Abstract

Hybrid poplar (Populus deltoides × Populus trichocarpa) and Douglas-fir (Pseudotsuga menziesii) wood specimens were densified with three variations of thermo-hydro-mechanical (THM) treatment. The THM treatments differed in the steam environment, including transient steam (TS), saturated steam (SS), and saturated steam with 1-min post–heat treatment at 200 °C (SS+PHT). The bending properties, FTIR spectra, and colour of the THM wood specimens were studied before and after exposure to two different wood decay fungi, brown rot Gloeophyllum trabeum, and white rot Trametes versicolor. The results showed that the performance of densified hybrid poplar wood was considerably poorer than the performance of Douglas-fir heartwood. The FTIR spectra measurements did not show changes in the densified hybrid poplar wood, while some changes were evident in densified Douglas-fir specimens. After fungal degradation, the most prominent changes were observed on the SS+PHT specimens. Colour is one of the most important parameter predominantly influenced by the wood species and the intensity of the densification process for both wood species, while after fungal exposure, the colour of all densified Douglas-fir specimens obtained more or less the same appearance, and densified hybrid poplar specimens resulted in lighter colour tones, indicating that the pattern of degradation of the densified and non-densified specimens are similar. The 3-point bending test results determined that the THM treatment significantly increased the modulus of rupture (MOR) and modulus of elasticity (MOE) of the densified wood specimens, while fungal exposure decreased the MOE and MOR in hybrid poplar and Douglas-fir specimens.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Wood as the ultimate renewable material possesses qualities that have made it a material of choice for millennia, and it is recognized for its positive influence on carbon sequestration and comparatively little energy is required to convert into products. However, as a biological material, it suffers the same fate as many natural materials, namely degradation. There are environmentally friendly methods to enhance wood properties. Thermal treatments are controlled pyrolysis of wood in absence of oxygen. Several technologies have been introduced using various heating media, including nitrogen gas, steam, and hot oil (Homan and Jorissen 2004). Furthermore, mechanical properties of wood can be improved by combined use of temperature, moisture, and mechanical action—so-called thermo-hydro-mechanical (THM) treatments. THM processing can improve the intrinsic properties of wood, to produce new materials and to acquire a form and functionality desired by engineers without changing its environmentally friendly characteristics. There are numerous THM processing techniques, and the number of these processes is growing continuously (Seborg et al. 1945; Inoue et al. 1993; Dwianto et al. 1999; Navi and Girardet 2000; Blomberg and Persson 2004; Kamke and Sizemore 2008). The simultaneous effects of heat, moisture, and compression generate chemical and physical changes, which can be seen as significant colour changes (Tjeerdsma et al. 1998; Koch et al. 2003; Sundqvist et al. 2006; Varga and van der Zee 2008) and which have a strong influence on the surface properties of the THM wood (Jennings et al. 2006; Kutnar et al. 2008a). Moreover, the morphology of THM-densified wood can change considerably depending on the degree of densification (Blomberg et al. 2006; Kutnar et al. 2009).

The hydrothermal treatment in the THM process could account for increased resistance to fungal degradation. Schwarze and Spycher (2005) reported that THM-densified wood post-treated at 180 °C is more resistant to colonization and degradation by brown rot fungi. In contrast, results obtained by Welzbacher et al. (2008) showed that “very durable” to “durable” THM-densified wood is produced only when the thermo-mechanical densification is used in combination with oil-heat treatment. Additionally, Skyba et al. (2008) found that THM treatment increased the resistance of spruce wood to degradation by soft rot fungi, but not of beech wood. Furthermore, Kutnar et al. (2011) determined that viscoelastic thermal compression (VTC) of hybrid poplar did not change decay resistance to fungi-like Pleurotus ostreatus and T. versicolor. Additionally, Ünsal et al. (2008) found that specimens subjected to thermal compression had higher mass losses after a 12-week-decay resistance test than control wood specimens.

The main problem associated with the process of compression is the fixation of compressive deformation. Kutnar and Kamke (2010, 2012a) suggest that the fixation problem of densified wood can be overcome by wood compression under saturated steam conditions at 170 °C and post–heat treatment at 200 °C. These conditions of compression influenced the build-up of residual internal stresses, stress relaxation, thermal decomposition, development of chemical bonds in the cell wall, and loss of hygroscopicity. Since the thermal decomposition in the THM treatment under saturated steam and post–heat treatment at 200 °C could increase resistance to fungal degradation, the aim of this paper was to examine the resistance of the THM-treated wood to fungal degradation. Furthermore, the aim was to determine the bending properties, FTIR spectra, and colour changes of the THM wood produced in different steam environments before and after fungal exposure. It is presumed, that densified material will perform better against wood decay fungi resulting in the reduced rate of the degradation process. Influence of densification process on decay resistance is supposed to be more evident in poplar wood when compared to the more durable Douglas fir.

Materials and methods

Material

Wood of low density hybrid poplar (P. deltoides × P. trichocarpa) from a plantation located in north-eastern Oregon and of Douglas-fir heartwood (Pseudotsuga menziesii) was air-dried and then placed in an environmental controlled room (20 °C, 65 % relative humidity) until equilibrium moisture content of approximately 12 % was achieved. The strips were then planed to reduce thickness to 6 mm (radial) and cut to a length and width of 100 mm (longitudinal) and 60 mm (tangential).

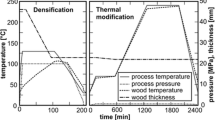

Compression procedures

The densification process was performed in a pressurized vessel equipped with a heated hydraulic press at a temperature of 170 °C. In all processes, the uncompressed specimens were first exposed to saturated steam for 3 min. After the initial steaming phase, the procedures differed during the application of compression loading as listed in Table 1. In the process with transient conditions (TS), the compression load was applied 10 s after steam release such that transient conditions of moisture content and temperature occurred in the specimens during compression. In the process with saturated steam (SS), specimens were compressed under constant saturated steam pressure. In both processes, the specimens were loaded under constant stress of 5.5 MPa for 3 min. In the process with the post–heat treatment at 200 °C (SS+PHT), specimens were compressed like SS specimens, and then the temperature of the platens was increased to 200 °C over a period of 90 s while the compression load was maintained. When the temperature of the platens reached 200 °C, specimens were held under compression at 5.5 MPa for 1 min. All three processes were completed with a final cooling stage below 100 °C while the specimens were held under compression at 5.5 MPa.

Before and after treatment, the specimen weight and dimensions were measured. The compressed specimens were placed in a controlled environment with 65 % relative humidity at 20 °C. For comparison, non-densified Douglas-fir and poplar samples were prepared as well.

Mechanical analysis

To determine the influence of fungal exposure on the modulus of rupture (MOR) and modulus of elasticity (MOE) of THM-densified wood, 3-point bending tests were performed. Prior to fungal exposure, all tested specimens (45 by 16 mm) were tested in bending to determine the MOE; specimens were loaded to 30 % maximum loading force. After fungal exposure, specimens were tested in bending to failure; the MOE and MOR after fungal exposure were determined. Bending test specimens were conditioned in an environment room (20 °C, 65 % relative humidity) prior to testing. Although the thickness of compressed specimens differed depending on the applied compression process and set recovery of the compressed deformation after fungal exposure, the bending test span was constant at 30 mm. The load was applied at the midpoint in 3-point bending. The loading rate was 2 mm min−1. MOR and MOE were calculated based on the thickness at the time of the bending test.

Fungal exposure

Preconditioned specimens 40 mm long (longitudinal) and 16 mm wide (tangential)) were steam sterilized (121 °C) for 30 min and exposed to two different wood decay fungi; brown rot G. trabeum (ZIM L018) and white rot T. versicolor (ZIM L057) for 2, 4, 6, or 8 weeks according to the modified EN 113 procedure (EN 113:2004). Those two fungal species were chosen as they are standard fungal species used for durability assessment and particularly G. trabeum appears on the thermally modified timber in above ground applications in the Ljubljana field test site. Two specimens were exposed in the same incubation jar (V = 600 mL). The surface of the inoculated nutrient medium was approximately 115 cm2. After fungal exposure, specimens were isolated, oven-dried, and weighed again. For comparison, beech wood (Fagus sylvatica) and Norway spruce wood (Picea abies) specimens were exposed to the fungi as well. The decay resistance tests were performed with five replicate specimens.

FTIR and colour measurements

Diffuse reflectance infrared Fourier transform DRIFT spectra of wood samples were recorded between 4,000 and 450 cm−1 with a Perkin Elmer FTIR Spectrum 2000 ONE Spectrometer using Abrasive Pad 600 Grit-Coated, PK/100 (Perkin Elmer) paper. Spectra were collected at 4 cm−1 resolution by co-adding 16 scans. Spectra were displayed in transmittance and limited to the region of interest: 2,000–600 cm−1. The colour of the specimens was recorded with HP Scanjet G4050 scanner. A scanner was chosen, as specimens were too narrow for measurements with colorimeter. The colour obtained with scanner and colorimeter gives comparable results (Noč 2006). The reported values are average values of seven replicate measurements performed on seven separate specimens. The colour was expressed in CieL*a*b* format (Brock et al. 2000).

Results and discussion

Density of compressed wood

The density of the compressed specimens was significantly influenced by the compression treatment (Tables 2, 3). Lower initial density of hybrid poplar specimens resulted in lower compression modulus and consequently in higher compression deformation. The THM treatments caused higher increase in density in hybrid poplar specimens, where the compression increased the density from 424 kg/m3 to approximately 1,150 kg/m3 regardless of the steam condition of the THM treatment. In Douglas-fir specimens, higher initial density when compared to hybrid poplar caused smaller increase in density. Furthermore, density of THM-treated Douglas-fir specimens under saturated steam conditions and specimens that were post–heat treated at 200 °C after compression was approximately the same, while compression under transient condition caused lower increase in density (Table 2).

Biological durability

Results of decay test of beech wood specimens and Norway spruce specimens confirmed that both fungi used in the study were vital (Tables 2, 3). Norway spruce wood, exposed to brown rot fungus A. vaillantii lost almost 39 % of the mass after 8 weeks of exposure, while beech wood specimens decayed by white rot fungus T. versicolor on average lost 46 % of their mass. Mass loss of both, beech and spruce wood continuously increases with exposure time. Even rather short periods of 2 weeks were sufficient to result in a mass loss of 7 % for both wood species. This clearly shows the degrading ability of both fungal strains tested.

Performance of Douglas-fir against brown rot fungus A. vaillantii can be resolved from Table 2. The results are in line with the classification in EN 350-2 (1994), where Douglas-fir is classified as a moderately durable wood species. Mass loss of the control Douglas-fir specimens after 8 weeks of exposure was almost five times lower (8.4 %) than mass loss of spruce wood specimens (38.7 %). Densification of the specimens with TS and SS treatment did not have a statistically significant influence on the performance against brown rot fungus. Mass losses of the TS and SS specimens were comparable to mass losses of control Douglas-fir specimens. On the other hand, mass losses of Douglas-fir SS+PHT specimens were slightly higher than mass losses of non-densified specimens after all exposure times. A main reason for decreased wood durability after post–heat treatment may lie in the degradation of extractives during heating procedure. Similar findings are reported for panel boards produced from pine wood (Ünsal et al. 2008). It is presumed that extractives were at least partially degraded during post–heat treatment, which consequently decreased the natural durability of the SS+PHT specimens.

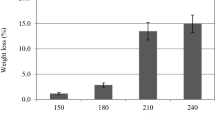

Performance of densified hybrid poplar wood was considerably poorer than the performance of Douglas-fir wood (Tables 2, 3). The most important reason for low performance of densified poplar lies in low natural durability of poplar wood (EN 350-2 1994). Mass losses of densified hybrid poplar wood after 8 weeks were between 24.8 and 31 %, which is only slightly lower than mass losses of non-densified hybrid poplar. The results in Table 3 clearly show that time of wood exposure to high temperature and steam environment in the densification processes is too short to ensure better performance of poplar wood against wood decay fungi. Even more, the pattern of mass losses regarding the fungus exposure time in densified wood and non-densified wood was similar, which demonstrated that duration of densification process is too short to increase the durability of hybrid poplar wood specimens.

FTIR analysis

The purpose of this research was not only to determine the durability of densified wood, but also to determine chemical and mechanical properties of partially decayed material. The chemical changes were determined with FTIR spectroscopy. During interpretation of these results, the spectra were recorded only on the surface of the specimens. The surface was in direct contact with wood decay fungi, therefore these changes do not reflect overall chemical changes in wood. Previous results clearly indicated that most of the material of the size used in this experiment is colonized within 1 week of exposure (Humar et al. 2006a).

A number of chemical changes in heat-treated wood have already been reported. Sundqvist (2004) reviewed the studies of chemical changes caused by heat and hydrothermal treatment. The first chemical changes begin at temperatures within the 40–90 °C range; these are predominately caused by certain extractives. At temperatures in the range 90–150 °C, changes occur in all wood components. Splitting of β-aryl ethers and the formation of lignin condensation products at 100–120 °C were found for maple, and haemolytic cleavage of phenolic β-aryl ether in wood lignin was found at around 130 °C. At temperatures between 150–250 °C, major changes occur in wood components, both degradations and modifications. The degradation rate of wood is reported to be higher for steaming and in the presence of air during heating than for dry and air-free conditions.

Changes in the FTIR spectra of the heat-treated wood have been extensively studied (Tjeerdsma and Militz 2005; Hakkou et al. 2005, 2006; Yildiz and Gümüskaya 2007). For example, Hakkou et al. (2005) recorded FTIR spectra on beech samples treated at 160 and 260 °C for 8 h and found that a number of spectral modifications appeared after the heat treatment, even if the general aspect of the spectra remained unchanged.

Changes of the FTIR spectra of the densified hybrid poplar wood were not as evident as could be presumed from the cited literature (Tjeerdsma and Militz 2005; Hakkou et al. 2005, 2006; Yildiz and Gümüskaya 2007). The heat treatment in the densification process was too mild to be evident from the FTIR spectra of hybrid poplar specimens (Fig. 1a). Changes in the FTIR spectra would likely be more evident if treatment time and temperature were increased. On the other hand, more changes were evident for densified Douglas-fir specimens (Fig. 1b). Most prominent was the decrease in the carbonyl band at 1,730 cm−1, indicating degradation of hemicelluloses (Tjeerdsma and Militz 2005). Another smaller change was observed at 1,330 cm−1 for specimens densified according to the most intense process SS+PHT. This peak is assigned to crystallized cellulose I content and indicated that crystallinity of the cellulose might be affected (Hakkou et al. 2005, 2006). However, spectra were recorded on the surface, thus changes in the chemical structure inside the specimens are probably less prominent.

The first evidence of white rot degradation in hybrid poplar became evident after the second week of exposure (Fig. 2) and remained similar, but less prominent, even after 8 weeks of fungal exposure. The reason for the detection of rapid changes by FTIR lies in the fact that the surface, where analysis was performed, was in direct contact with fungal mycelium. White rot fungi degrades predominately lignin and hemicelluloses, therefore the most prominent changes were observed at peaks at 1,730 cm−1 which are assigned to hemicelluloses and 160 cm−1 peaks which are assigned to lignin. Surprisingly, these changes in the FTIR spectra of exposed surfaces were not visible at the less intense treatments (TS and SS), but on the hybrid poplar specimens densified according to the SS+PHT process (Fig. 2). A reason for this occurrence lies in the fact that the hemicelluloses were partly degraded during the post–heat treatment in the densification process SS+PHT. However, differences in the FTIR spectra of various densified hybrid poplar wood specimens after fungal degradation are not that distinctive. This result is in line with other results in the paper. THM treatments did not have significant influence on the fungal decay resistance, thus THM treatment presumably did not affect the structure of the wood to such an extent that fungi should use other degradation patterns.

Similar results were obtained for Douglas-fir heartwood (Fig. 3). However, it should be considered that Douglas-fir heartwood is more durable than hybrid poplar. The exposure to the brown rot fungi did not lead to changes in the FTIR spectra of TS-, SS-, and SS+PHT-densified wood specimens. The most prominent difference was noticed at peaks assigned to hemicelluloses (1,730 cm−1) and aromatic band at 1,595 cm−1. However, similar to hybrid poplar, the SS+PHT-densified Douglas-fir specimens resulted in the most prominent changes. Besides already mentioned differences, the most notable change was observed at the peak assigned to cellulose (1,160 cm−1).

Colour changes

The simultaneous effects of heat and moisture in the densification process generate radical changes in wood structure and a dynamic colour change to a darker tonality. Colour of wood thus clearly represents the severity of the process (Welzbacher 2010). The higher the temperature and/or the longer the treatment time, the darker is the colour, which can be achieved by hydrothermal treatment of wood (Esteves et al. 2008). The effect of thermal and hydrothermal treatment on the colour changes of wood has been studied extensively (Tjeerdsma et al. 1998; Koch et al. 2003; Sundqvist et al. 2006; Varga and Van der Zee 2008). However, the chemical reasons for wood colour changes have not yet been fully clarified, although they seem to originate from complex changes and degradation of hemicelluloses, lignin, and certain extractive compounds (Sundqvist and Morén 2002). In general, it was proved that dimensional stability and performance of the heat-treated material increases with darkness (L value) (Welzbacher 2010). However, the colour enables comparison only between the same species and no significant criterion for interspecies comparison.

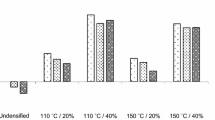

The colour parameters listed in Tables 2 and 3 are a consequence of the process and fungal degradation. Past studies clearly showed that chemical changes are sometimes identified by colour changes (Curling et al. 2002; Humar et al. 2006b). The colour of Douglas-fir heartwood was darker than the colour of hybrid poplar (Tables 2, 3). This result reflects the darker colour of Douglas-fir heartwood compared with poplar wood. Furthermore, Douglas-fir wood is more reddish (7.35) and yellowish (17.1). After the densification, a and b values remained in the same range, but as expected, specimens became darker. Douglas-fir wood that was subjected to the more intense processes SS (L = 58.1) and SS+PHT (L = 54.3) were darker than the TS specimens (L = 66.2). However, after fungal exposure, the colour of all specimens obtained more or less the same appearance, indicating that there were similar degradation patterns involved in all tested materials exposed to brown rot fungus. Values a and b remained in the same range as before exposure. On the other hand, control non-densified specimens after fungal exposure became darker, while the L values of densified specimens remained almost the same. These results were expected, as brown rot fungi in principal degrade cellulose and oxidize lignin (Tomak et al. 2011). However, in densified wood, lignin was oxidized already during the THM treatment (Bekhta and Niemz 2003), therefore the samples were dark. Additionally, the time of exposure to the fungi did not influence the colour of the specimens. Most of the changes appeared rather fast and remained constant during exposure (Table 2). However, it should be considered that colour was determined on the bottom surface of the samples that were in direct contact with fungi. The colour changes of the sample interior were less prominent.

The colour of untreated hybrid poplar wood was rather light, with L values around 97.4, with slightly greenish (a = −0.9) and reddish (b = 8) tones (Table 3). After exposure, the samples became darker (L = 83.0), more yellowish (a = 4.7), while reddish became more prevalent (b = 17.8). As colour is mostly a surface phenomena, the first changes became visible after 2 weeks of exposure and changed very little during further exposure. The densified hybrid poplar was darker than the control specimens. From the data in Table 3, it can be concluded that the colour of the densified material significantly depends on the process. The darkness (L value) was the most significant indicator of the process intensity. Namely, L value of the TS specimens was 68.6, while considerably lower L values were determined for SS (54.7) and SS+PHT specimens (54.9), while other parameters (a and b value) remained almost the same. Exposure of the densified hybrid poplar to T. versicolor in contrast to control specimens did not result in darker colour, but in lighter colour tones. On average, L values increased by 4–22 units (Table 3). The change was more influenced by the initial colour of the specimens than by the exposure time. Thus, this change was more prominent in the SS and SS+PHT specimens than the TS specimens. These results were somehow expected, as white rot fungi are known to possess a mechanism for bleaching of wood.

Bending properties

Applied stress level, temperature, and conditions of steam environment during densification affect the properties of the resulting densified material (Kutnar and Kamke 2012b; Kamke and Kutnar 2011). When deformations in the densification process are largely the result of the viscous buckling of cell walls without any fracture taking place, the strength and stiffness of the wood material are increased approximately in proportion to the increase in density. Kutnar et al. (2008b) studied the mechanical properties of viscoelastic thermally compressed (VTC) wood and found that the increase in the modulus of rupture (MOR) and modulus of elasticity (MOE) was approximately proportional to the increase in density. However, Kutnar and Kamke (2012b) reported that in hybrid poplar specimens compressed under saturated steam MOR and MOE were increased proportionally to the increase in density, while the compression under superheated steam produced a lower increase in MOE and MOR than expected based on the increase in density. While it was reported that compression in transient conditions produced densified wood material with the greatest MOE and MOR, which were increased more than the proportional increase in density.

The analysis of variance of the 3-point bending test results determined that the compression process significantly increased the MOE and MOR of the compressed wood in comparison to untreated specimens (Tables 2, 3). Furthermore, the fungal exposure of densified specimens decreased the MOE in hybrid poplar and Douglas-fir specimens. In Douglas-fir specimens, after 4 weeks of fungal exposure, the highest decrease in the MOE was obtained in the TS specimens and the lowest in the SS+PHT specimens (Table 2). The saturated steam environment caused a smaller decrease in the MOE, and the post–heat treatment at 200 °C contributed to some additional resistance to deterioration. With increasing time of fungal exposure, the MOE decreased, approximately in proportion to the percentage mass loss in all studied groups of specimens. However, the smallest decrease in the MOE after 8 weeks of exposure to fungi was obtained in the SS+PHT specimens and the highest in the TS specimens. Moreover, higher percentage mass loss in the SS+PHT specimens when compared to SS and TS specimens resulted in lower decrease in MOE. The results show that the THM treatment in the saturated steam conditions caused some chemical changes resulting in a smaller effect on the MOE, while the resistance of Douglas-fir wood to degradation by soft rot fungi was not significantly influenced by the THM treatment. Fungal exposure and corresponding mass loss affected also the MOR. In general, higher percentage mass loss resulted in lower MOR (Table 2). After 8 weeks of exposure of Douglas-fir specimens to G. trabeum, the lowest MOR was determined in the control Douglas-fir specimens and the highest in the SS specimens.

The MOE and MOR of THM-treated hybrid poplar specimens were also affected by fungal exposure (Table 3). The lowest decrease in the MOE after 2 weeks of exposure to fungi was determined in control specimens and the highest in the SS specimens. Increased time of fungal exposure caused additional decrease in the MOE, approximately proportional to increased mass loss. However, the rate of decrease with increasing percentage of mass loss was less distinctive than in Douglas-fir specimens. After 8 weeks of exposure to T. versicolor, the highest decrease in the MOE was determined in the TS specimens, although the highest mass loss was obtained in the control specimens. Furthermore, the MOR was affected by fungal exposure. In the control specimens, the MOR decreased after 8 weeks of fungal exposure to 15.5 N/mm2, in the TS specimens to 33.1 N/mm2, in the SS specimens to 70.9 N/mm2, and in the SS+PHT specimens to 60.5 N/mm2.

Conclusion

The mass loss determination, 3-point bending tests, FTIR spectra, and colour measurements of the THM wood specimens before and after exposure to brown rot and white rot fungi established that the degradation resistance of densified hybrid poplar wood was less than that of Douglas-fir heartwood. However, hybrid poplar has very low natural durability. Furthermore, the decay resistance of THM-treated wood was the same or even worse than the decay resistance of control non-densified wood. This was probably due to the short time of the THM densification treatments. Namely, time of wood exposure to high temperature and steam environment in the densification processes was too short to cause better performance of THM wood against wood decay fungi. FTIR analysis revealed only minor changes due to the THM treatment. After fungal exposure, only the SS+PHT-densified specimens revealed pronounced changes in the FTIR spectra. Furthermore, the colour of the specimens after THM treatments was related to the intensity of the process for both wood species, while after fungal exposure, the colour of all densified Douglas-fir specimens became more or less the same appearance and densified hybrid poplar specimens resulted in lighter colour tones, indicating that fungi utilized similar degradation patterns of the material regardless of the densification process. The 3-point bending test results determined that the THM treatment significantly increased the MOR and MOE due to increase in density, while fungal exposure decreased the MOE and MOR in all specimens tested.

Since the THM-treated wood is intended to be used in structural applications, its durability is of great importance. Therefore, future studies should focus on treatments that could improve the durability of THM-treated wood.

References

Bekhta P, Niemz P (2003) Effect of high temperature on the change in color, dimensional stability, and mechanical properties of spruce wood. Holzforschung 57:539–546

Blomberg J, Persson B (2004) Plastic deformation in small clear pieces of Scots pine (Pinus sylvestris) during densification with the CaLignum process. J Wood Sci 50(4):307–314

Blomberg J, Persson B, Bexell U (2006) Effects of semi-isostatic densification on anatomy and cell-shape recovery on soaking. Holzforschung 60:322–331

Brock T, Groteklaes M, Mischke P (2000) European coatings handbook. Hannover, Vincentz Verlag 410 p

Curling SF, Clausen CA, Winandy JE (2002) Relationship between mechanical properties, weight loss and chemical composition of wood during incipient brown-rot decay. Forest Prod J 52:34–39

Dwianto W, Morooka T, Norimoto M, Kitajima T (1999) Stress relaxation of Sugi (Cryptomeria japonica D. Don) wood in radial compression under high temperature steam. Holzforschung 53(5):541–546

EN 350-2 (1994) Durability of wood and wood-based products—Natural durability of solid wood—Part 2: guide to natural durability and treatability of selected wood species of importance in Europe

EN 113 (2004) Wood preservatives—test method for determining the protective effectiveness against wood destroying basidiomycetes—determination of the toxic values

Esteves B, Marques AV, Domingos I, Pereira H (2008) Heat-induced colour changes of pine (Pinus pinaster) and eucalyptus (Eucalyptus globulus) wood. Wood Sci Technol 42:369–384

Hakkou M, Petrissans M, Zoulalian A, Gerardin P (2005) Investigation of wood wettability changes during heat treatment on the basis of chemical analysis. Polym Degrad Stab 89:1–5

Hakkou M, Petrissans M, Gerardin P, Zoulalian A (2006) Investigations of the reasons for fungal durability of heat-treated beech wood. Polym Degrad Stab 91:393–397

Homan WJ, Jorissen AJM (2004) Wood modification developments. Heron 49(4):361–386

Humar M, Amartey SA, Pohleven F (2006a) Influence of corn steep liquor and glucose on colonization of control and CCB (Cu/Cr/B)-treated wood by brown rot fungi. Waste Manage (Oxford) 26(5):459–465

Humar M, Bučar B, Pohleven F (2006b) Brown-rot decay of copper-impregnated wood. Int biodeterior biodegrad 58(1):9–14

Inoue M, Norimoto M, Tanahashi M, Rowell RM (1993) Steam or heat fixation of compressed wood. Wood Fiber Sci 25(3):224–235

Jennings JD, Zink-Sharp A, Frazier CE, Kamke FA (2006) Properties of compression densified wood. Part 2: surface energy. J Adhesion Sci Technol 20(4):335–344

Kamke FA, Kutnar A (2011) Influence of stress level on compression deformation of wood in 170 °C transient steam conditions. Wood Mater Sci Eng 6(3):105–111

Kamke FA, Sizemore H (2008) Viscoelastic thermal compression of wood. US Patent Application No. US Patent No. 7.404.422

Koch G, Puls J, Bauch J (2003) Topochemical characterisation of phenolic extractives in discoloured beechwood (Fagus sylvatica L.). Holzforschung 57(4):339–345

Kutnar A, Kamke FA (2010) The influence of heat treatment on the set recovery of compressive deformation. In: Teischinger A (ed), Processing technologies for the forest and biobased products industries: PTF BPI 2010. Salzburg University of Applied Sciences. Kuchl. Austria. (Austria: Forschung und Wissenschaft. Technik. 1). Berlin: Lit.: 42–47

Kutnar A, Kamke FA (2012a) Influence of temperature and steam environment on set recovery of compressive deformation of wood. Wood Sci Technol 46(5):953–964

Kutnar A, Kamke FA (2012b) Compression of wood under saturated steam, superheated steam, and transient conditions at 150, 160, and 170. Wood Sci Technol 46(1/3):73–88

Kutnar A, Kamke FA, Petrič M, Sernek M (2008a) The influence of viscoelastic thermal compression on the chemistry and surface energetics of wood. Colloids Surf A: Physicochem Eng Aspects 329:82–86

Kutnar A, Kamke FA, Sernek M (2008b) The mechanical properties of densified VTC wood relevant for structural composites. Holz Roh Werkst 66(6):439–446

Kutnar A, Kamke FA, Sernek M (2009) Density profile and morphology of viscoelastic thermal compressed wood. Wood Sci Technol 43(1):57–68

Kutnar A, Humar M, Kamke FA, Šernek M (2011) Fungal decay of viscoelastic thermal compressed (VTC) wood. Eur J Wood Prod 69(2):325–328

Navi P, Girardet F (2000) Effects of thermo-hydro-mechanical treatment on the structure and properties of wood. Holzforschung 54(3):287–293

Noč L (2006) Comparison of colour measurements with a colorimeter and an optical reader. Graduation thesis. University of Ljubljana. Biotechnical faculty. Ljubljana. 56

Schwarze FWMR, Spycher M (2005) Resistance of thermo-hydro-mechanically densified wood to colonisation and degradation by brown-rot fungi. Holzforschung 59:358–363

Seborg RM, Millet MA, Stamm AJ (1945) Heat-stabilized compressed wood. Staypak. Mechanical Eng. 67:25–31

Skyba O, Niemz P, Schwarze FWMR (2008) Degradation of thermo-hygro-mechanically (THM)-densified wood by soft-rot fungi. Holzforschung 62(3):277–283

Sundqvist B (2004) Colour changes and acid formation in wood during heating. Ph. D. Dissertation. Luleą University of Technology, Division of Wood Material Science, Skellefta, Sweden

Sundqvist B, Morén T (2002) The influence of wood polymers and extractives on wood colour induced by hydrothermal treatment. Holz Roh-Werkst 60:375–376

Sundqvist B, Karlsson O, Westermark U (2006) Determination of formic-acid and acetic acid concentrations formed during hydrothermal treatment of birch wood and its relation to colour. strength and hardness. Wood Sci Technol 40(7):549–561

Tjeerdsma BF, Militz H (2005) Chemical changes in hydrothermal treated wood: FTIR analysis of combined hydrothermal and dry heat-treated wood. Holz Roh-Werkst 63:102–111

Tjeerdsma BF, Boonastra M, Pizzi A, Tekely P, Militz H (1998) Characterization of thermally modified wood: molecular reasons for wood performance improvement. Holz Roh Werkst 56(3):149–153

Tomak ED, Viitanen H, Yildiz UC et al (2011) The combined effects of boron and oil heat treatment on the properties of beech and Scots pine wood. Part 2: water absorption, compression strength, color changes, and decay resistance. J Mater Sci 46(3):608–615

Ünsal O, Kartal SN, Candan Z, Arango R, Clausen CA, Green F (2008) Preliminary investigation of biological resistance. Water absorption and swelling of thermally compressed pine wood panels. IRG/WP; 08-40396. Stockholm. Sweden: IRG Secretariat 11

Varga D, Van der Zee ME (2008) Influence of steaming on selected wood properties of four hardwood species. Holz Roh Werkst 66(1):11–18

Welzbacher CR (2010) TMT—interlab—test to establish suitable quality control techniques—Structure and first results. 2010—IRG/WP 10-40503

Welzbacher CR, Wehsener J, Rapp AO, Haller P (2008) Thermo-mechanical densification combined with thermal modification of Norway spruce (Picea abies Karst) in industrial scale—dimensional stability and durability aspects. Holz Roh Werkst 66:39–49

Yildiz S, Gümüskaya E (2007) The effect of thermal modification on crystalline structure of cellulose in soft and hardwood. Build Environ 42:62–67

Acknowledgments

The project was supported by the National Research Initiative of the USDA Cooperative State Research, Education and Extension Service, grant number 2006-35504-17444 and USDA Wood Utilization Research Center Special Grant number 2008-34158-19302. The authors would like to thank the Slovenian Research Agency for financial support within the frame of project P4-0015-0481. Technical support of Mr. Simon Eržen is appreciated as well.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lesar, B., Humar, M., Kamke, F.A. et al. Influence of the thermo-hydro-mechanical treatments of wood on the performance against wood-degrading fungi. Wood Sci Technol 47, 977–992 (2013). https://doi.org/10.1007/s00226-013-0553-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-013-0553-8