymerization. J Polym Sci Part A Polym Chem 44:3202–3209

Yijun Y, Bo C, Zhihua S, Liang L, Wei C, Gi X (2005) Carbon nanotube/polyaniline core–shell nanowires prepared by in situ inverse microemulsion. Synth Metals 150:271–277

Peng L (2006) Facile preparation of monodispersed core/shell zinc oxide-polystyrene (ZnO-PS) nanoparticles via soapless seeded microemulsion polymerization. Colloids Surf A Physicochem Eng Aspects 291:155–161

Yu R, Hong-Zheng C, Gang W, Mang W (2005) Preparation and characterization of titanium dioxide nanoparticle/polystyrene composites via radical polymerization. Mat Chem Phys 91:370–374

Kai Z, Linli Z, Xuehai Z, Xin C, Bai Y (2006) Silica-PMMA core–shell and hollow nanospheres. Colloids Surf A Physicochem Eng Aspects 277:145–150

Mahdavian AR, Ashjari M, Bayat Makoo A (2007) Preparation of poly (styrene–methyl methacrylate)/SiO2 composite nanoparticles via emulsion polymerization. An investigation into the compatiblization. Eur Polym J 43:336–344

Supaphol P, Harnsiri W, Junkasem J (2004) Effects of calcium carbonate and its purity on crystallization and melting behavior, mechanical properties, and processability of syndiotactic polypropylene. J Appl Polym Sci 92:201–212

De Lazaro S, Longo E, Sambrano JR, Beltran A (2004) Structural and electronic properties of PbTiO3 slabs: a DFT periodic study. Surf Sci 552:149–159

Erdem B, David S, Victoria L, Dimonie VL, El-Aasser MS (2000) Encapsulation of inorganic particles via miniemulsion polymerization. I. Dispersion of titanium dioxide particles in organic media using OLOA 370 as stabilizer. J Polym Sci Part A Polym Chem 38:4419–4430

Erdem B, David S, Victoria L, Dimonie VL, El-Aasser MS (2000) Encapsulation of inorganic particles via miniemulsion polymerization. II. Preparation and characterization of styrene miniemulsion droplets containing TiO2 particles. J Polym Sci Part A Polym Chem 38:4431–4440

Erdem B, David S, Victoria L, Dimonie VL, El-Aasser MS (2000) Encapsulation of inorganic particles via miniemulsion polymerization. III. Characterization of encapsulation. J Polym Sci Part A Polym Chem 38:4441–4450

Tiarks F, Landfester K, Antonietti M (2001) Encapsulation of carbon black by miniemulsion polymerization. Macromol Chem Phys 202:51–60

Mahdavian AR, Ashjari M, Salehi-Mobarakeh H (2008) Nanocomposite particles with core–shell morphology II. Encapsulation of Fe3O4 nanoparticles via ultrasonically-initiated miniemulsion polymerization. J Appl Polym Sci 110:1242–1249

Mustarelli P, Quartarone E, Tomasi C, Magistris A (1996) New lithium-based polyethylene oxide-glass solid electrolytes. Solid State Ionics 86:347–351

Lambert CK, Gonzalez RD (1999) Effect of binder addition on the properties of unsupported g-Al O membranes. Mater Lett 38:145–149

Wen ZH, Wu MM, Takahito I, Masataka K, Lin ZX, Osamu Y (2002) Effects of alumina whisker in (PEO)8–LiClO4-based composite polymer electrolytes. Solid State Ionics 148:185–191

Hui L, Hongqi Y, Yingchao Z (2008) Preparation and characterization of PMMA/flaky aluminum composite particle in the presence of MPS. Colloids Surf A Physicochem Eng Aspects 315:1–6

Duguet E, Abboud M, Morvan F, Maheu P, Michel F (2000) PMMA encapsulation of alumina through aqueous suspension polymerization processes. Macromol Symp 151:365–370

Zeng Z, Yu J, Guo Z-X (2005) Preparation of functionalized core–shell alumina/polystyrene composite nanoparticles, I. Encapsulation of alumina via emulsion polymerization. Macromol Chem Phys 206:1558–1567

Sudol ED, El-Aasser MS, Lovell PA (1997) In: El-Aasser MS (ed) Emulsion polymerization and emulsion polymer. Wiley, Chichester, p 699

Landfester K, Bechthold N, Tiarks F, Antonietti M (1999) Formulation and stability mechanisms of polymerizable miniemulsions. Macromolecules 32:5222–5228

Suslick KS (1990) Interparticle collisions driven by ultrasound. Science 3:1439–1445

Li C-Y, Chen C-H, Yeh A-I, Lai VM-F (1999) Preliminary study on the degradation kinetics of agarose and carrageenans by ultrasound. Food Hydrocolloids 13:477–481

Ding X, Zhao J, Liu Y, Zhang H, Wang Z (2004) Silica nanoparticles encapsulated by polystyrene via surface grafting and in situ emulsion polymerization. Mater Lett 58:3126–3130

Acknowledgments

We wish to express our gratitude to Iran polymer and Petrochemical Institute (IPPI) for financial support of this work (Grant #24762126). Also helpful assistance of Mr. Hashemi for taking TEM micrographs from Faculty of Science, University of Tehran is greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mahdavian, A.R., Sarrafi, Y. & Shabankareh, M. Nanocomposite particles with core–shell morphology III: preparation and characterization of nano Al2O3–poly(styrene–methyl methacrylate) particles via miniemulsion polymerization. Polym. Bull. 63, 329–340 (2009). https://doi.org/10.1007/s00289-009-0090-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-009-0090-7