Abstract

This paper develops a modified chain group acceptance sampling inspection plan (MChGSIP) for inverse log-logistic distribution with known shape parameter when the life test is truncated at a pre-assumed time. The proposed modified sampling plan requires a smaller sample size than the commonly used sampling inspection plan, such as group acceptance sampling inspection plan (GSIP) and in particular single acceptance sampling inspection plan (SSIP). The values of the minimum number of groups with fixed group size and operating characteristic function for various quality levels are obtained and presented in tabular form for the proposed plan. A comparative study has been done for the MChGSIP, GSIP and SSIP. Illustrate the performance of the proposed plan by means of four real data sets and results show that the MChGSIP has better performance as compared to GSIP and SSIP in terms of the number of minimum groups, the probability of lot acceptance, the cost and the inspection time.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

An extremely important aspect of a product is its quality. On the basis of lot quality, one may take a decision to accept or reject the lot. Often 100% inspection of the lot is not feasible due to time, cost, risk, etc. Sometimes, testing is destructive and expensive, so it would be better to inspect the sample taken from the lot and make a decision whether to accept or reject the lot on the basis of quality of the considered sample of that submitted lot. Acceptance sampling inspection plan (ASIP) was developed in the 1930s for inspection of incoming lot [see, Dodge and Roming (1941)]. The main aim of using ASIP was to reduce the cost of inspection, time of experiment and to provide protection to the producer as well as the consumer. ASIP may be classified in two broad areas, viz., ASIP by attributes and by variables. In literature, many attributes sampling inspection plans are available viz., single acceptance sampling inspection plan (SSIP), double acceptance sampling inspection plan (DSIP), group acceptance sampling inspection plan (GSIP), sequential acceptance sampling inspection plan (SeSIP), multiple acceptance sampling inspection plan (MSIP) etc., where the measurements of the quality characteristics are classified as conforming (or non-defective) or non-conforming (or defective), while variable sampling plans uses the accurate measurements of the quality characteristics. For details of the ASIPs, readers may refer to Montgomery (2009). Both types of ASIPs are used for judging a lot based on the sample selected from the lot. The parameters in ASIPs are called plan parameters which are determined with the help of two point approaches: acceptable quality level (AQL) and limiting quality level (LQL), where the lot quality is measured either by lot fraction defective or by lot mean.

2 Related work

In recent years, GSIP and in particular SSIP are frequently used by several researchers for various probability models using time truncated life test. Notable among them are: Aslam et al. (2009), Aslam and Jun (2009), Aslam et al. (2011) for gamma, Weibull and Birnbaum Saunders distributions, respectively. Rao (2011) and Tripathi et al. (2021) developed GSIP for Marshall-Olkin extended exponential and inverse log logistic distribution, respectively. Time truncated SSIP has been studied by several authors which includes Dodge and Roming (1941), Gupta (1962), Gupta and Groll (1961), Rosaiah and Kantam (2005), Tsai and Wu (2006), Baklizi et al. (2004), Balakrishnan et al. (2007), Aslam et al. (2010), Al-Omari (2015), Tripathi et al. (2020) and Saha et al. (2021). Also, GSIP is widely used by engineers in corporate world as GSIP is cheaper than any other ASIP because it minimises the cost as well as time. Most of the ASIPs mentioned above take into account quality of the present lot but do not consider the quality of previous lot(s). In this scenario, chain sampling plan (ChSP) [see, Dodge (1955)] occupies an important place in the literature of ASIP(s). In ChSP, for sentencing a lot, one is not only dependent on the quality of the current sample but also depends on the quality of the past sample(s). ChSP is also known as ChSP-1 plan [see, Dodge (1955)]. ChSP-1 is a plan with zero acceptance number and was developed for inspection by attributes as well as by variables [see, Govindaraju (2006), Govindaraju and Balamurali (1998)]. It depends on chain of the past lot results, i.e., quality of past lot or inspection of past lot plays an important role in the decision making process for sentencing a lot. For more details, the readers may refer to Balamurali and Usha (2013), Govindaraju and Subramani (1993). Usually, ChSP-1 uses the past results only when a non-conforming unit is observed in the current sample. Govindaraju and Lai (1998) developed a modified version of ChSP-1 plan, known as MChSP-1 plan. However, the MChSP-1 plan can only be used for inspection by attributes based on Poisson model. Recently, Luca (2018) developed an extension of MChSP-1 plan, known as MChSP plan. MChSP is applicable for both attribute as well as variable inspection plan. Tripathi et al. (2021) extended the work of Luca (2018) under the time truncated scheme for Darna distribution. Several authors have carried out numerous studies on production and process analysis related to manufacturing industries and some of them are: Qu et al. (2020), Eldib et al. (2018), Ding et al. (2021), Han and Xiao (2020), Moslehi et al. (2021), Sarkar and Gunturi (2021), Zhou (2021), Zhang et al. (2020), Gan et al. (2020) and Li et al. (2020).

The main purpose of this article is to introduce a new sampling inspection plan called a modified chain-group sampling inspection plan (MChGSIP) which is basically a combination of MChSP and GSIP. This sampling plan is particularly useful for cases where quality characteristics are described by attributes only. The motivation to perform the life test in groups for the proposed plan is that the use of groups allow the experimenter to accommodate multiple items in a tester and conduct the time truncated life test for more than one item simultaneously. The multiple number of items in a tester is called a group and the number of items in a group is called the group size. When the required number of testers are equal to the number of items to be inspected in SSIP, the cost of inspection increases as compared to GSIP. Hence, by using GSIP, substantial testing time and cost can be reduced. The proposed MChGSIP makes use of previous lot results and perform life test in groups. Due to this, MChGSIP is preferable to GSIP and SSIP. Presently, due to time and cost constraint, quality control engineers and researchers in industries prefer to use the time truncated life test during the inspection process. In this kind of test, inspection may have to be stopped at a pre-specified time point. Hence, a decision rule may be made and the lot may be considered good and acceptable if the number of defective items found in the sample did not exceed the acceptance number during the pre-specified time point.

Rest of the article is organized as follows: Related work is discussed in Sect. 2. In Sect. 3, methodology of the proposed plan is discussed. Brief description of inverse log-logistic distribution (ILLD) and proposed plan for ILLD is described in Sect. 4. Results are presented and discussed in Sect. 5. For illustrative purposes, four real data sets are analyzed in Sect. 6. Finally, concluding remarks and future scope of the proposed study are placed in Sects. 7 and 8.

3 Methodology of MChGSIP for attributes

In this section, methodology of MChGSIP for attributes is discussed. Here the plan parameters of the MChGSIP are number of groups (g), acceptance number (c) and the number of chained sample results (i). The MChGSIP plan is determined by the triple of natural numbers (g, c, i) and the flowchart of the proposed plan is displayed in Fig. 1.

The values of group size (r), truncation time (\(t_0\)), producer’s risk (\(\alpha \)) and consumer’s risk (\(\beta \)) are assumed to be pre-fixed. Now, procedure of the time truncated MChGSIP plan for a pre-specified truncation time \(t_0\) is:

-

1.

Select n items from a particular lot and allocate r items to g groups, i.e, \(n=r \times g\). Start with normal inspection for a pre-fixed experiment time \(t_0\).

-

2.

Inspect all the groups simultaneously and record the number of non-conforming units (\(\Delta \)) upto pre-fixed experiment time \(t_0\).

-

3.

If \(\Delta \le c\) the lot is accepted provided that there is at most 1 lot of the preceding i lots in which the number of defective units \(\Delta \) exceeds the criterion c, otherwise, reject the lot.

Two point approach is used for the determination of plan parameters of the proposed plan for the pre-fixed values of r, \(t_0\), \(\alpha \) and \(\beta \). However, these pre-fixed values are not the plan parameters of the proposed plan. The probability of acceptance of GSIP, denoted by \(P_a\), is given by:

where p is the probability that the observed number of failures occur before the pre-specified experimental time \(t_0\), i.e., \(F(t_0)\) is the cumulative distribution function (CDF) of lifetime of sample items of submitted lot. Then the probability of failure (p) of the items before experimental time \(t_0\) is obtained from the Eq. (3.2) and is given by:

Now, the OC function of MChSP, denoted by \(P_{ac}(p)\) is given by [see for details, Luca (2018)]:

where \(P =P(d_{n,p} \le c)\) is defined as the probability that the observed number of defective units found in a lot is less than the criterion c [see, Luca (2018)]. By using Eq. (3.1), we can obtain the OC function of the proposed MChGSIP, denoted by \(P_{acg}(p)\) and is given by:

Now, our interest is to determine the parameters of the proposed plan, which are mentioned above by triplet of natural number (g, c, i). To obtain the OC function of MChGSIP, first we have to find out the probability of acceptance of GSIP under the AQL and LQL, respectively and are given by

With the help of Eqs. (3.5) and (3.6), we will determine the expressions of OC functions of the proposed MChGSIP plan at the considered two points AQL and LQL, respectively and are given in Eqs. (3.7) and (3.8) as

Producer’s risk (probability of rejection of a good lot), denoted by \(\alpha \) and consumer’s risk (probability of acceptance of a bad lot), denoted by \(\beta \) is used in the computation for determination of plan parameters of the proposed plan. The objective of the producer is that sampling plan which minimizes the chance of rejection of a good lot at acceptable quality level (AQL) while consumer wants to minimize the chance of accepting a bad lot at limiting quality level (LQL). Determine the plan parameters of the proposed plan in such a way that the lot acceptance probability of a good lot is larger than the producer’s confidence level \((1-\alpha )\) and that the lot acceptance probability of a bad lot is smaller than consumer’s risk (\(\beta \)). Therefore, two-point approach (at AQL and LQL) is used to determine the plan parameters of the proposed plan by using the following non-linear optimization problem:

The plan parameters are determined by using the above non-linear optimization problem for various values of producer’s risk and consumer’s risk. In the above optimization problem, our aim is to minimize sample size n, where n depends on number of groups g with each of group size r, i.e., minimize the number of groups g in such a way that g satisfies the above optimization problem for given r. Results are reproducible for various choices of AQL, LQL, \(\alpha \) and \(\beta \). For achieving this, the experimenter should follow the following steps for the determination of plan parameters of the proposed plan:

-

1.

Choose the values of plan parameters of MChGSIP (g, c, i).

-

2.

Now check whether, (g, c, i) satisfies the Eqs. (3.9)–(3.11) simultaneously for prefixed values of AQL, LQL, \(\alpha \) and \(\beta \) or not.

-

3.

If satisfies the Eqs. (3.9)–(3.11) then finalize chosen value of the plan parameters, otherwise repeat the steps 1 and 2.

4 MChGSIP for ILLD

Chiodo et al. (2018) proposed a new distribution for extreme wind speed modelling called the ILLD. This distribution is a particular case of inverse Burr distribution [see, Chiodo and De Falco (2016)] and also known as Dagum distribution. The probability density function (PDF) and the CDF of ILLD with shape parameter \(\lambda \) and scale parameter \(\tau \) are given by

and

The rth moment about origin is obtained by Chiodo et al. (2018) and is given by

The mean of ILLD is given as

where B(u, v) is the beta function and is defined as \(B(u,v)=\frac{\Gamma (u) \Gamma (v)}{\Gamma (u+v)}\).

Survival characteristics of any life time model is often measured in terms of it’s hazard rate function (HRF). The HRF for a specified value at \(t=t_0\) is given as

The ILLD exhibits increasing, decreasing and up-side down bathtub (uni-modal) hazard rate shapes [see, Fig. 2] which are very common in reliability studies and lifetime data analysis. In quality control analysis, if shape parameter of a distribution is unknown it is very difficult to design the acceptance sampling plan. Thus, in quality control analysis, the scale parameter is sometimes called quality/characteristic parameter. Therefore, it is assumed that the distribution function depends on time only through the termination ratio (\(t_0/\mu _0\)). Hence, it is better to use ILLD for the truncated life test of MChGSIP.

Now to describe the computation of truncated life test of the MChGSIP plan when items of a lot belongs to the ILLD. Lot quality is measured by the lot mean and we have observed that the higher value of \(\mu \), better is the lot’s quality, where \(\mu \) is defined in Eq. (4.3). Suppose in a production process, a producer claims that the specified mean lifetime of the units of a process is \(\mu _0\), while the actual mean lifetime of the item is \(\mu \), where

i.e.,

Now, if our interest is to make inference whether the actual mean lifetime \(\mu \) is larger than specified lifetime \(\mu _0\), then the usual procedure is to take a random sample from that lot and perform a truncated life test for pre-fixed time point, say, \(t_0\), where \(t_0\) can be some multiple of \(\mu _0\), i.e., \(t_0=a \times \mu _0\), where a is a positive constant. A product is considered to be acceptable for consumer’s use, if the sample information supports the hypothesis

The expression of Pacg(p) can be written in terms of p, where p is the CDF of ILLD. Now, p can be written in the form of \(\mu _0\) and is given by:

p can be obtained for the given values of (\(\mu /\mu _0\)), (\(t_0/\mu _0\)) and known value of shape parameter \(\lambda \). Now for the given producer’s risk \(\alpha \) and consumer’s risk \(\beta \), determine the plan parameters of the proposed plan, which ensure \(\mu \ge \mu _0\), can be found by the solution of above discussed two point approach [see, Eqs. (3.9)–(3.11)]. All the plan parameters have been recorded for the defined termination ratio (\(t_0/\mu _0\)), quality level (\(\mu /\mu _0\)), group size r and the known values of shape parameter \(\lambda \).

5 Results

5.1 Comparative study

In this section, a comparative study has been done among the proposed MChGSIP, GSIP and SSIP. For comparison of all the three plans, the minimum number of groups g is required for taking decision regarding the acceptance or rejection of the lot. Here, minimum number of groups g in case of MChGSIP for a prefixed value of group size \(r=5,10\), producer’s risk \(\alpha =0.05\), consumer’s risk \(\beta =0.10\) and various values of AQL and LQL are presented in Tables 4 and 5, respectively. Similarly, two point approach is used to obtained the minimum number of groups for the GSIP and SSIP for the same given set-up as MChGSIP plan. A comparison table [see, Table 6] is presented to show that the proposed plan performs better than the GSIP and SSIP in terms of minimum number of groups g under the same set-up of known values of r, \(\alpha \) and \(\beta \). In some of the cases, MChGSIP is required same number of groups as in case of GSIP and SSIP for sentencing the lot. Hence, use of the proposed plan is preferable rather than the GSIP and SSIP, where decision (acceptance or rejection of the lot) is taking on the basis of current sample only, for the reason that past information plays a significant role to take a decision regarding the lot sentencing criteria.

An advantage to develop MChGSIP is that it uses the past information about the quality of the lot and this advantage makes the proposed plan very special over the GSIP and in particular SSIP. Also, mathematical support has been provided to show the performance of the MChGSIP as compared to GSIP and SSIP. Hence it can be concluded that it would be better to adopt proposed MChGSIP in place of GSIP and SSIP.

5.2 Discussion of tables, figures and hypothetical examples

Table 1 represents the plan parameters (g, c, i) of the proposed plan for the group size \(r=5,~10\) when the producer’s risk \(\alpha =0.05\) and consumer’s risk \(\beta =0.10\) for the given values of AQL(\(p_0\)) and LQL\((p_1)\). From Table 1, it is observed that the number of groups decreases for fixed values of AQL with increasing values of LQL. Also, when AQL increases, required number of groups decreases rapidly and the similar trends hold for both the considered group sizes (\(r=5,~10\)). In some cases, we can not find out the minimum number of groups which is denoted by blank space (—) in the Table 1. One more interesting result we have noted from Table 1 that when the group size is just doubled, i.e., \(r=5\) to \(r=10\), then the minimum number of groups are just becoming half (or near to half) of the minimum number of groups required in \(r=5\).

Table 2 represents the minimum number of groups of the proposed MChGSP for the different group sizes \(r=5,~10,~15\) respectively and for the given values of AQL(\(p_0\)) and LQL\((p_1)\). In Table 2, similar results are observed, i.e., the number of groups decreases for fixed values of AQL(\(p_0\)) with increasing values of LQL\((p_1)\) and also this results hold for each group size \((r=5,~10,~15)\). When group size increases, number of groups decreases for the same set of values of AQL(\(p_0\)) and LQL\((p_1)\). In some cases, required number of groups is same irrespective of the groups size and also found that the same number of groups required when the value of LQL\((p_1)\) is too large. Sometimes we are not able to figure out the minimum number of groups required for the same considered set-up of AQL(\(p_0\)) and LQL\((p_1)\) which is denoted by blank space (—) in Table 2.

Table 3 contains the plan parameters of GSIP for the same group sizes as considered in MChGSIP, i.e., (\(r=5,10\)) at the pre-fixed values of AQL(\(p_0\)) and LQL\((p_1)\). If AQL(\(p_0\)) is fixed and LQL increases then the minimum number of groups deceases for both the considered group sizes \((r=5,~10)\). Also, it is observed from Table 3 that when the group size increases from \(r=5\) to \(r=10\), the required number of groups is just half (or near to half). Blank space (—) in Table 3 denotes that we are unable to find out the minimum number of groups required for the considered set-up of AQL(\(p_0\)) and LQL\((p_1)\) in case of GSIP.

Tables 4 and 5 represents the plan parameters (g, c, i) of the proposed MChGSIP when the items of the lot follow the IILD with known shape parameters \(\lambda =2,~3\), for the pre-fixed group sizes \(r=(5,~10)\), producer’s risk \(\alpha =0.05\) and for the different values of consumer’s risk \(\beta =(0.25,0.10,0.05,0.01)\) corresponding to the given termination ratio \((t_0/\mu _0)=(0.5,1)\), respectively. Also, probability of acceptance \(P_{acg}(p)\) of the proposed MChGSIP have been presented in Tables 4 and 5 corresponding to given quality level \((\mu /\mu _0)=(2,3,4,5,6,7,8)\). From Tables 4 and 5, it is observed that as \(\beta \) decreases for a given set of values of r, \(a=(t_0/\mu _0)\) and \((\mu /\mu _0)\), the minimum number of groups are also decreases for that set up. Also, when quality level \(\mu /\mu _0\) increases with fixed \(\beta \), the minimum number of groups are also decreases. However, this decreasing behaviour of required number of groups are not true for all the quality levels considered here. For example, considered the set up from Table 4, where group size \(r=5\), termination ratio \((t_0/\mu _0)=0.5\), \(\beta =0.25\) and quality level \((\mu /\mu _0)=5\), minimum number of groups \(g=2\) and acceptance number \(c=2\) respectively. As increase the quality level for this set up, minimum number of groups and acceptance number are remain same. Also, as \(\beta \) decreases for the fixed values of quality level \((\mu /\mu _0)\), termination ratio \(t_0/\mu _0\) and group size r, the required number of groups g increases. Another important observation from Tables 4 and 5 is that the number of groups decreases when termination ratio \((t_0/\mu _0)\) increases in both cases of group sizes \(r=5,~10\).

Table 6 shows the comparison study among the MChGSIP, GSIP and SSIP in terms of minimum number of groups g which is required for taking decision regarding the acceptance or rejection of the lot. For the more details discussion of Table 6, the readers may see the Sect. 5.1.

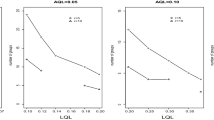

Figure 3 is a graphical representation of Tables 1 and 2 which shows the trend of minimum number of groups for the fixed value of AQL(\(p_0\)) and various choices of LQL(\(p_1\)). From Fig. 3, we observe that if group size increases (\(r=5~\text{ to }~10\)), then the required number of groups decreases. Break point (or blank space) in Fig. 3 indicates that no value of required number of groups g found for the corresponding combination of AQL(\(p_0\)) and LQL(\(p_1\)).

Figure 4 shows the comparison of required minimum number of groups for different choices of group size \(r=5,10,15\) when AQL is fixed with varying LQL. The trend of required number of groups g in Fig. 4 is similar to the trend that it is observed in Fig. 3, i.e., required number of groups decreases when the group size increases \(r=5~\text{ to }~15\).

The motivation of incorporating the Fig. 5 is to compare the proposed plan MChGSIP with GSIP and SSIP in terms of required number of groups for given values of LQL(\(p_1\)) and for group size \(r=5,~10\). From Fig. 5 it is observed that the performance of the proposed MChGSIP is better than the GSIP and SSIP in terms of required number of groups for the same set up. For more details of comparison aspect of the proposed plan, the readers may refer to Sect. 5.1 and Table 6. Also, it is observed that the number of groups get closer for MChGSIP and GSIP for all considered set-up of AQL(\(p_0\)) when LQL(\(p_1\)).

Hypothetical example 1 Suppose that the producer’s risk \(\alpha \) and consumer’s risk \(\beta \) are assumed to be 0.05 and 0.10, respectively. Also, the values of AQL \((p_0)\) and LQL \((p_1)\) are 0.05 and 0.14, respectively and these values are known to experimenter to apply the two point approach for the estimation of plan parameters of the proposed plan. From Table 1, the obtained plan parameters are \(g=13\), \(c=6\) and \(i=2\) for pre-fixed group size \(r=5\). Hence, based on these plan parameters, the proposed MChGSIP is described as:

-

Select a sample of size 65 from a submitted lot. Allocate 5 items to 13 groups, i.e., \(n=r \times g\) and start with normal inspection.

-

Inspect all the groups simultaneously and record the number of non-conforming units (\(\Delta \)).

-

If \(\Delta \le 6\) the lot is accepted provided that there is at most 1 lot of the preceding 2 lots in which the number of defective units \(\Delta \) exceeds the criterion 6, otherwise, reject the lot.

Hypothetical example 2 Suppose that producer claims specified mean lifetime of items is \(\mu _0=4\) unit and the lifetime of items follow the ILLD quality characteristic with shape parameter \(\lambda =3\), consumer’s risk \(\beta =0.10\), producer’s risk \(\alpha =0.05\), group size \(r=5\) and true mean of items \(\mu =12\). Now experimenter wants to test lifetime of the items for 2 units. For the above explained specifications, we have termination ratio \((t_0/\mu _0)=0.5\) and quality level \(\mu /\mu _0=3\). From Table (6), plan parameters are \(g=66\), \(c=54\) and \(i=2\). Now the MChGSIP is described as:

-

Select a sample of size 330 from a submitted lot. Allocate 5 items to 66 groups, i.e., \(n=r \times g\) and start with normal inspection.

-

Inspect all the groups simultaneously and record the number of non-conforming units (\(\Delta \)).

-

If \(\Delta \le 54\) the lot is accepted provided that there is at most 1 lot of the preceding 2 lots in which the number of defective units \(\Delta \) exceeds the criterion 54, otherwise, reject the lot.

Probability of acceptance of the lot under the above mentioned specification is 1.0000000 for the quality ratio \((\mu /\mu _0)=3\).

If practitioners conduct the experiment under the same set-ups using the proposed plan for ILLD, then they can use presented results for the decision purpose to judge the quality of lot and also able to determine the probability of acceptance to the corresponding set-up. This study contribute to the industry and save the producers as well consumers. Moreover, practitioners can extend the results for different choices for shape parameter in a similar line.

6 Real life examples

To illustrate our proposed methodology, four real life examples are considered and the actual data sets are provided in “Appendix” for reference. For the applications of these data sets, at first, check whether the considered data sets comes from ILLD or not by goodness-of-fit test and two discrimination criteria (AIC and BIC) based on the likelihood-function evaluated at the MLEs of the parameters. The values of MLEs of the parameters, \(l({\hat{\Theta }})\), AIC, BIC, K-S Statistic with corresponding p values are displayed in Table 7. It can be observed from Table 7 that the ILLD is reasonably well fitted for the considered data sets. Further, Histogram-density, Empirical and Theoretical CDFs and P–P plot of the considered model are also displayed in the Figs. 6, 7, 8 and 9, respectively and these figures are used to show how well data sets are fitted the probability distribution.

Data I For the empirical analysis, we use a dataset from Nichols and Padgett (2006). The data set consists of 100 breaking stress of carbon fibers (in Gba). Assumed that the lifetime of breaking stress of carbon fibers follow ILLD and MLEs of \(\tau \) and \(\lambda \) are \({{\hat{\tau }}}=2.4985\) and \({{\hat{\lambda }}}=4.1185\). Suppose, the experimenter wants to establish the mean lifetime of breaking stress of carbon fibers is 1.65 unit with consumer’s risk 0.05, when the shape parameter \(\lambda =4.1185\). Also assume that the life test would be terminated at 0.825. This leads to termination ratio \((t_0/\mu _0)=0.75\). Optimal plan parameters for the considered specifications are \(g=15\), \(c=3\) and \(i=2\) when group size \(r=5\). Now, if the experimenter desires to set up the MChGSIP plan for the above mentioned specifications, then procedure is as follows:

-

Select a sample of size 75 from a submitted lot. Allocate 5 items to 15 groups, i.e, \(n=r \times g\) and start with normal inspection and test the units upto truncation time 1.65 Gba.

-

Inspect all the groups simultaneously and record the number of non-conforming units (\(\Delta \)).

-

If \(\Delta \le 3\) the lot is accepted provided that there is at most 1 lot of the preceding 2 lots in which the number of defective units \(\Delta \) exceeds the criterion 3, otherwise the lot is rejected.

If true mean lifetime of breaking stress of carbon fibers is 3.30 minutes, i.e., quality ratio is \((\mu /\mu _0)=2\) then probability of acceptance of lot for the considered specifications of experimenter is 0.9994453.

Data II This data set was considered by Lawless (2003) which represents the number of millions revolutions to failure for 23 ball bearings and is considered to illustrate the proposed plan. Assumed that the lifetime of above ball bearings data set follow ILLD and MLEs of \(\tau \) and \(\lambda \) are \(\tau =63.9946\) and \(\lambda =3.3465\). Suppose, experimenter wants to set the mean life time for ball bearings is 45 minutes with consumer’s risk 0.25 and with shape parameter \(\lambda =3.3465\). Also assume that the life test would be terminated at 22.5 minutes with consumer’s risk 0.25. This leads to termination ratio \((t_0/\mu _0)=0.5\). Hence, the optimal plan parameters for the considered specifications are \(g=5\), \(c=1\) and \(i=2\) when group size \(r=3\). Now, if the experimenter desires to set up the MChGSIP plan for the above mentioned specifications, then procedure is as follows:

-

Select a sample of size 15 from a submitted lot. Allocate 3 items to 5 groups, i.e, \(n=r \times g\) and start with normal inspection and test the units up to truncation time 22.5 minutes.

-

Inspect all the groups simultaneously and record the number of non-conforming units (\(\Delta \)).

-

If \(\Delta \le 1\) the lot is accepted provided that there is at most 1 lot of the preceding 2 lots in which the number of defective units \(\Delta \) exceeds the criterion 1, otherwise reject the lot.

If true mean lifetime of the ball bearings is 0 minutes, i.e., quality ratio is \((\mu /\mu _0)=2\) then probability of acceptance of lot for the considered specifications of experimenter is 0.9766474.

Data III The data set is taken from Lawless (2003) and represents the break down times (in minutes) of electrical insulating fluid subject to a 30 KV voltage stress. Assumed that the lifetime of above data set follow ILLD and the MLEs of \(\tau \) and \(\lambda \) are \(\tau =44.6332\) and \(\lambda =1.5332\). Suppose the experimenter wants to set the mean lifetime of small electric carts is 30.5 minutes with consumer’s risk 0.05 and shape parameter \(\lambda =1.5332\). Assuming that life test would be terminated at 15.25 minutes. This leads to termination ratio \((t_0/\mu _0)=0.5\). Optimal parameters for the considered specifications are \(g=3\), \(c=3\) and \(i=2\) when group size \(r=3\). If experimenter desires to set up the MChGSIP plan for the above mentioned specifications then procedure is:

-

Select a sample of size 9 from a submitted lot. Allocate 3 items to 3 groups, i.e, \(n=r \times g\) and start with normal inspection and test the units upto truncation time 15.25 minutes.

-

Inspect all the groups simultaneously and record the number of non-conforming units (\(\Delta \)).

-

If \(\Delta \le 3\) the lot is accepted provided that there is at most 1 lot of the preceding 2 lots in which the number of defective units \(\Delta \) exceeds the criterion 3, otherwise reject the lot.

If true mean lifetime of small electric carts is 122 minutes, i.e., quality ratio is \((\mu /\mu _0)=4\), then probability of acceptance of lot for the considered specifications of experimenter is 0.9789872.

Data IV Data set is given in Montgomery et al. (2011). The data set represents the time to failure in hours of an electronic component subjected to an accelerated life test. Assuming that the data set follows ILLD distribution and MLEs of \(\tau \) and \(\lambda \) are \(\tau =128.73733\) and \(\lambda =28.01468\). Suppose, the experimenter wants to set the mean lifetime of electronic component subjected to an accelerated life test is 132 minutes with consumer’s risk 0.25 and shape parameter \(\lambda =28.01468\). Also assume that the life test would be terminated at 118.8 minutes. This leads to termination ratio \((t_0/\mu _0)=0.90\). Optimal parameters for the considered specifications are \(g=20\), \(c=1\) and \(i=2\) when group size \(r=2\). If experimenter desires to set up the MChGSIP plan for the above mentioned specifications then procedure is:

-

Select a sample of size 40 from a submitted lot. Allocate 2 items to 20 groups, i.e, \(n=r \times g\) and start with normal inspection and test the units upto truncation time 118.8 minutes.

-

Inspect all the groups simultaneously and record the number of non-conforming units (\(\Delta \)).

-

If \(\Delta \le 1\) the lot is accepted provided that there is at most 1 lot of the preceding 2 lots in which the number of defective units \(\Delta \) exceeds the criterion 1, otherwise reject the lot.

If true mean lifetime of electronic component subjected to an accelerated life test is 264 minutes, i.e., quality ratio is \((\mu /\mu _0)=2\) then probability of acceptance of lot for the considered specifications of experimenter is 1.

7 Conclusions

In this article, a new ASIP, MChGSIP is introduced. Methodology of MChGSIP for attributes under time truncated scheme is discussed along with the flowchart of proposed ASIP. Further, ILLD is used to develop the time truncated MChGSIP. To show the performance of MChGSIP over SSIP and GSIP, a comparative study is included in the paper and it is found that MChGSIP is more efficient than SSIP and GSIP. Also, plan parameters of time truncated MChGSIP are calculated for different sets of \((\alpha ,\beta )\). Results regarding the plan parameters of the proposed plan are represented through the figures for better comprehension of trends of findings. Moreover, tables for plan parameters of time truncated MChGSIP for ILLD are presented for various values of shape parameter. Discussion on tables, figures and hypothetical examples is provided. Further, four real life examples are provided to show the applicability of the proposed plan in real life situation. In a nutshell, the MChGSIP plan enables us to reduce the minimum number of groups to reach a decision about sentencing a lot by using past samples and save the cost and time of an experimenter. Hence, it would be preferable to use MChGSIP over other existing plans.

8 Future scope

Development of proposed time truncated MChGSIP for some other lifetime distributions may be a fruitful area in the future research. These developments are beneficial for the practitioners or industrialist so they can use the tables directly for determination of plan parameters and take a decision regarding lot quality based on plan parameters.

Availability of data and material

The link of the dataset used in this study is included within the article, and data set also provided in the article.

References

Aslam M, Jun CH, Ahmad M (2009) A Group sampling plan based on truncated life test for gamma distributed items. Pakistan J Stat 25(3):333–340

Aslam M, Jun CH (2009) A group sampling plan for truncated life test having Weibull distribution. J Appl Stat 36(9):1021–1027

Aslam M, Jun CH, Ahmad M (2011) New acceptance sampling plans based on life tests for Birnbaum-Saunders distribution. J Appl Stat 81(4):461–470

Aslam M, Kundu D, Ahmed M (2010) Time truncated acceptance sampling plans for generalized exponential distribution. J Appl Stat 37(4):555–566

Al-Omari AI (2015) Time truncated acceptance sampling plans for generalized inverted exponential distribution. Electron J Appl Stat Anal 8(1):1–12

Baklizi A, Masri EL, A.E.K. (2004) Acceptance sampling plan based on truncated life tests in the Birnbaum Saunders model. Risk Analysis 24(6):1453–1457

Balakrishnan N, Lieiva V, Lopez J (2007) Acceptance sampling plan from truncated life tests based on generalized Birnbaum Saunders distribution. Commun Stat-Simul Comput 34(3):799–809

Balamurali, S, Usha M (2013) Optimal designing of variables chain sampling plan by minimizing the average sample number, Int J Manuf Eng 1-12

Chiodo E, De Falco P, Di Noia LP, Mottola F (2018) Inverse log-logistic distribution for extreme wind speed modelling: genesis, identification and Bayes estimation. AIMS ENERGY 6(6):926–948

Chiodo E, De Falco P (2016) The inverse Burr distribution for extreme wind speed prediction: genesis, identification and estimation. Electr Power Syst Res 141:549–561

Dodge HF, Roming HG (1941) Single sampling and double sampling inspection tables. Bell Syst Tech J XX(1)

Dodge HF (1955) Chain sampling inspection plan. Ind Qual Control 11(4):10–13

Ding A, Zhang Y, Zhu L (2021) Intelligent recognition of rough handling of express parcels based on CNN-GRU with the channel attention mechanism. J Ambient Intell Humaniz Comput. https://doi.org/10.1007/s12652-021-03350-2

Eldib M, Deboeverie F, Philips W, Aghajan H (2018) Discovering activity patterns in office environment using a network of low-resolution visual sensors. J Ambient Intell Humaniz Comput 9(2):381–411

Gupta SS (1962) Life test sampling plans for normal and lognormal distributions. Technometrics 4(2):151–175

Gupta SS, Groll PA (1961) Gamma distribution in acceptance sampling based on life test. J Am Stat Assoc 56(296):942–970

Govindaraju R (2006) Chain sampling. In: Pham H (ed) Springer handbook of engineering statistics. Springer, London, pp 263–279

Govindaraju K, Balamurali S (1998) Chain sampling plan for variables inspection. J Appl Stat 25(1):103–109

Govindaraju K, Subramani K (1993) Selection of chain sampling plans ChSP-1 and ChSP-(0,1) for given acceptable quality level and limiting quality level. Am J Math Manag Sci 13(1–2):123–136

Govindaraju K, Lai CD (1998) A modified ChSP-1 chain sampling plan, MChSP-1, with very small sample sizes. Am J Math Manag Sci 18(3–4):343–358

Gan YS, Chee SS, Huang YC (2020) Automated leather defect inspection using statistical approach on image intensity. J Ambient Intell Humaniz Comput. https://doi.org/10.1007/s12652-020-02631-6

Han W, Xiao Y (2020) Edge computing enabled non-technical loss fraud detection for big data security analytic in Smart Grid. J Ambient Intell Humaniz Comput 11:1697–1708

Luca S (2018) Modified chain sampling plans for lot inspection by variable and attribute. J Appl Stat 45(8):1447–1464

Lawless JF (2003) Statistical models and methods for lifetime data, vol 362. Wiley, New York,

Li T, Song Y, Xia X (2020) Research on remote control algorithm for parallel implicit domain robot patrol inspection on 3D unstructured grid. J Ambient Intell Humaniz Comput 11(12):6337–6347

Montgomery DC (2009) Introduction to statistical quality control, 6th edn. Wiley

Montgomery DC, Jennings CL, Pfund ME (2011) Managing, controlling and improving quality. Wiley, New Jersey

Moslehi MS, Sahebi H, Teymouri A (2021) A multi-objective stochastic model for a reverse logistics supply chain design with environmental considerations. J Ambient Intell Humaniz Comput 12:8017–8040

Nichols MD, Padgett WJ (2006) A bootstrap control for Weibull percentiles. Qual Reliab Eng Int 22(2):141–151

Qu W, Cao W, Su YC (2020) Design and implementation of smart manufacturing execution system in solar industry. J Ambient Intell Human Comput. https://doi.org/10.1007/s12652-020-02292-5

Rao GS (2011) A group acceptance sampling plans for lifetimes following a Marshall-Olkin extended exponential distribution. Appl App Math: Int J 6(2):592–601

Rosaiah K, Kantam RRL (2005) Acceptance sampling plan based on the inverse Rayleigh distribution. Econ Qual Control 20(2):77–286

Sarkar D, Gunturi SK (2021) Wind turbine blade structural state evaluation by hybrid object detector relying on deep learning models. J Ambient Intell Humaniz Comput 12:8535–8548

Saha M, Tripathi H, Dey S (2021) Single and double acceptance sampling plans for truncated life tests based on transmuted Rayleigh distribution. J Ind Prod Eng 1–13

Tripathi H, Dey S, Saha M (2021) Double and group acceptance sampling plan for truncated life test based on inverse log-logistic distribution. J Appl Stat 48(7):1227–1242

Tripathi H, Saha M, Alha V (2020) An application of time truncated single acceptance sampling inspection plan based on generalized half-normal distribution. Ann Data Sci 1–13

Tripathi H, Al-Omari AI, Saha M, Alanzi AR (2021) Improved attribute chain sampling plan for Darna distribution. Comput Syst Sci Eng 38(3):381–392

Tsai TR, Wu SJ (2006) Acceptance sampling plan based on truncated life tests for generalized Rayleigh distribution. J Appl Stat 33(6):595–600

Zhou W (2021) Systemic financial risk based on analytic hierarchy model and artificial intelligence system. J Ambient Intell Humaniz Comput. https://doi.org/10.1007/s12652-021-03037-8

Zhang J, Chen M, Hu E (2020) Data mining model for food safety incidents based on structural analysis and semantic similarity. J Ambient Intell Humaniz Comput. https://doi.org/10.1007/s12652-020-01750-4

Acknowledgements

The authors express their sincere thanks to the esteemed Reviewers and the Editor for making some useful suggestions on an earlier version of this manuscript which resulted in this improved version.

Funding

This research received no external or internal funding.

Author information

Authors and Affiliations

Contributions

All authors contributed equally to this work, have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Informed consent for publication

Consent given to IJSA.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Data set I

0.39, 0.81, 0.85, 0.98, 1.08, 1.12, 1.17, 1.18, 1.22, 1.25, 1.36, 1.41, 1.47, 1.57, 1.57, 1.59, 1.59, 1.61, 1.61, 1.69, 1.69, 1.71, 1.73, 1.8, 1.84, 1.84, 1.87, 1.9, 1.92, 2.0, 2.03, 2.03, 2.05, 2.12, 2.17, 2.17, 2.17, 2.35, 2.38, 2.41, 2.43, 2.48, 2.48, 2.5, 2.53, 2.55, 2.55, 2.56, 2.59, 2.67, 2.73, 2.74, 2.76, 2.77, 2.79, 2.81, 2.81, 2.82, 2.83, 2.85, 2.87, 2.88, 2.93, 2.95, 2.96, 2.97, 2.97, 3.09, 3.11, 3.11, 3.15, 3.15, 3.19, 3.19, 3.22, 3.22, 3.27, 3.28, 3.31, 3.31, 3.33, 3.39, 3.39, 3.51, 3.56, 3.60, 3.65, 3.68, 3.68, 3.68, 3.70, 3.75, 4.20, 4.38, 4.42, 4.70, 4.90, 4.91, 5.08, 5.56.

Data set II

17.88, 28.92, 33, 41.52, 42.12, 45.60, 48.40, 51.84, 51.96, 54.12, 55.56, 67.80, 68.64, 68.64, 68.88, 84.12, 93.12, 98.64, 105.12, 105.84, 127.92, 128.04, 173.40.

Data set III

7.74, 17.05, 20.46, 21.02, 22.66, 43.40, 47.30, 139.07, 144.12, 175.88, 194.90.

Data set IV

127, 124, 121, 118, 125, 123, 136, 131, 131, 120, 140, 125, 124, 119, 137, 133, 129, 128, 125, 141, 121, 133, 124, 125, 142, 137, 128, 140, 151, 124, 129, 131, 160, 142, 130, 129, 125, 123, 122, 126.

Rights and permissions

About this article

Cite this article

Tripathi, H., Saha, M. & Dey, S. A new approach of time truncated chain sampling inspection plan and its applications. Int J Syst Assur Eng Manag 13, 2307–2326 (2022). https://doi.org/10.1007/s13198-022-01645-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13198-022-01645-x