Abstract

This study reports a novel analytical approach for the simultaneous determination of ethylene-thiourea (ETU) and propylene-thiourea (PTU) in fruits and vegetables by (reverse phase) high-performance liquid chromatography (HPLC) coupled to inductively coupled plasma-tandem mass spectrometry (ICP-QQQMS or ICP-MS/MS). A baseline separation of ETU and PTU was achieved in less than 5 min. A robust method validation by using the accuracy profile approach was performed by carrying out four measurement series in duplicate at six different levels over a timespan of 4 weeks (different days). The recovery factors ranged from 87 to 101% for ETU and from 98 to 99% for PTU (depending on the spiking level). The coefficient of variation in terms of repeatability (CVr) ranged from 1 to 4.7% for ETU and from 1.8 to 3.9% for PTU (depending also on the analyte level) while the coefficient of variation in terms of intermediate reproducibility (CVR) ranged from 3.4 to 10% for ETU and from 1.8 to 10.8% for PTU. The limit of quantification was 0.022 mg kg−1 (wet weight) for ETU and 0.010 mg kg−1 (ww) for PTU. This novel approach was proved to be highly robust and suitable for the determination of ETU and PTU in foodstuffs of vegetal origin.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

A better understanding of the humans’ contamination with chemical hazards via food ingestion is important as food is in most cases the predominant exposure pathway to such health hazards [1, 2]. Nevertheless, this task is difficult to achieve because the organic and the inorganic contaminants are present at trace and ultra-trace levels in foodstuffs hence requiring the development and validation of ultra-sensitive analytical approaches for their determination.

The intense industrial and agricultural activities of the modern society have introduced a large number of toxic substances into the environment having an impact on the food quality and ultimately on the human health. Many of such chemicals have been used in agriculture as pesticides, fungicides, etc. to enhance the productivity. This is the case of dithiocarbamates (DTCs) which are one of the largely used fungicides in agriculture as they are cost-effective against a broad spectrum of fungi and plant diseases [3, 4]. Current European and worldwide DTCs consumption figures are not well documented, but between 25,000 and 35,000 tons of DTCs were used per year both in the last two decades in agriculture and industry [3, 5].

The main representatives of DTCs that are currently in use worldwide are ziram, ferbam, thiram, maneb, zineb, nabam, metiram, mancozeb, and propineb [4]. It is very interesting to note that DTCs are highly unstable, and hence they decompose in the environment but also in the foodstuffs matrix, into ethylenethiourea (ETU) and propylene thiourea (PTU) [4]. These degradation products of DTCs are very stable and are also worth monitoring both in the environment and the food chain because of their toxicity [6, 7].

Depending on their carbon skeleton, DTCs can be categorized into three distinct classes: dimethyl-dithiocarbamates (DMDs), ethylenebis-dithiocarbamates (EBDs) and propylenebis-dithiocarbamates (PBDs). With few exceptions, generally, DTCs are reported to be rather unstable both on the surface of the fruits and vegetables where they are spayed as well as in the commonly used extraction solvents [8]. Previous literature in the field refers to ETU and PTU as DTCs metabolites or degradation products [9,10,11]. Therefore, ETU is acknowledged to be generated through the EBDs degradation, while PTU is reported to be a PBDs degradation compound. Although for DTCs, specific maximum residue levels (MRLs) are set by current European legislation, for their degradation products such as ETU and PTU, no specific MRLs are set since they are treated as a residue definition of their parent compounds. However, a better understanding of the formation, presence, and fate of ETU and PTU in food might help for improving regulation for such compounds. As a consequence, given that DTCs are among the most commonly employed organic fungicides in current agricultural practice, ETU and PTU monitoring in food products potentially exposed to DTCs became important.

The levels of organic contaminants such as DTCs, ETU, and PTU are currently determined using organic-based (molecular) mass spectrometry techniques (MS or MS/MS) coupled to high-performance liquid chromatography (HPLC) [9,10,11,12,13]. It is interesting to note that due to the sulphur (S) moiety in their structure, they can also be determined using inorganic-based MS techniques such as inductively coupled plasma-mass spectrometry (ICP-MS) coupled to HPLC. Actually, with the development of the triple quadrupole (or tandem) ICP-MS techniques (ICP-QQQMS or ICP-MS/MS), nonmetals such as S, which is known to be highly interfered by oxygen-based species (e.g., 16O16O on 32S and 16O18O & 17O17O on 34S) can be accurately detected [14,15,16,17,18]. It is also worth noting that ICP-MS/MS is more robust over the organic MS/MS techniques for the detection of organic molecules containing heteroatoms (e.g., S, Se, P) due to the high energy of the ICP over the conventional electrospray ionization-MS/MS hence ensuring less severe matrix effects [19]. Another major advantage of ICP-MS/MS for the determination of organic contaminants is the possibility to apply the isotope dilution (ID) approach, which is one of the most powerful and accurate methods for the determination of chemical amounts in all types of matrices [20].

This work reports the development and the validation of a novel method for accurate, selective, and robust determination of ETU and PTU in fruits and vegetables by using the HPLC-ICP-MS/MS. To our knowledge, this is the first time that an inorganic MS approach is employed for the simultaneous determination of ETU and PTU in foodstuffs. The method was validated using the accuracy profile methodology, which is one of the most robust approaches for this purpose. In this respect, the performance criteria in terms of limits of quantification (LOQ), accuracy, repeatability, and intermediate precision were assessed. The method was successfully applied to the analysis of a selection of real-life foodstuffs (fruits and vegetables) hence proving its full capacity to be applied to routine determination of ETU and PTU.

Material and methods

Instrumentation

An Agilent ICP-QQQMS 8900 (Agilent Technologies, Courtaboeuf, France) (referred here as ICP-MS/MS) was employed for the online detection of ETU and PTU after their separation by HPLC (Bio inert Infinity lab 1260 I, Agilent Technologies) using an Aqua C18 reverse phase (RP) column (3 µm × 125 Å × 150 mm × 2 mm purchased from Phenomenex, France).

The chromatographic signals were acquired in the time-resolved analysis (TRA) mode of the ICP-MS/MS software (MassHunter). The optimum analytical conditions for the HPLC-ICP-MS/MS method are provided in Table 1.

Reagents and standards

Analytical reagent grade pure chemicals and ultrapure water (18.2 MΩ cm) (Millipore Milli-Q™, Merck Millipore, Saint Quentin en Yvelines, France) were used throughout the study.

The standards of ETU (99.9%) and PTU (99%) were purchased from LGC Standards (Molsheim, France). (NH4)2SO4·10H2O (normapur), which was employed as a source of inorganic sulphur (SO42-), was purchased from VWR (Fontenay-sous-Bois, France).

Stock solutions (250 mg L−1) of ETU and PTU were prepared in methanol (MeOH) of HPLC grade from Sigma-Aldrich (Saint-Quentin-Fallavier, France) and stored at − 20 °C during 1-month maximum. Working standard solutions were prepared the day of experiments by subsequent dilutions of the stock solution using 5% (v/v) MeOH.

Ultrapure grade (99.9995%) argon and helium (collision gas) employed for ICP-MS/MS were supplied by Linde Gas (Montereau-Fault-Yonne, France).

A tuning multi-element solution (10 mg L−1, Agilent) was used to prepare a tuning solution containing lithium (Li), yttrium (Y), thallium (Tl), cobalt (Co), and cerium (Ce) at 1.0 ng mL−1 covering a wide range of the mass spectrum, including S.

For total S determination internal quality control, the CRM SPS-SW2 Batch 132 for measurement of elements in surface waters (Spectrapure Standards, Oslo, Norway) was analyzed daily.

Analytical procedures

Portions of 50 g of sample were accurately weighted (± 0.01 g) and fortified with standard mixtures containing ETU and PTU, at six different concentration levels. For each batch of samples, both reagent blanks and unfortified real-life fruit and vegetable samples were also included in the analysis being similarly processed as the fortified samples. The samples fully immersed in the extraction solvent were kept at room temperature for 30 min with manual shaking after each 5 min. The extracts were afterwards transferred in a 50-mL polypropylene tube, filtered by 0.22-µm PTFE syringe filters, and further transferred into an HPLC injection vial.

The calibration standard solutions were prepared in the same solvent as the sample extracts final composition.

The extracts were injected into the HPLC-ICP-MS/MS operated in optimized conditions given in Table 1 and the quantification for ETU and PTU was performed for the transitions acquired during analysis [32]S – [48]SO and [34]S – [50]SO using the external calibration approach. All results are expressed in mg kg−1 of wet weight (ww).

Results and discussion

Extraction

This study aimed on establishing the conditions to determine ETU and PTU as target analytes from fruits and vegetable samples as potentially degradation products generated by DTCs low stability, and therefore the extraction procedure applied for ETU and PTU determination was derived from conditions employed for DTCs extraction from fruit and vegetable samples [8]. DTCs are non-systemic fungicides, so their residues remain mostly on the surfaces of fruits and vegetables. Beside reported problems associated with their solubility, another specific aspect which influenced the extraction conditions in relation to DTCs low stability is the presence of plant matrix. Especially when coming into contact with acidic plant juices, DTCs rapidly degrade, since free dithiocarbamic acids are unstable and will decompose into carbon disulphide (CS2) and the respective amine, basically reversing the synthesis. There was therefore reported that homogenizing plant samples in order to effectively extract DTCs by the use of common organic solvents, as is standard procedure in pesticide-residue analyses, cannot be applied in this particular case [21,22,23,24].

As a consequence, a surface extraction procedure using 50 mL of 5% MeOH in MilliQ water (v/v) as extraction solvent was applied on whole fruit or vegetable samples such as strawberries, grapes, or cherry-tomatoes, as mentioned in the section above.

Optimization of the HPLC separation

In this study, both the baseline separation of ETU and PTU and their separation of inorganic sulphur (sulphate) which are commonly present in fruits and vegetables were considered. In this respect, the HPLC separation was optimized using a mixture of ETU, PTU, and inorganic sulphur as SO42−. In order to improve the HPLC separation, MeOH concentration in mobile phase was also optimized by testing out different concentrations, from 2% of MeOH (v/v) to 7% of MeOH (v/v). The analysis was carried out in duplicate.

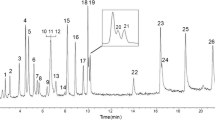

Figure 1 shows the chromatograms obtained for the separation of ETU, PTU, and SO42− using different MeOH concentrations in the mobile phase. Satisfactory baseline separation was achieved in all cases within ~ 5 min. To choose the optimum MeOH concentration, the retention time for each peak (tR), the peak intensities, and the intensity per noise ratio (S/N) were considered. These parameters are reported in Table 2. The best S/N for both ETU and PTU while analysis of ETU and PTU standard mixture at 50 µg L−1 was obtained when using 5% of MeOH (v/v) with 3.2 ± 0.03 for ETU and 2.4 ± 0.03 for PTU and for 6% of MeOH (v/v) with 3.3 ± 0.09 for ETU and 2.7 ± 0.17 for PTU. However, the use of concentrations of MeOH above 5% (v/v) led to a decrease of the species intensity (e.g., 7% MeOH, v/v) but caused also a plasma instability. Thus, a mobile phase consisting of 5% (v/v) of MeOH was chosen for further experiments.

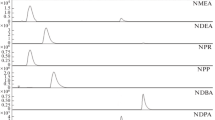

Optimization of the ICP-MS/MS detection in mass shift mode

In this study, O2 was used as reaction gas to oxidize the sulphur (32S → 32S16O) to avoid spectral interferences from 16O16O, 14N18O, and 15N16OH species as well as 48Ca, 48Ti, or 36Ar12C. Gas flow rate of O2 was optimized since it could have an impact on the global sensitivity. For this purpose, five levels were tested out from 10 to 50% by analysis of a standard mixture at 50 µg L−1 in duplicate. As can be seen in Fig. 2, 30% of O2 is the optimum to obtain the best intensities for both ETU and PTU.

Method validation by means of the accuracy profile approach

The method was validated using the approach of the accuracy profile according to the NF V03-110 (French) standard [25]. Basically, the accuracy profile is an expression of the systematic error (trueness) and the random error (repeatability and intermediate precision) for a series of analyte’s level determination in various matrices and within a range of concentrations called validity domain [26]. The trueness is expressed either through the bias in case of the analysis of certified reference materials (CRM) or by means of the spike recovery factor if CRM are not available (the case of our study). More details about this approach can be found in previous publications [27,28,29].

A preliminary step before the method validation by using the accuracy profile approach is the estimation of the method’s limits of quantification (LOQs), as generally the first level of the validity domain is the estimated LOQ or ½ LOQ. For this purpose, a number of 21 reagent blanks were analyzed during 3 different days to estimate the LOQ (10 × standard deviation of the blank). LOQ values were 6.0 µg L−1 for ETU and 10.1 µg L−1 for PTU, which corresponds to 0.006 mg kg−1 for ETU and 0.010 mg kg−1 for PTU, taking into account the sample mass (50 g) and the extract volume (50 mL). A chromatogram obtained for the analysis of a sample of tomatoes spiked with ETU and PTU at 20 µg.L-1 is shown in Fig. 3.

The accuracy profile was constructed by carrying out four measurement series in duplicate on different days over a timespan of 4 weeks using various genuine (non-spiked) and spiked real-life fruits matrices, such as tomatoes (levels 1 and 2), grapes (levels 3 and 4), and strawberries (levels 5 and 6). It is worth to note that the levels of ETU and PTU in the non-spiked samples were < LOQ in all cases.

The acceptability interval (λ) was set at 25% for ETU and PTU, while the tolerance interval (β-expectation interval) was set at 75–125% for ETU and PTU. The validity domain was set between 10 and 400 (10, 20, 50, 100, 200, and 400) µg L−1 for both ETU and PTU while the linear range comprised between 10 and 1000 µg L−1 (10, 25, 50, 75, 100, 250, 500, and 1000). The parameters characterizing the method development are listed in Table 3.

The accuracy profiles obtained for the validation of the determination of ETU and PTU by HPLC-ICP-MS/MS are shown in Fig. 4a and Fig. 4b, respectively. Each spiking level was tested for all matrices included in this study, namely tomatoes, grapes, and strawberries, and therefore the estimated method LOQ for each compound was not assessed separately for each tested matrix.

Accuracy profiles obtained for the determination of ETU (a) and PTU (b) in fruits and vegetables by HPLC-ICP-MS/MS (β = 85% in both cases while λ = 25%) at six levels: Li (i = 1–6) in µg L−1 (in the extract solution): L1 (tomatoes): 10; L2 (tomatoes): 20; L3 (grapes): 50; L4 (grapes): 100; L5 (strawberries): 200; L6 (strawberries): 400. Note: 1 + λ = upper acceptance limit and 1 − λ = lower acceptance limit; + β: upper tolerance limit; − β: lower tolerance limit

As can be seen in Fig. 4a, LOQ assessed for ETU determination using the accuracy profile, which corresponds to the intersection of the acceptability (λ) and the tolerance limits (β), was 21.4 μg L−1, which corresponds to 0.022 mg kg−1 (ww) taking into account 50 g of sample and 50 mL of the final extract. The accuracy for PTU was validated for the entire validity domain intended for validation, which means a LOQ of 10.0 μg L−1, corresponding to 0.010 mg kg−1 (ww). The PTU LOQ value corresponds to the minimum set levels for pesticides in such matrices by the current EU regulations [30, 31].

The spike recovery ranged from 87% (lowest level) to 101% (highest level) for ETU and from 98% (lowest level) to 99% (highest level) for PTU. The ETU and PTU levels measured in both reagent blanks and in the unfortified real-life fruit and vegetable samples were below the method LOQs. These very satisfactory recovery factors indicate the method applicability for the analysis of real samples.

For ETU, the coefficient of variation in terms of repeatability (CVr) ranged from 1 to 4.7%, while the coefficient of intermediate precision (CVR) varied from 3.4% (highest level) to 10% (for the second level which was validated). Similarly, for PTU, CVr ranged from 1.8% (highest level) to 3.9% (lowest level) and CVR from 1.8% (highest level) to 10.8% (lowest level). It can be noted that both the repeatability and the intermediate precision are slightly better for PTU compared to ETU.

The measurement expanded uncertainty (U) was calculated based on the maximum CVR (%) value (≅ 10% for ETU and ≅ 11% for PTU) and as it is known to be the most significant source of combined uncertainty (Eq. 1) [27]:

where

- k=2:

-

(p = 95%)

- C,:

-

measured concentration (mg kg−1); and

- N,:

-

number of independent measurement replicates.

It must be noted that CVR assessed based on the accuracy profile takes into account the intra- and inter-series variability [27].

These results are better or similar compared with studies using LC–MS/MS for ETU and PTU analysis in foodstuff. In fact, recoveries were reported from 64.9 to 89.8% for ETU and 70–127% for PTU; RSD repeatability from 3.8 to 9.9% for ETU and 5.13–33.8% for PTU; and RSD reproducibility from 7.25 to 14% for ETU and 12.7–36.2% for PTU [12]. Other studies reported 71–121% for ETU recoveries and < 20% in RSD repeatability [9] and 73 to 104% for ETU recoveries in water [10].

In another study, HPLC/diode array detection was used for ETU and PTU detection in strawberries and apples. Recoveries from 70.7 to 88.2% were obtained with 8.1% and 10.7% for repeatability and reproducibility RSDs respectively for ETU, while recoveries from 75 to 94.1% were obtained with 9.4% and 13.9% for repeatability and reproducibility RSDs respectively for PTU [11].

Conclusion

A rapid, robust, and accurate method for the determination of ETU and PTU in fruits and vegetables by HPLC-ICP-MS/MS was optimized and validated. Both ETU and PTU species were baseline separated in less than 5 min using a C18 reverse phase HPLC column.

The method was validated by means of the accuracy profile approach under conditions of intermediate reproducibility and excellent analytical parameters were obtained.

The novel analytical methodology reported in this work deals for the first time with the analysis of ETU and PTU from fruits and vegetables by liquid chromatography and inorganic tandem mass spectrometry for their detection. This opens the possibilities to apply alternative techniques and further extends the method capabilities for the determination of organic contaminants in foodstuffs.

References

John J. Brown, Handbook of Pesticide Toxicology, Vol. 1, 2, and 3. Am Entomol. 1991;37(4):244

Caballero B, Finglas P, Toldrá F. Encyclopedia of food and health. Elsevier Science; 2015. Disponible sur: https://books.google.fr/books?id=FdG2AQAACAAJ. Accessed 1 Aug 2023.

World Health Organization, International Programme on Chemical Safety & WHO Task Group on Environmental Health Criteria for Dithiocarbamate Pesticides, Ethylenethiourea and Propylenethiourea. Dithiocarbamate pesticides, ethylenethiourea, and propylenethiourea : a general introduction / published under the joint sponsorship of the United Nations Environment Programme, the International Labour Organisation, and the World Health Organization. World Health Organization. 1988. https://iris.who.int/handle/10665/39117

Chung SW, Wong WW. Chromatographic analysis of dithiocarbamate residues and their metabolites in foods employed in dietary exposure studies—a review. Food Addit Contam Part A. 2022;39(10):1731–43.

WHO recommended classification of pesticides by hazard and guidelines to classification, 2019 edition. Geneva: World Health Organization; 2020. Licence: CC BY-NC-SA 3.0 IGO

Stadler K, Li X, Liu B, Bao W, Wang K, Lehmler HJ. Systematic review of human biomonitoring studies of ethylenethiourea, a urinary biomarker for exposure to dithiocarbamate fungicides. Environ Pollut. 2022;292:118419.

Li Y, Wang X, McKenzie JF, Mannetje A’ t, Cheng S, He C, et al. Pesticide exposure in New Zealand school-aged children: urinary concentrations of biomarkers and assessment of determinants. Environ Int. 2022;163:107206.

Crnogorac G, Schwack W. Residue analysis of dithiocarbamate fungicides. TrAC Trends Anal Chem. 2009;28(1):40–50.

Tran K, Mactal LP, Cromer MR, Vocque RH, Smith RE. Development and validation of ethylenethiourea determination in foods using methanol-based extraction, solid-phase extraction cleanup and LC–MS/MS. Food Chem. 2013;140(1):340–2.

Ripollés C, Sancho JV, López FJ, Hernández F. Liquid chromatography coupled to tandem mass spectrometry for the residue determination of ethylenethiourea (ETU) and propylenethiourea (PTU) in water. J Chromatogr A. 2012;1243:53–61.

López-Fernández O, Rial-Otero R, Cid A, Simal-Gándara J. Combined determination and confirmation of ethylenethiourea and propylenethiourea residues in fruits at low levels of detection. Food Chem. 2014;145:1002–10.

Bonnechère A, Hanot V, Van Loco J. A rapid and environmental friendly determination of the dithiocarbamate metabolites ethylenethiourea and propylenethiourea in fruit and vegetables by ultra high performance liquid chromatography tandem mass spectrometry. J Chromatogr A. 2011;1218(29):4627–31.

Lemes VRR, Martins-Júnior HA, de Souza SVC, Colacioppo S. Ethylenethiourea in fruits: optimization and in-house validation of a method by liquid chromatography tandem mass spectrometry, occurrence and dietary exposure assessment. Food Control. 2014;42:321–8.

Giner Martínez-Sierra J, Galilea San Blas O, MarchanteGayón JM, García Alonso JI. Sulfur analysis by inductively coupled plasma-mass spectrometry: a review. Spectrochim Acta Part B At Spectrosc. 2015;108:35–52.

Lajin B, Braeuer S, Goessler W. Parallel and comparative non-targeted metabolomic speciation analysis of metalloids and their non-metal analogues by HPLC-ICPMS/MS in mushrooms. Metallomics. 2021;13(8):mfab047.

Lajin B, Goessler W. Exploring the sulfur species in wine by HPLC-ICPMS/MS. Anal Chim Acta. 2019;1092:1–8.

Christopher SJ, Ellisor DL, Davis WC. Investigating the feasibility of ICP-MS/MS for differentiating NIST salmon reference materials through determination of Sr and S isotope ratios. Talanta. 2021;231:122363.

Balcaen L, Woods G, Resano M, Vanhaecke F. Accurate determination of S in organic matrices using isotope dilution ICP-MS/MS. J Anal At Spectrom. 2013;28(1):33–9.

Raab A, Ronzan M, Feldmann J. Sulphur fertilization influences the sulphur species composition in Allium sativum: sulphomics using HPLC-ICPMS/MS-ESI-MS/MS†. Metallomics. 2017;9(10):1429–38.

Amais RS, Long SE, Nóbrega JA, Christopher SJ. Determination of trace sulfur in biodiesel and diesel standard reference materials by isotope dilution sector field inductively coupled plasma mass spectrometry. Anal Chim Acta. 2014;806:91–6.

Greulich K, Alder L. Fast multiresidue screening of 300 pesticides in water for human consumption by LC-MS/MS. Anal Bioanal Chem. 2008;391:183–97.

Alder L, Greulich K, Kempe G, Vieth B. Residue analysis of 500 high priority pesticides: better by GC–MS or LC–MS/MS? Mass Spectrom Rev. 2006;25(6):838–65.

Payá P, Anastassiades M, Mack D, Sigalova I, Tasdelen B, Oliva J, et al. Analysis of pesticide residues using the Quick Easy Cheap Effective Rugged and Safe (QuEChERS) pesticide multiresidue method in combination with gas and liquid chromatography and tandem mass spectrometric detection. Anal Bioanal Chem. 2007;389:1697–714.

Pang GF, Fan CL, Liu YM, Cao YZ, Zhang JJ, Li XM, et al. Determination of residues of 446 pesticides in fruits and vegetables by three-cartridge solid-phase extractiongas chromatography-mass spectrometry and liquid chromatography-tandem mass spectrometry. J AOAC Int. 2006;89(3):740–71.

AFNOR. Analyse des produits agricoles et alimentaires - Protocole de caractérisation en vue de la validation d’une méthode d’analyse quantitative par construction du profil d’exactitude. 2010. Disponible sur: https://www.boutique.afnor.org/fr-fr/norme/nf-v03110/analyse-des-produits-agricoles-et-alimentaires-protocole-de-caracterisation/fa159944/35346#AreasStoreProductsSummaryView. Accessed 1 Aug 2023.

Mermet J, Granier G. Potential of accuracy profile for method validation in inductively coupled plasma spectrochemistry. Spectrochim Acta Part B At Spectrosc. 2012;76:214–20.

Ghosn M, Chekri R, Mahfouz C, Khalaf G, Guérin T, Amara R, et al. Toward a routine methodology for speciation analysis of methylmercury in fishery products by HPLC coupled to ICP-MS following the validation based on the accuracy profile approach. Int J Environ Anal Chem. 2022;102(14):3343–56.

Ghosn M, Mahfouz C, Chekri R, Ouddane B, Khalaf G, Guérin T, et al. Assessment of trace element contamination and bioaccumulation in algae (Ulva lactuca), bivalves (Spondylus spinosus) and shrimps (Marsupenaeus japonicus) from the Lebanese coast. Reg Stud Mar Sci. 2020;39: 101478.

Ribeiro M, Zephyr N, Silva J, Danion M, Guérin T, Castanheira I, et al. Assessment of the mercury-selenium antagonism in rainbow trout fish. Chemosphere. 2022;286: 131749.

Medina-Pastor P, Triacchini G, European Food Safety Authority (EFSA). The 2018 European Union report on pesticide residues in food. EFSA J. 2020;18(4):e06057.

Anastassiades M, Kolberg DI, Benkenstein A, Eichhorn E, Zechmann S, Mack D, Barth A. Quick method for the analysis of numerous highly polar pesticides in foods of plant origin via LC-MS/MS involving simultaneous extraction with methanol (QuPPe-method). EU reference laboratory for pesticides requiring single residue methods (EURL-SRM). CVUA, Stuttgart, Germany. 2015.

Funding

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under the Marie Sklodowska-Curie Grant Agreement No. 753053.

Author information

Authors and Affiliations

Contributions

Ibtihel BenDhiab: data curation, formal analysis, investigation, methodology, validation, roles/writing—original, writing—review and editing. Alin C. Dirtu: conceptualization, data curation, formal analysis, funding acquisition, investigation, investigation, methodology, validation, writing—review and editing. Nathalie Marchond: formal analysis, methodology; thierry guérin: resources, writing—review and editing. Petru Jitaru: conceptualization, data curation, funding acquisition, investigation, methodology, project administration, resources, supervision, validation, roles/writing—original draft, writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bendhiab, I., Dirtu, A.C., Marchond, N. et al. A novel analytical approach for the determination of ethylene-thiourea and propylene-thiourea in vegetal foodstuffs by high-performance liquid chromatography hyphenated to inductively coupled plasma-tandem mass spectrometry. Anal Bioanal Chem 416, 431–438 (2024). https://doi.org/10.1007/s00216-023-05034-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-023-05034-6