Abstract

The synthesis of galactoglucomannan sulfates using a sulfamic acid/urea mixture in 1,4-dioxane was studied for the first time. The effect of the galactoglucomannan sulfation time and temperature on the sulfur content in the galactoglucomannan sulfates was investigated. The introduction of sulfate groups into the galactoglucomannan structure was confirmed by the elemental analysis and Fourier transform infrared spectroscopy. The initial and sulfated galactoglucomannans were identified by X-ray diffraction, electron microscopy, and gel permeation chromatography. The thermal analysis has shown that sulfated galactoglucomannan, after the endothermic peak related to the moisture removal, yields a pronounced high-intensity exothermic peak with a maximum at 216 °C, and above 230 °C, the heat absorption effect (endothermic peak) characteristic of decomposition of the parent substance in the range of 230–335 °C is observed. According to the scanning electron microscopy data, the initial galactoglucomannan consists of irregular asymmetric particles with an average size from 400 to 900 µm, and the sulfated galactoglucomannan ammonium salt consists of particles 200–500 µm in size with different shapes. It was shown by gel permeation chromatography that, after the sulfation process, the main galactoglucomannan peak shifts toward higher molecular masses (from 24 to 26 kDa).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Plant biomass is a promising inexhaustible source for producing valuable organic matter, including natural polymers and their derivatives. At present, plant-derived polysaccharides have found increasing application as bioactive agents. They exhibit the immunomodulatory, hypolipidemic, mitogenic, prebiotic, hepatoprotective, antimutagenic, and gastroprotective properties (Medvedeva et al. 2003; Dushkin et al. 2013; Willför et al 2008; Liun et al. 2015; Hu et al. 2018; Singh et al. 2015). In addition, polysaccharides have many benefits, including the low toxicity, high water solubility, ability to lock in fat and moisture, and the dispersing properties. With such a wide range of unique properties, polysaccharides are candidates for use in medicine, pharmacy, veterinary, food manufacturing, and cosmetics industry (Dushkin et al. 2013; Willför et al. 2008).

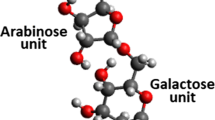

Galactoglucomannans (GGMs) belonging to hemicelluloses are of particular importance for different fields of industry (pulp and paper, textile, pharmaceutical, food, and agricultural) (Willför et al 2008; Kopania et al. 2012). They occur in nature as components of coniferous and deciduous wood hemicelluloses and as reserve substances in legume seeds. The highest natural content (from 10 to 20%) of water-soluble GGMs was found in conifers, although their composition and structure are different for different plant resources (Willför et al. 2008). The study of the structure, properties, modification, biogenesis, and application of GGMs is highly urgent, which is evidenced by the ever-growing number of research findings in this class of biopolymers (Willför et al 2008; Kopania et al. 2012; Xu et al. 2007; Lozhechnikova et al. 2014; Martinichen-Herrero et al. 2005).

A promising direction in the modification of polysaccharides is the synthesis of their derivatives containing sulfate groups. The sulfate groups included in polysaccharides can increase their specific and nonspecific binding to a wide range of biologically important proteins. To date, it has been established that the anticoagulant properties are inherent, to a greater or lesser extent, to different sulfated polysaccharides, both natural (chondroitin sulfates and other sulfated glycosaminoglycans) and synthetic (dextran sulfates, chitosan sulfates, etc.) (Liun et al. 2015; Mestechkina and Shcherbukhin 2010; Alban et al. 2002; Drozd et al. 2006; Fan et al. 2012; Kostyro et al. 2011; Xu et al. 2019; Pereira et al. 2002; Dore et al. 2013; Oliveira et al. 2016; Vo and Kim 2010; Martinichen-Herrero et al. 2005). Sulfated polysaccharides are widespread in nature. They are found in animals, plants, and microorganisms (Dore et al. 2013; Oliveira et al. 2016; Vo and Kim 2010). Some sulfated polysaccharides, in addition to their functional properties, exhibit various pharmacological activities: antiviral, antiparasitic, antiproliferative, anticoagulant, antithrombotic, antiatherosclerotic, antiulcer, radioprotective, and others (Mestechkina and Shcherbukhin 2010; Alban et al. 2002; Drozd et al. 2006; Fan et al. 2012; Kostyro et al. 2011; Xu et al. 2019; Pereira et al. 2002; Dore et al. 2013; Oliveira et al. 2016; Vo and Kim 2010). Among sulfated polysaccharides, special attention is paid to the compounds that suppress retroviral propagation (Vo and Kim 2010).

The biological activity of polysaccharides is believed to be directly related to their structural features, i.e., the length and structure of the main and side carbohydrate chains, the molecular mass, and the ability to form intramolecular and intermolecular complexes (Xu et al. 2019; Oliveira et al. 2016). In sulfation of polysaccharides and related compounds, the complexes of sulfuric anhydride with different basic reagents are widely used (Xu et al. 2019; Martinichen-Herrero et al. 2005; Fan et al. 2012; Gilbert 1965; Huang and Zhang 2010). In Martinichen-Herrero et al. (2005) and Il’ina et al. (2009), sulfation of GGM with chlorosulfonic acid in the presence of formamide and pyridine at a temperature of 4 °C for 12 h was reported. However, the sulfating agents used are toxic and corrosive, which imposes certain restrictions on their large-scale production.

The obvious advantages of sulfamic acid over chlorosulfonic acid are that the former is nontoxic and noncorrosive (Al-Horani and Desai 2010).

The aim of this study was to synthesize GGM sulfates by sulfamic acid in 1,4-dioxane and to investigate them by Fourier transform infrared spectroscopy (FTIR), X-ray diffraction (XRD), scanning electron microscopy (SEM), and gel permeation chromatography (GPC).

Experimental

The sawdust (a fraction of 2.0–5.0 mm) of the Siberian larch (Larix sibirica) grown in the Krasnoyarsk Territory was used. The main larch wood components (wt%) were cellulose (42.2), lignin (28.1), hemicelluloses (26.7), extractive substances (2.0), and ash (1.0).

The larch wood was analyzed using the conventional techniques described in Sjöström and Alén (1999)

Preparation of galactoglucomannan sulfate

Isolation of arabinogalactan

The air-dried larch wood sawdust (a fraction of 2.0–5.0 mm) was loaded in a glass reflux flask by stirring; then, distilled water (HYDROKIT 15) was added and incubated in water bath for 5 h. The hot solution was separated from the wood using a Buchner filtering funnel. The solution was concentrated to 20 vol% on a rotary evaporator. Arabinogalactan was isolated by precipitation with the quintuple ethanol volume (96 wt%) under stirring. The solution with the precipitate was kept in a refrigerator for 12 h; after that, the isolated arabinogalactan was separated by filtering and dried in an Inei-6 freeze dryer. The arabinogalactan yield was 8.3 wt%.

Larch wood delignification

The shredded larch wood was delignified in a 250-ml glass reactor equipped with a stirrer and a reflux condenser. The delignification solution consisted of glacial acetic acid (30 wt%), hydrogen peroxide (6 wt%), and distilled water. The hydromodulus (HM) was 15. The process was carried out for 4 h at 90 °C under constant stirring. When the delignification was completed, a fixed residue (the cellulosic product) was separated from the liquid delignification products using a Buchner filtering funnel, washed until neutral pH, and dried in air.

The residual hemicellulose content in the obtained cellulose product was found to be 3.8 wt%.

Galactoglucomannan extraction

The liquid delignification products were concentrated to 20 vol% with a rotary evaporator. Then, solvent was removed with rotary evaporator. To remove acetic acid, the procedure was repeated twice. Galactoglucomannan was precipitated with the quintuple ethanol volume (96 wt%) under slow stirring and, then, kept for 12 h at a temperature of 4 °C. The obtained white hemicellulose precipitate was separated from the lignin depolymerization products using a Buchner filtering funnel, followed by washing with ethanol, freezing, and drying in an Inei-6 freeze dryer.

The hemicellulose yield was 12.9 mass% of the wood quantity or 88.4 wt% of the hemicellulose content in the initial wood. To determine the monosaccharide composition of the obtained hemicelluloses, the latter were subjected to hydrolysis in the HCl solution (2%) for 3 h. The individual composition and monosaccharide content in the hydrolysates were determined using a Varian-450 GC gas chromatograph. The hydrolysate test portion was pre-derivatized using the technique proposed in Ruiz-Matute et al. (2011) with the formation of trimethylsilyl derivatives.

The monosaccharides contained in the obtained hemicelluloses were (wt%) xylose (4.4), arabinose (1.8), glucose (15.9), mannose (49.5), and galactose (16.8). The high mannose, galactose, and glucose contents in the hemicelluloses indicate that the dominant polysaccharide is GGM with a mannose: galactose: glucose ratio of 3:1:1, which is typical of conifers and consistent with the literature data (Bajpai 2018; Timell 1967).

Sulfation of galactoglucomannan in the presence of urea

Galactoglucomannan was sulfated by sulfamic acid in dioxane in the presence of urea under different conditions (Table 1). For this purpose, dioxane (40 ml), sulfamic acid (4.9–12.1 g or 50–125 mmol), and urea (3.0–7.5 g or 50–125 mmol) were placed into a 100-ml three-neck reflux flask with a thermometer and a mechanical stirrer. The mixture was heated to 70–90 °C under constant stirring, and then, air-dried GGM was added (2 g) and thermostated for 0.5–2.5 h at a specified temperature. After completion of sulfation, the solvent was decanted and the residue was dissolved in water (25 ml). The excess sulfamic acid was neutralized with aqueous ammonia (25%) until neutral reaction. The target product was purified by dialysis against distilled water. After that, the aqueous solution of sulfated GGM (SGGM) was evaporated to dryness in vacuum on a rotary evaporator with the formation of a fixed residue, which was the SGGM ammonium salt.

Sulfation of galactoglucomannan in the presence of organic bases

Galactoglucomannan was sulfated by sulfamic acid in dioxane in the presence of different organic bases (pyridine, dimethylformamide, piperidine, and morpholine). The reagent dosing and purification of the product were performed as described in Sect. “Sulfation of galactoglucomannan in the presence of urea”. The sulfation was carried out for 2.5 h at a temperature of 90 °C using sulfamic acid (12.1 g or 125 mmol) and one of the above-listed organic bases (125 mmol). The sulfation results are given in Table 2.

Dialysis of sulfated galactoglucomannan

The SGGM ammonium salt was purified by dialysis against distilled water in an MF-503-46 MFPI cellophane dialyzing sac (US) with a pore size of 3.5 kDa (− 0.1 μm). The product was dialyzed for 10 h with replacing the water every 1–2 h.

Calculating the yield

The theoretical yield as a function of the sulfur content in the product was calculated using the formula

where mtheor is the theoretical SGGM yield (g), m is the SGGM mass (g), and S is the sulfur content (wt%).

The experimental yield (%) was calculated using the formula

where Yexp is the experimental SGGM yield (%) and mexp is the mass of the obtained SGGM (g).

Methods of the physicochemical analysis

Determining the sulfur content

The sulfur content in the SGGM was determined on a ThermoQuest FlashEA-1112 elemental analyzer (Italy).

Fourier transform infrared spectroscopy

The FTIR spectra of the initial GGM and SGGM were recorded on a Shimadzu IRTracer-100 FTIR spectrometer (Japan) in the wavelength range from 400 to 4000 cm‒1. The spectral data were analyzed using the OPUS software (version 5.0). Solid specimens in the form of tablets in a KBr matrix (2-mg specimen/1000 mg of KBr) were prepared for the analysis.

X-ray diffraction

The XRD study was carried out on a DRON-3 X-ray diffractometer (CuKα-monochromatized radiation with λ = 0.154 nm) at a voltage of 30 kV and a current of 25 mA. The scanning step was 0.02°, and the intervals were 1 s per data point. The measurements were taken in the Bragg angle (2Θ) range from 5.00 to 70.00.

Scanning electron microscopy

Electron microscopy images were obtained on a Hitachi TM-1000 scanning electron microscope (Japan) at an accelerating voltage of 15 kV, a magnification from 100 to 10,000 × , and a resolution of 30 nm. The images were processed using the ImageJ software (version 1.8.0_112).

The GGM and SGGM specimens for the SEM analysis were prepared in the following way. A specimen with a weight of 2 g was dissolved in 20 ml of distilled water; then, 150 ml of ethanol (96 wt%) was added. The forming precipitate was filtered on a paper filter and dried in air to constant weight.

Thermogravimetric analysis (TGA), derivative thermogravimetry (DTG), and differential scanning calorimetry (DSC)

The TGA, DTG, and DSC study was carried out on a NETZSCH STA 449 F1 Jupiter simultaneous thermal analysis instrument (Germany). The thermal decomposition of the samples was analyzed in argon in the temperature range from 30 to 600 °C. The protective and blowout gas flow rates were 20 and 50 ml/min, respectively. The samples were heated in corundum crucibles in the dynamic temperature regime (10 °C/min). The measurement data were processed using the NETZSCH. Proteus Thermal Analysis. 5.1.0 software supplied with the instrument.

Gel permeation chromatography

The weight-average molecular mass Mw, number-average molecular mass Mn, and polydispersity of the SGGM samples were determined by GPC using an Agilent 1260 Infinity II Multi-Detector GPC/SEC System chromatograph with two detectors: a refractometer (RI) and a viscometer (VS). The separation was made on two Agilent PL aquagel-OH columns using the aqueous solution of 0.2 M NaNO3 + 0.01 M NaH2 PO4 (pH 7) as a mobile phase. The column was calibrated using the polyethylene glycol standards (Agilent, US). The eluent flow rate was 1 ml/min, and the sample volume was 100 μl. Prior to the analysis, the samples were dissolved in the mobile phase (1–5 mg/ml) and filtered through a 0.22-μm Agilent PES membrane filter. The data were collected and processed using the Agilent GPC/SEC MDS software.

Results and discussion

Sulfation of galactoglucomannan by sulfamic acid in 1,4-dioxane

The sulfation of GGM by sulfamic acid in dioxane in the presence of urea was performed for 0.5–2.5 h at a temperature of 70–90 °C and different ratios between GGM and the sulfating complex (SC), which was an equimolar mixture of sulfamic acid and urea. The data on the effect of the GGM sulfation conditions on the SGGM yield and sulfur content are given in Table 1.

According to these data, the SGGM yield is no higher than 91.76% and increases with a decrease in the process temperature. Obviously, along with the sulfation of GGM by sulfamic acid, the simultaneous depolymerization occurs, which is caused by the rupture of glycosidic bonds in both the GGM macromolecule and the sulfated biopolymer. This is supported by the GPC data (Sect. “Gel permeation chromatography”). At the SGGM extraction, the depolymerized polymers are removed during the dialysis of the reaction mass. With an increase in the sulfation temperature, the depolymerization rate grows, which reduces the GGM sulfate yield. The study of sulfation of GGM by sulfamic acid in dioxane showed that the maximum sulfur content (16.7%) in SGGM can be obtained at a GGM: SC ratio of 1: 31.25 g/mmol, a process temperature of 90 °C, and a process time of 2.5 h.

The investigation of sulfation of GGM by sulfamic acid in dioxane demonstrated that the maximum sulfur content (16.7%) in the synthesized SGGM is comparable with that in the SGGM obtained using the well-known technique proposed in Martinichen-Herrero et al. (2005) and can be attained at a GGM: SC ratio of 1: 31.25 g/mol and a process temperature of 90 °C for 2.5 h. Note that, under these conditions, an increase in the ratio SC:GGM to 62.5 mmol/g does not significantly affect the sulfur content and the reaction yield. For comparison, during sulfation of arabinogalactan (AG)—a water-soluble biologically active polysaccharide of the Siberian larch wood—by sulfamic acid in dioxane in the presence of the base catalyst (urea), the high degree of AG sulfation (11.5–11.8%) is obtained when it is performed for 2.5–3.0 h at 85–90 °C and an AG: SC reagent ratio of no less than 1: 14 g/mmol (Vasil’eva et al. 2015).

The lower degree of sulfation of AG as compared with sulfation of GGM is probably related to the difference between the AG and GGM structures. The AG molecule has a highly branched structure; the AG macromolecules are believed to exist in a highly compact spherical form (Babkin et al. 2016). Due to the linear structure of GGM and the lower degree of its branching as compared with AG, the GGM hydroxyl groups are easier to sulfate (Kopania et al. 2012).

According to the data given in Table 1, the SGGM yield increases with a decrease in the process temperature and does not exceed 91.76%. Obviously, along with the sulfation of GGM by sulfamic acid, the parallel depolymerization occurs, which is caused by the rupture of glycosidic bonds of both the GGM macromolecule and the sulfated biopolymer. This was confirmed by the GPC data (see Sect. “Gel permeation chromatography”). In the process of SGGM isolation, the depolymerized polymers are removed during the dialysis of the reaction mass. As the sulfation temperature increases, the depolymerization rate grows, which leads to a decrease in the SGGM yield.

The sulfation of the initial GGM was performed with sulfamic acid in dioxane in the presence of urea, pyridine, dimethylformamide, piperidine, morpholine and in the absence of a base catalyst for 2.5 h at a temperature of 90 °C at a GGM: SC ratio of 1: 31.25 g/mmol. The sulfation results are given in Table 2.

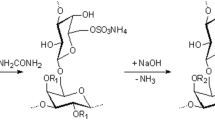

The mechanism of sulfation of polysaccharides by sulfamic acid remains understudied. However, it was assumed (Al-Horani and Desai 2010; Spillane and Malaubier 2014) that, upon sulfation of alcohols, the reaction is first order for sulfamic acid and zero order for alcohol. This points out that the limiting stage is a certain transformation in the acid molecule, which can be its decomposition into ammonia and sulfur trioxide (Fig. 1).

It was found that the rate of the direct interaction of alcohols with sulfamic acid is lower than the catalyzed sulfation rate (Table 2). The enhanced reactivity of sulfamic acid in the presence of base catalysts is explained by the formation of a donor–acceptor complex. Since the S–N bond in donor–acceptor complex I (Fig. 1) is weaker than in sulfamic acid, at the limiting stage the rate of decomposition of sulfamic acid into sulfur trioxide and ammonia increases. In addition, complex I can transform into stable products of interaction between sulfamic acid and a base, for example, in the complexes of this base and sulfur trioxide (Fig. 1); the reactivity of these complexes is determined by the strength of the base.

The use of bases stronger than urea, for example, piperidine or morpholine, as catalysts leads to the lower degree of GGM sulfation because of the possible formation of the lower-reactivity complexes of sulfuric anhydride with these bases (Fig. 1) (Gilbert 1965). The lower degree of sulfation of GGM by sulfamic acid in dioxane with the use of dimethylformamide (weaker base than urea) confirms the above assumption (Benson and Spillane 1980) with regard to the effect of bases on the sulfation rate.

The increased reactivity of sulfamic acid in the presence of base catalysts is explained by the formation of a donor–acceptor complex with high sulfation reactivity (Spillane and Malaubier 2014; Akman et al. 2020; Kazachenko et al. 2020a, b). The rate of direct interaction of alcohols with sulfamic acid is lower than the catalyzed sulfation rate, since the S–N bond in sulfamic acid is stronger than in the donor–acceptor complex (Spillane and Malaubier 2014; Kuznetsov et al. 2020; Benson and Spillane 1980).

The preliminary experiments showed that, in the absence of the base catalyst, sulfation of GGM with sulfamic acid almost does not occur.

Based on the results obtained, it can be assumed that the use of strong bases, for example, piperidine or morpholine, as catalysts leads to a lower degree of GGM sulfation, probably due to the formation of lower-reactivity complexes of these bases with sulfur trioxide at the limiting stage. A low degree of GGM sulfation was also observed with dimethylformamide used as a catalyst.

Thus, the data obtained showed that it is expedient to catalyze the GGM sulfation by sulfamic acid in dioxane with urea.

The process of sulfation of the larch wood GMM by the sulfamic acid–urea complex is illustrated in Fig. 2.

Gel permeation chromatography

The initial larch wood GGM samples, as most plant oligosaccharides, have a low molecular mass (see Table 3 and Fig. 3). Their fairly high polydispersity (2.3) is ensured by the bimodal distribution of the polymer molecular masses in the sample: the main peak is located at MM 24 kDa and the shoulder, around MM 8 kDa.

After the sulfation, the molecular masses in the modified SGGM polysaccharide sample containing 16.7 wt% of sulfur are redistributed. In particular, the main GGM peak shifts toward higher (up to 26 kDa) molecular masses, which suggests a “soft” action of the reagents during the sulfation process, while the side hydrolysis almost does not occur. In the region of lower molecular masses, the picture is somewhat different. The minor peak with MM 8 kDa becomes more pronounced, probably due to the higher reactivity. In this case, the peak almost does not shift, since, in the shorter oligosaccharide chains, the contribution of partial depolymerization of the polymer chains can increase, which leads to the appearance of a peak with MM 3 kDa, and smaller molecules are removed during dialysis. The combination of these factors leads to a slight (up to 2.5) increase in polydispersity.

FTIR spectroscopy study of galactoglucomannan sulfates

The initial and sulfated larch wood GGMs were studied by FTIR spectroscopy (Fig. 4).

The introduction of a sulfate group into the GGM macromolecule was confirmed by the FTIR spectroscopy data (Fig. 4). The FTIR spectra of SGGM, in contrast to those of the initial GGM, contain a high-intensity band at 1251 cm‒1 corresponding to the asymmetric stretching vibrations υas (O=S=O) and consistent with the results reported in Martinichen-Herrero et al. (2005). The absorption bands in the range of 795–810 cm–1, which are not observed in the FTIR spectrum of the initial GGM, are also indicative of the presence of a sulfate group in the GGM sulfate and ammonium salts. The absorption band in the range of 3434–2925 cm‒1 corresponding to the stretching vibrations of the O–H and C–H bonds is broadened due to the superposition of the absorption bands of the stretching vibrations of the N–H bond in the ammonium cation. In addition, there is a high-intensity band at 1445 cm‒1, which corresponds to the vibrations of the N–H bonds of the ammonium cation (Akman et al. 2020; Kazachenko et al. 2020b).

X-ray diffraction

As is known, the galacto- and glucomannans are X-ray amorphous (Mudgil et al. 2012; Ogawa et al. 1991). The comparison of XRD patterns of the GGM samples and the ammonium salt of the GGM sulfate showed (Fig. 5) that, during sulfation, the structure of a material is further amorphized. The XRD pattern of the GGM sulfate ammonium salt sample shows that the peaks in the angular range between 12 and 30° 2°Θ are smoothed (Fig. 5). According to the XRD data, the introduction of a sulfate group into the polysaccharide structure leads to its amorphization, which is consistent with the data from various studies (Kuznetsov et al. 2014; Romanchenko et al. 2015; Šimkovic et al. 2014; Vasilyeva et al. 2014).

The XRD pattern of SGGM differs from the patterns of some natural sulfated polysaccharides, which, in contrast to GGM, are semicrystalline polymers with five main crystal reflections at 13.1°, 23.2°, 26.4°, 32.6°, and 39.4° (Kolsi et al. 2016; Alves et al. 2010).

As was shown in some studies (Kundu et al. 2016; Dassanayake et al. 2019; Su et al. 2013; Adeyanju et al. 2017), the chemical modification of different mannans leads to their amorphization.

Scanning electron microscopy

According to the SEM data, the GGM sample contains irregular asymmetric particles with an average size ranging from 400 to 900 µm (Fig. 6). After sulfation, the patterns have a morphology somewhat different from the initial GGM morphology (Fig. 6). The SGGM ammonium salt consists of particles 200–400 µm in size and of different shapes.

Thermal analysis

Figure 7a shows the thermal effects of substance decomposition. At the initial heating stage (up to 180 °C), the endothermic effect related to the moisture removal was observed. In the GGM sample, no noticeable thermal effects were detected upon further heating. For the sulfated sample after the endothermic peak related to the moisture removal, a pronounced exothermic peak with a maximum at 216 °C appears. Taking into account that, at this temperature, the intense mass loss is observed in the TG curve (Fig. 7b), this is, most likely, a point of decomposition of the sulfate groups with the change in the oxidation degree (the redox reactions). This hypothesis is supported by the fact that this temperature (216 °C) corresponds to the high-intensity narrow peak in the DTG curve (Fig. 7c) and indicates the similar character of decomposition of the compounds.

Above 230 °C, the sulfated sample exhibits the thermal effect of heat absorption (endothermic peak) typical of the primary decomposition of the substances (range of 230–335 °C).

In the TG/DTG curves (Fig. 7b, c), one can distinguish three portions: (I) removal of moisture and volatile components from 30 to 210 °C, where both samples lose about 6% of their initial mass; (II) the main decomposition from 210 to 320 °C for GGM and from 210 to 325 °C for SGGM (a weight loss of 53 and 74%, respectively), where the precipitation of sulfate groups is assumed and, probably, the weight loss can occur both due to the dehydration of pyranose rings and the opening of the latter (Novikov et al. 2020); and (III) the final thermolysis stage from 320 to 600 °C. At the end of the thermolysis, the GGM sample has a residue of 28% and the SGGM sample of 18%; hence, the sulfated sample consists of compounds with a lower decomposition temperature than the initial sample.

Conclusion

In this study, an environmentally friendly method for sulfating GGM by sulfamic acid in 1,4-dioxane in the presence of urea was proposed. It was shown that the water-soluble GGM sulfate with high (17 wt%) sulfur content can be prepared at a temperature of 90 °C for 2.5 h.

The introduction of sulfate groups into the GGM structure was confirmed by the elemental analysis and FTIR spectroscopy. The FTIR spectra of the SGGM include the absorption bands at 1251 and 795–810 cm‒1, which are indicative of the presence of a sulfate group in the GGM molecule.

The initial and sulfated GGMs were analyzed by the XRD, TGA/DSC, SEM, and GPC techniques. The XRD data showed that amorphization of GGM is intensified during the sulfation. The thermograms of galactoglucomannan sulfate show an exothermic peak with a maximum at 216 °C, and an endothermic peak is observed above 230 °C. Decomposition of galactoglucomannan sulfate is observed in the temperature range from 230 to 335 °C.

According to GPC data, the sulfation process does not degrade the main chain of the polysaccharide. The main MMD peak shifts to the high molecular weight area in proportion to the number of introduced sulfate groups (from 24 to 26 kDa). The absence of a low molecular weight area in the SGGM is a consequence of the dialysis process.

References

Adeyanju O, Ewaoche EA, Plavec J (2017) Effect of chemical modification by oxidation on the physicochemical properties of sweitenia mycrophylla gum. Aa potential excipient. J Pharm Appl Chem 3(3):189–194

Akman F, Kazachenko AS, Yu VN, Malyar YuN (2020) Synthesis and characterization of starch sulfates obtained by the sulfamic acid-urea complex. J Mol Struct 1208:127899. https://doi.org/10.1016/j.molstruc.2020.127899

Alban S, Schauerte A, Franz G (2002) Anticoagulant sulfated polysaccharides: part I. Synthesis and structure-activity relationships of new pullulan sulfates. Carbohydr Polym 47(3):267–276. https://doi.org/10.1016/S0144-8617(01)00178-3

Al-Horani RA, Desai UR (2010) Chemical sulfation of small molecules—advances and challenges. Tetrahedron 66(16):2907–2918. https://doi.org/10.1016/j.tet.2010.02.015

Alves A, Caridade SG, Mano JF, Sousa RA, Rei RL (2010) Extraction and physico-chemical characterization of a versatile biodegradable polysaccharide obtained from green algae. Carbohyd Res 345(15):2194–2200. https://doi.org/10.1016/j.carres.2010.07.039

Babkin VA, Neverova NA, Medvedeva EN, Fedorova TE, Levchuk AA (2016) Investigation of physicochemical properties of arabinogalactan of different larch species. Russ J Bioorg Chem 42(7):23. https://doi.org/10.1134/S1068162016070025

Bajpai P (2018) Chapter 2—wood and fiber fundamentals. In: Bajpai P (ed) Biermann’s handbook of pulp and paper, 3rd edn. Elsevier, London, pp 19–74. https://doi.org/10.1016/B978-0-12-814240-0.00002-1

Benson GA, Spillane WJ (1980) Sulfamic acid and its N-substituted derivatives. Chem Rev 80(2):151–186. https://doi.org/10.1021/cr60324a002

Dassanayake RS, Rajakaruna E, Abidi N (2019) Borax-cross-linked guar gum-manganese dioxide composites for oxidative decolorization of methylene blue. J Nanomater 2019:1–11

Dore CM, Faustino DC, Alves MG, Will LS, Costa TG, Sabry DA, de Souza Rêgo LA, Accardo CM, Rocha HA, Filgueira LG, Leite EL (2013) A sulfated polysaccharide, fucans, isolated from brown algae Sargassum vulgare with anticoagulant, antithrombotic, antioxidant and anti-inflammatory effects. Carbohyd Polym 91:467–475

Drozd NN, Bannikova GE, Makarov VA, Varlamov VP (2006) Anticoagulant activity of sulfated polysaccharides. Experim Clin Pharmacol (rus) 69(6):51–60

Dushkin AV, Meteleva ES, Tolstikova TG, Pavlova AV, Khvostov MV (2013) Gel chromatographic and toxicological studies of the mechanochemical transformations of water-soluble polysaccharides. Pharm Chem J 46(10):630–633

Fan L, Gao S, Wang L, Wu P, Cao M, Zheng H, Xie W, Zhou J (2012) Synthesis and anticoagulant activity of pectin sulfates. J Appl Polym Sci 124:2171–2178. https://doi.org/10.1002/app.35239

Gilbert EE (1965) Sulfonation and related reactions. Wiley, New York, pp 217–239

Hu L, Du M, Zhang J (2018) Hemicellulose-based hydrogels present status and application prospects: a brief review. Open J for 8(1):15–28. https://doi.org/10.4236/ojf.2018.81002

Huang H, Zhang W-D (2010) Preparation of cellulose sulphate and evaluation of its properties. J Fiber Bioeng Inf 3(1):32–39. https://doi.org/10.3993/jfbi06201006

Il’ina AV, Levov AN, Mestechkina NM, Drozd NN, Orlovd VN, Makarov VA, Shcherbukhin VD, Varlamov VP, Skryabin KG (2009) The production of nanoparticles based on sulfated polysaccharides and a study of their anticoagulant activity nanotech. Russia 4(3–4):244–252

Kazachenko AS, Malyar YuN, Vasilyeva NYu, Bondarenko GN, Korolkova IV, Antonov AV, Karacharov AA, Fetisova OY, Skvortsova GP (2020a) «Green» synthesis and characterization of galactomannan sulfates obtained using sulfamic acid. Biomass Conv Bioref. https://doi.org/10.1007/s13399-020-00855-2

Kazachenko AS, Vasilyeva NYu, Malyar YuN (2020b) Environmentally friendly guar gum sulfation with a sulfamic acid-urea mixture. J Phys CS 1515:042018. https://doi.org/10.1088/1742-6596/1515/4/042018

Kolsi RBA, Fakhfakh J, Krichen F, Jribi I, Chiarore A, Patti FP, Blecker C, Allouche N, Belghith H, Belghith K (2016) Structural characterization and functional properties of antihypertensive Cymodocea nodosa sulfated polysaccharide. Carbohydr Polym 151:511–522. https://doi.org/10.1016/j.carbpol.2016.05.098

Kopania E, Milczarek S, Bloda A, Wietecha J, Wawro D (2012) Extracting galactoglucomannans (GGM) from polish softwood varieties. Fibres Text East Eur 20/6B(96):160–166

Kostyro YN, Selezneva OA, Eskra AI (2011) Prospects for the development and use of drugs in medical practice based heparinoids. Bull ESSC SB RAMS. 4(80):249–254 (In Russ)

Kundu S, Abdullah MF, Das A, Basu A, Halder A, Das M, Samanta A, Mukherjee A (2016) Antifungal ouzo nanoparticles from guar gum propionate. RSC Adv 6(108):106563–106571

Kuznetsov BN, Levdansky VA, Krylov AS, Levdansky AV, Bondarenko GN, Romanchenko AS, Mazurova EV (2014) Study of products of microcrystalline cellulose sulfation with chlorosulfonic acid in dioxane by FT Raman, XRD, SEM and AFM methods. Chem Plant Raw Mater 3:85–91

Kuznetsov BN, Vasilyeva NYu, Kazachenko AS, Levdansky VA, Kondrasenko AA, Malyar YuN, Skvortsova GP, Lutoshkin MA (2020) Optimization of the process of abies ethanol lignin sulfation by sulfamic acid–urea mixture in 1,4-dioxane medium. Wood Sci Technol 54:365–381. https://doi.org/10.1007/s00226-020-01157-6

Liun J, Willfor S, Xun C (2015) A review of bioactive plant polysaccharides: biological activities, functionalization, and biomedical applications. Bioact Carbohydr Diet Fibre 5(1):31–61. https://doi.org/10.1016/j.bcdf.2014.12.001

Lozhechnikova A, Dax D, Vartiainen J, Willför S, Xu C, Österberg M (2014) Modification of nanofibrillated cellulose using amphiphilic block-structured galactoglucomannans. Carbohydr Polym 110:163–172. https://doi.org/10.1016/j.carbpol.2014.03.087

Martinichen-Herrero JC, Carbonero ER, Sassaki GL, Gorin PAJ, Iacomini M (2005) Anticoagulant and antithrombotic activities of a chemically sulfated galactoglucomannan obtained from the lichen Cladonia Ibitipocae. Int J Biol Macromol 35(1–2):97–102. https://doi.org/10.1016/j.ijbiomac.2004.12.002

Medvedeva EN, Babkin VA, Ostrouhova LA (2003) Larch arabinogalactan—properties and prospects of use (review). Chem Raw Plant Mat 1:27–37

Mestechkina NM, Shcherbukhin VD (2010) Sulfated polysaccharides and their anticoagulant activity (review). Appl Biochem Microbiol 46(3):291–298

Mudgil D, Barak S, Khatkar BS (2012) X-ray diffraction, IR spectroscopy and thermal characterization of partially hydrolyzed guar gum. Int J Biol Macromol 50(4):1035–1039. https://doi.org/10.1016/j.ijbiomac.2012.02.031

Novikov VYu, Konovalova IN, Kuchina YuA, Dolgopiatova NV (2020) Thermal destruction of chondroitin sulphate isolated from Barents Sea hydrobionts. Izv Vyssh Uchebn Zaved Khim Khim Tekhnol 63(1):39–44. https://doi.org/10.6060/ivkkt.20206301.6049

Ogawa K, Yui T, Mizuno T (1991) X-ray diffraction study of glucomannans and their acetates. Agricul Biol Chem 55(8):2105–2111

Oliveira RCR, Almeida RR, Gonçalves TA (2016) A review of plant sulfated polysaccharides and their relations with anticoagulant activities. J Dev Drugs 5:3

Pereira MS, Melo FR, Mourão PAS (2002) Is there a correlation between structure and anticoagulant action of sulfated galactans and sulfated fucans. Glycobiology 12(10):573–580

Romanchenko AS, Levdansky AV, Levdansky VA, Kuznetsov BN (2015) Study of cellulose sulfates by X–ray photoelectron spectroscopy. Russ J Bioorg Chem 41(7):719–724. https://doi.org/10.1134/S1068162015070134

Ruiz-Matute AI, Hernandez-Hernandez O, Rodriguez-Sanchez S, Sanz ML, Martinez CI (2011) Derivatization of carbohydrates for GC and GC–MS analyses. J Chromatogr B 879:1226–1240

Šimkovic I, Tracz A, Kelnar I, Uhliariková I, Mendichi R (2014) Quaternized and sulfated xylan derivative films. Carbohydr Polym 99:356–364. https://doi.org/10.1016/j.carbpol.2013.08.075

Singh RD, Banerjee J, Arora A (2015) Prebiotic potential of oligosaccharides: a focus on xylan derived oligosaccharides. Bioact Carbohydr Diet Fibre 5(1):19–30. https://doi.org/10.1016/j.bcdf.2014.11.003

Sjöström E, Alén R (1999) Analytical methods of wood chemistry. Pulping and papermaking. Springer, Berlin, p 318

Spillane W, Malaubier JB (2014) Sulfamic acid and its N- and O-substituted derivatives. Chem Rev 114(4):2507–2586. https://doi.org/10.1021/cr400230c

Su Y, Shen YD, Lai XJ, Wang XR (2013) Preparation and property of hydrophobic modified guar gum thickener. Adv Mater Res 631–632:260–264

Timell TE (1967) Recent progress in the chemistry of wood hemicelluloses. Wood Sci Technol 1:45–70. https://doi.org/10.1007/BF00592255

Vasil’eva NY, Levdansky AV, Kuznetsov BN, Skvortsova GP, Kazachenko AS, Djakovitch L, Pinel C (2015) Sulfation of arabinogalactan by sulfamic acid in dioxane. Russ J Bioorg Chem 41(7):725–731. https://doi.org/10.1134/S1068162015070158

Vasilyeva NY, Levdansky AV, Karacharov AA, Mazurova EV, Bondarenko GN, Levdansky VA, Kazachenko AS, Kuznetsov BN (2014) Study of structure of product’s obtained by sulfation of arabinogalactan from larch wood with chlorosulfonic acid in pyridine. J Sib Fed Univ Chem 4(7):547–555

Vo T-S, Kim S-K (2010) Potential anti-HIV agents from marine resources: an overview. Mar Drugs 8(12):2871. https://doi.org/10.3390/md8122871

Willför S, Sundberg K, Tenkanen M, Holmbom B (2008) Spruce-derived mannans—a potential raw material for hydrocolloids and novel advanced natural materials. Carbohydr Polym 72(2):197–210. https://doi.org/10.1016/j.carbpol.2007.08.006

Xu C, Willför S, Sundberg K, Petterson C, Holmbom B (2007) Physico-chemical characterization of spruce galactoglucomannan solutions: stability, surface activity and rheology. Cellul Chem Technol 41(1):51–62

Xu Y, Wu Y, Sun P, Zhang F, Linhardt RJ, Zhang A (2019) Chemically modified polysaccharides: SYNTHESIS, characterization, structure activity relationships of action. Int J Biol Macromol 132:970–977. https://doi.org/10.1016/j.ijbiomac.2019.03.213

Acknowledgements

The authors are grateful to G.N. Bondarenko for obtaining the X-ray data and I.V. Korol’kova for recording the FTIR spectra. This study was carried out on the equipment of the Krasnoyarsk Territorial Center for Collective Use, Krasnoyarsk Science Center, Siberian Branch of the Russian Academy of Sciences.

Funding

This study was supported by the Russian Foundation for Basic Research, Project No. 20-33-70256.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kazachenko, A.S., Malyar, Y.N., Vasilyeva, N. . et al. Isolation and sulfation of galactoglucomannan from larch wood (Larix sibirica). Wood Sci Technol 55, 1091–1107 (2021). https://doi.org/10.1007/s00226-021-01299-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-021-01299-1