Abstract

The aim of this study was to determine the drying and rehydration kinetics of freeze dried kiwi slices. Well-known thin layer drying models (Lewis, Page, Modified Page I, Henderson and Pabis, Modified Henderson and Pabis, Logarithmic, Midilli, Modified Midilli, Two-term, Two-term Exponential, Modified Two-term Exponential, and Wang and Singh) were fitted to the experimental data. A nonlinear regression analysis was used to evaluate the parameters of the selected models using statistical software SPSS 16.0. For the freeze drying process of the kiwi slices, the highest R2 value (0.997), and the lowest RMSE (0.018) as well as the χ2 (0.0004) values were obtained from the Two-term Exponential model. The effective moisture diffusivity (Deff) of the freeze dried kiwi slices was calculated with the Fick’s diffusion model as 7.302 × 10−10 m2/s. The rehydration behavior was determined using distilled water at different solid–liquid ratios at room temperature (18 ± 1 °C) using Peleg’s model. The kinetics of the total soluble solid loss was also determined.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Drying is one of the oldest methods in food preservation processes. Drying, which is usually carried out by convective drying, may cause many non-reversible physical and chemical changes in the material such as color, nutritional value, shrinkage, texture etc. With hot-air drying, the higher drying rate at the initial stage may cause case hardening of the product surface, considerable shrinkage, and formation of a dense structure and result in the loss of the ability for fast reconstitution [1]. In order to protect the quality characteristics of the product freeze drying can be used. It is expected that the high porosity developed in freeze-dried products plays a significant role in both rehydration capacity and rate [2]. Freeze-dried foods are considered as having a quality higher than other dehydrated products mainly because they can be reconstituted with water rapidly to products closely resembling the original food [1], which is especially important for rehydration of foods which are dried either as a whole (like berries) or in the form of slices.

Most of the dehydrated products are rehydrated before usage, therefore additional indicators of quality such as rehydration capacity and rate should be obtained [3]. Evaluated on the basis of the rehydration characteristics, product quality is influenced by processing conditions, sample preparation, sample composition, and the extent of the degree of cellular and structural disruption during drying [4]. However, rehydration behaviors of highly porous freeze-dried products have not been extensively studied, as of yet [5–8].

Kiwi with high amounts of vitamins, minerals, carotenoids, and phenolic content is susceptible to microbial spoilage and softening due to its high moisture content [9]. Therefore, drying is a suitable technique to prolong the shelf life of kiwi. Several researches have studied the drying of kiwi fruits such as convective, microwave, vacuum microwave, and freeze drying [10–22]. Among these only Benlloch-Tinoco et al. [20] and Çalışkan et al. [21] performed freeze dried kiwi puree and which indicates that a need for further studies. In the literature there exist several articles about the advantages of the freeze drying process. It’s well known that, during freeze drying no collapse of tissues is observed, therefore, the product is nice appealing and is highly porous. In addition, the heat sensitive nutrients within the food material are preserved since drying takes place at low temperatures. Another distinguishing aspect of freeze drying is that although in the early stages of freeze drying due a higher vapor pressure than ice some volatile compounds are lost in later stages and the dried porous layer acts as a barrier to the loss of these precious components [1]. In the study of Çalışkan et al. [21] the freeze drying of kiwi puree was studied together with the powder properties of the product. In that study, the crushed fruit in the form of puree was dried after the addition of MD. It should be noted that due to its attractive color, suitable size, and nutritional value, the use of kiwi fruits in the sliced form is much more desirable in food preparations (like decoration of cakes or as a snack food without the inclusion of excess amounts of sugar that osmotically dried products have). Since most dried foods are not suitable for direct utilization they should be rehydrated before usage and the producers should define the rehydration conditions for an acceptable product for the consumers. The rehydration behavior should be well defined in order to provide the dried product with properties very similar to the original material. For a freeze dried product this is more important since freeze dried materials are more fragile in structure due to the loss of elasticity and high values of porosity [1].

Describing dehydration and rehydration kinetics is important in the design and optimization of these processes [3]. From a processing and engineering point of view, it is interesting not only to know how fast the desorption and absorption of water can be accomplished, but also how it will be affected by processing variables, and how the drying and soaking time under given conditions can be predicted. Thin layer drying equations are important in the mathematical modeling of drying. They are practical and provide sufficiently good results [23]. Thin layer drying generally means to dry as one layer of sample which provides a uniform temperature assumption and is suitable for lumped parameter models [23, 24]. However, they strongly depend on the experimental conditions [25] and the drying-rate data has to be measured experimentally. In order to model the rehydration kinetics of fruits, different empirical or semi-empirical equations based on Fick’s second law (Peleg, Weibull, etc.) have been used by several researchers [7, 8, 26, 27]. The Peleg’s equation is a two-parameter, nonexponential, and empirical model for the description of moisture sorption curves. This model has been widely used due to its simplicity and has been reported to adequately describe the rehydration behavior of various food stuffs [28].

In this work, the aim was to study the freeze drying and rehydration behavior of kiwi fruit slices. A simulation model describing the simultaneous heat and mass transfer processes is proposed to describe the drying of kiwi slices. Furthermore, the rehydration characteristics and kinetics of the total soluble solid loss of the freeze dried kiwi slices was also determined.

2 Materials and methods

2.1 Material

Fresh kiwi fruits were obtained from a local supermarket in Izmir, Turkey. They were washed, peeled, and sliced into triangular pieces of a 3 mm thickness (10–14 identical slices in the middle parts were used by dividing into 6 identical triangles) (Fig. 1).

2.2 Drying experiments

Experiments were performed in a pilot scale freeze dryer (Armfield, FT 33 Vacuum Freeze Drier, England). The kiwi slices were frozen at −40 °C in an air blast freezer for 2 h, then freeze dried in a vacuum (13.33 Pa absolute pressure), at a −48 °C condenser temperature. The temperature of the heating plate was set to 30 °C which accelerated the sublimation process, and was constant during the drying process. For this process, each experiment with increasing time periods was carried out with new samples of equal mass, and moisture loss was determined by weighing the samples using a digital balance with 0.01 precision (Ohaus AR2140, USA). The dried kiwi slices (Fig. 1) were stored in closed glass jars in the dark at 20 ± 1 °C until further tests were carried out.

2.3 Mathematical modeling of drying data

The moisture ratio (MR) of kiwi slices during freeze drying was calculated using the following Eq. (1).

where the M t , M 0 , and M e are the moisture content at any time, initial, and equilibrium moisture content (kg water/kg dry matter), respectively.

Twelve well-known thin layer drying models were fitted to the experimental data and are given in Table 1. A nonlinear regression analysis was used to evaluate the parameters of the selected model using the statistical software SPSS 16.0 (SPSS Inc., USA). The proper fit was determined using the coefficient of determination (R2), the root mean square error (RMSE), and the reduced Chi square (χ2) that are described as Eqs. (2), (3), and (4), respectively.

where MR exp,i and MR pre,i is the experimental, and predicted moisture ratio at observation i; N is number of the experimental data points, and n is number of constants in the model.

For determination of the effective moisture diffusivity (Deff) of the freeze dried kiwi slices; Fick’s diffusion model was used in Eq. (5).

where t is the time (s), Deff is the effective diffusivity (m2/s) and L is the thickness of samples (m). For long drying times (MR < 0.6), a limiting case of Eq. (5) is obtained, and expressed in a logarithmic form [29];

The effective diffusivity is typically calculated by plotting experimental moisture ratio in logarithmic form versus drying time. From Eq. (6), a plot of ln MR versus drying time gives a straight line with the slope given in Eq. (7).

2.4 Physical analyses

The moisture content of the fresh kiwi slices and freeze dried kiwi slices was determined according to AOAC [30]. The water activity was measured using the Testo-AG 400, Germany, water activity measurement device. The color values of the kiwi slices (L*, a*, and b* values) were measured with the Minolta CR-400 Colorimeter, Japan and the results were expressed in accordance with the CIE Lab. System. The L* value, is a measure of lightness which ranges between 0 and 100. Increases in the a* value in the positive and negative scales correspond to the increases in the red or green color, respectively. The b* value represents the color ranging from yellow (+) to blue (−).

2.5 Determination and modeling of the rehydration behavior of the kiwi slices

Rehydration experiments were carried out in distilled water at a temperature of 18 ± 1 °C. Samples of the dehydrated kiwi slices were placed inside a beaker. For the experiments, the solid:liquid ratios were adjusted as 1:25, 1:50, 1:75, 1:100, and 1:125 (w:w) which represent possible rehydration conditions. The sample was removed from the water, drained (before weighing, the sample’s surface water was removed gently with filter paper), and the weight was measured every 1 min for the first 5 min of rehydration, then every 10 min for the next until a constant weight was reached (30 min). The change of sample weight and the total soluble solids value of rehydration water as a function of rehydration time were measured by digital balance (Ohaus AR2140, USA) and a digital refractometer (RFM 330, UK) respectively.

The rehydration data were modeled to Peleg’s, and Weibull’s, first-order rehydration kinetic and exponential association models. Peleg’s equation assumes the linear form which is given in Eq. (8) [31]:

where Mt is the moisture (kg H2O/kg dry matter) at time t, M0 (kg H2O/kg dry matter) the initial moisture, t is the rehydration time (min), k1 is the kinetic constant of the model [min. (kg dry matter/kg H2O)], and k2 is the characteristic of the model (kg dry matter/kg H2O). If the rehydration is long enough, the equilibrium moisture content (Me) (kg H2O/kg dry matter) is given in Eq. (9) as;

Weibull model can be represented by (Eq. 10) [32];

where here α is the shape parameter of the Weibull model (dimensionless) and β is the scale parameter(s).The experiments were completed when no more change was observed in the weight of the samples. In addition, the rehydration ratio and weight gain (%) were calculated by Eqs. (11) and (12);

The increase in the soluble solid content measured as °Brix was analyzed using Peleg's model and the following zero- and first-order kinetics in Eqs. (13) and (14).

where, A is the measured and A0 is the initial value of the total soluble solids in °Brix, t is the rehydration time and y0 and y1 are the reaction rate constants for zero and first order kinetic models, respectively.

2.6 Statistical analysis

The data was analyzed using the statistical software SPSS 16.0 (SPSS Inc., USA). The data was subjected to an analysis of variance (ANOVA) which was used to determine the difference between means. The drying and rehydration experiments were replicated twice and all the analyses were triplicated.

3 Results and discussion

3.1 Drying characteristic and evaluation of the models

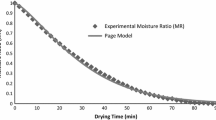

The drying behavior of the kiwi slices during freeze drying was determined from the mass loss in the samples of a known initial moisture content (83.90 ± 0.67 % (wet basis, wb)). The moisture loss was recorded at one hour intervals during freeze drying until a constant weight was achieved. As expected, the major part of the moisture was removed in the early stages of drying and it gradually decreased in later stages. The drying curves obtained by fitting the drying models to the experimental data and model equations are given in Fig. 2 and it was observed that only a falling-rate period took place during freeze drying.

The moisture content data was used in the form of the moisture ratio in the curve fitting computations with respect to the drying time by using twelve thin layer drying models (Lewis, Page, Modified Page I, Henderson and Pabis, Modified Henderson and Pabis, Logarithmic, Midilli, Modified Midilli, Two-term, Two-term Exponential, Modified Two-term Exponential, and Wang and Singh) [23]. The summary of the models parameters (k, n, a, c, b, g, h, k1 and k2) of the twelve thin layer drying models that were used for expressing drying characteristics and the statistical evaluation of the models using three different criteria (R2, RMSE and χ2) are presented in the Table 2. The calculated R2 values were >0.98 for the models except for the Lewis, Modified Page I, Modified Midilli, and Wang and Singh models. The coefficient of correlation (R2) was one of the primary criterions for selecting the best model to define the freeze drying behavior of the kiwi slices. In different studies, thin-layer drying models in which the (R2) value is highest and the RMSE, and χ2 values is the smallest were chosen to be the most suitable models [33–36]. Although the coefficient of correlation of the modified Two-term Exponential model (R2 = 0.997) is higher compared with the Two-term Exponential model, the RMSE (0.0277) and χ2 (0.0794) values of the modified Two-term Exponential model were found to be higher. Therefore, with respect to the given selection criteria, among all the drying tests, the Two-term Exponential model was chosen to estimate the moisture ratio of the kiwi slices at any time during the freeze drying process. The Two-term Exponential model was also found to be suitable by Kaya et al. [18] for the convective drying of kiwi slices. Figure 2 shows the experimental and predicted moisture ratios with the selected eight models which had the high R2 and low RMSE and χ2 values. As seen in Fig. 2 the Two-term Exponential model showed a good agreement with the experimental results for the kiwi slices. The constants, coefficients, and statistical results of the Two-term Exponential model are given in Eqs. (15), (16), and (17), respectively.

In the literature, the convective drying characteristics of kiwi slices were explained with the two term exponential [18], Page [13, 14], and Henderson and Pabis [17] models.

The effective moisture diffusivity (Deff) of the freeze dried kiwi slices was calculated from the Fick’s diffusion model as 7.302 × 10−10 m2/s. For long drying times (MR < 0.6), the first term of the series (n = 1) can be used (Eq. 5). Kaya et al. [18] reported that the effective moisture diffusivity values of kiwi slices which were dried under different drying conditions (air velocity, temperature, and relative humidity) varied between 0.589 and 6.574 × 10−10 m2/s. Simal et al. [13] reported that the effective moisture diffusivity of hot air dried kiwi slices (30–90 °C) ranged between 3.00 and 17.21 × 10−10 m2/s. The Deff value of freeze dried kiwi slices was found to be similar to the Deff value (7.13 × 10−10 m2/s) of the kiwi slices which were dried at a 50 °C hot air temperature [13]. Also, Erbay and Icier [23] reported that the effective moisture diffusivity values in foods were in the range of 10−12 to 10−6 m2/s and 75 % of these values were accumulated in the region 10−10 to 10−8 m2/s, were similar to this study.

3.2 Results of physical analyses

The freeze drying process removed 94 % of the water leading to a final moisture content of 5.01 % (wb). The water activity value of the dried kiwi slices was found to be 0.301 ± 0.01. The color values (L*, a*, and b*, CIE Lab System) of the fresh kiwi slices were found to be 42.40 ± 0.62, −1.87 ± 0.12, and 9.61 ± 0.18, respectively. As shown in Fig. 3, the L* and b* values of the freeze dried kiwi slices increased throughout the drying period and reached the final values of 76.38 ± 0.06 and 22.92 ± 0.02. However, the a* value decreased during drying and reached a final value of −8.38 ± 0.02 indicating an increase in green color.

3.3 Rehydration behavior of kiwi slices and evaluation of the models

For the determination of the rehydration behavior of the freeze dried kiwi slices, the effect of the amount of rehydration water, and time were observed. The moisture contents of the samples were measured during rehydration and it was observed that water uptake of the samples increased significantly during the initial period, but slowed gradually (Fig. 4). The rapid initial water uptake was likely because of the filling of capillaries on the surface of the kiwi slices. As water absorption proceeds, filling of free capillaries and intercellular spaces with water cause a decline of the soaking rate [27]. The results were consistent with other researches [6, 8, 26, 27, 37]. In the rehydration experiments, it was observed that after 15 min, the sample moisture content started become stationary, and the experiments continued until a constant moisture content was observed (30 min) (Fig. 4). Marques et al. [8] reported that rehydration of freeze dried tropical fruits such as pineapple, mango, and papaya occurred in the first 20 min of rehydration (at 25 ± 1 °C).

The kinetics of the moisture absorption of the kiwi slices was modeled by the application of Peleg’s, and Weibull’s, first-order rehydration kinetic and exponential association models. Peleg model has been applied to a large number of dried vegetables and fruits such as mushroom [38], carrot [3], apple [39] and tropical fruits (papaya, mango, guava, pineapple, and acerola) [8]. The results obtained by fitting Peleg’s model to the experimental data, the k1 and k2, and equilibrium moisture content (Xe) are shown in Table 3, together with the statistical results (R2, RMSE and χ2). The parameter k1 is the kinetic constant of the model and Solomon [40] reported that this parameter may be representative of the water absorption rate in the early phase of the rehydration process. The obtained k1 values showed that the fastest rehydration occurs in the lowest solid:liquid ratio and the rehydration decreases with decreasing solid:liquid ratios. Parameter k2 is considered as a characteristic (capacity) constant of the product [31]. In addition, Solomon [40] suggested that this parameter is inversely related to the absorption ability of foods or to equilibrium moisture content. Higher absorption capacity is correlated to a lower value of k2 and vice versa [27]. The values of the parameter k2 was found to be the highest for the rehydration experiments which were performed at the 1:25 (w:w) solid:liquid ratios. This result is correlated to the obtained minimum rehydration ratio (4.58) and water gain (%) (359.70 %) for the 1:25 (w:w) solid:liquid ratio rehydration experiment (Table 4). The minimum value of k2 (0.1755) and maximum value of the rehydration ratio (6.29) and water gain (%) (528.96) were obtained from the 1:50 (w:w) solid:liquid ratio rehydration experiment (Tables 3, 4). For the solid:liquid ratio being <1:50 (w:w), the water absorption capacity decreased according to the solid:liquid ratio. It is difficult to make a comparison between these values due to the differences in experimental conditions and rehydration times assayed by different authors. Nonetheless, the capacity constant (k2) of the freeze dried kiwi slices was found to be similar of freeze dried tropical fruits (0.172–0.456) which were studied by Marques et al. [8] Fig. 4 shows the experimental and predicted moisture ratios with the Peleg’s model. As seen in Fig. 4 the Peleg’s model showed a good agreement with the experimental results for the kiwi slices. Besides Peleg’s model, Weibull’s, first-order rehydration kinetic and exponential association models were also fitted to the experimental data. The results showed that the applied models were not well fitted to the experimental data due to low R2 values. The R2 values of the models were found in the range of 0.677–0.9232 for Weibull and 0.5288–0.8850 for the first-order rehydration kinetic and exponential association models, respectively. Due to the low value of the R2 the results of the model parameters are not given here.

The rehydration ratio and weight gain as water absorption (%) of the freeze dried kiwi slices are shown in Table 4. The rehydration ratio of the freeze dried kiwi slices ranged between 4.58 and 6.29. The results were found to be higher than the rehydration ratio of the freeze dried tropical fruits which ranged between 3.2 (for pineapple) and 5.8 (for acerola) [8] due to the structure of the food material. The results showed that, the rehydration ratios, and weight gain of the dried slices were not significantly affected by the amount of rehydration water. The freeze dried kiwi slices absorbed the highest amount of water in the experiment which was performed at a 1:50 solid:liquid ratio. However, the minimum amount of water was absorbed in the experiment of the solid:liquid ratio of 1:25. Maskan [12] reported that, the weight gain of hot air, microwave, and hot air-microwave dried kiwi slices were found to be around 240, 230, and 170 %. Although, the differences between the weight gains of kiwi slices in these two studies may arise due to the different drying operations and rehydration conditions, freeze dried kiwi slices absorbed almost twice the amount water than hot air, microwave, and hot air-microwave dried kiwi slices due to their porous structure.

The loss in soluble components is unimportant in terms of total mass, but implies possible changes in the structure inside the matrix, and may act to facilitate nutrient losses in foods mechanisms which take place during soaking [41]. The loss of the total soluble solid of the kiwi slices was determined by measuring the total soluble solid content of rehydration water which increased depending on time. The highest total soluble solid content value was observed for the experiment performed with a solid:liquid ratio of 1:25, and was measured as 1.6°Brix. The total soluble solid content values decreased according to amount of rehydration water, and ranged between 0.2, and 1.6°Brix (Fig. 5).

Zero order kinetics, first order kinetics, and Peleg’s models were fitted to data in order to describe the reaction rate as a function of rehydration time and to predict the total soluble solids value. Table 5 shows the parameters, coefficient of determination (y0, y1, k1 and k2), and R2 values. The R2 values changed between 0.7919 and 0.9218 for zero-order, 0.8923 and 0.9906 for first-order kinetic and 0.8499 and 0.9755 for Peleg’s model. These values indicate that first-order models fitted better than zero-order kinetic and Peleg’s models. The reaction kinetic rate (y1) of the total soluble solid content generally decreased with the decreasing solid:water ratios. The larger value of k indicates faster total soluble solids changes in the rehydration water. Several authors described the kinetics of the water uptake and solids dissolution that occurred simultaneously during the rehydration of such food products as dried apple slices [39]. They observed that the amount of solids leaching was significant even for short periods of time.

4 Conclusion

In this study, the freeze drying kinetics and rehydration behavior of kiwi slices were studied. In addition, the physical properties and changes in color values during freeze drying were determined. The results showed that freeze drying can satisfactorily be applied for drying of kiwi slices. Depending on the results, the moisture content (5.01 %, wb) and the water activity (0.301) of kiwi slices are in acceptable limits for safe storage of products. According to the results of the statistical analysis among the 12 thin layer-drying models, the Two-term Exponential model (\(MR = 2.595e^{ - 0.731t} - 1.595e^{ - 0.731*2.595t}\), R2 = 0.997) could adequately describe the thin layer drying behavior of kiwi slices. The rehydration behavior of the freeze dried kiwi slices was determined by the Peleg’s model (R2 = 0.9958–0.9989). Due to the porous structure of freeze-dried kiwi slices, the rehydration process involved high initial water uptake rate followed by a decreased rate and finally approaching a saturation condition. The kinetics of the total soluble solid loss during rehydration were followed the first order reaction kinetic (R2 = 0.8923–0.9906). For further studies, the effect of rehydration temperature and different rehydration solution such as milk, sugar solution etc. might be studied.

References

Krokida MK, Philippopoulos C (2005) Rehydration of dehydrated foods. Drying Technol 23:799–830

Giraldo G, Va´Sques R, Marti´N-Esparza ME, Chiralt A (2006) Rehydration kinetics and solids lixiviation of candied mango fruit as affected by sucrose concentration. J Food Eng 77:825–834

Planinic´ M, Velic´ D, Tomas S, Bilic M, Bucic´ A (2005) Modelling of drying and rehydration of carrots using Peleg’s model. Eur Food Res Technol 221:446–451

Krokida MK, Zacharias B, Maroulis ZB (2001) Structural properties of dehydrated products during rehydration. Int J Food Sci Technol 36:529–538

Mastrocola D, Rosa MD, Massini R (1997) Freeze-dried strawberries rehydrated in sugar solutions: mass transfers and characteristics of final products. Food Res Int 30:359–364

Meda L, Ratti C (2005) Rehydration of freeze-dried strawberries at varying temperatures. J Food Process Eng 28:233–246

Lee KT, Farid M, Nguang SK (2006) The mathematical modelling of the rehydration characteristics of fruits. J Food Eng 72:16–23

Marques LG, Prado MM, Freire JT (2009) Rehydration characteristics of freeze-dried tropical fruits. Lwt Food Sci Technol 42:1232–1237

Cassano A, Figoli A, Tagarelli A, Sindona G, Drioli E (2006) Integrated membrane process for the production of highly nutritional kiwi fruit juice. Desalination 189:21–30

Kiranoudis CT, Tsami E, Maroulis ZB, Marinos-Kouris D (1997) Drying kinetics of some fruits. Dry Technol 15:1399–1418

Ancos B, Cano MP, Hernandez A, Monreal M (1999) Effects of microwave heating on pigment composition and colour of fruit purees. J Agric Food Chem 79:663–670

Maskan M (2001) Kinetics of colour change of kiwifruits during hot air and microwave drying. J Food Eng 48:169–175

Simal S, Femenia A, Garau MC, Rossell C (2005) Use of exponential, Page’s and diffusional models to simulate the drying kinetics of kiwi fruit. J Food Eng 66:323–328

Ceylan I, Aktas M, Dogan H (2007) Mathematical modeling of drying characteristics of tropical fruits. Appl Thermal Eng 27:1931–1936

Kaya A, Aydın O, Dincer I (2008) Experimental and numerical investigation of heat and mass transfer during drying of Hayward kiwi fruits (Actinidia Deliciosa Planch). J Food Eng 88:323–330

Mohammadi A, Rafiee S, Emam-Djomeh Z, Keyhani A (2008) Kinetic models for colour changes in kiwifruit slices during hot air drying. World J Agric Sci 4:376–383

Doymaz I (2009) Mathematical modelling of thin-layer drying of kiwifruit slices. J Food Process Preserv 33:145–160

Kaya A, Aydin O, Kolayli S (2010) Effect of different drying conditions on the vitamin C (Ascorbic Acid) content of Hayward kiwifruits (Actinidia deliciosa Planch). Food Bioprod Process 88:165–173

Ergün K (2012) Investigation of the effects of cooking methods and formulation on the quality characteristics of cakes prepared by the addition of freeze dried kiwi puree powder, M.S. Thesis, Ege University, Graduate School of Natural and Applied Science (In Turkish)

Benlloch-Tinoco M, Moraga G, del Mar Camacho M, Martínez-Navarrete N (2013) Combined drying technologies for high-quality kiwifruit powder production. Food Bioprocess Technol 6:3544–3553

Çalışkan G, Ergun K, Dirim SN (2015) Freeze drying of kiwi (Actinidia deliciosa) puree and the powder properties. Ital J Food Sci 27(3):385–396

Tian Y, Wu S, Zhao Y, Zhang Q, Huang J, Zheng B (2015) Drying characteristics and processing parameters for microwave‐vacuum drying of kiwifruit (Actinidia Deliciosa) slices. J Food Process Preserv 39(6):2620–2629

Erbay Z, Icier F (2009) A review of thin layer drying of foods: theory, modeling, and experimental results. Crit Rev Food Sci Nutr 50:441–464

Akpinar EK (2006) Determination of suitable thin layer drying curve model for some vegetables and fruits. J Food Eng 73:75–84

Keey RB (1972) Introduction. In: Keey RB (ed) Drying principles and practice. Pergamon Press, Oxford, pp 1–18

Krokida MK, Marinos-Kouris D (2003) Rehydration kinetics of dehydrated products. J Food Eng 57:1–7

Noshad M, Mohebbi M, Shahidi F, Mortazavi SA (2012) Kinetic modeling of rehydration in air-dried quinces pretreated with osmotic dehydration and ultrasonic. J Food Process Preserv 36:383–392

Goula AM, Adamopoulos KG (2009) Modeling the rehydration process of dried tomato. Dry Technol 27:1078–1088

Bennamoun L, Kahlerras L, Michel F, Courard L, Salmon T, Fraikin L, Belhamri A, Léonard A (2013) Determination of moisture diffusivity during drying of mortar cement: experimental and modeling study. Int J Energy Eng 3(1):1–6

AOAC, Official Methods of Analysis (2000) Association of Official Analytical Chemists (17th Edn). Gaithersburg, Md, USA

Peleg M (1988) An empirical model for the description of moisture sorption curves. J Food Sci 53:1216–1219

Garcia P, Sanjua´N N, Bon JE, Carreres JE, Mulet A (2005) Rehydration process of Boletus edulis mushroom: characteristics and modelling. J Sci of Food Agric 85:1397–1404

Yaldiz O, Ertekin C, Uzun HI (2001) Mathematical modelling of thin layer solar drying of sultana grapes. Energy 26:457–465

Togrul YT, Pehivan D (2002) Modelling of drying kinetics of single apricot. J Food Eng 58:23–32

Akpinar E, Midilli A, Bicer Y (2003) Single layer drying behaviour of potato slices in a convective cyclone dryer and mathematical modeling. Energy Convers Manage 44:1689–1705

Ertekin C, Yaldiz O (2004) Drying of eggplant and selection of a suitable thin layer drying model. J Food Eng 63:349–359

Balasubramanian S, Sharma R, Gupta RK, Patil RT (2011) Validation of drying models and rehydration characteristics of betel (Piper Betel L.) leaves. J Food Sci Technol Mysore 48:685–691

Hernando I, Sanju´An N, P´Erez-Munuera I, Mulet A (2008) Rehydration of freeze-dried and convective dried Boletus edulis mushrooms: effect on some quality parameters. J Food Sci 73:356–362

Atarés L, Chiralt A, González-Martínez C (2009) Effect of the impregnated solute on air drying and rehydration of apple slices (Ct. Granny Smith). J Food Eng 91:305–310

Solomon W (2007) Hydration kinetics of lupin (Lupines Albus) Seeds. J Food Process Eng 30:119–130

Fito P, Lemaguer M, Betoret N, Fito PJ (2007) Advanced food process engineering to model real foods and processes: the ‘‘Safes” methodology. J Food Eng 83:173–185

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ergün, K., Çalışkan, G. & Dirim, S.N. Determination of the drying and rehydration kinetics of freeze dried kiwi (Actinidia deliciosa) slices. Heat Mass Transfer 52, 2697–2705 (2016). https://doi.org/10.1007/s00231-016-1773-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-016-1773-x