Abstract

An enhanced swift indirect method for the determination of both free and bound 3-monochloropropane-1,2-diol has been established. The advantages include reduced sample preparation time (1 h instead of several hours), rapid triple quadrupole gas chromatography−mass spectrometry detection (12 min rather than 30 min in average) combined with amplified selectivity and sensitivity. The enhanced method has been entirely validated. The limits of quatification and detection were estimated and were found to be less than 2 and 0.5 µg/kg, respectively. The recoveries at different spiked levels ranged from 98 to 106%. The reproducibility (expressed as relative standard deviation) was less than 8% while measurement uncertainty was in the range of ±18%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Since 1978, a new class of contaminants termed chloropropanols was identified in acid-hydrolyzed vegetable protein (HVP) [1]. Esters and free 3‑monochloropropane-1,2-diol (3-MCPD) were identified in 1980 during lipid hydrolysis experiments using hydrochloric acid [2]. Many foodstuffs like oil, fried food, baby food, and infant’s formula became of immense concern because of their reported common contamination with 3-MCPD [3–7].

Carcinogenicity and genotoxicity of 3-MCPD in rats have been evidenced by toxicological studies [8–10]. The International Agency for Research on Cancer (IARC) considered 3-MCPD as a possible human carcinogen (Group 2B) [11]. Esters of 3-MCPD showed similar toxicity like its free analog but with the milder effect proportional to the urinary excretion of metabolites [12]. The Scientific Committee on Food in 2001 has reported a tolerable daily intake (TDI) of 2 μg/kg body weight for 3-MCPD [10]. Recently, the European Food Safety Authority established a new TDI of 0.8 μg/kg body weight [13]. The European Commission stated maximum levels of 20 μg/kg of 3-MCPD in liquid soy sauce and HVP [14].

Recent publications for the determination of 3‑MCPD and its esters can be characterized in terms of direct and indirect methods.

Direct methods mostly aimed to determine free 3‑MCPD [15, 16]. However, they were not sensitive enough to determine 3-MCPD at ultrasensitive level owing to its low molecular weight as well as nonexistence of chromophore in its structure [17]. Other direct methods based on liquid chromatography-mass spectrometry or liquid chromatography-quadrupole time-of-flight mass spectrometry are targeting the determination of miscellaneous ester classes of 3‑MCPD including monoesters, diesters, homoesters and heteroesters [6, 18–20]. Although these methods have simple sample treatment steps, they are suffering from diverse separation difficulties, in addition to their reliance on using excessive analyte standards to cover the whole 3-MCPD esters scope [21].

Indirect methods include extraction, transesterification reaction (mostly takes 16 h to convert 3-MCPD esters into their free analog form), additional liquid-liquid extraction steps (for clean-up), followed by derivatization prior to gas chromatography-mass spectrometry (GC−MS) injection. Transesterification is conducted either in acidic or alkaline media [22, 23]. Three main types of derivatizing agents are typically applied in derivatization step including heptafluorobutyrate, ketones and phenylboronic acid (PBA). Heptafluorobutyrate derivatizing agent [24–26] reacts with nucleophilic co-extract causing incomplete derivatization and producing interfering peaks at GC chromatogram that may affect the quantification limit (LOQ) [27]. Ketones derivatization [27–29] is always completed in anhydrous conditions, and this is impractical to apply to food samples. Moreover, ketone derivatives are fairly soluble in water causing losses of the derivatized 3-MCPD [29]. Nowadays, PBA derivatization is preferred by most recent published methods due to its stability and selectivity to di-alcohols [7, 22, 30–39]. Owing to these impediments, indirect methods are preferred for 3-MCPD quantification [21].

This current work is aiming to enhance and validate a rapid and ultrasensitive analytical method in order to quantify free and bound 3-MCPD in selected foodstuffs. It applies simultaneous extraction, short hydrolysis time (only 1 h), simple PBA-based derivatization, and quick triple quadrupole GC-MS determination using deuterium-labeled 3-MCPD-d5 as an internal standard. Moreover, during this work an improved triple quadrupole GC−MS functioning in multiple reaction monitoring (MRM) mode with the realistic runtime (about 12 min) using a DB-35 GC capillary column was applied for detection and quantification. It introduces extra advantages over the published MS-based methods in terms of selectivity, ultra-sensitivity and efficient determination of free and bound 3‑MCPD simultaneously.

The performance parameters of this enhanced method were fully validated and investigated for compliance with the European Commission Regulation No. 836/2011 in terms of selectivity, sensitivity as well as simplicity [40]. This enhanced method was applied to study the occurrence levels of 3-MCPD free and bound analogs in some soya sauce and oil samples collected from the local markets.

EXPERIMENTAL

Chemicals and reagents. Sodium methoxide (>90%), glacial acetic acid (>99%), acetone (>99%), diethyl ether (>99%), ethyl acetate (>99%), t-butyl methyl ether (>99%), n-hexane (>99%), PBA (>95%), 3-MCPD (>99%) and 3-MCPD-d5 (>99%) were purchased from Sigma-Aldrich (USA), while 3‑MCPD-1,2-dipalmitoyl ester (>99%) and 3‑MCPD-1,2-dipalmitoyl ester-d5 (>99%) were purchased from Toronto Research Chemicals Inc. (Canada).

Preparation of standard solutions. 100 µg/mL stock solutions of 3-MCPD and 3-MCPD-d5 were prepared by their individual dissolving in deionized water and stored in the refrigerator. 1 µg/mL solutions of 3-MCPD and 3-MCPD-d5 were prepared by diluting appropriate volumes in deionized water and stored in the refrigerator. Calibration standard solutions with concentrations of 1, 5, 10, 20 and 50 µg/L were prepared by diluting 1 µg/mL 3-MCPD standard working solution with deionized water. 100 and 132 µg/mL standard solutions of 3-MCPD-1,2-dipalmitoyl ester and 3-MCPD-1,2-dipalmitoyl ester-d5, respectively, were prepared by dissolving both of them separately in 25 mL of tert-butyl methyl ether and stored in the refrigerator. 1 and 1.3 µg/mL standard solutions of 3-MCPD-1,2-dipalmitoyl ester and 3-MCPD-1,2-dipalmitoyl ester-d5, respectively, were prepared by diluting appropriate volumes in tert-butyl methyl ether and stored in the refrigerator.

Derivatization of calibration standards. An exact volume of 2 mL was taken separately from each 3‑MCPD calibration standard solution into 4 mL capped vials. A 40 µL aliquot of 3-MCPD-d5 (1 µg/mL) was added as an internal standard, followed by the addition of 400 µL of 20% PBA. The mixture was well shaken for 1 min, transferred into a water bath, kept at 85°C for 20 min and left to cool at room temperature. A 2 mL aliquot of n-hexane was added, and the mixture was well shaken for 1 min. n-Hexane layer was filtered through a 0.45 µm membrane filter before injection into triple quadrupole GC-MS.

Sample collection. For the method development and validation, soya sauce and virgin olive oil samples were obtained from the local market. The materials were stored in the dark. Because of the unfeasibility of finding blanks, samples with the lowest amount of free and bound 3-MCPD were used throughout the validation steps using the proposed method.

For application purposes, 7 samples including vegetable oils and soy sauce were purchased from different local markets.

To extract free 3-MCPD, 2.0 ± 0.1 g of sample (soya sauce) was weighed in a 50 mL centrifuge tube, 200 µL of 1 µg/mL 3-MCPD-d5 was added as an internal standard. Then, 8 mL of deionized water was added. The mixture was well shaken for 2 min and centrifuged at 4000 rpm for 5 min, 2 mL of the aqueous layer was taken into a 4 mL capped vial and 400 µL of 20% PBA was added. The vial was put into a water bath at 85°C for 20 min. It was left to cool, and 2 mL of n‑hexane was added and well shaken for 1 min. n‑Hexane layer was filtered through a 0.45 µm pore size membrane before injection.

For bound 3-MCPD extraction, 2 ± 0.1 g of sample (oil) was weighed in a 50 mL centrifuge tube, 777 µL of 1.3 µg/mL 3-MCPD-1,2-dipalmitoyl ester was added as an internal standard, then, 8 mL of diethyl ether was added. The mixture was well shaken for 2 min followed by addition of 200 µL of 2 M sodium methoxide. After 10 min, 100 µL of glacial acetic acid was added. 5 mL of deionized water was added prior to the tube well shaking for 2 min, followed by centrifugation at 4000 rpm for 5 min. 2 mL of aqueous layer was taken into a 4 mL capped vial and 400 µL of 20% PBA was added. The vial was put into a water bath at 85°C for 20 min. It was left to cool, and 2 mL of n-hexane was added, followed by well shaking for 1 min. n-Hexane layer was filtered through a 0.45 µm pore size membrane before injection.

Instrumentation and analysis conditions. Chromatographic analysis was carried out using a triple quadrupole GC-MS system. A 7890B series gas chromatograph (Agilent Technologies) was used. Inlet system was split/splitless with inlet deactivated (inert) liner (Agilent Technologies, USA) with an Agilent Column J&W Ultra Inert DB-35MS GC column (20.0 m length, 0.18 mm internal diameter and 0.18 μm film thicknesses). 2 MRM transitions were used (2 precursor and 2 product ions), one for quantification and the other for qualification. MRM details are represented in Table 1.

RESULTS AND DISCUSSION

Method enhancement and optimization. Sample preparation conditions. Sample preparation is one of the most problematic stages in 3-MCPD determination as it requires in several published methods about 17 h for hydrolysis and multi-liquid−liquid extraction for clean-up. Therefore, this current work is aiming to reduce the sample preparation time. Free 3-MCPD was directly derivatized using PBA. In order to determine the proper amount of PBA for derivatization, a series of standards was prepared by derivatizing 500 ng/mL free 3-MCPD with 20% (wt/vol) PBA amounts varying from 50 to 700 µL. It has been found that using 400 µL of PBA is the best volume for complete derivatization upon detecting the triple quadrupole GC−MS analyte peak responses.

Bound 3-MCPD has been hydrolyzed by sodium methoxide instead of sodium hydroxide that is usually used for hydrolysis [32]. Several published methods have applied ultra-freezing conditions of –20°C for 16 h to overcome the problem that arises from sodium hydroxide high reactivity in replacing chloride ions [34]. Therefore, during this work the usage of sodium methoxide as an efficient hydrolytic agent has been confirmed by the recovery tests and gave a privilege in reducing the hydrolysis time to just 1 min at room temperature [41, 22].

The efficiency of this sample preparation scheme has been evidenced through recovery experiments and by Food Analysis Performance Assessment Scheme (FAPAS) Proficiency Test as mentioned later in this paper.

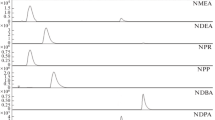

Chromatographic conditions were enhanced and optimized by studying the separation of derivatized 3‑MCPD using two types of Agilent GC columns, namely HP5-MS UI (30 m, 0.25 mm, 0.25 µm, Agilent J&W, 19091S-433UI) and DB 35-MS UI (20 m, 0.18 mm, 0.18 µm). Initially HP5-MS UI column was tested by injecting target analytes at the lowest standard level (1 ng/mL) using the following conditions: initial oven temperature 90°C kept for 2 min, heated from 90 to 190°C at 20 grad/min, heated from 190 to 280°C at 10 grad/min and held for 10 min. The resulting analyte peak showed low sensitivity and unsymmetrical peak shape as shown in Fig. 1.

The second study on HP5-MS UI column was performed according to the following conditions: initial oven temperature was 90°C and kept for 1.5 min, heated from 90 to 270°C at 25 grad/min, held for 3.5 min. The resulting analyte peak still had low sensitivity and unsymmetrical peak shape as shown in Fig. 2.

As HP5-MS UI column did not give good chromatographic efficiency and satisfied sensitivity, another column (DB 35-MS UI) was tested with injecting studied analytes at the lowest standard level (1 ng/mL) with the following conditions: initial oven temperature was 90°C that was kept for 1.5 min, heated from 90 to 270°C at 25 grad/min, held for 3.5 min. The resulting peak had high sensitivity with good peak shape and symmetry as shown in Fig. 3.

The runtime has been reduced to 12 min, which is better and faster than the commonly published methods that reported runtimes from 30 to 45 min. This gives the advantage to the possibility of adopting this method in routine laboratories for the determination of 3-MCPD in different foodstuffs.

Validation and uncertainty measurement study. During this work, Eurachem guidelines for validation characteristics and uncertainty estimation scheme were used [40, 42]. For the accepted method performance criteria, the EU official regulation for 3‑MCPD detection methods was applied [43]. Based on these reference protocols, method validation was carried out to study the accuracy (in terms of precision and trueness), selectivity, sensitivity (in terms of detection (LOD) and quantification limits), instrument linearity, and method range using different types of food commodities (soya sauce and olive oil).

Method selectivity. In this study, application of GC coupled to triple quadrupole mass spectrometer operating in MRM mode in combination with DB 35-MS UI column permits revoking multi-liquid-liquid extraction steps for clean-up in the reported methods, consequently, reducing the sample analysis turnaround time. Additionally, the application of MRM mode diminishes the interferences and subsequently the method selectivity is high. This was confirmed by studying the injection of a derivatized blank reagent. The resulting chromatogram showed no interfering peak (Fig. 4).

Additionally, a derivatized glycidol has been injected over these conditions, and the chromatogram also showed no interfering peaks at the 3-MCPD signal window.

Method sensitivity. The LOQs and LODs for both free and bound 3-MCPD were studied by testing 6 repeated spiked soya sauce and olive oil samples at the lowest spiked level of 5 µg/kg (Fig. 5).

The LOD is estimated as 3 times the standard deviation of these repeated spiked samples, while the LOQ is estimated as 10 times the standard deviation as shown in Table 2.

The obtained results were less than 0.5 µg/kg for LODs and less than 2 µg/kg for LOQs reflecting the method ultra-sensitivity when compared with the recent publications. The results were shown to comply with the requirements of the official European method performance [43].

Instrument linearity. The multilevel calibration curve was plotted using 1, 5, 10, 20 and 50 ng/mL derivatized 3-MCPD standards with 20 ng/mL 3-MCPD-d5 as an internal standard. The instrument linearity was expressed in terms of the determination coefficient (r2) and was found to be ≥0.999 according to the equation:

Method range and recoveries. In this study, samples have been tested using the newly enhanced method. 6 repeated soya sauce and olive oil samples spiked with both free and bound 3-MCPD at 3 different levels of 5, 50 and 100 μg/kg were used for recovery studies as demonstrated in Table 3.

The recovery results of 98–105% were found to be within the accepted recovery range of the official European method performance for 3-MCPD testing method (75–110%) [43]. Moreover, the closeness of these obtained recovery results in the range from 5 to 100 µg/kg of free and bound 3-MCPD to the true value was considered as a verification of high method performance and good ruggedness/robustness of sample preparation.

Method accuracy. In order to express the method accuracy, 2 components including trueness and precision were studied.

Method precision. The method precision was evaluated using within-lab reproducibility experiments by analysis of 10 soya sauce and olive oil samples spiked with 20 µg/kg free and bound 3-MCPD (Table 4). The obtained results (Table 4) revealed high precision with the relative standard deviation (RSD) less than 8%. The results of recovery and reproducibility experiments (Tables 3 and 4, respectively) revealed virtuous performance over the studied method range. This can be attributed to several factors including the application of GC coupled to triple quadrupole mass spectrometer operating in MRM mode combined with DB 35-MS UI column, and the use of 3-MCPD-d5 as an internal standard that evades the potential effects of matrix and spectral interferences.

Method trueness. The trueness of this enhanced method was evaluated by participating in several rounds of Proficiency Tests that were organized by FAPAS. The accepted Z-score of the results should lie between ±2. Table 5 shows the FAPAS Proficiency Tests Trueness Results at several rounds. These results have demonstrated additional evidence for the method performance in terms of high accuracy and robustness. Moreover, the closeness of the Z-score results revealed high method stability over different foodstuff types.

Uncertainty estimation. According to Eurachem guidelines, the measurement uncertainty sources were estimated using precision (within-lab reproducibility) and bias data (Table 6). Combined and expanded uncertainty results were calculated, the expanded uncertainty was found to be 18%. This low uncertainty can be justified by high precision and robustness of this method.

Method applications. This method has acquired the international accreditation by the Finish Accreditation Service (FINAS) for fulfilling the requirements of ISO/IEC 17025 standard. It was applied to quantify both free and bound 3-MCPD in 2 soya sauce samples and 5 oil samples that were sampled from and local food facilities (Table 7).

The results indicated that the amounts of free 3‑MCPD in soya sauce samples were within the international permissible limits [14]. Moreover, the bound 3-MCPD levels in oil samples are relatively high when compared to other monitoring studies [3, 4]. In the view of its reported carcinogenicity and genotoxicity evidences, complete toxicity and risk assessment studies are still needed to set maximum permissible limits for bound 3-MCPD in different foodstuffs. It is also recommended to reassess the manufacturing strategies of vegetable oils in order to control bound 3-MCPD levels [44].

CONCLUSIONS

In the course of this work, an enhanced swift analytical method for the determination of bound and free 3-chloropropane-1,2-diol in some foodstuffs has been optimized. The method enhancements include shorter sample preparation time, a rapid run program in triple quadrupole GC-MS, besides augmented selectivity and sensitivity. It has been verified for fitness-for-use in terms of selectivity, sensitivity, accuracy, range and measurement uncertainty for compliance with the international performance requirements. It is recommended to introduce this enhanced method for the determination of free and bound 3-MCPD in foodstuffs for regulatory control purpose.

REFERENCES

Velíšek, J., Davidek, J., Hajšlová, J., Kubelka, V., Janíček, G., and Mánková, B., Eur. Food Res. Technol., 1978, vol. 167, p. 241.

Velisek, J., Davidek, J., Kubelka, V., Janicek, G., Svobodova, Z., and Simicova, Z., J. Agric. Food Chem., 1980, vol. 28, p. 1142.

Svejkovská, B., Novotny, O., Divinová, V., Reblova, Z., Doležal, M., and Velíšek, J., Czech J. Food Sci., 2004, vol. 22, p. 190.

Zelinková, Z., Svejkovská, B., Velíšek, J., and Doležal, M., Food Addit. Contam., 2006, vol. 23, p. 1290.

Divinová, V., Doležal, M., and Velíšek, J., Czech J. Food Sci., 2007, vol. 25, p. 39.

Chai, Q., Zhang, X., Karangwa, E., Dai, Q., Xia, S., Yu, J., and Gao, Y., RSC Adv., 2016, vol. 6, 113 576.

Leigh, J., and MacMahon, S., Food Addit. Contam., Part A, 2017, vol. 34, p. 356.

Cho, W.S., Han, B.S., Nam, K.T., Park, K., Choi, M., Kim, S.H., Jeong, J., and Jang, D.D., Food Chem. Toxicol., 2008, vol. 46, p. 3172.

Joint FAO/WHO Expert Committee on Food Additives: Evaluation of Certain Contaminants in Food, World Health Organ. Tech. Rep. Ser., 2017, p. 1.

Opinion of the Scientific Committee on Food on 3-Mo-nochloropropane-1,2-Diol (3-MCPD), Updating the SCF Opinion of 1994, Scientific Committee on Food, 2001, vol. 1.

Some Chemicals Present in Industrial and Consumer Products, Food and Drinking-Water, IARC Monographs on the Evaluation of Carcinogenic Risks to Human, Int. Agency Res. Cancer (IARC), 2013.

Barocelli, E., Corradi, A., Mutti, A., and Petronini, P.G., EFSA Supporting Publ., 2011, vol. 8, no. 9, 187E.

Alexander, J., Barregard, L., Bignami, M., Ceccatelli, S., Cottrill, B., Dinovi, M., Edler, L., Grasl-Kraupp, B., Hogstrand, C., Hoogenboom, L., Knutsen, H.K., Nebbia, C.S., Isabelle, Oswald., Petersen, A., Rogiers, V.M., Rose, M., Roudot, A.C., Schwerdtle, T., Vleminckx, C., Vollmer, G., and Wallace, H., EFSA J., 2016, vol. 14, no. 5, e04426.

European Commission. Commission Regulation (EC) no. 1881/2006, Setting maximum levels for certain contaminants in foodstuffs, Off. J. Eur. Union, 2006, p. 5.

Spyres, G., J. Chromatogr. A, 1993, vol. 683, p. 71.

Xing, X. and Cao, Y., Food Control, 2007, vol. 18, p. 167.

Hamlet, C.G., Sadd, P.A., Crews, C., Velisek, J., and Baxter, D.E., Food Addit. Contam., 2002, vol. 19, p. 619.

Haines, T.D., Adlaf, K.J., Pierceall, R.M., Lee, I., Venkitasubramanian, P., and Collison, M.W., J. Am. Oil Chem. Soc., 2011, vol. 88, p. 1.

Moravcova, E., Vaclavik, L., Lacina, O., Hrbek, V., Riddellova, K., and Hajslova, J., Anal. Bioanal. Chem., 2012, vol. 402, p. 2871.

Yamazaki, K., Ogiso, M., Isagawa, S., Urushiyama, T., Ukena, T., and Kibune, N.A., Food Addit. Contam., 2013, vol. 30, p. 52.

Dubois, M., Tarres, A., Goldmann, T., Empl, A.M., Donaubauer, A., and Seefelder, W., J. Chromatogr. A, 2012, vol. 1236, p. 189.

Kuhlmann, J., Eur. J. Lipid Sci. Technol., 2011, vol. 113, p. 335.

Weißhaar, R., Eur. J. Lipid Sci. Technol., 2008, vol. 110, p. 183.

Van Bergen, C.A., Collier, P.D., Cromie, D.D.O., Lucas, R.A., Preston, H.D., and Sissons, D.J., J. Chromatogr. A, 1992, vol. 589, p. 109.

Xu, X., Ren, Y., Wu, P., Han, J., and Shen, X., Food Addit. Contam., 2006, vol. 23, p. 110.

El-Haj, S., Bogusz, M.J., Ibrahim, Z., Hassan, H., and Tufail, M.Al., Food Control, 2007, vol. 18, p. 81.

Retho, C. and Blanchard, F., Food Addit. Contam. 2005, vol. 22, p. 1189.

Meierhansa, D.C., Bruehlmanna, S., Meilib, J., and Taeschlera, C., J. Chromatogr. A, 1998, vol. 802, p. 325.

Dayrit, F.M. and Ninonuevo, M.R., Food Addit. Contam., 2004, vol. 21, p. 204.

Divinová, V., Svejkovská, B., Doležal, M., and Velíšek, J., Czech J. Food Sci., 2004, vol. 22, p. 182.

Svejkovská, B., Novotný, O., Divinová, V., Réblová, Z., Doležal, M., and Velíšek, J., Czech J. Food Sci., 2004, vol. 22, p. 190.

Weißhaar, R., Eur. J. Lipid Sci. Technol., 2008, vol. 110, p. 183.

Doležal, M., Kertisova, J., Zelinkov, Z., and Velíšek, J., Czech J. Food Sci., 2009, vol. 27, p. 417.

Miyazakir, K., Koyama, K., Sasako, H., and Hirao, T., J. Am. Oil Chem. Soc., 2012, vol. 89, p. 1403.

Schallschmidt, K., Hitzel, A., Pöhlmann, M., Schwägele, F., Speer, K., and Jira, W., J. Consum. Prot. Food Saf., 2012, vol. 7, p. 203.

Kim, W., Jeong, Y.A., On, J., Choi, A., Lee, J.G., Lee, K., and Pyo, H., Toxicol. Res., 2015, vol. 31, p. 313.

Wenzl, T., Samaras, V., Giri, A., Buttinger, G., Karasek, L., and Zelinkova, Z., EFSA Supporting Publ., 2015, vol. 12, no. 3, 779E.

Karl, H., Merkle, S., Kuhlmann, J., and Fritsche, J., Eur. J. Lipid Sci. Technol., 2016, vol. 118, p. 406.

Jędrkiewicz, R., Głowacz-Różyńska, A., Gromadzka, J., Konieczka, P., and Namieśnik, J., Anal. Bioanal. Chem., 2017, vol. 409, p. 4267.

Ellison, S.L.R., Williams, A., DaSilva, R.B., Bremser, W., and Brzyski, A., Quantifying Uncertainty in Analytical Measurement, Eurachem/CITAC, 2012, 3rd ed.

Hrncirik, K., Zelinkova, Z., and Ermacora, A., Eur. J. Lipid Sci. Technol., 2011, vol. 113, p. 361.

Barwick, V., Bravo, P.P.M., Ellison, S.L.R., Engman, J., Gjengedal, E.L.F., Lund, U.O., Müller, H.-T., Patriarca, M., Pohl, B., Robouch, P., Sibbesen, L.P., Theodorsson, E., Vanstapel, F., Vercruysse, I., Yilmaz, A., and Ömeroglu, P.Y., The Fitness for Purpose of Analytical Methods: A Laboratory Guide to Method Validation and Related Topics, Eurachem, 2014, 2nd ed.

Commission Regulation (EU) No 836/2011 Amending Regulation (EC) No 333/2007, Laying down the methods of sampling and analysis for the official control of the levels of lead, cadmium, mercury, inorganic tin, 3-MCPD and benzo(a)pyrene in foodstuffs, Off. J. Eur. Union, 2011, p. 9.

Pudel, F., Fehling, P., Vosmann, K., Freudenstein, A., and Mattha, B., J. Lipid Sci. Technol., 2011, vol. 113, p. 380.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

No potential conflict of interest was reported by the authors.

Rights and permissions

About this article

Cite this article

AlaaEldean Fathy Ahmed Aboelhassan, Gomaa, A.M., El-Dien, F.A. et al. Validation of an Enhanced Swift Analytical Method for the Determination of Bound and Free 3-chloropropane-1,2-Diol in Foodstuffs using Gas Chromatography–Tandem Mass Spectrometry. J Anal Chem 75, 1469–1476 (2020). https://doi.org/10.1134/S1061934820110027

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061934820110027