Abstract

The paper focuses on the economic design of group chain sampling plans (GChSP) for the Weibull distribution using Bayesian methodology. The GChSP is a technique to accept or reject a product based on a sample from a lot. The study addresses situations where destructive testing is costly and utilizes the Bayesian approach to make informed decisions. The research outlines the methodology of developing GChSP including the stages of construction, performance evaluation, and cost estimation. The study compares the proposed plans with an existing one and demonstrates that the Bayesian approach generally yields lower costs. We will provide tables, figures, and calculations related to various aspects of the proposed plans and their comparison with existing methods.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

As stated by Balakrishnan et al. [2] the significance of quality has evolved from being a mere option or aspiration for companies to become an essential requirement in the global business landscape. Quality now serves as a pivotal factor distinguishing competitive enterprises. Within this context, two pivotal methodologies for ensuring quality are statistical quality control and acceptance sampling. Acceptance sampling, a prevalent technique within statistical quality control, involves inspecting a sample of products to make a determination of acceptance or rejection. This method was originally introduced by Dodge and Romig during World War II for testing bullets, as referenced in Schilling and Neubauer [1]. The rationale behind acceptance sampling is rooted in the understanding that subjecting every individual bullet to testing is both impractical due to destructiveness and time constraints, and refraining from testing any bullet poses substantial risks, potentially leading to accidents. The cornerstone of global industrial manufacturing lies in quality assurance. Within the framework of acceptance sampling, a random sample is extracted from a larger batch, and the decision to accept or reject the entire batch hinges upon the insights gleaned from this sample. It's important to note that while acceptance sampling is a quality control technique facilitating batch-level acceptance or rejection, it doesn't inherently provide a direct means of estimating the overall quality of the entire batch.

Dodge [6] proposed a chain sampling plan that utilizes historical lot data. Dodge and Stephan [7] proposed two-stage chain sampling, proceeds into two steps. The basic feature was the utilization of cumulative results, where the cumulative criteria are based on two acceptance numbers \({c}_{1}=0,{c}_{2}=1\) into two stages. Additionally, the concept of grouping in sampling plans is introduced, aiming to enhance efficiency by enabling the simultaneous testing of multiple items. Building on this, Mughal et al. [12] introduced a group chain acceptance sampling plan based on the second kind of Pareto distribution, incorporating a minimum sample size and a lot acceptance probability determined by meeting consumer risk criteria. Extending this work, Mughal [21] presented a range of group chain acceptance sampling plans founded on truncated life tests.

Various forms of acceptance sampling techniques have been extensively documented in the literature. These techniques serve a central purpose: determining whether submitted products should be accepted or rejected. The ordinary scheme comes into play when an experimenter is only capable of inspecting one product at a time. In such a scenario, the products submitted for testing are grouped together, forming the basis for a group acceptance sampling plan. This approach is operationalized as follows: a sample \(\left(\text{n=rg}\right)\) is drawn from the lot size, \(N\), with the sample size, \(n\), being a multiple of both the number of testers, \(r\), and the number of groups, \(g\). The submitted products are deemed acceptable for consumer use if the number of defective items found in the acceptable quantity, denoted as c, and does not exceed a certain threshold. For instance, if an experimenter aims to test 10 products, they would employ 10 testers to handle these products individually. Conversely, group acceptance sampling plans are enacted when the experimenter has the capacity to assess multiple products simultaneously. This approach offers advantages in terms of time and cost efficiency. In the case of testing 10 products as a group, the experimenter can employ 5 testers, thus requiring 2 groups for testing. Notably, the group acceptance sampling plan also ensures rigorous inspection prior to products being cleared for consumer use. Aslam et al. [3] investigated and demonstrated the efficacy of this group sampling plan, highlighting its superiority over established plans in terms of achieving the minimum required sample size. Aslam et al. [30] used the Pareto distribution of the second kind as lifetime distribution and through results they proved that their proposed plan provides better results than Aslam and Jun [20] plan based on Weibull distribution. In their plan, the minimum sample size was determined and L(P) was determined by different ratios of true mean life to the specified mean life and it was proven that the established plan reduced the cost and time of the experiments. Mughal et al. [13] developed a group acceptance sampling plan tailored for Pareto distribution of the 2nd kind using two-sided chain sampling. Mughal et al. [14] extended this work by proposing a generalized group chain acceptance sampling plan based on truncated life tests. Additionally, Aziz et al. [5] introduced a generalized modified group chain sampling plan that takes into account non-symmetrical data distributions.

Addressing economic aspects, Hsu [8] outlined the economic design of a single acceptance sampling plan, while Aslam et al. [19] adopted a Bayesian approach with Weibull distribution to propose an economic design for a group sampling plan. Hafeez and Aziz [27] proposed a Bayesian Group Chain Sampling Plan Based on Beta Binomial Distribution through Quality Region. They introduced BGChSP by considering beta as prior distribution and considering the producer’s as well as consumer’s risk. They utilized BGChSP for the Quality Region for the specified AQL and LQL. Latha and Suresh [24] explored construction and performance measures through a Bayesian chain sampling scheme employing a gamma prior. Belbachir & Benahmed [35] developed a two-sided sampling plan for exponential distribution under type II censored samples in which an exponential distribution single variable sampling strategy is based on type II censored samples and a random decision function. Furthermore, The Bayesian Sampling Plan was applied by Belbachir and Benahmed [36] for the Weibull Distribution with Type II Hybrid Censoring under Random Decision Function.

M. Hafeez et al. [22] devised a group chain sampling plan for quality regions. Tanveer and Khattak [25] introduced economical group and modified group chain sampling plans applicable to the Weibull distribution. Hafeez et al. [31] suggested a Bayesian group chain sampling scheme in which the Gamma distribution is utilized as a prior distribution with the Poisson distribution. In Hafeez et al. [32] proposed Bayesian Two-sided GChSP for Poisson distribution with Gamma prior. Hafeez et al. [29] proposed a Bayesian new two-sided group chain sampling plan for quality regions based on beta as prior distribution.

Despite the existing literature, no prior work has ventured into an economic model for a group chain sampling plan utilizing the Bayesian approach with the Weibull distribution. The primary objective of this study is to present an economic model for such a group chain sampling plan, employing the Bayesian methodology. The overall cost is estimated using the economic model proposed by Aslam et al. [19] for the group sampling plan. This research outlines the phases involved in developing and accessing the performance of the economic model for the group chain sampling plan (GChSP) using the Bayesian approach. In the initial phase, the complete procedure of the group chain sampling plan (GChSP) is elucidated. The subsequent phase focuses on constructing the economic design for group chain acceptance sampling. Finally, the last phase involves developing the economic model for the group chain sampling plan using the Bayesian approach.

2 Methodology

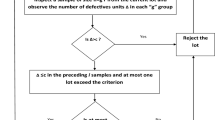

As mentioned earlier, in the group acceptance sampling plan, the sample size n is distributed to \(g\) groups and \(r\) items. Such that \(r\) items are put into \(g\) groups and tested simultaneously on each different tester for a pre-assigned time \(a\). The lot is accepted if the number of failures in the sample is smaller than the acceptance number c, otherwise, reject it. Also, the lot will be considered good quality if the average mean life (\(\mu\)) of a product is greater than the specified mean life (\({\mu }_{0}\)). The main purpose is to achieve the maximum acceptance probability with a minimum sample size. This acceptance sampling plan is the extension of the work of Dodge [6] the probability of lot acceptance for the group chain sampling plan (GChSP) can be derived by using acceptance sampling procedures shown in Table 1 and in Fig. 1.

Mughal et al. [12] introduced a truncated version of the GChSP specifically tailored for the Pareto distribution of the second kind. The cumulative distribution function (CDF) of the Weibull distribution is as follows:

Furthermore, the average value of the Weibull distribution is given by

where \(\mu\), the mean of Weibull distribution is based on the m scale and λ shape parameters.

In this acceptance sampling strategy, various design parameters are analysed to ensure that the average lifespan (\(\mu\)) of a product is greater than a specified life value (\({\mu }_{0}\)). We consider a product as acceptable if its average lifespan \(\mu \ge {\mu }_{0}\), under predetermined design parameters, using the minimal sample size values (\(n=r*g\)). Our primary focus is on the consumer, so we adopt a one-point approach to construct the operating characteristic (OC) curve. The process of determining the required sample size and the sampling plan involves solving an inequality while considering different values of \(\beta\). Specifically, we aim for the condition \(L\left(p\right)\le\upbeta\) to hold, where \(L\left(p\right)\) represents the lot acceptance probability for the GChSP. This is achieved through a systematic evaluation of various values, ensuring that the product consistently meets quality standards. The OC function of the group Chain Sampling plan is given by

Upon examining the general expression of \(L\left(p\right)\) in Eq. (3), it becomes evident that the binomial distribution is the suitable choice for handling scenarios involving zero and one defective item. After simplifying \(L\left(p\right)\) for GChSP, we obtain the following result:

where p is the probability of failure of the product during the test termination time \({t}_{0}\),which is the multiple of the specified mean life \({\mu }_{0}\) as \({t}_{0}=a{\mu }_{0}.\)

It is important to emphasize that \(L(p)\) and \(p\) can be easily calculated for the group chain sampling plan by utilizing predefined values of,\(r\), \(i\) and\(\mu /{ \mu }_{0}\). Various parameters are set for the acceptance sampling plan, including consumer's risk\((\beta )\), pre-specified termination ratio\((a)\), the number of testers\((r)\), and the number of preceding lots\((i)\). The next step is to find the minimum number of groups for sampling plans by satisfying the inequality as

In this approach, recommended plan combinations are developed based on predefined design parameter values provided in Table 2. This methodology has also been utilized in prior studies by Mughal et al. [11], Mughal and Aslam [10], and Aslam et al. [4]. The primary focus here is on consumer risk at various levels of\(\beta\),\(a\),\(r\), and\(i\), all of which are used to determine the number of groups. For a shape parameter of \(m\)=2 in the Weibull distribution, Table 3 displays the optimal number of groups. It's noteworthy that the number of groups decreases as the\(a\),\(r\), and \(i\) increase. Once the optimal number of groups is determined using the predefined design parameters, the next step is to assess the lot acceptance probability for the desired design parameters across various mean ratio values (1, 2, 4, 6, 8, and 10). Specifically, when considering \(r\)=3 and \(i\)=2, Table 4 presents the lot acceptance probability for a shape parameter of \(m\)=2. It is evident that for \(m\)=2, under the same design parameters such as \(r\)=3, \(i\)=2, \(\beta\)=0.01, \(a\)=1.0, and \(g\)=2, the lot acceptance probability increases rapidly from 0.00898 to 0.9975 as the mean ratio is raised from 1 to 12. With the data derived from the Group Chain Sampling Plan (GChSP), which includes values like,\(r\),\(i\), and\(L(p)\), it becomes invaluable in determining the design parameters for the economic model. The mathematical structure of this model, designed to minimize the overall cost for the GChSP, takes the following form

In the context of Eq. (7), the symbols hold distinct meanings: \({C}_{i}\) denotes the inspection cost per item, \({C}_{f}\) represents the cost associated with internal failures, \({C}_{0}\) encompass the cost linked to outgoing defectives, and \({C}_{g}\) signify the cost per group, as elucidated in Hsu [8].

where

When considering specific values for the\(r\),\(i\),\(a\), the total required cost is calculated. Additionally, the optimal parameter for the economic model of the GChSP plan is determined using the Weibull distribution with a shape parameter of \(m\)=2, as indicated in Table 5. To account for stochastic variability, the Bayesian technique becomes essential for establishing the defect distribution from one lot to another. The prior distribution represents the expected quality distribution of a lot before undergoing inspection. This distribution is termed "prior" because it is formulated prior to the sample collection process. As demonstrated by Aslam [19], the Bayesian approach was employed to estimate the value of \(p\) for the group acceptance sampling plan. Within the Bayesian framework, the prior distribution of \(p\) is assumed to follow a beta distribution characterized by parameters \(\delta\) and\(\tau\), both of which are greater than 0. The probability density function (PDF) governing the beta distribution is given by:

In order to calculate the average cost for lots of size N with x defectives, Hald [33] used the Bayesian approach and suggested using the prior distribution according to the percent defective \(p\) that will be the beta distribution. Wetherill [34] utilized the Bayesian approach of designing a sampling plan. To assess the costs and losses involved in operating the plan he tried to minimize the total costs by multiplying with prior distribution. By considering the Hald [33] in which the average cost function is multiplied with prior distribution the Eq. 8 through Eq. 11, incorporating a mixture of beta distribution, can be reformulated as follows:

Now, Average total inspection (ATI) and Average outgoing quality AOQ is:

We have investigated various pairs of hyper-parameter values in the proposed model, ranging from (1, 1) to (3, 3). Amongst these pairs, (1, 3) consistently yield the lowest cost compared to others. Consequently, for the sake of simplification, we have chosen to employ the hyper-parameter values \(\delta\)=1 and \(\tau\)=3. The outcomes of the mixture with the beta distribution are as follows:

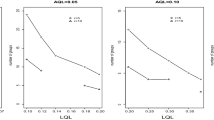

The Bayesian approach is employed to determine the optimal parameter of the economic model for the GChSP plan, using the Weibull distribution with a shape parameter of \(m\)=2 as outlined in Table 6. For \(m\)=2 and \(\beta\)=0.01, the total cost is 1276.850 when \({\prime}a{\prime}\) is 0.7 (Fig. 2). However, this cost decreases from 1276.850 to 854.850 as \({\prime}a{\prime}\) increases from 0.7 to 2.0, as illustrated in Fig. 3. Optimal parameter of the economic model for the GChSP with shape parameter \(m=2\) and \(\beta\)=0.01, the total cost is 1638.043 when \(a\) is 0.7, and it rises from 1638.043 to 2916.429 as \(a\) increases from 0.7 to 2.0, as depicted in Fig. 2.

The process for optimizing the group size and inspection cost is outlined through the following steps:

-

Step #1: We initiate by deriving the OC function, denoted as \(L(p)\), and proceed to determine the minimum group size \((g)\). This is accomplished by satisfying the inequality \(L(p) \le \beta\) across various levels of β defined as per Eq. (6).

-

Step #2: Utilizing the optimization function incorporated within the cost model, we ascertain the inspection cost as detailed in Eq. (7). We further identify the optimal parameters (ATI, Dd, Dn, and AOQ) for the cost model, as explained in Eq. (8–11).

-

Step #3: We proceed to design the plan by employing a Bayesian approach, specifically to estimate the parameter \(p\). In this context, the prior distribution of \(p\) conforms to a beta distribution, as described in Eq. (12).

-

Step #4: To refine our approach, we multiply and integrate the optimal parameters (ATI, Dd, Dn, and AOQ) of the cost model using the Bayesian approach in conjunction with the prior distribution, as elaborated in Eq. (13–16).

-

Step #5: Following simplification, we arrive at the desired parameters of the cost model, as specified in Eq. (17–20). These parameters enable us to determine the minimum total cost through the Bayesian approach for GChSP.

3 Comparison of Proposed Plans

A comparison is conducted between the total costs of Group Chain Sampling plans with and without the Bayesian approach. Furthermore, the results are also juxtaposed with the total cost of the established plan by Aslam et al. [19]. These comparisons are based on data derived from the number of million revolutions before the failure of 23 ball bearings in the truncated life tests previously discussed by Rao and Ramesh [18], as presented in Table 7. The suitability of the data distribution in Table 7 is determined using the Kolmogorov–Smirnov (K-S) goodness of fit test. The K-S statistic for the Weibull distribution is found to be 0.2202, compared to a tabulated value of 0.3295 at a 1% level of significance. Given the smaller K-statistic compared to other tabulated values, it is evident that the Weibull distribution offers the best fit for the submitted product's lifetime data. Considering the aforementioned design parameters (\(\beta\)=0.10, \(r\)=3, \(i\)=2, and \(i=j=1\)), the total cost of Group Chain Sampling plans is compared with the established plan by Aslam et al. [19], as detailed in Table 8. From Table 8, it can be observed that the total cost fluctuates with changes in the sample size \((n=r*g)\), both increasing and decreasing. For all sample sizes, the Bayesian approach consistently yields the lowest cost, proving to be more cost-effective in terms of total expenditure for both sampling plans. Horizontally across the tables, it is evident that the Bayesian approach consistently results in the lowest total cost compared to the economic model and the previously proposed plan by Aslam et al. [19]. The impact of termination time \({\prime}a{\prime}\) in Group Chain Sampling plans on the total cost, while maintaining the aforementioned design parameters (\(\beta =0.10, r=3, i=2\), and \(i=j=1\)), is presented in Table 9. The economic model for Group Chain Sampling plans shows that the total cost increases with an extended termination time \({\prime}a{\prime}\). In contrast, the economic model using the Bayesian approach demonstrates that the total cost remains unaffected by the termination time \({\prime}a{\prime}\) due to the incorporation of prior information. Clearly, the Bayesian approach consistently offers the lowest cost compared to the economic model and the existing plan developed by Aslam et al. [19]. This proposed plan effectively utilizes maximum information about the lot, combining current experimental data with past knowledge, referred to as prior information, to minimize the total cost (Fig. 4).

4 Concluding Remarks

In conclusion, this study has contributed significantly to the field of quality control and acceptance sampling, particularly in the context of group chain sampling plans (GChSP) for the Weibull distribution. The integration of Bayesian methodology into the economic design of GChSP has proven to be a valuable approach for making informed decisions while optimizing cost-efficiency. Through a meticulous exploration of various design parameters, such as consumer's risk, termination time, number of testers, and preceding lots, this research has provided a comprehensive framework for developing and evaluating GChSP. The proposed economic model, which considers inspection costs, internal failures, outgoing defectives, and group costs, is a practical tool for industries seeking to enhance their quality control processes. The comparison of the Bayesian approach with existing methods has demonstrated its superiority in terms of minimizing total costs, thus making it a compelling choice for organizations aiming to maintain high-quality standards while optimizing resource allocation. This study has filled a significant gap in the literature by offering a comprehensive economic model for GChSP with Weibull distribution, further emphasizing the importance of Bayesian techniques in modern quality management. Overall, the findings of this research provide valuable insights for practitioners and researchers alike, offering a robust foundation for the implementation of cost-effective group chain sampling plans in various industries, ultimately contributing to improved product quality and customer satisfaction.

Data Availability

The data is given in the paper.

References

Schilling, E.G., Neubauer, D.V.: Acceptance sampling in quality control. CRC Press, Taylor & Francis Group, New York, USA. (2009). https://doi.org/10.1201/9781584889533

Balakrishnan, N., Leiva, V., Lopez, J.: Acceptance sampling plans from truncated life tests based on the generalized Brinbaum-Saunders distribution. Commun. Stat.-Simul. Comput. 36(3), 643–656 (2007)

Aslam, M., Mughal, A.R., Ahmed, M., Yab, Z.: Group acceptance sampling plan for Pareto distribution of the second kind. J. Test. Eval. 38(2), 1–8 (2009)

Aslam, M., Mughal, A.R., Hanif, M., Ahmad, M.: Economic reliability group acceptance sampling based on truncated life tests using Pareto distribution of the second kind. Commun Stat. Appl. Methods 17(5), 725–731 (2010)

Aziz, N., Mughal, A.R., Zain, Z., Haron, N.H.: Generalized modified group chain sampling plan based on non-symmetrical data. Int. J. Supply Chain Manag. 6(4), 241–245 (2017)

Dodge, H.F.: Chain sampling inspection plan. Ind. Qual. Control 11, 10–13 (1955)

Dodge, H.F., Stephens, K.S.: A general family of chain sampling inspection plans. Rutgers University Statistics Center, Technical Report No. N-20 (1964)

Hsu, J.T.: Economic design of single sample acceptance sampling plans. J. Hungkuang Univ. 56, 108–122 (2009)

Hsu, L.F., Hsu, J.T.: Economical design of acceptance sampling plans in a two-stage supply chain. Adv. Decis. Sci. 2012, 14 (2012). https://doi.org/10.1155/2012/359082

Mughal, A.R., Aslam, M.: Efficient group acceptance sampling plans for family Pareto distribution. Cont. J. Appl. Sci. 6(3), 40–52 (2011)

Mughal, A.R., Zain, Z., Aziz, N.: Economic reliability GASP for Pareto distribution of the 2nd kind using Poisson and weighted Poisson distribution. Rec. J. Appl. Sci. 10(8), 306–310 (2015)

Mughal, A.R., Zain, Z., Aziz, N.: Time truncated generalized chain sampling plan for pareto distribution of the 2nd kind. Res. J. Appl. Sci. Eng. Technol. 11(3), 343–346 (2015)

Mughal, A.R., Zain, Z., Aziz, N.: Group acceptance sampling plan for pareto distribution of the 2nd kind using two-sided chain sampling. Int. J. Appl. Eng. Res. 16(10), 37240–37242 (2015)

Mughal, A.R., Zain, Z., Aziz, N.: Generalized group chain acceptance sampling plan based on truncated life test. Res. J Appl. Sci. 11(12), 1470–1472 (2016)

Teh, M.A.P., Aziz, N., Zain, Z.: Modified group chain acceptance sampling plans (MGChSP) based on the minimum angle method. Int. J. Supply Chain Manag. 8(5), 1087–1094 (2019)

Teh, M.A.P., Aziz, N., Zain, Z.: Group chain acceptance sampling plans for truncated life test by using the minimum angle method. In AIP Conf. Proc. 2184(1), 050011 (2019). (AIP Publishing LLC)

Pawan Teh, M.A., Aziz, N., Zain, Z.: A new method in designing group chain acceptance sampling plans (GChSP) for generalized exponential distribution. Int. J. Qual. Reliab. Manag. 38(5), 1116–1129 (2021)

Srinivasa Rao, G., Ramesh Naidu, C.: Group acceptance sampling plans for resubmitted lots under exponentiated half logistic distribution. J. Ind. Prod. Eng. 33(2), 114–122 (2016)

Aslam, M., Azam, M., Balamurali, S., Jun, C.H.: An economic design of a group sampling plan for a Weibull distribution using a Bayesian approach. J. Test. Eval. 43(6), 1497–1503 (2014)

Aslam, M., Jun, C.H.: A group acceptance sampling plan for truncated life test having Weibull distribution. J. Appl. Stat. 36(9), 1021–1027 (2009)

Razzaque, A.B.D.U.R.: A family of group chain acceptance sampling plans based on truncated life test (Doctoral dissertation, PhD. thesis, Universiti Utara Malaysia) (2018)

Hafeez, W., Aziz, N., Zain, Z., Kamarudin, N.A.: Designing Bayesian new gr- oup chain sampling plan for quality regions. CMC-Comput. Mater. Continua 70(2), 4185–4198 (2022)

Fallahnezhad, M.S., Aslam, M.: A new economical design of acceptance sam- ling models using Bayesian inference. Accred. Qual. Assur. 18, 187–195 (2013)

Latha, M., Suresh, K.K.: Construction and evaluation of performance measures for Bayesian chain sampling plan (BChSP-1). For East J. Theor. Stat. 6(2), 129–139 (2002)

Tanveer, K., Khattak, Y.A.: Economical group and modified group chain sampling plans for weibull distribution. J. Stat. 26, 54–64 (2022)

Razzaque Mughal, A., Zain, Z., Aziz, N.: Time truncated group chain sampling strategy for Pareto distribution of the 2nd kind. Res. J. Appl. Sci. Eng. Technol. 10(4), 471–474 (2015)

Hafeez, W., Aziz, N.: Bayesian group chain sampling plan based on beta binomial distribution through quality region. Int. J. Supply Chain Manag. 8(6), 1175–1180 (2019)

Latha, M., Arivazhagan, R.: Selection of Bayesian double sampling plan based on beta prior distribution index through quality region. Int. J. Recent Sci. Res. 6(5), 4328–4333 (2015)

Hafeez, W., Aziz, N., Du, J.: Designing Bayesian new two-sided group chain sampling plan for quality regions based on beta prior. Qual. Reliab. Eng. Int. 39(6), 2215–2229 (2023)

Aslam, M., Mughal, A.R., Ahmed, M., Zafar, Y.: Group acceptance sampling plan Pareto distribution of the second kind. J. Test. Eval. 38(2), 1–8 (2010)

Hafeez, W., Aziz, N., Zain, Z., Kamarudin, N.A.: Bayesian Group Chain Sampling Plan for Poisson Distribution with Gamma Prior. Computers, Materials & Continua, 70(2) (2022). https://doi.org/10.32604/cmc.2022.019695

Hafeez, W., Aziz, N.: Bayesian two-sided complete group chain sampling plan for poisson distribution with gamma prior. Sains Malaysiana 51(6), 1915–1926 (2022)

Hald, A.: Bayesian single sampling attribute plans for discrete prior distributions. Mat. Fys. Skr. Dan. Vid. Selsk. 3, 1–88 (1965)

Wetherill, G.B., Chiu, W.K.: A review of acceptance sampling schemes with emphasis on the economic aspect. Int. Stat. Rev./Rev. Int. Stat. 43(2), 191–210 (1975)

Belbachir, H., Benahmed, M.: Two-sided sampling plan for exponential distribution under type II censored samples. Hacet. J. Math. Stat. 51(1), 327–337 (2022)

Belbachir, H., Benahmed, M.: “Bayesian sampling plan for Weibull distribution with type ii hybrid censoring under random decision function”: Accepted: August 2022. REVSTAT-Stat. J. (2022). file:///C:/Users/hp/Downloads/FP_REVSTAT2022_aug1%20(2).pdf

Acknowledgements

We are deeply thankful to the editor and reviewers for their valuable suggestions to improve the quality and presentation of the paper.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

K.T, A.R.M, I.S, M.A.B and M.A wrote the paper.

Corresponding author

Ethics declarations

Competing Interests

No conflict of interest regarding the paper.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tanveer, K., Mughal, A.R., Shahzadi, I. et al. Economical Group Chain Sampling Plans for Weibull Distribution Using Bayesian Approach. J Stat Theory Appl 23, 129–144 (2024). https://doi.org/10.1007/s44199-024-00075-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s44199-024-00075-x