Abstract

The effect of nitrogen replenishment on the kinetics of secondary carotenoids, triacylglycerol (TAG) and primary cell components was studied in nitrogen-starved Chromochloris zofingiensis (Chlorophyta), an oleaginous and carotenogenic microalga. Nitrogen resupplied after a period of starvation was initially consumed at a more than four times higher rate than in an equivalent nitrogen-replete culture. Simultaneously, chlorophylls, primary carotenoids, polar (membrane) lipids and proteins were rapidly produced. After 2 days, the contents of these primary metabolites, as well as the nitrogen consumption rate and the overall biomass production rate, had returned to values equivalent to those of cells grown under nitrogen-replete conditions, indicating that culture recovery required 2 days. Nitrogen resupply was immediately followed by rapid degradation of TAG and starch, suggesting that these metabolites served as carbon and energy source for the recovery process. Also, the secondary carotenoids canthaxanthin and ketolutein were rapidly degraded upon nitrogen resupply, whereas degradation of astaxanthin, the main secondary carotenoid, started only when the cells were fully recovered 2 days after nitrogen resupply. This is the first time that such culture recovery has been described in detail and, moreover, that astaxanthin was found to be not immediately degraded after nitrogen resupply. The observed rapid recovery of C. zofingiensis and the delay in astaxanthin degradation suggest that a repeated batch cultivation may result in a higher secondary carotenoid productivity than a series of classical single batch cultivations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Natural carotenoids, such as astaxanthin, β-carotene and lutein, and triacylglycerol (TAG) are important biotechnological products. Natural carotenoids are claimed to have beneficial health effects due to their anti-oxidative activity and are therefore used in the cosmetic, food and feed industry (Spolaore et al. 2006). TAG is a promising feedstock for the generation of biofuels, thereby replacing petroleum-derived transport fuels, and a possible replacer for vegetable oils (Chisti 2013; Draaisma et al. 2013; Hu et al. 2008). Secondary carotenoids and TAG are produced in excess by specific microalgae. However, the production costs are still too high to make microalgae-based production economically competitive with synthetic production (carotenoids) or production by higher plants (TAG and most carotenoids). One of the requirements for economically feasible TAG and carotenoid production is that maximal areal productivities are obtained.

In a selection of green algae, secondary carotenoids and TAG are produced under adverse growth conditions, such as a high light intensity, extreme temperatures or a nitrogen starvation (Ben-Amotz 1996; Ben-Amotz and Avron 1983; Hu et al. 2008; Lamers et al. 2010; Lamers et al. 2012; Mulders et al. 2014a). Under nitrogen starvation conditions, excess electrons derived from photosynthesis are incorporated in TAG and secondary carotenoids, which prevents photo-oxidative cell damage. Besides, carbon and energy are stored (Hu et al. 2008; Lemoine and Schoefs 2010; Mulders et al. 2014a), which may be mobilized during culture growth resumption upon nitrogen resupply (Solovchenko 2013). In addition, secondary carotenoids can function as sunscreen, protecting the cells by absorbing part of the excess irradiation (Lamers et al. 2008; Mulders et al. 2014a).

Besides secondary carotenoid and TAG accumulation, nitrogen starvation also affects the cellular content of other essential macromolecules, such as photosynthetic pigments (chlorophylls and primary carotenoids) (Falkowski and LaRoche 1991; Mulders et al. 2014c; Rhiel et al. 1985), proteins (Turpin 1991; Pribyl et al. 2013), carbohydrates, such as starch (Breuer et al. 2014; Turpin 1991; Zhu et al. 2014) and polar (membrane) lipids (Goncalves et al. 2013; Xiao et al. 2013). In addition, nitrogen starvation leads to a significant decrease in photosynthetic rate (Klok et al. 2013a; Klok et al. 2013b). Consequently, nitrogen-starved and nitrogen-sufficient grown microalgae deviate substantially in cellular composition and physiological state.

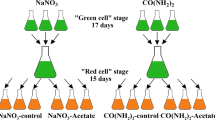

Traditionally, secondary carotenoids and TAG are produced in a two-phase process. A (nitrogen-sufficient) biomass production phase is followed by a nitrogen-depleted phase in which the secondary metabolites are accumulated. Subsequently, all biomass is harvested. Alternatively, secondary carotenoids and TAG may be produced using a repeated batch cultivation, which has been suggested as a potentially more productive approach (Feng et al. 2011; Hsieh and Wu 2009). This semi-continuous production process starts the same as a two-phase batch cultivation, but instead of that all biomass is harvested at the end of the accumulation phase, only part of the biomass is harvested. The remaining biomass is resupplied with a limited amount of nitrogen resulting initially in culture growth resumption. During growth resumption the biomass returns presumably towards a macromolecular composition equivalent to biomass grown under nitrogen-sufficient conditions (referred to as recovery). Subsequently, the biomass is again nitrogen depleted, which results in repeated secondary carotenoid and TAG accumulation.

Whether a repeated batch cultivation may indeed result into higher overall TAG and secondary carotenoid productivities than a classical two-phase process depends on multiple factors, including the recovery rate of the culture (i.e. the nitrogen consumption rate and the production rate of primary cell components required to resume photosynthesis) and the dynamics of TAG and secondary carotenoids upon nitrogen resupply. Therefore, insight in the physiological changes occurring during the recovery of a nitrogen-replenished microalga is important and may enable optimization of a TAG and secondary carotenoid production process.

So far, only some TAG-rich microalgae (Parachlorella kessleri, Chlorella vulgaris and Chlamydomonas reinhardtii) have been nitrogen replenished, after which the dynamics of TAG, total lipids, starch, chlorophyll and/or total dry weight concentrations have been reported (Fernandes et al. 2013; Pribyl et al. 2013; Siaut et al. 2011). These studies revealed rapid TAG and starch degradation after nitrogen resupply, which coincided with rapid chlorophyll and total biomass production. However, other parameters required to draw conclusions on the recovery rate of the culture, such as the nitrogen-uptake rate and protein production rate, were not determined. Moreover, because the investigated species were not carotenogenic, the dynamics of secondary carotenoids after nitrogen resupply have not yet been studied.

An oleaginous and carotenogenic microalga potentially suitable for the production of TAG and/or secondary carotenoids is Chromochloris zofingiensis (used to be called Chlorella zofingiensis until recently). This species was previously identified as an efficient TAG producer (Breuer et al. 2012; Mulders et al. 2014b), and it produces several secondary carotenoids, including astaxanthin, canthaxanthin and ketolutein (Del Campo et al. 2004; Mulders et al. 2014c; Orosa et al. 2000; Orosa et al. 2001; Rise et al. 1994).

The aim of this paper is to study the dynamics of TAG, secondary carotenoids and primary cell components in nitrogen-resupplied C. zofingiensis to obtain more insights in the physiology and rate of culture recovery.

Materials and methods

Culture and nitrogen-starved pre-cultivation

C. zofingiensis was obtained as Chlorella zofingiensis UTEX B32 from the University of Texas Culture Collection of Algae (UTEX). C. zofingiensis cultures were nitrogen-starved in a batch-wise operated, 1.75 L flat-panel, airlift-loop photobioreactor with a light path (reactor depth) of 20.7 mm (Labfors, Infors HT, 2010) as described in Mulders et al. (2014b), under the conditions as described in Mulders et al. (2014b). In short, continuous illumination with 245 μmol m−2 s−1 incident light, an air to CO2 ratio of 98:2 v/v sparged at 1.5 L/min, pH maintained at 7, temperature maintained at 25 °C and antifoam addition upon visible foaming. Off gas was analysed online by mass spectrometry.

In a previous study, C. zofingiensis cultures were nitrogen starved at three different biomass concentrations (2.5, 3.4 and 4.1 g L−1) to investigate how TAG and secondary carotenoid accumulation are affected by the biomass concentration at the moment of nitrogen depletion (Mulders et al. 2014b). After 2 weeks of nitrogen depletion, these cultures were used in this work to study the recovery process upon nitrogen replenishment.

Batch replenish experiments

Replenish experiments were performed in the same photobioreactor and under the same conditions as described for the nitrogen-starved pre-cultivation.

The nitrogen replenish medium (modified M-8 medium (Mandalam and Palsson 1998)) consisted of KNO3 494.5 mM; MgSO4.7H2O 3.25 mM; CaCl2.2H2O 0.18 mM; Na2HPO4.2H2O 13.8 mM; NaFeEDTA 0.56 mM; Na2EDTA.2H2O 0.9 mM; H3BO3 2.0 μM; MnCl2.4H2O 0.13 mM; ZnSO4.7H2O 22.3 μM; CuSO4.5H2O 15 μM; Biotin 2 μg L−1; vitamin B1 0.4 mg L−1; and vitamin B12 2 μg L−1. The medium pH was adjusted to pH 7.0 with HCl and filter sterilized prior to use. The nitrogen concentration of the replenish medium was chosen in such a way that, after addition, nitrogen would be in excess throughout the experiment (supporting a theoretical biomass increase of ∼14 g L−1).

Replenish medium (200 mL) was added to the nitrogen-depleted cultures (1550 mL) when the biomass productivity was reduced to a value below 5 % of the maximum biomass productivity, and a maximal time-averaged productivity of secondary carotenoids was reached, thereby signifying the optimal point for harvest and possible regrowth of the culture (typically 2 weeks after nitrogen depletion) (Mulders et al. 2014b). As at that point the cultures had become more or less metabolically inactive, the specific time of nitrogen resupply (i.e. one day earlier or later) was not expected to have a large effect on the physiology and rate of culture recovery. The moment of nitrogen resupply was considered the start of the experiment and is referred to as t = 0.

One to three times a day, a sample was taken directly from the reactor. The sample volume (15–25 ml) was precisely determined to allow estimation of the remaining culture volume. The sample was analysed for dry weight concentration, nitrogen, pigment, TAG, polar acyl lipid, protein, starch and total carbohydrate contents.

Off-gas analysis

The composition of the gas leaving the reactor was analysed using a mass spectrometer (PRIMA δB process MS, Thermo Scientific, USA). In addition, a reference measurement was performed analysing the composition of the gas mixture entering the reactor. Thereby, the volumetric oxygen production rate (r O2, mol L−1 day−1) and the carbon dioxide consumption rate (r CO2, mol L−1 day−1) could be calculated as follows:

with x O2,out, x O2,in, x CO2,out and x CO2,in as the molar fraction of oxygen and carbon dioxide in the gas (−) and F gas,in and F gas,out as the total molar gas flow rates entering and leaving the reactor (mol L−1 day−1), respectively. Due to cellular respiration, F gas,out differed from F g,in. Assuming a constant absolute N-inflow and N-outflow, F gas,out could be determined using Eq. 3.

Absorbed photon flux density

During the cultivations, the outgoing photon flux density (PFDout,pbr) was determined as the average of 12 measurements spread over the surface of the outside of the back glass panel of the reactor. This value was corrected for light loss due to the water jacket, the glass plates and medium (PFDblank). PFDblank was determined as the average of 44 measurements spread over the entire surface of the outside of the back glass panel of the reactor which contained (transparent) medium. The absorbed photon flux density (PFDabs) was calculated as described by Santos et al. 2013, using Eq. 4

with PFDabs, PFDout, PFDout, pbr, PFDblank and PFDin in μmolph m−2 s−1.

Dry weight concentration

Cell dry weight concentrations were determined gravimetrically in triplicate by filtering and drying of the biomass (∼2 mg dry weight (DW)) as described by Kliphuis et al. (2011).

Nitrogen content

To determine the nitrogen content of the biomass, sampled cells (∼10 mg DW) were washed twice with MiliQ water to remove the salt and extracellular nitrogen present in the medium. Washing was performed by centrifugation of cells at 9391×g for 3 min and subsequent resuspension of the cell pellet in 1 mL miliQ water. Washed cell pellets were stored at −20 °C until later use. Cell pellets were freeze dried (to a water content below 1 % (w/w)) and dried further overnight in a stove of 100 °C. Dry cell pellets were cooled at room temperature in a desiccator, to prevent rewetting; after which, the mass of each sample was determined. The nitrogen content was determined using Dumas analysis (Nitrogen analyser, FlashEA 1112 series, Thermo Scientific, Interscience), with methionine as standard.

TAG and polar acyl lipid extraction, identification and quantification

TAG and polar acyl lipids were extracted from a precisely determined amount of biomass (within the range of 4–6 mg DW) with methanol/chloroform as solvent as described by Breuer et al. (2013a). TAG and polar acyl lipids were separated from each other using a solid phase extraction (SPE) column as described by Breuer et al. (2013b). After transesterification to FAMEs, fatty acids from TAG and polar acyl lipids were identified and quantified using GC-FID as described by Breuer et al. (2013a). An internal standard (C15:0) was added to the samples prior to extraction, which ended up in the TAG pool. This internal standard was used for TAG fatty acid quantification and for the quantification of fatty acids from the polar acyl lipids assuming that TAG and polar acyl lipids were extracted and transesterified with a similar efficiency.

Pigment extraction, identification and quantification

Pigments were extracted from a precisely determined amount of biomass (∼4 mg DW) with methanol/chloroform as solvent as described by Lamers et al. (2010), with the exceptions as described in Mulders et al. (2014c). Pigments identification and quantification were performed using reversed phase ultra-high performance liquid chromatography photo diode array tandem mass spectrometry (RP-UHPLC-PDA-MSn) analysis as described in Mulders et al. (2014c).

Proteins

The protein content of a precisely determined amount of biomass (∼8 mg DW) was determined using a DC protein assay (BioRad) as described by De Winter et al. (2013). Freeze dried biomass was dissolved in 1 mL of lysis buffer, containing 60 mM Tris, 2 % SDS, 10 % glycerol and 10 mM DTT. Cells were physically disrupted by employing a Precellys® 24 bead beater (Bertin Technology, France). To inhibit excessive cell heating, 60 s of disruption at 6500 rpm was followed by 120 s of cooling on ice. For each sample, three series of disruption/cooling cycles were performed. Another milliliter of lysis buffer was added and samples were incubated for 30 min at 100 °C in a heating block. After incubation, samples were centrifuged for 10 min at 3500 rpm. The protein content of the supernatant was analysed by measuring absorbance at 750 nm using a plate reader (EL800, BioTek Instruments, USA). BSA was used as a standard.

Starch

The starch content of a precisely determined amount of biomass (∼10 mg DW) was determined using the Total Starch Kit of Megazyme (Megazyme International, Ireland, 2011), as described by De Winter et al. (2013). Freeze-dried biomass was dissolved in 1 mL of 80 % (v/v) ethanol. Cells were physically disrupted by employing a Precellys® 24 bead beater (Bertin Technology, France). To inhibit cell heating, 60 s of disruption at 6000 rpm was followed by 60 s of cooling on ice. For each sample, three series of disruption/cooling cycles were performed. Another 4 mL of 80 % (v/v) ethanol was added to the biomass, and from that point, the standard procedure of the Total Starch kit was followed. Absorbance was measured at 510 nm on a spectrophotometer (DU 640, Beckman, USA). Pure glucose was used as standard.

Non-starch carbohydrates

The non-starch carbohydrate content was determined as the difference between the total carbohydrate content and the starch content. To determine the total carbohydrate content of the biomass, a precisely determined amount of biomass (∼10 mg DW) was transferred to beat beating tubes (containing Lysing Matrix E (MP Biomedicals, Santa Ana, CA, USA)) and centrifuged at 9391×g for 3 min. Cell pellets were freeze dried and 1 mL of 2.5 M HCl was added to the bead beating tubes. Thereafter, cells were physically disrupted using a Precellys® 24 beat beater (Bertin technology, Montigny-le-Bretonneux, France). To prevent excessive heating of the tubes, 60 s of disruption, at 6000 rpm, was followed by 2 min of cooling in ice. For each sample, two series of disruption/cooling were performed. To hydrolyse the carbohydrates, the content of the tubes was transferred to glass tubes and another 4 mL of 2.5 M HCl was added; after which, the samples were incubated at 100 °C for 3 h while being vortexed every hour. Samples were cooled down at room temperature and neutralized by addition of 5 mL 2.5 M NaOH. The biomass was treated with a phenol solution and concentrated sulphuric acid, according to Dubois et al. (1956) and Herbert et al. (1971). The absorbance of the resulting solution was measured at 483 nm. Pure glucose was used as standard.

Results

We studied the dynamics of TAG, secondary carotenoids and primary cell components in nitrogen-resupplied C. zofingiensis. The starting points of this replenishment study were three different cultures which were nitrogen depleted at different biomass concentrations. As a result, each culture contained a different assimilated nitrogen concentration at the start of the replenishment. To each culture, an excess amount of nitrogen was added after a nitrogen starvation phase of 2 weeks. The moment of nitrogen resupply was considered as the start of the cultivation and is referred to as t = 0.

Total biomass, CO2 and O2

Immediately after nitrogen resupply (t = 0), the cultures contained total biomass dry weight concentrations of 7.4, 7.7 and 8.7 g L−1. During the first day after nitrogen resupply, these concentrations decreased in each culture with 13 ± 3 %. Thereafter, biomass concentrations increased in each culture reaching a more or less constant biomass productivity of 0.66 ± 0.08 g L−1 day−1 (Fig. 1a). Prior to nitrogen resupply, each culture net produced O2 and consumed CO2 (not shown). During the first 2 days after nitrogen resupply, the cultures net consumed O2 and produced CO2, whereas 2 days after nitrogen resupply, all cultures net produced O2 and consumed CO2 again. After those 2 days, volumetric CO2 consumption and O2 production rates decreased slightly (Fig. 1b, c).

Time courses of a dry weight biomass concentration, b CO2 consumption rate and c O2 production rate of nitrogen resupplied C. zofingiensis for cultures with different assimilated nitrogen concentrations after nitrogen resupply: 0.12 g L−1 (black circle, black line), 0.18 g L−1 (white square, light grey) and 0.23 g L−1 (grey triangle, dark grey). Error bars in a represent standard deviations of triplicate dry weight measurements. Lines in a are for visual guidance. O2 production rates of the 0.18 g L−1 culture were not measured due to a technical failure

Nitrogen consumption

The cultures, with total biomass concentrations of 7.4, 7.7 and 8.7 g L−1, had assimilated nitrogen concentrations (per culture volume) of 0.12, 0.18 and 0.23 g L−1, respectively, immediately after nitrogen resupply (Fig. 2a). At that point, the average assimilated nitrogen content (on a dry weight basis) was on average 2.2 ± 0.5 % DW (w/w) (Fig. 2b). In each culture, nitrogen was consumed quickly the first 2 days after nitrogen resupply (with 0.20 ± 0.01 g L−1 day−1), resulting in a fast increase in assimilated nitrogen content (reaching 7.5 ± 0.3 % DW (w/w) after 2 days) (Fig. 2). Two days after nitrogen resupply, the nitrogen consumption rate decreased (to 0.038 ± 0.003 g L−1 day−1), resulting in a more or less constant assimilated nitrogen content (of 6.7 ± 0.2 % DW (w/w)) (Fig. 2b).

Time courses of a assimilated nitrogen concentration (in the reactor) and b assimilated nitrogen content (on a dry weight basis) of nitrogen resupplied C. zofingiensis for cultures with different assimilated nitrogen concentrations after nitrogen resupply: 0.12 g L−1 (black circle), 0.18 g L−1 (white square) and 0.23 g L−1 (grey triangle). Error bars represent standard deviations of triplicate assimilated nitrogen measurements

TAG

Immediately after nitrogen resupply, the TAG content was on average 33 ± 6 % DW (w/w). In each culture, TAG concentrations decreased rapidly for 2 days (with 1.0 ± 0.05 g L−1 day−1), resulting in a TAG content of 7 ± 2 % DW (w/w) (Fig. 3). As a comparison, the maximal TAG accumulation rate during the nitrogen starvation period was 0.32 g L−1 day−1. Remarkably, the TAG concentration decreased in each culture with approximately the same amount (2.0 ± 0.1 g L−1), rather than that the same final content or concentration was reached in each culture (Fig. 3). In each culture, 2 days after nitrogen resupply, the TAG concentration as well as the TAG content remained more or less constant (Fig. 3).

Time courses of a total TAG concentration and b total TAG content of nitrogen resupplied C. zofingiensis for cultures with different assimilated nitrogen concentrations after nitrogen resupply: 0.12 g L−1 (black circle), 0.18 g L−1 (white square) and 0.23 g L−1 (grey triangle). TAG concentrations were measured in duplicate; both data points are shown

Secondary carotenoids

Immediately after nitrogen resupply, the secondary carotenoids astaxanthin, canthaxanthin and ketolutein were present. At that point, contents of these carotenoids were on average 0.2 ± 0.02, 0.1 ± 0.02 and 0.06 ± 0.003 % DW (w/w), respectively. From the moment of nitrogen resupply, canthaxanthin and ketolutein concentrations and contents decreased, resulting after 6 days in an average content below 0.01 % DW (w/w) for both carotenoids. In each culture, the astaxanthin concentration remained constant the first 2 days after nitrogen resupply (Fig. 4a). After these 2 days, the astaxanthin concentration decreased (at a rate of 0.9 ± 0.2 g L−1 day−1), resulting also in a decrease in astaxanthin content (Fig. 4a, b).

Time courses of a total astaxanthin concentration (free, mono- and diesters), b total astaxanthin content, c canthaxanthin concentration and d total ketolutein concentration (free, mono- and diesters) of nitrogen resupplied C. zofingiensis for cultures with different assimilated nitrogen concentrations after nitrogen resupply: 0.12 g L−1 (black circle), 0.18 g L−1 (white circle) and 0.23 g L−1 (grey triangle). Pigment concentrations were measured in duplicate; both data points are shown

Polar lipids

Immediately after nitrogen resupply, the polar lipid content was on average 6 ± 0.5 % DW (w/w). In each culture, the polar lipid concentration increased after nitrogen resupply at a more or less constant rate (of 0.07 ± 0.01 g L−1 day−1) (Fig. 5). This resulted after 2 days in a polar lipid content of 9.5 ± 1 % DW (w/w), which thereafter remained more or less constant.

Time course of total polar lipid concentration of nitrogen resupplied C. zofingiensis for cultures with different assimilated nitrogen concentrations after nitrogen resupply: 0.12 g L−1 (black circle), 0.18 g L−1 (white square) and 0.23 g L−1 (black triangle). Polar lipid concentrations were measured in duplicate; both data points are shown

Primary pigments

Immediately after nitrogen resupply, the primary (light harvesting) pigments chlorophyll a and b, lutein, violaxanthin and neoxanthin were present. At that point, total chlorophyll and total primary carotenoid contents were on average 0.8 ± 0.4 and 0.1 ± 0.06 % DW (w/w), respectively (Fig. S1). In each culture, chlorophyll and primary carotenoid concentrations remained constant for at least 5 h after nitrogen resupply (Fig. 6). Thereafter, in each culture, chlorophyll and primary carotenoid concentrations increased rapidly for 2 days, resulting in a fast increase in chlorophyll and primary carotenoid contents (Fig. S1). Two days after nitrogen resupply, the production of chlorophylls and primary carotenoids decreased in each culture, by at least a factor 1.5, whereas the chlorophyll and primary pigment content still increased slightly (Fig. S1). In all cultures, the ratio between primary pigments remained more or less constant.

Time courses of a total chlorophyll concentration (chlorophyll a and b) and b total primary carotenoid concentration (lutein, violaxanthin and neoxanthin) of nitrogen resupplied C. zofingiensis for cultures with different assimilated nitrogen concentrations after nitrogen resupply: 0.12 g L−1 (black circle), 0.18 g L−1 (white square) and 0.23 g L−1 (black triangle). Pigment concentrations were measured in duplicate; both data points are shown

Proteins

The protein dynamics were measured for two cultures only. Immediately after nitrogen resupply, the protein content was on average 18 ± 3 % DW (w/w) (Fig. 7b). In both cultures, protein concentrations seemed to remain constant for at least 5 h after nitrogen resupply (Fig. 7a). Thereafter, protein concentrations increased rapidly for 2 days (with 0.6 ± 0.05 g L−1 day−1), resulting in a fast increase in protein content (reaching after 2 days 33 ± 0.1 % DW (w/w)). In each culture, 2 days after nitrogen resupply, the production of proteins slowed down (Fig. 7a), resulting in a slight decrease in protein content (Fig. 7b).

Time courses of a protein concentration and b protein content of nitrogen resupplied C. zofingiensis for cultures with different assimilated nitrogen concentrations after nitrogen resupply: 0.18 g L−1 (white square) and 0.23 g L−1 (grey triangle). Error bars represent standard deviations of triplicate protein measurements

Starch and non-starch carbohydrates

The dynamics of the starch and non-starch carbohydrates were measured for two cultures only. Immediately after nitrogen resupply, the starch and non-starch carbohydrate contents were on average 11 ± 2 and 20 ± 1 % DW (w/w), respectively (Fig. 8b). In both cultures, starch and non-starch carbohydrate concentrations decreased rapidly the first day after nitrogen resupply (with 0.7 ± 0.1 and 0.3 ± 0.01 g L−1 day−1, respectively). Thereafter, until day four, these concentrations increased again (with 0.1 ± 0.02 and 0.25 ± 0.03 g L−1 day−1, respectively). From the fourth day after nitrogen resupply, starch and non-starch carbohydrate production rates slowed down (Fig. 8a). This resulted in a constant starch content from day four, whereas the non-starch carbohydrate content became constant from approximately day two (Fig. 8b).

Time courses of a concentrations of starch (dashed) and non-starch carbohydrates (solid line) and b contents of starch (dashed) and non-starch carbohydrates (solid line) of nitrogen resupplied C. zofingiensis for cultures with different assimilated nitrogen concentrations after nitrogen resupply: 0.18 g L−1 (white square) and 0.23 g L−1 (white triangle). Error bars represent standard deviations of triplicate starch and non-starch carbohydrate measurements. Lines are for visual guidance

Discussion

The starting points of this replenishment study were three different cultures which were nitrogen depleted at different biomass concentrations. As a result, each culture contained a different assimilated nitrogen concentration when nitrogen was resupplied (2 weeks after the onset of nitrogen depletion). In addition, at that point, all other biomass components were present in different concentrations as well. This probably will have caused the observed minor differences in the production and degradation rates of these compounds between the three cultures (Figs. 1, 2, 3, 4, 5, 6, 7 and 8). However, most importantly, the general trends in the dynamics of TAG, secondary carotenoids and the primary cell components were very similar in the three cultures, which alludes to the existence of a general recovery mechanism that was independent of the varying starting material tested in this study. Therefore, the section below focusses on these similarities, rather than on the differences between the cultures.

Recovery metabolism

Below, the physiological changes occurring after nitrogen resupply are interpreted, which leads to the conclusion that 2 days after nitrogen resupply, the nitrogen-starved cells seemed fully recovered.

Nitrogen was consumed very quickly the first 2 days after nitrogen resupply. Compared to an equivalent nitrogen-replete culture (i.e. a culture that was cultivated under the same conditions as the nitrogen-replenished cells but which contained sufficient nitrogen throughout the cultivation), nitrogen was consumed four times more rapidly (0.20 vs. 0.045 g L−1 day−1 (Table 1)) in the nitrogen-replenished cultures. This rapid nitrogen consumption is likely linked to biochemical actions that occurred at the expression level of nitrogen assimilation mechanisms (Ahmad and Hellebust 1984; Hipkin et al. 1983).

In addition, TAG and starch were quickly degraded immediately after nitrogen replenishment. In comparison to the maximal TAG accumulation rate during the nitrogen starvation period (0.32 g L−1 day−1 (Mulders et al. 2014b)), TAG was degraded at a more than three times higher rate (1 g L−1 day−1).

The initial TAG and starch degradation was accompanied by net CO2 production, net O2 consumption, a decreasing overall dry weight concentration and a constant cell number (not shown), indicating that these storage compounds were respired, most likely to fuel the recovery processes. Besides, TAG and starch degradation likely also provided carbon required for the production of primary cell components such as proteins, primary pigments and thylakoid membranes, which were needed to recover the photosynthetic machinery.

The observed TAG respiration supports the assumption that TAG is accumulated under nitrogen-starved conditions as an energy reserve for when more favourable conditions appear. Besides, this finding is in agreement with observations in other nitrogen-starved TAG-rich microalgae (e.g. Parachlorella kessleri, Chlorella vulgaris and Chlamydomonas reinhardtii), which also degraded TAG very quickly upon nitrogen resupply (within 1 to 2 days, which are similar rates compared to those described in this work) (Fernandes et al. 2013; Pribyl et al. 2013; Siaut et al. 2011). It was suggested in these works that accumulated TAG, and starch, may serve as sources of energy and carbon for recovery and reproductive processes.

After a starch degradation period of 1 day, starch was produced again. In contrast, TAG was continuously degraded during the first 2 days after nitrogen resupply. Apparently, although both TAG and starch are energy storage compounds which are accumulated under nitrogen-starved conditions, they have different roles in C. zofingiensis. It has been proposed by Zhu et al. (2014) that starch is accumulated in C. zofingiensis as a quick response to environmental stress, whereas TAG is accumulated for long-term energy storage. A similar division of roles has also been discussed for other microalgae, such as Pseudochlorococcum sp. and C. reinhardtii (Li et al. 2011; Siaut et al. 2011).

From the moment of nitrogen resupply all supplied light (1 molph L−1 day−1) was completely absorbed by the cultures. However, it is unlikely that immediately after nitrogen replenishment, this light energy was effectively turned into chemical energy. Firstly, because at that point, the primary photosynthetic machinery likely had a limited capacity to generate energy, as indicated by the low photosynthetic rate at the end of the nitrogen starvation phase (i.e. at that point the biomass productivity was reduced to a value below 5 % of the maximal biomass productivity observed under nitrogen-replete conditions) (Mulders et al. 2014b). This is confirmed by the net O2 consumption and CO2 production observed immediately after nitrogen resupply, which is in agreement with the data discussed by Turpin et al. (1988) and Huppe and Turpin (1994) who explained the complex biochemical interactions between photosynthesis, nitrogen metabolism and carbon metabolism after nitrogen resupply. Secondly, immediately after nitrogen replenishment, 30 % (w/w) of the total pigment content consisted of secondary pigments (astaxanthin, canthaxanthin and ketolutein). These red and orange pigments were most likely situated in cytosolic oil bodies at the outer part of the cell, as discussed by Mulders et al. (2014c). Consequently, these protective pigments undoubtedly absorbed a part of the light, reducing the ability to generate energy by photosynthesis.

During the first 2 days after nitrogen resupply, a physiological transition took place. After approximately 5 h of nitrogen consumption, rapid production of the nitrogen-containing chlorophylls and proteins followed. The delay of chlorophyll and protein production in respect to nitrogen assimilation (Fig. S2 and S3) can be explained by assuming that other nitrogen-containing compounds (such as RNA and amino acids) were synthesized first or that internal storage pools of nitrate and ammonium were initially formed, as was reported for the nitrogen resupplied macroalgae Fucus vesiculosus and Fucus serratus (Young et al. 2009).

In addition, primary carotenoids (mainly lutein) were rapidly produced for 2 days from approximately 5 h after nitrogen resupply. As a result, 2 days after nitrogen replenishment the protein and primary pigment contents (on a dry weight basis) were similar to the contents of an equivalent nitrogen-replete culture (Table 1). Besides, from that point, the nitrogen consumption rate decreased and approached the consumption rate of an equivalent nitrogen-replete culture.

The further increase in chlorophyll and primary carotenoid content 2 days after nitrogen resupply, which occurred at a rate comparable to the chlorophyll and primary carotenoid production in equivalent nitrogen-replete cells, was most probably due to photoacclimation which is generally observed when cells are cultured under low irradiance levels (Falkowski 1980; Falkowski and LaRoche 1991; MacIntyre et al. 2002; Telfer et al. 2008). In addition to the changes in primary pigment contents, also the contents of polar lipids were restored during the first 2 days after nitrogen replenishment.

Besides, shortly after nitrogen replenishment, the secondary carotenoids canthaxanthin and ketolutein were degraded. Remarkably, degradation of astaxanthin, which immediately after nitrogen replenishment made up more than 50 % (w/w) of the total amount of secondary carotenoids, started only 2 days after nitrogen resupply.

Altogether, these physiological changes resulted after 1 day into an increasing total biomass dry weight concentration and after 2 days the biomass approached a productivity and yield on light of an equivalent nitrogen-replete culture (Table 1). At that point, the biomass production was accompanied by net CO2 consumption and net O2 production, indicating that also the photosynthetic capacity, and thus the ability to generate energy, was recovered 2 days after nitrogen resupply.

Strikingly, when 2 days after nitrogen replenishment TAG was hardly oxidized anymore, the TAG content was reduced to approximately 7 % DW (w/w). Cells grown under nitrogen-replete conditions contained less than 1 % (w/w) TAG (Table 1), indicating that in the nitrogen-resupplied cultures, TAG breakdown stopped before TAG was completely degraded to baseline-levels. This is remarkable because the energy-rich TAG could theoretically have been used to enhance the specific biomass production rate (which was at that moment approximately ten times lower than the maximally observed specific growth rate of 1 day−1 (Del Campo et al. 2004)). Apparently, a regulation mechanism was present that prevented further degradation of TAG.

Thus, taking into account that 2 days after nitrogen replenishment the nitrogen and CO2 consumption rates, the biomass and O2 production rates and the primary biomass composition had all returned to values similar to those of an equivalent nitrogen-replete culture, we conclude that the cells fully recovered from nitrogen depletion 2 days after nitrogen replenishment.

Implications for a repeated batch production process

The maximally observed secondary carotenoid content of C. zofingiensis is relatively low (0.6 % DW (w/w) (Orosa et al. 2001), compared to, for example, 4 % DW (w/w) observed for the green alga Haematococcus pluvialis (Boussiba et al. 1999)). A higher secondary carotenoid content would be ideal, as a too low content increases the downstream processing costs of the biomass and thus the carotenoid production costs.

The low secondary carotenoid content of C. zofingiensis, obtained after a single batch cultivation, may be increased by applying a repeated batch cultivation. Namely, it was shown that the astaxanthin accumulated during nitrogen starvation was not degraded during the 2 days following nitrogen replenishment. Therefore, a second nitrogen starvation, starting 2 days after nitrogen resupply, may lead to a further increase in astaxanthin content. Perhaps even higher astaxanthin contents may be reached with multiple subsequent cycles of nitrogen starvation and replenishment (i.e. when a true repeated batch is performed). Likewise, similar sequential accumulation of canthaxanthin and ketolutein, which were degraded to approximately one third of their maximal contents 2 days after nitrogen replenishment, may also contribute to an increased secondary carotenoid content. Besides, as canthaxanthin and ketolutein were selectively degraded the first 2 days after nitrogen resupply, a repeated batch may lead to a more selective (astaxanthin-rich) carotenoid profile.

In addition, due to the rapid recovery of the cells, a repeated batch cultivation may lead to an increased overall productivity of secondary carotenoids, compared to a series of single batch cultivations.

In contrast to the secondary carotenoids, accumulated TAG was almost completely degraded 2 days after nitrogen resupply. Although a repeated batch may still be beneficial for TAG accumulation, it will be less beneficial than for the case of astaxanthin due to this degradation of TAG.

Because light energy was not effectively converted into chemical energy during the first period after nitrogen resupply, nitrogen may best be resupplied around sunset, thereby preventing wastage of light energy. The culture will likely initiate recovery in the dark, as indicated by fast degradation of TAG by TAG-rich C. reinhardtii which was nitrogen replenished in the dark (Siaut et al. 2011).

Finally, although the results suggest that a repeated batch may lead to a higher overall productivity of secondary carotenoids than a series of classical single batch cultivations, with C. zofingiensis, follow-up research is required to confirm this. Most importantly, secondary carotenoids dynamics during subsequent cycles of nitrogen depletions and replenishments need to be investigated.

In conclusion, irrespective of the assimilated nitrogen concentration at the moment of nitrogen replenishment, nitrogen was consumed at a more than four times higher rate than under equivalent nitrogen-replete conditions, leading to quick resumption of photosynthesis and biomass production. Within 2 days, the content of all primary macromolecular compounds as well as the nitrogen consumption rate and the overall biomass production rate had returned to values equivalent to those of cells grown under nitrogen-replete conditions, indicating that culture recovery required 2 days. Whereas culture recovery coincided with degradation of TAG, ketolutein and canthaxanthin, astaxanthin was not immediately degraded. Because the cells were able to recover very quickly without immediately degrading astaxanthin, a repeated batch cultivation may result in a higher secondary carotenoid productivity than a series of classical single batch cultivations.

References

Ahmad I, Hellebust JA (1984) Nitrogen metabolism of the marine microalga Chlorella autotrophica. Plant Physiol 76:658–663

Ben-Amotz A (1996) Effect of low temperature on the stereoisomer composition of β-carotene in the halotolerant alga Dunaliella bardawil (Chlorophyta). J Phycol 32:272–275

Ben-Amotz A, Avron M (1983) On the factors which determine massive β-carotene accumulation in the halotolerant alga Dunaliella bardawil. Plant Physiol 72:593–597

Boussiba S, Bing W, Yuan J-P, Zarka A, Chen F (1999) Changes in pigments profile in the green alga Haeamtococcus pluvialis exposed to environmental stresses. Biotechnol Lett 21:601–604

Breuer G, Lamers PP, Martens DE, Draaisma RB, Wijffels RH (2012) The impact of nitrogen starvation on the dynamics of triacylglycerol accumulation in nine microalgae strains. Bioresour Technol 124:217–226

Breuer G, Evers WAC, de Vree JH, Kleinegris DMM, Martens DE, Wijffels RH, Lamers PP (2013a) Analysis of fatty acid content and composition in microalgae. J Vis Exp 80:e50628

Breuer G, Lamers PP, Martens DE, Draaisma RB, Wijffels RH (2013b) Effect of light intensity, pH, and temperature on triacylglycerol (TAG) accumulation induced by nitrogen starvation in Scenedesmus obliquus. Bioresour Technol 143:1–9

Breuer G, de Jaeger L, Artus VPG, Martens DE, Springer J, Draaisma RB, Eggink G, Wijffels RH, Lamers PP (2014) Superior triacylglycerol (TAG) accumulation in starchless mutants of Scenedesmus obliquus: (II) evaluation of TAG yield and productivity in controlled photobioreactors. Biotechnol Biofuels 7:70

Chisti Y (2013) Constraints to commercialization of algal fuels. J Biotechnol 167:201–214

de Winter L, Klok AJ, Cuaresma Franco M, Barbosa MJ, Wijffels RH (2013) The synchronized cell cycle of Neochloris oleoabundans and its influence on biomass composition under constant light conditions. Algal Res 2:313–320

Del Campo JA, Rodriguez H, Moreno J, Vargas MA, Rivas J, Guerrero MG (2004) Accumulation of astaxanthin and lutein in Chlorella zofingiensis (Chlorophyta). Appl Microbiol Biotechnol 64:848–854

Draaisma RB, Wijffels RH, Slegers PM, Brentner LB, Roy A, Barbosa MJ (2013) Food commodities from microalgae. Curr Opin Biotechnol 24:169–177

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

Falkowski PG (1980) Light-shade adaptation in marine phytoplankton. In: Falkowski PG (ed) Primary productivity in the sea. Plenum Press, pp 99–119

Falkowski PG, LaRoche J (1991) Acclimation to spectral irradiance in algae. J Phycol 27:8–14

Feng P, Deng Z, Hu Z, Fan L (2011) Lipid accumulation and growth of Chlorella zofingiensis in flat plate photobioreactors outdoors. Bioresour Technol 102:10577–10584

Fernandes B, Teixeira J, Dragone G, Vicente AA, Kawano S, Bišová K, Přibyl P, Zachleder V, Vítová M (2013) Relationship between starch and lipid accumulation induced by nutrient depletion and replenishment in the microalga Parachlorella kessleri. Bioresour Technol 144:268–274

Goncalves E, Johnson J, Rathinasabapathi B (2013) Conversion of membrane lipid acyl groups to triacylglycerol and formation of lipid bodies upon nitrogen starvation in biofuel green algae Chlorella UTEX 29. Planta 238:895–906

Herbert D, Phipps PJ, Strange RE (1971) Chemical analysis of microbial cells. In: Norris JR, Ribbons DW (eds) Methods in microbiology. Academic, London, pp 209–344

Hipkin CR, Thomas RJ, Syrett PJ (1983) Effects of nitrogen deficiency on nitrate reductase, nitrate assimilation and photosynthesis in unicellular marine algae. Mar Biol 77:101–105

Hsieh C-H, Wu W-T (2009) Cultivation of microalgae for oil production with a cultivation strategy of urea limitation. Bioresour Technol 100:3921–3926

Hu Q, Sommerfeld M, Jarvis E, Ghirardi M, Posewitz M, Seibert M, Darzins A (2008) Microalgal triacylglycerols as feedstocks for biofuel production: perspectives and advances. Plant J 54:621–639

Huppe HC, Turpin DH (1994) Integration of carbon and nitrogen metabolism in plant and algal cells. Annu Rev Plant Physiol Plant Mol Biol 45:577–607

Kliphuis AMJ, Janssen M, van den End EJ, Martens DE, Wijffels RH (2011) Light respiration in Chlorella sorokiniana. J Appl Phycol 23:935–947

Klok AJ, Martens DE, Wijffels RH, Lamers PP (2013a) Simultaneous growth and neutral lipid accumulation in microalgae. Bioresour Technol 134:233–243

Klok AJ, Verbaanderd JA, Lamers PP, Martens DE, Rinzema A, Wijffels RH (2013b) A model for customising biomass composition in continuous microalgae production. Bioresour Technol 146:89–100

Lamers PP, Janssen M, De Vos RCH, Bino RJ, Wijffels RH (2008) Exploring and exploiting carotenoid accumulation in Dunaliella salina for cell-factory applications. Trends Biotechnol 26:631–638

Lamers PP, Janssen M, De Vos RCH, Bino RJ, Wijffels RH (2012) Carotenoid and fatty acid metabolism in nitrogen-starved Dunaliella salina, a unicellular green microalga. J Biotechnol 162:21–27

Lamers PP, van de Laak CCW, Kaasenbrood PS, Lorier J, Janssen M, De Vos RCH, Bino RJ, Wijffels RH (2010) Carotenoid and fatty acid metabolism in light-stressed Dunaliella salina. Biotechnol Bioeng 106:638–648

Lemoine Y, Schoefs B (2010) Secondary ketocarotenoid astaxanthin biosynthesis in algae: a multifunctional response to stress. Photosynth Res 106:155–177

Li Y, Han D, Sommerfeld M, Hu Q (2011) Photosynthetic carbon partitioning and lipid production in the oleaginous microalga Pseudochlorococcum sp. (Chlorophyceae) under nitrogen-limited conditions. Bioresour Technol 102:123–129

Lourenço SO, Barbarino E, Marquez UML, Aidar E (1998) Distribution of intracellular nitrogen in marine microalgae: basis for the calculation of specific nitrogen-to-protein conversion factors. J Phycol 34:798–811

MacIntyre HL, Kana TM, Anning T, Geider RJ (2002) Photoacclimation of photosynthesis irradiance response curves and photosynthetic pigments in microalgae and cyanobacteria. J Phycol 38:17–38

Mandalam RK, Palsson B (1998) Elemental balancing of biomass and medium composition enhances growth capacity in high-density Chlorella vulgaris cultures. Biotechnol Bioeng 59:605–611

Mulders KJM, Lamers PP, Martens DE, Wijffels RH (2014a) Phototrophic pigment production with microalgae: biological constraints and opportunities. J Phycol 50:229–242

Mulders KJM, Martens DE, Wijffels RH, Lamers PP (2014b) Effect of biomass concentration on secondary carotenoids and triacylglycerol (TAG) accumulation in nitrogen-depleted Chlorella zofingiensis. Algal Res 6, Part A:8–16

Mulders KJM, Weesepoel Y, Bodenes P, Lamers PP, Vincken J-P, Martens DE, Gruppen H, Wijffels RH (2014c) Nitrogen-depleted Chlorella zofingiensis produces astaxanthin, ketolutein and their fatty acid esters: a carotenoid metabolism study. J Appl Phycol. doi:10.1007/s10811-014-0333-3

Orosa M, Torres E, Fidalgo P, Abalde J (2000) Production and analysis of secondary carotenoids in green algae. J Appl Phycol 12:553–556

Orosa M, Valero JF, Herrero C, Abalde J (2001) Comparison of the accumulation of astaxanthin in Haematococcus pluvialis and other green microalgae under N-starvation and high light conditions. Biotechnol Lett 23:1079–1085

Pribyl P, Cepak V, Zachleder V (2013) Production of lipids and formation and mobilization of lipid bodies in Chlorella vulgaris. J Appl Phycol 25:545–553

Rhiel E, Morschel E, Wehrmeyer W (1985) Correlation of pigment deprivation and ultrastructural organization of thylakoid membranes in Cryptomonas maculata following nutrient deficiency. Protoplasma 129:62–73

Rise M, Cohen E, Vishkautsan M, Cojocaru M, Gottlieb HE, Arad SM (1994) Accumulation of secondary carotenoids in Chlorella zofingiensis. J Plant Physiol 144:287–292

Santos AM, Lamers PP, Janssen M, Wijffels RH (2013) Biomass and lipid productivity of Neochloris oleoabundans under alkaline-saline conditions. Algal Res 2:204–211

Siaut M, Cuine S, Cagnon C, Fessler B, Nguyen M, Carrier P, Beyly A, Beisson F, Triantaphylides C, Li-Beisson Y, Peltier G (2011) Oil accumulation in the model green alga Chlamydomonas reinhardtii: characterization, variability between common laboratory strains and relationship with starch reserves. BMC Biotechnol 11:7

Solovchenko AE (2013) Physiology and adaptive significance of secondary carotenogenesis in green microalgae. Russ J Plant Physiol 60:1–13

Spolaore P, Joannis-Cassan C, Duran E, Isambert A (2006) Commercial applications of microalgae. J Biosci Bioeng 101:87–96

Telfer A, Pascal A, Gall A (2008) Volume 4: natural functions. In: Britton G, Liaanen-Jensen S, Pfander H (eds) Carotenoids. Birkhäuser, Verlag, Basel, pp 189–211

Turpin DH (1991) Effects of inorganic N availability on algal photosynthesis and carbon metabolism. J Phycol 27:14–20

Turpin DH, Elrifi IR, Birch DG, Weger HG, Holmes JJ (1988) Interactions between photosynthesis, respiration, and nitrogen assimilation in microalgae. Can J Bot Rev Can Botan 66:2083–2097

Xiao Y, Zhang J, Cui J, Feng Y, Cui Q (2013) Metabolic profiles of Nannochloropsis oceanica IMET1 under nitrogen-deficiency stress. Bioresour Technol 130:731–738

Young EB, Berges JA, Dring MJ (2009) Physiological responses of intertidal marine brown algae to nitrogen deprivation and resupply of nitrate and ammonium. Physiol Plant 135:400–411

Zhu S, Huang W, Xu J, Wang Z, Xu J, Yuan Z (2014) Metabolic changes of starch and lipid triggered by nitrogen starvation in the microalga Chlorella zofingiensis. Bioresour Technol 152:292–298

Acknowledgments

We gratefully thank Yannick Weesepoel of Wageningen University, Laboratory of Food Chemistry, for performing the pigment identification and quantification and helping with the Dumas analyses. This work was supported by FeyeCon D&I and by grants from Rijksdienst voor Ondernemend Nederland (Project no. FND09014).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 134 kb)

Rights and permissions

About this article

Cite this article

Mulders, K.J.M., Lamers, P.P., Wijffels, R.H. et al. Dynamics of biomass composition and growth during recovery of nitrogen-starved Chromochloris zofingiensis . Appl Microbiol Biotechnol 99, 1873–1884 (2015). https://doi.org/10.1007/s00253-014-6181-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-014-6181-x