Abstract

Pretreatment is a critical step in the enzymatic conversion of lignocellulosic substrate to sugars. A unique pretreatment sequence involving thermochemical treatment (steam explosion) followed by biological treatment (fungal exposure) was evaluated for Pinus radiata as a biofuel substrate. The effect of biological treatment using the white rot Trametes versicolor was investigated on control (sapwood blocks) and steam-exploded wood (SEW) for changes in the profile of fungal enzyme activity and lignocellulose composition. The results indicated that compared to blocks, Trametes versicolor expressed more lignocellulose-degrading enzymes when grown on SEW for 6 and 12 weeks. After fungal exposure, the biomass was mixed with a commercial enzyme cocktail for enzymatic hydrolysis. The maximum conversion of biomass to sugars was obtained for Trametes versicolor-treated SEW, with a yield of 4.80 g of glucose l−1, which is greater compared to that obtained from non-fungal-treated SEW (3.80 g of glucose l−1) and Trametes versicolor-treated sapwood blocks (0.80 g of glucose l−1). Examination by microscopy suggests relative increase in the porosity of SEW after fungal treatment, and compositional analysis indicates reduction in lignin content. Both these factors are likely to contribute to the improved hydrolysis of SEW.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Production of energy from lignocellulosic feedstocks, such as wood and wood residues, is an approach which is steadily gaining momentum because of the sustainability of the substrate and environmental acceptability of the processes involved, particularly those based on the application of enzymes and microorganisms. Rapid advances made with biotechnological processes on biomass-based energy generation are showing potential also in economic terms (Somerville 2014). Efficient conversion of biomass into energy products, such as bioethanol, requires enzymatic hydrolysis of the substrate. However, enzyme accessibility of polysaccharides in the native lignocellulosic cell walls is restricted and a pretreatment is required to enhance substrate accessibility, resulting in greater polysaccharide conversion yield (da Costa Sousa et al. 2009). Several thermochemical pretreatment processes have been studied in combination with enzymatic hydrolysis. These include steam explosion, steam treatment with diluted sulphuric acid or sulphur dioxide, organosolv extraction, ionic liquid extraction, and subcritical and supercritical water treatment (Taniguchi et al. 2010). Steam explosion is among the most economical thermochemical pretreatment for enzymatic hydrolysis of cell wall polysaccharides (Brown and Saddler 1987).

The steam explosion couples physical fibre disruption and chemical high-temperature cooking. As a result of steam treatment at high pressure and temperature in the steam explosion process, hemicelluloses are readily hydrolysed within a short period of time and become water-soluble. Lignin may also depolymerise, flow and redeposit on other parts of the substrate, but cellulose is not generally degraded (Tanahashi 1990; Yin et al. 2011). The enhancement in enzyme accessibility of the substrate due to steam explosion treatment results from an increase in cell wall porosity (pore size and volume and surface area of the polymer substrate), as measured by solute exclusion, dextran probes and other techniques (Wong et al. 1988; Michalowics et al. 1991). High-pressure steam treatment often employs an agent that impregnates into lignocellulosic cell walls and exerts an additive effect on destructuring of lignocellulosic cell walls during the steam explosion treatment. Traditionally, SO2 has been successfully used as an impregnation agent (Newman et al. 2013). Other agents, such as CO2, offer advantages from environmental and health perspectives, but compared to SO2, higher temperature and longer residence time are required to achieve comparable outcomes (Ferreira-Leitao et al. 2010).

Biological pretreatments based on microorganisms are attractive as they are less energy demanding and contribute to environmental benefits. Among biological agents attempted so far, basidiomycetes fungi have shown greatest promise in enhancing the yield of glucose alone or in combination with other pretreatment processes, such as thermochemical treatments (Sawada et al. 1995; Zhang et al. 2007; Ray et al. 2010; Taniguchi et al. 2010; Vaidya and Singh 2012).

The work presented here is based on a unique, two-step integrated pretreatment approach (represented schematically in Fig. 1), where Pinus radiata lignocellulosic substrate was first treated thermochemically (steam explosion) followed by fungal treatment using the white rot Trametes versicolor. The response of the sapwood blocks and SEW to fungal treatment was compared from the determination of lignocellulose composition and enzyme profiling. The fungal-treated substrate was hydrolysed using a commercial enzyme cocktail to evaluate whether fungal treatment enhances the glucose yield (g l−1). In addition, for fundamental understanding, microscopy was used to examine microstructural changes in the substrates before and after fungal treatment. The results obtained demonstrate that the novel sequence of substrate pretreatment involving thermochemical treatment (steam explosion) followed by biological treatment (fungal exposure) was very effective for conversion of the biomass to sugars.

Materials and methods

The commercial enzymes were purchased from Novozymes (Bagesward, Denmark), and sodium citrate and sodium azide from Sigma-Aldrich. The fungus used for the pretreatment was white rot Trametes versicolor L. Lloyd. The two biomass materials of Pinus radiata were: sapwood of sawn timber (blocks) and steam-exploded wood (SEW). Wood chips were used to prepare the SEW (Newman et al. 2013). Approximately 0.75 kg chips were taken with a moisture content of 60 %, impregnated with SO2 (3 % w/w) and heated with steam at 215 °C for 3 min. The pulp was washed four times with water and oven-dried at 110 °C to obtain a 54 % yield (Cameron et al. 2015). The wood biomass samples (2 g) were transferred aseptically into sterile containers (Sutter jars) containing 2 % (wv−1) malt extract agar and had an active growth of the test fungus inoculated 2 weeks prior to the placement of blocks or SEW in the jars. A perforated Perspex mat was placed between the fungus growing on the malt extract agar and blocks to prevent contact of the wood with the agar medium. The SEW was placed in a plastic plate with minute-perforated holes in the bottom to give uniform access of the substrate to fungal hyphae. Both biomass samples were exposed to the test fungus for 6 and 12 weeks at 26 °C and 75 % relative humidity. Three replicates per biomass and per incubation time were used. At the end of the exposure period, the biomass (blocks or SEW) was brushed carefully to remove any adhering mycelium and placed on racks to air-dry for 3–4 days. The blocks and SEW were Wiley-milled and sieved to a defined particle size of 250 μm. The biomass composition was determined by the standard NREL method, using ion chromatography extraction according to Sluiter et al. (2006). The change in biomass composition after fungal treatment was calculated (Yu et al. 2010) from following equation:

The values of the three components cellulose, hemicellulose and lignin were measured with an average of three replicates with standard deviation. The cellulose was measured as total glucan.

The crude enzymes were extracted from 0.5 g pretreated biomass, suspended in 5 ml of 0.05 M of Na-citrate buffer (pH 5) and incubated on a rotatory shaker at 15 °C for 2 h at 220 rpm. This incubation time was selected as further incubation did not show any improvement in enzyme activities. Crude enzyme was recovered by centrifugation at 4000×g for 20 min. The profiling of key lignocellulose-degrading enzymes such as cellulase (EC 3.2.1.4), β-glucosidase (EC 3.2.1.21) and laccase (EC 1.10.3.2) was performed. β-Glucosidase (Bailey and Nevalainen 1981), cellulase (IUPAC 1987) and laccase (Narayanan Niladevi et al. 2008) activities were measured from the separated filtrate.

Confocal microscopy was performed using lignin autofluorescence (Donaldson 2013) in combination with FITC-labelled wheat germ agglutinin (WGA) to label fungal hyphae (Meyberg 1988). Samples were mounted in 50 % glycerol in phosphate buffer at pH9 (Donaldson 2013) and examined with a Leica SP5 II confocal microscope. Sequential excitation wavelengths were 488 and 561 nm with emission of 500–570 (green) and 570–700 (red) nm. The transmission electron microscopy (TEM) of the samples was processed according to Singh et al. (2002). Briefly, the samples were dehydrated in acetone and embedded in Spurr’s resin. Ultrathin sections were cut with a diamond knife, stained with 1 % aqueous KMnO4 and viewed with a TEM. Using example images of SEW and SEW + white rot, porosity was measured using digital image analysis with ImageJ software (Arganda-Carreras et al. 2010). Images were binarised to distinguish lignin from pores assumed to be areas containing unstained polysaccharides including cellulose (Donaldson et al. 1988). A Euclidean distance map was calculated for all of the pores, and the central position, equivalent to the radius of each pore, was masked by skeletonisation of the binary image and multiplied by a factor of 2 to convert radius to diameter, yielding a histogram of pore size distribution with appropriate calibration in nm (Russ 1995).

The fungal-treated substrate was hydrolysed using a commercial enzyme cocktail as follows: The biomass used for this experiment had been incubated for 12 weeks. Enzymatic hydrolysis was carried out in 20-ml screw-capped glass tubes, taking 1.5 % biomass concentration in 5 ml of 0.05 M sodium citrate buffer pH 4.8 containing 0.01 % wv−1 sodium azide at 50 °C. The tubes were agitated at 180 rpm on an inclined vibratory shaker. Enzyme loading of Celluclast 1.5 L was 20 FPU g−1 of dry substrate, and β-glucosidase was supplemented with Novozyme 188 to 25 IU g−1 of dry substrate. The samples for glucose analysis were taken after 24 h of hydrolysis. The enzyme reaction was stopped by plunging the tube into boiling water for 5 min and then cooling in a water bath to bring it to room temperature. The mixture was then centrifuged at 4000×g for 10 min at 25 °C, and the clear supernatant was collected for glucose estimation using YSI 2700D glucose analyser. Each experiment was run in triplicate, and average values are reported. The untreated SEW and control wood blocks Wiley-milled to obtain 250-μm particles were used as controls.

Results and discussion

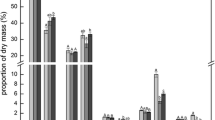

The analysis of substrate composition of P. radiata blocks exposed to T. versicolor for 6 weeks of incubation showed minor (5 %) cellulose hydrolysis (Table 1). Enzyme profiling showed low levels of enzyme activities. There was no change in the relative activity of β-glucosidase (12.0 %) from 6- to 12-week incubation, whereas cellulase activity increased from 26.5 to 33.7 % in the same incubation period. Interestingly, lignin was not degraded, though laccase was expressed (26.2 and 28.6 %, respectively), which may be because lignin in the intact blocks was not accessible to laccase. In the case of SEW, the content of cellulose and lignin was noticeably reduced during fungal incubation, with a greater reduction in cellulose after 12 weeks (40 %). In a previous study on the degradation of beech wood meal holocellulose using Phanerochaete chrysosporium ME446, Sawada et al. (1995) reported 50 % loss of cellulose after 70 days of incubation, and rapid degradation of lignin to 42 % during an incubation time of 28 days. In comparison, there was less reduction in lignin content (13 %) by T. versicolor grown on SEW. The lower degradation of lignin in SEW may be because lignin softens during steam explosion treatment and is redistributed within the substrate, becoming less accessible to the fungal enzymes, or lignin becomes more condensed and recalcitrant during steam explosion (Chen et al. 2012).

The data on enzyme profiling support the results from the analysis of substrate composition. The activity was greater for all three enzymes with SEW compared to blocks (Table 2). It is plausible that compared to blocks, changes in the chemistry of the SEW and increased porosity during thermochemical treatment elicited greater expression of enzyme activity. The main change in the composition of the substrate by steam explosion is loss of hemicelluloses (only 2 % left) at high temperature and pressure. Using FTIR analysis of early and late softwood, Yin et al. (2011) reported continuous reduction in xylan band at 1738 cm−1 and mannan band at 810 cm−1, suggesting a continuous breakdown and loss of hemicellulose when the steam temperature reached 160 °C or higher. Additionally, acetic acid is produced during hydrothermal treatment mainly due to a split-off of acetate groups from the hemicelluloses (Sundqvist et al. 2006). The little hemicellulose left in the SEW (2 % w/w) substrate remained unchanged during fungal treatment (Table 1). Therefore, there was no reason to monitor xylanase and mannanase (hemicellulase) activities after 6 and 12 weeks of fungal incubation.

The higher expression of fungal enzymes and greater lignin degradation (13 %) in SEW facilitated subsequent hydrolysis with commercial enzymes (Table 3), resulting in six times higher glucose yield from fungal-treated SEW (4.80 g of glucose l−1) compared to untreated blocks (0.8 g of glucose l−1). Commercial enzymatic hydrolysis of non-fungal-treated SEW gave 3.80 g of glucose l−1. Thus, fungal exposure of the substrate after thermochemical treatment gave almost 20 % increase in the glucose yield. Similarly, Ray et al. (2010) and Sawada et al. (1995) independently reported similar increases in glucose yield. In another study, biological pretreatment using E. taxodii in combination with post thermochemical treatment of corn straw, gave higher yield of sugar compared to only thermochemical treatment (Yu et al. 2010). This suggests that fungal pretreatment works synergistically (Schilling et al. 2009) with hydrolysis by commercial enzymes, leading to higher glucose yields from SEW substrates. In sharp contrast, there was little difference in the glucose yield of wood blocks with and without fungal treatment which again points to the restriction in accessibility of the fungal/commercial enzymes. The effect of pretreatment was further investigated by microscopy to obtain fundamental information on microstructural changes (Fig. 2).

Fluorescence micrographs: a Untreated radiata pine using lignin autofluorescence showing the middle lamella (ML) and secondary wall (S2). b White rot-decayed radiata pine wood stained with WGA to show fungal hyphae (arrow) and lignin autofluorescence. c White rot-decayed radiata pine wood showing natural autofluorescence. A thin modified layer can be seen adjacent to the lumen surface of decayed tracheids (arrow). d Steam-exploded wood showing fibre fragments and fines containing middle lamella (ML) and secondary wall (S). Scale bars 30 μm

The tissues of untreated P. radiata blocks typically consist of intact cell walls. Transmission electron microscopy showed the secondary wall layers clearly distinguished individually and from each other, based on differences in their thickness, position within the double wall, density and texture (Fig. 3a). The margins of cell walls from fungal pretreated blocks appeared highly irregular in places, an indication that the fungal attack progressed from exposed faces of the cell wall (Fig. 3b, c). Fluorescence images show a thin (~1 μm) degraded layer adjacent to the eroded lumen surface of decayed tracheids (Fig. 2c). Interior cell wall regions appeared sound and relatively intact similar in appearance to cell walls from control blocks.

Transmission electron micrographs: a Tracheid cell walls in untreated radiata pine wood. Cell walls appear compact, with middle lamella (ML) and secondary cell wall layers (S1, S2, S3) readily identifiable. b Steam-exploded wood showing variable nanostructure varying from dense structures to granular porous regions of secondary wall where lignin distribution has been altered by the pretreatment. c Steam-exploded wood showing detail of porous secondary wall fragments. A region of this image (box) was used for the pore size measurement in Fig. 4. Lignin appears as darkly stained lamellae (arrow). d Steam-exploded wood exposed to white rot fungus showing a wide range of porosity in various cell wall fragments from relatively compact to granular textures. A region of this image (box) was used for the pore size measurement in Fig. 4. Scale bars 2 μm

Steam explosion treatment caused extensive destruction of tracheid walls, resulting in fibre fragments, fines and small particles (Fig. 2d). TEM shows electron-dense particles largely representing lignin, while lucent regions result from a combination of cell wall loosening, dissolution and removal of remaining hemicelluloses (Fig. 3c, d). These changes in ultrastructure came from separation of lignin and polysaccharides as a result of the pretreatment process (Donaldson et al. 1988; Kallavus and Gravitis 1995; Li and Chen 2014; Yin et al. 2011). Similar variations in the microstructure of SEW have been observed, likely related to wood type and conditions of steam explosion treatment (Kallavus and Gravitis 1995).

Incubation of SEW with T. versicolor and measurement of porosity by image analysis indicate that pore sizes in SEW and SEW treated with white rot are comparable although a higher distribution of greater than 260-nm size pores can be seen in the white rot pretreated sample (Fig. 4). The heterogeneity of the SEW samples makes a quantitative comparison very difficult, so further examination was considered impractical. These results suggest that relative increase in porosity (>260 nm) and reduction in lignin content of SEW possibly due to selective lignin biodegradation (Dias et al. 2010) account for the beneficial effect of the white rot pretreatment in the subsequent enzymatic hydrolysis.

Porosity measurements based on transmission electron micrographs of: a steam-exploded wood as shown in Fig. 3c. b White rot (T. versicolor)-treated steam-exploded wood as shown in Fig. 3d. Measurements are based on image analysis using Euclidean distance maps of regions which did not stain for lignin assumed to contain cellulose substrate. The mean value for steam-exploded wood is 57 nm with a maximum of 243 nm. The mean value for white rot (T. versicolor)-treated wood steam-exploded wood is 39 nm with a maximum of 561 nm. The pore sizes are thus more or less comparable but with a small number of larger pores in the white rot-treated sample

Scientific and technological advances are continually being made to improve the yield of glucose from lignocellulosic substrates, with greatest attention given to modifying pretreatment processes. Basidiomycete fungi deploy radical generating systems (Enoki et al. 1997; Hammel et al. 2002), which are effective in loosening the structure of lignocellulosic cell walls, facilitating entry of enzymes into the cell wall resulting in increased yield of fermentable sugars from subsequent enzymatic action on the pretreated substrate (Itoh et al. 2003). However, it is necessary to properly tune pretreatment conditions, because under more extreme conditions, a loss in the digestibility of the substrate can occur due to its structural collapse (Wong et al. 1988).

Conclusion

The correlative compositional and micromorphological information contributed to understanding why the unique pretreatment sequence (thermochemical followed by fungal pretreatment) employed resulted in greater biomass to glucose yield with SEW. Compared to untreated blocks, the already loosened SEW substrate was more readily accessible to radicals and enzymes secreted from the white rot fungus, resulting in reduction in lignin content, greater cellulose hydrolysis and consequent enhancement in enzymatic hydrolysis. The information provided can form an important basis for further improvements in pretreatment processes for enhancing glucose yield based on the novel sequence of substrate pretreatment employed.

References

Arganda-Carreras I, Fernandez-Gonzalez R, Munoz-Barrutia A, Ortiz-De-Solorzano C (2010) 3D reconstruction of histological sections: application to mammary gland tissue. Microsc Res Tech 73:1019–1029

Bailey MJ, Nevalainen KMH (1981) Induction, isolation and testing of stable Trichoderma reesei mutants with improved production of solubilizing cellulase. Enzyme Microb Technol 3:153–157

Brown H, Saddler JN (1987) Steam pretreatment of lignocellulosic materials for enhanced enzymatic hydrolysis. Biotechnol Bioeng 29:228–235

Cameron H, Campion SH, Singh T, Vaidya AA (2015) Improved saccharification of steam exploded Pinus radiata on supplementing crude extract of Penicillium sp. 3. Biotech 5:221–225

Chen WH, Tsai CC, Lin CF, Tsai PY, Hwang WS (2012) Pilot-scale study on the acid-catalyzed steam explosion of rice straw using a continuous pretreatment system. Bioresour Technol 128:297–304

Dias AA, Freitas GS, Marques GSM et al (2010) Enzymatic saccharification of biologically pre-treated wheat straw with white-rot fungi. Bioresour Technol 101:6045–6050

da Costa Sousa L, Chundawat SP, Balan V, Dale BE (2009) ‘Cradle-to-grave’ assessment of existing lignocellulosic pretreatment technologies. Curr Opin Biotechnol 20:339–347

Donaldson LA, Wong KKY, Mackie KL (1988) Ultrastructure of steam exploded wood. Wood Sci Technol 22:103–114

Donaldson LA (2013) Softwood and hardwood lignin fluorescence spectra of wood cell walls in different mounting media. IAWA J 34:3–19

Enoki A, Itakura S, Tanaka H (1997) The involvement of extracellular substances for reducing molecular oxygen to hydroxyl radical and ferric iron to ferrous iron in wood degradation by woo decay fungi. J Biotechnol 53:265–272

Ferreira-Leitao V, Perrone CC, Rodrigues J et al (2010) An approach to the utilisation of CO2 as impregnating agent in steam pretreatment of sugar cane bagasse and leaves for ethanol production. Biotechnol Biofuels 3:7–12

Hammel KE, Kapich AN, Jensen KA, Ryan ZC (2002) Reactive oxygen species as agents of wood decay fungi. Enzyme Microb Technol 30:445–453

IUPAC (1987) Measurement of cellulase activity. (International Union of Pure and Applied Chemistry) Pure Appl Chem 59:257–268

Itoh H, Wada M, Honda Y, Kuwahara M, Watanabe T (2003) Bioorganosolve pretreatments for simultaneous saccharification and fermentation of beech wood by ethanolysis and white rot fungi. J Biotechnol 103:273–280

Kallavus U, Gravitis J (1995) A comparative investigation of the ultrastructure of steam exploded wood with light, scanning and transmission electron microscopy. Holzforschung 49:182–188

Li G, Chen H (2014) Synergistic mechanism of steam explosion combined with fungal treatment by Phellinus baumii for the pretreatment of corn stalk. Biomass Bioenergy 67:1–7

Meyberg M (1988) Selective staining of fungal hyphae in parasitic and symbiotic plant-fungus associations. Histochemistry 88:197–199

Michalowics G, Toussaint B, Vignon MR (1991) Ultrastructural changes in poplar cell wall during steam explosion treatment. Holzforschung 45:175–179

Narayanan Niladevi K, Jacob N, Prema P (2008) Evidence of a halotolerant- alkaline laccase in Streptomyces psammoticus: purification and characterization. Process Biochem 43:654–660

Newman RH, Vaidya AA, Imroz Sohel M, Jack MW (2013) Optimizing the enzyme loading and incubation time in enzymatic hydrolysis of lignocellulosic substrates. Bioresour Technol 129:33–38

Ray M, Leak D, Spanu PD, Murphy R (2010) Brown-rot fungal early stage decay mechanism as a biological pretreatment for softwood biomass in biofuel production. Biomass Bioenergy 34:1257–1262

Russ JC (1995) The image processing handbook, 2nd edn. CRC Press, Boca Raton

Sawada T, Nakamura Y, Kobayashi F, Kuwahara M, Watanabe T (1995) Effects of fungal pretreatment and steam explosion pretreatment on enzymatic saccharification of plant biomass. Biotechnol Bioeng 48:719–724

Schilling JS, Tewalt JP, Duncan SM (2009) Synergy between pretreatment lignocellulose modifications and saccharification efficiency in two brown-rot fungal systems. Appl Microbiol Biotechnol 84:465–475

Singh AP, Daniel G, Nilsson T (2002) High variability in the thickness of the S3 layer in Pinus radiata tracheids. Holzforschung 56:111–116

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D (2006) Determination of sugars, byproducts and degradation products in liquid fraction process samples. Golden, CO: National Renewable Energy Laboratory, NREL/TP-510-42623. http://www.nrel.gov/biomass/pdfs/42623.pdf

Somerville C (2014) How big is the bioenergy piece of the energy pie? Who cares—it’s pie! Biotechnol Bioeng 111:1717–1718

Sundqvist B, Karlsson O, Westermark U (2006) Determination of formic-acid and acetic acid concentrations formed during hydrothermal treatment of birch wood and its relation to colour, strength and hardness. Wood Sci Technol 40:549–561

Tanahashi M (1990) Characterisation and degradation mechanisms of wood components by steam explosion and utilization of exploded wood. Wood Research No. 77

Taniguchi M, Takahashi D, Watanabe D, Sakai K, Hoshino K, Kouya T, Tanaka T (2010) Effect of steam explosion pretreatment on treatment with Pleurotus ostreatus. J Biosci Bioeng 110:449–452

Vaidya AA, Singh T (2012) Pre-treatment of P. radiata substrate by basidiomycetes fungi to enhance enzymatic hydrolysis. Biotechnol Lett 34:1263–1267

Wong KKY, Deverell KF, Mackie KL, Clark TA, Donaldson LA (1988) The relationship between fibre porosity and cellulose digestibility in steam-exploded Pinus radiata. Biotechnol Bioeng 31:447–456

Yin Y, Berglund L, Salmén L (2011) Effect of Steam Treatment on the Properties of Wood Cell Walls. Biomacromolecules 12:194–202

Yu H, Zhang X, Song L, Ke J, Xu C, Du W, Zhang J (2010) Evaluation of white-rot fungi-assisted alkaline/oxidative pretreatment of corn straw undergoing enzymatic hydrolysis by cellulase. J Biosci Bioeng 110:660–664

Zhang X, Xu C, Wang H (2007) Pretreatment of bamboo residues with Coriolus versicolor for enzymatic hydrolysis. J Biosci Bioeng 104:149–151

Acknowledgments

This work was supported by the Scion core funding. We would like to thank Sylke Campion and Sunita Jeram for their help with enzymatic assays and compositional analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, T., Vaidya, A.A., Donaldson, L.A. et al. Improvement in the enzymatic hydrolysis of biofuel substrate by a combined thermochemical and fungal pretreatment. Wood Sci Technol 50, 1003–1014 (2016). https://doi.org/10.1007/s00226-016-0838-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-016-0838-9