Abstract

In this study, texture profile analysis (TPA) at 40 and 80% compression and a newly proposed penetration test were used to evaluate the effects of amylolytic and non-amylolytic enzymes on the textural properties of fresh and stored brown pan breads. The correlations between instrumental parameters and sensory attribute results obtained by a trained panel of assessors were also investigated. Comparison of the results obtained through TPA at the two compression rates was very useful, as the 40% compression TPA hardly reflected the changes that took place in the enzyme-supplemented bread samples over a storage time of 20 days. The penetration curve profiles provided very valuable information, which complemented the TPA for the purposes of assessing bread ageing and the effect of adding enzymes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Freshness is one of the characteristics that consumers most appreciate in pan bread. They associate a tender, elastic and cohesive crumb that is soft to the touch with bread freshness. However, as the storage time lengthens the crumb hardens, is easily crumbled and loses its softness and elasticity, although increased crumb firmness is the ageing attribute most commonly recognised by the consumer. It is believed that both the structure and mechanical properties of the crumb play a role: cell walls as thin as possible yet strong and stiff enough to recover from some degree of deformation [1].

The useful life of pan bread is approximately twenty days before mould spoilage appears. However, its sensory quality deteriorates earlier and lengthening the duration of freshness characteristics is an objective that has long been pursued. During storage, changes in flavour and, normally, a loss of ‘freshly baked’ aroma also take place. All these negative changes are associated with staling. Although a considerable number of authors have associated staling with starch retrogradation [2], wheat proteins [3] and lipids [4] also seem to play a significant role in its development.

The effects of a number of enzymes that prolong bread freshness qualities or inhibit staling have been described [5]. Some of these enzymes act on the starch and others on other carbohydrates. The use of bacterial maltogenic α-amylase, which catalyses a small amount of starch hydrolysis, has been reported as being effective in delaying crumb hardening as a result of its action on the amylose and amylopectin fraction of the starch during bread baking, until its activity ceases. The use of xylanases, enzymes with more limited action than pentosanases, has been reported as effective in increasing volume and improving texture [6]. Fungal enzyme preparations with high endoxylanase, β-xylosidase, and α-l-arabinosidase activities have delayed bread staling considerably without affecting porosity or loaf volume [7]. The degradation of the non-starch polysaccharides leads to better water binding in the flour and also changes the interaction between arabinoxylans and gluten. As a result, the gluten is capable of building up an extensible, stable network. Some synergistic effects of enzymes for dough conditioning and extended shelf-life have been studied for specific breadmaking systems [6, 8–10].

Like most foods, bread crumb is a viscoelastic solid and applying a force to it obviously does not cause a proportional deformation in excess of its elastic limit. Although recommended instrumental methods exist for determining the degree of staling in pan bread [11], being empirical they are heavily dependant on the experimental conditions; moreover, the correlation of their results with the sensory parameter results obtained by tasting panels is not always satisfactory. The AACC also quantifies staling organoleptically (method 74-30) with degree of ‘freshness’ as the sole descriptor [11], although a large number of terms associated with loss of freshness are employed, such as ‘bread firming’, ‘crust staling’ or ‘organoleptic staling’.

Applying methods to investigate the mechanical behaviour of pan bread would contribute greater information and be a useful means to investigate the relations between these properties and loss of sensory quality during storage.

The objectives of this study are:

To compare the information provided by TPA primary parameter values at 40 and 80% compression in order to assess the effect of storage time on brown pan bread.

To assess the usefulness of the proposed methods for analysing the effects of adding an amylolytic enzyme, a non-amylolytic enzyme and a combination of the two on the texture properties of fresh brown pan bread and the effect of the action of these enzymes on the appearance of signs of ageing over 20 days’ storage.

To correlate the values for the different mechanical measurements with those obtained by descriptive sensory analysis.To evaluate the information provided by a penetration test.

Materials and methods

Ingredients and additives

Commercial Spanish whole wheat flour (13.84 moisture, 1.33% ash, 15.31% protein and 61 gluten index). Vegetable fat (80% hydrogenated palm oil Lambrecht 80 Palm-H, Tecom Ingredients, Spain), lactoserum (Laktein 30, Lactofrance, France) and commercial pressed yeast (1010 cells/g, L'hirondelle, France).

Enzymes

Maltogenic α-amylase (Novamyl 10,000 BG; 10,000 manu/g), from Bacillus stearothermophilus with intermediate thermal resistance and 1,4-endoxylanase (Pentopan Mono BG, 2,500 fxu w/g) from Thermomyces lanuginosus, both from Novozymes (Denmark).

Bread preparation

A base dough formulation (Table 1) was used. Twenty loaves of each formulation were prepared: (1) control with no added enzymes, (2) with xylanase, 30 mg/100 g flour, (3) with maltogenic amylase, 7.5 mg/100 g flour, and (4) with both xylanase and maltogenic amylase (30+7.5 mg respectively)/100 g flour. Enzyme doses were selected according to supplier indications and a previous work [10].

The loaves were prepared as follows: all the yeast was sponged with 50% of the flour and 50% of the water in a mixer for 10 min then allowed to ferment for 2 h at 28 °C, overnight (20 h) at 5 °C and 1.5 h at 28 °C before being added to the dough. All the ingredients were mixed in a 10 kg capacity mixer at 60 rpm until optimum dough consistency was reached. The fermented doughs were obtained by bulk fermentation (30 min), division (600 g), rounding, resting (10 min), panning and proofing until they attained their maximum volume (1 h, 28 °C, and 85% RH). The loaves were baked for 20 min at 180 °C; after cooling for 2 h the fresh loaves were cut into 20 mm slices and kept in a storage room at 20 °C for 0, 4, 7, 10, 13, 16 and 20 days before freezing in order to obtain different storage times from a single batch. Before manufacturing the bread loaves for the present study, a number of breads of each formulation were elaborated and stored to assure their microbiological safety during the whole storage period. Microbiological counts of these breads were: total aerobic mesophiles <1,000 cfu/g, and mold and yeast counts <500 cfu/g which fit Spanish Standards [12].

Sensory analyses

Sensory evaluation was carried out in a normalised sensory laboratory equipped with individual booths [13]. Seven samples (one slice from each storage time) were analysed in a single session. A panel of 11 assessors with wide experience in descriptive analysis evaluated “crumbliness” (ease of breaking up a piece of crumb against the palate with the tongue), “softness” (perceived by touching the bread crumb), “soft central area” (percentage of the total area that remained soft), “hardness” (force necessary to compress the slice on a flat surface with one finger), “cohesiveness” (ease of kneading the crumb into a ball for 5 s, using a piece of crumb from the centre of the slice), and “difficulty in swallowing” (effort required to shape a bolus ready for swallowing). Consensus was reached on the use of descriptors to quantify attribute intensity, including precisely how to evaluate them. After standardisation, six 30 min sessions were devoted to training and sensory tests were carried out in duplicate. Ten centimetres unstructured scales labelled “nil” and “high” at the extremes were used for scoring. Each bread slice was served on a plate, covered with odourless plastic film and coded with random three-digit numbers. Water was used for rinsing between samples. Two replicates were made for sensory analyses. Means and standard deviations for sensory scores were calculated and used for correlation analysis.

Instrumental analysis of texture

Instrumental parameters were measured with a TA.XTplus Texture Analyzer using the Texture Exponent software (version 2.0.0.7 Stable Microsystems Ltd., Godalming, England). Triplicate measurements were made for each sample (three different slices), excluding the first three slices from each end of the loaf. Slice thickness was 20 mm.

Texture profile analysis

Two series of texture profile analyses (TPA), one to 40% and the other to 80% compression, were carried out on the samples using a 35 mm flat aluminium disc and a test speed of 1.0 mm/s; a resting time of 5 s and a trigger force of 10 g were the selected settings. Bread slices were compressed twice to give a TPA from which the three primary textural parameters [15] were obtained: hardness (bread firmness), springiness, and cohesiveness, as calculated by the texturometer software. Means and standard deviations for TPA parameters were calculated and used for correlation analysis.

Punching or penetration test

The test was conducted by placing slices of bread on a platform with one aluminium plate with a 15 mm diameter hole for through testing; the samples were punched through once with a cylindrical probe, 1.27 cm in diameter (P/0.5). The probe descended 30 mm (a sufficient distance to pass through the slice of bread). The test speed was 1 mm/s and the trigger force was set at 10 g.

Statistical analyses

All statistical analysis were performed using Statgraphics 5.1 program (Bitstream, Cambridge, Massachussets, 1994–2001). Sample differences in TPA parameter values and in sensory scores with storage time and among different enzymes were examined using ANOVA. Matrix correlation between texture profile analyses and sensory scores was also performed.

Results

Instrumental analysis of texture

TPA at 40% compression

The AACC-recommended instrumental method for determining bread firmness consists of a single cycle in which the sample is compressed to 25% of its initial height (method 74-09) [11]. The texture profile analysis method, which consists of two compression cycles, provides the value of three parameters known as primary parameters [14, 15]; in a single test; the AIB recommends TPA at 20% compression [16]. Other TPA compression values have been reported for bread, such as 50% [10, 17], 75% [4, 18], or 31.5% [19], indicating that there is no clear criterion for selecting this experimental condition.

The TPA results obtained at 40% compression in this study reflect certain changes that took place in the samples over the storage time and distinguish the samples prepared with the addition of different enzymes, as described below.

The ‘hardness’ parameter of the control formula doubled over the 20 days’ storage. Recently baked loaves with the xylanase supplement were much softer than the control sample (their value was practically half that of the latter) although their hardening pattern over time was very similar. In this case it may be stated that xylanase is effective in obtaining a softer bread but does not diminish the signs of ageing; in other words, it does not improve on the control loaves’ behaviour during storage. Loaves with the amylase and amylase/xylanase combination supplements initially presented very similar hardness values to each other, even lower than those for the control or sample with xylanase. In these samples the hardness values also increased with storage time, but at 20 days they remained low, indicating that the crumb develops far less firmness over time and demonstrating the effectiveness of the enzymes in maintaining freshness (Fig. 1a).

The ‘springiness’ parameter did not provide information of any great value: the figures were high (near 0.95 for all the samples analysed) and none presented significant differences with storage time, although the values were slightly lower for the control sample.

The ‘cohesiveness’ value of the control sample at 0 days was much lower than that of all the samples prepared with enzymes and fell significantly with storage time, indicating a tendency to present a crumblier or less cohesive structure. The cohesiveness value of the two samples with amylase supplements was quite high and did not fall over the storage period, whereas in the sample prepared with xylanase, despite a day 0 value resembling those of other enzyme-supplemented samples, it fell slightly over time, showing an ageing pattern more similar to that of the control bread (Fig. 1b).

On observing the TPA curves to 40% compression of the four types of bread, it was found that the control sample was the only one to diverge from the elastic linear area (resistance directly proportional to punch travel), with a change in slope on the first curve that corresponds to the first compression (Fig. 2a), whereas the enzyme-supplemented samples’ curves were symmetrical in relation to the maximum peak force reached (Fig. 2b, see example of the sample supplemented with xylanase); the same pattern could be observed in both samples aged 16 days although with higher values of ‘hardness’. The change in slope is associated with the onset of crumb cell collapse. The symmetry of the curves for the enzyme-supplemented samples indicates that all the deformation at the compression percentage applied (40%) corresponds to instant recovery [20] and therefore the results are not very informative because the curves − corresponding to the first and second compression − are practically identical.

TPA at 80% compression

So that all the samples would reach the inflection zone at the first compression, it was decided to conduct a series of TPA tests at 80% compression; in this way, the initial structure of the samples was subjected to greater distortion, so the four type of samples showed a second-compression curve different from the corresponding first one (Fig. 3a and b). In normal consumption, bread suffers handling entailing considerable deformations which would be more faithfully reflected by tests of this type.

Although the ‘hardness’ parameter values obtained were obviously higher (Fig. 4a) in order to attain 80% compression, they evolved in a very similar way to those already described for the TPA at 40% compression: a slow increase over storage time, being amylose-supplemented samples softer.

The ‘springiness’ values for all the samples were high at day 0 and fell significantly with storage time (Fig. 4b); the enzyme-supplemented samples showed lower values that diminished slowly with storage time. Unlike the behaviour observed with the 40% compression TPA, all the samples surpassed the linear elasticity limit. The springiness value registered therefore corresponds to the part of the sample that retains the capacity to recover its shape (elastic components) after greater compression, although the recovery of part of the structure is inhibited (viscous components) in agreement with previous findings [21].

The ‘cohesiveness’ parameter values at 80% showed a pattern of significant falls over storage time (Fig. 4c), very similar for all the samples and contrary to the cohesiveness value behaviour in the TPA at 40%, where only the control and the xylanase-supplemented sample showed a certain drop with storage time. During the TPA at 80% compression, the fact that the samples suffered greater structural distortion during the first compression cycle meant that greater differences were found between the samples in the second compression and greater changes could be recorded over the storage times.

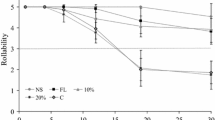

Sensory analysis

Sensory analysis detected a worsening over storage time for all the sensory parameters studied: loss of cohesiveness, increased hardness and crumbliness and reduction in softness and in the size of the soft area with time. Except for sample supplemented with amylase alone, most of the sensory parameters were already showing significant changes on day 4, indicating that the tasters were very sensitive in detecting signs of ageing. ‘Hardness’ and ‘cohesiveness’ were the sensory parameters that exhibited the greatest quantitative changes in all the samples (Fig. 5a–d).

Forty percent TPA instrumental hardness was significantly and positively correlated with sensory “difficulty in swallowing”, “crumbliness”, “hardness” and “oral dryness”, and significantly and negatively correlated with sensory “cohesiveness”, “softness”, and “size of soft zone”. There were practically no significant correlations between 40% TPA instrumental springiness and cohesiveness and the majority of the sensory attributes, whereas there was significant correlation with the same parameters for the 80% TPA (data not shown). These results indicate that TPA values obtained at compressions that ‘force’ the structure of the samples to a greater extent provide more information or information that is better correlated to sensory perception.

Penetration tests

The idea of applying penetration tests with a punch that goes right through the bread slice arose as a way to imitate the forces and actions undergone by the bread slices as they are eaten: breaking off a piece of bread in the fingers before putting it into the mouth or biting a piece off. The proposal to use this method was also related to the way in which the tasters were to evaluate parameters such as ‘sensory cohesion’ (ease of kneading the crumb into a ball).

The shapes of the penetration test curves obtained for the control sample exhibit very evident differences with storage time. The fresh bread had a large, smooth deformation area before the punched section was punched through and detached, which occurred when the punch had travelled almost 20 mm (Fig. 6a). From the fourth day, the crumb had hardened and the force required to compress it was considerably higher (reflected in the increased slope of the 7-days’ curve); the profile had changed considerably: breaking took place at approximately 8 mm punch travel; this pattern was repeated as the storage time lengthened, although as this increased the slope also rose, as did the force required to punch through the sample.

The behaviour of the samples with amylase was completely different. Irrespective of the storage time, all the profiles obtained were similar to each other and to those of the fresh control sample: the samples were compressed and even showed the first signs of surface cutting (marked by a first lowering in the force values) but the punched area was not really cut through and detached until the punch had travelled 20 mm; this behaviour indicates that the addition of amylase causes a change in the nature of the sample compared to the control. The slope of the curves increased with storage time, indicating sample hardening, but did so far more gradually than in the control sample and always with lower force values (Fig. 6b).

The xylanase-supplemented samples exhibited a penetration profile corresponding to a very soft sample on day 0: the sample was torn but in no case was a piece detached. From storage day 4 the profiles ‘hardened’: the curves rose spectacularly and reached very similar values to those of the control samples for the same storage times, with clear cutting peaks (zones with significant decrease of force) close to 8 mm penetration that were far higher than those for the amylase-supplemented samples (Fig. 6c).

The profiles obtained for the samples with the combined enzyme supplement corresponded to soft samples with very attenuated signs of ageing (initial slopes not very sharp and force values that never exceeded 2.45 N even for the top storage time). No peaks were detected before 20 mm penetration, which indicates that the cut was not very clean (Fig. 6d).

The results indicate that analysis of the penetration profiles provides very valuable information which complements the texture profiles (TPA) for the purposes of assessing bread ageing and the effect of adding enzymes.

References

Liu Z, Scalon G (2003) Trans IchemE 81:224–238

Davidou S, Le Meste M, Deveber E, Bekaert D (1996) Food Hydrocolloid 10:375–383

Don C, Lichtendonk W, Plijter JJ, Hamer RJ (2003) J Cereal Sci 37:1–7

Collar C, Martínez JC, Rosell CM (2002) Food Sci Technol Int 7:501–510

Haros M, Rosell C, Benedito C (2002) Eur Food Res Technol 215:425–430

Qi Si J (1997) Cereal Foods World 42:802–807

Rodionova NA, Kilimnik AY, Kaprelyants LV, Serednitskii PV, Martinovich LI, Zagustina NA, Bezborodov AM (1995) Appl Biochem Microbiol 31:370–376

Collar C, Andreu P, Martínez-Anaya MA (1998) Z. Lebensm. Unters. Forsch 207:133–139

Collar C, Bollaín C (2004) Eur Food Res Technol 218:139–146

Bollaín C, Angioloni A, Collar C (2005) Eur Food Res Technol 220:83–89

AACC (2000) Approved Methods of the American Association of Cereal Chemists, 10th edn, vol II. Methods 74-09 and 74-30, AACC. St. Paul, MN

Ministerio de presidencia (1978) Real decreto 2419/1978. BOE, Madrid

International Standard Organization (1998) ISO 8589 Sensory Analysis. General guidance for the design of test rooms. Geneva, Switzerland

Friedman HH, Whitney JE, Szczesniak AS (1963) J Food Sci 28:390–396

Pons M, Fiszman SM (1996). J Texture Stud 27:597–624

The American Institute of Baking. Standard procedure for firmness measurement of bread crumb by compression. AIB, Manhattan, KA

Hug-Iten S, Escher F, Conde-Petit B (2003) Cereal Chem 80:654–661

Armero E, Collar C (1997) Z Lebensm Unters Forsch 204:136–145

Engelsen SB, Jensen MK, Pedersen HT, Norgaard L, Munck L (2001) J Cereal Sci 33:59–69

Fiszman SM, Pons M, Damásio MH (1998) J Texture Stud 29:499–508

Carson L, Sun XS (2001) Cereal Chem 78:101–104

Acknowledgements

The authors are indebted to the Comisión Interministerial de Ciencia y Tecnología for financial support (Project AGL 2003-09208-C03-02) and to the Ministerio de Educación y Ciencia (Spain) for the grant awarded to author P. Varela

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fiszman, S.M., Salvador, A. & Varela, P. Methodological developments in bread staling assessment: application to enzyme-supplemented brown pan bread. Eur Food Res Technol 221, 616–623 (2005). https://doi.org/10.1007/s00217-005-0082-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-005-0082-2