Abstract

Cyanobacteria are oxygen-evolving photosynthetic bacteria. Established genetic manipulation methods and recently developed gene-regulation tools have enabled the photosynthetic conversion of carbon dioxide to biofuels and valuable chemicals in cyanobacteria, especially in unicellular cyanobacteria. However, the oxygen sensitivity of enzyme(s) introduced into cyanobacteria hampers productivity in some cases. Anabaena sp. PCC 7120 is a filamentous cyanobacterium consisting of a few hundred of vegetative cells, which perform oxygenic photosynthesis. Upon nitrogen deprivation, heterocysts, which are specialized cells for nitrogen fixation, are differentiated from vegetative cells at semiregular intervals. The micro-oxic environment within heterocysts protects oxygen-labile nitrogenase from oxygen. This study aimed to repurpose the heterocyst as a host for the production of chemicals with oxygen-sensitive enzymes under photosynthetic conditions. Herein, Anabaena strains expressing enzymes of 1-butanol synthetic pathway from the anaerobe Clostridium acetobutylicum within heterocysts were created. A strain that expressed a highly oxygen-sensitive Bcd/EtfAB complex produced 1-butanol even under photosynthetic conditions. Furthermore, the 1-butanol production per heterocyst cell of a butanol-producing Anabaena strain was fivefold higher than that per cell of unicellular cyanobacterium with the same set of 1-butanol synthetic pathway genes. Thus, our study showed the usefulness of Anabaena heterocysts as a chassis for anaerobic production driven by oxygen-evolving photosynthesis.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cyanobacteria are prokaryotes that perform oxygen-evolving photosynthesis. The metabolism of cyanobacteria can be engineered via conventional genetic manipulations and recently developed gene-regulation tools (Carroll et al. 2018). Thus, cyanobacteria have been of great interest as platforms for the photosynthetic production of useful substances in the last decade (Humphreys and Minton 2018; Knoot et al. 2018). The heterologous expression of genes from various organisms in cyanobacteria, especially fast-growing unicellular cyanobacteria, leads to the successful conversion of carbon dioxide into valuable fuels and chemicals, including sucrose (Ducat et al. 2012), fatty acids (Kato et al. 2017), and 2,3-butanediol (Oliver et al. 2013), using solar energy. However, the productivity of some chemicals in cyanobacteria is low, and improvement is required for industrial production (Knoot et al. 2018). One of the reasons for low productivity is the low flux of glycolysis and the TCA cycle under photosynthetic conditions, which reduces substrate availability (Hirokawa et al. 2015). For example, the production of isopropanol in the unicellular cyanobacterium Synechococcus sp. PCC 7942 (S. 7942) requires dark anaerobic conditions or the introduction of a heterologous pta encoding phosphate acetyltransferase to increase the supply of acetyl-CoA (Hirokawa et al. 2015; Hirokawa et al. 2017). The oxygen sensitivity of some enzymes involved in the synthesis of desired products also hampers productivity in oxygen-evolving cyanobacteria. Some enzymes of 1-butanol synthetic pathway in the anaerobe Clostridium acetobutylicum are oxygen-sensitive (Lan and Liao 2011; Lan et al. 2013). Replacing oxygen-sensitive enzymes of this pathway with oxygen-tolerant ones was required for the production of 1-butanol in S. 7942 (Lan and Liao 2011; Lan et al. 2013).

Heterocyst-forming cyanobacteria have evolved an ability to simultaneously perform oxygen-evolving photosynthesis and oxygen-sensitive nitrogen fixation by spatially separating the two reactions. Among the heterocyst-forming cyanobacteria, Anabaena sp. PCC 7120 (A. 7120) has been extensively studied as a model organism for heterocyst differentiation (Flores et al. 2018; Kumar et al. 2010). A. 7120 is a filamentous cyanobacterium consisting of a few hundred of vegetative cells that perform oxygen-evolving photosynthesis. Upon nitrogen deprivation, 5–10% of the vegetative cells differentiate into heterocysts, which are specialized cells for nitrogen fixation. Inactivation of oxygen-evolving photosystem II activity, formation of a thick envelope comprising polysaccharide and glycolipid layers outside of the cell wall, and the enhancement of respiration enable the heterocysts to maintain micro-oxic environments within cells. The intracellular O2 concentration of A. 7120 heterocyst was estimated to be as low as 600 nM (Tomitani et al. 2006), thereby enabling nitrogen fixation within heterocysts even under photosynthetic conditions. Large flux of catabolic pathways, such as glycolysis and the pentose phosphate pathway, is another feature of heterocysts. Sucrose, produced from CO2 in vegetative cells, is transported into heterocysts, where it is degraded by invertase and catabolized through glycolysis and the pentose phosphate pathway to supply ATP and the reductants required for nitrogen fixation (Nürnberg et al. 2015). Active catabolism of sucrose in heterocysts results in high ethanol productivity of heterocyst cells (Ehira et al. 2018). Thus, heterocysts are promising cells for chemical production, particularly for chemicals that require oxygen-sensitive enzymes.

The usefulness of A. 7120 heterocysts was examined as a host of 1-butanol production with a pathway of C. acetobutylicum. Under oxygen-evolving photosynthetic conditions, 1-butanol was produced in an Anabaena strain expressing the 1-butanol synthetic pathway in heterocysts, including the Bcd/EtfAB complex, which is highly oxygen-sensitive (Atsumi et al. 2008; Inui et al. 2008). In addition, it was demonstrated that the 1-butanol production per heterocyst cell of a butanol-producing strain was fivefold higher than that per cell of S. 7942 with the same set of 1-butanol synthetic pathway genes (Lan and Liao 2012). Thus, this study demonstrated the application of heterocyst cells as a host of chemical production using oxygen-sensitive enzymes.

Materials and methods

Bacterial strains and growth conditions

Anabaena strains were routinely grown at 30°C under continuous illumination provided by a fluorescent lamp (FL20SW; Toshiba Lighting & Technology Corporation, Kanagawa, Japan) at 30–35 μmol photons m−2 s−1 (an optimal light conditions for growth as well as heterocyst formation) in a BG11 medium (Rippka et al. 1979) supplemented with 20 mM HEPES-NaOH (pH 7.5), which contains NaNO3 as a nitrogen source. Two μg/ml of each spectinomycin and streptomycin was added to the medium. Liquid culture was bubbled with air containing 1.0% (v/v) CO2. For butanol production, the filaments that were grown in the BG11 medium until they reached an OD750 of approximately 1 were washed twice with nitrogen-free BG11 medium (BG110) and then resuspended to OD750 of 0.2 in BG110 medium. The cultures were incubated under conditions described above.

Plasmid construction

All plasmids were constructed via the hot fusion method (Fu et al. 2014) by using Escherichia coli HST08 (Takara Bio, Shiga, Japan). DNA fragments containing the promoters, riboswitches, and genes for 1-butanol synthesis were amplified via by PCR and inserted between the BamHI and KpnI sites of pSU102-cyaA (Higo et al. 2018a), a genome-integrating vector for A. 7120. Accuracy of cloned PCR fragments was confirmed by DNA sequencing. Nucleotide sequences of nphT7 and ter were codon optimized for A. 7120 (GenBank accession numbers: MH998375 and MH998376, respectively) and synthesized by Integrated DNA Technologies, Inc. (Skokie, IL). Detailed sequences are described in the supplemental information. pBU11 was constructed to inactivate ddh (alr0058) encoding D-lactate dehydrogenase. The DNA fragments of a ddh upstream region, the nptII gene, and a ddh downstream region, amplified by PCR using primers Dddh1 and Dddh2, KmF and KmR, and Dddh3 and Dddh4, respectively, were inserted into the PstI site of pRL271 (Cai and Wolk 1990). To over-express ald encoding alanine dehydrogenase or invB encoding invertase in heterocysts, Pald-ald or PnifB-invB (Ehira et al. 2018) was amplified by PCR using primers, ET12_F and ET12_R or ET14_F and ET14_R, respectively, and then inserted into the SmaI site of pBU11, which is located between the nptII gene and the ddh downstream region, generating pBU12 or pBU14, respectively. Primers used in this study are listed in Table S1.

Strain construction

Strains used in this study are listed in Table 1. A. 7120 was transformed via triparental mating, as described previously (Elhai and Wolk 1988). Double recombinants were achieved by selecting cells resistant to sucrose (Cai and Wolk 1990). Completely segregated mutant strains were obtained by transferring sucrose-resistant colonies to a new plate once, which was confirmed through PCR analysis using primers ddh_seq3 and ddh_seq4.

Quantification of 1-butanol

Culture samples were centrifuged at 21,500×g for 5 min, and the supernatants (99 μl) were mixed with 1 μl of 0.1% (v/v) 2-butanol as the internal standard. 1-Butanol was measured using gas chromatography (GC-2014; Shimadzu, Kyoto, Japan) with a flame ion detector and a 2-m stainless steel column (internal diameter, 3 mm) filled with Gaskuropack 54 60/80 (GL Sciences, Tokyo, Japan). The column temperature was maintained at 190°C, and the injector and detector temperatures were maintained at 240°C.

Results

Design of a 1-butanol synthetic pathway and production of 1-butanol in heterocysts

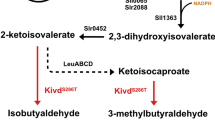

1-butanol synthetic pathway genes—crt, bcd, etfB, etfA, hbd, and adhE2—from C. acetobutylicum were introduced as an operon into A. 7120 (Fig. 1a). To conditionally induce the expression of the whole operon exclusively in heterocysts, a heterocyst-specific gene induction system was utilized that was recently developed by us (Higo et al. 2018b). The operon was expressed using a heterocyst-specific nifB promoter (PnifB) (Wang and Xu 2005) with the theophylline-responsive riboswitch. Only one gene could be regulated by the theophylline-responsive translational ON riboswitches that have been frequently used in cyanobacteria (Ma et al. 2014; Nakahira et al. 2013; Ohbayashi et al. 2016), hence, the theophylline-responsive transcriptional ON riboswitch that could induce a whole operon (Higo et al. 2018b) was used. In a transcriptional ON riboswitch, transcription terminates at the riboswitch region located upstream of the target genes in the absence of an inducer. The transcription proceeds in the presence of the inducer, leading to the induction of target genes. In contrast, in a translational ON riboswitch, the translation of only one gene located downstream of the riboswitch is prevented by hindering the binding of the ribosome to the ribosome-binding site in the absence of an inducer. In addition, nphT7, which is required for acetoacetyl-CoA production through the ATP-driven malonyl-CoA pathway, was introduced (Lan and Liao 2012). Because excessive production of acetoacetyl-CoA from acetyl-CoA could lead to imbalanced cellular intermediate distribution and poor productivity (Ku and Lan 2018), the expression of nphT7 was independently regulated by the heterocyst-specific coxBII promoter (PcoxBII) (Wang and Xu 2005) and the 2-aminopurine (2-AP)-responsive transcriptional ON riboswitch (Higo et al. 2018b) (Fig. 1b). These two transcriptional units were integrated at the neutral site within cyaA (Higo et al. 2018a) through single homologous recombination, generating a strain BU1. Note that we confirmed that use of the heterocyst-specific promoters such as PnifB or PcoxBII does not affect growth and heterocyst formation.

Construction of butanol synthetic pathways in heterocysts. a Butanol synthetic pathway expressed in heterocysts. As an enzyme that convers crotonyl-CoA to butyryl-CoA, Bcd/EtfAB complex or Ter was used. b The schematic representation of plasmids for butanol synthetic pathways introduced into A. 7120. nphT7 was expressed under the control of heterocyst-specific promotor PcoxBII with 2-aminopurine responsive transcriptional riboswitch (pbuE). In pBU1, a synthetic operon crt-bcd-etfB-etfA-hbd-adhE2 was expressed under the control of heterocyst-specific promoter PnifB with a theophylline-responsive transcriptional riboswitch (theo). In pBU2, genes bcd-etfB-etfA were replaced with ter. These butanol synthetic pathways were integrated into the cyaA locus. Note that sizes of genes in the map are not proportional to the sequence length

BU1 was cultivated in a nitrogen-free medium for 24 h to induce heterocyst formation, followed by the addition of the inducers 2-AP (0.1 mM) and theophylline (1 mM) to the culture. After 10 days of induction, the strain produced 1.14 mg/l 1-butanol (Fig. 2a). Because the Bcd/EtfAB complex (Atsumi et al. 2008; Inui et al. 2008; Lan and Liao 2012) and AdhE2 (Chen and Liao 2016; Fontaine et al. 2002; Lan and Liao 2011) have been deemed oxygen-sensitive, producing 1-butanol using these enzymes in oxygen-evolving cyanobacteria should be challenging (Lan and Liao 2011). Even in oxygen-consuming heterotrophic bacteria, such as E. coli and Bacillus subtilis, 1-butanol production is low under aerobic conditions as compared with that in anaerobic conditions (Atsumi et al. 2008; Nielsen et al. 2009). Here, oxygen-evolving photosynthesis and oxygen-sensitive 1-butanol production were shown to be compatible in heterocyst-forming multicellular cyanobacterium using heterocysts as producing cells, which provide micro-oxic conditions.

1-Butanol production in genetically engineered A. 7120. a 1-Butanol production in BU1 and BU2 strains. Cells grown in the nitrate-containing medium were transferred to the nitrogen-free medium to induce heterocyst differentiation. 1-Butanol was measured 10 days after the addition of inducers theophylline and/or 2-aminopurine (2-AP). b Time course analysis of 1-butanol production in the BU2 strain in the presence of theophylline and 2-AP. The data represents the mean ± SD (n = 3 from independent cultures)

The Bcd/EtfAB complex requires oxidized ferredoxins as the electron acceptor to convert crotonyl-CoA into butyryl-CoA (Fig. 1). Selectivity of the Bcd/EtfAB complex for ferredoxins could prevent its function in heterologous hosts (Lan and Liao 2011; Li et al. 2008). In heterocyst cells, heterocyst-specific ferredoxin FdxH is expressed to transfer electrons to nitrogenase (Magnuson and Cardona 2016). FdxH might function with the Bcd/EtfAB complex, although, whether FdxH is more optimal for Bcd/EtfAB as compared to ferredoxin(s) from C. acetobutylicum is yet to be determined.

Improvement of 1-butanol production by replacing Bcd/EtfAB with Ter

To exclude a potential incompatibility of ferredoxin, a strain BU2 was also created, wherein bcd-etfB-etfA was replaced with ter that encodes trans-2-enoyl-CoA reductase (Ter). Ter requires only NADH as a cofactor (Shen et al. 2011). 1-Butanol production in BU2 was induced by the addition of 0.1 mM 2-AP and 1 mM theophylline. During the 10-day production period, the 1-butanol concentration increased linearly (Fig. 2b). After 10 days, BU2 produced 2.17 mg/l 1-butanol, which is approximately twice the amount produced by BU1 (Fig. 2a). The cell density between BU1 and BU2 after 10 days induction was similar. A strain BU3, wherein an nphT7 codon optimized for A. 7120 was replaced with the original nphT7 from Streptomyces sp. strain CL190 (Okamura et al. 2010), was also produced. BU3 produced 1-butanol similar to BU2 (data not shown).

1-butanol was not produced at all in the absence of inducers (Fig. 2a). However, the addition of either inducer led to 1-butanol production; when only theophylline was added, BU2 produced 0.95 mg/l 1-butanol, which was 56% lower than when both inducers were added, and addition of only 2-AP produced 1.33 mg/l 1-butanol, which was 39% lower (Fig. 2a). A. 7120 has no intrinsic enzymes that convert acetyl-CoA to acetoacetyl-CoA. Thus, NphT7 would be expressed at low levels even without the inducer 2-AP, and the limited NphT7 activity could produce acetoacetyl-CoA. Similarly, 1-butanol could be produced even when the expression levels of crt-ter-hbd-adhE2 were low. These results suggest that the cellular environment of heterocsysts, particularly the micro-oxic environment, is adequate for 1-butanol production. However, 1-butanol production was only doubled by the full induction of the 1-butanol synthetic pathway.

Improvement of 1-butanol production by removing a competitive pathway for pyruvate and NADH by disruption of the ddh gene

To improve 1-butanol production of BU2, the ddh gene encoding d-lactate dehydrogenase, which competes with the 1-butanol synthetic pathway for the utilization of pyruvate and NADH (Fig. 1a), was disrupted in BU2, generating a strain BU11. In addition to ddh disruption, ald encoding alanine dehydrogenase or invB encoding invertase was integrated at the ddh locus under the control of heterocyst-specific promoter Pald or PnifB, respectively, to enhance pyruvate supply in heterocysts (Fig. 3a, BU12, and BU14). These two enzymes function as catabolic enzymes in heterocysts (Nürnberg et al. 2015; Pernil et al. 2010), and an over-expression of them in heterocysts enhanced the ethanol production (Ehira et al. 2018). Complete disruption of ddh in strains BU11, BU12, and BU14 was confirmed via PCR analysis (Fig. 3b).

Genetic modifications to improve the 1-butanol production of BU2. a Gene disruption of ddh and integration of ald and invB. Strain BU11 was constructed from strain BU2 by replacing ddh with neomycin-resistant cassette. Strains BU12 and BU14 were constructed from strain BU2 by replacing ddh with the neomycin-resistant cassette and Pald-ald or PnifB-invB, respectively. b Segregation check of BU11, BU12, and BU14. PCR was performed with primer pairs ddh_seq3 and ddh_seq4 using a genomic DNA from each strain as a template

After 5 or 10 days of induction by 0.1 mM 2-AP and 1 mM theophylline, 1-butanol was measured in strains BU2, BU11, BU12, and BU14 (Fig. 4). 1-Butanol production in BU11 increased by 30% more than that in BU2 after 10 days. 1-Butanol production in BU12 or BU14, in which ald or invB was integrated, did not increase as compared to that in BU11. The cell density among the 4 strains after 5 or 10 days induction was similar. These results suggest that the disruption of ddh improved the influx of acetyl-CoA and that reaction(s) in the 1-butanol synthetic pathway were a limiting step for 1-butanol production in BU12 and BU14.

1-Butanol production by genetically modified A. 7120. Cells grown in the nitrate-containing medium were transferred to the nitrogen-free medium to induce heterocysts. 1-Butanol was measured 5 or 10 days after the addition of inducers 1 mM theophylline and 0.1 mM and 2-AP. The asterisk indicates a significant difference (p < 0.05 with Student’s t tests). The data represents the mean ± SD (n = 3 from independent cultures)

Discussion

In this study, it was demonstrated that the oxygen-sensitive 1-butanol synthetic pathway from C. acetobutylicum functioned in heterocysts, in which a micro-oxic environment is maintained even under oxygenic photosynthetic conditions. In addition, it was shown that the productivity of heterocysts is higher than that of the unicellular cyanobacterium S. 7942, which performs both oxygen-evolving photosynthesis and 1-butanol production within a single cell. Strain EL20, which is a genetically modified strain of the unicellular cyanobacterium S. 7942 with the same 1-butanol synthetic genes as BU2, produced approximately 4 mg/l 1-butanol in 10 days (Lan and Liao 2012). Assuming that 1-butanol is produced in heterocysts that constitute only 10% of the total cells in BU2, the 1-butanol production per heterocyst cell of BU2 was fivefold higher than that per cell of EL20, demonstrating the high productivity of 1-butanol production in heterocysts. Heterocysts would be suitable for the production of acetyl-CoA-based chemicals because the glycolipids of the heterocyst-specific envelope are synthesized via fatty acid synthases and polyketide synthases using acetyl-CoA and malonyl-CoA as substrates (Fan et al. 2005). Hence, the influx of acetyl-CoA and malonyl-CoA in heterocysts would be much higher than that in unicellular cyanobacteria, in which acetyl-CoA often limits production using acetyl-CoA-based synthetic pathways (Kusakabe et al. 2013).

While disruption of ddh increased 1-butanol production, the presence of the rate-limiting step downstream of pyruvate was indicated (Fig. 4). Heterocysts mainly produce NADPH as a reductant for nitrogen fixation (Summers et al. 1995). Thus, the supply of NADH might be a limiting factor of 1-butanol production. Substituting NADPH-utilizing enzymes for NADH-utilizing ones would improve the productivity of 1-butanol, as previously indicated in unicellular cyanobacteria (Lan and Liao 2012). Quantification of metabolites in the 1-butanol synthetic pathway should clarify the step(s) to be improved (Fathima et al. 2018; Noguchi et al. 2016). In addition, optimization of cultivation condition is required. Increase of light intensity and/or CO2 concentration would promote carbon flux toward acetyl-CoA in heterocysts. The evaporation of 1-butanol was not prevented in this study, and sealing with parafilm (Anfelt et al. 2015) or culturing in screw cap flasks (Lan and Liao 2012) should improve the 1-butanol production of our strains. Metabolic engineering specific to heterocysts would also lead to increased production of 1-butanol. ddh was disrupted by the conventional gene inactivation method to reroute the carbon flux toward acetype-CoA. This conventional method could not be applied to genes that are essential for growth. Recently, a heterocyst-specific gene repression system was developed (unpublished data); heterocyst-specific repression of essential genes, such as ppc encoding phosphoenolpyruvate carboxylase (Luinenburg and Coleman 1990), should improve the productivity by increasing pyruvate supply without impairing growth.

1-Butanol production was demonstrated in heterocysts using oxygen-sensitive enzymes as proof of concept. Although the replacement of oxygen-sensitive enzymes with oxygen-tolerant ones improved 1-butanol production in S. 7942 (Lan et al. 2013), oxygen-tolerant enzymes could not always be found. The concept should be applied to the production of other chemicals using oxygen-sensitive enzyme(s), as has been demonstrated to formate (Ihara et al. 2013) and H2 (Avilan et al. 2018). Hence, heterocysts are potent cells for photosynthetic fermentation.

References

Anfelt J, Kaczmarzyk D, Shabestary K, Renberg B, Rockberg J, Nielsen J, Uhlén M, Hudson EP (2015) Genetic and nutrient modulation of acetyl-CoA levels in Synechocystis for n-butanol production. Microb Cell Factories 14:167. https://doi.org/10.1186/s12934-015-0355-9

Atsumi S, Cann AF, Connor MR, Shen CR, Smith KM, Brynildsen MP, Chou KJ, Hanai T, Liao JC (2008) Metabolic engineering of Escherichia coli for 1-butanol production. Metab Eng 10:305–311

Avilan L, Roumezi B, Risoul V, Bernard CS, Kpebe A, Belhadjhassine M, Rousset M, Brugna M, Latifi A (2018) Phototrophic hydrogen production from a clostridial [FeFe] hydrogenase expressed in the heterocysts of the cyanobacterium Nostoc PCC 7120. Appl Microbiol Biotechnol 102:5775–5783

Cai Y, Wolk CP (1990) Use of a conditionally lethal gene in Anabaena sp. strain PCC 7120 to select for double recombinants and to entrap insertion sequences. J Bacteriol 172:3138–3145

Carroll AL, Case AE, Zhang A, Atsumi S (2018) Metabolic engineering tools in model cyanobacteria. Metab Eng 50:47–56

Chen CT, Liao JC (2016) Frontiers in microbial 1-butanol and isobutanol production. FEMS 363:fnw020

Ducat DC, Avelar-Rivas JA, Way JC, Silver PA (2012) Rerouting carbon flux to enhance photosynthetic productivity. Appl Environ Microbiol 78:2660–2668

Ehira S, Takeuchi T, Higo A (2018) Spatial separation of photosynthesis and ethanol production by cell type-specific metabolic engineering of filamentous cyanobacteria. Appl Microbiol Biotechnol 102:1523–1531

Elhai J, Wolk CP (1988) Conjugal transfer of DNA to cyanobacteria. Methods Enzymol 167:747–754

Fan Q, Huang G, Lechno-Yossef S, Wolk CP, Kaneko T, Tabata S (2005) Clustered genes required for synthesis and deposition of envelope glycolipids in Anabaena sp. strain PCC 7120. Mol Microbiol 58:227–243

Fathima AM, Chuang D, Laviña WA, Liao J, Putri SP, Fukusaki E (2018) Iterative cycle of widely targeted metabolic profiling for the improvement of 1-butanol titer and productivity in Synechococcus elongatus. Biotechnol Biofuels 11:188. https://doi.org/10.1186/s13068-018-1187-8

Flores, E., Picossi, S., Valladares, A., Herrero, A. (2018) Transcriptional regulation of development in heterocyst-forming cyanobacteria. Biochim Biophys Acta. https://doi.org/10.1016/j.bbagrm.2018.04.006

Fontaine L, Meynial-Salles I, Girbal L, Yang X, Croux C, Soucaille P (2002) Molecular characterization and transcriptional analysis of adhE2, the gene encoding the NADH-dependent aldehyde/alcohol dehydrogenase responsible for butanol production in alcohologenic cultures of Clostridium acetobutylicum ATCC 824. J Bacteriol 184:821–830

Fu C, Donovan WP, Shikapwashya-Hasser O, Ye X, Cole RH (2014) Hot fusion: an efficient method to clone multiple DNA fragments as well as inverted repeats without ligase. PLoS One 9:e115318

Higo A, Isu A, Fukaya Y, Ehira S, Hisabori T (2018a) Application of CRISPR interference for metabolic engineering of the heterocyst-forming multicellular cyanobacterium Anabaena sp. PCC 7120. Plant Cell Physiol 59:119–127

Higo A, Isu A, Fukaya Y, Hisabori T (2018b) Spatio-temporal gene induction systems in the heterocyst-forming multicellular cyanobacterium Anabaena sp. PCC 7120. Plant Cell Physiol. 59:82–89

Hirokawa Y, Suzuki I, Hanai T (2015) Optimization of isopropanol production by engineered cyanobacteria with a synthetic metabolic pathway. J Biosci Bioeng 119:585–590

Hirokawa Y, Dempo Y, Fukusaki E, Hanai T (2017) Metabolic engineering for isopropanol production by an engineered cyanobacterium, Synechococcus elongates PCC 7942, under photosynthetic conditions. J Biosci Bioeng 123:39–45

Humphreys CM, Minton NP (2018) Advances in metabolic engineering in the microbial production of fuels and chemicals from C1 gas. Curr Opin Biotechnol 50:174–181

Ihara M, Kawano Y, Urano M, Okabe A (2013) Light driven CO2 fixation by using cyanobacterial photosystem I and NADPH-dependent formate dehydrogenase. PLoS One 8:e71581

Inui M, Suda M, Kimura S, Yasuda K, Suzuki H, Toda H, Yamamoto S, Okino S, Suzuki N, Yukawa H (2008) Expression of Clostridium acetobutylicum butanol synthetic genes in Escherichia coli. Appl Microbiol Biotechnol 77:1305–1316

Kaneko T, Nakamura Y, Wolk CP, Kuritz T, Sasamoto S, Watanabe A, Iriguchi M, Ishikawa A, Kawashima K, Kimura T, Kishida Y, Kohara M, Matsumoto M, Matsuno A, Muraki A, Nakazaki N, Shimpo S, Sugimoto M, Takazawa M, Yamada M, Yasuda M, Tabata S (2001) Complete genomic sequence of the filamentous nitrogen-fixing cyanobacterium Anabaena sp. strain PCC 7120. DNA Res 8:205-13

Kato A, Takatani N, Ikeda K, Maeda SI, Omata T (2017) Removal of the product from the culture medium strongly enhances free fatty acid production by genetically engineered Synechococcus elongatus. Biotechnol Biofuels 10:141. https://doi.org/10.1186/s13068-017-0831-z

Knoot CJ, Ungerer J, Wangikar PP, Pakrasi HB (2018) Cyanobacteria: promising biocatalysts for sustainable chemical production. J Biol Chem 293:5044–5052

Ku JT, Lan EI (2018) A balanced ATP driving force module for enhancing photosynthetic biosynthesis of 3-hydroxybutyrate from CO2. Metab Eng 46:35–42

Kumar K, Mella-Herrera RA, Golden JW (2010) Cyanobacterial heterocysts. Cold Spring Harb Perspect Biol 2:a000315

Kusakabe T, Tatsuke T, Tsuruno K, Hirokawa Y, Atsumi S, Liao J, Hanai T (2013) Engineering a synthetic pathway in cyanobacteria for isopropanol production directly from carbon dioxide and light. Metab Eng 20:101–108

Lan EI, Liao JC (2011) Metabolic engineering of cyanobacteria for 1-butanol production from carbon dioxide. Metab Eng 13:353–363

Lan EI, Liao JC (2012) ATP drives direct photosynthetic production of 1-butanol in cyanobacteria. Proc Natl Acad Sci U S A 109:6018–6023

Lan EI, Ro S, Liao JC (2013) Oxygen-tolerant coenzyme A-acylating aldehyde dehydrogenase facilitates efficient photosynthetic n-butanol biosynthesis in cyanobacteria. Energy Environ Sci 6:2672–2681

Li F, Hinderberger J, Seedorf H, Zhang J, Buckel W, Thauer RK (2008) Coupled ferredoxin and crotonyl coenzyme A (CoA) reduction with NADH catalyzed by the butyryl-CoA dehydrogenase/Etf complex from Clostridium kluyveri. J Bacteriol 190:843–850

Luinenburg I, Coleman JR (1990) A requirement for phosphoenol-pyruvate carboxylase in the cyanobacterium Synechococcus PCC 7942. Arch Microbiol 154:471–474

Ma AT, Schmidt CM, Golden JW (2014) Regulation of gene expression in diverse cyanobacterial species by using theophylline-responsive riboswitches. Appl Environ Microbiol 80:6704–6713

Magnuson A, Cardona T (2016) Thylakoid membrane function in heterocysts. Biochim Biophys Acta 1857:309–319

Nakahira Y, Ogawa A, Asano H, Oyama T, Tozawa Y (2013) Theophylline-dependent riboswitch as a novel genetic tool for strict regulation of protein expression in cyanobacterium Synechococcus elongatus PCC 7942. Plant Cell Physiol. 54:1724–1735

Nielsen DR, Leonard E, Yoon SH, Tseng HC, Yuan C, Prather KL (2009) Engineering alternative butanol production platforms in heterologous bacteria. Metab Eng 11:262–273

Noguchi S, Putri SP, Lan EI, Laviña WA, Dempo Y, Bamba T, Liao JC, Fukusaki E (2016) Quantitative target analysis and kinetic profiling of acyl-CoAs reveal the rate-limiting step in cyanobacterial 1-butanol production. Metabolomics 12:26. https://doi.org/10.1007/s11306-015-0940-2

Nürnberg DJ, Mariscal V, Bornikoel J, Nieves-Morión M, Krauß N, Herrero A, Maldener I, Flores E, Mullineaux CW (2015) Intercellular diffusion of a fluorescent sucrose analog via the septal junctions in a filamentous cyanobacterium. mBio 6:e02109–e02114

Ohbayashi R, Akai H, Yoshikawa H, Hess WR, Watanabe S (2016) A tightly inducible riboswitch system in Synechocystis sp. PCC 6803. J Gen Appl Microbiol 62:154–159

Okamura E, Tomita T, Sawa R, Nishiyama M, Kuzuyama T (2010) Unprecedented acetoacetyl-coenzyme A synthesizing enzyme of the thiolase superfamily involved in the mevalonate pathway. Proc Natl Acad Sci U S A 107:11265–11270

Oliver JWK, Machado IMP, Yoneda H, Atsumi S (2013) Cyanobacterial conversion of carbon dioxide to 2,3-butanediol. Proc Natl Acad Sci U S A 110:1249–1254

Pernil R, Herrero A, Flores E (2010) Catabolic function of compartmentalized alanine dehydrogenase in the heterocyst-forming cyanobacterium Anabaena sp. strain PCC 7120. J Bacteriol 192:5165–5172

Rippka R, Deruelles J, Waterbury JB, Herdman M, Stanier RY (1979) Generic assignments, strain histories and properties of pure cultures of cyanobacteria. J Gen Microbiol 111:1–61

Shen CR, Lan EI, Dekishima Y, Baez A, Cho KM, Liao JC (2011) Driving forces enable high-titer anaerobic 1-butanol synthesis in Escherichia coli. Appl Environ Microbiol 77:2905–2915

Summers ML, Wallis JG, Campbell EL, Meeks JC (1995) Genetic evidence of a major role for glucose-6-phosphate dehydrogenase in nitrogen fixation and dark growth of the cyanobacterium Nostoc sp. strain ATCC 29133. J Bacteriol 177:6184–6194

Tomitani A, Knoll AH, Cavanaugh CM, Ohno T (2006) The evolutionary diversification of cyanobacteria: molecular-phylogenetic and paleontological perspectives. Proc Natl Acad Sci U S A 103:5442–5447

Wang Y, Xu X (2005) Regulation by hetC of genes required for heterocyst differentiation and cell division in Anabaena sp. strain PCC 7120. J Bacteriol 187:8489–8493

Acknowledgments

This work was supported in part by the Institute for Fermentation, Osaka, Japan, and by a Grant-In-Aid for Scientific Research (C) 18K05395 from the Japan Society for the Promotion of Science. We thank NITE Biological Resource Center (NITE, Kisarazu, Japan) and Dr. Tomohisa Kuzuyama (The University of Tokyo, Japan) for kindly providing Clostridium acetobutylicum NBRC 13948 (ATCC 824) genomic DNA and an nphT7 vector, respectively.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Ethics statement

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(PDF 123 kb)

Rights and permissions

About this article

Cite this article

Higo, A., Ehira, S. Anaerobic butanol production driven by oxygen-evolving photosynthesis using the heterocyst-forming multicellular cyanobacterium Anabaena sp. PCC 7120. Appl Microbiol Biotechnol 103, 2441–2447 (2019). https://doi.org/10.1007/s00253-019-09635-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-019-09635-z