Abstract

In this study, the impacts of transglutaminase (TGase)-induced glycosylation and limited enzymatic hydrolysis on the foaming property of soy protein isolates (SPI) and the possible underlying mechanisms were investigated. SPI were first glycosylated with oligochitosan by TGase to produce glycosylated samples (GSPI). GSPI were further hydrolyzed using Protamex with controlled degree of hydrolysis (DH of 1%, 2% and 4%). As compared to native SPI, the foaming stability of GSPI sample was increased from 24.3% ± 3.1% to 40.4% ± 7.6%, and the hydrolyzed GSPI showed enhanced foaming property. GSPI-1% DH showed the best foaming capacity and foam stability, increasing about 2.12 folds and 2.33 folds, respectively. Hydrodynamic-size of dominant distribution peak in GSPI and its hydrolysates (1% DH) were about 3090 and 531 nm, respectively, which were bigger than that of SPI (about 220 nm). The presence of oligochitosan in GSPI decreased surface hydrophobicity, and the subsequent hydrolysis generated an opposite effect. GSPI and its hydrolysates had more flexible tertiary conformations as revealed by intrinsic fluorescence study. Overall, high values of negative zeta potential and apparent viscosity of samples might be responsible for the improved foaming property. This study suggested that TGase-induced glycosylation and limited enzymatic hydrolysis are promising techniques for enhancing the foaming property of SPI, which would broaden the applications of SPI in food industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Soy proteins possess some characteristics such as easy availability, enhanced sustainability and cost-effectiveness [1], combining some desirable nutrition and functional properties. As a result, soy proteins have been widely used as functional ingredients in many foods, including ice cream, breads, cakes, meat, dairy alternatives, noodles and soups [2]. Hence, functional properties of soy proteins can be effectively enhanced by many approaches such as modifying their molecular weight (Mw), net charge and specific amino acids [3].

Some modifications techniques, such as glycosylation, can improve the functional properties of food proteins [4,5,6,7]. The method started with good intentions to combine the characteristics of proteins and saccharides. Proteins are well-characterized for their surface-active properties, such as foaming and emulsifying properties; whereas, saccharides usually exhibit outstanding in strong water holding and thickening properties [8]. Furthermore, it has been demonstrated that protein–saccharide conjugates prepared by covalent linking method have great potential to combine their characteristics, and thus generate new food ingredients with a broader range of food applications [8]. One of the crosslinking methods to produce protein–saccharides conjugates (glycoprotein) is enzymatic glycosylation [8]. Currently, transglutaminase (EC 2.3.2.13, TGase), has been used for the preparation of glycoproteins through covalently cross-linking glutamine side chain and primary amine–saccharides [9]. Actually, TGase was widely used in food industry, basing on the mechanism of TGase catalyzed intra- and inter-molecular cross-linking of the proteins between residues of lysine and glutamine, the products had varied functional properties and biological properties [9, 10]. Through TGase-induced glycosylation, saccharide groups were conjugated into food proteins, the cross-linking of proteins was simultaneously occurred [9]. To enhance functional properties (i.e., emulsion stability) and biological properties (i.e., antioxidant and antimicrobial activities), many food proteins were successfully glycosylated by TGase to generate new glycoproteins or glycopeptides, such as casein, soy proteins, fish gelatin and zein [4,5,6,7].

Limited enzymatic hydrolysis, by cleaving of peptide bonds in a protein, is well-established method to improve functional properties, including solubility and foaming characteristics of proteins. The conducted hydrolysis would confer the products low Mw, exposed ionisable and hydrophobic groups at the interface [11], thus modifying the structure and conformation of the protein, i.e., increase molecular flexibility [2].

Our previous studies showed that a glycosylated and cross-linked soy protein could be generated by TGase-induced oligosaccharide (oligochitosan) glycosylation and crosslinking [5]. The modified soy protein products exhibited improved water binding capacity and emulsion stability [5]. However, the impacts of TGase-induced glycosylation and hydrolysis with Protamex on foaming properties have not been investigated so far.

The objective of the present work is to characterize the foaming properties of soy proteins generated by the treatments of TGase-induced glycosylation and limited hydrolysis. In addition, the possible underlying mechanisms in the protein foam formation and stability were characterized by tertiary structure, hydrodynamic radius and zeta potential, as well as solubility and apparent viscosity.

Materials and methods

Materials and chemicals

SPI was extracted from the commercial defatted soy flour (Harbin Binxian Yuwang Vegetable Protein Co., Ltd., Harbin, Heilongjiang, China) using previously described method [12], and protein content was 92.5% (w/w) determined by the Kjeldahl method. Oligochitosan with an average Mw of 1 kDa and 90% degree of deacetylation was purchased from Zhejiang Golden-Shell Biochemical Co. (Hangzhou, Zhejiang, China). TGase was purchased from Jiangsu Yiming Fine Chemical Industry Co., Ltd. (Qinxing, Jiangsu, China) with an enzymatic activity of 1000 U/g. Protamex is a Bacillus protease complex from Novozymes A/S, (Bagsvaerd, Denmark). 1–anilino–8–naphthalene–sulfonate (ANS) was purchased from Sigma-Aldrich Co. (St. Louis, MO, USA). Milli-Q water was used throughout this study (Millipore Corporation, New York, NY, USA).

Preparation of glycosylated soy protein isolate (GSPI)

GSPI was prepared as previously reported [5]. Briefly, preheated (90 °C, 10 min) stock SPI dispersion at pH 7.5 was mixed with the oligochitosan solution to make a final soy protein content of 4% (w/v), a molar ratio of protein donor to acyl acceptor (oligochitosan) of 1:3. TGase at the level of 10 U/g protein was added into the mixture. The reaction was carried out at 37 °C for 3 h and then the enzyme was deactivated at 85 °C for 15 min. GSPI was obtained after isoelectric precipitation (pH 4.5) and washing twice with water at pH 4.5 to remove free oligochitosan. The precipitation was then resuspended at pH 7.0, and followed by lyophilised and ground to obtain GSPI sample.

Preparation of GSPI hydrolysates using Protamex

GSPI was dispersed in water to obtain the protein concentration of 3.5% (w/v) at pH 7.0 and 60 °C. Then the protease Protamex was added at the level of enzyme/substrate of 1% (w/w). The pH of the mixture was kept constant at 60 °C through the reaction with a pH–stat. The reaction process was monitored by the consumption of 1 mol/L NaOH. Degree of hydrolysis (DH) was quantified according to the method of Adler-Nissen [13]:

where B is the amount of alkali consumed (mL), Nb is the normality of alkali, Mp is the mass of the substrate (protein in grams, % N × 6.25), 1/α is the calibration factors for pH–stat, and htot is the number of peptide bonds (7.8 mequiv/g protein) [13]. GSPI hydrolysates samples with different DHs (1%, 2% and 4%) were prepared. After hydrolysis, the resulting hydrolysates were heated at 85 °C for 15 min to inactivate the enzyme, followed by lyophilization. Crude protein contents of the prepared samples (GSPI-1% DH, GSPI-2% DH and GSPI-4% DH) was determined by the Kjeldahl method.

Solubility

Solubility was evaluated as the method of [14] with minor modification. Samples were dissolved in milli-Q water and adjusted to pH 7.0 using NaOH before the addition of water to give the final protein concentration of 1 mg/mL. The samples were centrifuged at 3500×g for 5 min. Finally, the protein content of the supernatants was determined by Lowry’s method. The solubility was expressed as percentage of as:

Foaming properties

Aliquot (50 mL) of protein dispersions (0.05% w/v, pH 7.0) was agitated at 10,000 rpm for 1 min with an IKA T-25 ULTRA-TURRAX digital mixer. After agitation, sample was immediately poured into the glass cylinder sealed with Parafilm M (Bemis, Neenah, WI, USA) to avoid foam disruption by air circulation. After the foams were prepared, the measurement of foaming capacity was carried out exactly 2 min after the start of agitation. The foaming capacity was calculated according to the following equation [15]:

The whipped sample was allowed to stand at 20 °C for 30 min and the volume of whipped sample was then recorded. Foam stability was calculated as follows:

Intrinsic fluorescence emission spectroscopy

Intrinsic emission fluorescence spectra of five samples (herein SPI, GSPI without hydrolysis, GSPI with DH of 1%, 2%, and 4% samples) were analyzed as described by [16] using a RF-5301 PC fluorophotometer (Shimadzu Corp., Kyoto, Japan). Sample (1 mg/mL in 0.01 mol/L phosphate buffer, pH 7.0) was excited at 290 nm, and the spectra were collected from 300 to 400 nm at 25 °C with a constant slit of 5 nm. All emission spectra were background subtracted using PBS solution.

Measurement of surface hydrophobicity

Surface hydrophobicity was determined fluorometrically using 8–anilinon 1–aphthalenesulphonate sulfonic acid (ANS), according to the method of [17], with slight modifications. Briefly, stock solutions of 0.1–1 mg/mL (on protein basis) were prepared in 10 mmol/L phosphate buffer (pH 7.0). Aliquots (20 μL) of ANS solution (8.0 mmol/L in the same buffer) were mixed with 4 mL of the samples and vortex for 5 s. Samples were then equilibrated at room temperature for 15 min in dark. Fluorescence intensity (FI) was measured in a RF-5301PC fluorescence spectrophotometer (Shimadzu Co., Kyoto, Japan) at 390 nm (excitation) and 470 nm (emission). The linear slope of the FI versus protein content plot was calculated by linear regression analysis and used as an index of surface hydrophobicity.

Hydrodynamic radius and zeta potential

Samples in dispersions (1.0 mg/mL in 10 mmol/L phosphate buffer, pH 7.0) with 10-folds dilution with the buffer were previously prepared and poured into a disposable sizing cuvette. The measurement was conducted using Malvern Zetasizer Nano ZS (Malvern Instruments, Ltd., Malvern, UK) at 25 °C. The refractive index of the aqueous phase was 1.33. The two indices were thus reported based on the Stokes–Einstein and Henry equations, respectively. Each measurement was conducted at least three times.

Apparent viscosity

Apparent viscosity was measured using a controlled shear rheometer (Kinexus Pro + , Malvern Instruments, PA) equipped with a cone-and-plate (40 mm diameter, 4° cone angle) with a 1 mm gap. Protein samples (0.05%, w/v) at pH 7.0 were fully hydrated at room temperature before being loaded on the rheometer. All tests were performed at 25 °C and give 5 min for the sample to relax the stress. The apparent viscosity curves of the dispersions were obtained by monitoring shear rate (s−1) between 0.1 and 100. The error in almost of the apparent viscosity data was less than 0.5%.

Statistical analysis

All experiments or analyses were carried out three times. All reported data were expressed as means or means ± standard deviations. Differences between the means of multiple groups were analyzed by one-way analysis of variance (ANOVA) with Duncan’s multiple range tests (P < 0.05). SPSS 13.0 software (SPSS Inc., Chicago, IL, USA).

Results and discussion

Solubility and foaming properties

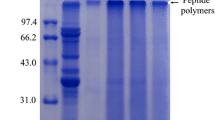

Protein solubility could remarkably affect other properties, such as thickening and foaming activities. Solubility at pH 7.0, representing the neutral conditions and the same pH as evaluation of foaming property, was evaluated (Table 1). GSPI showed less soluble at the tested pH condition. Generally, hydrophilic saccharides conjugation into the protein could improve the solubility, while TGase-treated protein samples were composed of high Mw bands compared to the native protein [18]. Polymers have a strong tendency to aggregate which may decrease their water solubility. The following hydrolysis expectedly increased the solubility, and the obtained hydrolysates in GSPI-DH 4% showed comparable solubility to native SPI (P > 0.05) (Table 1). High solubility would favor the solubility-related functional properties in the food processing, i.e., soluble proteins with high potential to reach the air–water interface by diffusion, adsorption [19], resulting in the foam formation.

Foaming properties of GSPI and its hydrolysates at pH 7.0 were determined by measuring the foaming capacity and foam stability (Table 1). GSPI exhibited similar foaming capacity (29.0% ± 5.8% vs. 26.9% ± 1.5%) but significantly higher foam stability (24.3% ± 3.1% vs. 40.4% ± 7.6%) (P < 0.05) compared to SPI. Saccharide (glucose or galactose) conjugation [20] or polymers generated from TGase-induced cross-linking showed better foam stability and reduced the foam drainage rate [21]. More importantly, the greater improvements in foaming property of GSPI hydrolysates were observed, with high foaming capacity (71.4% ± 9.5% to 90.5% ± 3.8%) and a wide range of foam stability (23.4% ± 9.6% to 80.8% ± 1.8%). GSPI hydrolysates with DH of 1% strongly improved foaming property compared to the native SPI and extensively hydrolyzed GSPI. The values of foaming capacity and foam stability were more than 2-folds increases compared to SPI, reached to 90.5% ± 3.8% and 80.8% ± 1.8%, respectively. The results showed that a soy protein with desirable foaming property could be generated by the treatments of TGase-induced glycosylation and limited hydrolysis.

Intrinsic fluorescence to probe tertiary structure of GSPI and its hydrolysates

Fluorescence emission spectroscopy is a common method to probe conformational features of proteins. Intrinsic tryptophan fluorescence spectra of proteins by monitored the altered peak maxima (λmax) indicate the changes in the tertiary structures [22]. Tryptophan residues are commonly buried within the protein molecules [23]. The λmax of tryptophan emission can range from 302 to 350 nm as tryptophan surface exposed to water [23]. The native SPI exhibited the λmax of tryptophan emission at 342 nm; Red shift (increase in emission λmax of tryptophan) was observed in GSPI and its hydrolysates (343–349 nm) (Fig. 1), indicating the protein unfolding and exposure of the buried tryptophan residues (the chromophors) to aqueous phase [24]. Intrinsic fluorescence studied revealed that combining TGase-induced glycosylation and the following proteolysis disrupted the tertiary structure of SPI and made it more unfolding. Proteins with flexible structure that can be opened and quickly adsorbed benefit to present better foaming properties. Therefore, GSPI and its hydrolysates had enhanced foaming property than SPI, which structure is more difficult to be opened in the interface and slowly adsorbed [19].

Intrinsic tryptophan emission fluorescence spectra of soy protein isolate (SPI) samples with concentration of 1 mg/mL in 0.01 mol/L phosphate buffer at pH 7.0. Excitation wavelength used was 290 nm. GSPI, a glycosylated SPI and without hydrolysis; GSPI-1% DH, GSPI-2% DH and GSPI-4% DH, GSPI with DH of 1%, 2% and 4%

Hydrodynamic-size and zeta potential

Hydrodynamic size corresponds to the core and the swollen corona of the micelles, was evaluated by dynamic light scattering (DLS). Hydrodynamic-size distribution curve of GSPI and its hydrolysates were shown in Fig. 2. After glycosylation by TGase, hydrodynamic sizes lower than 1000 nm in SPI were almost replaced by drastic larger particles, exhibiting a dominant size of about 3090 nm. The larger particles result from TGase-induced cross-linking of proteins and an incorporation of oligochitosan [25]. The following hydrolysis resulted in the cleavage of peptide bonds, the hydrodynamic shifted toward smaller. Significantly decreasing sizes were observed even with 1% of DH, the size of dominant distribution peak significantly decreased from about 3090 to 531 nm, even as low as about 122 nm. Hence, the hydrodynamic sizes in GSPI-DH 4% finally presented almost a single main peak ranging from about 58.7–1484 nm, which was similar to those of native SPI.

These results indicated that the different DHs resulted in hydrolysates with significantly different Mw distribution profile, which might affect the formation of strong interfacial membrane [14, 26]. Both low Mw and amphipathic molecules are benefit for the fast foam formation [19]. Smaller size peptides generating from limited proteolysis could allow more available protein to adsorb at the air–water interface, thereby increasing the foam expansion [27], whereas large peptides and unhydrolyzed proteins may exhibit an inhibitory effect on the foaming properties by hydrophobic interaction and/or steric hindrance at the interface of the foam [28].

Zeta potential is a parameter characterizing electrochemical equilibrium on interfaces. Generally, higher zeta potential could yield stronger repulsion, thereby more stable the system becomes. Zeta potentials of GSPI and its hydrolysates with different DHs treated by Protamex are shown in Table 1. The surface charge in GSPI (− 22.8 ± 0.7 mV) at neutral pH was statistically the same with the natural SPI (− 21.4 ± 0.8 mV) and zeta potentials of its hydrolysates with the increases of DH from 1 to 4% were − 34.6 ± 1.1, − 42.8 ± 2.1 and − 37.5 ± 0.9, respectively.

GSPI was a cross-linked and glycosylated product, the synthetic effects of oligochitosan conjugation and crosslinking of the proteins was probably exhibited: cross-linking led to a more negative zeta potential [29], whereas conjugated saccharide (oligochitosan) provided the positive charge at neutral pH [30]. For GSPI hydrolysates, a high absolute value of zeta potential generally generates a repulsive electrostatic force between the molecules [31], and is almost certainly a consequence of hydrolysis increasing the exposure of charged amino acids previously hidden within the protein’s interior.

The suitable structural attractive electrostatic interactions that enable intermolecular associations improve foaming properties. However, the exceedingly repulsive electrostatic interactions lessen foaming ability, i.e., reduce foam stability and delay the film formation [19]. It could be explained that GSPI hydrolysates exhibited much higher foaming capacity than GSPI and SPI, along with the foaming capacity decreased as the much higher zeta potential observed in high DH of the hydrolysates.

Surface hydrophobicity

Surface hydrophobicity of proteins is usually assessed by ANS fluorescence probe binding technique. This method provides information predicting the behavior of proteins in model systems in the presence of other variables [17]. The surface hydrophobicity of GSPI was significantly lower (P < 0.05) than that of SPI (5.6 ± 0.1 vs. 17.4 ± 0.1) (Table 1), indicating a reduction in overall molecular surface hydrophobicity. Although TGase-treated soy protein resulted in higher surface hydrophobicity [32], surface hydrophobicity environment still deceased with the conjugation of oligochitosan due to the presence of hydrophilic groups. Conjugation of glucose or acacia gum with soy proteins led to lower surface hydrophobicity [33, 34].

Upon hydrolysis, some groups buried inside were exposed after partial hydrolysis [35], which resulted in the increases of the surface hydrophobicity. Surface hydrophobicity of the GSPI hydrolysates was gradually thereby increased with increasing of DHs, while GSPI-DH 4% exhibited statistically the same value as SPI (16.3 ± 0.9 vs. 17.4 ± 0.1), indicated chromophores become more exposed to solvent during the hydrolysis of GSPI, i.e. stronger interactions of ANS with hydrophobic binding sites [19]. It is well established that GSPI hydrolysates had improved foaming capacities compared to GSPI.

Besides hydrophobic interaction, hydrogen bonding between protein molecules was also the main beneficial factors affecting foaming properties [19]. In comparison with SPI, although GSPI had low surface hydrophobic value, hydrogen bonding from hydrophilic groups in conjugated oligochitosan may partially contribute to improve the foam stability in GSPI.

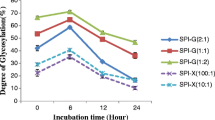

Apparent viscosity

Steady shear flow behaviors of GSPI and its hydrolysates at 0.5% (w/w) are shown in Fig. 3. The apparent viscosities of all suspending systems decreased with the increase in shear rate from 0.1 to 100 s−1, i.e., all the evaluated SPI samples showed shear thinning flow property. In addition, at beginning of the shear, there were obvious differences in apparent viscosity among the samples. GSPI dispersions and GSPI-1% showed significantly higher apparent viscosity than those of other samples. When shear rate was higher than 1 s−1, the apparent viscosity showed the similar level at 1 to 3 mpa·s. The cross-linking of protein molecules and oligochitosan conjugation led to the increased molecular size and thus the increased molecular volume of the SPI [36]. More polar groups from conjugated saccharide (oligochitosan) also contributed to higher apparent viscosity [37]. The following hydrolysis decreased the apparent viscosity compared to that of GSPI samples due to the reduction in molecular size.

Apparent viscosity versus shear rate flow curves for the aqueous soy protein isolate (SPI) dispersions (0.05%, w/v; pH 7.0). The data were recorded at 25 °C and the shear rate was 0.1−100 s−1. GSPI, a glycosylated SPI and without hydrolysis; GSPI-1% DH, GSPI-2% DH and GSPI-4% DH, GSPI with DH of 1%, 2% and 4%

The decrease of liquid viscosity is associated with the drainage of the foam increase [19]. High apparent viscosity of the liquid partially contributed to higher foam stability in GSPI and GSPI-1%. Specificity, GSPI sample and GSPI-1% DH had 182.5 or 52.6 mpa·s at the beginning of the shear, which showed higher foam stabilities (40.4% ± 7.6% or 80.8% ± 1.8%).

Conclusions

Although soy protein was conferred improved foam stability and apparent viscosity due to oligochitosan conjugation by TGase-induced glycosylation, an intra-/inter- cross-linking of protein exists which produce problem, such as polymer insolubility, for industrial applications. Therefore, hydrolysis of the prepared soy protein should be carried out to avoid such problem. Limited Protamex hydrolysis (DH of 1–4%) on oligochitosan-glycosylated soy protein improved functional properties, as evidenced by the homogeneous droplet size, flexible tertiary structure, and markedly enhanced foaming properties, solubility as well as suspension stability.

References

Ruíz-Henestrosa VP, Carrera Sánchez C, Del Mar Yust M et al (2007) Limited enzymatic hydrolysis can improve the interfacial and foaming characteristics of β-conglycinin. J Agri Food Chem 55:1536–1545

Martínez KD, Sanchez CC, Ruíz-Henestrosa VP et al (2007) Effect of limited hydrolysis of soy protein on the interactions with polysaccharides at the air-water interface. Food Hydrocoll 21:813–822

Sun XH, Acquah C, Aluko RE, Udenigwe CC (2020) Considering food matrix and gastrointestinal effects in enhancing bioactive peptide absorption and bioavailability. J Funct Foods 64:103680

Jiang SJ, Zhao XH (2011) Transglutaminase-induced cross-linking and glucosamine conjugation of casein and some functional properties of the modified product. Int Dairy J 21:198–205

Song CL, Zhao XH (2014) Structure and property modification of an oligochitosan-glycosylated and crosslinked soybean protein generated by microbial transglutaminase. Food Chem 163:114–119

Hong PK, Gottardi D, Ndagijimana M et al (2014) Glycation and transglutaminase mediated glycosylation of fish gelatin peptides with glucosamine enhance bioactivity. Food Chem 142:285–293

Wang XJ, Zheng XQ, Liu XL et al (2017) Preparation of glycosylated zein and retarding effect on lipid oxidation of ground pork. Food Chem 227:335–341

Flanagan J, Singh H (2006) Conjugation of sodium caseinate and gum Arabic catalyzed by transglutaminase. J Agric Food Chem 54:7305–7310

Kieliszek M, Misiewicz A (2014) Microbial transglutaminase and its application in the food industry. A review. Folia Microbiol 59:241–250

Romano A, Giosafatto CVL, Di Pierro P et al (2016) Impact of transglutaminase treatment on properties and in vitro digestibility of white bean (Phaseolus vulgaris L.) flour. Food Res Int 88:239–246

Yu C, Cha Y, Wu F et al (2018) Effects of limited hydrolysis and high-pressure homogenization on functional properties of oyster protein isolates. Molecules 23:729

Petruccelli S, Añón M (1994) Relationship between the method of obtention and the structural and functional properties of soy proteins isolates. 1. Structural and hydration properties. J Agri Food Chem 42:2161–2169

Adler-Nissen J (1982) Limited enzymic degradation of proteins: a new approach in the industrial application of hydrolases. J Chem Technol Biotechnol 32:138–156

Martínez KD, Sánchez CC, Patino JMR et al (2009) Interfacial and foaming properties of soy protein and their hydrolysates. Food Hydrocoll 23:2149–2157

Mahajan A, Bhardwaj S, Dua S (1999) Traditional processing treatments as a promising approach to enhance the functional properties of rapeseed (Brassica campestris var. toria) and sesame seed (Sesamum indicum) meals. J Agric Food Chem 47:3093–3098

Zhao GL, Liu Y, Zhao MM et al (2011) Enzymatic hydrolysis and their effects on conformational and functional properties of peanut protein isolate. Food Chem 127:1438–1443

Alizadeh-Pasdar N, Li-Chan EC (2000) Comparison of protein surface hydrophobicity measured at various pH values using three different fluorescent probes. J Agric Food Chem 48:328–334

Mahmoud R, Savello PA (1993) Solubility and hydrolyzability of films produced by transglutaminase catalytic crosslinking of whey protein. J Dairy Sci 76:29–35

Alleoni CAC (2006) Albumen protein and functional properties of gelation and foaming. Scientia Agricola 63:291–298

Chevalier F, Chobert JM, Popineau Y et al (2001) Improvement of functional properties of β-lactoglobulin glycated through the Maillard reaction is related to the nature of the sugar. Int Dairy J 11:145–152

Babiker EFE, Khan MAS, Matsudomi N et al (1996) Polymerization of soy protein digests by microbial transglutaminase for improvement of the functional properties. Food Res Int 29:627–634

Gorinstein S, Goshev I, Moncheva S et al (2000) Intrinsic tryptophan fluorescence of human serum proteins and related conformational changes. J Protein Chem 19:637–642

Sharma VK, Kalonia DS (2003) Steady-state tryptophan fluorescence spectroscopy study to probe tertiary structure of proteins in solid powders. J Pharm Sci 92:890–899

Halder UC, Chakraborty J, Das N et al (2012) Tryptophan dynamics in the exploration of micro-conformational changes of refolded β-lactoglobulin after thermal exposure: a steady state and time-resolved fluorescence approach. J Photochem Photobiol B 109:50–57

Mellema M, de Groot PWN, Golding M (2009) Impaired or accelerated aggregation of proteins in sterilised milk by adding surfactants. Int Dairy J 19:728–736

Ren J, Song CL, Zhang HY et al (2017) Effect of hydrolysis degree on structural and interfacial properties of sunflower protein isolates. J Food Process Pres 41:e13092

Davis J, Doucet D, Foegeding E (2005) Foaming and interfacial properties of hydrolyzed β-lactoglobulin. J Colloid Interface Sci 288:412–422

Tsumura K, Saito T, Tsuge K, H, et al (2005) Functional properties of soy protein hydrolysates obtained by selective proteolysis. LWT Food Sci Technol 38:255–261

Sariçay Y (2014) New insight into enzymatic cross-linking of globular proteins: from nanostructure to functionality, Wageningen University, The Netherlands

Corredig M, Sharafbafi N, Kristo E (2011) Polysaccharide-protein interactions in dairy matrices, control and design of structures. Food Hydrocoll 25:1833–1841

Liu Y, Li X, Chen Z et al (2014) Characterization of structural and functional properties of fish protein hydrolysates from surimi processing by-products. Food Chem 151:459–465

Tang CH, Jiang Y, Wen QB et al (2005) Effect of transglutaminase treatment on the properties of cast films of soy protein isolates. J Biotechnol 120:296–307

van Teeffelen AM, Broersen K, de Jongh HH (2005) Glucosylation of β-lactoglobulin lowers the heat capacity change of unfolding; a unique way to affect protein thermodynamics. Protein Sci 14:2187–2194

Mu LX, Zhao HF, Zhao MM, Cui C, Liu LY (2011) Physicochemical properties of soy protein isolates-acacia gum conjugates. Czech J Food Sci 29:129–136

Wu W, Hettiarachchy N, Qi M (1998) Hydrophobicity, solubility, and emulsifying properties of soy protein peptides prepared by papain modification and ultrafiltration. J Am Oil Chem Soc 75:845–850

Bönisch MP, Huss M, Weitl K et al (2007) Transglutaminase cross-linking of milk proteins and impact on yoghurt gel properties. Int Dairy J 17:1360–1371

Branca C, Magazù S, Maisano G et al (2001) Α α-trehalose/water solutions. 5. Hydration and viscosity in dilute and semidilute disaccharide solutions. J Phys Chem B 105:10140–10145

Acknowledgements

This study was funded by the Foundation for the Characteristic Discipline of Processing Technology of Plant Foods (No. YSTSXK201818), Educational Commission of Heilongjiang Province of China (No. 135309370) and National Natural Science Foundation of China (No. 31401639).

Author information

Authors and Affiliations

Contributions

CS conceptualization; formal analysis; visualization; funding acquisition; resources; supervision; and writing, original draft, review, and editing. XS formal analysis, validation, writing, review and editing. JY investigation, validation, formal analysis. JR formal analysis, review and funding acquisition. BV formal analysis, review and editing. XL formal analysis and validation. YF review.

Corresponding author

Ethics declarations

Conflict of interest

The authors report no conflicts of interest.

Compliance with ethics requirements

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Song, C., Sun, X., Yang, J. et al. TGase-induced glycosylated soy protein products with limited enzymatic hydrolysis showed enhanced foaming property. Eur Food Res Technol 247, 2557–2563 (2021). https://doi.org/10.1007/s00217-021-03815-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-021-03815-w