Abstract

Prompt gamma-ray neutron activation analysis (PGNAA) using the internal mono-standard method was tested for its applicability to analyzing large solid samples including irregularly shaped meteorite samples. For evaluating the accuracy and precision of the method, large quantities of the Geological Survey of Japan standardized rock powders (JB-1a, JG-1a, and JP-1) were analyzed and 12 elements (B, Na, Mg, Al, Cl, K, Ca, Ti, Mn, Fe, Sm, and Gd) were determined by using Si as an internal standard element. Analytical results were mostly in agreement with literature values within 10 %. The precision of the method was also shown to be within 10 % (1σ) for most of these elements. The analytical procedure was then applied to four stony meteorites (Allende, Kimble County, Leedey, Lake Labyrinth) and four iron meteorites (Canyon Diablo, Toluca (Mexico), Toluca (Xiquipilco), Squaw Creek) consisting of large chunks or single slabs. For stony meteorites, major elements (Mg, Al, Si, S, Ca, and Ni), minor elements (Na and Mn) and trace element (B, Cl, K, Ti, Co, and Sm) were determined with adequate accuracy. For iron meteorites, results for the Co and Ni mass fractions determined are all consistent with corresponding literature values. After the analysis, it was confirmed that the residual radioactivity remaining in the sample after PGNAA was very low and decreased down to the background level. This study shows that PGNAA with the internal mono-standard method is highly practical for determining the elemental composition of large, irregularly shaped solid samples including meteorites.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

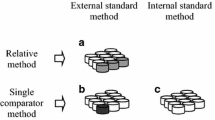

Prompt gamma (γ)-ray neutron activation analysis (PGNAA), a type of neutron activation analysis (NAA), is an isotopic and elemental analysis method which measures prompt γ-rays emitted from the excited state of nuclei within 10−14 s after neutron capture. A practical method for PGNAA was first introduced in the 1960s (e.g., [1]). Since then, its use for multi-element analysis has expanded into several different fields of study. For instance, PGNAA can be used to non-destructively determine several elements (e.g., H, B, N, Si, S, Cd, and Gd) in geological materials, which are difficult or impossible to determine by more commonly used techniques such as instrumental neutron activation analysis (INAA). For this reason, it is sometimes used as a complementary analytical tool to INAA [2]. As the PGNAA system can be attached to a neutron guide tube extending outside the nuclear reactor, it allows a wider range of sample shapes and sizes than that for INAA, which requires the sample irradiation inside the reactor [3]. Despite its capability for analyzing voluminous samples, PGNAA is also typically used for analyzing small (≤0.5 g), thin samples [4] because the problems incurred when using larger samples such as neutron absorption and scattering effects, and γ-ray self-absorption effects are mostly restrained [5].

Relatively small, thin samples of meteorite chips or powders (≤400 mg; <5 mm thickness) are effectively transparent to the neutron beam and the high-energy prompt γ-rays emitted [5]. A small aliquot (∼200 mg) of homogenized rock powder makes a good compositional standard in such a case [6]. But how does one handle the neutron absorption and scattering effects of a meteorite “chunk” ranging up to 1 kg in mass and several cm in thickness? And how does one prepare elemental “standards” for such large samples in order to determine accurate elemental mass fractions? Sueki et al. [7] applied an internal mono-standard method for analyzing large, irregularly shaped pottery samples, and showed that the method was effective for minimizing the problems with absorption and scattering of neutrons and self-absorption of γ-rays. The method requires a relative detection efficiency curve of γ-rays to be determined for each particular irradiation and γ-ray detection setup. This study tests the method for the analysis of large, irregular meteorite samples, which are physically quite different from pottery samples.

Meteorites can be grouped into three basic types; stony, iron and stony-iron meteorites. Stony meteorites, which consist of mostly silicate minerals, are generally much coarser-grained than potteries composed of very fine-grained (<0.1 mm) clay minerals. The most common stony meteorites (ordinary chondrites) contain small spheroidal grains (known as chondrules) or inclusions ranging from sub-mm up to cm in size. They also contain small blebs of metal (Fe–Ni alloy) and sulfide (usually FeS), inhomogeneously distributed throughout the meteorite. Although iron meteorites may appear to be homogeneous Fe-Ni alloys, most are actually made up of “bands” of a low-Ni alloy called kamacite and a thin layer of a high-Ni alloy called taenite. The kamacite bands can range from less than 0.1 mm to several cm in thickness. Various amounts of sulfides, phosphides and carbides can also be inhomogeneously distributed throughout the iron meteorite. Stony-iron meteorites are approximately half silicate material and half metal. Silicate crystals and metal aggregates can be cm-sized or greater. Therefore, determining the “bulk” composition of a large meteorite sample is a great challenge and is essentially important to determine the genuine chemical compositions of meteorite samples for the cosmochemical study.

One can, of course, minimize homogeneity problems by grinding several tens of grams of a stony meteorite to powder and analyze a small aliquot, or by slicing a small, carefully selected slab from an iron meteorite for analysis. Both of these methods can be very labor-intensive and time-consuming. “As is” meteorite specimens could be surveyed by the large sample PGNAA technique with minimum sample preparation. It is also not always desirable or possible to breakup and/or grind a meteorite specimen for analysis. For example, a certain specimen may be too valuable as a display piece to justify breaking it up. Such a display piece could be analyzed by large sample PGNAA method without disrupting its physical appearance. Furthermore, a display piece could not be analyzed by INAA simply because an unacceptable level of residual radioactivity would likely remain in the sample over the long term. This is less or none of a problem with PGNAA which uses a much lower neutron fluence [8].

In this study, we determined the elemental compositions in three geological rock powder samples using thermal neutron beam PGNAA with internal mono-standard method. An Allende meteorite standard powder sample was also analyzed as a control. After evaluating the effectiveness of the method, the same procedure was applied to eight relatively large, irregularly shaped meteorite specimens (four stony and four iron). As will be shown, the large sample PGNAA method can be a well-suited analytical technique for such meteorite samples.

Experimental procedure

Sample preparation

Large samples of standardized rock powders, JB-1a, JG-1a, and JP-1 prepared by the Geological Survey of Japan (GSJ), were first analyzed. These finely powdered samples can be considered to be homogeneous in chemical composition. Each standard rock powder was placed in a PTFE bottle (2.5 cm diameter × 2.0 cm height), which was then sealed in fluorinated ethylenepropylene resin (FEP) film. The meteorite samples analyzed in this study include both stony and iron meteorites. All of these samples (except the Allende powder; see below) were irregularly shaped chunks or thick slabs. Two typical samples (stony and iron each) are shown in Fig. 1. The meteorite chunk samples were cleaned with ethanol and sealed in FEP films. The Allende meteorite was analyzed for homogenized powder sample as well as for chunk samples. The Allende standard powder sample was prepared at the Smithsonian Institution (SI) [9] and was used as a control as well as reference sample in this study. An aliquot (257 mg) of the SI Allende meteorite standard powder (split 11, position 11) was sealed between two layers of FEP films. The samples used in this study were listed in Table 1.

In order to determine some parameters for the quantification (σ x b x /σSibSi and σ x b x /σFebFe ratios; see below), small-sized chemical reagent samples containing known amounts of individual elements concerned were prepared. These samples were also sealed in FEP films.

Sample irradiation and counting

All of the samples were irradiated several times using the thermal neutron beam tube extending from the JRR-3M reactor of Japan Atomic Energy Agency (JAEA) (former Japan Atomic Energy Research Institute, JAERI). We used the thermal neutron beam rather than the cold neutron beam. Because the neutron capture cross section is inversely proportional to the velocity of neutrons, that is, the neutron energy, the emission rate of prompt γ-rays is increased with the cold neutrons, and the dead time of the counting system becomes too high. The beam cross-sectional area was 2.0 cm × 2.0 cm, which has rather homogeneous neutron density. The SI Allende powder and chemical standards were suspended in the beam using Teflon string. For large samples, bottled standard rock powders were suspended just like chemical standards while solid meteorite chunk samples were mounted on a Teflon pedestal set to an appropriate height. Each of the sealed samples was then irradiated for durations ranging from 5,000 to 15,000 s with a thermal neutron flux of 2.4 × 107 cm−2 s−1. During the irradiation, γ-ray counting was accomplished using a high-resolution HPGe detector (30 % relative efficiency for 1.33 keV γ-ray of 60Co) equipped with a Compton-suppression system using a bismuth germanium oxide (BGO) detector. The samples were irradiated in He gas atmosphere in order to minimize background γ-ray contributions from atmospheric N.

Data analysis

The γ-ray spectra (except for the boron peak) were analyzed using a conventional γ-ray spectrum analysis program. The line width of the 478 keV γ-ray of B is Doppler-broadened due to recoil of the nucleus during photon emission. The broadened 478 keV peak is interfered by overlap of the Na 472 keV peak. Samples containing measurable Na required correction of the broadened B 478 keV peak area due to the overlapping Na 472 keV peak. The peak area contributed by the Na 472 keV peak was estimated using a computer fitting method [10] and subtracted from the B 478 keV peak area.

The elemental mass fractions in all samples were calculated by the internal mono-standard method, using Si or Fe as an internal reference element. Silicon was used for geological standard rock powders because Si is well certified for these samples. For stony and iron meteorite samples, Fe was chosen because it is a major element in these meteorites and its mass fraction can be reliably determined by other methods like INAA and electron-probe microanalysis (EPMA). The Fe mass fraction used for each meteorite sample was obtained either from the same meteorite (as determined by PGNAA comparison method analyses), from a mean literature value for the individual meteorites, or from a mean value for other meteorites of the same compositional group. The relative abundance of the element to be determined and an internal standard element, here Fe for example, in the sample, n x /nFe, can be calculated by using the following equation [7]:

where n is the number of atoms, C is the count rate of a prompt γ-ray of energy Eγ, b is the number of its γ-ray emitted per neutron capture (emission efficiency), σ is the effective neutron capture cross-section, w is the normalized spatial density distribution of the prompt γ-ray source (target element), η is the γ-ray counting efficiency, and r is the position vector with its origin at the sample where the neutron capture reaction occurs and its endpoint at the center of the γ-ray detector. The σ x b x /σFebFe ratio is specific to the neutron spectrum at the irradiation site and to the prompt γ-ray used for the analysis.

The σ x b x /σFebFe ratios for the elements concerned were determined by using appropriate chemical reagents prior to the analyses of meteorite samples and shown in Table 2, where σ x b x /σSibSi ratios from this study and literatures are also given. The integral term in the above equation was obtained by constructing the relative counting efficiency curve for each irradiation in order to minimize the effects of neutron absorption and scattering which cause variation of the effective reaction volume within the sample and the effect of γ-ray absorption by the sample itself. The relative counting efficiency needs to be measured for every irradiation as it critically depends on the geometry of the sample placed with respect to the neutron beam and the Ge detector, and the chemical composition of the sample. A curve of the relative counting efficiency against γ-ray energy can be constructed by using the prompt γ-rays emitted from an element which is relatively abundant and uniformly distributed in the sample. The element must emit several intense γ-rays over a wide range of energy, but does not necessarily need to be a comparator element. Multiple elements rather than a single element can effectively work in some cases.

The relative counting efficiency curve was constructed by dividing the photopeak areas of prompt γ-rays from any of Si, Ti, Fe, Co, and Ni by their relative emission efficiencies (b r ). Because some literature values of emission efficiencies (probabilities) [11] for these elements were found to be incorrect, new br values for certain prompt γ-rays of the aforementioned elements were determined in this study by use of small sized chemical reagent samples, where prompt γ-rays were measured for samples of high-purity Si, reagent-grade TiO2, and high-purity Fe, Co, and Ni (99.9 % of purity) using a Ge detector whose photopeak counting efficiencies were carefully determined. The determined b r values with corresponding prompt γ-rays are listed in Table 3. An advantage of this method is that because the reference element is internal to each sample, the results are insensitive to variations in the neutron beam flux on the assumption that a reference element and an element to be determined are homogeneously distributed in the sample.

Results and discussion

Accuracy and precision of data obtained by the internal mono-standard method

The accuracy of the internal mono-standard method applied in this study was first tested using a relatively small-sized Allende standard powder of 250 mg. The analytical results are shown in Table 4. The weighted mean mass fractions for most of the elements determined are consistent with literature values or within the range reported in literatures, implying that the accuracy of this method is as high as that of the conventional method (comparison method). Data reproducibility (precision) for most of the elements in the Allende meteorite standard powder is satisfactory. Boron seems to be exceptional. Considering individual values coupled with large counting statistics errors, however, a value of weighted mean with a relatively large uncertainty may be reasonable. Mass fraction data for the replicate analysis of the same Allende meteorite sample on different days are identical within the experimental uncertainty.

The accuracy of the internal mono-standard method for the voluminous samples was then tested using GSJ standardized rock powders of JB-1a, JG-1a, and JP-1 packed in PTFE bottles with a size of 2.0 cm height × 2.5 cm ϕ. In these measurements, Si was used as an internal reference element because Si contents are generally reliably determined for geological standard rocks including the three samples tested in this study. The JB-1a sample was analyzed three times, with the two analyses being conducted on the same day and the remaining analysis on the different day. The calculated elemental mass fractions along with literature values for JB-1a are listed in Table 5. Essentially identical values were obtained for all the elements determined between the two measurements on the same day and no inconsistency was confirmed between the two data sets from different days. Mean values of the three determinations are generally in good agreement (within 10 %) with literature values except for Mg, Mn, Fe, and Gd. Among these four elements, Mg and Gd show notable exceptions (20 % and more), followed by Mn and Fe with about 10 % differences. Our data for JG-1a and JP-1 are compared with their literature values in Fig. 2. For both samples, all elemental mass fractions are within 10 % of literature values with the exception of B, Mg and Gd for JG-1a, and B and Mn for JP-1, as illustrated by Fig. 2.

It may be worth noting that, even as a major (or sub-major) element, Mg shows disagreements for JB-1a and JG-1a, whereas such a disagreement of Mg was not observed for JP-1. This can be understood in terms of Mg contents in these rock samples; JB-1a and JG-1a have 4.67 % and 0.45 % Mg contents while JP-1 contains 27.0 % Mg. As the sensitivity of Mg in PGNAA is rather low (Table 2), it cannot be reliably determined when its content is not high enough (≤10 %) [19]. Excepted for JG-1a, Mg results tend to be lower than corresponding literature values, suggesting no overlapping of interfering peak(s) over the Mg peak but the contribution of interfering peak(s) to the background area adjacent to the Mg peak in γ-ray spectrometry. An opposite situation can be seen for B; a B content of JB-1a (7.88 ppm) is a few times to an order of magnitude higher than those of JG-1a (2.6 ppb) and JP-1 (1.0 ppm). As already mentioned, the B content needs to be corrected for the contribution of Na. Since Na contents of JB-1a and JG-1a are similar (2.03 % and 2.53 %, respectively), the correction of B is larger for JG-1a compared with that for JB-1a. The Na content of JP-1 (0.0155 %) is two orders of magnitude lower than those for JB-1a and JG-1a and, hence, its contribution to the broadened 478 keV B peak is negligible. A mass fraction level of several ppm B seems to be a limit for the reliable determination of B for silicate rock samples like JB-1a, JG-1, and JP-1. As for Gd and Mn, PGNAA values are generally higher and lower, respectively, than their literature values. Presumably, unknown interference(s) can be a reason for increasing Gd values, while a similar explanation suggested for Mg may be applied to Mn. Manganese and Gd contents of rock samples can be much more reliably determined by INAA and isotope dilution mass spectrometry, respectively, than those by PGA. Nevertheless, as voluminous samples cannot be non-destructively determined by these analytical methods, the internal mono-standard method of PGNAA has a merit in determining those elements in rock samples even though their values are not so accurate.

Application to large meteorite samples

Allende chunk sample

As shown in Table 4, the internal mono-standard method is suitable for determining elemental mass fractions in small meteorite samples, where the samples are smaller in cross-sectional size than the neutron beam and thin enough for not effectively attenuating the neutron beam intensity. This is, however, not the case for large, voluminous meteorite samples. Therefore, experiments were performed with large samples.

An initial test of the accuracy of the internal mono-standard method for large meteorite samples was performed on a moderately large-sized (24 g) chunk of Allende (hereafter referred to as Allende A as listed in Table 1). Because the SI Allende standard powder sample was prepared by homogeneous mixing, it was used as a benchmark for comparison. Two irradiations were performed on the Allende A for testing accuracy as well as precision. Analytical results are summarized in Table 6, where mean values for the Allende powder sample (Table 4) together with literature values are compared. Between the two measurements for the Allende A chunk sample, no elements show disagreements beyond uncertainties due to counting statistics (1σ). As can be seen in Table 6, mean values of mass fractions determined in the Allende A sample are very similar to those in the SI Allende standard powder. For most elements, the data agree within 10 %. Only the Ti and Mn mass fractions showed disagreement by slightly larger than 10 %. Compared with the literature values, mean values of the two determinations for the chunk sample showed disagreements of more than 10 % for Na and Ni. In the Allende meteorites, both Na and Ni are known to reside in specific minerals (sodalite and nepherine for Na and pentlandite for Ni), which are heterogeneously dispersed in the matrix material. The determination of Mg showed systematically smaller value in not only the two measurements on the chunk sample but also in the determinations of the Allende powder sample, compared with the literature value, showing that the accurate determination of Mg cannot be performed by PGNAA even at 15 % mass fraction level. Except for Mg, it can be concluded that the precision and accuracy of the data obtained by the internal mono-standard method of PGA are satisfactory even for chunk samples of meteorites for practical use.

Other large stony meteorite samples

Elemental mass fractions determined for three other large stony meteorite samples (Kimble County, Leedey and Lake Labyrinth) are shown in Table 7. There can be seen generally good agreement between the determined mass fractions and those in the literatures. The Leedey meteorite shows the best overall agreement, while Kimble County shows the largest scatter.

The Leedey sample is a thick sawn slab of the meteorite, not an irregular chunk like both Kimble County and Lake Labyrinth, so the data quality is probably helped by the more uniform analyses volume presented by this sample. All of the Leedey data and most of the Lake Labyrinth data are compared to actual analyses of those meteorites reported in the literature. The literature data used for comparison with the Kimble County data are H chondrite group mean values, not actual analyses of Kimble County, because there are no Kimble County data available for comparison. This could explain, at least in part, why the Kimble County data show more scatter in Table 7.

The B mass fractions in Kimble County, Leedey, and Lake Labyrinth are all high compared to the typical ranges shown by their respective chondrite groups as shown in Table 7. The simplest explanation is that the meteorites were contaminated with B. This is not an unreasonable assumption for Kimble County and Lake Labyrinth because they are meteorite “finds,” i.e., they were found lying on the ground and not seen to fall, and therefore, they were likely exposed to the outside environment for a considerable length of time. Leedey, however, is a meteorite “fall,” i.e., it was picked up soon after being seen to fall and therefore, in principle, should be free of terrestrial contamination. Nevertheless, the determined B mass fraction for Leedey seems to be also a little higher than the literature value. Boron analyses have traditionally been problematic, because of the potential for contamination of even meteorite falls. The element B is ubiquitous to the environment, being used in household products, as a fuel additive, etc. Mass fraction values often vary over a wide range within the same meteorite group, and even analyses in the literature for the Leedey meteorite vary by a factor of three [22]. It may be that the B is naturally very homogeneous in chondritic meteorites. As with past analyses, the present data are inconclusive.

Large iron meteorite samples

Iron meteorites consist mostly of metallic Fe–Ni with a scattering of sulfide, carbide, and occasionally silicate inclusions. Compositional analyses of iron meteorites reported in the literatures are always of the metallic portion, free of inclusions as much as possible. So for these initial experiments we were only concerned with elements in the metal phase. Because Fe, Ni, and Co comprise almost 100 % of the metallic portion, only those elements were determined. The mass fractions of Ni and Co were calculated using Fe as the internal reference element.

Samples of four iron meteorites were studied; Canyon Diablo, Squaw Creek, Toluca (Mexico), and Toluca (Xiquipilco). The Canyon Diablo sample (Fig. 1, right) was irregular “chunk.” The other meteorites were thick sawn slabs. Elemental mass fractions for the four meteorites are listed in Table 8. The Co and Ni mass fractions determined in all meteorites agree within 10 % of literature values. The analysis of the Canyon Diablo chunk, which is still covered with a weathered crust, appears to be just as good as the analyses on the sawn slabs having fresher surfaces. This would suggest that no special preparation of the surface of the meteorite is necessary (i.e., sawing, etching, etc.) for PGNAA unless the weathering is limited only on the surface. The elemental mass fractions were also recalculated assuming Fe + Co + Ni = 100 wt.% and showed only minor changes.

A test for the compositional difference in chemical composition of a large meteorite sample

As PGNAA with the internal mono-standard method was proved to be highly practical for determining chemical composition of voluminous solid samples, this method was applied to the large meteorite samples to see whether and how large the compositional different is present in such samples. A chunk sample of the Allende stony meteorite names Allende B, which is two times bigger in mass (48.5 g) than the Allende A (24.0 g), was chosed for this test, because Allende was well examined in this study for powder and chunk samples. Being similar to the case of Allende A, the Allende B chunk sample is also partly covered with black fusion crust. The Allende B sample was irradiated at three different positions using a 2.0 × 2.0-cm neutron beam. The irradiation positions are illustrated by the photos in Fig. 3 (upper part), with the approximate area of the neutron beam represented by the white squares. These three positions were chosen from completely different locations from each other. The same suite of elements as shown in Table 6 was determined and their compositional data are shown also in Fig. 3 (lower part), where histogram plots of the relative amount mass fractions of each element (relative to Si) at three positions are compared. Each histogram is normalized to the maximum value for easier comparison. For the most part, the elements are uniformly distributed in the chunk sample. Only B and Sm show significant variations at different irradiation positions.

The chondritic meteorite is generally a mixture of fine-grained matrix and small chondrules (0.5–2.0 mm). Besides these constituents, the Allende meteorite contains occasionally inclusions and xenoliths of up to cm-size. Therefore, one would expect most elements to be uniformly distributed on the scale of the 2.0 cm × 2.0 cm beam size, with a possible exception of elements that might preferentially occur in inclusions. Most of these inclusions contain high abundances of “refractory” elements represented by rare earth elements. The low relative Sm values at positions 1 and 2 could possibly imply an underabundance of refractory inclusions at those irradiation sites. Because the Allende B sample is still covered with fusion crust, it is not possible to visually determine the abundance or size of inclusions at the irradiation sites. The PGNAA procedure with internal mono-standard method developed in this study thus can be a practical tool not only to perform the elemental quantification of large, voluminous solid samples but also to probe the unexposed substance in such samples.

Residual radioactivity—can it be a possible defect of this procedure when applied to museum displays?

To evaluate the usefulness of the proposed method for analysis of precious samples such as archaeological displays at museums, the residual radioactivity remaining in the sample is a critical factor. Because the neutron flux used in this study was in the order of 107 cm−2 s−1, which is four to six orders of magnitude lower than that for conventional NAA, the production of neutron-capturing radionuclides is considerably restrained. Therefore, the residual radioactivity remaining in the sample was very low. The most active radionuclide just after the analysis is 28Al but it decays quickly because of its short half life (2.24 min). After 30 days cooling, the 24 g Allende sample (Allende A) used for analysis had an activity of ∼4 Bq (mainly from 60Co), as compared to the permissible level (0.1 MBq or 10 Bq/g) for a substance to be taken outside a radiation-controlled area in most countries. Therefore, the PGNAA procedure described in this study can be applied to such samples preserved at museums and accessed by the public.

Only possible effect caused by neutron irradiation could be detected in isotopic compositions of noble gases [8]. Because some halogen isotopes like 79Br and 127I have large neutron capture cross sections for thermal and cold neutron, and mass-spectrometry has extremely high sensitivity for noble gases, isotopic modification could be identified for such extreme cases as that samples have very high halogen (Br and I, for example) contents and low (or normal) abundances of noble gases (Kr and Xe, for example), where neutron-induced 80Kr and 128Xe produced by (n.γ) reaction on 79Br and 127I followed by beta-decay contributes to indigenous 80Kr and 128Xe, respectively. Under the experimental condition applied in this study, such contributions are less than 10−3 for 80Kr and 10−7 for 130Xe. The contribution of neutron-induced 80Kr is in the range for being able to recognize the isotopic shift by noble gas mass spectrometry, while that for 130Xe is far below the detection limit. Therefore, the sample once analyzed by PGNAA can be safely reused for other scientific studies except for such an extreme case.

Conclusions

-

(1)

The accuracy and precision of PGNAA using the internal mono-standard method was first tested using the Allende meteorite standard powder. Accuracy of the determined elemental mass fractions for B, Na, Mg, Al, Cl, K, Ca, Ti, Mn, Fe, Sm, and Gd was generally good (<10 % for most elements) compared with literature values. The precision of the method was also shown to be good as mass fraction data determined in the identical sample during different irradiations on different days showed good agreement.

-

(2)

The applicability of the PGNAA procedure using the internal mono-standard method to voluminous samples was tested using GSJ standardized rock powders in PTFE-bottles. Accuracy of the determined elemental mass fractions for B, Na, Mg, Al, Cl, K, Ca, Ti, Mn, Fe, Sm, and Gd was generally good (mostly within 10 %). Mass fraction data determined in identical samples during different irradiations on the same day and different irradiations on different days showed good precision.

-

(3)

This method was then applied to chunks or sawn slabs of stony (Allende, Kimble County, Leedey, Lake Labyrinth) and iron meteorites (Canyon Diablo, Squaw Creek, Toluca) for determining B, Na, Mg, Al, Si, S, Cl, K, Ca, Ti, Mn, Fe, Ni, Co, and Sm in stony meteorites, and for determining Fe, Ni and Co in iron meteorites. The data generally showed good agreement with literature analyses of the same or similar meteorites. The largest deviations were seen in weathered meteorites, such as Kimble County.

-

(4)

Overall, the results seem to show that PGNAA using the mono-standard method for evaluating elemental mass fractions is a practical means of determining the composition of large meteorite samples. Furthermore, the residual radioactivity remaining in the sample is very low. Therefore, PGNAA using the mono-standard method is well-suited to the analysis of large chunks or polished sawn slabs used as museum pieces, which cannot be broken-up and sampled for normal small-sample PGNAA or INAA.

References

Isenhour TL, Morrison GH (1966) Anal Chem 38:162–167

Anderson DL, Failey MP, Zoller WH, Walters WB, Gordon GE, Lindstrom RM (1981) J Radioanal Chem 63:97–119

Sueki K, Oura Y, Sato W, Nakahara H, Tomizawa T (1998) J Radioanal Nucl Chem 234:27–31

Failey MP, Anderson DL, Zoller WH, Gordon GE, Lindstrom RM (1979) Anal Chem 51:2209–2221

Islam MA, Matsue H, Ebihara M (2011) Anal Sci 27:1143–1147

Latif SKA, Oura Y, Ebihara M, Kallemeyn GW, Nakahara H, Yonezawa C, Matsue H, Sawahata H (1999) J Radioanal Nucl Chem 239:577–580

Sueki K, Kobayashi K, Sato W, Nakahara H, Tomizawa T (1996) Anal Chem 68:2203–2209

Ebihara M, Oura Y (2001) Earth Planets Space 53:1039–1045

Jarosewich E, Clarke RS Jr, Barrows JN (1986) Smithson Contrib Earth Sci 27:49

Magara M, Yonezawa C (1998) Nucl Inst Methods A 411:130–136

Lone MA, Leavitt RA, Harrison DA (1981) Atom Data Nucl Data Tables 26:511–559

Reedy RC, Frankle SC (2002) Atom Data Nucl Data Tables 80:1–34

IAEA (2007) Database of prompt gamma rays from slow neutron capture for elemental analysis. Vienna, pp 251

Ebihara M, Ozaki H, Kato F, Nakahara H (1997) J Radioanal Nucl Chem 216:107–112

Langenauer M, Krahenbuhl U (1993) Meteoritics 28:98–104

Dreibus G, Spettel B, Wänke H (1979) In: Ahrens JH (ed) Origin and distribution of the elements. Pergamon, Oxford

Kallemeyn GK, Wasson JT (1981) Geochim Cosmochim Acta 45:1217–1230

Imai N, Terashima S, Itoh S, Ando A (1995) Geochem J 29:91–95

Karouji Y, Ebihara M (2008) Anal Sci 24:659–663

Wasson JT, Kallemeyn GK (1988) Philos Trans R Soc Lond A 325:535–544

Jarosewich E (1990) Meteoritics 25:323–337

Zhai M, Shaw DM (1994) Meteoritics 29:607–615

Dyakonova MI (1968) Meteoritika 28:131–138

Choi B, Ouyang X, Wasson JT (1995) Geochim Cosmochim Acta 59:593–612

Greenland L, Lovering JF (1965) Geochim Cosmochim Acta 29:821–858

Vogt JR, Ehmann WD (1965) Geochim Cosmochim Acta 29:373–383

Schmitt RA, Goles GG, Smith RH, Osborn TW (1972) Meteoritics 7:131–214

Malvin DJ, Wang D, Wasson JT (1984) Geochim Cosmochim Acta 48:785–804

Acknowledgments

The present work was partly supported by the committee of University of Tokyo for the cooperative use of JAEA facilities. We are grateful to G. Kallemeyn for the language. C. Yonezawa and H. Matsue are thanked for their technical assistances. This study was financially supported by grants-in-aid defrayed by Ministry of Education, Science and Technology (No. 19340169 and 22224010 to ME).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Latif, S.A., Oura, Y., Ebihara, M. et al. Non-destructive elemental analysis of large meteorite samples by prompt gamma-ray neutron activation analysis with the internal mono-standard method. Anal Bioanal Chem 405, 8749–8759 (2013). https://doi.org/10.1007/s00216-013-7331-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-013-7331-1