Abstract

Molecularly imprinted microspheres (MIMs) were synthesized by micro-suspension polymerization using matrine (MT) as template. The MIMs were employed for solid-phase extraction (SPE) and as chromatographic stationary phase for the determination of MT from the Chinese medicinal plant Sophora flavescens. The effects of the various eluents, their concentrations and volumes on the retention behavior were investigated. The selectivity and capacity of the imprinted microspheres against MT was also discussed. The results showed that the MIMs exhibited stronger specific affinity to MT than to oxymatrine (OMT). Methanol–water (3:7, v/v) was used for washing impurities from the MIMs-SPE cartridge loaded with the herb extracts, while methanol–glacial acetic acid (9:1, v/v) was used for eluting MT. The maximum load of MT and the recovery of MIMs cartridge towards MT were 38.7 μg g–1 and 71.4%, respectively. The method developed might be used to separate and extract effective constituents from Chinese medicinal plants on a large scale.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The root of Sophora flavescens is a widely used traditional Chinese herbal drug. The primary components of S. flavescens are matrine (MT) and oxymatrine (OMT), which possess strong biological activities. MT plays an important role in the treatment of antifebrile, ache, diuretic, tussis, antidote, tumor and arrhythmia [1, 2]. MT and OMT also act as abirritatives, increasing leucocyte and protecting liver function [3, 4]. Therefore it is of importance to develop efficient methods for the separation and determination of MT and OMT from Chinese herbs. There have been a few reports on the separation of these two compounds including pH-zone-refining counter-current chromatography (CCC) [5], high-performance liquid chromatography (HPLC) [6], and thin-layer chromatography (TLC) [7]. The separation capacity of classical HPLC is lower, limited by the column capacity and the stationary phase may be affected by losses. Although CCC has been used to separate and purify a large amount of active components from traditional Chinese medicinal herbs and other natural products [5, 8], too much harmful solvent has to be used with the method. TLC is an inexpensive method, but the operational processes are fussy and tedious. The methods for the determination of MT and OMT mainly include HPLC and capillary zone electrophoresis (CZE) [9, 10].

Molecularly imprinted polymers (MIPs) are crosslinked polymers with specific binding sites, which are tailor-made in situ by the copolymerization of the crosslinker and functional monomer in the presence of the template molecule [11, 12, 13]. After removal of the template from the polymers, the recognition sites, in terms of size, shape and functionality, are complementary to the template molecule [14, 15, 16]. MIPs possess several advantages including physical robustness, high strength, resistance to elevated temperature and pressure, and resistance to erosion by acids, bases, metal ions and organic solvents compared to enzymes [17, 18, 19]. MIPs have been used in biosensors [20, 21, 22], to mimic enzyme catalysis [23, 24], and as HPLC stationary phases [25, 26, 27, 28, 29, 30] and materials for solid-phase extraction (SPE) [31, 32, 33, 34, 35, 36]. In recent years, molecularly imprinted solid-phase extraction (MISPE) sorbents were extensively used to clean up the impurities in environmental and biological samples [34, 35] and for the enrichment of effective components from complicated media [36]. In the present study, the molecularly imprinted microspheres (MIMs) using MT as template molecule were synthesized by aqueous micro-suspension polymerization. The MIMs obtained were employed as SPE sorbent to separate MT from S. flavescens and were packed into a stainless steel column as chromatographic stationary phase to determine MT. The method developed may be used to separate and enrich other trace constituents from complicated media on a large scale.

Experimental

Chemicals and materials

MT and OMT were purchased from the National Institute for the Control of Pharmaceutical and Biological Products (Beijing, China). The chemical structures are shown in Fig. 1. The Chinese herb, S. flavescens (Kushen), was purchased from a Chinese herbal drug store in Guangxi province, China. Poly(vinyl alcohol) 500 (d.p. 400–600, saponification degree 96.0 mol%) was purchased from Wako Pure Chemical Industries (Osaka, Japan). Methacrylic acid (MAA) and ethylene glycol dimethacrylate (EGDMA) were purchased from Aldrich Chemical (Milwaukee WI, USA). 2,2′-Azobis(2-isobutyronitrile) (AIBN) was supplied by Special Chemical Reagent Factory of Nankai University (Tianjin, China). Methanol, dichloromethane, chloroform and acetonitrile were purchased from BDH Laboratory Supplies (Poole, UK). All solutions were prepared using high-purity water that had been purified by a Milli-Q plus system (Millipore, Molsheim, France).

Preparation of MIMs

Poly(vinyl alcohol) 500 (3.4 g) was dissolved in 120 mL of high-purity water while stirring at 90–95 °C and cooled to room temperature. Then the aqueous solution was transferred into a 250-mL three-neck flask. MT as template molecule (1 mmol) and MAA as functional monomer (6 mmol) were mixed in a glass flask. Chloroform (8 mL) was added as progen. The organic mixture was placed in a freezer and maintained at 0 °C for 30 min. Then 50 mmol EGDMA (cross-linker) and 150 mg AIBN (initiator) were added to this mixture and sonicated to dissolve. The total mixture was added to the water phase in the three-neck flask while stirring at 410 rpm under a gentle stream (at 0.8 L min-1) of nitrogen (99.99%). The temperature was then elevated to 60 °C for polymerization. The polymerization process was maintained for 24 h. The microspheres were washed with high-purity water, methanol and the mixture of methanol–glacial acetic acid (9:1, v/v), successively. Non-imprinted microspheres were prepared in the same way without the addition of the template molecule.

Extraction of crude matrine from S. flavescens Ait

Raw roots of S. flavescens Ait (5.0 g) were wetted with 10.0 mL of 2.0% ammonium hydroxide for 4 h [6]. Then the wetted roots were crushed by a high-speed disintegrator (Braun, Mexico). The crushed S. flavescens Ait was extracted three times with 10.0 mL of the mixture of chloroform and methanol (5:5, v/v), successively. The combined extracts were evaporated to dryness under reduced pressure with a Rotavapor R-114 (Buchi, Switzerland). The residue obtained was dissolved in 10.0 mL methanol. The solution was filtered by PTF membrane (0.45 μm; Millipore, Bedford, MA, USA). The filtrate obtained was directly used for SPE or analyzed with molecularly imprinted microspheres-high performance liquid chromatography (MIMs-HPLC).

Solid-phase extraction

An appropriate amount of dry MIMs (i.d. 20–40 μm, 1.0 g) was suspended in the mixture of methanol and 2-propanol (5:5, v/v), sonicated in a water-bath for 10 min and packed into a 10-mL empty polypropylene SPE cartridge with a porous flat frit at the bottom to support the MIMs, and an outlet stopcock. The top of the cartridge was plugged with glass wool. The SPE cartridge was connected to a vacuum manifold. The loaded SPE cartridge was washed with 30 mL of methanol–glacial acetic acid (9:1, v/v) and equilibrated with 20 mL of methanol, successively. The flow-rate was controlled at 0.2 mL min–1. The cartridge was dried under vacuum after each wash. A blank cartridge was subjected to the same procedure.

In the following experiments, 5.0 mL standard solution or the above extracts were passed through the cartridges (MIMs and blank polymers) at a flow rate of 0.2 mL min–1. To evaluate the effect of different eluents on the elution, the loaded cartridge was washed with 5.0 mL of methanol–water (3:7, v/v), methanol–water (5:5, v/v), methanol, methanol–dichloromethane (8:2, v/v) and methanol–glacial acetic acid (9:1, v/v), successively. The effluent from each elution was collected and directly analyzed with MIMs-HPLC.

MIMs-HPLC method

The microspheres (8–20 μm) obtained by means of a gravitational settling sieve were packed into a stainless steel column (250×4.6 mm i.d.) by the slurry method using a mixture of methanol and 2-propanol (5:5, v/v) as slurry medium. The HPLC system consisted of two Waters 510 pumps, a Waters temperature-control module and a Waters 996 photodiode array detector. Column oven temperature was controlled at 50 °C. Detection wavelength was 215 nm. The column was rinsed on-line with a mixture of methanol and glacial acetic acid (9:1, v/v) until a stable baseline was obtained. The flow-rate was maintained at 1.0 mL min–1. The volume of injection was 20 μL. The capacity factor (k′) was calculated according to the standard chromatographic procedure as k′=(t–t0)/t0, where t and t0 were retention time and void time, respectively. The void time (t0) was determined by the elution time of a solvent peak observed. The imprinting factor (α) was calculated as α=k′ imp /k′ non-imp, where k′ imp and k′ non-imp were the capacity factors of template molecules on the imprinted column and non-imprinted column, respectively. To serve as a control an additional column was packed with non-imprinted microspheres and conditioned using an identical procedure.

Results and discussion

Selection of washing solvents and eluents for MISPE

First of all, the terms " washing solvent" and "eluent" in MISPE must be differentiated and defined. The term " washing solvent" refers to a solvent to wash the impurities, but not the target substrates, from the MISPE cartridge. In contrast, "eluent" means a solvent specially used to elute the target substrates. According to the previous study the selection of an appropriate eluent was critical for the retention behavior of the MIMs column in a chromatographic model [29]. It is also very important to select an appropriate washing solvent and eluent in the MISPE process. To select an appropriate washing solvent for the MISPE process, several washing solvents, including methanol–water (3:7, v/v, MW37), methanol–water (5:5, v/v, MW55), methanol (M), methanol–dichloromethane (8:2, v/v, MDCM), dichloromethane (DCM) and methanol–glacial acetic acid (9:1, v/v, MGAA), were employed to wash the MISPE cartridge successively. The washing-out solutions were directly separated by MIPs-HPLC. As can be seen from Fig. 2, there were no chromatographic peaks of MT and OMT in the washing-out solution when MW37 was used as washing solvent in the first step (Fig. 2c). A very small amount of MT and OMT was present in the washing-out solution when MW55 was used as washing solvent in the second step (Fig. 2d). In the third step, MT and OMT in the cartridge could be washed out when M or MDCM was employed as washing solvent (Figs. 2e and 2f). In the fourth step, the washed cartridge (as mentioned above) was washed successively with DCM and MGAA. Fig. 2g shows that there was no corresponding signal for MT and OMT in the washing-out solution washed with DCM while Fig. 2h shows a very small amount of MT was present in the washing-out solution washed with MGAA. The results indicated that a small amount of residual MT was retained on the cartridge. Therefore, in the present study, MW37 was used as the washing solvent while methanol–glacial acetic acid (9:1, v/v) was employed as the eluent in order to elute MT completely.

Chromatograms of eluates from MIMs cartridges by MIMs-HPLC (cartridge condition: packed weight 1.0 g dry MIMs; loaded extract volume 5.0 mL; eluent volume 10.0 mL; flow rate 0.2 mL min–1. ( a) OMT standard solution, ( b) MT standard solution, ( c) eluate washed with methanol–water (3:7, v/v), ( d) eluate washed with methanol–water (5:5, v/v), ( e) eluate washed with methanol, ( f) eluate washed with methanol–dichloromethane (8:2, v/v), ( g) eluate washed with dichloromethane, ( h) eluate washed with methanol–glacial acetic acid (9:1, v/v); HPLC conditions: please refer to the experimental section)

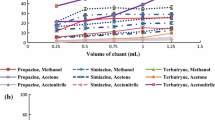

Influence of methanol concentration and volume on MISPE

According to the previous report, there were about 10 alkaloids in S. flavescens Ait [8]. Among them, the most important and active components were MT and OMT. The results showed that the proportions of impurities were very large in the chloroform extracts from S. flavescens Ait. As discussed above, MW37 was employed as washing solvent in the present study because a high concentration of methanol in the washing solvent might lead to the wash-out of MT and OMT. On the contrary, a low concentration of methanol was unable to clean up the impurities. To determine an optimal methanol concentration, methanol solutions of various concentrations were investigated. As can be seen from Fig. 3, at a low methanol concentration (<30%), no leakage of MT was observed by chromatographic analysis while the leakage increased at higher methanol concentrations (>30%). In addition, the amount of eluent was investigated. The impurities could not be cleaned up completely if the amount of eluent was too little. On the contrary, MT leakage was observed if a large amount of eluent was employed. Fig. 4 (open circle) showed that leakage from imprinted cartridge appeared when the volume of eluent was greater than 25 mL. Therefore, 25 mL of 30% methanol solution was used to wash the impurities in the cartridge packed with 1.0 g dry MIMs.

Selectivity of MIMs cartridge and column

To evaluate the effect of molecular imprinting, both imprinted cartridge (IC) and non-imprinted cartridge (NIC) were investigated in the washing process. Fig. 4 shows that no visible difference was observed between the eluates from the IC and from the NIC by chromatographic analysis at the beginning of washing. This indicated both IC and NIC possessed nonspecific binding. As washing progressed, the differences between IC and NIC became evident. As shown in Fig. 4, the leakage of NIC was observed when the volume of eluent was larger than 10 mL (open triangle) whereas the leakage of IC was found only when the volume of eluent was larger than 25 mL (open circle). This indicated that the capability of IC binding MT was stronger than that of NIC. To evaluate the imprinting effect further OMT was also investigated. Fig. 5 shows that the capacity factor of OMT on the imprinted column (6.18) was close to that on the blank column (4.66) at an α value of 1.33. In contrast, the capacity factors of the template MT on imprinted column and blank column were apparently different. The k′ values were 12.15 and 7.04, respectively, and the α value was 1.73. This indicated the specific affinity of the imprinted column for MT.

Leakage load, maximum load and recovery of the cartridges

The leakage load is the load (weight) of the target molecule on the cartridge when leakage is observed. It is calculated from the LL=cLVL/WMIP, where LL is the leakage load (μg g–1), cL is the concentration of the tested substrate (μg mL–1), VL is the leakage volume (mL) of the tested substrate, and WMIP (g) is the weight of dry MIPs packed in the cartridge. According to this formula, the LL values of MT on the NIC and IC were 15.0 μg g–1 and 30.0 μg g–1, respectively. The maximum load (Lmax) was calculated from Lmax=csVs/WMIP, where cs is the concentration of the tested substrate in the elution solution, Vs is the volume of the eluent when saturation adsorption on the cartridge is achieved. According to this definition, the maximum loads (Lmax) of MT on the NIC and IC were 22.4 μg g–1 and 38.7 μg g–1, respectively. It indicated that the Lmax value was always larger than the corresponding LL value. In another word, leakage always occurred before saturation adsorption was achieved.

In addition, the recoveries of MT and OMT on IC and NIC were investigated. MT and OMT methanol solution (1.0 μg mL–1, 5 mL) was added to the extraction sample (5 mL) from S. flavescens. The mixture was passed through the cartridge at a flow rate of 0.2 mL min–1. The loaded MT and OMT on the cartridge were eluted with 5.0 mL of a mixture of methanol–glacial acetic acid (9:1, v/v) and directly analyzed by MIMs-HPLC. The results are shown in Table 1. The recovery of MT on the imprinted cartridge was 71.4% while the recovery of OMT was 57.3%.

The actual sample test

S. flavescens extract (5 mL) was loaded onto the imprinted cartridge at a flow rate of 0.2 mL min–1. The loaded cartridge was then washed and eluted with methanol–water (3:7, v/v) and methanol–glacial acetic acid (9:1, v/v), respectively. The chromatograms of the extracts and eluate are shown in Fig. 6. As can be seen from Fig. 6a, many impurities existed in the initial extract of S. flavescens. However, when the extract was loaded onto the cartridge, which was washed with 25 mL of methanol–water (3:7, v/v), an evident difference was observed. Most impurities were removed from the cartridge and more pure MT and OMT were obtained (Fig. 6b). Due to great similarity in chemical structure between MT and OMT (Fig. 1), however, it was very difficult to further separate MT from OMT. This part of research is still under way in our laboratory.

Comparison of the chromatograms of crude extract and eluate. (Cartridge condition: packed weight, 1.0 g dry MIMs; loaded sample volume, 5.0 mL; flow rate, 0.2 mL min–1. ( a) crude extract from Sophora flavescens, ( b) eluate on the MIMs cartridge, washing with methanol–water (3:7, v/v) and eluting with methanol–glacial acetic acid (9:1, v/v))

Conclusion

In the present study, molecularly imprinted microspheres were synthesized by micro-suspension polymerization and simultaneously used for solid-phase extraction (SPE) and high performance liquid chromatography (HPLC). Both the MISPE cartridge and the MIMs-HPLC column exhibited specific affinity to the template molecule matrine (MT). The MISPE approach might be more stable, repeatable, manageable and anticorrosive than the traditional C18 reversed-phase column. Furthermore, special MISPE cartridges/ columns could be tailor-made and synthesized for special application. Although there are numerous constituents present in Chinese medicinal plants, only a few are proved biologically active. This justifies the need to employ molecular imprinting technology for the extraction of these biologically active compounds. Research is continuing in our laboratory to determine specific affinity of more molecularly imprinted microspheres to the biologically active compounds in Chinese herbs and optimize the elution conditions.

References

Xin HB, Liu SF (1987) Acta Pharmacol Sinica 8:501

Hu ZL, Zhang JP, Yu XB, Lin W, Qian DH, Wan MB (1996) Acta Pharmacol Sinica 17:351

Chen X, Wang GJ, Cai X, Yu HY, Hu YP (2001) World J Gastroenterol 7:49

Liu J, Liu YP, Klaassen CD (1994) J Ethnopharmacol 42:183

Yang FQ, Quan J, Zhang TY, Ito Y (1998) J Chromatogr A 822:316

Ma CH, Cao TH (2000) J Parametr Anal 20:408

Li XY, Yang SQ (1994) J Chin Med 19:671

Li HB, Lai JP, Jiang Y, Chen F (2002) J Chromatogr A 943:235

Song JZ, Xu HX, Tian SJ, But PPH (1999) J Chromatogr A 857:303

Su XD, Wang XK, Li Y, Li JS, Yan YN, Chen YT, Liu HW (2001) J Microcolumn Sep 13:221

Masque N, Marce RM, Borrull F (2001) Trends Anal Chem 20:477

Takeuchi T, Matsui J (1996) Acta Polym 47:471

Mosbach K, Ramstrom O (1996) Bio-Technology 14:163

Quaglia M, Chenon K, Hall AJ, De Lorenzi E, Sellergren B (2001) J Am Chem Soc 123:2146

Deore B, Chen ZD, Nagaoka T (1999) Anal Sci 15:27

Mullett WM, Lai EPC (1998) Anal Chem 70:3636

Piletsky SA, Piletska EV, Chen BN, Karim K, Weston D, Barrett G, Lowe P, Turner APF (2000) Anal Chem 72:4381

Wulff G, Gross T, Schonfeld R (1997) Angew Chem Int Ed Eng 36:1962

Piletsky SA, Piletska EV, Bossi A, Karim K, Lowe P, Turner APF (2001) Biosens Bioelectron 16:701

Kriz D, Ramstrom O, Svensson A, Mosbach K (1995) Anal Chem 67:2142

Piletsky SA, Piletskaya EV, Panasyuk TL, El'skaya AV, Levi R, Karube I, Wulff G (1998) Macromolecules 31:2137

Kroger S, Turner APF, Mosbach K, Haupt K (1999) Anal Chem 71:3698

Rich JO, Dordick JS (1997) J Am Chem Soc 119:3245

Ye L, Ramstrom O, Mansson MO, Mosbach K (1998) J Mol Recognit 11:75

Hosoya K, Yoshizako K, Shirasu Y, Kimata K, Araki T, Tanaka N, Haginaka J (1996) J Chromatogr A 728:139

Haginaka J, Takehira H, Hosoya K, Tanaka N (1999) J Chromatogr A 849:331

Yu C, Mosbach K (2000) J Chromatogr A 888:63

Lai JP, Lu XY, Lu CY, Ju HF, He XW (2001) Anal Chim Acta 442:105

Lai JP, Cao XF, Wang XL, He XW (2002) Anal Bioanal Chem 372:391

Lai JP, Cao XF, He XW, Li YY (2002) Acta Chim Sinica 60:322

Rashid BA, Briggs RJ, Hay JN, Stevenson D (1997) Anal Commun 34:303

Bjamason B, Chimuka L, Ramstrom O (1999) Anal Chem 71:2152

Mullett WM, Dirie MF, Lai EPC, Guo HS, He XW (2000) Anal Chim Acta 414:123

Baggiani C, Giovannoli C, Anfossi L, Tozzi C (2001) J Chromatogr A 938:35

Crescenzi C, Bayoudh S, Cormack PAG, Klein T, Ensing K (2001) Anal Chem 73:2171

Xie JC, Zhu LL, Luo HP, Zhou L, Li CX, Xu XJ (2001) J Chromatogr A 934:1

Acknowledgements

This research was supported by the CRCG (The University of Hong Kong Committee on Research and Conference Grants), RGC (the Hong Kong Research Grants Council) and the National Natural Science Foundation of China (No.29775014, No. 20175009).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lai, JP., He, XW., Jiang, Y. et al. Preparative separation and determination of matrine from the Chinese medicinal plant Sophora flavescens Ait by molecularly imprinted solid-phase extraction. Anal Bioanal Chem 375, 264–269 (2003). https://doi.org/10.1007/s00216-002-1675-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-002-1675-2