Abstract

The present research is about to draw a comparison between heat transfer characteristics of gold/deionized water (DIW) and silver/DIW based nanofluid under same heat flux for laminar flow. Experiments are performed on both nanofluid by using different concentrations (0.015, 0.045, 0.0667%) of nano-particles (NPs) in DIW as a base fluid. The experimental study concludes that an appreciable intensification in heat transfer coefficient (HTC) of both nanofluid has been attained as compare to base fluid. However, gold/DIW based nanofluid exhibit better convective heat transfer intensification compared with silver/DIW based nanofluid but Shah correlation cannot predict as much augmentation as in experimental work for both nanofluid. It is also noticed that the anomalous enhancement in Nusselt number and HTC is not only due to the accession in thermal properties but also by the formation of thinner thermal boundary layer at the entrance of the tube due to NPs.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Innovative methods are required to decrease the effect of global warming on our planet. The bad effect of Greenhouse gases on our environment is the main cause of global warming by using inefficient thermal fluid heat transfer systems in many industries. Energy consumption can be reduced by boosting the efficiency of thermal fluid systems.

In earlier, a colloidal mixture, which was formed by micro sized particle with base fluid, was used for the intensification of convective HTC and thermal conductivity of fluids by Maxwell [1]. The increased size of particles caused sedimentation and higher pressure drop when a fluid was passed through any closed channel path. Due to this effect, this technology cannot be used practically on industrial scale. Instead of using micro sized particles, a very small amount of nps mixed in a base fluid can impressively enhance the physical properties of the base fluid which are affected by temperature. Nanofluids, made of nano sized particles (100 nm) suspended in any base fluid to form a colloidal mixture, is first used by Choi in 1995 at the AN laboratory [2].

The conventional method to intensify the HT is by enhancing the flow rate of fluid that results in more pumping power and higher pressure drop which is undesirable. So to overcome such type of problems, nano-fluids are used. The second most common approach which is used for increasing HT rate is the use of extended surfaces like fins. But these conventional approaches for improving heat transfer rate cannot meet the present requirements due to lesser thermos-physical properties. Due to these reasons, it is necessary to build a system for producing highly improved techniques and more efficient heat transfer fluids for cooling and heating purpose. Recent researches on these nanoparticles in base fluids find a solution of such type of problems. The basic idea of using the solid particles is due to their high thermal conductivities which can be hundred times greater than some base fluids. Enhancement in physical properties by micro sized particles was not exhibited as nano sized particles on molecular level because the size of nano particle is very close to the size of atoms or molecules so the settling due to gravitational force is negligible for nano sized particles. That’s why these particles are suspended easily in conventional fluids [3].

Improvement in heat transfer techniques was also studied by Ahuja [4, 5] who did experiments by using micro sized particles of polystyrene suspension in water under laminar flow. Remarkable intensification was seen in Nusselt number as compared to base fluid. Keblinski et al. [6] and Eastman et al. [7] proposed four reasons for the exceptional behavior of thermal conductivity of NF, 1—haphazard movement of nanoparticles, 2—formation of layers of molecules of liquid phase at the interaction between nano particle and liquid, 3—heat transport phenomena, 4—effect of nanoparticles agglomeration.

Xaun and Roetzel [8], Xuan et al. [9], Buongiorno [10, 11], Ding and Wen [12], Roy et al. [13], Maiga et al. [14], Kim et al. [15], Mansour et al. [16], Palm et al. [17], did theoretical analysis on convective heat transfer processes by considering a single phase fluid approach. Most of them described the enhancement in heat transfer properties dramatically by decreasing the particle size. They investigated the improvement was not only by the accession in thermal conductivity but also due to the two necessary slip mechanism, thermophoresis and Brownian diffusion. From many years, researchers and engineers have been tried to mitigate the problems of heat loses by enhancing convective heat transfer characteristics. In forced convective heat transfer field, Choi and Lee conducted the experiments on unspecified nanofluid in parallel channel and concluded the thermal resistance decreased by factor 2 as compared to base liquid [18]. Heris et al. [19] did comparison between Al2O3/DIW and CuO/DIW based NFs by studying their convective heat transfer characteristics through experiments. He concluded, the enhancement in overall HTC was due to increasing peclet # and fraction of NPs while the enhancement was more prominent for Al2O3/water nanofluid. Yang et al. [20] did experiments on graphite nanofluid with disc like shape of nanoparticles. They observed the unexpected intensification in HTC that is very lower as the increment in thermal conductivity itself. From this experimental data we can conclude that the aspect ratio of solid particles is a great factor to change the thermo physical properties of NFs. Literature survey shows many researches related copper [21], alumina [22], tin [23], carbon nano tubes [24], iron [25] and their oxides nanofluids with different base fluid are published but few reports are published on gold and silver based nanofluid. Therefore, this paper is about the comparative study of HT characteristics of gold/DIW and silver/DIW based nanofluid.

2 Materials and methods

2.1 Sample preparation

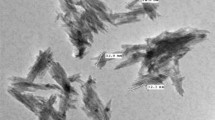

For comparative investigation of heat transfer properties of gold and silver nanofluid, three samples of different concentration of each nanofluid are prepared. Concentrations of the both fluids are same for comparison. For the testing purpose, first pure deionized water is run through the setup then the results are compared with the Shah correlation under same heat flux condition in laminar flow. Sample preparation of NF is not very easy because it’s not a just simple mixing of solid and liquid phases. To attain good and accurate results, proper agitation and homogenized mixture is required. Nanofluid samples were prepared by laser ablation method by suspending vol% (0.015, 0.045, 0.0667%) concentration of nanoparticles of silver and gold in DIW (deionized water) individually. To ensure proper agitation and mixing of nanoparticles, ultrasonic agitator was used.

3 Experimental procedure and setup

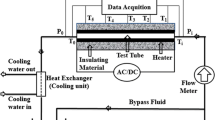

An experimental setup for investigation of convective HTC consists of a straight annular circular stainless steel tube, two magnetic pump, seven thermocouples of K type which are soldered on the tube, DC power supply (E.S. Roland PSN 310EC accuracy ±2%), cooling section, a storage tank with agitator, flow meter (rotameter, accuracy ±2% to ±10%) for measuring the flow rate of nanofluid, and HP data logger (USB TC-08 PICO, UK, ±0.2% and ±0.5 °C) which is connected with the computer as in Fig. 1.

The test section consists of stainless steel tube of length L = 580 mm, inner diameter Di = 2.27 mm and thickness of the tube is δ = 2 mm. The tube is well insulated to avoid heat loses. Temperature of heat transfer fluid at different location on the tube is measured by K type thermocouples. These K type thermocouples are attached to data logger and the readings are recorded by computer. Both ends temperature of the processing nanofluid is measured by two thermocouples which are fixed at the entrance and end position of the tube for temperature measurement of bulk fluid and the remaining thermocouples measure the wall temperature of the tube under constant heat flux conditions. Two gauges for pressure measurement are fixed at the end points of tube to measure the pressure drop. Two magnetic pumps are installed in this setup, one is used for pumping the nanofluid through the test section and the second one is used for pumping the cooling media through heat exchanger which is water.

Nanofluids of silver and gold nanoparticles of different concentrations are passed through this setup. Electric power supply is provided to heatup the heat transfer fluid through the test section and the temperatures are recorded from each thermocouple through data logger. Test samples of different concentration were passing through this setup at different flow rate (20 mL, 30 mL, 40 mL) and readings were recorded.

4 Data modeling

Before modeling the experimental data, all the physical properties data of the NFs should be collected. Some of the empirical correlations are used to calculate these properties. The Bachelor’s model [26] equation used for calculating the viscosity of nanofluid of gold and silver,

Under different concentrations, viscosity of each nanofluid is calculated by using this correlation.

Effective thermal conductivity is calculated by classical Hamilton Crosser model [27] of nanofluid which is shown here:

The value of n is 3 for spherical shape nanoparticles.

Specific heat and density is calculated by mixture rule of different volume fraction using these expressions [28].

Density is calculated with the same rule by using the following relation:

The convective local HTC is calculated by Newton’s law of cooling for cooling heat transfer of nanofluids is as under:

where, \(h_{nf}\) (W/m2K) is the local HTC of nanofluid at axial position of test section, \(T_{i,w} \left( x \right)\) is the temperature of inner wall of test section tube, \(T_{mb} \left( x \right)\) is the mean temperature of bulk fluid, \(q^{^\circ }\) is the heat flux which is calculated by this heat equation,

It’s a heat flux that’s why it is divided by the area of the tube where, \(q^{^\circ }\) = heat flux (W/m2), \(m^{^\circ }\)(mass flow rate, kg/s) = \(\mu \rho A_{C}\), \(c_{p}\) = heat capacity of fluid, \(D_{i}\) = inner diameter of the test section tube, L = length of tube.

Inner wall temperature could not be measured by direct method so it is calculated in cylindrical coordinates by heat conduction equation,

where, \(T_{o,w} \left( x \right)\) = outer wall temperature which is measured by thermocouples, \(q\) = power supply to test section (W), \(D_{^\circ }\) = outer diameter of tube, \(k_{s}\) = thermal conductivity of stainless steel, \(x\) = longitudinal location of required test section from the inlet of the tube.

The mean temperature of the NF is determined on any section of tube by applying energy balance on control volume of length of tube \(dx.\) According to energy balance on control volume, the equation will be

where \(dT_{mb}\) is the mean T of the bulk fluid and P is the perimeter of the tube, P = π\(D_{i}\).

The variations in mean T with respect to the length x of the tube is calculated by integrating with limits from 0 to x, then the resultant equation will be,

To obtain convective HTC, the values of \(T_{mb} \left( x \right)\) and \(T_{i,w} \left( x \right)\) are substituted in Eq. (5).

By putting the values of heat flux, temperature of bulk fluid at the entrance of tube and the outer wall temperature, the HTC can be determined by the above equation. To find Nusselt number, this expression is used after calculating the HTC.

where \(k_{nf}\) is calculated by classical Hamilton–Crosser model. After calculating the experimental Nusselt number, the results are compared with the well-known Shah correlation for laminar flow under constant heat flux conditions.

Reynold number and Prandtl number are calculated in uniform cross sectional area for incompressible and steady flow of fluid by theses relations,

5 Results and discussions

To make a baseline for comparison of convective HT characteristics of NFs, first the tests are taken on DIW to check the authenticity of experimental results. Experimental readings for DIW are compared with Shah correlation under constant heat flux and laminar flow in Fig. 2, there is better approximation between the experimental data and predicted results from Shah correlation, which shows the accuracy of the results. The calculated results from Shah correlation are little bit more than the experimental results. This discrepancy is due to the flow channel because Shah correlation is used for large channels and in this research work it is used for smaller diameter tube. The reason of this problem was also discussed by Wen and Ding [29]. This type of over prediction was also reported by Mursheed et al. [30], when he used a 4 mm diameter tube during his research work.

Experimental tests were performed on both nanofluids Gold/DIW and Silver/DIW at concentrations (0.015, 0.045, 0.0667 vol%). The range of Reynold number is between (150 and 600) and all the experiments are done under constant heat flux condition. Figure 3 is a plot of Nusselt number with different concentrations of both silver/DIW and gold/DIW based nanofluids at axial distance x/D = 8.81. Reynold number changes for each test fluid at different temperature due to change in physical properties but these changes are not significant that’s why the selected value 200 is in the range of ±50. The graph shows significant increase in Nusselt number with increasing concentration of nanoparticles for both nanofluids but this improvement is more prominent for gold/DIW nanofluid as compare to silver/DIW nanofluid. For example, the percent increase in Nusselt number as compare to base fluid is 8.5% for gold/DIW based nanofluid and 4.3% increase for silver/DIW based nanofluid at 0.015% concentration by volume. At higher concentrations, the percent increase in Nusselt number is more significant which can be seen from graph.

Figure 4 is a graphical representation of convective HTC “hx” versus axial distance from the inlet section of tube at each concentration of both fluids. This axial profile shows that increase in convective HTC is more prominent at the starting end of the tube for both nanofluid by increasing NP fraction but the intensification is more prominent for gold/DIW based nanofluid as compare to silver/DIW nanofluid at same volume fraction of nanoparticles. At nano particle concentration 0.045 and 0.0667% by volume, the enhancement in convective HTC is 19 and 29% respectively for gold nanofluid but in case of silver/DIW based nanofluid, the enhancement is 12 and 20% respectively at x/D = 8.81 and Reynold number 400 ± 50.

Enhancement is more prominent at the starting point of the tube due to the formation of thermal boundary layer by adding NPs. Heat transfer coefficient is basically the ratio (k/δ) of thermal conductivity and the thickness of boundary layer [29]. The two factors, enhancement in thermal conductivity or reduction in the compactness of thermal boundary layer are responsible for the improvement in heat transfer characteristics at the inlet section. That’s why at the entering end of the tube the thermal boundary layer is thinner that results in increase the HTC. Another reason for increased HT coefficient can be the exchange of energy within the fluid because of the random motion of particles. Godson et al. [31] discused the heat transfer characteristics of silver NF in his research work. They found 12.4% augmentation in local convective HT coefficient at particle volume concentration 0.04% in turbulent flow.

Figure 5 exhibits the response of Nusselt number by changing average velocity of both nanofluid at dimensionless distance x/D = 8.81. This plotted experimental data shows the enhancement in Nusselt number with increasing average velocity for both nanofluid but increase in Nusselt number for gold is more prominent than silver due to greater thermal conductivity of gold. As Petal et al. [32] reported the k-values of gold and silver NFs at very low concentrations. They investigated 7–14% intensification in thermal conductivity of gold/DIW based NF for loading of 0.011% by volume.

Kim et al. [33] also studied the increment in thermal conductivity of gold/H2O based nanofluid upto 9.3 ± 5.4% as compare to base fluid with nano particle loading 0.018%. Figure 6 illustrates the axial profile of both nanofluids with these concentrations, (0.015, 0.045, 0.0667%). The graph shows the enhancement in Nu # at the entrance end of the tube with increase in concentration of nanoparticles at Reynold number 200 ± 50.

In the above Fig. 7 the Nu # versus Re # of both nanofluids for each tested concentration at dimensionless distance x/D = 13.21. Nusselt number is tend to increase with increasing Reynold number The percent increase in Nu # for 0.045 vol% concentration of nanoparticles of gold/DIW and silver/DIW based nanofluids is 15 and 11% respectively at Reynold number 200 ± 50. The increase is more significant for gold/DIW based nanofluid.

Figure 8 represented the ratio of experimental calculated Nu.# to the calculated Nu.# from Shah correlation versus Re.# for gold/DIW and silver/DIW based nanofluids at two volume fractions (0.015, 0.045 vol%). From graphical behavior it can be observed that Shah correlation cannot predict the accurate results for both nanofluids with increasing Re.#. The ratio of experimental calculated Nusselt number and the predicted Nusselt number from Shah correlation is self-explanatory. If the prediction is accurate then the ratio should not tend to decrease with the Reynold number. The difference between calculated and experimental values of Nusselt number is goes on increasing that’s why the ratio is decreasing at high Reynold number.

Similar results were observed by Wen and Ding, when they studied the heat transfer coefficient of alumina/water based nanofluid and compares their results with Shah correlation [29]. This discrepancy confirms that heat transfer depends upon more factors other than physical properties. Because during the flow of nano fluid through any flow channel, the nano particles are interacting with each other, with the walls of the tube and exchange their energy.

6 Conclusion

This research paper shows a comprehensive study on experimental work about convective heat transfer augmentation for gold/DIW and silver/DIW based nanofluids under similar conditions. Both nanofluid shows remarkable intensification in Nusselt number and HT coefficient by increasing flow rate or Re.# and nano particle volume fraction. But results indicate that gold/DIW nanofluid shows more enhancements in Nusselt number and heat transfer coefficient as compare to silver/DIW nanofluid due to its high effective thermal conductivity for the same volume fractions of nanoparticles. The enhancement in Nusselt number is 8.5 and 4.3% at volume concentration 0.015% for gold/DIW and silver/DIW based nanofluid respectively. Further, experimental and theoretical work is needed for more detailed comparative study of convective HT characteristics of different nanofluids in laminar and turbulent flow region.

Abbreviations

- Cp:

-

Specific heat capacity, kJ/(kg K)

- D:

-

Diameter of tube/pipe, m

- h:

-

Average heat transfer coefficient, W/(m2 K)

- c p,nf :

-

Heat capacity of nanofluid, W/(m2 K)

- c p,bf :

-

Heat capacity of water which is a basic fluid, W/(m2 K)

- c p,p :

-

Heat capacity of nano sized particles, W/(m2 K)

- ρ bf :

-

Density of basic fluid (DIW), kg/m3

- ρ p :

-

Density of nanoparticles, kg/m3

- ρ nf :

-

Nanofluid density, kg/m3

- hx :

-

Local heat transfer coefficient, W/(m2 K)

- k:

-

Thermal conductivity, W/(m K)

- L:

-

Length of pipe, m

- m˚:

-

Mass flow rate through test rig, kg/s

- Nu:

-

Nusselt number

- p:

-

Pressure, Pa

- P:

-

Electric supply, W

- Pr:

-

Prandtl # of nanofluid

- q″:

-

Heat flux density from pipe to fluid, W/m2

- Re:

-

Reynolds #

- Tin :

-

Inlet fluid temperature, °C

- Tout :

-

Outlet fluid temperature, °C

- v:

-

Nanofluid velocity, m/s

- Q:

-

Volume flow rate, m3/s

- X:

-

Length of the tube from inlet to test section

- Δ:

-

Difference

- μ :

-

Viscosity, kg/(m s)

- ρ:

-

Density, kg/m3

- Φ :

-

Volume fraction of nanoparticles, %

- DIW:

-

Deionized water

- NPs:

-

Nanoparticles

- HTC:

-

Heat transfer coefficient

- nf:

-

Nano fluid

- AN:

-

Argon national labortary

References

Maxwell JC (1881) A treatise on electricity and magnetism, 2nd edn. Clarendon Press, Oxford

Choi SUS, Eastman JA (1995) Enhancing thermal conductivity of fluids with nanoparticles. Argonne, IL

Sharma P, Baek I-H, Cho T, Park S, Lee KB (2011) Enhancement of thermal conductivity of ethylene glycol based silver nanofluids”. Powder Technol 208:7–19

Ahuja AS (1975) Augmentation of heat transport in Laminar flow of polystyrene suspensions. J Appl Phys 46(83):408–3416

Ahuja AS (1982) Thermal design of heat exchanger employing Laminar flowof particle suspensions. Int J Heat Mass Transf 25(5):725–728

Keblinski P, Phillpot SR, Choi SUS, Eastman JA (2002) Mechanisms of heat flow in suspensions of nano-sized particles (nanofluids). Int J Heat Mass Transf 45:855–863

Eastman JA, Phillpot SR, Choi SUS, Keblinski P (2004) Thermal transport in nanofluids. Annu Rev Mater Res 34:219–246

Xuan Y, Roetzel W (2000) Conceptions for heat transfer correlation of nanofluids. Int J Heat Mass Transf 43:3701–3707

Xuan Y, Li Q (2000) Heat transfer enhancement of nanofluids. Int J Heat Fluid Flow 21:58–64

Buongiorno J (2006) Convective transport in nanofluids. ASME J Heat Transf 128:240–250

Buongiorno J (2006) Convective heat transfer enhancement in nanofluids. Heat and mass transfer conference, January, 2006, HMT-2006-C335

Ding Y, Wen D (2005) Particle migration in a flow of nanoparticles suspensions. Powder Technol 149:84–92

Roy G, Nguyen CT, Lajoie PR (2004) Numerical investigation of laminar flow and heat transfer in a radial flow cooling system with the use of nanofluids. Superlattices Microstruct 35:497

Maiga SEB, Paim SJ, Nguyen CT, Roy G, Galanis N (2005) Heat transfer enhancement by using nanofluids in forced convection flows. Int J Heat Fluid Flow 26:530

Kim J, Kang YT, Choi CK (2007) Soret and Dufour effects on convective instabilities in binary nanofluids for absorption application. Int J Refrig 30(2):323–328

Mansour RB, Galanis N, Nguyen CT (2007) Effect of uncertainties in physical properties on forced convection heat transfer with nanofluids. Appl Therm Eng 27(1):240–249

Palm SJ, Roy G, Nguyen CT (2006) Heat transfer enhancement with the use of nanofluids in radial flow cooling systems considering temperature-dependent properties. Appl Therm Eng 26(17–18):2209–2218

Lee S, Choi SUS (1996) Application of metallic nanoparticle suspensions in advanced cooling systems. In: 1996 International mechanical engineering congress and exhibition, Atlanta, USA, 1996

Heris S, Etemad SG, Esfahany M (2006) Experimental investigation of oxide nanofluids laminar flow convective heat transfer”. Int Commun Heat Mass Transf. 33(4):529–535

Yang Y, Zhang ZG, Grulke EA, Anderson WB, Wu G (2005) Heat transfer properties of nanoparticle-in-fluid dispersions (nanofluids) in laminar flow. Int J Heat Mass Transf 48(6):1107–1116

Liu MS, Lin MCC, Tsai CY, Wang C-C (2006) Enhancement of thermal conductivity with Cu for nanofluids using chemical reduction method. Int J Heat Mass Transf 49:3028–3033

Zhu Dongsheng, Li Xinfang, Wang Nan, Wang Xianju, Gao Jinwei, Li Hua (2009) Dispersion behavior and thermal conductivity characteristics of Al2O3–H2O nanofluids. Curr Appl Phys 9:131–139

Habibzadeh S, Kazemi-Beydokhti A, Khodadadi AA, Mortazavi Y, Omanovic S, Shariat-Niassar M (2010) Stability and thermal conductivity of nanofluids of tin dioxide synthesized via microwave-induced combustion route. Chem Eng J 156:471–478

Hwang Y, Lee JK, Lee CH, Jung YM, Cheong SI, Lee CG, Ku BC, Jang SP (2007) Stability and thermal conductivity characteristics of nanofluids, Thermochim. Acta 455:70–74

Yu W, Xie H, Chen L, Li Y (2010) Enhancement of thermal conductivity of kerosene-based Fe3O4 nanofluids prepared via phase-transfer method. Colloids Surf A Physicochem Eng Aspects 355:109–113

Batchelor GK (1977) The effect of Brownian motion on the bulk stress in a suspension of spherical particles. J Fluid Mech 83:97–117

Hamilton R, Crosser O (1962) Thermal conductivity of heterogeneous 2-component systems. Ind Eng Chem Fundam 1:187–191

Pak BC, Cho YI (1998) Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp Heat Transf 11:151

Wen DS, Ding YL (2004) Experimental investigation into convective heat transfer of nanofluids at the entrance region under laminar flow conditions. Int J Heat Mass Transf 47:5181–5188

Murshed SMS, Leong KC, Yang C (2008) Convective heat transfer characteristics of aqueous tio2 nanofluid under laminar flow conditions. Int J Nanosci 7(6):325–331

Godson L, Deepak K, Enoch C, Jefferson B, Raja B (2013) Heat transfer characteristics of silver/water nanofluids in a shell and tube heat exchanger. Arch Civ Mech Eng 14(2014):489–496

Patel HE, Das SK, Sundararagan T, Nair AS, Geoge B, Pradeep T (2003) Thermal conductivities of naked and monolayer protected metal nanoparticle based nanofluids: manifestation of anomalous enhancement and chemical effects. Appl Phys Lett 83:2931–2933

Kim HJ, Bang IC, Onoe J (2009) Characteristic stability of bare Au/water nanofluids fabricated by pulsed laser ablation in liquids. Opt Lasers Eng 47:532–538

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Muryam, H., Ramzan, N., Umer, A. et al. Comparative study of convective heat transfer characteristics of nanofluids. Heat Mass Transfer 53, 2309–2316 (2017). https://doi.org/10.1007/s00231-017-1980-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-017-1980-0