Abstract

d-Phenylalanine (d-Phe) is a small chiral organic molecule that is both an important pharmaceutical intermediate and used as a calibrator for quantifying amino acids in liquid chromatography-circular dichroism. We have developed a process for a national certified reference material (CRM) for d-Phe following ISO 17034:2016. The identity of d-Phe was confirmed using mass spectrometry (MS) and nuclear magnetic resonance (NMR), infrared, and ultraviolet (UV) spectroscopy. The absolute optical conformation was also determined using circular dichroism (CD) spectroscopy and optical rotation measurements. Impurities were identified via liquid chromatography (LC) with a UV–Vis detector and a charged aerosol detector (CAD) and LC–MS. Both mass balance and quantitative NMR were employed for value assessment, and the associated uncertainty was evaluated. The certified purity was determined to be 0.995 ± 0.003 g/g, a validation that was confirmed by CD using l-Phe CRM as a calibrator. Twenty milligrams of raw material was packed in sealed brown glass tubes for storage, and no inhomogeneity was observed. Stability tests revealed that the d-Phe CRM remained stable at −20 °C for at least 26 months, at 4 °C for at least 14 days, and at 25 °C and 60 °C for at least 7 days. The d-Phe CRM can be used to ensure the accuracy and reliability of d-Phe quantitation in the pharmaceutical field and also as a calibrator to ensure traceability to the International System of Units (SI) for l-Phe quantitation and protein purity analysis using LC-CD methods. The approach outlined in this paper also has potential for use in the development of other chiral CRMs.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Certified reference materials (CRMs), which are defined as reference materials accompanied by documentation issued by an authoritative body, providing one or more property values with associated uncertainties and traceabilities using valid procedures, play an important role in both industry and scientific research. The use of CRMs ensures consistency, accuracy, and traceability in measurements across diverse fields and regions. CRMs are typically used to calibrate measurement systems, evaluate measurement methods, and assign values to materials for calibration and assessment purposes. Moreover, CRMs contribute to establishing measurement hierarchies, enabling reproducible and comparable results across different laboratories and timeframes [1, 2]. A notable example of a measurement hierarchy in clinical laboratories is well described in ISO 17511 [3].

Ideally, all measurement results are traced to Système International d’Unités (SI units) and in the chemical and biological fields, the value source typically begins with a purity CRM [3, 4]. From there, the value is transferred downstream to a commutable secondary CRM, then to a working calibrator, then a product calibrator, and finally to the ultimate result, as detailed in Model 1 of ISO 17511 [3]. Moving down the measurement hierarchy, the uncertainties tend to increase. Thus, the purity CRM at the top of the hierarchy considerably impacts the accuracy of the final measurement results and the magnitude of uncertainty. To develop accurate purity CRMs, several primary methods have been established. Mass balance (MB), quantitative nuclear magnetic resonance (qNMR), differential scanning calorimetry, freezing point depression, and isotope dilution mass spectrometry (IDMS) are widely employed for the value assessment of CRMs for small organic molecules, peptides, and proteins. Numerous studies have reported on the development and application of purity CRMs related to small organic molecules, peptides, and proteins [5,6,7,8,9,10,11,12].

As a pharmaceutical intermediate, d-Phe is used in the synthesis of drugs used in the prevention and treatment of various diseases, including osteoporosis, cardiovascular conditions, diabetes mellitus, and atherosclerosis [13,14,15,16,17]. For instance, d-Phe is used in the synthesis of nateglinide, which is an important therapeutic drug for treating type II diabetes mellitus [17, 18]. Beyond pharmaceutical applications, d-Phe is used in cosmetics and other beauty products, as a food additive, and in the chemical synthesis of a wide array of compounds. We have previously established a method using d-amino acids as calibrators to quantify l-amino acids [7, 19], which demonstrated good accuracy and precision.

While many national metrology institutes have developed l-Phe CRMs [5, 20,21,22], no d-Phe CRM is currently available. Consequently, the development of a d-Phe CRM is important in ensuring the accuracy and comparability of measurements for both d- and l-Phe, as well as for protein purity measurements, and to ensure that measurement results are traceable to SI units. Having a d-Phe CRM will fill a crucial gap in the availability of reference materials and enhance the reliability of measurements in various fields.

Materials and methods

Chemicals and reagents

The l-Phe CRM (GBW09235 (99.8% ± 0.4%)) was obtained from the National Institute of Metrology (Beijing, China). The creatinine CRM (NIST SRM 914a, (99.7 ± 0.3)%) was purchased from the National Institute of Standards and Technology (Gaithersburg, MA, USA). Hydrochloric acid (HCl) was from Tamachemicals Co. Ltd. (Kawasaki City, Kanagawa, Japan). Heavy water (99.96% D) was obtained from Cambridge Isotopes Laboratories Inc. (Cambridge, MA, USA). Formic acid, trifluoroacetic acid, potassium bromide, and acetonitrile were all of analytical grade from various chemical companies in China. The water (18.2 MΩ·cm) used was purified by a Milli-Q system.

Instruments

The nuclear magnetic resonance (NMR) spectrometer (Ascend 800) with quadruple inverse 5-mm CPQCI cryo-probe head (H-P/C/N) was from Bruker (Billerica, MA, USA). The gas chromatography (GC) system (Trace 2000 series), injector (AI 3000), Fourier transform infrared spectrometer (Thermo Nicolet IS50 St), rotational vacuum concentrator (SpeedVac SPD140DDA), and linear ion trap mass spectrometer (LTQ) were purchased from Thermo Scientific Corp. (Waltham, MA, USA). The vortex mixer (SCI-VS) was obtained from SCILOGEX Corp. (Rocky Hill, CT, USA). Pipettors (10, 100, 200, and 1000 μL and 10 mL) were from Gilson (Villiers-Le-Bel, France). The high-performance liquid chromatography (HPLC) instrument (1260) and capillary column (DB-1701; 60 m, 0.250 mm, 0.25 μm) were purchased from Agilent Corp. (Palo Alto, CA, USA). The triple quadrupole tandem mass spectrometer (QTRAP 5500) was from AB Sciex (Foster City, CA, USA). The circular dichroism (CD) spectrometer (J-815) was purchased from JASCO Corp. (Tokyo, Japan). The ultra-performance liquid chromatography (UPLC) system was from Waters Corp. (Milford, MA, USA). The electronic balances (XP56, UMX5) were from Mettler Toledo Corp. (Greifensee, Switzerland). The oven (UFE500) was purchased from Memmert Corp. (Schwabach, Germany). The water used in the experiments was produced by an ultrapure water system from Millipore Corp. (Bedford, MA, USA). The ultrasonic cleaner (KQ-500DE) was purchased from KunShan Ultrasonic Instrument Corp. (Kunshan, China). The nitrogen-blowing instrument (ND200-2) was purchased from Ruicheng Instrument Corp. (Hangzhou, China).

Experimental

Preparation of candidate d-Phe CRM

To prevent moisture alterations during storage and potential changes in impurity types and concentrations induced by light and oxygen, we used brown melt-sealed glass tubes for storage. Purified d-Phe, obtained from commercial sources, was distributed into these melt-sealed tubes, with a minimum of 20 mg per tube, and then stored in a refrigerator at − 20 °C.

Identity of d-Phe

Mass spectrometry analysis

d-Phe was dissolved in water containing 0.1% formic acid to obtain a concentration of approximately 0.1 mg/mL. The molecular weights of both the intact molecule and fragments were determined using flow injection analysis on a linear ion trap mass spectrometer. The analysis conditions were configured as follows: the spray voltage was set at 3.5 kV, the sheath gas flow was regulated at 40 arb, the auxiliary gas flow was set to 20 arb, the capillary temperature was maintained at 350 °C, and a flow rate of 15 μL/min was employed. Spectra in the m/z range of 100–200 were collected for analysis.

NMR analysis

Approximately 20 mg of d-Phe was weighed and dissolved in 0.5 mL of heavy water. The mixture was thoroughly shaken until the d-Phe was completely dissolved. Subsequently, the solution was transferred into a 5-mm-diameter NMR tube for measurement. The excitation pulse angle was set to 30°, and the time-domain data point was 32 k. The scan width was 16,024.641 Hz, and the relaxation time was 32 s, with a cumulative sampling of 16 times. The sample temperature was maintained at 296 K, with a frequency-domain data point of 64 k and an excitation center δ of 6.18 ppm.

Infrared spectroscopy analysis

Approximately 20 mg of d-Phe was mixed with 0.3 g of KBr, and the mixture was thoroughly ground and blended for 5 min. Then, the powder was compressed into a clear pellet using a tablet presser. Subsequently, the pellet was analyzed using an infrared spectrometer to acquire the spectrum of d-Phe.

UV–Vis spectroscopy analysis

The raw material of d-Phe was dissolved in 0.01 mol/L HCl to obtain a 1 mg/mL solution, and the UV absorption spectra were scanned from 210 to 400 nm.

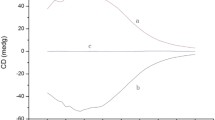

Determination of the absolute optical conformation

Both the d-Phe sample and the l-Phe CRM (GBW09235) were dissolved in 0.01 mol/L HCl to achieve a concentration of 0.1 mg/mL. Equal volumes of the d-Phe and l-Phe solutions were then mixed to obtain a blend of l- and d-Phe. Subsequently, the CD spectra of l-Phe, d-Phe, and the blend were scanned using a CD spectrometer.

As a chiral molecule, d-Phe also exhibits optical activity. An aliquot of 0.0489 mg of d-Phe was used for optical rotation analysis, which was carried out in a 1 dm long test tube with an automatic polarimeter.

Purity assessment

Purity assessment by MB method

Determination of structure-related impurities

The structure-related impurities were initially separated using UPLC under the following conditions: 10 μL of a 1 mg/mL d-Phe solution was injected and separated using an AQUITY BEH C18 column (150 mm × 2.1 mm) with a flow rate of 0.2 mL/min. Isocratic gradient elution was employed with a mobile phase of water and acetonitrile (98:2). An UV–Vis detector was used and the detection wavelength was set to 210 nm. A Thermo HPLC instrument equipped with a charged aerosol detector (CAD) and an Agilent Sb-Aq C18 column (150 mm × 2.1 mm) was also used to detect potential impurities without UV absorbance. The same sample volume and flow rate were adopted as used for UPLC.

To further verify the potential presence of known amino acid residues in the d-Phe sample, HPLC-mass spectrometry (MS) analysis was conducted. Three microliters of a 1 mg/mL d-Phe solution was injected and separated using a KINETEC C18 column (2.1 mm × 150 mm) with an isocratic elution comprising 91% water, 9% acetonitrile, and 0.1% trifluoroacetic acid. The following known amino acids were monitored along with their respective transitions: Gln (147.1 → 84.1), Lys (147.1 → 84.1), GABA (104.0 → 87.0), Arg (175.1 → 70.1), Cit (176.0 → 159.2), Glu (148.0 → 83.9), Orn (133.0 → 116.2), Pro (115.9 → 70.2), Tyr (182.2 → 136.3), Ala (90.0 → 44.2), Asp (134.1 → 88.2), His (156.0 → 110.2), Met (150.1 → 104.1), Ser (106.1 → 88.2), Thr (120.2 → 74.1), Val (118.2 → 72.2), Trp (205.2 → 72.2), Gly (76.2 → 30.2), and Leu and Ile (132 → 120).

To ascertain the possible presence of l-Phe in the d-Phe sample, we used a chiral stationary phase to assess the optical purity of d-Phe. The chromatographic setup was as follows: the column used was CROWNPAK CR + (4.0 mm × 150 mm; Daicel, Japan); the mobile phase consisted of aqueous perchloric acid, adjusted to a pH of 1.55; the flow rate was set at 0.8 mL/min; the volume injected was 10 μL; and the detection was performed at a wavelength of 200 nm.

Moisture content determination

The moisture content was assessed using the drying loss method. Six clean weighing flasks were individually dried to a constant weight in an oven at 105 °C. Approximately 20 mg of accurately weighed d-Phe solids was then added to each flask and dried to a constant weight in the same oven at 105 °C. Subsequently, the moisture content of d-Phe was calculated from the mass loss before and after drying.

Ignition residue analysis

The crucible was thoroughly cleaned and then heated in a muffle furnace until it reached a constant weight. Subsequently, approximately 20 mg of d-Phe was weighed and added to the crucible. The sample was then incinerated at a temperature range of 700–800 °C until complete ashing had occurred. Upon completion, the crucible was removed from the furnace, cooled in a desiccator, and weighed again. This incineration process was repeated at 700–800 °C until a constant weight was achieved, enabling the calculation of the ash content from the mass of the residue post-burning.

Inductively coupled plasma (ICP)-MS analysis

The presence of common elements in the CRM candidate was further determined using ICP-MS. The sample was weighed and placed into a cleaning tank, followed by the addition of 5 mL of high-purity nitric acid. The tank was then placed in an oven and heated for 120 min at 180 °C. After cooling, the sample was transferred into a 25-mL volumetric flask. The tank was rinsed three times with high-purity water, and all washings were combined in the volumetric flask. Subsequently, the flask was filled to the marked volume for ICP-MS analysis.

Anion analysis

Ion chromatography was used to determine possible anions present in the d-Phe CRM candidate. Various common anions, including phosphate, nitrate, sulfate, trifluoroacetate, carbonate, chloride, and fluoride, were analyzed using a Thermo ICS5000 + DP ion chromatography system equipped with an AS16 anion exchange column (4 mm × 250 mm). The column temperature was set at 35 °C, and the sample injection volume was 10 μL. A flow rate of 0.5 mL/min was maintained with a current of 44 mA, and an isocratic elution of 35 mmol/L NaOH was used over a period of 0 to 15 min.

Determination of volatile organic compounds

Headspace injection-gas chromatography-mass spectrometry (GC–MS) was used to identify potential volatile organic compounds (VOCs) in the CRM candidate, targeting VOCs such as ethanol, acetonitrile, acetone, isopropanol, dichloromethane, n-hexane, ethyl acetate, and trichloromethane. Approximately 20 mg of the CRM candidate was dissolved in DMSO for GC–MS analysis. Helium was used as the carrier gas with a flow rate of 1.0 mL/min. The injection volume was set at 1000 μL with a split ratio of 1:30. The initial column temperature was set to 30 °C and held for 10 min, then increased at a rate of 7 °C/min to 140 °C and held for 2 min. Subsequently, the temperature was raised at a rate of 15 °C/min to 220 °C and maintained for 10 min. The transfer line temperature was maintained at 240 °C.

Purity assessment by qNMR

Approximately 20 mg of d-Phe CRM candidate and 20 mg of creatinine were accurately weighed into the same glass vial and dissolved completely in 0.5 mL of heavy water. The solution was then transferred into a 5-mm-diameter NMR tube for analysis. To ensure an accurate quantitation result, a relaxation delay (D1) of at least five times T1 was selected. An exponential multiplication window function with a line broadening of 0.3 Hz was applied. Integration was precisely performed using the baseline-peak coincidence within a narrow range of ± 0.1 Hz, ensuring detailed and accurate NMR analysis. Data acquisition and processing were performed using Topspin 3.5 software, which involved automatic and manual phase adjustment, baseline calibration, and chemical shift correction using spectral data from the deuterated solvent.

The purity results were calculated according to Formula (1).

where P is the purity of d-Phe, g/g; Is is the peak area of the quantification peak of d-Phe; Istd is the peak area of the quantification peak of creatinine; ns is the number of protons of the quantification peak of d-Phe; nstd is the number of protons of the quantification peak of creatinine; Ms is the molecular weight of d-Phe; Mstd is the molecular weight of creatinine; mstd is the mass of weighed creatinine, g; ms is the weighed mass of d-Phe, g; and Pstd is the purity of creatinine, g/g.

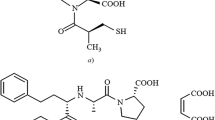

Purity validation by CD spectrometry

Two milligrams of l-Phe CRM (99.8% ± 0.4%) and the d-Phe CRM candidate were each weighed and dissolved in 20 mL of 0.1 mol/L hydrochloric acid (HCl) to prepare a 0.1 mg/g solution. Subsequently, 500 mg of both the l-Phe and d-Phe solutions was separately sampled using a balance and then mixed to measure the CD value. Trials were repeated until the CD value of the mixture fell within the range of 3 sigma (standard deviation) of that of the blank solution (0.1 mol/L HCl). Then, the mass and concentration of l-Phe were used to calculate the purity of d-Phe [19].

Results and discussion

Identity of d-Phe CRM candidate

The main component of the d-Phe CRM was identified using mass spectrometry and NMR, IR, and UV–Vis spectroscopy. The mass spectra showed a peak at 166.04, corresponding to [M + H]+ of d-Phe, and after fragmentation, a peak at 120.05 corresponding to a d-Phe fragment was observed (Fig. 1).

The 1H-NMR spectra (Fig. 2a) chemical shift values were as follows: 2.95, 2.97, 2.98, 3.00, 3.12, 3.13, 3.16, and 3.17 ppm for H1 (Fig. 2b); 3.83, 3.84, 3.85, and 3.86 ppm for H2 (Fig. 2b); and 7.17, 7.19, 7.21, 7.23, 7.24, 7.26, 7.28, and 7.30 ppm for H3, H4, and H5 (Fig. 2b).

The infrared spectra (Fig. 3a) showed characteristic absorption peaks indicative of the structure of d-Phe, including a carboxyl group at 1600 cm−1 and a carboxylic acid anion at 1720 cm−1. N–H stretching absorption peaks were observed in the ranges of 2600–3100 cm−1, 1700–1900 cm−1, and 600–800 cm−1, characteristic of a single substitution on the benzene ring. The UV–Vis spectra (Fig. 3b) exhibited a maximum absorption peak near 257 nm. These infrared and UV–Vis absorption peaks were consistent with the structure of d-Phe.

Determination of the absolute optical conformation

The scanned CD spectra of both l-Phe and d-Phe have already been reported [19]. The spectra of l-Phe and d-Phe solutions at identical concentrations showed optical conformations of equal magnitude but opposite direction. An equimolar mixture of l- and d-Phe appeared as a straight line, indicating no optical activity. Because the CD spectra were obtained with an l-Phe CRM solution and the CRM candidate had an opposite optical conformation, the CRM candidate must be the enantiomer of l-Phe, i.e., d-Phe. Thus, when mixed with an equal amount of l-Phe CRM, no optical activity was observed, confirming that the candidate CRM was d-Phe. The optical rotation was also measured to confirm the optical conformation. The measured specific rotation was 33°, which was similar to the reported value of 33.5°, providing further optical conformation.

Purity assessment

Purity assessment by MB

The MB method is widely used for the purity assessment of small organic molecules and peptides, and has the potential for measurements with high accuracy and low uncertainty. This method requires the identification of all possible impurities and the subsequent subtraction of their content from a potential purity of “1.” To identify the impurities, structure-related impurities in the d-Phe sample were separated and detected using UV–Vis and CAD detectors to detect potential impurities with and without absorbance. The chromatographic columns, mobile phases, sample concentrations, and detection wavelengths were optimized to detect as many impurities as possible. A comparison between the AQUITY BEH C18 (150 mm × 2.1 mm) and AQUITY T3 (150 mm × 2.1 mm) columns revealed that the former had higher efficiency. The optimal separation was achieved using a mobile phase ratio of A (water) to B (acetonitrile) of 98:2 (Fig. 4). A detection wavelength of 210 nm yielded the maximum response of all the tested wavelengths. Various sample concentrations ranging from 0.125 to 5 mg/mL were injected, with a flat-head peak observed when the concentration exceeded 2 mg/mL. Good linearity was observed within the concentration range of 0.125 to 1 mg/mL. Thus, a concentration of 1 mg/mL of d-Phe was used for analysis. Subsequently, six d-Phe vials were each analyzed three times under the optimal chromatographic conditions. The peak area ratios of the main components and impurities are summarized in Table 1. The average main peak area ratio of the six vials was 99.69% with a relative standard deviation of 0.026%.

The largest impurity, with a retention time of 8.322 min, was manually collected for MS identification, and the impurity was determined to be Tyr. To identify other potential amino acid residues in the d-Phe sample, 19 transitions identified from various publications were used to analyze for Gln, Lys, GABA, Arg, Cit, Glu, Orn, Pro, Tyr, Ala, Asp, His, Met, Ser, Thr, Val, Trp, Gly, Leu, and Ile. However, no additional amino acid residue was detected. To detect potential impurities without UV–Vis absorbance, the d-Phe sample was also analyzed by LC-CAD with a solvent blank for comparison. Despite optimizing the separation conditions and analyzing the sample, no impurity was detected using LC-CAD.

To identify whether l-Phe residues were present in the d-Phe sample, a chiral column was used for d-Phe separation, as described in the “Determination of the absolute optical conformation” section. The results showed that the two chiral isomers of Phe were effectively separated (Fig. S1a). The results of the analysis of the d-Phe CRM candidate by chiral stationary phase (CSP)-HPLC are shown in Fig. S1b, with baseline magnification shown in Fig. S1c. Notably, l-Phe was not detected with limit of detection (LOD) and limit of quantitation (LOQ) of 8.2 × 10−5 mg/g and 1.9 × 10−4 mg/g, respectively.

Following the experimental procedures outlined in the previous sections, measurements were conducted for moisture, ignition residue, elements, anions, and VOCs, and the results are summarized in Tables S1 to S5. The summed element content obtained from ICP-MS was 5.86 × 10−4 g/g, considerably lower than the results obtained by the ignition residue method (1.0 × 10−3 g/g). Although this discrepancy may be attributed to element oxidation during the heating process, it should be noted that the results obtained using the ignition residue method align with the standards specified in the Chinese Pharmacopoeia. Therefore, the results of the ignition residue method were used for MB calculations. No VOCs and 3.13 × 10−4 g/g of CF3COO– were detected. Hence, the purity of d-Phe was obtained using the mass balance method according to Formula (2).

where P is the purity of d-Phe, PHPLC is the peak area ratio of d-Phe determined by reversed-phase HPLC, Xa is the moisture content, Xb is the ignition residue content, Xc is the anion content, and Xd is the solvent residue. Then, each value (PHPLC (99.69%), Xa (7.6 × 10−4 g/g), Xb (1.0 × 10−3 g/g), Xc (3.13 × 10−4 g/g), and Xd (0)) was introduced into Formula (2) and the purity of d-Phe was calculated as 99.48%.

Purity assessment by qNMR

Initially, benzoic acid and creatinine were compared as potential internal standards. However, because of the limited solubility of benzoic acid in heavy water, the presence of particles in the solution, and the lack of sharp NMR signals, creatinine was ultimately selected as the internal standard. In the NMR spectra (Fig. 5), the hydrogens of the -CH3 of creatinine were used as an internal standard peak, while the hydrogens of the -CH2- of d-Phe were used for the purity assessment.

The relaxation time (D1) plays a considerable role in determining purity. Therefore, an optimization of D1 was conducted initially while keeping the pulse width at 30°, as outlined in Table S6. As shown in Table S6, the measured purity gradually decreased as the set relaxation time increased. However, the measurement results stabilized when the relaxation time reached or exceeded 26 s. Hence, the relaxation time for the quantitative experiments was set at 32 s.

Following optimization, the parameters used for purity assessment by qNMR were as follows: excitation pulse angle of 30°, time-domain data point of 32 k, scan width of 16,024.641 Hz, relaxation time of 32 s, cumulative sampling of 16 times, sample temperature of 296 K, frequency-domain data point of 64 k, and excitation center δ = 6.18 ppm. Analysis of six samples yielded purity values of 0.9951, 0.9946, 0.9951, 0.9929, 0.9965, and 0.9956 g/g. Consequently, the average purity determined by qNMR was calculated to be 0.9950 g/g. Subsequently, the arithmetic average obtained from both the MB and qNMR methods was used as the certified purity value of d-Phe, resulting in a value of 0.9949 g/g.

Validation of d-Phe CRM

The certified value of d-Phe was validated using CD in accordance with previously published reports [19]. The purity measured by CD was determined to be 0.997 ± 0.008 g/g, with an En value calculated from the Formula (3) as 0.234. This value aligned well with the certified purity value of 0.995 ± 0.003 g/g, confirming the accuracy and reliability of the certified value.

Homogeneity examination

To conduct a homogeneity examination, 11 units were randomly selected from the total 200 units of CRMs. Three sub-samples were taken from each unit for analysis. The sub-samples were analyzed with HPLC as described in the “Purity assessment by MB” section. The purity data for d-Phe were subjected to analysis of variance (ANOVA). If the obtained F value was less than the critical F value, it can be inferred that there were no significant differences between the data, indicating homogeneity among the samples. The homogeneity data are shown in Table S7 and the ANOVA test showed the calculated F value was 1.45, which was less than the critical value of 2.30, indicating no inhomogeneity was detected.

Stability test

Long-term stability testing was conducted at intervals of 0, 2, 4, 6, 12, and 26 months. For each time point, three units were randomly selected and analyzed. The d-Phe CRM candidate was packaged in sealed vials, and the sealed vials prevented volatile substances, such as moisture, from changing during the storage period. Therefore, the purity was calculated using HPLC, and the predetermined impurities were used for trend examination, which is shown in Fig. S2. The t-test indicated that the slope was not significant, suggesting that throughout the stability monitoring period, no significant trend was observed in purity. Therefore, it can be concluded that the d-Phe CRM candidate could be stored at − 20 °C and remain stable over 26 months.

The short-term stability was investigated with storage at 4 °C for 14 days and 25 °C and 60 °C for 7 days, and the results are shown in Fig. S3. The t-test indicated that the slope was not significant, which suggested that the certified values for the d-Phe CRM candidate remained stable over a period of 14 days at 4 °C, and over a period of 7 days at both 25 °C and 60 °C.

Uncertainty evaluation

The uncertainty of certified purity includes the uncertainty components from value assessing process (uchar), homogeneity examination (ubb), short-term stability (usts), and long-term stability (ults), as shown in Formula (4).

Uncertainty component from value assignment by MB

Based on the measurement principle of MB shown in Formula (5), the uncertainty from the value assignment by MB was calculated as shown in Formula (6):

where P is the purity of d-Phe, PHPLC is the peak area ratio of d-Phe determined by reversed-phase HPLC, Xa is the moisture content, Xb is the ignition residue content, and Xc is the anion content.

where u(PMB) was the uncertainty of d-Phe purity determined by MB; u(PHPLC) was the uncertainty of peak area ratio of d-Phe determined by reverse HPLC; u(Xa) was the uncertainty of moisture measurement; u(Xb) was the uncertainty of ignition residue measurement; and u(Xc) was the uncertainty of anion measurement.

Evaluation of u(P HPLC)

The uncertainty introduced by peak area ratio of d-Phe determined by reverse HPLC is further comprised of uncertainty components introduced by measurement repeatability (ua) and by wavelength difference (ub). The standard deviation s = 0.000257 of the mean value of peak area ratio was taken as ua. Uncertainty (ub) introduced by the difference in the response of each component at different detection wavelengths was calculated by Formula (7).

where Bimaxλ is the maximum percentage content of impurity component i at different detection wavelengths; Bi minλ is the minimum percentage content of impurity component; and ub-i is the uncertainty component of impurity component i. The evaluation results are listed in Table S8. Therefore, u(PHPLC) can be calculated as follows:

Evaluation of u(X a)

The uncertainty introduced by moisture measurement is further comprised of uncertainty components introduced by measurement repeatability (ua(Xa)) and weighing process (ub(Xa)). The standard deviation of the measurement s = 0.000143 was used to calculate ua(Xa):

According to the moisture calculation formula (mp-m2)/(m2-mn), the each weighing uncertainty by balance was 0.005 mg (k = 2), and the constant-weight criterion was ± 0.002 mg; hence, the uncertainty introduced by the constant-weight weighing was as follows:

Since mn and mp are weighed on a constant-weight basis, the uncertainties u(mn) and u(mp) are both 0.00276 mg; m2 does not need to be weighed on a constant-weight basis, so its uncertainty u(m2) is 0.0025 mg. According to the formula for calculating the moisture content: y = (m2-mp)/(m2-mn), a typical data of mp = 5637.256 mg, m2 = 5637.270 mg, mn = 5619.269 mg were used for calculation. The sensitivity coefficients were calculated as follows:

Therefore, the uncertainty of ub(Xa) is calculated and shown in Table S9. Thus, the u(Xa) can be combined as follows:

Evaluation of u(X b)

The uncertainty introduced by ignition residue measurement is further comprised of uncertainty components introduced by measurement repeatability (ua(Xb)) and weighing process (ub(Xb)). The standard deviation of the measurement s = 0.000184 was used to calculate ua(Xb):

According to the ignition residue calculation formula y = (m3-m1)/(m2-m1), the each weighing uncertainty by balance was 0.005 mg (k = 2), and the constant-weight criterion was ± 0.002 mg; hence, the uncertainty introduced by the constant-weight weighing was as follows:

Since m1 and m3 are weighed on a constant-weight basis, the uncertainties u(m1) and u(m3) are both 0.00276 mg; m2 does not need to be weighed on a constant-weight basis, so its uncertainty u(m2) is 0.0025 mg. According to the formula for calculating the ignition residue: y = (m3-m1)/(m2-m1), typical data of m1 = 12,869.131 mg, m2 = 12,886.406 mg, m3 = 12,869.152 mg were used for calculation. The sensitivity coefficients were calculated as follows:

Thus, the uncertainty of ub(Xb) is calculated and shown in Table S10, and the u(Xb) can be combined as follows:

Evaluation of u(X c)

The uncertainty introduced by anions measurement is further comprised of uncertainty components introduced by measurement repeatability (ua(Xc)) and type B uncertainties (ub(Xc)). The standard deviation of the measurement s = 1.01 × 10−7 was used to calculate ua(Xc):

Type B uncertainty for TFA measurement has already been evaluated in participating CCQM K115 (https://www.bipm.org/documents/20126/44695441/CCQM-K115.pdf/949f55e8-0a79-ccfa-121a-30e79c1543b8) as ub(Xc) = 0.00805 g/g. Because ua(Xc) was much less than ub(Xc), hence u(Xc) = ub(Xc) = 0.00805 g/g.

Therefore, uncertainty by MB was combined as follows:

Uncertainty component from value assignment by qNMR

The calculation model of d-Phe purity by qNMR is shown in Formula (8):

where P is the purity of d-Phe; Is is the peak area of quantification peak of d-Phe; Istd is the peak area of quantification peak of creatinine; ns is the number of protons of the quantification peak of d-Phe; nstd is the number of protons of the quantification peak of creatinine; Ms is the molecular weight of d-Phe; Mstd is the molecular weight of creatinine; mstd is the mass of weighed creatinine; ms is the weighted mass of d-Phe; and Pstd is the purity of creatinine.

Therefore, the uncertainty of purity measured by qNMR is derived from Formula (8) and shown as follows:

Uncertainty introduced by value assignment process

The uncertainty introduced by value assignment process (uchar) is calculated as follows:

where x(MB) is the purity obtained by MB; u(PMB) is the uncertainty introduced by MB method; x(qNMR) is the purity obtained by qNMR; and u(PqNMR) is the uncertainty introduced by qNMR method.

Uncertainty arised from homogeneity

According to ISO 17034:2016 [23], the uncertainty introduced by the homogeneity was calculated as follows:

Uncertainty introduced by stability

Since the d-Phe CRM is sufficiently stable at high temperatures, only the uncertainty component introduced by long-term stability is considered, and it is calculated as follows according to the results of long-term stability examination. The standard deviation of the trend line can be calculated by the following equation:

Thus, the uncertainty of the slope is calculated using the following equation:

Because the stability monitoring period was 26 months, and the predicted validity period was 12 months, the uncertainty introduced by long-term stability was as follows:

Combined standard uncertainty and expanded uncertainty

The combined standard uncertainty is calculated as follows:

Coverage factor (k) of 2 was applied and the expanded uncertainty is calculated as follows:

Conclusions

A d-Phe CRM has been developed by the National Institute of Metrology (NIM), P. R. China, and it has been approved as a national primary CRM (GBW06157). The identity of d-Phe was confirmed with MS and 1H-NMR, IR, and UV–Vis spectroscopy, and the optical conformation was determined by CD and optical rotation measurements. The content of structure-related impurities was measured by HPLC–UV, HPLC-CAD, and HPLC–MS. Then, the moisture, inorganic elements, anions, and VOCs were also measured to assess the purity. The certified value was 0.995 ± 0.003 g/g, validated using the CD method. No inhomogeneity was observed during the homogeneity examination. A stability examination demonstrated that the d-Phe CRM can be stored at − 20 °C for at least 26 months, at 4 °C for 14 days, and at 25 °C and 60 °C for at least 7 days. The d-Phe CRM can be used to ensure the accuracy and reliability of d-Phe purity analysis and protein quantification results. The use of the d-Phe CRM will ensure the accuracy and reliability of d-Phe quantitation in the pharmaceutical field and this CRM can also be used as a calibrator to ensure traceability to the SI for L-Phe quantitation and protein purity analysis using the LC-CD method. The approach outlined in this paper should be useful for the development of other chiral CRMs as well.

References

Breja SK. Role of certified reference materials (CRMs) in standardization, quality control, and quality assurance. Handbook of metrology and applications. Singapore: Springer Nature Singapore. 2022. 1–20. https://doi.org/10.1007/978-981-99-2074-7_29.

Kiełbasa A, Gadzała-Kopciuch R, Buszewski B. Reference materials: significance, general requirements, and demand. Crit Rev Anal Chem. 2016;46(3):224–35.

International Organization for Standardization ISO 17511:2020. In vitro diagnostic medical devices—requirements for establishing metrological traceability of values assigned to calibrators, trueness control materials and human samples. 2020. https://www.iso.org/standard/69984.html. Accessed 1 Mar 2024

Westwood S, Lippa K, Shimuzu Y, et al. Methods for the SI-traceable value assignment of the purity of organic compounds (IUPAC Technical Report). Pure Appl Chem. 2023;95(1):1–77.

Liu H, Cheow P, Yong S, et al. Determination of purity values of amino acid reference materials by mass balance method: an approach to the quantification of related structure impurities. Anal Bioanal Chem. 2020;412:8023–37.

Li X, Zhang W, Li X, et al. Purity assessment of dinotefuran using mass balance and quantitative nuclear magnetic resonance. Molecules. 2023;28:3884.

Wang X, Wu L, Huang Y, et al. Development of a human insulin certified reference material with SI-traceable purity. Anal Bioanal Chem. 2022;414:3443–57.

Li M, Josephs R, Daireaux A, et al. Structurally related peptide impurity identification and accurate quantification for synthetic oxytocin by liquid chromatography–high-resolution mass spectrometry. Anal Bioanal Chem. 2021;413:1861–70.

Yan J, Wang M, Yang M, et al. Study of SI-traceable purity assessment of bovine lactoferrin using mass balance approach and amino acid-based isotope dilution liquid chromatography-mass spectrometry. Food Chem. 2022;385:132674.

Oztug M, Saban E, Asicioglu M, et al. Development of UME CRM 1008: certified reference material for C-reactive protein. Accred Qual Assur. 2024;29:19–29.

Zhou J, Li F, Wang M, et al. Preparation of clorprenaline certified reference material: Purity determination and uncertainty evaluation. Microchem J. 2022;179:107502.

Shimizu Y, Yamazaki T, Bao X, et al. Reliable purity assay of highly hygroscopic trichloroacetic acid for the development of high-purity reference material of NMIJ CRM 4074-a. Anal Bioanal Chem. 2023;415:2261–9.

Amin A, Frampton J, Liu Z, et al. Differential effects of L-and D-phenylalanine on pancreatic and gastrointestinal hormone release in humans: a randomized crossover study. Diabetes Obes Metab. 2021;23(1):147–57.

Hirayama M, Tsunoda M, Yamamoto M, et al. Serum tyrosine-to-phenylalanine ratio is low in Parkinson’s disease. J Parkinson Dis. 2016;6(2):423–31.

Wood D, Reimherr F, Wender P. Treatment of attention deficit disorder with DL-phenylalanine. Psychiatry Res. 1985;16(1):21–6.

Nandi S, Pyne A, Ghosh M, et al. Antagonist effects of l-phenylalanine and the enantiomeric mixture containing d-phenylalanine on phospholipid vesicle membrane. Langmuir. 2020;36(9):2459–73.

Shinde S, Shraddha G. A review of nateglinide in the management of type 2 diabetes. Tablet. 2020;60:1.

Pollegioni L, Rosini E, Molla G. Advances in enzymatic synthesis of D-amino acids. Int J Mol Sci. 2020;21(9):3206.

Luo Y, Wu L, Yang B, et al. A novel potential primary method for quantification of enantiomers by high performance liquid chromatography-circular dichroism. Sci Rep. 2018;8(1):7390.

Kato M, Yamazaki T, Goto M, et al. Comparison of three amino acid analysis methods and their application to the amino acid impurity analysis for the development of high-purity amino acid certified reference materials. Accred Qual Assur. 2013;18:481–9.

Kato M, Yamazaki T, Kato H, et al. Development of high-purity certified reference materials for 17 proteinogenic amino acids by traceable titration methods. Anal Sci. 2015;31(8):805–14.

Lowenthal M, Yen J, Bunk DM, et al. Certification of NIST standard reference material 2389a, amino acids in 0.1 mol/L HCl—quantification by ID LC-MS/MS. Anal Bioanal Chem. 2010;397:511–9.

International Organization for Standardization ISO 17034:2016 General requirements for the competence of reference material producers. 2016. https://www.iso.org/standard/29357.html. Accessed 1 Mar 2024

Acknowledgements

Victoria Muir, PhD, from Liwen Bianji (Edanz) (www.liwenbianji.cn/), edited the English text of a draft of this manuscript.

Funding

This work was supported by internal funding (AKYZD1907-1) of the National Institute of Metrology (NIM), P. R. China, and the Key R&D Plan of the Ministry of Science and Technology with grant nos. 2021YFF0600802 and 2022ZD040200703.

Author information

Authors and Affiliations

Contributions

Shiwen Luo—investigation, methodology, data curation, and writing—original draft.

Yahui Liu—investigation and methodology.

Xianxia Wang—data curation, investigation, and methodology.

Ziliang Wang—formal analysis.

Bin Yang—investigation and methodology.

Jing Wang—supervision and conceptualization.

Liqing Wu—conceptualization, project administration, and writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

The Supplementary Materials are available free of charge on the Analytical and Bioanalytical Chemistry Publications website.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Luo, S., Liu, Y., Wang, X. et al. Development of a certified reference material for d-phenylalanine with evaluation of enantiomeric purity. Anal Bioanal Chem 416, 5177–5189 (2024). https://doi.org/10.1007/s00216-024-05456-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-024-05456-w