Abstract

Nickel(II) and lead(II) ionic imprinted 8-hydroxyquinoline polymers were synthesized by a precipitation polymerization technique and were used as selective solid phase extraction supports for the determination of nickel and lead in seawater by flow injection solid phase extraction on-line inductively coupled plasma-optical emission spectrometry. An optimum loading flow rate of 2.25 mL min−1 for 2 min and an elution flow rate of 2.25 mL min−1 for 1 min gave an enrichment factor of 15 for nickel. However, a low dynamic capacity and/or rate for adsorption and desorption was found for lead ionic imprinted polymer and a flow rate of 3.00 mL min−1 for 4-min loading and a flow rate of 2.25 mL min−1 for 1-min elution gave a enrichment factor of 5. The limit of detection was 0.33 µg L−1 for nickel and 1.88 µg L−1 for lead, with a precision (n = 11) of 8% (2.37 µg Ni L−1) for nickel and 11% (8.38 µg Pb L−1) for lead. Accuracy was also assessed by analyzing SLEW-3 (estuarine water) and TM-24 (lake water) certified reference materials, and the values determined were in good agreement with the certified concentrations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nickel and lead have long been recognized to be toxic metals for marine ecosystems. Both elements enter the aquatic environment from the dissolution of rocks and soils, from atmospheric fallout, but mainly from industrial processes and water disposal [1, 2]. This last fact is especially important for estuarine systems because they are near different industries and villages located along the coast. In addition, estuaries are also used for different aquaculture activities, such as mollusk production, and the levels of heavy elements in estuarine water are limited by several legislation directives [3]. Therefore, continuous development of reliable analytical methods to assess these elements in complex samples is of interest.

Heavy metals are present at very low concentrations in estuarine/seawater, whereas matrix concomitants such as chloride and alkaline elements (sodium, potassium, etc.) occur at very high levels [1]. Therefore, preconcentration/separation methods combined with sensitive and selective detectors are needed to perform nickel and lead determination in seawater. Among the preconcentration procedures for trace elements, solid phase extraction (SPE) techniques are quite popular because they offer a number of important advantages over other preconcentration methods. One of the main benefits is that adsorbent material can be packed into minicolumns or cartridges which provide sufficient exchange/adsorption capacity for many applications and ease of automation [4]. Most of the SPE procedures use ion-exchange/chelating resins, which have the disadvantage of a previous derivatization stage when preconcentrating inorganic species such as trace metals. This is because only uncharged (nonpolar) species can interact with most of the adsorbent materials [5]. For example, when high-purity C18 (silica-based materials) is used as an adsorbent material for lead and/or nickel, a chelating reagent such as 8-hydroxyquinoline (8-HQ) is needed to obtain interactions between uncharged complexes and the adsorbent [6–8]. In addition, another disadvantage of such materials for metal preconcentration is the lack of selectivity, which generates a matrix effect, and the use of the standard addition technique for carrying out the determinations [8].

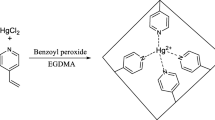

High selectivity for SPE procedures can be obtained by using solid supports synthesized by molecular imprinting polymerization or by ionic imprinting polymerization. These materials can be prepared (synthesized) using inexpensive reagents and with a general knowledge of synthesis. For either molecular imprinted polymer (MIP) or ionic imprinted polymer (IIP), a monomer is polymerized in the presence of a template (a molecule, an ion, or a metal complex) and an excess of a cross-linker, and after the template leaching, the MIP (IIP) is capable of recognizing and rebinding the target analyte (the template) with high selectivity and affinity [9, 10]. Among the different approaches for the synthesis of IIPs [11, 12], the trapping of a nonvinylated chelating ligand (complexing agent) via imprinting of binary/ternary mixed ligand complexes of metal ions with a nonvinylated chelating agent and a vinyl ligand is a popular method [12]. The complexing agent is trapped in the polymeric material, showing affinity for the ion (template) which was used for synthesis. Complexing agents such as dimethylglyoxime [13], diazoaminobenzene [14], cetyltrimethylammonium bromide [15], and derivates of quinoline (5,7-dichloroquinolin-8-ol) [16–25] have been successfully applied, mainly for lanthanides, although some applications can be found in the literature for transition metals such as nickel [24, 25].

All the IIP-based SPE procedures mentioned above are off-line processes, which are time-consuming. If the IIP materials can offer high dynamic capacity and/or rates for adsorption and desorption, preconcentration can be carried out without reaching the thermodynamic equilibrium in short times, being suitable for on-line preconcentration approaches. Some examples of on-line SPE using ionic imprinted sorbents can be found in the literature for both lanthanides [26] and transition metals such as copper [27]. Therefore, one of the goals of the current work is to evaluate the possibilities of two synthesized IIPs for the on-line preconcentration/separation of traces of nickel and lead from seawater samples. Synthesized IIP adsorbent material was packed into short cartridges which were incorporated in a six-way valve of an automatic flow injection manifold combined with inductively coupled plasma-optical emission spectrometry (ICP-OES) detection. Inexpensive reagents such as 8-HQ, as a nonvinylated reagent, 2-(diethylamino) ethyl methacrylate (DEM), as a monomer, and divinylbenzene-80 (DVB), as a cross-linker, were used for synthesis by the precipitation polymerization technique.

Experimental

Apparatus

An Optima 3300 DV inductively coupled plasma atomic emission spectrometer (PerkinElmer, Norwalk, CT, USA) equipped with an AS 91 autosampler (PerkinElmer) and a Gem-Cone cross-flow nebulizer (PerkinElmer) was used for lead and nickel determinations. The detection wavelengths were 231.604 and 224.688 nm for nickel and lead, respectively. The radiofrequency power was 1,300 W and the argon flow rates were 15.0 L min−1 for plasma, 0.5 L min−1 for the auxiliary gas, and 0.8 L min−1 for the nebulization. A Rheodyne (model 5020) six-port low-pressure flow-injection valve (Rheodyne, Cotati, CA, USA) with polytetrafluoroethylene tubes (0.8-mm inner diameter) was connected to a peristaltic pump (PerkinElmer) for direct introduction of the analyte to the nebulizer-plasma torch system, and to a Miniplus 3 peristaltic pump (Gilson, Middleton, WI, USA) for loading the sample and pumping the eluting solution. Solvent flexible tubing red/red, 1.14 mm (SCP Science, Montreal, Canada) was used for loading the sample and pumping the eluting solution through the cartridges, whereas solvent flexible tubing black/black, 0.76 mm, and white/black, 1.52 mm (SCP Science), was used for introduction of the eluate into the plasma torch and for waste removal, respectively. Synthesized IIP material (300 mg) was placed into empty Sep-Pak® cartridges (plus short) from Waters (Milford, MA, USA) between 20-µm-porosity Teflon frits (Supelco, Bellefonte, PA, USA). A Boxcult incubation camera from Selecta (Barcelona, Spain) with controlled temperature coupled with a low-profile roller (Stovall, Greensboro, NC, USA) was used for the polymerization process. An Orion 720A plus pH meter with a glass-calomel electrode (Orion, Cambridge, UK) was used for pH measurements.

Reagents

Chemicals were ultrapure grade and uultrapure water, resistance 18 MΩ cm (Millipore, Bedford, MA, USA), was used. Stock nickel and lead standard solutions (1.000 g L−1) were supplied by Merck (Darmstadt, Germany). Analytical grade nickel chloride (NiCl2.6H2O) and lead nitrate (Pb(NO3)2), used as templates, were purchased from Panreac (Barcelona, Spain). High-purity 69% nitric acid was from Panreac, and high-purity ammonia, ammonium chloride, and analytical grade 8-HQ were purchased from Merck. High performance liquid chromatography grade acetonitrile and toluene were obtained from Scharlab (Barcelona, Spain). DEM and DVB were from Sigma-Aldrich (Steinheim, Switzerland). DVB was treated to remove the polymerization inhibitor by passing a few milliliters of the reagent through a minicolumn containing approximately 0.5 g of neutral alumina (Sigma-Aldrich). 2,2′-Azobisisobutyronitrile was purchased from Fluka (Buchs, Switzerland). This reagent was purified by crystallization at −20 °C after dissolving the reagent in methanol (Merck) at 50–60 °C. After purification, this reagent was stored at 4 °C. Estuarine seawater (SLEW-3) certified reference material was obtained from the National Research Council of Canada. Lake water (TM-24) certified reference material was purchased from the National Water Research Institute of Canada.

Collection of seawater samples

Seawater samples (1 L) were collected from the Ría de Muros-Noia estuary (northwestern Spain) in precleaned high density polyethylene bottles. After collection, seawater samples were filtered through 0.45-µm polycarbonate membrane Nucleopore filters (Millipore) and then acidified at a pH lower than 2.0 by adding 1.0 mL of concentrated nitric acid to avoid metal adsorption onto the inner bottle walls. Acidified seawater samples were then stored at low temperature until they were used.

Synthesis of nickel and lead IIPs

Table 1 lists the amounts (weights or volumes) of template (nickel chloride or lead nitrate), monomer (DEM), complexing agent (8-HQ), cross-linker (DVB), and free radical initiator (2,2′-azobisisobutyronitrile) used in the synthesis of nickel IIP [25] and lead IIP. The general procedure was as follows. First, the template was mixed with the monomer and the complexing agent in 15-mL glass tubes before 12.5 mL of porogen (3:1 acetonitrile/toluene) was added. The mixture was then stirred for 5 min and filtered if necessary. Finally, the cross-linker and the initiator were added to the mixture (volumes or weights given in Table 1) and the glass tubes were purged with N2 and immediately sealed just before thermal induction of the precipitation polymerization. The temperature was increased from room temperature to 60 °C over 2 h, and then maintained at 60 °C for a further 24 h under a low stirring rate (33 rpm). The polymer particles obtained were then vacuum-filtered, washed with acetonitrile, and oven-dried overnight at 40 °C. It can be seen from Table 1 that the polymers were synthesized in the presence of a double amount of 8-HQ (complexing agent) with respect to DEM (monomer). This gives a template/DEM/8-HQ molar ratio of 1:2:4. The masses of polymer obtained after polymerization were around 0.300 g and the efficiency of the polymerization process, taking into account a theoretical amount of synthesized polymer of 0.5 g, was around 60%. Blank polymer particles (nonimprinted polymer, NIP) were also prepared in the same way as IIP, but without the template. The NIP was then subjected to the same washing pretreatment as described above.

Preparation of IIP cartridges

Empty Sep-Pak® cartridges were filled with 0.30 g of IIP or NIP adsorbents. The IIP or NIP material was between two Teflon frits. Once prepared, the IIP cartridge was incorporated in the six-way valve and the template [nickel(II) or lead(II) ions] was removed from the polymer particles by extensive washing with 2.0 M nitric acid. An efficient removal of the template from IIP particles was achieved after passing 50 mL of the washing solution. This was verified by ICP-OES measurements of nickel or lead in the washing (eluting) solutions from the cartridges (six-way valve in injection position, according to Fig. 1).

On-line preconcentration-ICP-OES determination

Under optimum conditions, the pH of the acidified seawater samples was adjusted to 9.0 for nickel preconcentration or to 8.5 for lead preconcentration by adding low amounts of 6.0 M ammonia solution or by preparing an aqueous standard in 0.1 M NH3/0.1 M NH4Cl buffer solution at pH 9.0 (nickel preconcentration) or 8.5 (lead preconcentration). A similar procedure was adopted when testing other pHs (6.0, 8.0, 8.5, and 9.0) as described in “Effect of pH: imprinting effect.” A diagram showing the loading (adsorption) and elution steps in the on-line nickel or lead IIP SPE is given in Fig. 1. In the preconcentration (loading) step, the seawater sample (at pH 9.0 for nickel or at pH 8.5 for lead) is drawn through the cartridge containing the IIP material by means of a flow rate of 2.25 mL min−1 for 120 s (nickel preconcentration) or 3.00 mL min−1 for 240 s (lead preconcentration). In the meantime, the eluting solution (3.0 M nitric acid) is pumped by pump 2 and pump 1 through the detector (Fig. 1a). In the elution step (Fig. 1b), the eluting solution is propelled through the column in the opposite direction to the loading at a flow rate of 2.25 mL min−1 for 60 s, time enough to elute the analytes completely, as is shown in Fig. 2 (FIAgrams for nickel and lead measurements). The eluting solution is directly introduced to the detector and the nickel or lead emission signals are continuously monitored. Previous to the loading step, the IIP material is conditioned by passing a 0.1 M NH3/0.1 M NH4Cl buffer solution at pH 9.0 (nickel preconcentration) or 8.5 (lead preconcentration) through the cartridge at a flow rate of 2.25 mL min−1 for 60 s (optimum conditions), or by passing 0.1 M NH3/0.1 M NH4Cl buffer solution at other pHs for optimization studies (see “Effect of pH: imprinting effect”). Similarly, the same buffer solution at the same flow rate and time conditions was passed through the cartridges just before the elution step to remove adsorbed matrix concomitants from the IIP material.

Determinations were performed by using aqueous standard solutions in 0.1 M NH3/0.1 M NH4Cl at pH 9.0 (nickel) or 8.5 (lead) covering nickel concentrations within the 0–50 µg L−1 range and lead concentrations until 100 µg L−1.

Results and discussion

Preliminary evaluation of IIPs under static conditions

To measure the static adsorption capacity, 300 mg of imprinted (nickel IIP and lead IIP) sorbents were saturated (flow rate of 10 mL min−1) with several 3.0-mL aliquots of 200 µg mL−1 nickel(II) or 100 µg mL−1 lead(II) solutions at pH 8.5 [8, 25] and then the nickel or lead content in the eluates was directly measured by ICP-OES. The static adsorption capacities of the nickel IIP and lead IIP were 0.023 and 0.0015 mmol g−1, respectively, which implies calculated retention capacities of 11 and 7% for nickel IIP and lead IIP, respectively. These calculated retention capacities are around 10% of the theoretical retention capacity, which agrees with reported retention capacities for MIPs [28].

Similarly, the breakthrough volume was determined under static conditions. Different volumes (25, 100, and 200 mL) of aqueous nickel(II) or lead(II) standard solution, both at 50 µg L−1, were adjusted to pH 8.5 [8, 25], and were passed through cartridges packed with 300 mg of both IIPs at a flow rate of 10 mL min−1. The retained nickel or lead was then eluted with 2.5 mL of 2.0 M nitric acid and determined by ICP-OES. It was observed that large volumes of loading solutions can be used for both IIPs containing 300 mg of the polymeric material and the breakthrough volume is not reached even after loading with 200 mL of sample solutions, showing an enhancement factor of 80 under static conditions.

Optimization of loading conditions (dynamic adsorption conditions)

The loading flow rate and loading time were first studied under fixed elution conditions: an elution flow rate of 3.0 mL min−1, a nitric acid concentration in the eluting solution of 2.0 M, and an elution time of 1.0 min. Aqueous standard solutions containing nickel(II) or lead(II) at 50.0 µg L−1 or seawater samples spiked with nickel(II) or lead(II) at 20.0 µg L−1 were used as samples. Nickel(II) or lead(II) aqueous standards were prepared in a 0.1 M NH3/0.1 M NH4Cl/ buffer solution at pH 8.0. The pH of the spiked seawater samples, acidified with nitric acid added, was increased to 8.0 by adding small volumes of 5.0 M NH3. This pH was selected on the basis of previous off-line experiments for metal-8-HQ complexes and C18 support materials and also for IIPs for Ni(II) preconcentration [8, 25]. A washing stage just before the elution stage was applied by pumping a 0.1 M NH3/0.1 M NH4Cl buffer solution at pH 8.0 at a flow rate of 3.0 mL min−1 for 1.0 min.

Figure 3 shows the average peak height (three replicates) for spiked seawater samples when varying the loading flow rate from 1.25 to 3.5 mL min−1 and for loading times within the 0.5–4.0-min range. It was found that the nickel intensity slowly decreased when the load flow rate was increased from 2.25 to 3.50 mL min−1, whereas high lead signals were obtained for high load flow rates (Fig. 3a). Similarly, the highest nickel signals were obtained for load times above 2.0 min. However, a higher load time is needed to obtain the highest lead signal (Fig. 3b). These results imply a low dynamic capacity and/or rate for adsorption/desorption for lead IIP. A load flow rate of 3.00 mL min−1 for a load time of 4.0 min is needed to preconcentrate lead, whereas a load flow rate of 2.25 mL min−1 for a load time of 2.0 min is enough for the use of nickel IIP. Similar results were obtained when nickel(II) or lead(II) buffered aqueous standard solutions were used. Therefore, under these loading conditions, a volume of 14 mL was passed through the cartridge containing lead IIP but only 4.5 mL was required for nickel IIP.

Optimization of elution conditions (dynamic adsorption conditions)

By fixing the loading conditions at 2.25 mL min−1 for 2.0 min (nickel IIP) and at 3.00 mL min−1 for 4.0 min (lead IIP), we studied the elution flow rate from 1.25 to 3.5 mL min−1. A 2.0 M nitric acid solution was used as the eluting solvent and also either nickel(II) or lead(II) aqueous standard solutions and spiked seawater samples were buffered at pH 8.0. Figure 4a shows the nickel signal decreases when elution with a flow rate higher than 2.25 mL min−1 is used, whereas the lead signal remains constant within the elution flow rate studied.

The effect of the nitric acid concentration on the nickel and lead signals is plotted in Fig. 4b for an elution flow rate of 2.25 mL min−1. It can be seen that a nitric acid concentration of 3.0 M was sufficient to elute both metals from the polymer particles.

Similar results were obtained for the use of nickel(II) or lead(II) buffered aqueous standard solutions. In addition, the time for the washing stage between the loading and injection steps was not found to be significant, and a washing time of 1.0 min was finally selected.

Effect of pH: imprinting effect

The effect of the pH on the nickel(II) or lead(II) retention was studied for cartridges filled with synthesized nickel IIP and lead IIP materials as well as for nickel and lead NIPs. Different buffered aqueous standards (at the pHs studied) covering nickel or lead concentrations between 0 and 50 µg L−1 and an unspiked seawater sample and seawater spiked with 20 µg L−1 nickel(II) or lead(II) were used for the experiment. The results as analytical recoveries are shown in Fig. 5, plot a for nickel IIP and nickel NIP, and in Fig. 5, plot b for lead IIP and lead NIP. It can be seen that nickel is quantitatively retained when a pH between 8.0 and 9.0 is used (nickel recoveries from 104 ± 4 to 100 ± 2%), whereas nickel recoveries when the NIP is used are lower than 6% for all pHs. This means that interactions between nickel ions and the polymer particles are specific interactions (imprinting effect) even at pH 6.0 (nonquantitative retention). Therefore, it can be said that imprinted cavities for nickel(II) were produced during the synthesis of nickel IIP.

Quantitative lead recoveries (Fig. 5, plot b) were only reached at pHs of 8.0 and 8.5 (lead recoveries of 99 ± 5 and 103 ± 4%, respectively), giving lead recoveries of around 80% when using pHs of 6.0 and 9.0. However, lead recoveries close to 60% were obtained for the use of lead NIP at pHs of 8.0 and 8.5. This means that interactions between lead ions and the polymer particles can be attributed to specific (imprinting) and nonspecific (adsorption) interactions. Although a high percentage extraction (around 60% in Fig. 5, plot b) was obtained for the use of lead NIP, the lead IIP offers imprinting capabilities for lead(II) ions because the difference between the percentage extraction of the lead IIP and lead NIP is close to 40%. In this sense, other IIPs reported in the literature have produced differences lower than 30% [16, 23] or even lower than 20% [17]. It must be noted that the lead IIP does not work as an imprinted polymer at pH 6.0 since lead recoveries close to 80% for both nickel IIP and lead NIP are obtained.

From the results obtained, a pH of 9.0 was finally chosen for nickel preconcentration, whereas a pH of 8.5 was preferred for lead.

Effect of major components from seawater

A set of experiments was carried out to observe interactions between the polymeric materials and the major metals present in seawater (Na, K, Ca, and Mg). A seawater sample was subjected seven times to the proposed procedure and the concentrations of the major ions were determined by ICP-OES. After preconcentration, concentrations lower than 20 mg L−1 were determined for sodium, potassium, magnesium and calcium, which are very low concentration taking into account the concentration of such elements in seawater, around 11,490, 399, 1,293 and 413 mg L−1, for sodium, potassium, magnesium, and calcium, respectively [1]. Therefore, it can be concluded that the salt matrix is efficiently removed for the use of either nickel IIP or lead IIP.

Cross-reactivity among nickel/lead and other trace elements

To evaluate the cross-reactivity among nickel or lead and other transition metals (Cd, Cu, Cr, Fe, Mn, Sn, V, and Zn), aqueous solution containing 50 µg L−1 of the target element [nickel(II) or lead(II)] and the other trace metals (also at 50 µg L−1) were passed through the nickel IIP (and nickel NIP), and also the lead IIP (and lead NIP), in triplicate after the pH had been fixed at 9.0 (nickel IIP and nickel NIP) or 8.5 (lead IIP and lead NIP). The results, expressed as percentage extraction, distribution ratios, and selectivity coefficients are listed in Tables 2 and 3 for nickel IIP/NIP and lead IIP/NIP, respectively. From these results (Table 4), it can be stated that lead IIP showed good selectivity for lead over other transition metals, and imprinting properties are only observed for lead. In should be mentioned that chromium is quantitatively retained in lead IIP, but this retention is unspecific (a similar percentage extraction is obtained for chromium when lead NIP is used). However, nickel IIP showed a certain imprinting effect for copper, lead, and zinc, and also nonspecific interactions for chromium (Table 3). The relatively low selectivity of nickel IIP can be attributed to the fact that the hydroxyquinoline ring (8-HQ as a ligand) is not linked to the polymeric chains forming rigid imprinting cavities. In this case, 8-HQ is trapped in the polymeric matrix after polymerization and the imprinting cavities appear to offer certain “flexibility”. Because of the multielement capabilities of nickel IIP, this polymer can be used for the simultaneous preconcentration of nickel, copper, lead, and zinc from seawater samples.

Analytical performances

Five different buffered aqueous calibrations and standard addition graphs (pH 9.0 for nickel or 8.5 for lead), both covering nickel concentrations from 0 to 50 µg L−1 or lead concentrations from 0 to 100 µg L−1, were obtained. Mean slopes of 126.2 ± 9.161 and 109.5 ± 10.73 L µg−1 were obtained for nickel aqueous standard and nickel standard addition graphs, respectively, whereas a mean value of 49.1 ± 2.44 L µg−1 was obtained for lead aqueous standards and a mean value of 48.2 ± 1.72 L µg−1 was obtained for lead standard addition.

After application of Cochran’s and Bartlett’s tests at the 95.0% significance level to comparing variances and an analysis of variance test for comparison of means, also at the 95.0% significance level, it could be concluded that the slopes of the aqueous calibration and standard addition graphs for nickel and lead are statistically comparable (95.0%) and therefore a matrix effect is not observed for both determinations.

To obtain the enrichment factor as the ratio of slopes from an aqueous calibration through the cartridges (internal calibration) and from an aqueous calibration without preconcentration (external calibration by direct aspiration of standard solutions), three different aqueous calibrations covering nickel and lead concentrations between 0 and 100 µg L−1 were obtained. A mean slope of 8.50 ± 0.955 L µg−1 was calculated for nickel determination, which means an enrichment factor of 14.8. Similarly, a mean slope of 9.50 ± 1.23 L µg−1 was obtained for the lead external aqueous calibration, meaning an enrichment factor of 5.

The limit of detection (3SD/m) and the limit of quantification (10SD/m), where SD is the standard deviation of 11 measurements of a blank and m is the mean slope of the aqueous calibration graph, were 0.33 and 1.10 µg L−1, respectively, for nickel. Values of 1.88 and 6.27 µg L−1 for the limit of detection and the limit of quantification, respectively, were obtained for lead.

The repeatability of the overall procedure was assessed by analyzing a surface seawater sample 11 times by the on-line IIP-SPE-ICP-OES method. The relative SD was 8% for nickel determination (nickel concentration of 2.37 ± 0.181 µg L−1) and 11% for lead (lead concentration of 8.38 ± 0.907 µg L−1).

The accuracy of the method was assessed by analyzing two certified reference materials: TM-24 (lake water) and SLEW-3 (estuarine water). Each certified reference material was subjected three times to the optimized on-line preconcentration-ICP-OES procedure. Table 4 lists the nickel and lead concentrations found in both certified reference materials. It can be seen that the nickel and lead levels were within the certified concentration ranges, although the results appear to show a small negative bias because both the lead and the nickel values found are on the lower side of the certification range.

Study of the lifetime of the nickel IIP and lead IIP SPE supports

To determine the lifetime of both IIPs, two nickel IIP and two lead IIP cartridges were tested to find out the number of sequential loading/elution cycles that can be performed without loss of preconcentration efficiency. Experiments were carried out by treating estuarine seawater samples (five different SPE cycles) followed by an aqueous standard solution containing 50 µg L−1 nickel or 50 µg L−1 lead. Analytical recovery was assessed after preconcentrating the nickel or lead aqueous standard solution. The results show that nickel is efficiently retained (nickel IIP can be used at least 40 times; analytical recoveries higher than 95%). For the following ten SPE cycles, the nickel analytical recovery decreased (lower than 95%). However, quantitative analytical recoveries were obtained for lead up to 50 SPE cycles when using lead IIP. Therefore, both IIPs can be used at least 40 times without loss of retention efficiency.

Conclusions

A simple and cheap procedure for the synthesis of IIPs for nickel(II) and lead(II) ions based on trapping a complexing agent (8-HQ) in the polymeric matrix was developed by the precipitation polymerization technique. The IIP materials offer selectivity (imprinting effect) for the template ions [nickel(II) or lead(II)] and they allow a successful separation of these ions from the concomitant seawater matrix components. The synthesized IIP for nickel exhibits better imprinting properties as well as a fast adsorption and desorption rate, which implies an enrichment factor of 15. However, the synthesized IIP for lead exhibits worse imprinting characteristics than those offered by nickel IIP, and an enrichment factor of 5 is achieved for lead. Since the complexing agent is trapped in the polymeric matrix, a previous derivatization stage by the metal complexation is not needed and only a pH adjustment is required before preconcentration. In addition, the synthesized IIPs can be used at least 40 times without losing the adsorbent properties for the target analytes. Because of the long lifetime of the polymer and the low cost for synthesizing it, the nickel IIP is cost-effective compared with other adsorbents for SPE of trace metals. The incorporation of a cartridge filled with the IIP materials in a six-way valve of a flow-injection manifold allows an automated preconcentration and determination of nickel and lead in seawater by ICP-OES. Preconcentration and measurement cycles of 5.0 and 7.0 min were obtained for nickel and lead, respectively, which implies the analysis of 12 (nickel determinations) or eight (lead determinations) samples per hour. These times are as short as those offered by conventional off-line preconcentration SPE procedures.

References

Merian E (ed) (1991) Metals and their compounds in the environment. VCH, New York

Bermejo-Barrera P, Moreda-Piñeiro J, Moreda-Piñeiro A, Bermejo-Barrera A (1998) Anal Chim Acta 368:281–289

European Council (1979) Off J Eur Community L 281

Nickson RA, Hill SJ, Worsfold PJ (1995) Anal Proc 32:387–395

Fritz JS (1999) Analytical solid phase extraction. Wiley, New York

Abbasse G, Ouddane B, Fischer JC (2002) J Anal At Spectrom 17:1354–1358

Skinner CD, Salin ED (2003) J Anal At Spectrom 18:495–500

Otero-Romaní J, Moreda-Piñeiro A, Bermejo-Barrera A, Bermejo-Barrera P (2005) Anal Chim Acta 536:213–218

Ersöz A, Say R, Denizli A (2004) Anal Chim Acta 502:91–97

Martin-Esteban A (2001) Fresenius J Anal Chem 370:795–802

Rao TP, Daniel S, Gladis JM (2004) Trends Anal Chem 23:28–35

Rao TP, Kala R, Daniel S (2006) Anal Chim Acta 578:105–116

Daniel S, Gladis JM, Rao TP (2003) Anal Chim Acta 488:173–182

Liu Y, Chang X, Yang D, Guo Y, Meng S (2005) Anal Chim Acta 538:85–91

Lu YK, Yan XP (2004) Anal Chem 76:453–457

Biju VM, Gladis JM, Rao TP (2003) Anal Chim Acta 478:43–51

Kala R, Biju VM, Rao TP (2005) Anal Chim Acta 549:51–58

Biju VM, Gladis JM, Rao TP (2003) Talanta 60:747–754

Kala R, Rao TP (2006) Sep Sci Technol 41:233–246

Daniel S, Babu PEJ, Rao TP (2005) Talanta 65:441–452

Gladis JM, Rao TP (2003) Anal Lett 36:2107–2121

Gladis JM, Rao TP (2004) Mikrochim Acta 146:251–258

Metilda P, Gladis JM, Rao TP (2004) Anal Chim Acta 512:63–73

Praveen RS, Daniel S, Rao TP (2005) Talanta 66:513–520

Otero-Romaní J, Moreda-Piñeiro A, Bermejo-Barrera P, Martin-Esteban A (2008) Anal Chim Acta 630:1–9

Zhang N, Hu B, Huang C (2007) Anal Chim Acta 597:12–18

Walas S, Tobiasz A, Gawin M, Trzewik B, Strojny M, Mrowiec H (2008) Talanta 76:96–101

Wulff G, Gross T, Schonfeld R, Schrader T, Kristen C (1998) In: Bartsch RA, Maeda M (eds) Molecular and ionic recognition with imprinted polymers. American Chemical Society, Washington

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

García-Otero, N., Teijeiro-Valiño, C., Otero-Romaní, J. et al. On-line ionic imprinted polymer selective solid-phase extraction of nickel and lead from seawater and their determination by inductively coupled plasma-optical emission spectrometry. Anal Bioanal Chem 395, 1107–1115 (2009). https://doi.org/10.1007/s00216-009-3044-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-009-3044-x