Abstract

Recent progress in the development of various diamond-related materials (DRMs) has induced a strong interest in their use as a stationary phase in various separation techniques. DRMs meet many requirements for use as a stationary phase in chromatography, including excellent mechanical and chemical stability, high thermal stability, low chemical reactivity of the surface, and biocompatibility. The general physicochemical properties of diamond and the preparation of different types of DRMs are reviewed, and an overview is provided of current and possible future applications in solid-phase extraction and various separation technologies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The introduction of chromatography as a separation technique is usually associated with the outstanding separation of a mixture of coloured natural pigments [1]. However, it is a lesser known fact that to achieve this first liquid chromatographic separation, Mikhail Tswett tested the adsorption properties of more than 100 different adsorbents as potential column packings. The list of tested materials includes nonmetals (sulfur, coal, etc.), metals (silicon, zinc, iron, aluminium, lead, antimony), metal oxides (alumina, silica and others), hydroxides, inorganic chlorides, bromides, iodides, nitrates, sulfates, sulfides, sulfites, phosphates, carbonates, silicates, carbohydrates (starch, dextrin, inulin, etc.), proteins (ovalbumin), organic compounds (amides, alcohols, oxalates, acetates, etc.) and other substances and materials [1]. Many of these materials, such as silica, alumina, polysaccharides, inorganic chlorides and carbon, were later used successfully as stationary phases in various separation techniques.

Progress in chromatographic methods has always been associated with the development of new stationary phases and separation media. For example, reversed-phase high-performance liquid chromatography (HPLC) appeared during the 1970s as a result of the application of brush-type, chemically modified, microsized, uniform silica particles in combination with high-pressure delivery of the eluent through the chromatographic column. It caused a breakthrough in column efficiency that led to HPLC's current status as the most popular separation and analytical technique in biochemistry, medicine, biotechnology, pharmacology and other areas. The appearance of ion chromatography was related to the design of low-capacity, agglomerated, polymer-based ion exchangers. There are also many other examples.

Current trends in the development of separation science are associated with extending the possibilities of existing methods for faster and more efficient analyses of samples of ever-increasing complexity. In the case of HPLC, such a goal has to be achieved by carrying out the separation at very high pressures or elevated temperatures, and in eluents that are more chemically aggressive under these separation conditions. Progress in this area is restricted strongly by the absence of suitable adsorbents. Common adsorbents for HPLC, including inorganic oxides, organic polymers, porous graphitic carbon and carbon composites, all have some limitations. The present paper will focus attention on the new and intriguing possibility of using synthetic diamonds as an adsorbent with ideal mechanical, hydrolytic and thermal stability. Their unique properties make diamond and diamond-related materials attractive options for use in various preconcentration and separation methods. Another reason for the increased interest in the use of diamonds is their unique affinity to some classes of compounds.

Physicochemical properties of diamond

Diamond is an allotrope of carbon with the face-centered cubic crystal structure, also known as a diamond lattice, consisting of tetrahedrally bonded carbon atoms with an sp 3 configuration. In contrast to another carbon allotrope, graphite (sp 2 configuration), diamond displays exceptional physical characteristics such as hardness and chemical stability, which make it very attractive for use as an adsorbent or as a matrix for the production of stationary phases. The other amazing property of diamond is its very high thermal conductivity in combination with negligible thermal expansion at high temperatures (Table 1). Diamond converts to graphite at temperatures above 1700 °C in a vacuum or an inert gas atmosphere, and at ∼700 °C in air. The hardness and high thermal conductivity of diamond lead to its major industrial applications in abrasive, polishing and cutting tools. Their excellent chemical stability at high temperatures as well as their resistance to chemically aggressive liquids make diamonds and diamond-related materials (DRMs) very attractive as adsorption media for separations performed under severe conditions.

Most diamonds are excellent electrical insulators with resistivities of 1016–1018 Ω cm. However, their conductivities can be modified by doping with boron atoms, resulting in semiconducting properties. Significant conductivity due to the presence of hydrogen-related species adsorbed at the surface is also observed in diamonds grown using chemical vapor deposition (CVD) technology.

A synthetic diamond surface can be considered to be moderately hydrophobic. The reported value of the contact angle of water with the diamond crystal surface (111) is about 60° [2]. The surface of synthetic diamond has no functional groups, so either a special surface reaction should be carried out to activate the surface and introduce functionalities of interest, or the diamond particles can be coated with a functional polymer. Thus, a desirable selectivity for a DRM adsorbent can be achieved. An alternative is to use bare detonation nanodiamond, which is a particular type of DRM with extremely complex surface chemistry comprising 10–15 different types of functional groups, such as oxygen-containing hydroxyls, carboxyls, carbonyls, ether, anhydride, etc., nitrogen-containing amine, amide, nitro, cyano, and others. In this case, a special sequence of chemical transformations is required to obtain a surface that has acceptable homogeneity.

Finally, two important properties of DRMs are their biocompatibilities and low cytotoxicities [3], which make diamond adsorbents useful for biochromatographic separations [4–6].

Types of DRMs suitable for preparing chromatographic adsorbents

Because of their differing geographical origins, natural diamonds have various inclusions of other substances, which provide not only different colours but also variations in physicochemical properties. For this reason, only synthetic diamonds and DRMs can be of interest for the development of adsorbents because of the need for uniform properties.

To be used as an adsorbent, a DRM should have a high specific surface area (S, m2/g) in order to provide sufficient adsorption or loading capacity. Specific surface areas for typical chromatographic adsorbents typically fall in the range 30–800 m2/g. In the case of nonporous diamond, values in this range can be achieved in several ways.

-

1.

The first approach is to use very small diamond particles with diameters of less than 0.5 µm. The specific surface areas of a spherical particle and a cubic particle can be calculated as follows:

where r (m) is either the diameter of a spherical particle or the length of the side of a cubic particle, and ρ is the density of the particle matrix expressed in g/m3. According to Eq. 1, and taking into account the relatively high density of diamond (Table 1), the specific surface area of diamond powder containing particles of diameter 0.5 µm is approximately 3.4 m2/g. However, the actual S values are higher (in the range of 9.9–22.1 m2/g) because of the irregular shape of diamond particles and the nonuniform distribution of particle sizes [7].

-

2.

Detonation nanodiamond is one of the few nanomaterials to be produced at commercial scales. As the name suggests, it is synthesized by the detonation of explosives in an oxygen-deficient atmosphere [8]. Nanodiamond particles are characterized by a narrow size distribution, with most particles lying between 2 and 20 nm in diameter and with average particle sizes of ∼4–5 nm. The specific surface area of nanodiamond powder is 250–450 m2/g. Of course, the direct usage of fine particles in chromatography is limited because of high column backpressure. However, fine diamond particles have been entrapped in larger particles of other nonporous materials [9, 10], or have been deposited in narrow silicon channels [11], or gel-encapsulated within the pores of large porous particles [4].

-

3.

Single-crystal diamond has a small specific surface area and hence a limited adsorption capacity. However, micron-sized polycrystalline composites have significantly more surface area and hence are more suitable for use as HPLC adsorbents. Within the general class of polycrystalline diamonds, any particular diamond can be described by the average size of grains or compacts that consist of many microsized or nanosized crystals (usually referred to as “microcrystalline” and “nanocrystalline” diamond). The structure of detonation nanodiamond is almost ideal for building larger grains. A breakthrough in the preparation of such polycrystalline compacts occurred in 2001 due to the invention of important technology for sintering detonation nanodiamonds [12, 13]. Sintering for a few minutes at 1400 °C and at a pressure of 4.5–7.0 GPa results in grains above 20–30 microns in size, which can be crushed to a powder of particles 3–6 microns in size. The resultant material, referred to as microdisperse sintered nanodiamonds (MSND), has a specific surface area of about 140–250 m2/g. After special treatment, the original irregular shape of MSND particles can be changed to produce ovate or even spherical particles (Fig. 1a).

-

4.

The chemical vapor deposition (CVD) method of synthesizing nanocrystalline diamond was developed in 1956 in the former Soviet Union [14]. Depending on the substrate used, both diamond polycrystalline films and single-crystal diamond up to 2 mm in size can be produced. Therefore, a suitable material with the required surface properties can be coated with diamond film and used as a chromatographic stationary phase. In fact, the CVD method has been used for the preparation of diamond microchips [15]. A very promising CVD-based method of preparing core-–shell diamond or hollow spherical diamond particles was reported in 2007 [16]. Silica microspheres of a suitable diameter are plasma coated with diamond layers, with subsequent chemical dissolution of the supporting silica matrix in HF or in alkali. The wall thickness is controllable and can be varied oto be 5%–20% of the shell diameter. At present, the preparation of core–shell diamond particles 30–40 µm in diameter has been described (Fig. 1b).

Further important questions concerning the use of diamonds in separation science are the commercial availability and the cost of suitable types of DRM. There is large-scale production (at a level of hundred tonnes per year) of various technical grade micron-sized powders of single-crystal diamonds, nanodimonds and sintered particles for the production of abrasive compositions, so their cost is usually less than US$5 per gram. However, the cost of specially purified and fractionated diamonds, or chemically modified or doped diamonds for use in medical and biochemical applications, can be 3–40 times higher.

Scanning electron micrographs of an MSND particle (a) and a diamond microshell (b) [16]

Chemical modification of the diamond surface

The chemical modification of the diamond surface plays an important role in adjusting the adsorption properties of DRMs. Depending on the type of DRM, different approaches can be used to modify the surface properties. Sometimes the desired properties can be achieved during synthesis. There are no functional groups on the surface of common synthetic diamond, so strong reagents and severe conditions must be used to modify the surface properties. Hydrogen termination of diamond by heating in a furnace in a hydrogen atmosphere at 800–900 °C can be used to increase the hydrophobicity of the surface [17, 18]. Alternatively, oxidation of the powder in air at 425 °C can be used to increase the concentration of carboxylic groups at the surface [19], resulting in an increase in the cation-exchange capacity of the adsorbent, which is essential for applications associated with ion-exchange separations [20]. Chlorination in a flow of chlorine at 425 °C can be used to provide reactive chloro groups [21].

Detonation nanodiamonds represent a very special type of DRM. Nanodiamond has the most complex chemistry among DRMs, with two possible carbon phases (sp 2 and sp 3) and many different functional groups as a result of specific types of synthesis and the isolation of nanodiamond from the reaction soot, which includes the liquid-phase oxidation of graphite with different oxidative reagents [22]. Additional chemical purification of nanodiamonds is also required to ensure the complete removal of amorphous graphite or the sp 2 carbon phase as a possible contaminant. The resulting surface of nanodiamonds has a wide range of possible functional groups which can be chemically modified to attach specific functional groups that can attune the selectivity of the adsorbents for specific chromatographic modes [22].

Applications

The excellent physicochemical properties of DRMs are the main reason for their use in various separation techniques. However, the interesting adsorption properties of DRMs are also attracting increasing attention.

Solid-phase extraction

Sakurai et al. [23] studied the adsorption characteristics of coagulated nanodiamond particles for oxoacid anions, including arsenite, arsenate, perrhenate, selenite, selenate, dichromate, molybdite and tungstate from water solutions. A unique selectivity towards tungstate was discovered and used for its quantitative preconcentration from river waters. The other interesting property discovered for this carbonaceous material was its low reducing ability, as the investigators did not observe any reduction of Cr2O 2−7 during experiments.

Chang and coworkers [6, 24, 25] observed a remarkably high affinity of bare nanodiamond particles (with a nominal size of 100 nm) for the selective solid-phase extraction (SPE) of cytochrome C, bovine serum albumin, myoglobin, angiotensin I, gramicidin S, bradykinin and other peptides from highly diluted water solutions. The corresponding analytical method SPEED (solid-phase extraction and elution on diamond) was used successfully for proteome analysis of urine samples [6]. This research group has also exploited the unique optical transparency of diamonds in surface-enhanced laser desorption/ionisation (SELDI, a variant of matrix-assisted laser desorption/ionisation (MALDI)) time-of flight (TOF) mass spectrometry (MS). Proteins preconcentrated by SPE on diamond can be analysed directly by SELDI-TOF-MS with an enhancement in detection sensitivity of more than two orders of magnitude. The efficiency of a hyphenated SPEED–atmospheric pressure matrix-assisted laser desorption/ionization–Fourier transform ion cyclotron resonance mass spectrometry (AP-MALDI-FTICR) system is illustrated in Fig. 2.

Atmospheric pressure matrix-assisted laser desorption/ionization–Fourier transform ion cyclotron resonance (AP-MALDI-FTICR) mass spectra of a 5 nM cytochrome C trypsin digest solution before and after SPEED extraction. Spectrum A was recorded with 1 μl (∼5 fmol starting protein loaded on the sample target) of the digestion solution, and spectrum B was recorded with 200 μl (1 pmol starting protein) of the same digestion solution concentrated onto 2 μg of nanodiamonds [25]

Saini et al. developed C18, C8, and perfluorinated [26] diamond-based reversed-phase and aminated [18] SPE media. The prepared phases demonstrated not only good adsorption capacities for organic substances but also excellent stabilities. No change in properties was observed for C18-functionalised diamond powder after 38 h exposure to 2.5 M HCl or 2.5 M NaOH solutions.

Gas chromatography

The excellent thermostability and inertness of diamond were first utilised in gas chromatography (GC) in 1966, when Allied Chemical Corporation applied for a patent on the invention of “synthetic diamantiferous material composed of individual diamond particles having average diameter not exceeding 0.1 micron, a surface area between 40 and 400 square meter per gram and having at least 10% of the surface area containing hydroxyl, carboxyl and carbonyl functional groups…” [10], and presented the separation of corrosive gases, including HF, F2, ClF3, HCl [9] as an example of its possible application. The very small sizes of diamond particles restricted the direct use of nanodiamonds as a stationary phase, so a mixture of CaF2 with nanodiamonds was utilised. No publications have appeared in this area since 1969.

High-performance liquid chromatography

Because of very poor separation efficiency, the number of known attempts to use DRMs as the stationary phase in column liquid chromatography is very limited. The first attempt to use a chromatographic column packed with microparticles of natural diamonds was undertaken in 1973 [27]. Only partial separation of a two-component mixture was achieved on a 25 cm column packed with 10 µm natural diamond particles. A very poor column efficiency of only 380 theoretical plates was reported. For the obvious reasons of high cost, limited availability, nonhomogeneous adsorption properties due to entrapped admixtures, and the small surface areas of single-crystal particles, natural diamonds cannot be seriously considered as stationary phases for HPLC.

The use of microparticles of synthetic polydisperse synthetic diamonds as a stationary phase in HPLC was first reported only five years ago. Again, a very low column efficiency of 130 theoretical plates was observed and this did not allow the complete separation of a two-component mixture [28]. This column was packed with 4.0 µm polydisperse synthetic diamond particles with a specific surface area of 216 m2/g, and—theoretically—it should be more efficient than the natural diamond column used previously. The most significant problem encountered when preparing efficient chromatographic columns is the difficulty involved in preparing diamond fractions that have particles with a narrow size distribution. This is due to the known effect of the strong aggregation of diamond particles, especially in water-based suspensions.

Significant progress was achieved in 2007 [29], whereby a new approach for the isolation of a uniform fraction of MSND was achieved. This resulted in clearly superior separation performance, allowing the separation of 8–10 component mixtures of substituted benzenes (Fig. 3). The column efficiency was about 15400 theoretical plates per meter, and this is attributable to the narrow size distribution of the particles and their high specific surface area (191 m2/g).

Separation of a model mixture of organic substances on a 150 × 4.6 mm i.d. MSND column. Solutes: o-xylene (1), anisole (2), ethyl benzoate (3), nitrobenzene (4), benzonitrile (5), acetophenone (6), and benzophenone (7) Eluent: n-hexane–2-propanol (97.5 : 2.5, v/v), 0.6 ml/min; detection: UV 254 nm; column temperature: 30 °C. Reproduced from [29]

Ion chromatography

The presence of a large number of carboxylic groups at the surface of MSND is responsible for its high zeta potential: up to 100 mV. Thus, MSND can also function as a carboxylic type of cation exchanger that can be used in ion chromatography. Preliminary results [20] demonstrated the ability of bare MSND to retain cations in relatively acidic eluents. The separation of model mixtures of 3–4 alkali or alkaline-earth metal cations was achieved.

Electromodulated chromatography

The principle of electrochemically modulated liquid chromatography (EMLC) is based on the manipulation of the adsorption properties of the column packing and the resultant chromatographic retention through the application of an electrical potential to a conductive packing. As mentioned previously, the electroconductivity of diamond can be significantly increased to 2.4 S/cm by doping with boron atoms, so boron-doped diamond powder has been tested as a stationary phase in EMLC instead of porous graphitic carbon, which is used conventionally [30]. Diamond particles 8–12 μm in diameter were coated with a boron-doped diamond layer using microwave plasma-assisted CVD with a resulting specific surface area of 1 m2/g. The separation of 1,3-benzenedisulfonate, benzenesulfonate and 4-toluenesulfonate on the prepared phase was investigated at different potentials in the range from −1.2 V to +1.2 V. The optimum resolution of chromatographic peaks was achieved at positive potentials of 0.15–0.30 V.

Affinity chromatography

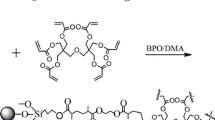

The exceptionally high affinity of carboxylated/oxidised nanodiamonds for proteins [24, 31] due to a combination of hydrophilic and hydrophobic interactions has been utilised in low-pressure liquid chromatography [4, 5]. Agglomerated adsorbents consisting of 60–200 micron crosslinked polysaccharide beads containing immobilized nanodiamond particles was used for the selective purification of cytochrome C, luciferase, lysozyme and other proteins [4, 5]. An example of the selective isolation of luciferase from a crude extract of proteins is shown in Fig. 4. However, the suitability of these adsorbents for liquid chromatography was limited by a narrow pH range (pH 4–9) of hydrolytic stability and by the softness of the polysaccharide matrix used to prepare the adsorbents.

Isolation of luciferase from a crude protein extract by liquid chromatography on a nanodiamond sorbent, and slab electropherograms of the initial extract (1); free unbound protein components from the first eluted peak (2); protein fractions at the maximum of luciferase activity from the last eluted peak (3). Reconstructed from [4]

Electrophoresis

Chemically modified detonation nanodiamonds (NDs) have been used for the selective electrophoretic isolation of streptavidin. The preparation of biospecific NDs included the amination of the ND surface followed by conjugation to N-hydroxysuccinimide derivatives of rhodamine and biotin. Streptavidin was captured by a prepared probe, and this ND–protein complex was collected from solution after electrophoresis at a gold electrode [32].

Microchip separations

Björkman et al. constructed microchips from low-cost polycrystalline diamond for the microfluidic separation of proteins [15]. The CVD method was used for the deposition of a diamond layer onto silicon wafers in combination with lithography and silicon etching. The constructed device had a 4 cm straight channel with a cross-sectional area in the range of 4000–7000 μm2. The channels were filled with a continuous polymer bed and used for the fast separation of myoglobin, conalbumin, ovalbumin and soybean trypsin inhibitor in 30 s. The authors underlined the advantages of the ability of diamond to transmit electromagnetic radiation over a very broad wavelength span, thereby facilitating photometric and fluorescent detection of the separated substances.

Outlook

The improvement in the technologies used to prepare DRMs has led to the appearance of new materials that are better suited to the demands of separation science. Among these materials, microdisperse sintered nanodiamonds and nanodiamond-related composites have attracted the most attention.

There are two key ways of utilising the advantageous properties of DRMs in separation technologies. The first approach is associated with the known unique physicochemical properties of diamond, which allow operation in highly corrosive environments, or the use of the excellent optical properties of diamond to achieve better sensitivity in MALDI-TOF-MS. However, a second (newer) approach exploits diamond’s unique selectivity in the adsorption of proteins and its superior biocompatibility. There is also considerable potential for improving the separation efficiency of nanodiamond adsorbents and for altering the separation selectivity by chemically modifying the nanodiamond surface.

At present, most of the achievements in this field have been obtained during preliminary work testing the applicability of DRMs to different separation technologies. Future investigations should be directed towards more detailed investigations of their adsorption properties and affinities for different classes of compounds.

References

Tswett MS (1906) Adsorption analysis and the chromatographic method. Application to the chemistry of chlorophyll. Ber Dtsch Botan Ges 24:384–393

Kutsay O, Loginova O, Gontar A, Perevertallo V, Zanevskyy O, Katrusha A, Ivakhnenko S, Gorokhov V, Stank S, Tkach V, Novikov N (2008) Surface properties of amorphous carbon films. Diam Relat Mater 17:1689–1691

Schrand AM, Huang HJ, Carlson C, Schlager JJ, Osawa E, Hussain SM, Dai LM (2007) Are diamond nanoparticles cytotoxic? J Phys Chem B 111:2–7

Purtov KV, Puzyr AP, Bondar VS (2008) Nanodiamond sorbents: new carriers for column chromatography of proteins. Dokl Biochem Biophys 419:72–74

Bondar VS, Pozdnyakova IO, Puzyr AP (2004) Applications of nanodiamonds for separation and purification of proteins. Phys Solid State 46:758–760

Chen WH, Lee SC, Sabu S, Fang HC, Chung SC, Han CC, Chang HC (2006) Solid-phase extraction and elution on diamond (SPEED): a fast and general platform for proteome analysis with mass spectrometry. Anal Chem 78:4228–4234

Tsubota T, Hirabayashi O, Ida S, Nagaoka S, Nagata M, Matsumoto Y (2002) Chemical modification of hydrogenated diamond surface using benzoyl peroxide. Phys Chem Chem Phys 4:806–811

Krueger A (2008) Diamond nanoparticles: jewels for chemistry and physics. Adv Mater 20:2445–2449

Hirschmann RP, Mariani TL (1968) Synthetic diamond—a solid absorbent for corrosive gases. J Chromatogr 34:78–80

Allied Chem (1969) Synthetic diamantiferous material. GB Patent 1154633

Guillaudeu S, Zhu X, Aslam DM (2003) Fabrication of 2-μm wide polycrystalline diamond channels using silicon molds for microfluidic applications. Diam Relat Mater 12:65–69

Yushin GN, Osswald S, Padalko VI, Bogatyreva GP, Gogotsi Y (2005) Effect of sintering on structure of nanodiamond. Diam Relat Mater 14:1721–1729

Bogatyreva GP, Voloshin MN, Padalko VI (2008) Detonation synthesized nanodiamond powder for the preparation of porous polycrystalline micron powders. Diam Relat Mater 17:213–216

Derjaguin BV, Fedoseev DV (1977) Growth of diamond and graphite from the gas phase. Nauka, Moscow

Bjorkman H, Ericson C, Hjerten S, Hjort K (2001) Diamond microchips for fast chromatography of proteins. Sensor Actuat B 79:71–77

Lee JK, Anderson MW, Gray FA, John P (2007) Fabrication of spherical diamond microshells. Diam Relat Mater 16:701–704

Korolkov VV, Kulakova II, Tarasevich BN, Lisichkin GV (2007) Dual reaction capacity of hydrogenated nanodiamond. Diam Relat Mater 16:2129–2132

Saini G, Yang L, Lee ML, Dadson A, Vail MA, Linford MR (2008) Amino-modified diamond as a durable stationary phase for solid-phase extraction. Anal Chem 80:6253–6259

Osswald S, Yushin G, Mochalin V, Kucheyev SO, Gogotsi Y (2006) Control of sp(2)/sp(3) carbon ratio and surface chemistry of nanodiamond powders by selective oxidation in air. J Am Chem Soc 128:11635–11642

Nesterenko PN, Fedyanina ON, Volgin YV, Jones P (2007) Ion chromatographic investigation of the ion-exchange properties of microdisperse sintered nanodiamonds. J Chromatogr A 1155:2–7

Miller JB, Brown DW (1996) Photochemical modification of diamond surfaces. Langmuir 12:5809–5817

Dolmatov VY (2007) Detonation nanodiamonds: synthesis, structure, properties and applications. Usp Khim 76:375–397

Sakurai H, Ebihara N, Osawa E, Takahashi M, Fujinami M, Oguma K (2006) Adsorption characteristics of a nanodiamond for oxoacid anions and their application to the selective preconcentration of tungstate in water samples. Anal Sci 22:357–362

Kong XL, Huang LCL, Hsu CM, Chen WH, Han CC, Chang HC (2005) High-affinity capture of proteins by diamond nanoparticles for mass spectrometric analysis. Anal Chem 77:259–265

Sabu S, Yang FC, Wang YS, Chen WH, Chou MI, Chang HC, Han CC (2007) Peptide analysis: solid phase extraction-elution on diamond combined with atmospheric pressure matrix-assisted laser desorption/ionization–Fourier transform ion cyclotron resonance mass spectrometry. Anal Biochem 367:190–200

Saini G, Wiest LA, Herbert D, Biggs KN, Dadson A, Vail MA, Linford MR (2009) C-18, C-8, and perfluoro reversed phases on diamond for solid-phase extraction. J Chromatogr A 1216:3587–3593

Telepchak MJ (1973) The mechanism of reverse phase liquid-solid chromatography. Chromatographia 6:234–236

Patel BA, Rutt KJ, Padalko VI, Mikhalovsky SV (2002) Use of industrial diamonds in HPLC. J Superhard Mater 6:51–54

Nesterenko PN, Fedyanina ON, Volgin YV (2007) Microdispersed sintered nanodiamonds as a new stationary phase for high-performance liquid chromatography. Analyst 132:403–405

Muna GW, Swope VM, Swain GM, Porter MD (2008) Electrochemically modulated liquid chromatography using a boron-doped diamond particle stationary phase. J Chromatogr A 1210:154–159

Yeap WS, Tan YY, Loh KP (2008) Using detonation nanodiamond for the specific capture of glycoproteins. Anal Chem 80:4659–4665

Hens SC, Cunningham G, Tyler T, Moseenkov S, Kuznetsov V, Shenderova O (2008) Nanodiamond bioconjugate probes and their collection by electrophoresis. Diam Relat Mater 17:1858–1866

Acknowledgments

This work was supported by an IRGS grant from the University of Tasmania to PNN.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nesterenko, P.N., Haddad, P.R. Diamond-related materials as potential new media in separation science. Anal Bioanal Chem 396, 205–211 (2010). https://doi.org/10.1007/s00216-009-3219-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-009-3219-5