Abstract

The transformation of explosives, including hexahydro-1,3,5-trinitro-1,3,5-triazine (RDX), by xenobiotic reductases XenA and XenB (and the bacterial strains harboring these enzymes) under both aerobic and anaerobic conditions was assessed. Under anaerobic conditions, Pseudomonas fluorescens I-C (XenB) degraded RDX faster than Pseudomonas putida II-B (XenA), and transformation occurred when the cells were supplied with sources of both carbon (succinate) and nitrogen (NH4 +), but not when only carbon was supplied. Transformation was always faster under anaerobic conditions compared to aerobic conditions, with both enzymes exhibiting a O2 concentration-dependent inhibition of RDX transformation. The primary degradation pathway for RDX was conversion to methylenedinitramine and then to formaldehyde, but a minor pathway that produced 4-nitro-2,4-diazabutanal (NDAB) also appeared to be active during transformation by whole cells of P. putida II-B and purified XenA. Both XenA and XenB also degraded the related nitramine explosives octahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine and 2,4,6,8,10,12-hexanitro-2,4,6,8,10,12-hexaazaisowurtzitane. Purified XenB was found to have a broader substrate range than XenA, degrading more of the explosive compounds examined in this study. The results show that these two xenobiotic reductases (and their respective bacterial strains) have the capacity to transform RDX as well as a wide variety of explosive compounds, especially under low oxygen concentrations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Past and current activities at sites where munitions are manufactured and tested have resulted in the release of munition-related compounds. The environmental fate of these contaminants is an issue of significant concern to the United States Department of Defense (DoD), regulators, and the public because their mobility and persistence allow them to contaminate ground water supplies (Tipton et al. 2003; Yamamoto et al. 2004). Recently, information describing the extent of soil and groundwater contamination at military training ranges has been published (Jenkins et al. 2001; Clausen et al. 2004; Pennington et al. 2006). Several of these compounds have been placed on the U.S. Environmental Protection Agency’s Contaminant Candidate List (http://www.epa.gov/safewater/ccl/ccl3.html#chemical).

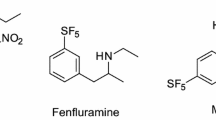

Extensive research has examined the biological transformation of explosive compounds by pure cultures of bacteria and mixed consortia in soil and groundwater (see review of Hawari et al. 2000a). Most research has focused on the dinitrotoluenes (DNT) and 2,4,6-trinitrotoluene (TNT), with interest in hexahydro-1,3,5-trinitro-1,3,5-triazine (RDX) increasing in recent years. RDX biodegradation has been observed under conditions ranging from fully aerobic (Binks et al. 1995; Coleman et al. 1998) to strictly anaerobic (Hawari et al. 2001; Maloney et al. 2002; Adrian et al. 2003; Pudge et al. 2003; Adrian and Arnett 2004; Bhatt et al. 2005), and at least three major degradation pathways have been elucidated (Fig. 1). Anaerobic processes involve either a direct attack on the ring structure or the successive reduction of the pendant nitro groups followed by ring cleavage (McCormick et al. 1981; Hawari et al. 2000a). Many bacterial strains can utilize RDX as a sole nitrogen source (Boopathy et al. 1998; Zhao et al. 2003; Thompson et al. 2005), but only recently has the use of RDX as a sole source of carbon, nitrogen, and energy by a single organism (Thompson et al. 2005) and mixed cultures (Adrian and Arnett 2006) been reported. Several bacterial enzyme systems that degrade RDX have been identified, including the XplA/XplB system of a number of geographically dispersed rhodococci (Jackson et al. 2007; Seth-Smith et al. 2008), the diaphorase of clostridia (Bhushan et al. 2002), and the type I nitroreductases of two enterobacteria (Kitts et al. 2000).

The degradation of nitroglycerin and TNT by the xenobiotic reductases (XenA and XenB) from the aerobes Pseudomonas putida II-B and Pseudomonas fluorescens I-C has been explored (Blehert et al. 1999; Pak et al. 2000). Though XenA and XenB are both members of the Old Yellow Enzyme family (flavoprotein oxidoreductases) and catalyze similar reactions, there are significant differences in the catalytic rates and substrate specificities between the two. For example, purified XenB catalyzes the transformation of TNT ∼5-fold faster than XenA, whereas the catalytic rates with nitroglycerin (NG) are approximately equal. However, XenA preferentially denitrates NG at the terminal positions (1 and 3 positions), whereas XenB preferentially denitrates NG at the interior position (2 position). Furthermore, the rate of TNT transformation by XenB was only slightly enhanced under anaerobic conditions, but the product distribution resulting from TNT transformation varied greatly under anaerobic conditions. Transformation of RDX by these enzymes was not characterized.

In the present study, the effect of decreasing O2 tension on the catalytic characteristics of XenA and XenB expressed in their native bacterial hosts and as purified enzymes were explored. The results reveal that both enzymes are capable of degrading RDX, octahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine (HMX), and a suite of related energetic compounds under reduced O2 concentrations, but not necessarily under fully aerobic conditions. The observation that RDX can be degraded by aerobic organisms under reduced oxygen tensions could lead to enhanced bioremediation technologies and a better understanding of natural attenuation process.

Materials and methods

Chemicals

All chemicals were reagent grade or purer. The three nitroso-containing metabolites (hexahydro-1-nitroso-3,5-dinitro-1,3,5-triazine; hexahydro-1,3-dinitroso-5-nitro-1,3,5-triazine; and hexahydro-1,3,5-trinitroso-1,3,5-triazine) of RDX were purchased from SRI International (Menlo Park, CA, USA). RDX (7% HMX as a manufacturing impurity) was a gift from James Phelan at Sandia National Laboratories (Albuquerque, NM, USA). HMX was a gift from Herb Fredrickson at the U.S. Army Engineer Research and Development Center (Environmental Laboratory, Vicksburg, MS, USA). [14C]-RDX (specific activity = 60.0 mCi/mmol) was purchased from PerkinElmer Life Sciences (Boston, MA, USA). The manufacturer stated the [14C]-RDX radiochemical purity of 99.9% based on radiochromatography. CL-20 (2,4,6,8,10,12-hexanitro-2,4,6,8,10,12-hexaazaisowurtzitane) was obtained from ATK Launch Systems (Corinne, Utah, USA). Neat standards of nitroaromatic compounds were purchased from ChemService (West Chester, PA, USA).

Bacterial strains

P. putida II-B and P. fluorescens I-C were maintained on R2A agar. The two strains were deposited in the open collection of the Agricultural Research Service (ARS) Culture Collection, National Center for Agricultural Utilization Research of the U.S. Department of Agriculture. The accession number of P. putida II-B is NRRL B-50270, and the accession number of P. fluorescens I-C is NRRL B-59269.

Whole cell biotransformation assays

P. putida II-B and P. fluorescens I-C possessing the xenA and xenB genes, respectively, were screened for transformation of RDX, HMX, and CL-20. A basal salts medium (BSM) (Hareland et al. 1975) was used for screening. The carbon source was succinate. Inocula were prepared by growing the strains in BSM plus succinate overnight, followed by concentration and washing of the cells twice with nitrogen-free BSM. The washed cells were used to inoculate vials (40 mL) of BSM medium (20 mL) amended with sodium succinate (6.2 mM) and RDX (22 µM) or HMX (∼3 µM). The initial optical density of the cultures at 550 nm (OD550) was approximately 0.15 (corresponding to 0.3 mg total cell protein per vial). Vials were incubated at room temperature with shaking, and samples were removed periodically, passed through 0.45 µm glass microfiber filters into 2-mL glass sample vials, and analyzed for RDX, HMX, and breakdown products by high-performance liquid chromatography (HPLC; see below). Aerobic vials were equipped with vents to allow 0.2-μm filtered air to enter and maintain oxygen concentrations. Experiments performed under anaerobic conditions were prepared, incubated, and sampled in a Coy anaerobic chamber (Coy Laboratory Products, Grass Lake, MI, USA).

Transformation of CL-20 (∼2 μM initial concentration) by the Pseudomonas strains was performed similarly, except that the screening was performed in polypropylene tubes instead of glass to prevent abiotic loss of CL-20 (Monteil-Rivera et al. 2004). Anaerobic treatments were prepared and incubated in an anaerobic glove box. Samples were removed periodically and centrifuged in polypropylene microfuge tubes to remove biomass, and the supernatant was transferred to polypropylene HPLC vials for analysis.

The effect that changes in the RDX concentration had on the rate and extent of transformation by P. putida II-B and P. fluorescens I-C was examined by adding washed cells to anaerobic BSM plus succinate amended with RDX at concentrations of 3, 13, 31, 63, and 126 μM. Samples were removed periodically and analyzed by HPLC. Direct toxicity of RDX (at 0, 86, and 153 μM) to these two strains was examined by monitoring cell density at 550 nm during aerobic growth in BSM plus succinate (a condition under which RDX was not degraded).

Production of nitrous oxide (N2O) and nitrite (NO -2 ) from RDX were determined by incubating cultures of P. putida II-B and P. fluorescens I-C with RDX and periodically removing samples of the headspace and liquid for analysis (see analytical section below). To identify the less common RDX breakdown products, cultures were incubated with ∼90 μM of RDX at room temperature with shaking, then frozen at −70°C after approximately 50% of the initial RDX had degraded. Frozen samples were shipped on dry ice to the Biotechnology Research Institute, National Research Council Canada for more extensive analysis of RDX breakdown products according to previously described methods (Hawari et al. 2000b).

Cell-free enzyme assays

Several experiments were performed to assess the catalytic properties of the xenobiotic reductases of P. putida II-B and P. fluorescens I-C, which were isolated and purified as previously described (Blehert et al. 1997; Pak et al. 2000). The explosive transformation assays were performed with the test compounds dissolved in sodium phosphate buffer (100 mM, pH 7.4). NADPH was added to a final concentration of 1.5 to 4.5 mM. Vials were purged with at least 20 volumes of O2-free N2 bubbled through the liquid, then transferred to an anaerobic chamber where 1 mL of the solutions were transferred to 2-mL glass screw cap auto-sampler vials (or polypropylene vials in the case of the explosive CL-20) and sealed with Teflon lined septa. To examine the effect of O2 on the rate of RDX and HMX transformation, pure O2 gas was added via a syringe needle inserted through the septum of the vial to bring the headspace O2 concentration up to the desired percentage on a (v/v) basis with the headspace and vigorously shaken. An assay was initiated by injecting 1 μL of purified XenB (0.017 mg) or 1 to 5 μL of purified XenA (0.014 to 0.070 mg) through the septum. For kinetic assays, the vials were automatically and repeatedly analyzed via HPLC (see below). Negative controls composed of substrate, buffer, and NADPH were included in all experiments and were used to detect and adjust for any non-enzymatic substrate losses.

The aerobic and anaerobic degradation rates of a range of explosive compounds with XenB were examined. Assays were performed as described, except that the amount of XenB protein was adjusted as needed to assure that degradation did not occur faster than could be measured based on the HPLC analysis times for a given compound. Assays were performed in duplicate, and the initial linear rates were calculated as micromoles compound degraded per milligram XenB protein per minute. Non-kinetic experiments were performed with the XenA enzyme in which only the 24-h endpoint result (degradation/no degradation) was measured. Degradation of CL-20 by both XenA and XenB was also assessed by an endpoint assay.

To determine if RDX was converted to MNX during transformation by XenB, an experiment utilizing radiolabeled RDX was conducted. Briefly, the enzyme assay procedure described above was followed, except that the XenB and XenA enzymes were mixed with 78 μM of MNX and 54 μM [14C]-RDX. Unlabeled MNX was included in the assay so that if very small amounts of MNX were being formed and subsequently degraded by XenB during the transformation of RDX, the large pool of unlabelled MNX would slow down the degradation of the enzymatically formed [14C]-MNX, which could then be detected using scintillation counting. The reaction vial was repeatedly sampled, and the loss of the target substrates was monitored via HPLC as described below, except that the HPLC eluant was also collected at 20-s intervals into scintillation vials pre-filled with 3 mL of Optiphase HiSafe scintillation cocktail (Perkin-Elmer, Boston MA, USA). The time of elution of the radioactive peaks was compared with the elution time of the known explosive compounds and metabolites (RDX, MNX, DNX, and TNX) to determine if any of the [14C]-RDX was being converted to [14C]-MNX or other related compounds. Under the analytical conditions described below, there is more than a full minute separating the elution of MNX and RDX, which would be easily resolved with the described protocol.

Analytical

Other than the analysis for the less common breakdown products of RDX performed by Biotechnology Research Institute noted above, the concentrations of the explosives and their common breakdown products in all experiments were determined using HPLC according to a modified EPA Method 8330A (http://www.epa.gov/epawaste/hazard/testmethods/sw846/pdfs/8330a.pdf) using a Hewlett-Packard 1100 HPLC equipped with a Allure C18 column (Restek, Bellefonte, PA, USA) and a UV detector (230 nm). The mobile phase was 50:50 methanol/water at a flow rate of 0.9 mL/min. The column temperature was 25°C. The lower detection limit was approximately 0.1 µM for RDX and 0.25 µM for the RDX breakdown products. CL-20 was analyzed on the same system, except that the mobile phase was adjusted to 55:45 methanol/water, and detection was at performed at 228 nm. Analytical standards of the parent explosive compounds (except CL-20) were obtained from Restek (Bellefonte, PA, USA). The standard for CL-20 was prepared from the neat material obtained from ATK Launch Systems (Corinne, Utah, USA). The standards for MNX, DNX, and TNX were prepared from the neat material obtained from SRI International (Menlo Park, CA, USA). Identity of peaks in the samples was based on retention time matching to peaks in the standards.

Nitrous oxide was measured using GC-TCD. Nitrite was determined colorimetrically (Hach Company, Loveland, CO, USA). Ammonia was measured spectrofluorometrically (Holmes et al. 1999). Hydrogen peroxide production by purified enzymes in the presence of oxygen was detected and quantified using either the Quantofix Peroxide Detection Kit (Macherey-Nagel, Bethlehem, PA, USA) or the Amplex Red Hydrogen Peroxide/Peroxidase Assay Kit (Invitrogen, Carlsbad, CA, USA) with fluorometric analysis using SpectraMax Gemini fluorescent plate reader (Molecular Devices, Sunnyvale, CA, USA).

Results

Transformation of RDX and other explosives by whole cells

During initial experiments, the two Pseudomonas strains examined here were able to degrade TNT under aerobic conditions, but no aerobic transformation of RDX, HMX, or CL-20 was observed (data not shown). Under anaerobic conditions, transformation of RDX was observed with P. putida II-B and P. fluorescens I-C (Fig. 2a). HMX was degraded anaerobically only by P. fluorescens I-C (Fig. 2b). The apparent first-order rate for RDX disappearance was about 14-fold higher for P. fluorescens I-C as compared to P. putida II-B (0.0084/h vs. 0.0006/h) at an initial RDX concentration of 31 μM. The RDX transformation rates of P. putida II-B and P. fluorescens I-C appeared to be concentration dependent. The transformation rate decreased 3- and 10-fold for P. putida II-B and P. fluorescens I-C, respectively, as the initial RDX concentration increased from 3 to 126 μM. However, the aerobic growth of these two strains was not affected by the presence of RDX even at 153 μM. When incubated under conditions in which an initially aerobic medium was allowed to become O2-depleted during the growth of the culture, both P. putida II-B and P. fluorescens I-C degraded RDX, but only P. fluorescens I-C degraded HMX. Transformation of CL-20 was observed by pure cultures under anaerobic conditions, with P. fluorescens I-C degrading the compound much faster than P. putida II-B (Fig. 2c). These findings suggested that O2 either inhibited the expression or the activity of the catalytic enzymes in these strains.

Degradation of a RDX, b HMX (in the presence of RDX), and c CL-20 by pure cultures of Pseudomonas spp. under anaerobic conditions. Sterile control (triangles); P. putida II-B (circles); P. fluorescens I-C (squares). Data points for live cultures represent average of two replicate vials; a single sterile control vial was used during RDX and HMX experiments. Error bars represent one standard deviation of the mean. Note difference in y-axis scales

RDX transformation by purified XenA and XenB enzymes

In order to assure that results of the whole cell degradation assays could be attributed to specific enzyme activities, experiments using purified XenA and XenB were conducted. Initial studies indicated that RDX was not degraded via a direct reduction of the nitro group (i.e., no nitroso-containing products were detected by HPLC), so a more detailed analysis of the transformation products was performed (Table 1). The product distribution resulting from RDX degradation differed not only between the XenA and XenB, but also between the purified enzymes and their source organisms. With both purified enzymes, the major products that accumulated indicated that RDX was degraded via the methylenedinitramine (MEDINA) pathway (Fig. 1, Anaerobic II pathway), yet MEDINA did not accumulate and was not detected in whole cell incubations. Formaldehyde was a major product of RDX metabolism by purified XenA and by XenB, whether assays were performed with pure enzymes or in whole cells. The carbon mass balances for the degradation of RDX by the enzymes and whole cells ranged from 60% to 100% (mole C basis). With purified XenA, production of trace amounts of 4-nitro-2,4-diazabutanal (NDAB) and MNX suggested that minor reactions occurred with this enzyme that did not occur with XenB. However, detection of MNX was not observed using the modified EPA Method 8330 and is therefore not believed to be produced from RDX by these enzymes. Indeed, the [14C]-RDX/MNX experiment gave no evidence that XenA or XenB produced MNX during the breakdown of RDX. All of the RDX-derived radioactivity was contained in a broad peak that eluted well before the unlabelled MNX peak. Furthermore, the rate of degradation of RDX by XenB is ∼10-fold faster than the degradation of MNX, which would have been expected to result in a buildup of [14C]MNX from [14C]RDX. This experiment, therefore, showed conclusively that MNX was not a typical product of RDX breakdown by XenB.

Nitrogen mass balances ranged from 56% to 78%. As shown in Fig. 1 (Anaerobic II pathway), RDX can be converted to MEDINA and bis(hydroxymethyl)nitramine, and these compounds decay to form formaldehyde and nitramide, the latter of which may further break down to form nitrous oxide and nitrogen gas (Hawari 2004). Therefore, measurement of these inorganic nitrogenous products was performed, and percentages were calculated on the basis of the nitrogen present in the amount of RDX degraded during a given experiment. Nitrous oxide was not detected during RDX degradation with the purified enzymes, but small amounts of nitrous oxide (1 to 2 mol%) were detected during whole cell assays. Nitrite was detected during RDX degradation by purified XenB at a level of ∼17 mol%. Nitrite was detected in whole cell assays with P. putida II-B and P. fluorescens I-C at levels ∼2 and ∼12 mol%, respectively. Ammonia was detected during transformation of RDX by whole cells at levels equal to ∼15 mol% and during degradation of RDX by XenB (∼23 mol%). However, the possibility that the assay was actually detecting one or more of the possible RDX breakdown products (e.g., nitramide) rather than ammonia could not be ruled out. Inclusion of these inorganic nitrogenous products increased the nitrogen mass balances of the products produced during RDX transformation by P. putida II-B and P. fluorescens I-C to 75% and 102%, respectively (compared to 56% and 74% based on only the organic products with nitrogen are considered; Table 1). Similarly, the overall nitrogen mass balance for RDX degradation by XenB was increased to 118% when both organic and inorganic nitrogenous products are considered.

Because HMX is a common contaminant of RDX preparations and because the two compounds are often found together in the environment, we investigated whether HMX was degraded sequentially or consecutively with RDX. With purified XenB, little to no HMX (present at approximately 10% the RDX concentration) was degraded in the presence of high concentrations of RDX. However, when RDX and HMX were present at approximately equal concentrations, HMX and RDX were degraded simultaneously by XenB. Similarly, in a mixture of RDX and the common breakdown products MNX, DNX, and TNX, XenB degraded all the compounds simultaneously.

Additional experiments were performed to determine the O2 inhibition characteristics for RDX and HMX transformation. While XenB degraded RDX much faster than XenA (∼30-fold), both enzyme systems had similar O2 inhibition characteristics (Fig. 3a and b). A similar effect was noted when HMX served as a substrate for XenB (Fig. 3c). The percentage of saturation for O2 that resulted in a 50% reduction in the initial linear degradation rates (derived from Fig. 3) were 1.5 ± 0.3% and 1.6 ± 0.3% for RDX degradation by XenA and XenB, respectively, and 2.3 ± 0.4% for HMX degradation by XenB.

Degradation of RDX by purified a XenA and b XenB enzymes and c HMX by purified XenB enzyme under different initial oxygen concentrations. The initial concentrations of RDX and HMX were 55, 83, and 9 μM in a, b, and c, respectively. Control contained ambient oxygen concentration (∼20%). Each line represents data from two duplicate vials that were alternatingly sampled during the course of the experiment; therefore, no error bars were calculated. Note difference in x-axis scales

Aerobic and anaerobic transformation of various explosives by XenA and XenB

A screening-level study of purified XenA and XenB was performed to assess their ability to degrade a range of nitroaromatic and nitramine explosive compounds under aerobic and anaerobic conditions. With XenB, ten of the compounds were degraded aerobically and 14 were degraded anaerobically (Table 2). The rates of degradation of the other compounds relative to the degradation rate of TNT varied considerably. The rate of aerobic TNT degradation by the XenB enzyme was 0.155 μmol/mg protein/min, which is within a factor of four of the specific activity based on previously published data (Pak et al. 2000). The degradation rate observed for TNB and tetryl were greater than for TNT under both aerobic and anaerobic conditions, while all the other nitroaromatic compounds were degraded slower than TNT. Among the nitramine compounds, the relative activity of XenB against RDX was the highest and that of HMX was the lowest, in both the presence and absence of oxygen.

Of the 16 compounds tested by an endpoint assay with XenA (tetryl was not tested with XenA), six were degraded by XenA under aerobic conditions, and nine were degraded anaerobically (data not shown). RDX, TNT, 2,4-DNT, 1,3-DNB, and TNB were degraded by XenA under both aerobic and anaerobic conditions. The RDX breakdown products MNX, DNX, and TNX, as well as HMX, were only degraded under anaerobic conditions by XenA (within the timeframe of the assays). Additionally, both the XenA and XenB purified enzymes degraded the relatively new explosive compound CL-20.

Discussion

Only a single previous report has described the aerobic transformation of the nitramine explosive RDX by a Pseudomonas sp., though the enzymes involved and the degradation pathway were not discussed (Chang et al. 2004). In our study, RDX and HMX transformation by two Pseudomonas sp. strains occurred under strictly anaerobic conditions, as well as under “anoxic” conditions created as cells consumed dissolved O2 while growing on succinate. The biodegradation pathway described herein for RDX by purified xenobiotic reductases and whole cells of P. putida II-B and P. fluorescens I-C leads to more labile products (formaldehyde) and less toxic (nitrous oxide) products, rather than the more toxic nitrosolated compounds like those produced during other anaerobic processes (Adrian and Sutherland 1999; Zhang and Hughes 2003) or dead-end products like NDAB that is produced during aerobic transformation by some Rhodococcus spp. (Fig. 1, Aerobic pathway). These products do not persist in the environment and thus are a more desirable end point for bioremediation applications.

Unlike previously described Rhodococcus spp. (Coleman et al. 1998; Nejidat et al. 2008), RDX transformation by pure cultures in this study was not inhibited, but rather was facilitated, by the presence of utilizable nitrogen (NH4 +). Transformation rates by whole cells decreased with increasing RDX concentrations, whereas the RDX transformation rate from purified XenB increased with increasing RDX concentration. Additionally, the aerobic growth rates of P. putida II-B and P. fluorescens I-C were not inhibited with increasing RDX concentration. Taken together, these results suggest that although RDX itself is not toxic to either the cells or the degradative enzymes described here, the breakdown products may exert toxicity by an unknown mechanism. This finding is in general agreement with previous results showing toxicity in another pseudomonad during aerobic transformation of RDX (Chang et al. 2004).

Previous studies with xenobiotic reductases (and related enzymes) have shown that the presence of O2 can impact the transformation of explosive compounds in more than one way. For example, Pak et al. (2000) noted that while TNT was degraded by XenB both aerobically and anaerobically, the presence of O2 changed the product distribution. Most notably, certain TNT dimers accumulated, resulting in the release of nitrite only in the presence of O2 (or other oxidants such as NADP+) via an abiotic mechanism. In another study investigating degradation of RDX by three Enterobacteriaceae isolates, O2 also played a key role in the final outcome, as RDX was degraded only under oxygen-depleted conditions (Kitts et al. 1994). Similarly, it was reported that RDX degradation by Klebsiella pneumoniae strain SCZ-1 was completely quenched by the presence of O2, though the concentrations of O2 required to stop RDX degradation was not reported (Zhao et al. 2002).

In the present study, O2 had a large impact on the activity of XenA and XenB. Several compounds that were not degraded (or degraded very slowly) aerobically were degraded under anaerobic conditions, and the rates of degradation observed during kinetic assays with XenB were always higher under anaerobic compared to aerobic conditions. RDX and HMX were among the compounds for which this was observed and studied in more detail. It is important to note that O2 did not function as a binary on/off switch for the transformation of RDX and HMX, but rather it caused a gradual decrease in RDX transformation as a function of the initial O2 concentration (Fig. 3). The mechanism by which oxygen interferes with the degradation of explosives has not yet been conclusively determined. Hydrogen peroxide was produced when XenB was incubated in the presence of NADPH and oxygen, but it was not observed in the absence of oxygen (data not presented). This would seem to indicate that oxygen is reduced by XenB in the absence of a more preferred substrate. Therefore, the concentration of oxygen would compete with explosive compounds for the active site of XenB and affect the degradation rates.

These results greatly expand the known substrate range of both XenA and XenB. Although only screening-level data were obtained and more mechanistic studies are warranted, some observations and possible explanations for the observed differences in degradation rates are presented here. Degradation rates increased as the degree of nitro-substitution increased for both the toluene (TNT > DNTs >> NTs) and the benzene (TNB > DNB >> NB) series under both aerobic and anaerobic conditions. Lack of activity of XenB against the mononitrotoluenes (2-, 3-, and 4-NT) was previously reported (Pak et al. 2000). It is interesting to note that the relative activity of XenB against 2,4-DNT was higher compared to 2,6-DNT under both aerobic and anaerobic conditions. These results also comport with the work of Pak et al. (2000), as well as previous literature reports indicating that the 2,4 isomer is generally more labile than the 2,6 isomer of DNT (Nishino et al., 1999; Nishino et al. 2000).

Of the nitramine explosives, RDX was degraded the fastest, followed by the nitroso-amines (in the order mononitroso > dinitroso > trinitroso) and then HMX. The decreasing degradation rate with increasing number of nitroso moieties seems to be counter-intuitive with respect to steric controls on the rate since the nitroso groups (–NO) would be expected to be less bulky than the nitro groups (–NO2), allowing the enzyme easier access. The observed rates may reflect the inherent specificity of some part of the XenB enzyme peripheral to the active site with preferences for nitro groups over nitroso groups. However, there must also be enough flexibility in these areas of the enzyme to allow some recognition of the nitroso moiety or TNX would not be expected to degrade at all. The difference in rates between RDX and HMX likely reflects the differences in the conformation of the heterocyclic rings, which affect the interaction of the active site of the enzyme with the molecule.

This work also adds to the information base for the new energetic compound CL-20. CL-20 was developed as more powerful and less sensitive replacement for RDX and HMX (Trott et al. 2003). In general, CL-20 has been found to be more labile than RDX in soil (Balakrishnan et al. 2004; Crocker et al. 2005). Our studies have demonstrated anaerobic transformation of CL-20 by purified xenobiotic reductase enzymes and whole cells. This new information adds to the few previously published reports, which demonstrated the transformation of CL-20 by monooxygenases (Bhushan et al. 2004b), nitroreductases (Bhushan et al. 2004a), and membrane-associated flavoenzymes (Bhushan et al. 2003).

The addition of RDX, HMX, and CL-20 to the list of known substrates for the xenobiotic reductases, under reduced O2 tension, has important implications for bioremediation efforts, assuming that ability to degrade these explosives is a common characteristic among xenobiotic reductases. Basic research in environmental microbiology is often directed toward the isolation and characterization of bacterial strains that use a target compound as a sole source nutrient (for carbon, nitrogen, or energy). However, actual field-scale bioremediation is dominated by biostimulation approaches (i.e., addition of nutrients to stimulate the indigenous microbial community) rather than the addition of specific strains, which derive nutrients from a pollutant. The results reported here support the practice of general biostimulation approaches to effect remediation of explosives-contaminated sites as follows: (1) Transformation occurs under a relatively broad range of O2 concentrations (anoxic to anaerobic); (2) transformation is not inhibited by the presence of utilizable nitrogen; and (3) transformation is performed by a class of enzyme that is widespread among bacterial genera. Several studies in our laboratory examining the microbial ecology of RDX biodegradation have detected Pseudomonas spp. 16S rDNA sequences in RDX-degrading enrichments were derived from groundwater from an explosives manufacturing site (unpublished data). Furthermore, given the widespread distribution of Pseudomonas spp. in the environment, it is likely that these organisms play a larger role in the transformation of nitramine explosives than previously thought, which could be further expanded when environmental conditions are manipulated to maximize their degradative potential.

References

Adrian NR, Arnett CM (2004) Anaerobic biodegradation of hexahydro-1, 3, 5-trinitro-1, 3, 5-triazine (RDX) by Acetobacterium malicum strain HAAP-1 isolated from a methanogenic mixed culture. Curr Microbiol 48:332–340. doi:https://doi.org/10.1007/s00284-003-4156-8

Adrian NR, Arnett CM (2006) Hexahydro-1,3,5-trinitro-1,3,5-triazine (RDX) serves as a carbon and energy source for a mixed culture under anaerobic conditions. Curr Microbiol 53:129–134. doi:https://doi.org/10.1007/s00284-005-0348-8

Adrian N and Sutherland K (1999) RDX biodegradation by a methanogenic enrichment culture obtained from an explosives manufacturing wastewater treatment plant. U.S. Army Corps of Engineers, Construction Engineering Research Laboratories. 99/15

Adrian NR, Arnett CM, Hickey RF (2003) Stimulating the anaerobic biodegradation of explosives by the addition of hydrogen or electron donors that produce hydrogen. Water Res 37:3499–3507. doi:https://doi.org/10.1016/S0043-1354(03)00240-9

Balakrishnan VK, Monteil-Rivera F, Gautier MA, Hawari J (2004) Sorption and stability of the polycyclic nitramine explosive CL-20 in soil. J Environ Qual 33:1362–1368

Bhatt M, Zhao J-S, Monteil-Rivera F, Hawari J (2005) Biodegradation of cyclic nitramines by tropical marine sediment bacteria. J Indust Microbiol Biotechnol 32:261–267. doi:https://doi.org/10.1007/s10295-005-0239-9

Bhushan B, Halasz A, Spain JC, Hawari J (2002) Diaphorase catalyzed biotransformation of RDX via N-denitration mechanism. Biochem Biophys Res Commun 296:779–784

Bhushan B, Paquet L, Spain JC, Hawari J (2003) Biotransformation of 2,4,6,8,10,12-hexanitro-2,3,6,8,10,12-hexaazaisowurtzitane (CL-20) by denitrifying Pseudomonas sp. strain FA1. Appl Environ Microbiol 69:5216–5221. doi:https://doi.org/10.1128/AEM.69.9.5216-5221.2003

Bhushan B, Halasz A, Hawari J (2004a) Nitroreductase catalyzed biotransformation of CL-20. Biochem Biophys Res Commun 322:271–276. doi:https://doi.org/10.1016/j.bbrc.2004.07.115

Bhushan B, Halasz A, Spain JC, Hawari J (2004b) Initial reaction(s) in biotransformation of CL-20 is catalyzed by salicylate 1-monooxygenase from Pseudomonas sp. strain ATCC 29352. Appl Environ Microbiol 70:4040–4047. doi:https://doi.org/10.1128/AEM.70.7.4040-4047.2004

Binks PR, Nicklin S, Bruce NC (1995) Degradation of hexahydro-1, 3, 5-trinitro-1, 3, 5-triazine (RDX) by Stenotrophomonas maltophilia PB1. Appl Environ Microbiol 61:1318–1322

Blehert DS, Knoke KL, Fox BG, Chambliss GH (1997) Regioselectivity of nitroglycerin denitration by flavoprotein nitroester reductases purified from two Pseudomonas species. J Bacteriol 179:6912–6920

Blehert DS, Fox BG, Chambliss GH (1999) Cloning and sequence analysis of two Pseudomonas flavoprotein xenobiotic reductases. J Bacteriol 181:6254–6263

Boopathy R, Gurgas M, Ullian J, Manning JF (1998) Metabolism of explosive compounds by sulfate-reducing bacteria. Curr Microbiol 37:127–131. doi:https://doi.org/10.1007/s002849900350

Chang H-W, Kahng H-Y, Kim S-I, Chun J-W, Oh K-H (2004) Characterization of Pseudomonas sp. HK-6 cells responding to explosive RDX (hexahydro-1,3,5-trinitro-1,3,5-triazine). Appl Microbiol Biotechnol 65:323–329. doi:https://doi.org/10.1007/s00253-004-1556-z

Clausen J, Robb J, Curry D, Korte N (2004) A case study of contamination on military ranges: Camp Edwards, Massachusetts, USA. Environ Pollut 129:13–21. doi:https://doi.org/10.1016/j.envpol.2003.10.002

Coleman NV, Nelson DR, Duxbury T (1998) Aerobic biodegradation of hexahydro-1,3,5-trinitro-1,3,5-triazine (RDX) as a nitrogen source by a Rhodococcus sp., strain DN22. Soil Biol Biochem 30:1159–1167. doi:https://doi.org/10.1016/S0038-0717(97)00172-7

Crocker FH, Thompson KT, Szecsody JE, Fredrickson HL (2005) Biotic and abiotic degradation of CL-20 and RDX in soils. J Environ Qual 34:2208–2216

Hareland WA, Crawford RL, Chapman PJ, Dagley S (1975) Metabolic function and properties of 4-hydroxyphenylacetic acid 1-hydroxylase from Pseudomonas acidovorans. J Bacteriol 121:272–285

Hawari J (2004) Microbial Degradation of RDX and HMX (Project ER-1213). Strategic Environmental Research and Development Program (SERDP)—Final Report (http://www.serdp.org/Research/upload/CU-1213-FR-01.pdf)

Hawari J, Beaudet S, Halasz A, Thiboutot S, Ampleman G (2000a) Microbial degradation of explosives: biotransformation versus mineralization. Appl Microbiol Biotechnol 54:605–618. doi:https://doi.org/10.1007/s002530000445

Hawari J, Halasz A, Sheremata T, Beaudet S, Groom C, Paquet L, Rhofir C, Ampleman G, Thiboutot S (2000b) Characterization of metabolites during biodegradation of hexahydro-1, 3, 5-trinitro-1, 3, 5-triazine (RDX) with municipal anaerobic sludge. Appl Environ Microbiol 66:2652–2657

Hawari J, Halasz A, Beaudet S, Paquet L, Ampleman G, Thiboutot S (2001) Biotransformation routes of octahydro-1, 3, 5, 7-tetranitro-1, 3, 5, 7-tetrazocine by municipal anaerobic sludge. Environ Sci Technol 35:70–75. doi:https://doi.org/10.1021/es0013531

Holmes RM, Aminot A, Kérouel R, Hooker BA, Peterson BJ (1999) A simple and precise method for measuring ammonium in marine and freshwater ecosystems. Can J Fish Aquat Sci 56:1801–1808

Jackson RG, Rylott EL, Fournier D, Hawari J, Bruce NC (2007) Exploring the biochemical properties and remediation applications of the unusual explosive-degrading P450 system XplA/B. Proc Nat Acad Sci 104:16822–16827

Jenkins TF, Pennington JC, Ranney TA, Berry TE, Jr., Miyares PH, Walsh ME, Hewitt AD, Perron NM, Parker LV, Hayes CA, Wahlgren EG (2001) Characterization of explosives contamination at military firing ranges. U.S. Army Corps of Engineers, Engineer Research and Development Center. ERDC TR-01-5

Kitts CL, Cunningham DP, Unkefer PJ (1994) Isolation of three hexahydro-1, 3, 5-trinitro-1, 3, 5-triazine-degrading species of the family Enterobacteriaceae from nitramine explosive contaminated soil. Appl Environ Microbiol 60:4608–4611

Kitts CL, Green CE, Otley RA, Alvarez MA, Unkefer PJ (2000) Type I nitroreductase in soil enterobacteria reduce TNT (2, 4, 6-trinitrotoluene) and RDX (hexahydro-1, 3, 5-trinitro-1, 3, 5-triazine). Can J Microbiol 46:278–282

Maloney SW, Adrian NR, Hickey RF, Heine RL (2002) Anaerobic treatment of pinkwater in a fluidized bed reactor containing GAC. J Hazard Mater 92:77–88. doi:https://doi.org/10.1016/S0304-3894(01)00375-2

McCormick NG, Cornell JH, Kaplan AM (1981) Biodegradation of hexahydro-1, 3, 5-trinitro-1, 3, 5-triazine. Appl Environ Microbiol 42:817–823

Monteil-Rivera F, Paquet L, Deschamps S, Balakrishnan VK, Beaulieu C, Hawari J (2004) Physico-chemical measurements of CL-20 for environmental applications: Comparison with RDX and HMX. J Chromatogr A 1025:125–132. doi:https://doi.org/10.1016/j.chroma.2003.08.060

Nejidat A, Kafka L, Tekoah Y, Ronen Z (2008) Effect of organic and inorganic nitrogenous compounds on RDX degradation and cytochrome P-450 expression in Rhodococcus strain YH1. Biodegradation 19:313–320. doi:https://doi.org/10.1007/s10532-007-9137-3

Nishino SF, Spain JC, Lenke H, Knackmuss H-J (1999) Mineralization of 2, 4- and 2, 6-dinitrotoluene in soil slurries. Environ Sci Technol 33:1060–1064. doi:https://doi.org/10.1021/es9808301

Nishino SF, Paoli GC, Spain JC (2000) Aerobic degradation of dinitrotoluenes and pathway for bacterial degradation of 2, 6-dinitrotoluene. Appl Environ Microbiol 66:21239–22147

Pak JW, Knoke KL, Noguera DR, Fox BG, Chambliss GH (2000) Transformation of 2, 4, 6-trinitrotoluene by purified xenobiotic reductase B from Pseudomonas fluorescens I-C. Appl Environ Microbiol 66:4742–4750

Pennington JC, Jenkins TF, Ampleman G, Thiboutot S, Brannon JM, Hewitt AD, Lewis J, Brochu S, Diaz E, Walsh MR, Walsh ME, Taylor S, Lynch JC, Clausen J, Ranney TA, Ramsey CA, Hayes CA, Grant CL, Collins CM, Bigl SR, Yost SL, Dontsova KM (2006) Distribution and fate of energetics on DoD test and training ranges: Final report. U.S. Army Engineer Research and Development Center, Environmental Laboratory. ERDC TR-06-13

Pudge IB, Daugulis AJ, Dubois C (2003) The use of Enterobacter cloacae ATCC 43560 in the development of a two-phase partitioning bioreactor for the destruction of hexahydro-1, 3, 5-trinitro-1, 3, 5-triazine (RDX). J Biotechnol 100:65–75. doi:https://doi.org/10.1016/S0168-1656(02)00229-8

Seth-Smith HMB, Edwards J, Rosser SJ, Rathbone DA, Bruce NC (2008) The explosive-degrading cytochrome P450 system is highly conserved among strains of Rhodococcus spp. Appl Environ Microbiol 74:4550–4552

Thompson KT, Crocker FH, Fredrickson HL (2005) Mineralization of the cyclic nitramine explosive hexahydro-1, 3, 5-trinitro-1, 3, 5-triazine by Gordonia and Williamsia spp. Appl Environ Microbiol 71:8265–8272. doi:https://doi.org/10.1128/AEM.71.12.8265-8272.2005

Tipton DK, Rolston DE, Scow KM (2003) Transport and biodegradation of perchlorate in soils. J Environ Qual 32:40–46

Trott S, Nishino SF, Hawari J, Spain JC (2003) Biodegradation of the nitramine explosive CL-20. Appl Environ Microbiol 69:1871–1874. doi:https://doi.org/10.1128/AEM.69.3.1871-1874.2003

Yamamoto H, Morley MC, Speitel GE Jr, Clausen J (2004) Fate and transport of high explosives in a sandy soil: adsorption and desorption. Soil Sediment Contam 13:459–477. doi:https://doi.org/10.1080/10588330490500419

Zhang C, Hughes JB (2003) Biodegradation pathways of hexahydro-1, 3, 5-trinitro-1, 3, 5-triazine (RDX) by Clostridium acetobutylicum cell-free extract. Chemosphere 50:665–671. doi:https://doi.org/10.1016/S0045-6535(02)00639-2

Zhao J-S, Halasz A, Paquet L, Beaulieu C, Hawari J (2002) Biodegradation of hexahydro-1, 3, 5-trinitro-1, 3, 5-triazine and its mononitroso derivative hexahydro-1-nitroso-3, 5-dinitro-1, 3, 5-triazine by Klebsiella pneumoniae strain SCZ-1 isolated from an anaerobic sludge. Appl Environ Microbiol 68:5336–5341. doi:https://doi.org/10.1128/AEM.68.11.5336-5341.2002

Zhao J-S, Spain J, Hawari J (2003) Phylogenetic and metabolic diversity of hexahydro-1, 3, 5-trinitro-1, 3, 5-triazine (RDX)-transforming bacteria in strictly anaerobic mixed cultures enriched on RDX as a nitrogen source. FEMS Microbiol Ecol 46:189–196. doi:https://doi.org/10.1016/S0168-6496(03)00216-2

Acknowledgments

The investigators acknowledge and thank the Strategic Environmental Research and Development Program (Mark Fuller, P.I., Project ER-1378) and NSF MCB-0316232 (Brian Fox., P.I.) for support of this research. Views, opinions, and/or findings contained herein are those of the authors and should not be construed as an official department of the army position or decision unless so designated by other official documentation. Thomas E. Malone was a trainee of the NIH Institutional Biotechnology Pre-Doctoral Training Grant T32 GM08349.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fuller, M.E., McClay, K., Hawari, J. et al. Transformation of RDX and other energetic compounds by xenobiotic reductases XenA and XenB. Appl Microbiol Biotechnol 84, 535–544 (2009). https://doi.org/10.1007/s00253-009-2024-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-009-2024-6