Abstract

Cross-laminated timber (CLT) has become a notable building material due to its structural efficiency, reliability and sustainability. In this study, the bending performance of three-layered CLT constructed from fibre-managed Eucalyptus nitens (E. nitens) was investigated under short-term and long-term loadings. Linear-elastic four-point bending testing was used to determine the maximum serviceability loading capacity before they reached the suggested deflection limits. A pilot study was conducted to investigate the creep behaviour of E. nitens CLT through long-term bending tests in a controlled environmental room. The study suggested that E. nitens CLT has higher serviceability loading capacity and lower creep ratio compared to CLT made from strength-class C24 spruce. The investigations of various configurations of E. nitens CLT panels based on structural grades implemented in top, cross, and bottom layers have revealed different short-term and long-term bending performances. The grade of transverse layers has been found to be the most important factor in improving the bending creep performance of E. nitens CLT. Two modelling equations were employed to perform curve fitting on the experimental creep ratio with time. The conventional power-law modelling tends to underestimate the longer-term creep ratio when compared to a recently developed nonlinear regression modelling equation that takes environmental conditions into account. The mean estimated creep ratio after 50 years was 1.77 for E. nitens CLT, and 1.89 for the C24 spruce CLT. The present study is a pilot investigation to increase the understanding of performance of the newly developed CLT made from fibre-managed plantations E. nitens, with particular emphasis on its creep behaviour. The results of this study provide valuable contributions for future research in this field, and ongoing commercial production of E. nitens CLT.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Cross-laminated timber (CLT) is a creative engineered wood product (EWP) that consists of no less than three layers of timber boards, glued with structural adhesives, and the grain direction of each layer is at right angles to the grain direction of previous layer, as described in standard ANSI/APA PRG 320 (2018). CLT products are normally used as walls and floors because of the strong in-plane and out-of-plane load carrying capacity (Jelec et al. 2018). Historically, most of the CLT products were constructed from softwood species such as spruce and pine (Brandner 2013; Espinoza and Buehlmann 2018). However, there has been an increasing interest in exploring the potential for making CLT with hardwood species, driven by the motivation to find value-added applications for underutilised hardwood species (Espinoza and Buehlmann 2018), such as large-leaf beech (Essoua and Blanchet 2017), yellow-poplar (Thomas and Buehlmann 2017) and hybrid poplar and chestnut (Callegari et al. 2010). Plantation E. nitens is the only commercial example of a hardwood CLT in Australia.

E. nitens, (shining gum), is mainly grown in Tasmania and forms the majority of plantation hardwood species grown in that state according to the ABARES research report (Legg et al. 2021). The plantations are primarily managed in unthinned and unpruned conditions to maximise the production of fibre (Derikvand et al. 2017), so-called fibre-manged planations. In previous literature (Nolan et al. 2005), the timber boards sawn from these plantation logs exhibited a significant number of strength-reducing characteristics (SRCs) such as knots, which make them difficult to be utilised in most structural applications, particularly when they are under high service loads (Derikvand et al. 2017). In addition, according to Derikvand et al. (2018a), fibre-managed E. nitens has been demonstrated to be non-compliant with the required specifications based on visual stress grading (VSG) in accordance with Australian Standard AS 2082 (2007). Therefore, there has been an increasing need for viable methods to reliably assess their structural grade, particularly regarding their values of modulus of elasticity (MOE). The four-point static bending test based on standard AS/NZS 4063.1 (2010) is an accurate way to grade timber boards. This test has traditionally been destructive; however, it can be non-destructive when determining the values of MOE only, which is based on the linear relationship between applied loads and displacement (Ettelaei et al. 2022a). In addition, acoustic wave velocity grading (Ettelaei et al. 2022a), longitudinal and transverse vibration testing (Opazo-Vega et al. 2021) have been demonstrated to be reliable and appropriate methods to determine the MOE of Eucalyptus nitens. Furthermore, Ettelaei et al. (2022a) demonstrated the accuracy of machine stress grading to measure the MOE of E. nitens sawn boards. Despite not meeting the criteria of the VSG method, it has been proved that plantation E. nitens has considerable potential for building applications through the grading methods above. These successful studies laid the foundation for further research, particularly in CLT manufacturing.

Current literature on fibre-managed E. nitens CLT focused on the mechanical properties including the bending (Ettelaei et al. 2022b) and rolling shear properties (Ettelaei et al. 2022c). Plantation E. nitens CLT has shown reliable properties of strength and stiffness, which have proved the feasibility of this alternative species in CLT production and use. The serviceability performance of E. nitens CLT including their bending and vibration behaviours has been investigated in a previous study (Liang et al. 2023). They have demonstrated that E. nitens CLT have better short-term serviceability performance than strength-class C24 Spruce CLT, based on EN 338 (2016). However, it is necessary to investigate their long-term behaviour under their service life as this knowledge still remains unknown. Wood is a viscoelastic material that deforms over time when subject to permanent loads; this phenomenon is called creep behaviour (Morlier 1994). To deal with the long-term creep behaviour in timber structural design, two main approaches are used in standards (Granello and Palermo 2019), that include the strength reduction factors to prevent the circumstance of the tertiary creep phase, and the creep factors to multiply the elastic deformation for predicting the long-term deformation (EN 1995-1-1 2004; AS 1720.1 2010). However, these factors are primarily supported by other types of structural timbers such as solid timber, glued-laminated timber (GLT) and laminated veneer lumber (LVL), so the values may not be representative of CLT.

Due to the orthogonal configuration, the creep behaviour of CLT will be different from other types of structural timbers. CLT has more time-dependent deformations under loads compared to GLT, according to the previous research which compared the creep behaviour of CLT and GLT under bending (Jöbstl and Schickhofer 2007). Investigating the creep properties is essential for ensuring the long-term serviceability of CLT constructed from new timber species, such as tropical hardwood species (merbau, teak, Japanese larch and tulip) (Park et al. 2020; Takanashi et al. 2021). The studies on creep properties of softwood CLT also contribute valuable knowledge in this area. For example, a previous study (Pirvu 2014) performed the bending creep and creep recovery tests on Spruce-Pine-Fir (SPF) and Hem-Fir CLT panels and compared their results with the criteria outlined in ASTM D6815-09 (2015). The previous study found that the creep rates were sensitive to the temperature and relative humidity (RH), and the stiffness of CLT samples after creep tests showed relatively small decrease. The knowledge of the previous research has also been generated in US and Canadian CLT handbooks (Karacabeyli and Douglas 2013; Karacabeyli and Gagnon 2019). In addition, Colling (2014) performed a creep test on CLT in outside environments for a period of 15 years. They found that higher creep factors should be used in design with CLT due to the rolling shear deformation. Derikvand et al. (2019b) performed the first creep test on fibre-managed E. nitens nail-laminated timber (NLT). However, the results of this study may not be representative of CLT panels made from the same species since the loading direction was based on edgewise bending for NLT.

The loading prototypes for creep tests usually focus on concentrated and uniformly distributed loading. Previously, concentrated loading, especially four-point bending, was a popular method (Park et al. 2020; Jöbstl and Schickhofer 2007; Takanashi et al. 2021; Pirvu 2014; Colling 2014) to determine the creep performance on timbers. These concentrated loads can create higher stress concentration and more significant deformation, so the changes of deformation over time could be detected more easily. However, the concentrated loading method may not represent real-world long-term loading prototypes. However, uniformly distributed loading (UDL) has recently become the preferred method over concentrated loading to test creep of timber, especially for testing of full-scale specimens. Various materials have been used to provide UDL in creep test, such as boxes filled with water (Suárez-Riestra et al. 2022), concrete blocks (Musselman et al. 2018; Derikvand et al. 2019b), concrete kentledges (Nie and Valipour 2022), and sandbags (Riccadonna et al. 2020).

In this study, the short-term and long-term bending performance of CLT constructed from fibre-managed E. nitens will be determined. The objectives of this study include:

-

Determining the serviceability loading capacity of fibre-managed E. nitens CLT when complying with the span limit requirements using non-destructively linear-elastic four-point bending tests.

-

Determining the bending creep properties of fibre-managed E. nitens CLT under controlled environmental conditions.

-

Determining the influence of structural grade of each layer on the serviceability loading capacity and bending creep properties of fibre-managed E. nitens CLT.

-

Comparing the experimental results of fibre-managed E. nitens CLT with the reference spruce CLT sample.

-

Estimating the creep ratio of CLT panels over a longer period of time using two modelling equations, and then comparing the values with standards and previous published resources.

2 Materials and methods

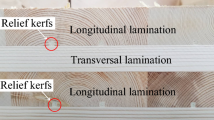

2.1 Properties of CLT specimens

The fibre-managed plantation E. nitens sawn boards were supplied by CUSP Building Solutions, Wynyard, Tasmania, Australia. The age of these fibre-managed plantation resources were 15 to 24 years old. The recovered timber boards from the resource exhibited a number of SRCs such as knots and surface checking. The boards were sawn, kiln dried, and machine dressed in accordance with standard commercial techniques. The depth and width of the finished boards were 33 mm and 100 mm, respectively. The average values of density and moisture content of the E. nitens timber boards used in CLT production were 517.5 kg/m3 and 9.7% respectively. The grading range of the plantation E. nitens timber boards were from 8.3 GPa to 13.1 GPa (Table 1). The structural grades of sawn boards were important variables in this research. The combination of grades in panel layup on the short-term and long-term bending behaviour of the E. nitens CLT would be investigated. Three configurations of E. nitens CLT panels according to different levels of MOE values were designed, and each configuration has four replicates. In addition, two homogeneous CLT panels constructed from strength-class C24 spruce (EN 338 2016) with average 440.2 kg/m3 of density and 14.8% of moisture content were included in this study. The spruce CLT samples were used as a reference to compare with the experimental results obtained from E. nitens CLT panels. Finger joints were included in the spruce sawn boards. Since the E. nitens sawn boards did not include finger joints, this study did not consider the difference between finger-jointed and non-finger-jointed. However, it is worthy to investigate this aspect in future research. The CLT panels were manufactured at CUSP Building Solutions, Tasmania, Australia. Before gluing, the boards underwent surface planing to ensure stronger bonding, resulting in a final thickness of 33 mm. The CLT panels were bonded with one-component polyurethan adhesive (LOCTITE HB S309) and pressed under vacuum pressure. These press and adhesive are employed in the industry for manufacturing CLT panels on a commercial scale. All the CLT panels were three-layered and measured 300 × 100 × 2000 mm3. Then, the elastic bending properties of the CLT panels were tested under non-destructive four-point bending and summarised in Table 2.

2.2 Non-destructive short-term bending tests

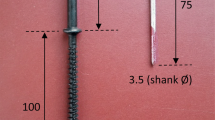

The experimental setup for linear-elastic four-point bending tests is shown in Fig. 1. Calibre STFE 10 machine was used to provide loads on CLT samples at a loading velocity of 5 mm/min. The loading process was stopped immediately when the deflection of samples reached 6 mm. The distance between two pinned supports and two loading heads is equal to 18 and 6 times the thickness of CLT samples, respectively, in accordance with Australian/New Zealand Standard (AS/NZS 4063.1 2010).

The first aim of this bending test was to determine the maximum load capacity of the CLT samples before the suggested deflection limit is reached. According to the suggested serviceability limit state criteria in AS/NZS 1170.0 (2002), the mid-span deflection of flooring under loads should be less than span/300 (6 mm in this case).

The theoretical results of deflection based on four-point bending can be determined by Eq. 1:

where wmax is mid-span deflection under loads, which is equal to 6 mm; \(\:\text{P}\) is the imposed load in N; L is the span length of the panels (mm), a is the distance between two loading heads, which is equal to 6 times of thickness (mm), and EI is the bending stiffness of the panels (N.mm2), where E is the young’s modulus of the panels (MPa), and \(\:\text{I}\) is the moment of inertia (mm4).

Hence, the allowable imposed load (P) can be determined by extrapolating Eq. 1:

To transfer the allowable imposed load to uniformly distributed load, the following equations were used:

where q is the imposed loads in kN/m, P is the experimental imposed load in kN, and L is the span length of the panels in meter (1.8 m in this case).

Then, the serviceability load capacity of CLT panels can be calculated by the following equation (Derikvand et al. 2019a):

where SLC is the amount of serviceability load (kN.m− 1/kN) that a unit weight of each panel can carry, q is experimental applied load corresponding to deflection up to 6 mm and M is the mass of the CLT panel (kN).

The Shear Analogy method (SAM) was used to determine the theoretical bending stiffness of CLT panels using Eq. 6. This method was firstly presented by Kreuzinger (1999). The values of bending stiffness can be calculated using the following equation:

where Ei represents the MOE of the ith layer (MPa), bi denotes the width of the ith layer (mm), hi indicates the depth of the ith layer, and zi represents the distance from the centroid of each layer to the neutral axis (mm). It should be noted that the values of Ei for transverse layers are estimated as 1/30 of the MOE in the parallel grain direction.

Then, the same bending testing setup would be employed to determine the apparent MOE values of CLT panels after the completion of creep tests. The aim of this test was to draw a comparison between the MOE values before and after the completion of the creep tests. The MOE values of CLT can be determined by the following equation:

where \(\:b\) is the width of the sample (mm), \(\:d\) is the thickness of the sample (mm), and \(\:\varDelta\:F/\varDelta\:e\) is the elastic slope of the load-strain curve.

After the short-term bending tests, the 14 CLT panels were subsequently divided into two groups. The first group conducted the creep test in the controlled environment, as outlined in Sect. 2.3. Meanwhile, the second group underwent the creep test in a completely uncontrolled environment, with further details to be presented in a future publication.

2.3 Long-term bending tests

Seven CLT samples were conditioned in the controlled room for one week prior to loading. The creep tests were conducted in a controlled test building established at the University of Tasmania (Fig. 2a). The test cell with a concrete floor has been proven to have the most consistent interior temperatures (Dewsbury et al. 2007). An air-conditioner was installed to control the temperature of the building by heating or cooling. A humidifier and a dehumidifier were used to add or remove water vapour to the building. A data acquisition system (DataTaker DT500) was used to control the heating, cooling, wetting and drying operations through the measurements of temperature and RH sensors. The sensors recorded the data of RH and temperature of the environment at 10-minute intervals.

In this study, the creep tests were conducted in a constant environment at 20 °C and 65% RH. A small CLT sample measuring 100 × 300 × 300 mm3 was manufactured using the same fibre-managed E. nitens feedstocks (Fig. 2b). This sample was placed in the controlled room to monitor changes in moisture content by weighting it periodically every time the creep data was collected. The initial weight of the small CLT sample was 4426.92 g before being placed into the test cell, and the initial moisture content of the feedstock before manufacturing the sample was 10.7% The moisture content of the small sample would be measured after the creep test for validating the initial moisture content of the small CLT sample.

In this investigation, the self-weight of the CLT panels was assessed at approximately 0.15 kN/m. Concrete pavers with an individual weight of around 0.1 kN were used as the imposed load. Each CLT panel was loaded by 30 concrete pavers. Therefore, the total uniform loads of 6.0 kN/m2 considering self-weight of the panels were used, including 0.5 kN/m2 of permanent load and 5.5 kN/m2 of imposed live load. The applied load in this study was approximately 25% of the maximum serviceability loading capacity that was determined by short-term bending tests. Each paver was wrapped in plastic to avoid weight changes from moisture absorption during testing. Each CLT panel was supported by two steel pipes positioned at a distance of 1800 mm. Dial gauges with 0.01 mm of resolution were used to measure the mid-span deflection of each CLT panel. The long-term bending deflections in the midspan of the panels were measured daily for 215 days (from 6th July 2022 to 6th February 2023) for E. nitens CLT and 181 days (from 9th August 2022 to 6th February 2023) for spruce CLT.

The creep ratio would be calculated by the following equation:

where \(\:\text{f}\left(\text{t}\right)\) is the creep ratio, wtis the mid-span deflection at time (mm), and w0is the initial mid-span deflection (mm).

The remaining creep was determined after unloading the panel for a period of 30 days, which can be determined by the following equation:

Where \(\:{{\text{w}}_{\text{t}}}^{{\prime\:}}\) is the remaining creep deflection over time (mm), \(\:{{\text{w}}_{0}}^{{\prime\:}}\) is the initial deflection after unloading.

The typical power law model (Eq. 10) and the non-linear regression model (Eq. 11) were applied to fit the experimental data to predict the long-term creep of CLT with different configurations and species. Equation 10 considered the creep data as pure time-dependent, while Eq. 11 considered the effects of changing environmental conditions.

where \(\:d\left(\text{t}\right)\) is the modelling creep ratio, t is time (days), a, b, ɑ1, ɑ2, ɑ3, and ɑ4are model constants. The moisture content for spruce was not monitored during the creep test, so the parameter of MC in this equation would be replaced by RH of the environment.

The constant model values of a, b, ɑ1, ɑ2, ɑ3, and ɑ4 are determined by fitting Eq. 10 and Eq. 11 to the experimental data using the Non-linear Least Squares Methods in MATLAB version R2021b. The power law modelling has been used in many studies on predicting long-term creep behaviour (Takanashi et al. 2021; Song et al. 2021), and has been proved to be a reliable mathematical modelling method for estimating relative creep values for longer periods based on the experimental results, while the non-linear regression model (Eq. 11) has been successfully employed in previous research on creep behaviour of E. nitens NLT (Derikvand et al. 2019b).

In addition, the relative creep values (\(\:{k}_{def}\)) can also be determined by Eq. 12

where f(t) is the creep ratio.

The experimental setup was similar to Derikvand et al. (2019b), who have performed the creep tests under varied environmental conditions on NLT constructed from Eucalyptus species. This study focused on the creep tests on CLT panels at controlled environmental conditions. However, the creep testing under completely uncontrolled environment is currently being conducted as part of a parallel separate study. When completed, the results will be compared to the findings of this paper.

3 Results and discussions

3.1 Serviceability loading capacity

Figure 3 shows the linear elastic load-deflection curves for all CLT panels. The load-deflection curves were determined by four-point bending testing, and the values of load and deflection were measured up to 6 mm of deflection as described in Sect. 2.2. Figure 4 exhibits the overall results of serviceability loading capacity for all CLT panels.

According to the average values of SLC up to 6 mm of span limit deflection in Table 3, the overall SLC of E. nitens CLT was 17.3% higher than the reference spruce CLT panels. Regarding the configurations of E. nitens CLT, HLH CLT exhibited higher serviceability load capacity than MLM and MMM CLT by 18.9% and 17.9%, respectively. The average values of experimental SLC of MLM and MMM CLT panels were almost the same, which suggested that using higher-graded timber boards as perpendicular layers had little effect on the serviceability loading capacity.

The analytical SLC using theoretical bending stiffness (EI)eff showed slightly higher results than experimental SLC. That is because the effective bending stiffness calculated by SAM was slightly higher than the experimental bending stiffness. This phenomenon is aligned with the previous study (Ettelaei et al. 2022b). However, the analytical SLC showed agreement with the experimental SLC with low percentage of variation (3.8% of average variation).

3.2 Creep and creep-recovery behaviour of CLT

The temperature and RH for the entire 245 days in the test cell were recorded and are plotted in Fig. 5. The temperature of the test cell experienced a cyclic change (intermittent condition) due to the temporary failure of the air-conditioner in the test cell at the early stage of the creep tests (from day 6 to day 29). Also, during summer, there was a temperature increase from day 183 to 191 reaching a maximum temperature of 24.5 degrees.

The RH of the test cell also experienced temporary fluctuations. A notable increase in RH occurred between days 100 and 102 due to a flood event, and the RH values of the environment reached to a maximum of 68.1%. Then, during the transition from late spring to early summer, there was a slight decrease in the average values of RH from day 123 to 129. The average values of RH from day 0 to 123 was 66.2% and decreased to the 65.3% of the average RH for the period between days 129 and 245.

The moisture content of the small sample (Fig. 6) during the test period was measured based on the initial moisture content measured before the manufacturing of small CLT sample and the changing weight of the sample over time. The values of moisture content were validated by re-measuring the moisture content of the small sample (10.70%) after the creep test using oven-dry assessment according to Australian Standard (AS 1080.1 2012). The negligible error (0.32%) when compared to the initial moisture content (10.74%) confirms the accuracy of the initial measurement. The purpose of the recorded data was to serve as an indicator of changing moisture content of wood during creep tests.

Figure 7 displays the creep ratio over time for individual CLT panels. The creep ratio of the CLT panels showed a rapid increase within the initial 30 days, although for E. nitens CLT panels, some fluctuations were observed due to malfunctioning of the air-conditioner. From day 30 to day 100, the curve displayed a stable and gradual rise. Subsequently, there was a sharp rise in the creep rate from day 100, and reaching the peak at day 120, but followed by a period of gradual creep recovery until day 180. This phenomenon may be because the increase in RH of the test cell due to a flood event, and subsequently followed by a slight decrease in RH due to the transition in season. The moisture content of the small CLT sample also reflected the variation in moisture content during this period (Fig. 6). After that, the curves exhibited slight fluctuations due to the variations of temperature in the test cell but maintaining a generally stable trend from day 180 to day 215.

Table 4 presents the initial deflection of the CLT panels under loads and the creep ratio determined by Eq. 8 after a period of constant loading (215 days for E. nitens CLT and 181 days for spruce CLT). the overall creep ratio of E. nitens CLT (1.35) was lower than the reference spruce CLT (1.46). The spruce CLT was tested over a shorter period, which may hint that E. nitens CLT may have better resistance to creep deformation over time. However, the initial moisture content of the spruce specimen before the creep test was 14.8%, and the temperature and RH of the test cell were set to nominal values of 20 °C and 65%, respectively, where the equilibrium moisture content would be approximately 12%. Therefore, the spruce specimen might experience moisture desorption, while E. nitens CLT experienced moisture absorption (Fig. 6) during the creep testing. This may also be the reason why the spruce CLT specimen has higher creep ratio. In addition, it was observed that the structural grade of transverse layers would play an important role in creep performance of E. nitens CLT. In this case, MMM CLT panels employed higher-MOE timber boards in transverse layers and showed the lowest values of creep ratio (1.29), though using higher-MOE boards in outer layers (HLH) also showed lower creep ratio (1.35) when compared to MLM CLT panels (1.42). In accordance with previous research (Ettelaei et al. 2022c), using higher-MOE sawn boards in transverse layers for E. nitens CLT was found to increase the shear modulus (Gr values) of CLT. Theoretically, the overall deformation of an element subjected to bending loads comprises both bending and shear deflection. In this case, the MOE values of the top and bottom layers primarily influence short-term bending deflection. However, when examining long-term bending behaviour, shear deformation becomes increasingly significant in controlling creep of CLT. Therefore, to achieve better creep performance of CLT products made from E. nitens, it should be advisable to utilise higher-graded timber boards in the transverse layers.

Figure 8 represents the creep recovery behaviour of individual CLT panels over 30 days. The initial creep recovery rates vary among different samples. Some samples (HLH2 and MMM1) showed rapid initial recovery followed by gradual stabilisation, while others display prolonged recovered periods. According to the final remaining creep after 30 days from Table 5, most E. nitens CLT showed comparable remaining creep (0.68–0.80), while MMM2 exhibited the lowest remaining creep (0.23) after 30 days of testing period. This outlier may indicate that there may be an underlying factor that requires further investigation. In addition, spruce CLT exhibited the highest remaining creep after 30 days, which may suggest that E. nitens CLT may have a better ability to recover from creep (see Table 6).

The residual MOE of CLT panels was determined by linear-elastic four-point bending tests and calculated by Eq. 7. In accordance with comparison analysis between the original MOE and residual MOE, most of the CLT panels (except MLM4) exhibited a slight decrease in values of MOE after performing creep tests. This phenomenon was also observed by previous research (Pirvu 2014).

3.3 Creep model and prediction

The creep data was analysed using both the power law model and the non-linear regression model with the least squared method to determine the best fitting parameters. Tables 7 and 8 present fitting parameters for Eq. 10 and Eq. 11, respectively. Figure 9 depicts the comparison between the modelled and experimental creep data.

When comparing the R2 values of the fitting results from these two model equations, it is evident that the non-linear regression model (Eq. 11) with consideration of environmental conditions displayed better fitting accuracy for the CLT specimens than the power-law model (Eq. 10). The MLM1 and MMM2 showed inferior fitting performance in both models, suggesting that these two samples may be more sensitive to varied RH and temperature, which caused significant fluctuations.

Table 9 shows the long-term predicted creep of CLT panels by both fitting equations, indicating the 10-year and 50-year creep ratios. The power-law model consistently underestimated the creep ratio for all CLT samples compared to the non-linear regression model. In predicting the creep ratio using Eq. 11 for 10-year and 50-year, it was assumed that the environmental conditions remained consistent over time. Specifically, 20 °C of temperature, 65% of RH and 12% of moisture content in wood were considered.

In this study, the environmental conditions (65% of RH and 20 °C of temperature) of the test cell could be categorised as service class 1. The anticipated relative creep (determined by Eq. 12) for all E. nitens CLT panels after 10-year of loading (0.72) (predicted by non-linear regression model) was expected to be slightly higher than those of solid timber, GLT and LVL (0.6), and lower than plywood (0.8), as outlined in Eurocode 5 (EN 1995-1-1 2004). In a previous study by Jöbstl and Schickhofer (2007), bending creep tests were conducted on five-layered C24 spruce CLT under constant environmental conditions (55% of RH and 20 °C of temperature) with 1-year loading period. Their findings revealed relative creep ranging from 0.3 to 0.4 for the CLT samples, with higher stress levels correlating to lower relative creep factors. In comparison, the relative creep factors within this research were already slightly higher than their values despite not having been tested for a one-year period. This may be due to two reasons: first, higher RH was used throughout the creep tests; and second, the CLT samples in this investigation were three-layered, where the use of more layers in CLT may result in lower creep factor, as discussed in the Swedish CLT handbook (Gustafsson et al. 2019).

The predicted relative creep after 50 years for HLH, MLM, MMM and spruce CLT panels was estimated to 0.67, 1.03, 0.60 and 0.89, respectively. These values correspond to 67%, 103%, 60% and 89% increases in the initial deflection of the CLT panels. According to the initial deflection of the panels (Table 4), the total creep after 50-year may not significantly influence the overall deflection for the given span lengths for this investigation, when compared to the deflection limit (6 mm) in accordance with AS/NZS 1170.0 (2002). Furthermore, the average creep ratio for E. nitens CLT was estimated to be 1.77 after 50-year loading, which was lower than the 50-year predicted average creep ratio of three-layered hybrid CLT made from SPF lumber and OSB (2.0) in accordance with the previous research (Yin et al. 2024). However, the test conducted by Yin et al. was performed in a completely uncontrolled environment, while in this study, the environmental conditions were more stable.

4 Conclusion

This study focused on the bending performance of fibre-managed E. nitens panels under short-term and long-term serviceability loads. The short-term bending behaviour was determined under the non-destructive four-point bending tests, while the long-term bending test was conducted under uniformly distributed loading provided by 5.5 kN/m2 of concrete pavers. It is the pilot study of the creep behaviour of CLT manufactured by fibre-managed E. nitens. The following are the key findings of this study:

-

HLH CLT exhibited the highest SLC among the E. nitens CLT configurations, and the use of higher-graded timber boards in the transverse layer had little effect on the experimental results. E. nitens CLT panels showed higher average values of SLC compared to the reference spruce CLT.

-

The analytical SLC was slightly higher than the experimental results. This is because of the higher bending stiffness determined by the SAM. However, the analytical results showed agreement with the experimental one.

-

The environmental conditions of the test cell for the creep test were set at 65% of RH and 20 °C of temperature. However, due to a malfunction of the air-conditioner and transition of seasons, the environmental condition of the test cell experienced a certain degree of fluctuations, which led to a certain degree of fluctuations on the creep results of all tested CLT panels.

-

MMM CLT panels showed the lowest creep ratio (1.29), followed by HLH (1.35) and MLM (1.42) CLT panels. This observation suggested that the grade of transverse layer (e.g. MOE) played an important role in creep behaviour of fibre-managed E. nitens CLT. In addition, all fibre-managed E. nitens CLT showed lower average creep ratio (1.35) when compared to the reference spruce CLT (1.46) given the testing period.

-

E. nitens CLT panels showed better ability for creep recovery than the spruce CLT. However, the remaining MOE of the CLT panels after the creep tests did not exhibit obvious relationship between various CLT configurations and species.

-

Two creep modelling equations were included to curve fit the experimental creep data in this study. The non-linear regression model considering the change of environmental conditions showed better fitting effect than the traditional power-law modelling.

-

The predicted creep ratios of CLT panels over a 50-year period, as estimated by two modelling equations, suggested that E. nitens timber boards sourced from fibre-managed plantations for CLT manufacturing demonstrate sufficient long-term performance to fulfill the deflection serviceability requirements in structural floor systems.

Data availability

No datasets were generated or analysed during the current study.

References

ANSI/APA PRG 320–2018 (2018) Standard for performance-rated cross-laminated timber. American National Standards Institute, New York, America

AS 1720.1 (2010) Timber structures - Part 1: Design methods Standard Australia, Sydney, Australia

AS 1080.1 (2012) Timber - methods of test moisture content. Standards Australia, Sydney, Australia

AS 2082 (2007) Timber - hardwood - visually stress-graded for structural purposes. Standards Australia, Australia

AS/NZS 4063.1 (2010) Characterisation of structural timber Test methods Standards Australia/Standards New Zealand, Sydney, Australia and Wellington, New Zealand

AS/NZS 1170.0 (2002) Structural design actions – Part 0: General principles Standards Australia/Standards New Zealand, Sydney, Australia and Wellington, New Zealand

ASTM D6815-09 (2015) Standard Specification for Evaluation of Duration of Load and Creep effects of Wood and Wood-based products. ASTM International, America

Brandner R (2013) Production and Technology of Cross Laminated Timber (CLT): A state-of-the-art Report In proceedings of Focus Solid Timber Solutions - European Conference on Cross Laminated Timber (CLT), University of Bath, Bath, UK, pp. 3–36

Callegari G, Cremonini C, Rocco VM, Spinelli A, Zanuttini R (2010) The production of hardwood X-Lam panels to valorise the forest-wood chain in piemonte In proceedings of WTCE 2010-World Conference on Timber Engineering, Riva del Garda, Trento, Italy, pp. 809–810

Colling F (2014) Creep behavior of cross-laminated timber in service class 2 Technical Report in Hochschule Augsburg, University of Applied Sciences, Germany

Derikvand M, Nolan G, Jiao H, Kotlarewski N (2017) What to do with structurally low-Grade Wood from Australia’s Plantation Eucalyptus; Building Application? BioResources. 12:4–7. https://doi.org/10.15376/biores.12.1.4-7

Derikvand M, Kotlarewski N, Lee M, Jiao H, Chan A, Nolan G (2018a) Visual stress grading of fibre-managed plantation eucalypt timber for structural building applications. Constr Build Mater 167:688–699. https://doi.org/10.1016/j.conbuildmat.2018.02.090

Derikvand M, Jiao H, Kotlarewski N, Lee M, Chan A, Nolan G (2019a) Bending performance of nail-laminated timber constructed of fast-grown plantation eucalypt. Eur J Wood Prod 77:421–437. https://doi.org/10.1007/s00107-019-01408-9

Derikvand M, Kotlarewski N, Lee M, Jiao H, Chan A, Nolan G (2019b) Short-term and long-term bending properties of nail-laminated timber constructed of fast-grown plantation eucalypt. Constr Build Mater 211:952–964. https://doi.org/10.1016/j.conbuildmat.2019.03.305

Dewsbury M, Fay R, Nolan G, Vale R (2007) The design of three thermal performance test cells in Launceston In proceedings of the 41st ANZAScA Annual Conference. pp. 91–100

EN 1995-1-1 (2004) Eurocode 5: design of timber structures - part 1–1: General - Common rules and rules for buildings. European Committee for Standardization (CEN), Brussels

EN 338 (2016) Structural timber - strength classes. European Committee for Standardization (CEN), Brussels

Espinoza O, Buehlmann U (2018) Cross-laminated timber in the USA: opportunity for hardwoods? Curr Forestry Rep 4:1–12. https://doi.org/10.1007/s40725-018-0071-x

Essoua GGE, Blanchet P (2017) Cross laminated timber made from large-leaf beech: Production, characterization and testing In proceedings of the 6th International Scientific Conference on Hardwood Processing, 208

Ettelaei A, Taoum A, Nolan G (2022a) Assessment of Different Measurement Methods/Techniques in Predicting Modulus of Elasticity of Plantation Eucalyptus nitens Timber for Structural Purposes. Forests, 13 https://doi.org/10.3390/f13040607

Ettelaei A, Taoum A, Shanks J, lee M, Nolan G (2022b) Evaluation of the bending properties of novel cross-laminated timber with different configurations made of Australian plantation Eucalyptus nitens using experimental and theoretical methods. Structures 42:80–90. https://doi.org/10.1016/j.istruc.2022.06.002

Ettelaei A, Taoum A, Shanks J, Nolan G (2022c) Rolling Shear Properties of Cross-Laminated Timber Made from Australian Plantation Eucalyptus nitens under Planar Shear Test. Forests, 13 https://doi.org/10.3390/f13010084

Granello G, Palermo A (2019) Creep in timber: Research Overview and comparison between code provisions. N Z Timber Des J 27:6–22

Gustafsson A, Crocetti R, Just A, Landel P, Olsson J, Pousette A, Silfverhielm M, Östman B (2019) The CLT Handbook: CLT structures - facts and planning. Swedish Wood, Sweden

Jelec M, Varevac D, Rajcic V (2018) Cross-laminated timber (CLT) - a state of the art report. Gradjevinar 70. https://doi.org/10.14256/jce.2071.2017

Jöbstl R, Schickhofer G (2007) Comparative examination of creep of GLT and CLT slabs in bending In proceedings of the Working Commission CIB W18—Timber Structures, Bled, Slovenia, 40, 1–15

Karacabeyli E, Douglas B (2013) CLT Handbook: cross-laminated timber U.S. Edition FPInnovations. U.S. Department of Agriculture, Forest Service, Forest Products Laboratory, Binational Softwood Lumber Council, Canada

Karacabeyli E, Gagnon S (2019) Canadian CLT Handbook 2019 Edition Volume 1, FPInnovations, Pointe-Claire, QC, Canada

Kreuzinger H (1999) Platten, Scheiben und Schalen – ein Berechnungsmodell für gängige Statikprogramme, (Panels, discs and shells - a calculation model for common statics programs) (In German). Bauen mit Holz 1:34–39

Legg P, Frakes I, Gavran M (2021) Australian plantation statistics and log availability report 2021. ABARES research report, Canberra, October. https://doi.org/10.25814/xj7c-p829

Liang Y, Taoum A, Kotlarewski N, Chan A, Holloway D (2023) Behavior of cross-laminated timber panels made from Fibre-Managed Eucalyptus nitens under short-term serviceability loads. Buildings 13:245. https://doi.org/10.3390/buildings13010245

Morlier P (1994) Creep in timber structures: report of RILEM Technical Commitee 112-TSC. E & FN Spon, London

Musselman ES, Dinehart DW, Walker SM, Mancini ML (2018) The effect of holes on the creep behavior and flexural capacity of laminated veneer lumber (LVL) beams. Constr Build Mater 180:167–176. https://doi.org/10.1016/j.conbuildmat.2018.05.186

Nie Y, Valipour HR (2022) Experimental and analytical study of timber-timber composite (TTC) beams subjected to long-term loads. Constr Build Mater 342. https://doi.org/10.1016/j.conbuildmat.2022.128079

Nolan GB, Greaves BL, Washusen R, Parsons M, Jennings S (2005) Eucalypt Plantations for Solid Wood Products in Australia - A Review ‘If you don’t prune it, we can’t use it’ Technical report, Forest Wood Products Research and Develoment Corporation

Opazo-Vega A, Rosales-Garces V, Oyarzo-Vera C (2021) Non-destructive Assessment of the dynamic elasticity Modulus of Eucalyptus nitens timber boards. Materials 14. https://doi.org/10.3390/ma14020269

Park H-M, Gong D-M, Shin M-G, Byeon H-S (2020) Bending Creep properties of Cross-laminated Wood panels made with Tropical Hardwood and Domestic Temperate Wood. J Korean Wood Sci Technol 48:608–617. https://doi.org/10.5658/wood.2020.48.5.608

Pirvu C (2014) Time-dependent behavior of cross-laminated timber Technical report: Transformative Technologies No. 1.1.12 W-3092, Natural Resources Canada, Canadian Forest Service

Riccadonna D, Walsh K, Schiro G, Piazza M, Giongo I (2020) Testing of long-term behaviour of pre-stressed timber-to-timber composite (TTC) floors. Constr Build Mater 236. https://doi.org/10.1016/j.conbuildmat.2019.117596

Song H, Wang Z, Li L (2021) Experimental Investigation on Bending Creep Properties of Hybrid Cross-laminated Timber Fabricated from Lumber and OSB In proceedings of the 4th International Symposium on Traffic Transportation and Civil Architecture (ISTTCA), 605–610 https://doi.org/10.1109/ISTTCA53489.2021.9654640

Suárez-Riestra F, Estévez-Cimadevila J, Martín-Gutiérrez E, Otero-Chans D (2022) Timber-timber-composite (TTC) beam long-term behaviour. Full scale experimental campaign and simplified analytical model. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2022.129649. 361 DOI

Takanashi R, Ohashi Y, Ishihara W, Matsumoto K (2021) Long-term bending properties of cross-laminated timber made from Japanese larch under constant environment. J Wood Sci 67. https://doi.org/10.1186/s10086-021-01997-1

Thomas RE, Buehlmann U (2017) Using low-grade hardwoods for CLT production: a yield analysis In proceedings of the 6th international scientific conference on hardwood processing. 25–28

Yin T, Song H, Wang Z, Li L, Zheng W, Ju Z, Gong Y, Gong M (2024) Long-term creep properties of hybrid CLT fabricated with lumber and OSB. Ind Crops Prod 211. https://doi.org/10.1016/j.indcrop.2024.118238

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions.

Author information

Authors and Affiliations

Contributions

Y.L. and N.K. prepared materials and test setup. Y.L. collected data, analysed data, prepared figures and tables and wrote the main manuscript. A.T. and A.C. provided comments on the manuscript. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Liang, Y., Taoum, A., Kotlarewski, N. et al. Bending performance of cross-laminated timber constructed from fibre-managed Eucalyptus nitens under short-term and long-term serviceability loads. Eur. J. Wood Prod. (2024). https://doi.org/10.1007/s00107-024-02111-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00107-024-02111-0