Abstract

Tibetan heritage building has attracted much attention recently for its historical and cultural value. Many of these buildings have different degree of damage after hundreds of years of service. A multivariate cumulative damage (CD) model and prediction model of strength degradation of timber in the ancient Tibetan building are proposed in this study. Experimental tests on old and new timber are conducted and a correction factor considering the effects of different influencing factors on the timber properties is introduced to modify the strength prediction model. Two failure criteria based on the ultimate strength capacity and allowable deformation are proposed to predict the service life of timber component. Finally, reliability-based analysis is conducted for the residual strength and service life prediction of timber component with consideration of the statistical uncertainty of different influencing factors. The analysed results show that the rate of residual strength degradation increases with time with consideration of different influencing factors. An ancient timber component with a longer history associates with a lower reliability.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Ancient Tibetan buildings in China can mainly be classified into four categories including the palace building, temple building, residential building and manor building (Ngawang et al. 2007; Chen 2007) as shown in Fig. 1. They have high historical, religious, cultural and artistic values and have always been the focus of world attention. However, many of them have shown different degrees of damage and the physical properties of timber have been reduced (Yang et al. 2012; Zhao et al. 2007) after hundreds of years of service. There is a need to know the degradation law of timber for evaluating the present state of the ancient structures and to provide scientifically protective measures to extend their service life.

Service life is defined as the period of time after erection during which a building or its parts meet or exceed the performance requirements. The estimation of residual service life can give a suggestion of the time of repair or replacement of components in the structures. The service life depends on many factors including the current status of the structures, the age, as well as the expected future use. Damage models (Gerhards and Link 1987; Barrett and Foschi 1978; Nielsen and Kousholt 1980; Van der Put 1986) are important tools to model the service life of timber structures. Some researchers (Wilcox 1978; Winandy and Morrell 1993) investigated the effects of fungal decay on material strength of timber experimentally. The effects of biological decay was modeled with a change of the effective cross-section, and damage models were derived to study the service life of a pile foundation (Van de Kuilen 2007; Van de Kuilen and Gard 2012) and cracked beams (Van de Kuilen and Gard 2012, 2013) for a number of loading scenarios. Models on the attack by fungi decay and termites were developed for durability design of timber construction based on data obtained from tests on small clear specimens of timber. They were also used for service life modeling of timber structures in Australia (Leicester and Foliente 1999; Leicester et al. 2002). Viitanen et al. (2010) presented an empirical model on wood decay development for evaluating the durability and service life of wooden products and developing the preliminary European wood decay risk level map. These works provide significant references and theoretical basis for service life prediction. Results obtained from these theories and models, however, have not been verified with experimental results.

Creep and aging of wood occur by a combination of long-term physical, chemical and biological actions that lead to the degradation of mechanical properties of timber. Some experimental studies (Ni and Li 1994; Chen 2003; Xu and Qiu 2011; Hirashima et al. 2004a, b, 2005) on the mechanical properties of old and new timber are summarized in Table 1. In this paper, old timber denotes samples coming from the structural component of an old building, while new timber denotes samples coming from present day timber of the same tree species. Table 1 shows that most of the mechanical properties of old timber decrease with time compared with those from new timber. However, extent of degradation in timber is different in a variety of ancient buildings, because the tree species and the surrounding environments are not the same. For example, Populus has a faster degradation rate in long-grain tensile strength, flexural strength and elastic modulus than the other species. The samples of the same species can also be different in their mechanical properties when taken from structures in different surrounding environment and service age, as can be told from samples S-YOH and S-BH, or B-JOB and B-JOT in Table 1.

Since data from old timber samples is scarce, it is usual to introduce a reduction factor to estimate the mechanical indices of old timber from related standards and specifications (CABP 1992, 2003, 2005). However, this reduction factor is determined empirically from experience on timber structures and knowledge of material properties of wood. The calculated values from this method may not be exact. Therefore, a reasonable mathematical model on the time-varying behavior of mechanical properties of timber is required for the condition evaluation of ancient timber buildings.

Studies on modeling the degradation law of mechanical properties of timber have been carried out in the last few decades. Wood (1951) presented an empirical curve relating the bending strength of timber and the duration of load (DOL). The empirical curve was determined from test results on clear wood specimens, and was used for design of the structures. Based on the analysis of a large number of long-term test data, three CD models (Gerhards 1979; Barrett and Foschi 1978; Nielsen and Kousholt 1980) were proposed to describe the time-related effects on timber strength. Foschi and Yao (1986) assessed and compared the three CD models for describing the trends of timber bending properties with explanation of their applicability and limitations. Gerhards and Link (1987) calibrated the CD model using test data obtained from two different types of load histories and developed a prediction model on the time-to-failure of timber. Subsequently, the effects of change of external environment on the timber performance were studied. Fridley et al. (1992a, b) investigated the effects of temperature and moisture on the elasticity modulus and rupture modulus when under different constant loads. They found that cyclic environmental conditions will cause a marked decrease in the mechanical properties of timber, and a damage parameter was introduced to account for this effect. Hanhijiirvi (2000a) reviewed researches on the mechano-sorptive effects of moisture condition and moisture changes on the long-term load-carrying performance of structural timber. A computational method (Hanhijiirvi 2000b) was presented and implemented as a non-linear finite element program combining the moisture transport and structural analysis to predict the long-term deformation and time-to-failure of timber beams. Other researchers (Leicester and Foliente 1999; Leicester and; Wang et al. 2008) established a model for assessing the risk of termite attack on timberworks based on statistics and analysis of field test data. Their investigations revealed that the damage degree induced by termite attack is greatly influenced by the moisture and temperature history.

Reliability analysis has also been conducted on timber material properties recently. Rosowsky and Bulleit (2002) described a simplified approach for cumulative damage analysis using order statistics. The reliability analyses including DOL behavior can be performed more efficiently using an order statistics approach than the complex stochastic cumulative damage analyses. Sørensen et al. (2005) studied the DOL effects based on simulation with three damage accumulation models under variable load according to the Danish structural codes. The duration factor \({k_{\bmod }}\) for the three types of load was estimated using the reliability theory. Kohler et al. (2007) presented a probabilistic model for the timber material properties to evaluate the structural conditions of timber structure. Later, Kohler and Svensson (2011) calibrated the parameters of the three damage models using test data and probabilistic model with consideration of uncertainties associated with the damage model and limited sample size.

However, the above damage models on material properties of timber were developed based only on test data from new timber and they have not been calibrated against the old timber. Most of them are the CD models with single influencing factor, while the timber components in ancient buildings are influenced by a variety of different factors, such as long-term loading, decay, termite attack and cracking, as well as their mutual coupling effects.

This paper studies the strength degradation law and service life prediction of timber in ancient Tibetan building. A presentation of the damage models of timber properties is given followed by a description of the degradation mechanism and failure mechanism of timber. A multivariate CD model of timber component in ancient Tibetan structure is proposed based on Gerhards CD model. In this model, the cumulative damage effects on mechanical properties of timber caused by the duration of load, decay and shrinkage crack are considered. According to the experimental mechanical properties (Yang et al. 2012) of the old and new Tibetan Populus cathayana, a correction factor considering the different influencing factors is introduced to modify the strength prediction model. Two failure criteria based on ultimate strength capacity and the allowable deformation are presented to predict the service life of timber component. Finally, reliability analysis for the residual strength and service life prediction of timber component in ancient Tibetan building is also conducted considering the statistical uncertainty of factors influencing the timber performance.

2 Ancient Tibetan timber structure system

The different components of a typical ancient Tibetan building are shown in Fig. 2a. The building features “flat roof” at the top. The floor system has closely spaced timber beams. The general compositions of the floor and roof are as follows: the ends of rafters are supported by beams or stone walls; Zhangun, made of logs or timber planks, on the rafters serves as the bearing layer; pebbles or macadam are on the Zhangun; then there is a layer of compacted and flattened clay lying on top of the pebbles; Agatu soil serves as the surface layer of the floor.

A timber beam-column connection in the building is composed of a column, a Ludou, a Dianmu, a Gongmu and two or more layers of beams. The beams are connected by tenon joint, and other components are connected by dowels. Detail of composition of a timber beam-column connection is shown in Fig. 2b.

3 Time-dependent damage models of timber properties

Wood is a natural material and its material properties are affected by many factors. The duration of load, material decay, termite attack and shrinkage crack are considered to be the most important factors influencing the material properties of timber.

3.1 Duration of Load

Some initial small cracks naturally exist in wood. Stress concentration occurs in the crack zone of timber component, and some wooden fibers will break under external load. This will result in the reduction of strength and an increment of deformation of the timber component, which occurs continuously when it is under load and the unrecoverable plastic deformation accumulates with time. It is the cumulative damage effect of timber due to the duration of load.

The damage accumulation model presented by Gerhards (1979) is written as

where \(A\) and \(B\) are constants; \(\sigma\) is the largest stress in the loading time history of the test section; \({f_0}\) is the initial short-term strength of component; \(\alpha\) is defined as the degree of damage ranging from 0.0 to 1.0, i.e. \(\alpha =0.0\) stands for no damage and \(\alpha =1.0\) stands for total damage or failure of the component.

The solution of the differential equation in Eq. (1) is given as

where \(t\) is the service life of component under stress \(\sigma\) associated with the failure criterion of creep damage.

Assuming \(f\) is the residual strength of timber under constant load, the residual strength ratio \({\varphi _M}(t)\) can be given as (Sørensen et al. 2005)

which is the prediction model on the strength degradation of timber with time. The residual strength of timber from Eq. (3) is noted to be a function of the short-term strength, the stress ratio, i.e., \({\sigma \mathord{\left/ {\vphantom {\sigma {{f_0}}}} \right. \kern-\nulldelimiterspace} {{f_0}}}\), and the duration of sustained load.

3.2 Decay

The phenomenon of rotting and disintegration of wood caused by growth of fungi is called timber decay. It is accompanied by degradation of the mechanical properties of timber. The bearing capacity of member section with decay will decrease greatly or will even be completely lost, with a reduction in the effective cross-sectional area of the timber component.

According to the analysis of collected data from the maintenance and rehabilitation of ancient Chinese buildings, Li (2005) gave an empirical time-dependent model on the thickness of the decay layer of timber as follows:

where \({\delta _0}\) is the existing thickness of decay layer calibrated statistically by multi-point field samples; \({T_0}\) is the present age of the old timber; \(t\) is the expected future service time of the old timber, and \(a\) is the index parameter related to the rate of change of \(\delta\). When \({T_0}<400\), \(a=1.0\); \(400<{T_0}<800\), \(a=1.5\) and Eq. (4) is not applicable when \({T_0}>800\).

3.3 Termite attack

The effective area of a component cross-section decreases when exposed to termite attack leading to a reduction of the ultimate carrying capacity and durability of the timber component.

The effect of termite attack can be divided into two stages: (a) initial stage spanning from the time when the timber structure is constructed to the time when termite moves into the building and breaks through the corrosion protection measure; (b) developmental stage spanning from the time when termite begins to attack the timber to the time when the timber component fails.

A damage factor on the compressive bearing capacity of timber caused by termite attack can be defined as

where \({A_0}\) is the initial cross-sectional area of timber component; \(A{(t)_{ter}}\) is the cross-sectional area of the void created by termite attack, and \(D(t)\) ranges from 0.0 to 1.0. There is no termite attack damage when \(D(t)=0.0\) and it represents failure of the timber component when \(D(t)=1.0\).

3.4 Shrinkage crack

The change of temperature and humidity causes a change in the moisture content (MC), w, resulting in swelling or shrinkage of the timber. The difference of drying shrinkage rate in the radial and chordwise directions induces longitudinal crack along the timber.

Wang (2008) derived an empirical equation from experimental data to describe the relationship between the crack depth and MC in timber component as shown in Fig. 3, as

where \({\xi _h}\) is the relative crack depth, i.e. the ratio of crack depth to the sectional height of timber component, and \({C_1}\) and \({C_2}\) are constants.

The general law of MC changes with time in natural air-dry process was given by Fan (1986) according to engineering practice as shown in Fig. 4. It is expected that the MC decreases faster in the initial stage of air-dry, and goes into a relative balance state after a period of time. The relationship can be described as

where \({C_{MC}}\) denotes the MC in relative balance stage, and \({C_3}\) and \(k\) are constants.

Substituting Eq. (7) into Eq. (6), a time-dependent model of relative crack depth can be established as

where \(E={C_1}+{C_2}{C_{MC}}\) and \(F={C_2}{C_3}{C_{MC}}\).

Yang et al. (2007) have found from experimental data that the cracking in timber has less effect on the compressive bearing capacity but it has larger effect on the flexural bearing capacity. As a matter of fact, the longitudinal crack of timber reduces the cross-sectional moment of inertia, and this influence is expressed as (Wang 2008)

where \({I_0}\) is the initial cross-sectional moment of inertia; \(I\) is the cross-sectional moment of inertia of the cracked component, and \({\xi _b}\) is the relative crack width. It is also assumed that

where \(\mu\) is the ratio of crack width to crack depth. The range of \(\mu\) is determined as (0.15, 0.25) according to the statistical analysis of a large number of field measurements in ancient Chinese timber structures (Wang 2008).

Putting Eqs. (8) and (10) into Eq. (9), the time-dependent model of the cross-sectional moment of inertia can be written as

4 Property degradation mechanism and failure mechanism

4.1 Property degradation mechanism of timber

Wood is an anisotropic material of complex biological polymer consisting of various compositions such as cellulose, hemicellulose and lignin, etc. Environmental force and bio-erosion are considered to be the two principle actions leading to a strength reduction of timber with time.

Decay and pulverization of timber occur when attacked by fungi with decomposition of the chemical composition such as hemicellulose, cellulose and lignin (Winandy and Morrell 1993), and wood will lose the original structure (texture) as well as the mechanical strength. The effective area of cross-section decreases leading to the reduction of ultimate carrying capacity and durability of the timber component. Uneven stress distribution in cross-section of timber component is caused by recurrent changes of temperature and humidity, hygroscopic expansion, and creeping effect due to external load. This will result in a weakened cross-section.

With the existence of the natural initial crack in wood, some timber fibers will fracture when the timber component is under external load. The extent of fiber fracture increases continuously under the sustained load. This unrecoverable plastic deformation increases with time resulting in a strength reduction and creep of timber in the component. The microstructure of timber in flexural creep state has been studied by Dai and Liang (1987), and they found that the tracheids were bent and wrinkles of cell wall in fibers appeared in the compression zone; relative slippage between fibers occurred and fibers were torn locally in the tension zone. The fiber structures lost their stability during the loading process with these micro changes, and the initial elastic state changes into the viscoelastic state. The mechanical properties such as the strength and the elasticity modulus, exhibit a reduction at the macro level as a consequence.

4.2 Failure mechanism of single timber component

The schematic diagram of failure mechanism of a single timber component due to different factors discussed above is shown in Fig. 5. Fungi and termite attack the timber and cause decay and damage when in appropriate environment. Swelling or shrinkage of timber occurs with changes of moisture and temperature. The difference of dry shrinkage rate in the radial and chordwise directions induces longitudinal cracking accelerating the decay of timber. These factors result in the reduction of effective cross-sectional area. Timber fibers fracture under long-term load leading to the accumulation of damage and creeping of timber. With a combination of the above factors and other factors such as wind and crowd load, the strength of timber decreases with increasing deformation. Failure of timber component occurs when either the ultimate strength capacity or allowable deformation is reached. A time-dependent model on the degradation law of timber performance with time is presented below.

5 Multivariate CD model

It is noted that Eqs. (1–3) are applicable when the structural component is under constant stress. When the factors of decay, termite attack and shrinkage crack are taken into account, the effective cross-sectional area reduces and the stress would increase with time such that these formulas are not applicable. However, the authors found that this rate of reduction of cross-sectional area is small from investigations on ancient Tibetan timber buildings. Therefore, the stress ratio of timber component under load is assumed constant in a year, and a cumulative damage index for timber in ancient structures with the consideration of multiple factors above can be approximated as follows:

where \(\tau (t)={{\sigma (t)} \mathord{\left/ {\vphantom {{\sigma (t)} {{f_0}}}} \right. \kern-\nulldelimiterspace} {{f_0}}}\) is the stress ratio of timber component in the ith year.

Field investigation results also indicate that the long-term load, decay and shrinkage crack are the three principle factors influencing the mechanical properties of timber in ancient Tibetan buildings. The timber components inside the ancient Tibetan buildings are rarely attacked by termites except for the rafters in underground chambers. Therefore, the effects of termite attack can be ignored in the following discussion.

The above single-factor time-dependent models are assumed independent, and the multivariate CD models for columns and beams in the ancient Tibetan timber structures are presented below.

5.1 CD model of column

The sectional shapes of column in Tibetan heritage buildings are usually in the form of squares, circles, corrugated and polygons (such as octagon, dodecagon, hexadecagon and icosagon etc.). The square and circular columns, with their relative simple geometry, are considered here, and the CD model of column under the influence of long-term load and decay is studied.

The strength of decayed timber was lower than that of the non-decayed timber, and the degree of strength degradation was generally determined by means of inspection (Van de Kuilen 2007; Van de Kuilen and Gard 2012). It may be assumed here that the decayed part of timber component has no strength at all with reduction of the effective cross-section with time. The effective cross-sectional area with decay changing with time may be written as follows according to Eq. (4),

where \(d\) is the diameter of circular section or side length of square section, and

is the rate of change of the decay layer thickness of timber with time, with

which is the rate of change of the effective cross-sectional area with time. The direct working stress in column is given as

where \(N\) is the working axial load on column. The stress ratio of column then becomes

Putting Eqs. (15) and (17) into Eq. (12), the time-dependent model of the cumulative damage index of column under the influence of the long-term load and decay are obtained as

where i denotes the number of years.

5.2 CD model of beam

According to Eqs. (4) and (9), the effective sectional moment of inertia under the influence of decay and shrinkage crack is

where \(b\) and \(h\) are the width and height of cross-section, respectively, and

is the rate of change of the effective sectional moment of inertia. The working flexural stress of beam is:

where \(M\) is the working bending moment. The stress ratio of beam then becomes

Putting Eqs. (20) and (22) into Eq. (12), the time-dependent model of the cumulative damage index of beam under the influence of the long-term load, decay and shrinkage crack are obtained as

It is noted that crack and different kinds of fungal decay in timber would reduce the effective cross-section of structural component, while the duration of load leads to a reduction of material strength \(f(t)\).

6 Time-dependent model of strength degradation of Tibetan Populus cathayana

Previous studies (Gerhards 1979; Nielsen and Kousholt 1980; Winandy and Morrell 1993) on strength degradation models were mostly based on test data obtained from artificially defective timber. These models have not been checked with experimental data from old timber, and they cannot be used directly in the analysis of ancient timber structures.

6.1 Material test of old and new timber

Tibetan Populus cathayana (TPC) is a tree species commonly found in ancient Tibetan structures (Zhao et al. 2007). Though material tests on the TPC has been conducted before (Yang et al. 2012), more material tests are conducted for this study, and the test details are described below.

The old and the new TPC, with air-dried densities of 0.418 and 0.519 g/cm3 at 12% MC, respectively, were tested. The old Populus samples are from a column and beam removed in the maintenance of an ancient Tibetan building with 350 years history. The old TPC segments have been stored for about 15 years in a room prior to the test. The temperature range in a year is 2–16 °C, and the range of relative humidity is 15–55%. All timber segments for the test are confirmed to be in air-dry condition. The equilibrium MC condition was approximately at 12%.

The internal defects of the timber segments are shown in Fig. 6. Cracking was very serious in the old Populus and there are knots both inside and on the surface of the segments. In addition, some segments had serious decay on the surface with total loss of material strength. No decay was found in the new Populus segment and the surface cracking was slight. It should be noted that the test specimens cut from the timber segments had no defects such as knots, cracks, decay and fibre deviation (CRIWI 1992), and so they could be regarded as “small and clear”. The number of samples for tests on the along-grain compression strength and flexural strength are listed in Table 2. Each test was carried out according to requirements in GB 1927–1943-91 (CRIWI 1992).

The statistic of results on the along-grain compression strength and flexural strength of old and new TPC is shown in Table 3. It is found that:

-

1.

The along-grain compression and flexural strength of the old TPC are much smaller compared with those of the new TPC. This indicates that the mechanical properties of TPC have a serious degradation after 350 years.

-

2.

The coefficients of variation of the along-grain compression and flexural strength of the old TPC are much higher than those of the new TPC. This indicates that in the 350 years of service life, the degree of degradation of strength in different parts of structural timber in different environment is different, and this uncertainty leads to the large variation in test results.

Since the test results have a large variation, the mathematical mean value of these properties cannot be used directly to estimate the load-carrying capacity of a structural component. The design strength of timber is determined based on the probability limit state design method (CABP 2005):

with

where \({f_k}\) is the design strength of timber; \({f_{sk}}\) is the characteristic strength of test samples with 5% confidence limit; \(\mu\) and \(\sigma\) are respectively the population mean and the standard deviation; \({K_M}\), \({K_A}\), \({K_P}\) are the uncertainty factors on the material property, geometric parameter and the calculating method respectively, and \({\mu _{{K_M}}}\), \({\mu _{{K_A}}}\), \({\mu _{{K_P}}}\) are respectively the mean values of the \({K_M}\), \({K_A}\), \({K_P}\) uncertainties. The values of \({\mu _{{K_M}}}\), \({\mu _{{K_A}}}\), \({\mu _{{K_P}}}\) are obtained from Code (CABP 2003).

The design strength of the old and new TPC were determined as shown in Table 4. The residual strength ratio (ratio of design strength of old timber to that of new timber) of the along-grain compression and flexural strength of old TPC are 55.65 and 26.17%, respectively.

6.2 Comparison of test results with the prediction model

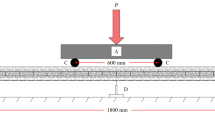

The damage prediction model proposed in Sect. 5 is compared with the test results obtained from Sect. 6.1. The stress ratio of component in ancient Tibetan building is relatively small because of its structural configuration. This has been confirmed by simulation (Yang et al. 2012) and field measurements with a typical beam-column joint in an ancient Tibetan building. The stress levels range from 20 to 40% in beams and columns.

The initial stress level is taken as 0.3 in this study. The test components in Sect. 6.1 have dimensions of: \(b=250\;{\text{mm}}\), \(h=400\;{\text{mm}}\), \(d=400\;{\text{mm}}\), and \({\delta _0}=4\;{\text{mm}}.\) Parameters for the damage model, \(A=13.9526\), \(B=25.0498\), \(E=1.82\), \(F= - 4.134\) and \(k{=} - {2}{.74} \times {1}{{0}^{ - {5}}}\) adopted from Wang (2008) were used in the prediction model. When substituted into Eqs. (3), (11), (18) and (23), the residual strength ratio of the TPC with 350 years of age were obtained as shown in Table 5. There are some differences between results from test and the prediction model with the predicted values higher than the test results. This may be explained by the following:

-

1.

Only the effects of long-term load, decay and shrinkage crack are considered in the prediction model. Other factors such as short-term wind and human loading, have not been included.

-

2.

The effects from different factors considered are assumed to be independent and their mutual coupling effects have not been considered in the prediction model.

-

3.

There is estimation error in the initial stress level and other parameters in the prediction model due to lack of test data, and they need to be calibrated with relevant experiments.

A modified time-dependent model is therefore proposed below to take account of these errors.

6.3 Modified prediction model on the strength degradation of timber

From comparison of the test results and predicted values calculated by existing models in Eq. (3), this model is found not applicable for direct use of the strength prediction of timber in ancient structures. For considering the mutual coupling effects of long-term load, decay, shrinkage crack and other factors on the cumulative damage model of the timber strength, a correction factor \(C(t)\) is proposed to modify the prediction model as

where \({\varphi _T}(t)\) and \({\varphi _M}(t)\) are the residual strength ratio from test and the initial prediction model respectively; \({C_0}\) is the correction factor of the strength in reference year \({t_0}\), and \(\beta (t,{t_0})\) denotes the variation of the correction factor with time.

According to the physical significance of the correction factor, the initial conditions of Eq. (26) can be determined as follows:

-

When \(t=0\), \(C(0)=1\), i.e. \(\beta (t{=}0,{t_0}){=}{\raise0.7ex\hbox{${1}$} \!\mathord{\left/ {\vphantom {{1} {{C_0}}}}\right.\kern-\nulldelimiterspace}\!\lower0.7ex\hbox{${{C_0}}$}}\).

-

When \(t={t_0}\), \(C({t_0})={C_0}\), i.e. \(\beta (t{=}{t_0},{t_0}){=}1\).

The correction factor has the following properties:

-

1.

It is valid for \(t \geqslant 0\).

-

2.

The first derivative of \(\beta\) is negative, i.e. \(\beta {'_t} \leqslant 0\), denoting the mutual coupling effect of various factors on the cumulative damage effects on the strength increases with time.

-

3.

The second derivative of \(\beta\) is negative, i.e. \(\beta '{'_t} \leqslant 0,\) denoting the rate of change of the mutual coupling effects of various factors on the cumulative damage effects on the strength increases with time.

-

4.

\(\beta '(t=0,{t_0})=0\) may be assumed when \(t=0\), which denotes that the influence of external factors on the timber strength is small in the early stage of the building and the speed of strength degradation is small and may be null.

Assuming the growth rate of the speed of change of the cumulative damage effects on material strength is stable, i.e. \(\beta '{'_t}=\text{constant}\), the form of the correction factor can be determined as follows with the above properties

Substituting the initial conditions into Eq. (27), \({L_1}=\frac{{{C_0} - 1}}{{{C_0}{t_0}^{2}}}\), \({L_2}=0\) and \({L_3}=\frac{1}{{{C_0}}}\), then

Combining Eqs. (3), (26) and (28), the modified time-dependent model of strength degradation of TPC can be obtained as

This is an attempt to improve the existing strength degradation model for analysis of ancient timber structures. Equation (29) includes the evolution of residual strength of timber based on the combination of an initial prediction model and experimental results of the old and new timber. It is noted that the mathematical form of the correction factor in Eq. (28) is based on a group of experimental results of the old and new TPC. Some assumptions can be neglected when multiple sets of experimental data of the old timber with different service age are obtained.

According to the multivariate CD models in Eqs. (18) and (23) and the modified time-dependent strength model in Eq. (29), the damage variable \(\alpha (t)\) and the residual strength ratio \({\varphi _m}(t)\) of column and beam varying with time are shown in Figs. 7 and 8, respectively. The rates of damage accumulation and strength degradation are small initially. The effective strength of timber decreases while the damage accumulation increases with time. The rate of increment of damage variable and the rate of effective strength degradation also increase with time. Computational results show that the effective strength drops sharply at \(t=345\) year. Therefore, \(t=345\) year should be taken as the time for maintenance or replacement of critical timber components to ensure the safety of the whole structure. With the above formulations on different models, the calculation of accumulative damage of timber component influenced by various factors can then be conducted easily with a computer rather than by solving complicated differential equations.

7 Failure criterion of timber component

The strength of timber decreases while deformation increases with time as noted in the failure process. Failure of timber component occurs when the ultimate capacity of strength or deformation is reached.

The instant of failure in Gerhard’s model (Gerhards and Link 1987) under constant load was taken as the time coinciding with the occurrence of sudden large deformation. When the failure of component occurs due to large deformation, the failure criterion can be expressed as

The researches by Yang et al. (2012) and Wang (2008) based on the initial prediction model, i.e. Equation (3), showed that the residual strength was not less than the working stress of component under load when failure of timber due to large deformation occurs. However, the rate of strength degradation calculated by the modified prediction model in Eq. (29) is higher than that from the initial prediction model since the proposed correction factor \(C(t)\) decreases with time. Based on the modified time-dependent model of strength degradation proposed in this paper, the failure criterion can be expressed as follows when the failure of component occurs due to large reduction of residual strength.

The time of failure of timber component is determined as min \([{t_{def}},{t_{st}}]\) when \({t_{def}}\) and \({t_{st}}\) are respectively calculated from Eqs. (30) and (31). Based on the ultimate strength capacity and allowable deformation, two failure criteria for a timber component were presented in this paper. This is different from the single failure criterion found in existing literatures.

8 Reliability-based analysis with the time-dependent model

A previous study (Yang et al. 2012) has shown that the size and strength of timber in ancient Tibetan building would follow the normal distribution. The stress ratio, depth of decay and depth of crack are taken as random with a normal distribution, and the mean and coefficient of variation of strength of the old and new TPC are shown in Table 3. The statistical characteristics of other parameters are assumed as shown Table 6. They are used for this study.

Based on the multivariate CD models and the modified strength degradation model proposed above, an example of reliability analysis on the residual strength and service life of timber component in ancient Tibetan building is conducted using Monte Carlo method.

The simulation procedure is as follows:

-

1.

Step 1: One thousand sets of pseudo-random values of material strength, stress ratio, decay depth and sectional size of component are generated according to the statistical characteristics of model parameters given in Tables 3 and 6.

-

2.

Step 2: The ith (i = 1–1000) group of model parameters generated in Step 1 are put into Eqs. (18) and (23) to calculate the damage variable \(\alpha\) of column and beam in the 1st to 1000th years. The corresponding service life \({t_{def}}\) is determined at failure of component due to large deformation when \(\alpha =1.0\).

-

3.

Step 3: Repeat Step 2 with the (i + 1)th group of model parameters for all sets of data (shown in Fig. 9).

-

4.

Step 4: The damage variable of the 350th years in the ith (i = 1–1000) group is put into the initial prediction model, i.e. Eq. (3), to calculate the residual strength of timber. The modified residual strength ratio \({\varphi _m}(t)\) of column and beam in the 1st to 1000th years can be obtained based on the modified time-dependent model of strength degradation in Eq. (29). Failure of component due to large reduction of residual strength occurs and the corresponding service life \({t_{st}}\) is determined when the residual strength decreases to the working stress of component.

-

5.

Step 5: Repeat Step 4 with the (i + 1)th group of damage variable for all sets of data (shown in Fig. 10).

-

6.

Step 6: Comparing the ith \({t_{def}}\) and \({t_{st}}\), the time of failure of timber component is determined as min \([{t_{def}},{t_{st}}]\).

-

7.

Step 7: Repeat Step 6 with the (i + 1)th group of \({t_{def}}\) and \({t_{st}}\) for all sets of data.

-

8.

Step 8: The mean, standard deviation and coefficient of variation of service life of column and beam are calculated (shown in Table 7) and the corresponding frequency distribution histograms are drawn (shown in Fig. 11). The curves on the reliability probability and reliability index for different service life are drawn (shown in Figs. 12, 13), and the service life corresponding to the reliability index of 1.0, 1.0306, 1.5, 2.0, 2.5 and 3.0 are calculated and shown in Table 8.

The simulations were carried out using MATLAB. The simulated results on \(\alpha\) for column and beam are shown in Fig. 9. Figure 10 shows the degradation law of residual strength ratio of column and beam with time. The rate of reduction of effective strength of timber is different when the components are in different service environment. It can be found from the simulated results that \({t_{def}}<{t_{st}}\), for most of the cases. This indicates that the failure of timber components is associated with large deformation instead of having the residual strength lowered below the working stress of component under load. Therefore, the service life of ancient timber structure could be extended if some effective measures were taken to prevent further deformation in the timber component.

The statistics of service life obtained from the simulated results are shown in Table 7. The mean service life of column and beam are 365 years and 356 years, respectively. It matches with observations in Sect. 6.1 that the old timber components need to be replaced in maintenance after 350 years. The coefficients of variation are 21.19 and 22.19%, respectively. This implies very large uncertainty of service life because of the large uncertainty in the influencing factors. Figure 11 is the frequency distribution histogram of service life of column and beam. The service life basically follows a normal distribution as shown.

Let R and S denote the structural resistance and load effect, respectively and they are taken as random with a normal distribution. The structural performance function is \(Z=g(R,S)=R - S\), and the limit state equation is \(g=R - S<0\). The structural failure probability is \({P_f}=1{-}{P_r}=P[R - S<0]=\Phi ( - \frac{{{\mu _Z}}}{{{\sigma _Z}}})=\Phi ( - \beta )\) where \({P_f}\), \({P_r}\) and \(\beta\) are the failure probability, reliability probability and reliability index, respectively. Figure 12 gives the reliability probability for different service life and Fig. 13 gives the curve of the reliability index. It can be found that a longer history of an ancient timber component is associated with a lower reliability. Table 8 gives the service life of column and beam corresponding to the reliability index of 1.0, 1.0306, 1.5, 2.0, 2.5 and 3.0, respectively. The analysis suggests that the expected service life of column and beam is 249 years when the reliability index is set as 1.0306 with a probability of failure of 0.15.

9 Conclusion

The mechanical property of timber and its degradation law are prerequisite for the condition assessment of ancient Tibetan timber structure. Based on Gerhards CD model, the multivariate CD models of column and beam were proposed, and the corresponding prediction model on the strength degradation of timber is obtained. The effects of duration of load, decay and shrinkage crack on the mechanical properties of timber are considered in the proposed multivariate CD models. A set of experimental results of the mechanical properties of old and new TPC is obtained, and a correction factor with full consideration of all influencing factors and their mutual coupling effect is proposed. A modified time-dependent model on the strength degradation for timber is obtained. Two failure criteria for a timber component are presented to predict the service life of timber component based on the ultimate strength capacity and allowable deformation. Finally, a specific example of reliability analysis on the residual strength and service life prediction of timber component is presented considering the statistical uncertainty of influencing factors. It provides a reference for the condition assessment of an ancient Tibetan building. Major observations of this study are as follows:

-

1.

The analysis of the strength degradation law of TPC with the modified time-dependent model indicates that the rate of residual strength degradation increases with time under the influence of a variety of different influencing factors.

-

2.

A long history of an ancient timber component associates with a lower reliability in service life when the statistical uncertainty of influencing factors is considered.

An acceptable method of condition assessment is of great need for the protection of ancient heritage building, and the mechanical property of material is the basis of such assessment. The factors that influence the performance of timber are plenty such that the research on degradation law of mechanical properties of timber needs to be based on the analysis of a large number of experimental data. Multiple sets of long-term experiments considering combinations of different factors can be carried out for further refinement of the proposed model.

References

Barrett JD, Foschi RO (1978) Duration of load and probability of failure in wood. Part 1: modelling creep rupture. Can J of Civ Eng 5(4):505–514

CABP (1992) Technical code for maintenance and strengthening of ancient timber buildings. GB 50165-92, China Architecture & Building Press, Beijing

CABP (2003) Code for design of timber structures. GB 50005–2003, China Architecture & Building Press, Beijing

CABP (2005) Handbook of timber structure design. China Architecture & Building Press, Beijing

Chen GY (2003) Study on material properties and nondestructive test of old timber of ancient architecture. Tradit Chin Archit Garden 8:49–52 (in Chinese)

Chen YD (2007) Chinese Tibetan architecture. China Architecture & Building Press in Chinese, Beijing

CRIWI (1992) Testing methods for physical and mechanical properties of wood. GB 1927-1943-91. Research Institute of Wood Industry, Chinese Academy of Forestry, Beijing

Dai CY, Liang BH (1987) Viscoelastic behavior of wood in long-term load. J Northeast For Univ 15(5):53–59 (Chinese)

Fan CM (1986) Timber structure engineering. China Architecture & Building Press, Beijing (in Chinese)

Foschi RO, Yao ZC (1986) Another look at three duration of load models. In: Proceedings 19th CIB/W18 Meeting, Florence, Italy

Fridley K, Tang RC, Soltis LA, Yoo CH (1992a) Hygrothermal effects on mechanical properties of lumber. J Struct Eng 118(2):567–581

Fridley K, Tang RC, Soltis LA (1992b) Hygrothermal effects on load-duration behaviour of structural lumber. J Struct Eng 118(4):1023–1038

Gerhards CC (1979) Time-related effects on wood strength: a linear cumulative damage theory. Wood Sci 11(3):139–144

Gerhards CC, Link CL (1987) A cumulative damage model to predict load duration characteristics of lumber. Wood Fiber Sci 19(2):147–164

Hanhijiirvi A (2000a) Advances in the knowledge of the influence of moisture changes on the long-term mechanical performance of timber structures. Mater Struct 33(1):43–49

Hanhijiirvi A (2000b) Computational method for predicting the long-term performance of timber beams in variable climates. Mater Struct 33(2):127–134

Hirashima Y, Sugihara M, Sasaki Y, Ando K, Yamasaki M (2004a) Strength properties of ages wood i: tensile strength properties of aged wood of kevaki and akamatsu. J Japan Wood Res Soc 50(5):301–309

Hirashima Y, Sugihara M, Sasaki Y, Ando K, Yamasaki M (2004b) Strength properties of aged wood II: compressive strength properties, shearing strength and hardness of aged kevaki and akamatsu woods. J Japan Wood Res Soc 50(6):368–375

Hirashima Y, Sugihara M, Sasaki Y, Ando K, Yamasaki M (2005) Strength properties of aged wood III: Static and impact bending strength properties of aged wood of kevaki and akamatsu. J Japan Wood Res Soc 51(3):146–152

Kohler J, Svensson S (2011) Probabilistic representation of duration of load effects in timber structures. Eng Struct 33:462–467

Kohler J, Sorensen JD, Faber MH (2007) Probabilistic modeling of timber structures. Struct Saf 29:255–267

Leicester RH, Foliente GC (1999) Models for timber decay and termite attack. Durab Build Mater Compon 1:756–765

Leicester RH, Foliente GC, Cole IS, Wang CH, Mackenzie C (2002) Prediction models for engineered durability of timber in Australia. 9th International Conference on Durability of Materials and Components

Leicester RH, Wang CH, Cookson LJ (2008) A reliability model for assessing the risk of termite attack on housing in Australia. Reliab Eng Syst Saf 93:468–475

Li TY (2005) The main structural damages and damage mechanism analysis on Yingxian Wooden Tower. Ph.D. thesis, Taiyuan University of Technology, Taiyuan, China

Ngawang R, Chi D, Pu C (2007) Tibetan architecture overview. Sichuan Fine Arts Publishing House, Chengdu (in Chinese)

Ni SZ, Li YZ (1994) Tree species investigation and material properties analysis of timber in ancient architecture. Sichuan Build Sci 20:11–14 (in Chinese)

Nielsen LF, Kousholt K (1980) Stress-strength-lifetime relationship for wood. Wood Sci 12(3):162–164

Rosowsky DV, Bulleit WM (2002) Load duration effects in wood members and connections: order statistics and critical loads. Struct Saf 24:347–362

Sørensen JD, Staffan S, Stang BD (2005) Reliability-based calibration of load duration factors for timber structures. Struct Saf 27(2):153–169

Van de Kuilen JWG (2007) Service life modeling of timber structures. Mater Struct 40:151–161

Van de Kuilen JWG, Gard WF (2012) Residual service life estimation using damage accumulation models. WCTE, Auckland

Van de Kuilen JWG, Gard WF (2013) Damage assessment and residual service life estimation of cracked timber beams. Adv Mater Res 778:402–409

Van der Put TACM (1986) A model of deformation and damage processes based on the reaction processes of bond exchange. In: Proceedings 19th CIB/W18 Meeting, Florence, Italy

Viitanen H, Toratti T, Makkonen L, Peuhkuri R, Ojanen T, Ruokolainen L, Räisänen J (2010) Towards modeling of decay risk of wooden materials. Eur J Wood Prod 68:303–313

Wang XL (2008) Research on evaluation method of reliability-based residual life of historic timber structure. Ph.D. thesis, Wuhan University of Technology, Wuhan, China

Wilcox WW (1978) Review of literature on the effects of early stages of decay on wood strength. Wood Fibre 9(4): 252–257

Winandy JE, Morrell JJ (1993) Relationship between incipient decay, strength, and chemical composition of Douglas-fir heartwood. Wood Fiber Sci 25(3):278–288

Wood LW (1951) Relation of strength of wood to duration of load. Report no. 1916. USDA Forest Service, Madison Forest Products Laboratory

Xu MG, Qiu HX (2011) Experimental study on properties of aged wood of ancient architecture. Earthq Resist Eng Retrofit 4:53–55 (in Chinese)

Yang XJ, Sun YF, Wu M, Zhang T (2007) Influence of the crack on compressive and bending strength of a wood beam. Wood Process Mach 1:11–13 (in Chinese)

Yang N, Li P, Law SS, Yang QS (2012) Experimental research on mechanical properties of timber in ancient Tibetan building. J Mater Civ Eng 24:635–643

Zhao JF, Duan XF, Feng DJ, Nie YJ (2007) Identification of wood species in Tibet ancient buildings. J Northwest For Univ 22:138–143

Acknowledgements

The authors gratefully acknowledge Professor S.S Law for his advice on this paper. The research presented in this paper was financially supported by the National Natural Science Foundation of China for Excellent Young Scholars (NSFC-51422801), National Natural Science Foundation of China (Key Program) (NSFC-51338001) and Beijing Natural Science Foundation of China (Key Program) (8151003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qin, S., Yang, N. Strength degradation and service life prediction of timber in ancient Tibetan building. Eur. J. Wood Prod. 76, 731–747 (2018). https://doi.org/10.1007/s00107-017-1211-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-017-1211-x