Abstract

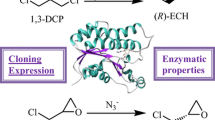

Rhodococcus opacus B-4 cells are adhesive to and even dispersible in water-immiscible hydrocarbons owing to their highly lipophilic nature. In this study, we focused on the high operational stability of thermophilic enzymes and applied them to a biocatalytic conversion in an organic reaction medium using R. opacus B-4 as a lipophilic capsule of enzymes to deliver them into the organic medium. A novel thermo- and organic-solvent-tolerant ene reductase, which can catalyze the enantioselective reduction of ketoisophorone to (6R)-levodione, was isolated from Geobacillus sp. 30, and the gene encoding the enzyme was heterologously expressed in R. opacus B-4. Another thermophilic enzyme which catalyzes NAD+-dependent dehydrogenation of cyclohexanol was identified from the gene-expression library of Thermus thermophilus and the gene was coexpressed in R. opacus B-4 for cofactor regeneration. While the recombinant cells were not viable in the mixture due to high reaction temperature, 634 mM of (6R)-levodione could be produced with an enantiopurity of 89.2 % ee by directly mixing the wet cells of the recombinant R. opacus with a mixture of ketoisophorone and cyclohexanol at 50 °C. The conversion rate observed with the heat-killed recombinant cells was considerably higher than that obtained with a cell-free enzyme solution, demonstrating that the accessibility between the substrates and enzymes could be improved by employing R. opacus cells as a lipophilic enzyme capsule. These results imply that a combination of thermophilic enzymes and lipophilic cells can be a promising approach for the biocatalytic production of water-insoluble chemicals.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The integration of biocatalysts to chemical conversion processes is a key technology necessary to promote sustainability in chemical industries (Bornscheuer et al. 2012). Although a certain number of water-soluble chemicals have already been enzymatically produced on a commercial scale, the biocatalytic conversion of water-insoluble compounds has applied with limited success mainly because of the incompatibility of enzymes with organic solvents. Biocatalytic conversions in anhydrous organic media have been intensively studied using lyophilized lipases, esterases, and proteases; however, most of these enzymes are relatively simple, single-step hydrolytic enzymes (Akkara et al. 1999; Carrea and Riva 2000; Klibanov 2001; Hudson et al. 2005). Aqueous/organic (A/O) two phase bioconversion systems with whole-cell catalysts, in which a series of enzymes involved in target reactions are packaged, have often been employed for more complex biocatalytic reactions, such as those catalyzed by multi-component enzymes, cofactor-dependent enzymes, and multiple enzymes (Schmid et al. 1998; Yamashita et al. 2007a; Verhoef et al. 2008; Wangrangsimagul et al. 2012). However, in A/O two phase systems, the mass transfer rate of water-insoluble substrates from the organic to aqueous phase tends to be rate limiting, and thus the whole-cell catalysts, which are resident only in the aqueous phase, often fail to fully exert their catalytic performance (Hamada et al. 2009).

The cell envelope of the genus Rhodococcus is dominated by long-chain 2-alkyl 3-hydroxy fatty acids, the mycolic acids (Sutcliffe 1998; Paul and Beveridge 1992). Owing to the lipophilic feature of the mycolate layer, rhodococcal cells exhibit a high affinity for water-immiscible hydrocarbons and are even dispersible in anhydrous organic solvents (Yamashita et al. 2007b; Sameshima et al. 2008; Iwabuchi et al. 2009) (Online Resource 1). We previously demonstrated that Rhodococcus opacus B-4 cells can easily access and take up water-insoluble substrates dissolved in the organic phase of an A/O two phase bioconversion system (Hamada et al. 2009). Furthermore, the wet cells of recombinant R. rhodochrous producing thermophilic alcohol dehydrogenases can be directly used as a whole-cell catalyst in anhydrous reaction media (Hibino and Ohtake 2013). Thus, lipophilic bacterial cells can serve as a ‘capsule’ to deliver enzymes into an organic medium.

However, although the high accessibility of the lipophilic cells to an organic solvent can improve the mass transfer rate of an oil-soluble substrate into the intracellular aqueous phase, enzymes contained in the lipophilic cells are exposed to higher levels of denaturing effects of the solvents than those in hydrophilic ones. Accordingly, for stable operation of a bioconversion system in the presence of a bulk amount of organic solvents, enzymes to be contained in the lipophilic cell capsule need to have a sufficient tolerance towards the solvents. Although the detailed mechanisms remain to be clarified, many thermophilic enzymes have been reported to display higher tolerance towards denaturants such as detergents and organic solvents than their mesophilic counterparts (Atomi 2005). On the basis of this premise, we isolated and characterized a novel thermophilic ene reductase from Geobacillus sp. The enzyme was heterologously produced in R. opacus B-4 and applied to the enantioselective reduction of ketoisophorone (3,5,5-trimethyl-2-cyclohexan-1,4-dione) to (6R)-levodione, which serves as a chiral building block for the synthesis of enantiomerically pure carotinoids (Kataoka et al. 2003).

Materials and methods

Microorganisms and cultivation conditions

Microorganisms and plasmids used in this study were listed in Online Resource 2. Geobacillus sp. 30, which was isolated from a soil sample collected from the campus of Osaka University, was aerobically cultivated at 50 °C in a nutrient medium comprised of 1 % (w/v) polypeptone (BD Bioscience, San Jose, CA), 0.2 % (w/v) yeast extract (BD Bioscience), and 0.1 % MgSO4 · 7H2O. When necessary, the medium was solidified with 1.6 % (w/v) gellan gum (Kanto Kagaku, Tokyo, Japan). Escherichia coli Rosetta2 (DE3) was cultivated in LB medium supplemented with 20 μg/ml chloramphenicol. For the cultivation of the recombinant E. coli, 100 μg/ml ampicillin was added to the culture medium. Isopropyl β-d-1-thiogalactopyranoside (IPTG) was added to the late log phase culture at a final concentration of 0.4 mM to induce gene expression. Cultivation of R. opacus B-4 was performed in tryptic soy broth (TSB; BD Bioscience). Tetracycline (20 μg/ml) and chloramphenicol (20 μg/ml) were used for the cultivation of the recombinant strain. Gene expression was induced by adding thiostrepton (20 μg/ml) at late log phase.

Geobacillus sp. 30 and R. opacus B-4 were deposited in the NBRC culture collection (http://www.nbrc.nite.go.jp/e/index.html) under the accession numbers of 109974 and 108011, respectively.

Enzyme assay

The standard assay mixture for the ene reductase comprised 2 mM ketoisophorone (Tokyo Chemical Industry, Tokyo, Japan), 0.2 mM NADPH, 20 mM bicine-NaOH (pH 8.0), and an appropriate amount of the enzyme. The mixture without ketoisophorone was preincubated at 50 °C for 2 min. The reaction was started by the addition of the substrate and the decrease of NADPH level was determined at 50 °C by measuring the decrease in the absorbance at 340 nm. Similarly, the activity of the Thermus thermophilus alcohol dehydrogenase was spectrophotometrically determined at 340 nm. The reaction mixture comprised 2 mM cyclohexanol, 0.2 mM NAD+, 20 mM bicine-NaOH (pH 8.0), and an appropriate amount of the enzyme. The reaction was initiated by the addition of the substrate and monitored at 50 °C. A molar adsorption coefficient of 6.2 mM−1 cm−1 for NADPH and NADH was used to estimate the enzyme activity. One unit of enzyme was defined as the amount catalyzing the oxidation or reduction of 1 μmol of the redox cofactor per minute. Protein concentration was measured with the Bio-Rad assay system (Bio-Rad, Hercules, CA, USA) using bovine serum albumin as the standard.

Enzyme purification from Geobacillus sp. 30

All purification procedures were done at 4 °C in 20 mM potassium phosphate buffer (pH 7.0).

Step 1. Preparation of cell-free extract

Cells collected from 3 l culture broth (12.3 g in wet weight) were suspended in 44 ml of the buffer and disrupted with an ultrasonicator. After the centrifugation at 12,000×g for 15 min, the supernatant was dialyzed against the same buffer.

Step 2. Ammonium sulfate fractionation

Solid ammonium sulfate was added to the cell-free extract to 20–60 % saturation. The precipitate was recovered by centrifugation at 12,000×g for 15 min, dissolved in the buffer, and dialyzed against the same buffer.

Step 3. HiTrap Q FF column chromatography

The dialyzed solution was put on a HiTrap Q FF column (GE Healthcare Japan, Tokyo, Japan) equilibrated with the buffer. After washing the column with the buffer, the enzyme was eluted with a linear gradient of NaCl (from 0 to 0.6 M). The combined active fractions were concentrated by ultrafiltration using an Amicon Ultra-15 (average cut off, 10,000; Merck Millipore, Darmstadt, Germany).

Step 4. Superdex-200 HiLoad 16/60 column chromatography

The concentrated enzyme solution was put on a Superdex-200 HiLoad 16/60 column (GE Healthcare Japan), equilibrated with the buffer containing 0.2 M NaCl. The enzyme was eluted with 1.2× column volumes (144 ml) of the buffer containing 0.2 M NaCl. The combined active fractions were dialyzed against NaCl-free buffer.

Step 5. Mono Q column chromatography

The dialyzed solution was put on a Mono Q 10/100 GL column (GE Healthcare Japan) and eluted in the same manner as described in Step 3.

Protein identification

Mass spectrometric identification of the protein was performed as described by Uchiyama et al. (2005). Briefly, proteins were separated by SDS-PAGE and gels containing the proteins of interests were cut out. Gel pieces were destained with 50 mM ammonium bicarbonate in 50 % methanol. After dehydration with acetonitrile, gel pieces were then incubated in 100 mM dithiothreitol in 100 mM ammonium bicarbonate, followed by replacement of the dithiothreitol solution with 100 mM iodoacetamide in 100 mM ammonium bicarbonate. Gel pieces were dehydrated with acetonitrile and dried in a vacuum dryer. Dried gels were rehydrated with 50 mM ammonium bicarbonate containing 0.1 pmol μl−1 trypsin (Wako Pure Chemical, Osaka, Japan) and incubated at 37 °C for 16 h. Digested peptides were eluted with 0.1 % trifluoroacetic acid in 50 % acetonitrile. The digested peptide solution was analyzed using an Esquire electrospray ionization MS/MS system (Bruker Daltonik GmbH, Germany) equipped with a liquid chromatography system (Agilent Technology, Palo Alto, CA, USA). Mass data extracted by Hystar Ver 2.3 (Bruker Daltonik GmbH) were analyzed using Biotools Ver 2.2 (Bruker Daltonik GmbH) employing the MASCOT search engine.

Genome analysis

The genomic DNA of Geobacillus sp. 30 was isolated using the Illustra bacteria genomic prep mini spin kit (GE Healthcare Japan). Whole genome sequencing was done at Hokkaido System Science Co. (Sapporo, Japan) using illumine MiSeq (Illumina Inc., San Diego, CA, USA) with a pair end method. A standalone BLAST analysis was performed using G-InforBio version 1.9 (Tanaka et al. 2006).

Expression and purification of recombinant enzyme

The gene encoding the ene reductase of Geobacillus sp. 30 was PCR-amplified from the bacterial genomic DNA using the following oligonucleotide primers: 5′-CATATGGAAACGATGCTTTTTTCACCG-3′ (the NdeI restriction site is underlined) and 5′-GAATTCTTAAAAACGCCATCCTCGTTC-3′ (the EcoRI restriction site is underlined). The amplified DNA was digested with NdeI and EcoRI and inserted into the corresponding restriction sites of pET21a (Merck, Darmstadt, Germany).

E. coli Rosetta2 (DE3) was used as a host for gene expression. For protein purification, the recombinant cells were suspended in 20 mM potassium phosphate buffer (pH 7.0) and disrupted by ultrasonication. After the removal of cell debris by centrifugation (4 °C, 12,000×g, 15 min), the supernatant was heated at 70 °C for 30 min and then centrifuged again to remove the denatured proteins. The heat-treated protein solution was applied to a Mono Q 10/100 GL column and eluted in the same manner as described above.

Screening for cofactor regenerating enzyme

Among the gene-expression library of T. thermophilus HB8 (Yokoyama et al. 2000), 48 plasmids encoding putative NAD(P)+-dependent dehydrogenases were selected and transformed in E. coli Rosetta 2 (Online Resource 3). Cultivation of the recombinant cells was performed in a 96-well plate containing 500 μl of an autoinduction medium (Zhou et al. 2010) in each well. Cells were harvested by centrifugation and resuspended in 500 μl of 100 mM Tris–HCl (pH 8.0). The cell suspension was incubated at 50 °C for 30 min and an aliquot (100 μl) was mixed with an equal volume of assay mixture comprised of 12 μM 1-methoxy-5-methylphenazinium methylsulfate (1-methoxy PMS; Dojindo, Kumamoto, Japan), 300 μM 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide (MTT; Nacalai Tesque, Kyoto, Japan), 2 mM NAD+, and 4 mM cyclohexanol. The mixture was kept at 50 °C for 30 min, and accumulation of formazan dye was visually evaluated.

Gene expression in R. opacus

The gene coding for the ene reductase from Geobacillus sp. 30 was amplified by PCR with the oligonucleotide primers, which were used for the construction of the E. coli expression vector (see above). After the digestion with NdeI and EcoRI, the DNA fragment was introduced into the corresponding site of pTip-QT2 (Nakashima and Tamura 2004). Similarly, the gene encoding the T. thermophilus alcohol dehydrogenase was PCR-amplified with following primers: 5′-CATATGAGGGCCGTGGTCTACAAGGG-3′ (the NdeI restriction site is underlined) and 5′-AGATCTTCAGGGCACGAGGGCGACCT-3′ (the BglII restriction site is underlined). The amplicon was digested with NdeI and BglII and then introduced into pTip-RC2 (Nakashima and Tamura 2004). Transformation of R. opacus was performed by electroporation as described elsewhere (Yamashita et al. 2007b).

Bioconversion

Wet cells (700 mg) of the recombinant R. opacus were mixed with 12 μl of 250 mM NADH solution, and suspended in a mixture of 0.572 g (5.71 mmol, 0.595 ml at 25 °C) cyclohexanol and 0.108 g (0.71 mmol, 0.105 ml at 25 °C) ketoisophorone. Alternatively, cell-free extract of the recombinant R. opacus was used instead of the cells. Cells (700 mg) were suspended in 20 mM potassium phosphate (pH 7.0) and disrupted by ultrasonication. After removing the cell debris by centrifugation, the supernatant was condensed to 700 μl by ultrafiltration using Amicon Ultra-15 (average cut off, 10,000). The reaction was performed at 50 °C at a shaking speed of 1,400 rpm on a thermomixer (Eppendorf, Hamburg, Germany). Aliquot (40 μl) of samples were intermittently taken and centrifuged to remove the cells. The organic phase was diluted with ethyl acetate and subjected to gas chromatography (GC) analysis.

Analytic methods

The enantiomeric excess (ee) of the product and the level of conversion were determined by GC (Model 14B; Shimadzu, Kyoto, Japan) equipped with a flame ionization detector and a β-cyclodextrin MEGA column (0.25 mm × 25 m; Legnano, Italy). Nitrogen was supplied as the carrier gas at a constant pressure of 75 kPa. The oven temperature was kept at 50 °C for 3 min, and then increased from 50 °C to 100 °C at 10 °C/min, from 100 °C to 120 °C at 1 °C/min, and 120 °C to 200 °C at 20 °C/min. Configuration of levodione produced by the enzyme reaction was confirmed by comparing its retention time on the chiral GC analysis with that of (6R)-levodione, which was prepared using the old yellow enzyme from Candida macedoniensis (Kataoka et al. 2002). Configuration of enzymatically produced 2-methyl cyclohexanone was assessed by measuring the CD spectrum using a J-820 CD spectrometer (Jasco, Tokyo, Japan) and comparing the polarity of the spectrum with that reported by Cirilli et al. (2007).

Gene accession number

The nucleotide sequence of the gene encoding the ene reductase of Geobacillus sp. 30 was deposited in the DDBJ/GenBank/EMBL database under the accession number AB900619.

Results

Purification of the ene reductase from Geobacillus sp. 30

Geobacillus sp. 30 was isolated from a soil sample and selected on the basis of its ability to grow at high temperatures (up to at least 70 °C) and activity for reducing crotonaldehyde to butylaldehyde (data not shown). Through the ammonium sulfate fractionation followed by three-step chromatographic separations, the ene reductase was 39-fold purified with an overall yield of 3.0 % (Table 1). SDS-PAGE analysis of the partially purified enzyme gave two major protein bands with molecular weights of 101,000 and 37,900 Da (data not shown). Mass spectrometric analysis and a Mascot database search of these protein bands revealed that the trypsin-digested peptide mass values of the upper and lower bands gave hits with the phosphoenolpyruvate carboxykinase (gi|312109854; Mascot score, 637) and NADH:flavin oxidoreductase (gi|312110330; Mascot score, 446) of Geobacillus sp. Y4.1MC1. NADH:flavin oxidoreductases belong to the ‘old yellow enzyme’ family and many are known to catalyze the saturation of the C=C double bonds of α,β-unsaturated carbonyl and nitro compounds (Stuermer et al. 2007; Williams and Bruce 2002). These results strongly implied that the protein with a subunit molecular weight of 37,900 Da was the enzyme of interest. The elution profile of the crude enzyme solution from the Superdex 200 gel filtration column indicated that the protein with the ene reductase activity has an apparent molecular weight of approximately 114,000 Da, suggesting that the enzyme has a homotrimer or homotetramer organization (Fig. 1).

Elution profile of the ene reductase from the Superdex 200 gel filtration column. A partially purified enzyme solution (9 ml with a total protein concentration of 14 μg ml−1) was put on Superdex-200 HiLoad 16/60 and eluted with a potassium phosphate buffer containing 0.2 M NaCl. The elution profile monitored at 280 nm is shown with a black line. The enzyme activities in the fractionated eluents (3 ml each) are shown as gray bars. The dotted line indicates the elution profile of the standard molecular weight marker (Oriental Yeast, Osaka, Japan), which consists of horse heart cytochrome c (molecular weight 12,400 Da), yeast myokinase (32,000 Da), yeast enolase (67,000 Da), pig heart lactate dehydrogenase (140,000 Da), and yeast glutamate dehydrogenase (290,000 Da). Inset: the semilogarithmic plot of the elution volume and the molecular weight of each protein

Gene identification and expression in E. coli

Whole genome analysis of Geobacillus sp. 30 gave draft sequences comprising 53 contigs with a total contig length of 3,913,363 bp. A TBLASTN search of the draft sequences using the amino acid sequence of the NADH:flavin oxidoreductase of Geobacillus sp. Y4.1MC1 as query led to the identification of the gene encoding a 340-amino acid protein with 93 % overall identity to the query sequence. The calculated molecular weight of the encoded protein was 37,881 Da. The deduced amino acid sequence of the gene exhibited high similarities to those of enzymologically characterized thermophilic old yellow enzymes from Geobacillus kaustophilus DSM7263 (87 % in overall identity) (Schittmayer et al. 2011) and Thermoanerobacter pseudethanolicus E39 (52 %) (Adalbjörnsson et al. 2010). The gene coding for the protein was cloned and expressed in E. coli, which yielded an active enzyme accounting for 1.15 % of the total protein in the cell extract. The recombinant protein was purified by heat treatment at 70 °C for 30 min followed by anion exchange and gel filtration column chromatography. The enzyme was enriched 56.7-fold with a 65.2 % yield and gave a single homogenous band on SDS-PAGE (data not shown). The purified recombinant enzyme was used for the characterization.

Effects of pH and temperature

Figure 2a shows the effects of pH on the activity of the Geobacillus ene reductase. The pH profile of the enzyme gave a broad peak in the range of pH 6.0–10.0. However, the enzyme showed no detectable activity at pH 5.0 or lower. The maximum enzyme activity was observed in bicine-NaOH buffer at pH 8.0. The effect of the reaction temperature is shown in Fig. 2b. The enzyme activity increased up to a temperature of 70 °C and then steeply decreased, most probably due to the thermal inactivation of the enzyme. This result was consistent with the thermal profile of the cyclohexanone desaturating activity of the old yellow enzyme from G. kaustophilus DSM7263 (Schittmayer et al. 2011).

Effects of pH (a) and temperature (b) on the activity of the Geobacillus ene reductase. Enzyme assays were performed under the standard assay conditions at the indicated pH and temperature. Sodium citrate (circle), potassium phosphate (diamond), bicine-NaOH (square), and borate-NaOH (triangle) buffers were used to adjust pH.

Enzyme stability

The thermal stability of the enzyme was assessed by incubating the enzyme at temperatures of 50 °C, 60 °C, and 70 °C (Fig. 3). Although the maximum activity was observed at 70 °C (Fig. 2b), the enzyme was almost completely inactivated by incubation for 2 h at this temperature. At 50 °C, the enzyme could retain more than 75 % of its initial activity for at least 8 h. Effects of organic solvents on the enzyme stability were investigated using water-miscible (methanol and dimethyl sulfoxide) and water-immiscible (cyclohexanol and cyclohexane) solvents (Fig. 4a). Overall, enzyme activity decreased in a dose-dependent fashion when the volumetric ratio of the organic solvents was increased, however more than 60 % of the initial activity could be retained for at least 12 h in the presence of 20 % (v/v) of the organic solvents. No significant relationship could be observed between the water miscibility of the solvents and their denaturation effects on the enzyme. We also assessed the synergistic effects of high temperature and the presence of an organic solvent. When the enzyme was incubated for 24 h at 50 °C with 50 % (vol/vol) cyclohexanol, the enzyme activity decreased to about 50 % of the initial activity (Fig. 4b). Furthermore, we investigated the ethanol tolerance of the enzyme under the experimental conditions described by Adalbjörnsson et al. (2010) for the comparative analysis of the solvent tolerance of the Geobacillus enzyme with that of a mesophilic counterpart. The enzyme could retain more than 85 % of the activity after the incubation in 80 % ethanol at 25 °C for 5 min. This value was comparable to the residual activity of the thermotolerant ene reductase from T. pseudethanolicus (approximately 80 %) and markedly higher than that of the mesophilic one from Enterobacter cloacae (under the detectable level) (Adalbjörnsson et al. 2010).

Effects of organic solvents on the enzyme stability. a The enzyme was incubated at 30 °C for 12 h with shaking at 1,400 rpm in the presence of 5 % (black bars), 10 % (gray bars), and 20 % (v/v) (white bars) of organic solvents. Relative activities were shown as percentages of the activity without the solvent treatment. b The enzyme was incubated with (square) and without (diamond) 50 % (v/v) cyclohexanol at 50 °C and a shaking speed of 1,400 rpm

Substrate and cofactor specificity

Members of the old yellow enzyme family typically catalyze the saturation of C=C double bonds of α,β-unsaturated ketones, aldehydes, nitroalkenes, carboxylic acids, and their derivatives (Stuermer et al. 2007; Williams and Bruce 2002). As expected, the ene reductase from Geobacillus sp. 30 also catalyzes the reduction of cyclic and linear alkenes having carbonyl and nitro groups (Table 2). The 2-position methylated α,β-unsaturated cyclic ketones served as good substrates of the enzyme. On the other hand, neither 3-methyl 2-cyclohenxene-1-one nor isophorone were substrates, implying that the enzyme could not accept 3-methylated ketones. The Geobacillus ene reductase preferably used NADPH as a reducing cofactor. However, similar to other old yellow enzymes (Williams et al. 2004), the cofactor specificity of the Geobacillus enzyme was not very strict and the enzyme showed comparable levels of activities with both NADH and NADPH. This feature is important for applications of thermophilic enzymes since the thermal stability of NADH is significantly higher than that of NADPH (Morimoto et al. 2014). As well as the saturation of ene compounds, the enzyme catalyzed NAD(P)H-dependent reduction of O2 (oxidation of NAD(P)H) under aerobic conditions to produce H2O2. The specific NADH and NADPH oxidase activities of the enzyme were estimated to be 2.13 and 2.91 U mg−1 protein under the standard assay conditions.

The enantioselectivity of the enzyme was assessed with the reduction products of 2-methyl 2-cyclohenxene-1-one and ketoisophorone. The enantiomeric excess of the enzymatically prepared 2-methyl cyclohexanone and levodione were estimated to be 96.0 % ee (for R-isomer) and 88.1 % ee (for R-isomer), respectively.

Screening for cofactor regenerating enzyme

Coupling with a second dehydrogenase, which can regenerate NAD(P)H through a NAD(P)+-dependent dehydrogenation of inexpensive substances, is crucial for bioreductive production of chiral compounds from prochiral substrates (Kataoka et al. 2003). Although several thermophilic NAD(P)+-dependent dehydrogenases involving 6-phosphogluconate dehydrogenase (Wang and Zhang 2009), glycerol dehydrogenase (Yao and Mikkelsen 2010), and lactate dehydrogenase (Wichmann and Vasic-Racki 2005), have been reported, their substrates are soluble only in water and not in organic reaction media. This limitation led us to search for another enzyme which is capable of catalyzing the NAD(P)+-dependent oxidation of an inexpensive, non-volatile, and oil-miscible substrate, cyclohexanol. The colorimetric screening of 48 putative NAD(P)H-dependent dehydrogenases involved in the T. thermophilus gene-expression library (Yokoyama et al. 2000) resulted in the identification of two NAD+-dependent dehydrogenases, the putative zinc-binding dehydrogenase (gi|55980369), and the Type II 3-hydroxyacyl-CoA dehydrogenase (gi|55772073), as possible candidates for cofactor regeneration with cyclohexanol (Online Resource 3). The genes encoding these dehydrogenases were cloned and expressed in R. opacus B-4. Although the recombinant E. coli having the zinc-binding dehydrogenase showed higher specific activity than that having the 3-hydroxyacyl-CoA dehydrogenase, the use of R. opacus as the expression host gave opposite results probably as a result of the difference in the codon usage biases between E. coli and R. opacus. On the basis of this observation, the hydroxyacyl-CoA dehydrogenase, designated as TtADH, was used for further study. The deduced amino acid sequence of TtADH showed 52 % identity with that of the alcohol dehydrogenase from Thermus sp. ATN1, of which cyclohexanol can serve as a good substrate (Höllrigl et al. 2008). The reductive activities of TtADH toward ketoisophorone and levodione were under the detectable level (data not shown).

Expression in R. opacus and the bioconversion assay

The Geobacillus ene reductase and TtADH were coexpressed in R. opacus B-4 using a pair of compatible expression plasmid vectors (Nakashima and Tamura 2004). The specific activities of the Geobacillus ene reductase and TtADH in the crude extract of the recombinant R. opacus B-4 were 113 and 16.7 mU mg−1 protein, respectively. Whole-cell bioconversion was performed by directly suspending the recombinant cells (700 mg in wet weight) in a 1.0 M ketoisophorone solution (approx. 700 μl) dissolved in cyclohexanol. R. opacus B-4 cells can retain metabolic activity and survive in non-aqueous solvents for at least 1 day at 30 °C (Yamashita et al. 2007a). However, no colony formation was observed when the cells suspended in cyclohexanol (approximately 2 × 109 colony-forming unit ml−1) were plated on a TSB agar after the incubation at 50 °C for 30 min, indicating that cells were not viable under the reaction conditions described herein because of the high temperature (data not shown). NADH was employed as the redox cofactor as it is more thermally stable than NADPH. When the reaction was performed with varied amounts of exogenous NADH, the conversion rate improved in a dose-dependent manner (Online Resource 4). This implies that the exogenous NADH could access the enzymes through the cell envelope. Owing to the high temperature and the organic-solvent stress, the cell membrane structure of R. opacus may be partly disrupted, resulting in diffusion of the cofactor through the cell envelope. The bioconversion was also conducted with an aqueous enzyme solution. An equal amount of the recombinant cells (700 mg) was disrupted by ultrasonication. The resulting crude extract was condensed to 700 μl by ultrafiltration and then used as the catalyst. Obviously, the conversion rate obtained with the cell-free enzyme solution (0.228 μmol min−1 for the initial 3 h) was lower than that observed in the whole-cell-mediated reaction (1.06 μmol min−1) (Fig. 5). The lower conversion rate observed with the enzyme solution seemed to have resulted from the loss of enzyme activity in the cell disruption and enzyme condensation steps. In fact, we found that approximately 5 % of the enzyme was lost by the ultracentrifugation. However, when the whole cells and enzyme solution were subjected to an ‘aqueous’-single-phase reaction with water-soluble concentrations of the substrates (100 mM each of ketoisophorone and cyclohexanol), the cell-free enzyme solution gave 3.3 times higher conversion rate (35.0 μmol min−1 for the initial 10 min) than the whole cells (10.6 μmol min−1) (Fig. 6). These observations indicated that the higher conversion rate obtained with the whole cells in the anhydrous substrate mixture was most likely attributed to better accessibility between the substrates and enzyme molecules but not to the difference in the enzyme titer. On the other hand, in the aqueous reaction mixture, penetration of the substrates and/or the cofactor through the cell membrane might be a limiting factor of the whole-cell catalyst, therefore yielding a lower conversion rate than the cell-free enzyme solution. In the whole-cell bioconversion, 634 mM of levodione could be produced by 24 h. The NADH turnover number was calculated to be 53. Although the enantiopurity of the product gradually decreased, it was maintained at 89.2 % ee after a 24-h reaction.

Bioconversion of ketoisophorone to (6R)-levodione with the wet cells (a) and the cell-free extract (b) of recombinant R. opacus. Concentrations of ketoisophorone (diamond) and (6R)-levodione (square) are shown as those in the organic phase. The enantiopurity of the product (triangle) was determined by gas chromatography

Conversion rates in the aqueous reaction mixture with whole cells and the cell-free extract of the recombinant R. opacus. Either 5 mg of the wet cells (diamond) or 50 μl of the cell-free extract (square), which was prepared from 5 mg of the wet cells, was incubated in a reaction mixture (1 ml) comprised of 1 mM NADH, 100 mM ketoisophorone, 100 mM cyclohexanol, and 20 mM bicine-NaOH (pH 8.0). The reaction was performed at 50 °C with shaking (1,400 rpm) and the concentrations of levodione were determined by GC analysis

Discussion

Use of organic solvents as reaction media for biocatalysis has the potential to greatly expand the repertoire of enzymatic and microbial production of value-added chemicals. Organic-solvent-tolerant microorganisms have attracted considerable attention as a promising tool to develop a biocatalytic conversion system in the presence of a large volume of organic solvents (Verhoef et al. 2008; Yamashita et al. 2007a; Wangrangsimagul et al. 2012; Blank et al. 2008). However, the tolerance of these microorganisms to organic solvents is largely attributed to their abilities to prevent the influx of cytotoxic solvents into the cells using their molecular machineries, including the active efflux of solvents from cell membranes, and the cis–trans isomerization of membrane fatty acids (Neumann et al. 2005; Ramos et al. 1998). Therefore, there seems to be a fundamental contradiction in the application of organic-solvent-tolerant microorganisms to the bioconversion of oil-soluble substrates. Whereas they exhibit excellent metabolic stability under organic-solvent-stress conditions, the conversion rate is only modest because of the poor accessibility between their intracellular enzymes and the substrates (Hamada et al. 2009). Several attempts have been made to promote the interaction between microbial cells and oil-soluble substrates, such as the immobilization of metabolically active cells in surfactant-mediated water-in-oil reverse micelles (Häring et al. 1985; Pfammatter et al. 1989; Stefan et al. 2003), and the development of a continuous bioreactor with engineered catalytic biofilms (Gross et al. 2013).

The solvent dispersibility of lipophilic bacterial cells would provide an alternative method to increase the accessibilities of microbial cells to organic solvents. The wet cells of R. opacus B-4 and related strains are dispersible in water-immiscible hydrocarbons in the form of small cell aggregates without any special pretreatment (Yamashita et al. 2007a; Iwabuchi et al. 2009; Hibino and Ohtake 2013). This feature provides a large specific interfacial area between the organic phase and the catalytic cells, and thus enables a high mass transfer rate of the oil-soluble substrates into the cells. In this study, we demonstrated that a considerably higher conversion rate can be achieved with a lipophilic whole-cell catalyst than that observed in the A/O two-phase reaction with the aqueous enzyme solution (Fig. 5).

Employment of an enzyme with sufficient organic-solvent tolerance is a key issue for developing a stable bioconversion system in organic-reaction media. Several organic-solvent-tolerant microorganisms are known to produce extracellular lipolytic enzymes with a high tolerance to organic solvents (Doukyu and Ogino 2010). However, as described above, the microbial solvent tolerance is often attributed to the ability of their molecular apparatus to prevent the solvent influx. Therefore, unlike the relationship between the growth temperature of microorganisms and the thermal stabilities of their enzymes, it is not reasonable to expect a positive correlation between the solvent tolerances of microorganisms and their intrinsic enzymes. In this study, we focused on the excellent operational stabilities of thermophilic enzymes and screened for thermophiles with an ene reductase activity. Many thermophilic enzymes are known to be tolerant to organic-solvent stresses (Owusu and Cowan 1989), and activities of some thermophilic enzymes are even improved with organic solvents (Pennacchio et al. 2008). In fact, Adalbjörnsson et al. (2010) reported that the thermostable ene reductase of T. pseudethanolicus showed significantly higher tolerance to ethanol than a mesophilic counterpart derived from Enterobacter cloacae. As expected, the Geobacillus ene reductase identified in the present study also exhibited a good tolerance to water-miscible and -immiscible organic solvents at moderate and high temperatures. Moreover, another thermophilic enzyme, which catalyzes the NAD+-dependent dehydrogenation of cyclohexanol, was identified from the gene-expression library of T. thermophilus. The employment of TtADH as a cofactor regenerator enabled us to develop a remarkably simple bioconversion system; except for the catalytic amount of NADH, the reaction mixture of this system was only comprised of the substrates and catalytic cells.

Since the identification of the first flavin-dependent enzyme, numerous studies have been carried out on the structural and functional characterization of the old yellow enzyme family proteins. Although their physiological role still remains to be elucidated, the members of the old yellow enzyme family are known to catalyze the enantioselective reduction of a wide range of activated α,β-unsaturated alkenes (Stuermer et al. 2007; Williams and Bruce 2002; Kataoka et al. 2002). In particular, reduction of ketoisophorone has been well studied owing to the industrial importance of the product, (6R)-levodione, as a chiral building block for the synthesis of stereochemically pure carotinoids (Wada et al. 2003; Kataoka et al. 2004). However, the enzymatic reduction of ketoisophorone often suffers from the low enantiopurity of the product because of the spontaneous racemization of levodione in aqueous reaction media particularly at high temperature (Adalbjörnsson et al. 2010; Fryszkowska et al. 2009). Although the enantiopurity of the product can be markedly improved by reducing the reaction time (thereby reducing substrate/water exposure time), this limitation often leads to an insufficient product titer. By contrast, in this study, both high concentration and high enantiopurity of the product could be achieved because of the elimination of aqueous reaction media.

Elimination of aqueous reaction media can offer practical advantages over conventional A/O two-phase bioconversion systems, such as less reaction volume, higher substrate loads, higher transfer rates of the substrate from the organic media to catalytic cells, simplified downstream processes for product recovery, and mitigation of water-mediated side reactions. Combination of thermophilic enzymes and lipophilic microorganisms is a promising approach for applications of a variety of enzymes to the bioconversion of water-insoluble chemicals.

References

Adalbjörnsson BV, Toogood HS, Fryszkowska A, Pudney CR, Jowitt TA, Leys D, Scrutton NS (2010) Biocatalysis with thermostable enzymes: structure and properties of a thermophilic ‘ene’-reductase related to old yellow enzyme. ChemBioChem 11:197–207

Akkara JA, Ayyagari MSR, Bruno FF (1999) Enzymatic synthesis and modification of polymers in nonaqueous solvents. Trends Biotechnol 17:67–73

Atomi H (2005) Recent progress towards the application of hyperthermophiles and their enzymes. Curr Opin Chem Biol 9:166–173

Blank LM, Ionidis G, Ebert BE, Bühler B, Schmid A (2008) Metabolic response of Pseudomonas putida during redox biocatalysis in the presence of a second octanol phase. FEBS J 275:5173–5190

Bornscheuer UT, Huisman GW, Kazlauskas RJ, Lutz S, Moore JC, Robins K (2012) Engineering the third wave of biocatalysis. Nature 485:185–194

Carrea G, Riva S (2000) Properties and synthetic applications of enzymes in organic solvents. Angew Chem 33:2226–2254

Cirilli R, Ferretti R, La Torre F, Secci D, Bolasco A, Carradori S, Pierini M (2007) High-performance liquid chromatographic separation of enantiomers and diastereomers of 2-methylcyclohexanone thiosemicarbazone, and determination of absolute configuration and configurational stability. J Chromatogr A 1172:160–169

Doukyu N, Ogino H (2010) Organic solvent-tolerant enzymes. Biochem Eng J 48:270–282

Fryszkowska A, Toogood H, Sakuma M, Gardiner JM, Stephens GM, Scrutton NS (2009) Asymmetric reduction of activated alkenes by pentaerythritol tetranitrate reductase: specificity and control of stereochemical outcome by reaction optimization. Adv Synth Catal 351:2976–2990

Gross R, Buehler K, Schmid A (2013) Engineered catalytic biofilms for continuous large scale production of n-octanol and (S)-styrene oxide. Biotechnol Bioeng 110:424–436

Hamada T, Maeda Y, Matsuda H, Sameshima Y, Honda K, Omasa T, Kato J, Ohtake H (2009) Effect of cell-surface hydrophobicity on bacterial conversion of water-immiscible chemicals in two-liquid-phase culture systems. J Biosci Bioeng 108:115–120

Häring G, Luisi PL, Meussdoerffer F (1985) Solubilization of bacterial cells in organic solvents via reverse micelles. Biochem Biophys Res Commun 127:911–915

Hibino A, Ohtake H (2013) Use of hydrophobic bacterium Rhodococcus rhodochrous NBRC15564 expressed thermophilic alcohol dehydrogenases as whole-cell catalyst in solvent-free organic media. Process Biochem 48:838–843

Höllrigl V, Hollmann F, Kleeb AC, Buehler K, Schmid A (2008) TADH, the thermostable alcohol dehydrogenase from Thermus sp. ATN1: a versatile new biocatalyst for organic synthesis. Appl Microbiol Biotechnol 81:263–273

Hudson EP, Eppler RK, Clark DS (2005) Biocatalysis in semi-aqueous and nearly anhydrous conditions. Curr Opin Biotechnol 16:637–643

Iwabuchi N, Sharma PK, Sunairi M, Kishi E, Sugita K, van der Mei HC, Nakajima M, Busscher HJ (2009) Role of interfacial tensions in the translocation of Rhodococcus erythropolis during growth in a two phase culture. Environ Sci Technol 43:8290–8294

Kataoka M, Kotaka A, Hasegawa A, Wada M, Yoshizumi A, Nakamori S, Shimizu S (2002) Old yellow enzyme from Candida macedoniensis catalyzes the stereospecific reduction of the C=C bond of ketoisophorone. Biosci Biotechnol Biochem 66:2651–2657

Kataoka M, Kita K, Wada M, Yasohara Y, Hasegawa J, Shimizu S (2003) Novel bioreduction system for the production of chiral alcohols. Appl Microbiol Biotechnol 62:437–445

Kataoka M, Kotaka A, Thiwthong R, Wada M, Nakamori S, Shimizu S (2004) Cloning and overexpression of the old yellow enzyme gene of Candida macedoniensis, and its application to the production of a chiral compound. J Biotechnol 114:1–9

Klibanov AM (2001) Improving enzymes by using them in organic solvents. Nature 409:241–246

Morimoto Y, Honda K, Ye X, Okano K, Ohtake H (2014) Directed evolution of thermotolerant malic enzyme for improved malate production. J Biosci Bioeng 117:147–152

Nakashima N, Tamura T (2004) Isolation and characterization of a rolling-cycle-type plasmid from Rhodococcus erythropolis and application of the plasmid to multiple-recombinant-protein expression. Appl Environ Microbiol 70:5557–5568

Neumann G, Kabelitz N, Zehnsdorf A, Miltner A, Lippold H, Meyer D, Schmid A, Heipieper HJ (2005) Prediction of the adaptability of Pseudomonas putida DOT-T1E to a second phase of a solvent for economically sound two-phase biotransformations. Appl Environ Microbiol 71:6606–6612

Owusu RK, Cowan DA (1989) Correlation between microbial protein thermostability and resistance to denaturation in aqueous:organic solvent two-phase systems. Enzym Microb Technol 11:568–574

Paul TR, Beveridge TJ (1992) Reevaluation of envelope profiles and cytoplasmic ultrastructure of mycobacteria processed by conventional embedding and freeze-substitution protocols. J Bacteriol 174:6508–6517

Pennacchio A, Pucci B, Secundo F, La Cara F, Rossi M, Raia CA (2008) Purification and characterization of a novel recombinant highly enantioselective short-chain NAD(H)-dependent alcohol dehydrogenase from Thermus thermophilus. Appl Environ Microbiol 74:3949–3958

Pfammatter N, Guadalupe AA, Luisi PL (1989) Solubilization and activity of yeast cells in water-in-oil microemulsion. Biochem Biophys Res Commun 161:1244–1251

Ramos JL, Duque E, Godoy P, Segura A (1998) Efflux pumps involved in toluene tolerance in Pseudomonas putida DOT-T1E. J Bacteriol 180:3323–3329

Sameshima Y, Honda K, Kato J, Omasa T, Ohtake H (2008) Expression of Rhodococcus opacus alkB genes in anhydrous organic solvents. J Biosci Bioeng 106:199–203

Schittmayer M, Glieder A, Uhl MK, Winkler A, Zach S, Schrittwieser JH, Kroutil W, Macheroux P, Gruber K, Kambourakis S, Rozzell JD, Winkler M (2011) Old yellow enzyme-catalyzed dehydrogenation of saturated ketones. Adv Synth Catal 353:268–274

Schmid A, Kollmer A, Mathys RG, Witholt B (1998) Developments toward large-scale bacterial bioprocesses in the presence of bulk amounts of organic solvents. Extremophiles 2:249–256

Stefan A, Palazzo G, Ceglie A, Panzavolta E, Hochkoeppler A (2003) Water-in-oil macroemulsions sustain long-term viability of microbial cells in organic solvents. Biotechnol Bioeng 81:323–328

Stuermer R, Hauer B, Hall M, Faber K (2007) Asymmetric bioreduction of activated C=C bonds using enoate reductase from the old yellow enzyme family. Curr Opin Chem Biol 11:203–213

Sutcliffe IC (1998) Cell envelope composition and organization in the genus Rhodococcus. Antonie Van Leeuwenhoek 74:49–58

Tanaka N, Abe T, Miyazaki S, Sugawara H (2006) G-InforBIO: integrated system for microbial genomics. BMC Bioinforma 7:368

Uchiyama S, Kobayashi S, Takata H, Ishihara T, Hori N, Higashi T, Hayashihara K, Sone T, Higo D, Nirasawa T, Takao T, Matsunaga S, Fukui K (2005) Proteome analysis of human metaphase chromosomes. J Biol Chem 280:16994–17004

Verhoef S, Wierckx N, Westerhof RGM, de Winde JH, Ruijssenaars HJ (2008) Bioproduction of p-hydroxystyrene from glucose by the solvent-tolerant bacterium Pseudomonas putida S12 in a two-phase water–decanol fermentation. Appl Environ Microbiol 75:931–936

Wada M, Yoshizumi A, Noda Y, Kataoka M, Shimizu S, Takagi H, Nakamori S (2003) Production of a doubly chiral compound, (4R,6R)-4-hydroxy-2,2,6-trimethylcyclohexanone, by two-step enzymatic asymmetric reduction. Appl Environ Microbiol 69:933–937

Wang Y, Zhang YHP (2009) Overexpression and simple purification of the Thermotoga maritima 6-phosphogluconate dehydrogenase in Escherichia coli and its application for NADPH regeneration. Microb Cell Factories 8:30

Wangrangsimagul N, Klinsakul K, Vangnai AS, Wongkongkatep J, Inprakhon P, Honda K, Ohtake H, Kato J, Pongtharangkul T (2012) Bioproduction of vanillin using an organic solvent-tolerant Brevibacillus agri 13. Appl Microbiol Biotechnol 93:555–563

Wichmann R, Vasic-Racki D (2005) Cofactor regeneration at the lab scale. Adv Biochem Eng Biotechnol 92:225–260

Williams RE, Bruce NC (2002) ‘New use for an old enzyme’ – the old yellow enzyme family of flavoenzymes. Microbiology 148:1607–1614

Williams RE, Rathbone DA, Scrutton NS, Bruce NC (2004) Biotransformation of explosives by the old yellow enzyme family of flavoproteins. Appl Environ Microbiol 70:3566–3574

Yamashita S, Sameshima Y, Konishi M, Kato J, Kishimoto M, Honda K, Omasa T, Ohtake H (2007a) Integrated biooxidation and acid dehydration process for monohydroxylation of aromatics. Process Biochem 42:46–51

Yamashita S, Satoi M, Iwasa Y, Honda K, Sameshima Y, Omasa T, Kato J, Ohtake H (2007b) Utilization of hydrophobic bacterium Rhodococcus opacus B-4 as whole-cell catalyst in anhydrous organic solvents. Appl Microbiol Biotechnol 74:761–767

Yao S, Mikkelsen MJ (2010) Metabolic engineering to improve ethanol production in Thermoanaerobacter mathranii. Appl Microbiol Biotechnol 88:199–208

Yokoyama S, Hirota H, Kigawa T, Yabuki T, Shirouzu M, Terada T, Ito Y, Matsuo Y, Kuroda Y, Nishimura Y, Kyogoku Y, Miki K, Masui R, Kuramitsu S (2000) Structural genomics projects in Japan. Nat Struct Biol 7:943–945

Zhou Y, Minami T, Honda K, Omasa T, Ohtake H (2010) Systematic screening of Escherichia coli single-gene knockout mutants for improving recombinant whole-cell biocatalysts. Appl Microbiol Biotechnol 87:647–655

Acknowledgments

We thank M. Kataoka for providing the authentic (6R)-levodione. We also thank S. Uchiyama and M. Noda for their technical assistance in mass spectrometric analysis, and G. Fukuhara for his help in CD spectral analysis. This work was supported in part by a Grant-in-Aid for Young Scientist from MEXT, Japan. This work was also partly supported by a JSPS Asian-Core Project.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Tsuji, N., Honda, K., Wada, M. et al. Isolation and characterization of a thermotolerant ene reductase from Geobacillus sp. 30 and its heterologous expression in Rhodococcus opacus . Appl Microbiol Biotechnol 98, 5925–5935 (2014). https://doi.org/10.1007/s00253-014-5668-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-014-5668-9