Abstract

A microbial fuel cell (MFC) is a relatively new type of fixed film bioreactor for wastewater treatment, and the most effective methods for inoculation are not well understood. Various techniques to enrich electrochemically active bacteria on an electrode were therefore studied using anaerobic sewage sludge in a two-chambered MFC. With a porous carbon paper anode electrode, 8 mW/m2 of power was generated within 50 h with a Coulombic efficiency (CE) of 40%. When an iron oxide-coated electrode was used, the power and the CE reached 30 mW/m2 and 80%, respectively. A methanogen inhibitor (2-bromoethanesulfonate) increased the CE to 70%. Bacteria in sludge were enriched by serial transfer using a ferric iron medium, but when this enrichment was used in a MFC the power was lower (2 mW/m2) than that obtained with the original inoculum. By applying biofilm scraped from the anode of a working MFC to a new anode electrode, the maximum power was increased to 40 mW/m2. When a second anode was introduced into an operating MFC the acclimation time was not reduced and the total power did not increase. These results suggest that these active inoculating techniques could increase the effectiveness of enrichment, and that start up is most successful when the biofilm is harvested from the anode of an existing MFC and applied to the new anode.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

It has been known for several years that microorganisms or enzymes can be used to produce electricity in microbial fuel cells (MFCs) (Allen 1972; Bennetto et al. 1983; Wingard et al. 1982; Allen and Bennetto 1993). Only recently, however, has it been shown that a MFC can be used as a fixed film bioreactor to convert dissolved organic matter to electricity without the need to add exogenous mediators (Bond and Lovley 2003; Kim et al. 2004; Liu et al. 2004a). Bacteria that are capable of using an electrode as a final electron acceptor without the need to add mediators include Shewanella putrefaciens (Kim et al. 1999a; b),Geobacter metallireducens (Bond et al. 2002; Bond and Lovley 2003), and Rhodoferax ferrireducens (Chaudhuri and Lovley 2003). The mechanisms used by these bacteria to transfer electrons to an electrode in a MFC are still being investigated. Geobacter sulfurreducens are known to localize the majority of their membrane-bound cytochromes on the outer membrane to facilitate direct contact with external ferric iron, and these cytochromes are believed to function in the same manner with a carbon electrode in a MFC (Bond and Lovley 2003; Leang et al. 2003; Magnuson et al. 2000).

Recently, efforts have been made to use domestic wastewater as a fuel for MFCs due to environmental concerns and the need to reuse waste (Liu et al. 2004a; Logan 2004). Anaerobic sewage sludge is a good candidate for inoculating a MFC because it is easily obtained from a wastewater treatment plant and it contains highly varied bacterial communities that contain electrochemically active strains of bacteria. The majority of bacteria in typical anaerobic wastewater sludge are believed to consist of fermentative bacteria, methanogens, and sulfate reducers (Angenent et al. 2002; Dollhopf et al. 2001; Wheatley 1990). Acetate is commonly used in MFCs as it is a non-fermentable substrate and it is a suitable electron donor for dissimilatory iron-reducing bacteria (Lovley and Phillips 1986; Thauer et al. 1989). Dissimilatory iron-reducing bacteria have been estimated to comprise as much as 3% of the total bacteria in activated sludge (Nielsen et al. 2002). Thus, it is possible that non-electrochemically active bacteria can occupy space on the electrode during the initial inoculation step preventing efficient power generation in the MFC.

When anaerobic sludge is used as an inoculum for MFCs, enrichment strategies should be devised to limit the growth of methanogens and to enhance the growth of the electrochemically active bacteria on the anode. Several reports have described MFCs inoculated with sludge, but they typically used passive techniques based on the addition of an inoculum into the anode solution (Kim et al. 2004; Lee et al. 2003; Liu et al. 2004a). In one study, it was found that serial enrichment of bacteria on the anode of a MFC resulted in increased power output and a change in the bacterial community (Rabaey et al. 2004), but a comparison of different inoculation procedures for MFCs has not been made. Of particular concern in different inoculation procedures is the competition of bacteria for space on the electrode. Non-growing bacteria which attach to the electrode could occupy electrode space that could instead be used by electrochemically active bacteria.

We hypothesized that there could be more effective inoculation techniques, based on different methods of enriching the abundance of electrochemically active bacteria, that could lead to more rapid power generation and higher power densities. We therefore tested the effect of several operational and inoculation procedures, including using a ferric oxide-coated electrode to enrich iron-reducing bacteria (Mavrocordatos and Fortin 2002; Nevin and Lovely 2002), and the use of 2-bromoethanesulfonate (BES) (a structural analog of cofactor M which is involved in the final enzyme reaction of methane formation) to inhibit methanogenic activity (Chidthaisong and Conrad 2000; Chiu and Lee 2001; Nielsen et al. 2002). We also examined enrichment of iron-reducing bacteria using a soluble ferric iron medium, applying biofilm scraped from an active MFC anode onto a new anode, and the effect of placing a second electrode (on a separate circuit) into the MFC in order to culture electrochemically active bacteria.

Materials and methods

Medium and inoculum source

Domestic wastewater (primary clarifier effluent) and anaerobic digester sludge samples were obtained from the Pennsylvania State University Wastewater Treatment Plant. Anaerobic sludge (10 ml) was used as the inoculum unless stated otherwise. Wastewater was filtered to remove bacteria (0.2 μm pore diameter) and amended with acetate (20 mM), and then used as the medium in enrichment experiments. After enrichment, the wastewater medium was replaced with a nutrient buffer solution (pH = 7.0) containing NH4Cl (0.31 g/l), KCl (0.13 g/l), NaH2PO4·H2O (2.69 g/l), Na2HPO4 (4.33 g/l); and metal (12.5 ml) and vitamin (12.5 ml) solutions (Lovley and Philips 1988). When electrodes were transferred into a fresh medium, they were first gently rinsed with autoclaved phosphate buffer (pH = 7.0, 50 mM). Sodium acetate (Sigma-Aldrich, USA) was used in all tests as the sole energy source for bacteria. In some experiments, 2-bromoethanesulfonate (BES; Sigma-Aldrich, USA) was used to inhibit methanogenic activity. To apply a high concentration of bacteria to an electrode, cells were scraped from the surface of the anode in an active MFC and spread onto a new carbon electrode using a sterilized razor blade. All cell transfers and inoculation procedures were conducted in an anaerobic glove box (Coy Scientific Products).

Batch tests using bacterial enrichments

In order to study the effect of pre-enrichment of iron-reducing bacteria on MFC performance, iron-reducing microorganisms were enriched in nutrient buffer containing ferric citrate (13.7 g/l) and acetate (20 mM) by successive transfer of samples (5 ml) into fresh medium (45 ml) every 2 weeks. The initial inoculum consisted of 5 ml of anaerobic sludge in 45 ml of medium containing ferric citrate and acetate. Cultures were incubated with shaking at 30°C.

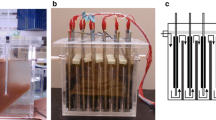

MFC construction and operation

MFCs were constructed from two media bottles (310 ml capacity; Corning, N.Y.) joined with a glass tube containing a 2.1-cm-diameter proton exchange membrane (PEM) (Nafion 117; Dupont, Del.) as previously described (Oh et al. 2004). All electrodes were made of plain porous carbon paper (TGPH-120 Toray carbon paper, E-TEC, 2.5 cm×4.5 cm, projected area of 22.5 cm2). In some experiments, carbon electrodes coated with ferric oxide by a chemical vapor deposition technique were used as the anode (Li and Logan 2004). The cathode contained a Pt catalyst (0.5 mg/cm2; 10% Pt; E-TEC). Copper wire inserted into fluorinated ethylene propylene tubing (Chemfluor FEP Tubing; inner diameter 0.8 mm) was used to connect the circuit, and all exposed metal surfaces were sealed with a nonconductive epoxy (Dexter, N.J.). Electrodes were soaked in pre-filtered, deionized water to wet the electrodes before placing them in the MFC. Phosphate buffer (50 mM, pH 7.0) was used in the cathode compartment that was continuously sparged with air (Oh et al. 2004). No special precautions were taken to remove oxygen that could diffuse into the anode chamber through the PEM as it was assumed that bacteria in the anode chamber would scavenge the oxygen. The anode chamber was continuously mixed using a magnetic stirrer. All experiments were conducted in a temperature-controlled room at 30°C.

Analyses

The voltage across a 470-Ω resistor in the circuit in the MFC was monitored (30-min intervals) using a multimeter (Keithley Instruments, Cleveland, Ohio) connected to a personal computer. Current (I), power (P) and Coulombic efficiency (CE) were calculated as previously described (Oh et al. 2004). The current (C/s) was calculated according to I=V/R, where V is the measured voltage and R (Ω) the resistance. The power density was obtained by normalizing power (P=IV) by the anode electrode surface area (22.5 cm2). The CE (%) was calculated as \(CE = (C_{\text{Ex}} /C_{\text{Th}} ) \times 100\), where CEx is the total Coulombs calculated by integrating the current measured at each time interval (i) over time, or \(C_{\text{Ex}} = \left( {\sum\limits_{i = 1}^T {V_i t_i } } \right)/R\). The theoretical amount of coulombs that is available from acetate oxidation (CTh) was calculated as CTh=F b M v, where F is Faraday’s constant (96,485 C/mol-e−), b the number of moles of electrons produced per mol of substrate (8 mol-e−/mol-acetate), M the acetate concentration (mol/l), and v the liquid volume (l).

Acetate concentrations were analyzed using a gas chromatograph (Agilent, 6890) equipped with a FID and a DB-FFAP fused-silica capillary column (Liu et al. 2004a). Gas compositions in the head space were measured using a gas chromatograph (GC; model 8610; SRI Instruments, Calif.) equipped with a thermal conductivity detector and a stainless steel column (1.8 m×1/8″) packed with Porapak Q (Alltech, Deerfield, Ill.). The concentration of ferrous ion was analyzed by the ferrozine method (Lovley and Phillips 1986; Stookey 1970).

Results

Enrichment with anaerobic sludge

When a MFC was inoculated with anaerobic sludge and wastewater using MFCs with either a carbon electrode, or a ferric-coated carbon electrode (Fig. 1), there was a 20-h lag phase followed by a rapid increase in cell voltage during the next 30 h. The cell voltage reached a maximum of 70 mV (4 mW/m2) with the cell voltage gradually decreasing as the organic matter in the wastewater was consumed. The MFC with the ferric iron electrode produced a voltage similar to that obtained with the reactor containing only a carbon electrode, but the voltage was maintained over a longer period of time with the ferric electrode.

To further explore this result with the ferric-coated carbon electrode, additional experiments were conducted using reactors inoculated with sludge and then fed wastewater amended with acetate. In order to determine the effect of methanogens on power generation, BES was added to a third reactor containing a carbon electrode in order to inhibit methanogenesis. The maximum voltage obtained in the three different reactors was similar, but the duration of electricity generation, and therefore the acetate consumption rate, was different (Fig. 2). The voltage obtained with the carbon electrode was slightly less (10–20 mV) than the voltages generated by the MFCs containing BES or a ferric-coated electrode (Fig. 2a). In the absence of BES, methane accumulated to a concentration of 40% in the headspace. In the MFC with the ferric oxide-coated electrode, acetate consumption was linked to an increased concentration of ferrous ion in solution (Fig. 2b, c). In this case only a small amount of methane (3–4%, v/v in the headspace) was produced after 120 h. This result shows that ferric-reducing bacteria selectively attached to the ferric oxide-coated electrode and that they outcompeted methanogenic bacteria for acetate. This is consistent with previous reports that iron-reducing bacteria grown with ferric iron and acetate will outcompete methanogens and limit methane production (Lovley and Phillips 1986).

Enrichment of MFCs with anaerobic sludge containing a carbon electrode (•), ferric electrode (○) or a carbon electrode with 2-bromoethanesulfonate (BES) (▵). a Voltage output at enrichment, b ferrous concentration in solution, c acetate concentration and d methane production in headspace of a MFC (error bars±SD based on duplicate measurements)

Methane production in the reactor containing BES and a carbon electrode was negligible (<2% methane headspace concentration) in comparison to the control (40%). Because methanogenesis was inhibited the rate of acetate consumption was reduced, and ∼10 mM of acetate was still present after 200 h of operation (Fig. 2c, d). Overall, there was a sustained generation of voltage at ∼100 mV for 250 h in the presence of BES.

Analysis of voltages and CE

In order to investigate the effect of substrate concentration on CE, the voltage generated in the MFC was monitored at acetate concentrations ranging from 0.05 mM to 2 mM. An example of voltages obtained using the carbon electrode MFC at different acetate concentrations is shown in Fig. 3. The ferric oxide-coated electrode MFC consistently generated a higher voltage (∼180 mV with 0.2 mM of acetate) than the MFCs containing a carbon electrode (control) or a carbon electrode and BES (Fig. 4a). The maximum voltage decreased in proportion to the acetate concentration. The CEs of the MFC containing the ferric oxide anode or BES were substantially larger (70–80%) than that obtained with the control (40%) (Fig. 4b). The voltage always increased immediately after the anode solution was replaced with fresh medium containing acetate. This suggests that power generation in these MFCs was primarily due to direct electron transfer by bacteria attached to the electrode and not suspended bacteria or bacteria producing mediators in the biofilm. Others have reached the same conclusion for similarly inoculated MFCs based on cyclic voltammograms and the observation of immediate power generation with the replacement of the medium (Liu et al. 2004b).

Effect of acetate concentration on voltage generation using a carbon electrode MFC. The enriched anode solution was replaced twice to remove suspended cells prior to conducting the experiment. Arrows indicate acetate injections according to the order shown of 0.5, 0.4, 0.3, 0.2 and 0.5 mM, respectively

Effect of enrichment in ferric medium on initial power generation

In order to increase the concentration of iron-reducing bacteria present in the anaerobic sludge prior to the addition of the inoculum into the MFC reactor, a sample was serially transferred (up to 25×) using a medium containing ferric citrate and acetate. Serial transfer gradually produced a reduction in methane generation by the culture, with methanogenesis eventually being completely repressed (Fig. 5a). The relative enrichment of iron-reducing bacteria is evidenced by the relative increase in the rate of iron reduction by the different enrichments (Fig. 5b). The acclimated culture yielded less power generation (50 mV, ∼2 mW/m2) than that of the control (unacclimated anaerobic sludge) in a MFC (Fig. 6).

Batch tests during acclimation of an anaerobic sludge to a ferric citrate medium showing: a methane production and b ferric iron reduction to ferrous iron. Tests were conducted in a serum bottle prior to inoculating the MFC (error bars±SD based on duplicate measurements). • Original anaerobic sludge, ○ first transfer, ▪ eighth transfer, □ 20th transfer in ferric citrate medium

Direct application of bacteria onto the anode

When a biofilm scraped from the anode electrode of an operating MFC was applied directly to a new anode, the lag period was similar to that obtained with unacclimated sludge. However, the voltage generated (205 mV or 40 mW/m2; 470 Ω) (Fig. 7) was much larger than that obtained with an unacclimated sludge (90 mV, 8 mW/m2; 470 Ω). The same procedure of applying a concentrated biomass with the iron-reducing enrichment from the 25th serial transfer was also examined, but power output was not greater than that observed with unacclimated sludge (data not shown).

Introduction of a second electrode into an operating MFC

In order to try to enrich an electrode with actively growing and electrochemically active bacteria, a second set of electrodes, on a completely separate circuit, was introduced into an operating MFC (Fig. 8). The voltage of the new circuit gradually increased, reaching 80 mV within 100 h. However, the voltage generated by the original electrodes decreased, eventually reaching the same voltage as the new electrode (Fig. 8a). As a result of the drop in voltage of the first electrode, the combined power density of the two electrode system essentially remained constant although the CE of the two electrode systems was slightly increased (∼10%; Fig. 8b). The decrease in the voltage by the original electrodes reflects a limitation of total power generation produced by the size of the PEM and cathode. It has been shown that the size of the PEM and the cathode can limit power generation in a two-chamber MFC (Oh et al. 2004; Oh and Logan in review).

The effect of introducing a second electrode into a MFC in order to enrich the electrochemically active bacteria on the new electrode. a Voltage output for each of the two electrodes: original electrode (•); new electrode (○). b Combined power output from both electrodes. Arrows indicate injections of acetate to produce final concentrations of 0.4, 0.5 and 1.0 mM in the order shown

To determine if the power produced by the second electrode was equal to or larger than that of the original electrode, the second electrode was removed and placed into a separate MFC. The second electrode showed approximately the same voltage and power output (140 mV, 18 mW/m2) as the original electrode (data not shown). This indicated that the addition of a new set of electrodes was a viable means of enriching bacteria growing in a MFC, but that overall power generation was not increased in this system likely due to limitations of the cathode and PEM on power generation.

Discussion

Some of the strategies investigated here were successful at increasing the performance of the MFC, although none of these procedures reduced the acclimation time needed for the system to reach peak power levels. In most studies, 50 h or longer were needed to increase the voltage to the maximum achieved in the system under the specific operating conditions. Using a ferric iron-coated carbon electrode as the anode we were able to increase power from 22 to 30 mW/m2. The most effective method for increasing power generation in a MFC was to apply biofilm obtained from the anode electrode in an operating MFC to a new electrode. This increased power up to ∼40 mW/m2, compared to power levels of 8 mW/m2 for a MFC inoculated with anaerobic sewage sludge.

Several methods were effective in increasing the CE. Adding the inhibitor BES inhibited methanogenesis in the enrichment, increasing the CE from 40 to 70%. In the absence of the inhibitor, we observed methane accumulation in the headspace of the reactors. Using a ferric iron electrode also increased CE, although the reasons for this increase are not known. It may be that the use of the ferric iron increased the efficiency of the initial contact of electrochemically active bacteria with the surface resulting in less initial colonization by methanogens. It was observed that methane accumulation was initially lower in the system with the ferric iron electrode than that with a carbon electrode, but methane was eventually produced in the MFC with the ferric iron electrodes. Alternatively, the faster growth of the iron-reducing bacteria may have just resulted in more successful competition for substrate by the added substrate. This is a more likely explanation as the CE remained high even though methane production was observed.

The application of the anode-grown biofilm to a new electrode increased the power levels (normalized to anode surface area), but the maximum possible power that could be generated by this approach could not be fully explored with the two-chambered system used here. Oh and Logan (in review) have shown that the surface area of the cathode and the PEM can affect the maximum power generated. For the surface areas of the electrodes and membranes used here the maximum power that can be generated in this system is predicted by the model of Oh and Logan (in review) to be 44 mW/m2. This is close to the maximum value obtained here of 40 mW/m2, indicating the power generation was limited by the MFC construction. The effect of the MFC construction on power generation is additionally shown by the fact that adding a second anode decreased the power generated by each individual circuit, with the overall power remaining near the maximum possible expected for the system. Although the maximum possible power generated by these different experimental techniques cannot be fully known, it is clear that serial transfer to enrich iron-reducing bacteria in a suspension prior to the inoculation of a MFC is not an effective method of producing rapid power generation or high power generation levels compared to other techniques. It is clear that the application of the biofilm from an existing MFC anode to a new electrode is an effective method of enriching electrochemically active bacteria.

Implications for future studies

The purpose of the current study was to examine methods that shortened the acclimation time or increased power generation over relatively short periods of operation. Additional research is needed to address the long-term stability of power generation in MFCs. Furthermore, the experimental results reported here were all based on using a cathode immersed in water, thus requiring aeration of the water to provide dissolved oxygen to the cathode. As the main engineering application for MFCs will likely be electricity production from wastewater, minimizing energy consumption will be important for the operation of such systems. Thus, it is likely that implementation of MFCs at larger scales will require the use of direct air cathode systems which have also been recently developed (Liu et al. 2004a, b). Further improvements can be made to MFC configurations to improve energy recovery or to increase voltages by linking MFCs in series, resulting in new technologies that will make electricity generation using MFCs a practical method of wastewater treatment.

References

Allen MJ (1972) Cellular electrophysiology. In: Norris JR, Ribbons DW (ed) Methods in microbiology. Academic Press, New York, pp 247–283

Allen RM, Bennetto HP (1993) Microbial Fuel-Cells: electricity production from carbohydrates. Appl Biochem Biotech 39:27–40

Angenent LT, Sung S, Raskin L (2002) Methanogenic population dynamics during startup of a full-scale anaerobic sequencing batch reactor treating swine waste. Water Res 36:4648–4654

Bennetto HP, Stirling JL, Tanaka K, Vega CA (1983) Anodic reactions in microbial fuel cells. Biotechnol Bioeng 25(2):559–568

Bond DR, Holmes DE, Tender LM, Lovley DR (2002) Electrode-reducing microorganisms that harvest energy from marine sediments. Science 295:483–485

Bond DR, Lovley DR (2003) Electricity production by Geobacter sulfurreducens attached to electrodes. Appl Environ Microbiol 69:1548–1555

Chaudhuri SK, Lovley DR (2003) Electricity generation by direct oxidation of glucose in mediatorless microbial fuel cells. Nat Biotechnol 21:1229–1232

Chidthaisong A, Conrad R (2000) Specificity of chloroform, 2-bromoethanesulfonate and fluoroacetate to inhibit methanogenesis and other anaerobic processes in anoxic rice field soil. Soil Biol Biochem 32:977-988

Chiu PC, Lee M (2001) 2-Bromoethanesulfonate affects bacteria in a trichloroethene-dechlorinating culture. Appl Environ Microbiol 67(5):2371–2374

Dollhopf SL, Hashsham SA, Dazzo FB, Hickey RF, Criddle CS, Tiedje JM (2001) The impact of fermentative organisms on carbon flow in methanogenic systems under constant low-substrate conditions. Appl Microbiol Biotechnol 56:531–538

Kim BH, Kim HJ, Hyun MS, Park DH (1999a) Direct electrode reaction of Fe(III) –reducing bacterium, Shewanella putrefaciens. J Microbiol Biotechnol 9:127–131

Kim BH, Park HS, Kim HJ, Kim GT, Chang IS, Lee J, Phung NT (2004) Enrichment of microbial community generating electricity using a fuel-cell-type electrochemical cell. Appl Microbiol Biotechnol 63:672–681

Kim HJ, Hyun MS, Chang IS, Kim BH (1999b) A microbial fuel cell type lactate biosensor using a metal-reducing bacterium, Shewanella putrefaciens. J Microbiol Biotechnol 9:365–367

Leang C, Coppi MV, Lovley DR (2003) OmcB, a c-Type Polyheme Cytochrome, Involved in Fe(III) Reduction in Geobacter sulfurreducens. J Bacteriol 185:2096–2103

Lee J, Phung NT, Chang IS, Kim BH Sung HC (2003) Use of acetate for enrichment of electrochemically active microorganisms and their 16S rDNA analyses. FEMS Microbiol Lett 223:185–191

Li B, Logan BE (2004) Bacterial adhesion to glass and metal-oxide surfaces. Colloids Surf B: Biointerface 36(2):81–90

Liu H, Ramnarayanan R, Logan BE (2004a) Production of electricity during wastewater treatment using a single chamber microbial fuel cell. Environ Sci Technol 38:2281–2285

Liu H, Cheng S, Logan BE (2004b) Production of electricity from acetate or butyrate using a single chamber microbial fuel cell. Environ Sci Technol (in press)

Logan BE (2004) Feature article: biologically extracting energy from wastewater: biohydrogen production and microbial fuel cells. Environ Sci Technol 38:160A–167A

Lovley DR, Phillips EJP (1986) Organic matter mineralization with reduction of ferric iron in anaerobic sediments. Appl Environ Microbiol 51:683–689

Lovley DR, Phillips EJP (1988) Novel mode of microbial energy metabolism: organic carbon coupled to dissimilatory reduction of iron or manganese. Appl Environ Microbiol 54:1472–1480

Magnuson TS, Hodges-Myerson AL, Lovley DR (2000) Characterization of a membrane-bound NADH-dependent Fe3+ reductase from the dissimilatory Fe3+-reducing bacterium Geobacter sulfurreducens. FEMS Microbiol Lett 185:205–211

Mavrocordatos D, Fortin D (2002) Qantitative characterization of biotic iron oxides by analytical electron microscopy. Am Mineral 87:940

Nevin PN, Lovley DR (2002) Mechanisms for accessing insoluble Fe(III) oxide during dissimilatory Fe(III) reduction by Geothrix fermentans. Appl Environ Microbiol 68:2294–2299

Nielsen JL, Juretschko S, Wagner M, Nielsen PH (2002) Abundance and phylogenetic affiliation of iron reducers in activated sludge as assessed by fluorescence in situ hybridization and microautoradiography. Appl Environ Microbiol 68:4629–4636

Oh SE, Min B, Logan BE (2004) Cathode performance as a factor in electricity generation in microbial fuel cells. Environ Sci Technol 38:4900–4904

Oh SE, Logan BE (in review) Physical design factor that affect power output in microbial fuel cells. Environ Sci Technol

Rabaey K, Boon N, Siciliano SD, Verhaege M, Verstraete W (2004) Biofuel cells select for microbial consortia that self-mediated electron transfer. Appl Environ Microbiol 70(9):1–10

Stookey LL (1970) Ferrozine-a new spectrophotometric reagent for iron. Anal Chem 42:779–781

Thauer RK, Moller-Zinkhan D, Spormann M (1989) Biochemistry of acetate catabolism in anaerobic chemotrophic bacteria. Annu Rev Microbiol 43:43–67

Wheatley A (1990) Anaerobic digestion: a waste treatment technology. In: Burkin AR (ed) Critical reports on applied chemistry, vol 31. Elsevier, London

Wingard LB Jr, Shaw CH, Castner JF (1982) Bioelectrochemical fuel cells. Enz Microbial Tech 4(3):137–142

Acknowledgements

The authors thank D. W. Jones (Penn State University) for help with analytical measurements and C. Steffak (PPG Industries) for preparation of the ferric oxide-coated electrodes. This research was supported by a National Science Foundation grants BES-0331824 and BES-0401885, a seed grant from the Huck Institutes of the Life Sciences Department at Penn State University, and the Stan and Flora Kappe endowment.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, J.R., Min, B. & Logan, B.E. Evaluation of procedures to acclimate a microbial fuel cell for electricity production. Appl Microbiol Biotechnol 68, 23–30 (2005). https://doi.org/10.1007/s00253-004-1845-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-004-1845-6