Abstract

To mitigate the increased CO2 emission, CO2 reduction to multi-carbon fuels or other useable substances is an appealing yet essential approach. Since, reduction of CO2 is a thermodynamically uphill process, an economical CO2 fixation is only achievable if energy source used is of renewable energy such as solar energy. Photocatalytic CO2 reduction is a complex process due to its dependency on catalyst design, selectivity, efficiency, and photostability. The competence of a photocatalytic CO2 reduction reaction is effected by factors, such as the type of photocatalyst used their band-gap energy, surface area, and structure of the crystal. This review discusses the kinetics and thermodynamics of photocatalytic CO2 reduction and considers the effects of parameters like defects and impurity doping on photocatalysis. The study also focusses on the selectivity of products, i.e., methane, methanol, formaldehyde, etc. This comprehensive review provides insights into the development and improvement of photocatalytic efficiency for CO2 photoreduction, contributing to the reduction of carbon emissions and a more sustainable future.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

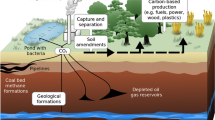

Human activities, particularly the combustion of fossil fuels, such as coal, oil, and natural gas, have markedly increased CO2 emissions. This surplus of CO2 intensifies the greenhouse effect, trapping heat within Earth's atmosphere, consequently leading to global warming and alterations in climate patterns. The mitigation of CO2 emissions stands as a pivotal aspect in addressing climate change and safeguarding the environment [1]. The stability of carbon dioxide arises from its molecular structure and the thermodynamics governing the chemical processes involved—specifically, the carbon–oxygen bonds in CO2 exhibit notable strength. The formation of this compound releases a substantial amount of energy [2]. To curtail CO2 emissions, diverse effective strategies exist. These encompass measures, such as transitioning to sustainable energy sources, advocating for energy conservation, adopting cleaner transportation methods, refining waste management practices, and supporting reforestation initiatives. One prevalent method employed for CO2 reduction is carbon capture and storage (CCS), which involves capturing CO2 emissions from industrial processes or power generation facilities and subsequently securely storing them underground. Another notable approach is carbon utilization or recycling, wherein captured CO2 is converted into valuable products such as fuels, chemicals, and construction materials. Furthermore, some researchers are engaged in developing innovative catalysts and processes for the direct conversion of CO2 into useful chemicals and fuels through electrochemical or chemical reactions [3]. These endeavors are geared toward converting CO2 from a greenhouse gas into valuable resources, thereby contributing to the reduction of CO2 emissions and fostering a more sustainable future. Robust research and development in this domain are imperative for combatting climate change and achieving practical carbon management. Another encouraging process known as artificial photocatalytic system (APS), involves photocatalysts, typically semiconductor materials, to harness solar energy for the conversion of CO2 into valuable products [4]. Catalytic environmental remediation holds paramount importance owning to its potential to expedite chemical reactions crucial to pollutant degradation without being consumed in process. Catalysts act by increasing reaction rates, lowering activation energy and fostering selectivity and specificity toward target contamination. This technology is promising avenue for mitigating CO2 emission and has the potential to play a crucial role in the transition toward a low carbon future. Photocatalysts can be used for the separation of water molecule into H2 and O2 utilizing solar energy for this purpose [5,6,7,8]. Photoreduction of CO2 is of great interest. It is studied globally to overcome the world’s energy crises [9, 10]. Researcher are dedicated to develop effective photocatalyst for the conversion of H2O to molecules and reduction of CO2 into fuels (H2, CH3OH, CH4, CO, HCHO, and HCOOH) [11]. Photocatalytic CO2 reduction is more complex due to reasons like selectivity, efficiency, catalyst design, energy requirements, and photostability [12,13,14]. Due to these reasons, an artificial need for photosynthesis is required which aims to improve the conversion of CO2 and water. The primary objective behind the development of efficient photocatalyst for water splitting and CO2 reduction is to harness the abundant and sustainable power of sunlight as a driving force for chemical reaction. This endeavor addresses two critical global challenges: the transition to clean energy sources and reduction of carbon emission. Catalysts that are explored so far are either homogenous or heterogeneous catalysts. Heterogeneous catalysts are in different phase from the reactants, making it easier to separate them from reaction mixture by catalysts’ recycling. This reduces the chances of contamination and provides larger surface area for reactants to interact [5, 15,16,17]. Various semiconductors are used for photoreduction of CO2 like TiO2 [18,19,20], BiVO4 [21,22,23], MOFs [24,25,26], metal halide perovskite [27,28,29], etc. The photoreduction is basically a surface/interface reaction [30]. The key requirements are needed to be met to effectively utilize the energy from visible-light spectrum for photocatalytic reaction, which include appropriate band gap [31], photogenerated charge separation [32, 33], selectivity, stability, and activity for existing photocatalytic CO2 photoreduction. Facilitating the efficient generation of charge carriers through light absorption and subsequent surface reactions are essential aspects of CO2 photoreduction as they determine the whole efficiency and selectivity of the process in converting CO2 into valuable fuels or chemicals [4, 34, 35]. Previous research has shown that defects in photocatalytic materials can alter their electronic structure and optical properties [36,37,38,39]. These defects could be minimized by doping, enabling the material to absorb a wider range of light and promoting efficient charge separation and reducing recombination rates [40,41,42]. There is an increasing interest in harnessing CO2, the most abundant and economically viable carbon-rich resource, for the progress of alternating energy innovation [43]. The concept of utilizing photocatalytic reactions for sustainable solar energy, to transform atmospheric CO2 waste into alternative fuels, offers a feasible resolution. This innovation strategy not only diminishes carbon dioxide emissions but also concurrently upcycle it as a renewable fuel increasing solar energy resources [44]. Effective photocatalytic performance hinges on various factors, in which the presence of highly efficient photocatalyst stands out as a pivotal determinant. Conversely, optimizing light absorption, minimizing photon losses, and mitigating charge carrier recombination have garnered considerable focus in shaping a more proficient designing of catalyst. The main goal of this review paper is to furnish an extensive literature overview concerning the evolution of various catalysts for conversion of CO2 to other fuels. In this context, the paper provides a thorough examination of the working mechanism, developmental aspects, and proactive measure aimed at addressing CO2 photocatalytic reduction. Additionally, it offers insight into future objectives and directions. The overarching aim of this review is to furnish essential background knowledge and outline general research pathways for individuals engaged or intending to enter the domain of CO2 conversion processes.

2 Thermodynamics of photocatalytic CO2 reduction

Thermodynamics of CO2 reduction reaction is found to be contingent on redox potential ΔE° and Gibbs free energy ΔG° [45]. Due to highly positive ΔG°, which indicates that the reaction is endothermic and not favorable under standard conditions, CO2 reduction is an energetically uphill and non-spontaneous process [46, 47], which means that it requires an input of energy to proceed and it is not favorable for normal temperature and pressure ranges. Compared to water splitting where ΔG° is negative, indicating thermodynamic favorability and spontaneity under standard conditions, CO2 reduction requires significantly more energy to drive the process. Therefore, the energy storage ratio of CO2 reduction, i.e., the amount of energy needed for the reaction compared to the energy stored in the resulting products, is generally much higher than that for water splitting [48,49,50]. The reactions along with the redox potential and Gibbs free energy are given below from Eqs. 1–6 in which Eq. 1 shows the water splitting, while Eqs. 2–6 shows CO2 reduction [51]

As shown in Fig. 1, the electrons are responsible for CO2 reduction to convert it into low carbon fuels like CO and HCOOH, while on the other hand, holes in valance band interact with water molecules to produce O2 [45].

In CO2 photoreduction, the band gap holds great importance. The photoreduction takes place if the conduction band level is higher than that of reduction potential of CO2, while valence band on the other hand is more positive than that of oxidation potential [45].

Photocatalytic properties arise when electron and hole charge carries are generated by absorbing incoming photons with energies equal or greater than that of band gap (Eg). Electrons in conduction band interact with H2O to produce of H2 and with CO2 to produce other useful fuels [7, 16, 53, 54]. Many potential semiconductors have been studied based on this basic principle; some of them are TiO2 [55, 56], ZnO [57,58,59,60,61], ZnS [61,62,63,64], SrTiO3 [65,66,67,68], SiC [57, 69,70,71], Cu2O [72,73,74,75], CdS [57, 76,77,78,79,80,81], GaP [57, 82], TaON [83,84,85,86], C3N4 [87,88,89], BiVO4 [90,91,92,93,94], and Ta3N5 [95,96,97,98]. Among them, TiO2 has been studied more because of its abundance, stability, photocatalytic activity, low toxicity, and versatility. One other main reason is it being primarily active under UV light due to its wide band gap, which restricts its ability to absorb visible-light wavelength effectively [99,100,101,102]. The remaining materials are good photocatalyst for CO2 photoreduction under visible light. These photocatalysts with more negative CB facilitates electron transfer and promote more efficient CO2 conversion [4], as shown in Fig. 2.

Energy band characteristics in various semiconductors’ photocatalysts and the redox potentials of CO2 reduction in an aqueous solution pH = 7 [4]

An electrochemical reaction with higher standard potential is more thermodynamically favorable and tends to proceed in forward direction. Table 1 shows some of the electrochemical reactions with standard potential ΔE° at 250 C temperature and pH kept at 0. These data are further illustrated using graphical plot in Fig. 3. The standard potential provides insight into the spontaneity of the electrochemical process and its feasibility under standard conditions [103, 104].

Illustration of the Langmuir–Hinshelwood (LH)-based kinetic model for CO2 photoreduction. [Step 1; H2O and CO2 diffuse to photocatalyst surface, step 2; molecules migrate within the active sites, step 3; light needed for rate of reaction, step 4; photoreaction start at active sites of two adjacent sites, Step 5; a the desired product is desorbed]

3 Kinetic study of CO2 photoreduction

The kinetics of CO2 photoreduction is well explained by empirically derived Langmuir Hinshelwood model which also leads to micro-kinetic modeling [109]. The advantage of describing heterogeneous catalysis is it provision of insights into reaction mechanism, surface adsorption, the reaction rates at the catalyst surface, and the irradiance. Using this information, the rate of the reaction can be found using Eq. 1 [45]. The major flaw of this LH-based model is that it is time taking and much effort is needed in gathering the CO2 photoreduction kinetics. Since heterogeneous catalytic reaction is majorly surface reactions, it is essential to determine the moles of reactants consumed or products generated per unit of time and per unit of reaction volume [109], while light is an additional requirement for some catalytic reaction. By maintaining both of these quantities, we can achieve the desired rate of reaction for CO2 photoreduction

Here, r is the rate of reaction (μmol gcat−1 h−1), k is the rate constant (μmol gcat−1 h−1), I is the irradiance, α is the reaction order of light intensity (dimensionless), ki represents the equilibrium adsorption constants for reactants and product (bar−1), pi refers to partial pressures for reactants and products (bar), n indicates the absorbed reactants that are involved in surface reaction, and z indicates all the reactants and products [45]. Selectivity of catalyst is also based on temperature, because increasing the temperature also enhances the diffusion rate of molecules which directly impacts the rate of reaction [45]. LH-based kinetic model for CO2 photoreduction is given by Fig. 3 [110,111,112,113,114,115].

An LH-based model kinetics equation was developed for the gathering of the photoreduction catalysts for carbonate by UV/TiO2 in aqueous solution [116]. Using UV light and TiO2 to reduce carbonate in a solution is more effective when the solution is slightly acidic compared to when it is alkaline. The result also indicates that the speed at which this reduction happens increases when you have stronger UV light; however, adding too much TiO2 actually blocks the UV light from penetrating the solution, as a result, slowing down the reaction [116, 117].

Hence, studies show that the photoreduction of CO2 is thermodynamically favorable than that of kinetics photoreduction due to the context of multi-electron reduction processes [4], The efficiency of photocatalytic CO2 reduction is influenced by factors such as the type of photocatalyst used, their band-gap energy, surface area, and structure of the crystal. Furthermore, several factors including lighting conditions (intensity, wavelength, and duration of illumination), along with reaction condition (temperature, pH), and co-catalyst enhance the photocatalytic efficiency. These factors improve adsorption, enable effective charge separation, and catalyze the conversion of reactants into valuable products. The choice of co-catalyst depends on the specific photocatalyst being used [118]. Basics of photocatalytic process can be summarized as follows:

-

(I)

Photon is absorbed with sufficient energy which generates e−/h+ pairs.

-

(II)

Separation of these charge carries and their transportation from valence band to conduction band.

-

(III)

The occurrence of the chemical reaction on the surface [7, 119, 120].

The most frequently employed type of light is ultraviolet (UV) light source for photocatalysis, even though only 4% of solar energy is UV light, while 43% is visible light [121,122,123]. Hence, using narrow band photocatalyst in visible-light spectrum would be more energy efficient [124, 125].

The efficiency of a photocatalytic material can be calculated by its product yield. R can be given by

The common unit for R is mol h−1 g−1 for the catalyst, while for the product, it is commonly measured in molar units (µmol) or in concentration units (ppm) [121]. The efficiency of photocatalyst depends upon the amount of photocatalyst, light intensity, the area exposed for their interaction, etc. The product which is formed by the photocatalyst can be measured by their quantum yield [121], using the formula below

As photocatalytic reaction strongly depends upon the photoabsorption, so the photocatalytic activity be contingent with the incident light wavelength. The quantum yield is calculated by calculating the intensity of light and amount of catalyst [126]. Experimental measurements required to determine the quantum yield for a photocatalytic process involving the production of carbon monoxide, formic acid, formaldehyde, methanol, and methane in a photocatalytic reaction are calculated. It is expressed as a percentage and is a measure of the efficiency of the process in converting absorbed photons into the formation of formic acid.

Numerous efforts have been dedicated to find suitable single-phase photocatalyst that can be driven by visible light (CdS [78, 81, 127], C3N4 [87, 128, 129], WO3 [130, 131], CaFe2O4 [132], LaCoO3 [133], BiVO4 [134, 135], Bi2WO4 [136, 137], Fe2V4O13 [138], and InTaO4 [139,140,141,142] are active photocatalyst under visible region), and various strategies have emerged in the field of photocatalytic CO2 reduction. These strategies include techniques like doping, alloying, utilizing surface plasmonic effects, introducing structural defects, sensitization, and forming solid solution [4, 143, 144]. Here, we will discuss two of these strategies, i.e., impurity doping and structural defects.

4 Impurity doping

To enhance the light-driven properties of utilizing semiconductors to enhance the photocatalytic reduction of CO2, doping is the first strategic process which modulates the arrangement of electrons within a material, optical properties, and surface chemistry of the photocatalyst, leading to improved catalytic activity, selectivity, stability, and reduced energy barriers. Doping can be a versatile and effective strategy to customize the properties of photocatalysts for CO2 reduction. The success of doping primarily hinges on the choice of dopants, dopants methods, and their potential impact on catalytic performance. Doping can create active sites on catalyst surface that facilitate CO2 adsorption, activation, and reduction, enabling achievement of two-step photoexcitation using photons with low-energy visible-light spectrum [145, 146]. On the other hand, nonmetal ion doping can shift the adsorption edge of the catalyst material toward longer wavelengths, enabling adsorption of visible light and that absorption is important for harnessing solar energy [147,148,149]. Nitrogen and iodine are well-studied material for their red shift optical behavior and they improve the visible-light absorption properties of wide-band-gap semiconductor materials [150]. TiO2 is considered to be very prominent and potentially studied semiconductor material which has been investigated and developed [151]. Some important parameter for selectivity of the product includes temperature, pressure, and nature of the photocatalyst [152]. On the basis of these parameters, liquid-phase system is preferable. Many up-to-date research efforts have primarily focused on liquid samples, leaving the gas phase largely unexplored. This bias toward liquid-phase studies is often due to analytical limitations, as it is easier to analyze and quantify products in a liquid medium. However, this focus on liquid-phase studies has left the investigation of gas-phase products relatively neglected and less well understood. Gas phase system are reported solar products which are strongly dependent on the photocatalytic process, CO and CH4 and their metal-doped properties are more functional for their production [153]. Among all metals, platinum (Pt) exhibits favorable results for methane due to higher surface electron density [154, 155]. Similarly, Cu [156], Ag [157], Ni [158], Mg [159], Au [160], Rh [161], and graphene [162] produce methane at a higher quantity in gas phase of CO2 reduction. While in liquid-phase conversion of CO2 reduction, the by-product is mostly methanol CH3OH. Materials like Cu [115, 163], Ag [157], Ni [164, 165], Zn [166], and graphene-based material [167] are mostly studied broadly for their selectivity in photocatalytic Co2 reduction, and their comparison is shown in Fig. 4.

The doping metal cations are more functional not only for creating space for active oxygen sites in reaction, but they are also for charge separation and adsorption through band-gap states. Contrary to this, we have to limit their concentration, because if dopant concentration increases, it will decrease the activity of photocatalytic CO2 reduction.

5 Structural defects

Structural defects have crucial role in the photocatalytic CO2 reduction process. These defects can include vacancies, interstitials atoms, grain boundaries, and other lattice imperfections in a photocatalytic material. Defects can impact the material’s electronic structure, surface reactivity, and charge carrier dynamics. All of these factors play a vital role in facilitating the CO2 reduction reaction. These defects introduce localized energy levels within the band gap of the material, promoting the absorption of a broader range of light wavelengths. An increased light absorption can improve the effectiveness of the photocatalytic process. Moreover, defects can assist as trapping sites for charge carriers, leading to prolonged lifetimes and improved segregation of electrons and holes, which is essential for redox reaction involved in CO2 reduction. However, excessive defects might lead to an increased recombination of charge carrier, offsetting the beneficial effects [170,171,172].

Liu et al.[173] performed an investigation on the nanocrystals structure of TiO2 and found that TiO2 polymers can exhibit various crystalline configuration including (anatase, rutile, brookite, and TiO2(B) polymorphs) [174]. It is worth noting that the formation of brookite is relatively infrequent or sporadic [175,176,177]. The photocatalytic CO2 reduction is found to follow the sequence anatase > brookite > rutile [4]. Increase in generation of CO and CH4 from CO2 photoreduction in the existence of oxygen vacancies provides additional electronic states that can capture charge carriers (e−/h+) generated upon light absorption. Ti+3 species can act as electron donor, and its presence can also influence the charge carrier dynamics and surface activity, leading to an enhanced catalytic activity [173, 178]. Dislocations and grain boundaries are areas of crystal lattice mismatch within a material. These regions can create charge separation and accumulation zones, enchasing the disentanglement of photogenerated electron–hole pairs, as a result, charge carries can migrate to these regions and participate in CO2 reduction reaction. Recognizing and addressing these defects through precise material design, controlled synthesis techniques, and innovative surface modification strategies are crucial steps toward maximizing the performance of photocatalytic CO2 reduction.

Stimulated by the essential researches of CO2 adsorption and dissociation at defect sites, incredible efforts have been done on the photocatalytic decrease of CO2 by means of defect-mediated materials. For illustration, the co-exposed (001) and (101) facets of oxygen-deficient TiO2 nanocrystals were described to accomplish a quantum yield of 0.134% for CO2 drop to CO underneath the expose of visible light [179, 180]. The electronic structure of catalyst is tuned by defect engineering, which extra advances the photocatalytic activity for the application of CO2 reduction. For example, the defect-rich BiVO4 nanosheets were produced and executed in CO2 photoreduction. In the accumulation of vacancies persuaded by defects, the addition of interstitial and substitutional atoms into material lattice by doping [181]. The exotic atoms can be employed as active sites to alter the adsorption of CO2 and related intermediates, forming various products. For illustration, it was described that the choosiness of CO2 reduction could be mostly transformed by acquaint with various single-atom metal sites to g-C3N4 matrix.

6 Graphene-based nanomaterials

The initial isolation of graphene occurred and characterized in 2004 [182]. The diverse synthesis methods and distinctive characteristics of nanomaterials based on graphene make them highly favorable contender for the future technologies. Graphene is like a super-thin layer of sheets composed of carbon atom arranged in hexagonal pattern and incredibly thin that its thickness of only 0.334 nm which makes it the slenderest material globally. And because one of a kind properties like larger surface area (~ 2600 m2/g) [183], higher electron mobility (200,000 cm2/Vs) [184], escalate thermal conduction (3000–5000 Wm/K) [185], maximal optical transparency (97.4%) [186], and possessing remarkable strength characterized by a high young’s modulus of 1TPa [187]. A carbon allotrope that exists primarily in a two-dimensional form composed of sp2 carbon atom with hybridize orbitals is typically referred to as graphene (Fig. 5) by (Armano and Agnello) [188].

Apart from graphene, reduced graphene oxide (RGO), in addition to pure graphene, can serve as a viable material for CO2 capture. When considering the production quantity, graphene oxide (GO) which is an intermediate product in graphene synthesis is also a valuable candidate. Between 2014 and 2022 in Fig. 6 [189], there has been remarkable threefold increase in the number of research publication focused on environmentally friendly methods for producing graphene from natural carbon resources.

Publication trends for graphene and its derivative over recent years [189]

Regarding the advancement of graphene, there have been significant development as considered a viable element for CO2 capture application [190]. Graphene-based nanomaterials are the strongest cross-linking systems with strong light absorption and many functional groups. However, mass production of catalysts is still a challenge in terms of morphology, composition, and yield and cost control. This review provides an in-depth discussion of the combination of graphene with other nanomaterials, leading to new nanocomposites that can exhibit good properties such as rapid separation, transport, high surface area, and better CO2 adsorption level. For charge transfer method heterojunctions, methods such as type II and type Z are common. In graphene heterojunctions, the graphene itself acts as electron tunneling, changing the Z type to the II type. Therefore, more attention should be paid to the Z shape of graphene-based nanomaterials (Table 2).

7 Summary and categories of graphene-based composite photocatalyst

Table 3 summarizes the graphene-based composite photocatalyst for CO2 reduction. In summary, the main finding indicates that the graphene-based composite designed for reducing CO2 through photocatalysis typically involves a combination of graphene and semiconductors. In this setup, semiconductor captures light energy, while graphene serves as a co-catalyst. Furthermore, there are reports indicating that substances derived from graphene, like graphene oxide (GO) and nitrogen-doped graphene, can act like semiconductors. These materials have been shown to effectively use light energy to reduce CO2. Hence, they can be seen as a different category of photocatalyst based on derivatives of graphene.

The CO2 transformation process comprises two essential steps: CO2 capture and subsequent transport to the catalytic site [216, 217]. Porous capture materials are rich in adsorptive sites, yet they exhibit lower catalytic activity for CO2 reduction compared to semiconductor or precious metals [218, 219]. Hence, the overall photoreduction efficiency is primarily contingent on the transfer of CO2 from the capture materials to the photocatalyst [220]. Consequently, to attain greater CO2 conversion rates, an effective photocatalyst must possess both a substantial CO2 adsorption capacity and minimum diffusion distance. Creating a porous composites structure involves integrating hyper-crosslinked polymers (HCP) onto graphene functionalized with TiO2 (TiO2-FG) through an in situ knitting process. The HCPs, which constitute organic microporous materials in their pure form, exhibit a substantial surface area, exceptional CO2 adsorption capacity, and remarkable physiochemical durability. Notability, this instance represents the integration of microporous organic polymers with photocatalyst for CO2 conversion, a distractive approach amid the numerous reported photocatalytic methods. The TiO2-G composite is first obtained through the reduction of graphene oxide (GO), followed by the in situ growth of anatase TiO2 crystal featuring reactive [32, 215], via solvothermal process [221]. Ultra-thin polymer layer is hyper-crosslinked onto TiO2-FG by knitting syn-PhPh3 and connecting them to the open phenyl groups on graphene. This well-defined HCP-TiO2-FG structure is expected to improve the adsorption capacity for CO2 due to the enhanced characteristics of HCPs, and the short diffusion distance around the TiO2 photocatalyst. This structure envisioned to boost the reactivity of CO2 molecules, fascinating the production of CH4. Well-defined structure is depicted in Fig. 7 [222].

(I) Enhancing the functionalization of TiO2-G through the formation of Diazonium salts. (II) Merging TiO2-FG with syn-PhPh3 via solvent knitting technique. Upper right corner provide the detailed sectional view of the HCP-TiO2-FG composite [221]

Morphology of as above composites HCP-TiO2-FG was inspected by FE-SEM, TEM, and atomic microscopy (AFM). Using FE-SEM analysis, we found that the pure HCPs, produced through our previous knitting technique, displayed structural layering within their bulk composition. In XRD, the samples compromised exclusively of anatase TiO2 crystals. Incorporating HCPs layer did not induce any change in the crystal phase of TiO2, but it did lead to a noticeable enlargement in the particular size in Fig. 8a, and the surface structure and composition is given by XPS measurement. In contrast to TiO2-G, the strength of Ti and O signal peaks in TiO2-FG and HCP-TiO2-FG gradually diminished, primarily because of TiO2 content. In high-resolution C1s spectra, the proportion of sp2 and sp3 signal exhibits an upward trajectory following the functionalizing and knitting. This change was attributed to an increase in the sp2 presence in comparison to the generation of sp3 C [223], as shown in Fig. 8b; notably, the peak of Ti2p experienced a shift of approximately (~ 0.2 eV) toward higher energy upon the creation of HCP layers. This electronic conformation shows the interaction between HCP and TiO2. FT-IR spectrum of TiO2-FG, the FT-IR spectrum of HCP-TiO2-FG distantly exhibits pronounced C–H-stretching vibration of methylene around 2920 cm−1 and distinctive peaks related to the vibrations of the aromatic ring skeleton at approximately 1485 cm−1 [224, 225]. Incorporating phenyl groups into TiO2-FG led to the emergence of supplementary peak at 136.7 ppm within the carbon region. This peak was attributed to the functionalization of TiO2-G. Additionally, the resonance at 127.2 ppm was assigned to the sp2 carbon of graphene. The increase intensity of resonance peak around 136.7 ppm can be attributed to the abundant introduction of sp2 carbon through the process of knitting syn-phph3 with TiO2-FG to create HCP-TiO2-FG and simultaneously the formation of methylene with new peak at 32.9 ppm Fig. 8c [222]. The composite structure HCP-TiO2-FG outstanding thermal stability even at temperature as high 400 °C due to presence of HCPs layers firmly on graphene. Porosity measurement is shown in Fig. 8d, both TiO2 and TiO2-FG shown IV isotherms, with less nitrogen adsorb quantity, these findings suggest limited surface area and the presence of mesoporous [226, 227]. The substantial specific surface area and the presence of numerous ultra-microspores in the HCP-TiO2-FG composite have prompted us to explore its gas adsorption capabilities [228, 229]. Remarkably, HCP-TiO2-FG exhibits CO2 uptake, impressive 12.87% at 1 bar and 273.15 K, to contextualization these findings comparative analysis with various porous photocatalysts reported under analogues condition, as shown in Fig. 8e, f.

Chemical composition, porous characteristics, and CO2 adsorption capacity of different photocatalyst. a XRD image, b C1 sketch HCP-TiO2-FG, c C13 (CP/MAS), d N2 adsorption at 77.3 K, and e, f volumetric CO2 adsorption and desorption at 273.15 K and at 298.15 K for 1 bar [221]

The integration of a semiconductor along with any photosensitizer or organic sacrificial reagent (Fig. 9a, b) shows the production CO2 conversion products within a 5 h photocatalytic reaction, facilitated under visible-light condition (λ = 420 nm). Notably, this processes yielded the primary gases CO and CH4, generated through 2e and 8e reduction processes [221]. The porous HCP-TiO2-FG catalyst exhibited a notable average conversion efficiency at rate Re of 264 µmol g−1 h−1. Additionally, CH4 and CO rates are 27.6 µmol g−1 h−1 and 21.63 µmol g−1 h−1. Figure 9c shows as HCP-TiO2-FG material displayed a remarkable 83.7% electron consumption selectivity for CH4 production, while also effectively preventing H2 evolution during the photocatalytic reaction. This underscores its high selectivity of CO2 photoreduction and the undesired H2O reduction. CO2 conversion products were scarcely observed (< 1 µmol g−1 h−1) in the case of commercial TiO2 (P25) and pure TiO2 featuring reactive (001) facets. This was primarily attributed to their constrained light absorption in the visible spectrum, in Fig. 9d. The combination of TiO2 with graphene, resulting in TiO2-G, and significantly enhanced CH4 production (to 2.42 µmol g−1 h−1) through the improvement of visible-light adsorption and electron transport properties [230,231,232]. Incorporating porous HCPs layers enriched the adsorption sites, leading to elevated CO2 uptake and enhanced visible-light absorption [233]. Consequently, the creation of the well-structural HCP-TiO2-FG composite significantly elevated the rate of photocatalytic CO2 reduction. To assess the effectiveness of charge separation, transparent amperometric I–T curves were recorded during exposure to visible light. As shown in Fig. 9e, the resulting materials demonstrate excellent photocurrent stability throughout light on–off cycles, aligning consistently with the photocatalytic assessments. Notably, the pure TiO2 system displayed a minimal signal, HCP-FG exhibits a weak photocurrent response, while the HCP-TiO2-FG composites show better current intensity [234]. The route for charge carrier transfer and separation is typically contingent on the band gap of the photocatalyst [235]. HCP-FG exhibits its highest occupied molecular orbital (HOMO) and lowest unoccupied molecular orbital (LUMO) energy levels positioned at − 5.34 eV and − 3.00 eV verses vacuum level shown in Fig. 9d obtained by optical absorption. An overarching framework delineating the CO2 conversion process over the HCP-TiO2-FG photocatalyst is hereby put forth in Fig. 9f, and when exposed to visible-light irradiation, HCP-FG plays a dual role as a CO2 adsorbent and a photosensitizer. It directly absorbs photons, thereby instigating the transition from the highest occupied molecular orbital (HOMO) to lowest unoccupied molecular orbital (LUMO) [236, 237].

The photoreduction of CO2, optical and photoelectrical characteristics, and the intricacies of the charge transfer pathways all contribute to the assessment of the photocatalytic efficiency, specifically: a CH4 and b CO in the context of photocatalytic CO2 reduction, c average conversion efficiency rate of CH4 and CO, d UV absorption of catalyst, e amperometric I–T curve of sample, and f suggested mechanism of charge separation and transfer in the composite photocatalyst HCP-TiO2-FG [221]

Another brief mechanism for CO2 reduction process over CuInSnS4 a single metal sulfides, the context of this study, in situ Fourier-transform infrared spectroscopy is employed to analyze and contrast the reaction intermediates present on the catalyst surface [238]. No discernible macroscopic infrared absorption peaks corresponding to reaction intermediate are observed on Cu2S SnS2 even in the presence of light irradiation. This absence may be attributed to their limited chemical interaction with CO2 [239]. Conversely, In2S3 exhibits a pronounced activation effect on CO2 adsorption at the surface when subjected to light irradiation [240] in Fig. 10a. Even in the absence of light, CO2 chemisorbs onto In2S3 evident from the 1150 cm−1 IR peak denoting an O–S-stretching vibration [241], sufficient oxygen–sulfur bonding. The oxygen atom of CO2 is chemically linked to the sulfur atom of In2S3 [242]. Under light exposure, specific infrared peaks on the catalyst surface are detected. 1225 cm−1 peak corresponding to bidentate bicarbonates vibrations, while the 1412 cm−1 peaks signifies monodentate bicarbonates vibration [243]. Of particular significance, the 1610 cm−1 peak is associated with the *COOH group, a critical intermediate in the CO2 reduction to CO process. Remarkably, the polymetallic sulfide CuInSnS4 displays robust CO2 chemisorption and substantial H2O physisorption (Fig. 10b).

In-situ FT-IR spectra for adsorbed CO2: a In2S3 and b CuInSnS4 [238]

The CO2 adsorption configuration on CuInSnS4 is pivotal in determining its outstanding CO2 photoreduction activity and selectivity. To investigate the CO2 conversion pathways on the CuInSnS4 photocatalyst surface, DFT calculation were conducted, as shown in Fig. 11.

a Calculate adsorption configuration of CO2 & reactive on CuInSnS4, and b Gibbs free energy of CO2 to CH4 [238]

The adsorption arrangement of CuInSnS4 is illustrated for each for each incremental step, encompassing CO2 adsorption through CH4 generation. Various intermediate states, including CO2*, COOH, CHO*, CH2O*, and CH3* and their corresponding C atom are depicted which consistently maintain strong bonds with electron-deficient sulfur atoms on the (111) plane of the CuInSnS4 nano-signal crystal.

8 Advantages of using carbon materials for CO2 reduction

Using carbon materials in photocatalytic reaction has advantages like providing more spaces for reactions, making CO2 easier to work with, separation of charges and absorbing more light energy for better performance. Materials made from carbon, like graphene oxide, graphene, carbon nanotubes (CNTs), and g-C3N4, offer an expanded surface area of the catalyst, when they are combined [244]. g-C3N4 has many imperfections on its surface, because it contains hydrogen atoms and has an abundance of electrons. These imperfections make it useful for catalytic reactions as they help electrons move around more easily on the surface of catalyst. Yang et al. created nanosheets made of NiAl-layered double hydroxide (NALDH). They then joined these nanosheets with g-C3N4 nanosheets and observed a very closed connection between the two nanosheets, forming a strong heterojunction [245, 246]. Additionally, they include graphene aerogels, which played a role in extending the structure into network-like structure. In this research, they used both graphene nanosheets as well as aerogels to enhance the performance of the photocatalyst. Creating these extremely close connections between sheets reduced the distance for the conveyance of electric charges and also gave plenty of active sites for chemical reaction to occur. Using N2 adsorption–desorption measurements, a significant enhancement in the specific surface area and pore volume was determine over a broad range, as shown in Fig. 12a [247]. In recent work by Chen et al. combined porous carbon nanofiber with added nitrogen with the mixture of nickel and molybdenum phosphide (Mo/Ni-PS@PAN), they used a method involving phosphatization to make the catalyst particular larger, increasing their size from 20 to 50 nm. They conducted carbonization to further enlarge the size. When nanoparticles of MoP were mixed with evenly spread-out nickel atoms, it produced a material known as NiMoP@NCPF, through the process of carbonization the size expend from 50 to 100 nm, as shown in Fig. 12b, c. The porous structure of the material they obtained played a pivotal role in enhancing CO2 adsorption while carrying out the photocatalytic reduction reaction as indicated in Fig. 12d [248].

Apart from the characteristic of pore structures, the way gases interact with the surface is also vital for CO2 adsorption. Therefore, when we modify the surface of carbon materials, we can make CO2 molecules more polar and thus enhance their adsorption. This is achieved by incorporating the fundamental functional group within the carbon framework [249,250,251]. Various forms of carbon materials have been utilized as support materials for the photoreduction of CO2. Carbon-based materials hold tremendous promise for their high efficiency in CO2 adsorption to their adjustable structure and ample surface area [252]. As g-C3N4, it can have a substantial surface area. In certain instance, graphene materials can be modified by adding protons, utilizing substances that protonate to boost area of interest. In recent research, Wu et al. conducted innovative research where they used g-C3N4 as a template. They created layer of g-C3N4 and introduced a combination of Ni/Co metal into the empty spaces within g-C3N4 using phosphoric acid [253,254,255]. With the addition different amounts metal dopants, it caused a transformation in the microstructure leading the formation of g-C3N4-Ni-Co with various sizes, as shown in Fig. 13a–c. And by adding bimetallic dopant will create more hole in g-C3N4 which increase the nitrogen vacancies [256]. Figure 13d shows the catalyst activity at different proportions and the by-product is formed is CO, the porous structure provides numerous spots and a broad catalytic surface area, speeding up the reaction. As a result, this significantly boost the CO production rate to 13.51 mmol/g/h, which is surpassing the achieved value by a factor 3.9 times, with g-C3N4, as shown in Fig. 13e [257].

a–c SEM visual representation of g-C3N4-Co1.6-Ni0.4 in various sizes, d CO generation time, and e CO production rate g-C3N4–Cox-Niy [257]

Numerous research articles have been extensively explored the field of CO2 photoreduction, with semiconductor like TiO2 emerging as the promising candidates for achieving reliable results. Despite notable achievements in this area, several challenges persist in the development of semiconductor photocatalyst, including low thermal and chemical stability, and reduced efficiency under specific conditions. In contrast, polymeric materials exhibit range of appealing characteristics, including cost-effectiveness, low toxicity, widespread availability, and light weight nature, ease of synthesis and use, and excellent flexibility [258, 259]. g-C3N4 stands out as an appealing polymeric photocatalyst, demonstrating superior performance even without the need for need metal composites of noble metal. In polymeric materials, the production of (e−) and (h+) pairs occurs more rapidly compared to semiconductor photocatalyst like g-C3N4, primarily due to the presence of piled π bonds [260,261,262,263]. These accumulated π bonds within polymers facilitate instant charge transfer processes, as they were well candidates for catalyzing the CO2 photocatalytic reduction [260, 264,265,266,267]. The role of these stacked π bonds in CO2 photoreduction is significant, although research in this area for π conjugated materials are is still in its nascent stages. These stacked π bonds can play a pivotal role in the photoreduction of CO2; however, research on π conjugated materials is still in nascent stages [258].

Intensified research into polymeric materials derived from carbon holds greater promise for enhancing the photocatalytic reduction of CO2 when compared to current semiconductor photocatalyst. While these promising materials have shown favorable outcomes, further adjustments and the fine-tuning of band gaps are essential to achieve optimal results. It is crucial to consider both materials design and reaction methodology in this context. However, equally significant is evaluating the overall performance and sustainability of the entire energy generation and conversion process. With the aim of producing environmentally friendly fuels and mitigating the greenhouse effect in the future, it necessitates a more through and expansive investigation. This entails employing advanced tools and conducting detailed studies to gain a deeper understanding of these reaction [267,268,269,270].

9 Conclusion

In a global context increasingly oriented toward sustainable solutions, photocatalytic carbon dioxide photoreduction emerges as a pioneering innovation, presenting a promising avenue for addressing carbon emissions. By leveraging the transformative potential of light to convert carbon dioxide into valuable resources, this approach not only tackles environmental challenges but also unveils a spectrum of possibilities for cleaner energy and greener technologies. This comprehensive review primarily centers on elucidating the factors influencing product outcomes in CO2 photoreduction.

CO2 photoreduction, while holding promise as a sustainable approach for mitigating carbon emissions, confronts several challenges. The primary hurdle lies in the inherently low efficiency of the photoreduction process due to the limited absorption of solar radiation by CO2 and the competitive reduction of protons to hydrogen. Furthermore, a significant challenge is the selectivity toward desired products, often resulting in the generation of undesired by-products. Product distribution forms the basis for tailoring catalyst yield of desired products, emphasizing the necessity of achieving a delicate equilibrium between product selectivity and overall process efficiency. Thermodynamic considerations, such as redox potential and Gibbs free energy, offer insights into the energy requirements and feasibility of the process, predicting electron pathways and routes for optimal conditions conducive to efficient CO2 reduction. Additionally, the adsorption and CO2 activation properties eliminate product oxidation, maximizing efficiency. This implies that a purposefully engineered semiconductor with an enhanced adsorption ratio facilitates reaction kinetics.

Optimizing the compositional balance between these factors, although challenging, is essential for achieving high efficiency in CO2 photoreduction, necessitating further modifications. To ascertain production yield, differentiation between derivation from CO2 and impurities is imperative, achievable through isotope labeling in nano-scale probes.

To address the challenges involved in engineering of photocatalytic materials with enhanced properties’ development of innovative reactor system is crucial. Perspective solutions involve the engineering of photocatalytic materials with enhanced light absorption properties and tailored catalytic sites for improved selectivity. Integration of tandem catalysis, wherein multiple catalytic processes are sequentially coupled, may further enhance overall efficiency. Future strategies should focus on the exploration of novel materials, such as semiconductor nanomaterial and molecular catalysts, and the implementation of advanced computational approaches to guide catalyst design. Concurrently, a thorough investigation into photostability is imperative. The development of a robust and stable photocatalytic system capable of sustained operation under diverse conditions remains a critical objective. Additionally, efforts toward understanding the fundamental mechanistic aspects of CO2 photoreduction will be pivotal for optimizing and scaling up this technology to contribute substantively to carbon management and sustainable energy systems.

References

J. Ma, N. Sun, X. Zhang, N. Zhao, F. Xiao, W. Wei, Y. Sun, A short review of catalysis for CO2 conversion. Catal. Today 148, 221–231 (2009)

Z. Sun, J. Dong, C. Chen, S. Zhang, Y. Zhu, Photocatalytic and electrocatalytic CO2 conversion: from fundamental principles to design of catalysts. J. Chem. Technol. Biotechnol. 96, 1161–1175 (2021)

S. Zhang, Q. Fan, R. Xia, T.J. Meyer, CO2 reduction: from homogeneous to heterogeneous electrocatalysis. Acc. Chem. Res. 53, 255–264 (2020)

X. Li, J. Wen, J. Low, Y. Fang, J. Yu, Design and fabrication of semiconductor photocatalyst for photocatalytic reduction of CO2 to solar fuel. Sci. China Mater. 57, 70–100 (2014)

A.J. Bard, M.A. Fox, Artificial photosynthesis: solar splitting of water to hydrogen and oxygen. Acc. Chem. Res. 28, 141–145 (1995)

M.G. Walter, E.L. Warren, J.R. McKone, S.W. Boettcher, Q. Mi, E.A. Santori, N.S. Lewis, Solar water splitting cells. Chem. Rev. 110, 6446–6473 (2010)

X. Chen, S. Shen, L. Guo, S.S. Mao, Semiconductor-based photocatalytic hydrogen generation. Chem. Rev. 110, 6503–6570 (2010)

D. Cheng, H.H. Ngo, W. Guo, S.W. Chang, D.D. Nguyen, Y. Liu, X. Zhang, X. Shan, Y. Liu, Contribution of antibiotics to the fate of antibiotic resistance genes in anaerobic treatment processes of swine wastewater: a review. Biores. Technol. 299, 122654 (2020)

S. Dahl, I. Chorkendorff, Towards practical implementation. Nat. Mater. 11, 100–101 (2012)

V.N.H. Nguyen, T.H. Nguyen, M.S. Lee, Review on the comparison of the chemical reactivity of Cyanex 272, Cyanex 301 and Cyanex 302 for their application to metal separation from acid media. Metals 10, 1105 (2020)

S. Lingampalli, M.M. Ayyub, C. Rao, Recent progress in the photocatalytic reduction of carbon dioxide. ACS Omega 2, 2740–2748 (2017)

S. Sato, T. Arai, T. Morikawa, K. Uemura, T.M. Suzuki, H. Tanaka, T. Kajino, Selective CO2 conversion to formate conjugated with H2O oxidation utilizing semiconductor/complex hybrid photocatalysts. J. Am. Chem. Soc. 133, 15240–15243 (2011)

S.-Y. Liu, A. Zada, X. Yu, F. Liu, G. Jin, NiFe2O4/g-C3N4 heterostructure with an enhanced ability for photocatalytic degradation of tetracycline hydrochloride and antibacterial performance. Chemosphere 307, 135717 (2022)

Z. Liao, Y. Wu, S. Cao, S. Zhao, X. Yan, S. Yuan, K. Dong, J. Qin, C. Ou, J. Zhu, Facile engineering of PES ultrafiltration membranes using polyoxometalates for enhanced filtration and antifouling performance. Sep. Purif. Technol. 308, 122911 (2023)

A. Kudo, Y. Miseki, Heterogeneous photocatalyst materials for water splitting. Chem. Soc. Rev. 38, 253–278 (2009)

K. Maeda, K. Domen, New non-oxide photocatalysts designed for overall water splitting under visible light. J. Phys. Chem. C 111, 7851–7861 (2007)

P. Dhull, A. Sudhaik, V. Sharma, P. Raizada, V. Hasija, N. Gupta, T. Ahamad, V.-H. Nguyen, A. Kim, M. Shokouhimehr, An overview on InVO4-based photocatalysts: electronic properties, synthesis, enhancement strategies, and photocatalytic applications. Mol. Catal. 539, 113013 (2023)

N. Shehzad, M. Tahir, K. Johari, T. Murugesan, M. Hussain, Improved interfacial bonding of graphene-TiO2 with enhanced photocatalytic reduction of CO2 into solar fuel. J. Environ. Chem. Eng. 6, 6947–6957 (2018)

L. Wei, C. Yu, Q. Zhang, H. Liu, Y. Wang, TiO2-based heterojunction photocatalysts for photocatalytic reduction of CO2 into solar fuels. J. Mater. Chem. A 6, 22411–22436 (2018)

J. Cai, F. Shen, Z. Shi, Y. Lai, J. Sun, Nanostructured TiO2 for light-driven CO2 conversion into solar fuels. APL Mater. 8, 1 (2020)

X. Yu, V.V. Ordomsky, A.Y. Khodakov, Selective deposition of cobalt and copper oxides on BiVO4 facets for enhancement of CO2 photocatalytic reduction to hydrocarbons. ChemCatChem 12, 740–749 (2020)

X. Wang, Y. Wang, M. Gao, J. Shen, X. Pu, Z. Zhang, H. Lin, X. Wang, BiVO4/Bi4Ti3O12 heterojunction enabling efficient photocatalytic reduction of CO2 with H2O to CH3OH and CO. Appl. Catal. B 270, 118876 (2020)

X. Li, D. Wei, L. Ye, Z. Li, Fabrication of Cu2O-RGO/BiVO4 nanocomposite for simultaneous photocatalytic CO2 reduction and benzyl alcohol oxidation under visible light. Inorg. Chem. Commun. 104, 171–177 (2019)

B. Han, X. Ou, Z. Deng, Y. Song, C. Tian, H. Deng, Y.J. Xu, Z. Lin, Nickel metal–organic framework monolayers for photoreduction of diluted CO2: metal-node-dependent activity and selectivity. Angew. Chem. Int. Ed. 57, 16811–16815 (2018)

K. Song, X. Qiu, B. Han, S. Liang, Z. Lin, Efficient upcycling electroplating sludge and waste PET into Ni-MOF nanocrystals for the effective photoreduction of CO2. Environ. Sci. Nano 8, 390–398 (2021)

H.-N. Wang, H.-X. Sun, Y.-M. Fu, X. Meng, Y.-H. Zou, Y.-O. He, R.-G. Yang, Varied proton conductivity and photoreduction CO2 performance of isostructural heterometallic cluster based metal–organic frameworks. Inorgan. Chem. Front. 8, 4062–4071 (2021)

M. Que, Y. Zhao, Y. Yang, L. Pan, W. Lei, W. Cai, H. Yuan, J. Chen, G. Zhu, Anchoring of formamidinium lead bromide quantum dots on Ti3C2 nanosheets for efficient photocatalytic reduction of CO2. ACS Appl. Mater. Interfaces 13, 6180–6187 (2021)

K. Ren, S. Yue, C. Li, Z. Fang, K.A. Gasem, J. Leszczynski, S. Qu, Z. Wang, M. Fan, Metal halide perovskites for photocatalysis applications. J. Mater. Chem. A 10, 407–429 (2022)

S. Park, S. Choi, S. Kim, K.T. Nam, Metal halide perovskites for solar fuel production and photoreactions. J. Phys. Chem. Lett. 12, 8292–8301 (2021)

Y. Cui, P. Ge, M. Chen, L. Xu, Research progress in semiconductor materials with application in the photocatalytic reduction of CO2. Catalysts 12, 372 (2022)

R. Sharma, M. Khanuja, S.N. Sharma, O.P. Sinha, Reduced band gap & charge recombination rate in Se doped α-Bi2O3 leads to enhanced photoelectrochemical and photocatalytic performance: theoretical and experimental insight. Int. J. hydrog. Energy 42, 20638–20648 (2017)

J. Xiong, M. Zhang, M. Lu, K. Zhao, C. Han, G. Cheng, Z. Wen, Achieving simultaneous Cu particles anchoring in meso-porous TiO2 nanofabrication for enhancing photo-catalytic CO2 reduction through rapid charge separation. Chin. Chem. Lett. 33, 1313–1316 (2022)

H. Yu, J. Huang, L. Jiang, X. Yuan, K. Yi, W. Zhang, J. Zhang, H. Chen, Steering photo-excitons towards active sites: intensified substrates affinity and spatial charge separation for photocatalytic molecular oxygen activation and pollutant removal. Chem. Eng. J. 408, 127334 (2021)

F. Khodabandeloo, S. Shahsavarifar, B. Nayebi, K.P. Niavol, B. Nayebi, R.S. Varma, J.H. Cha, H.W. Jang, D. Kim, M. Shokouhimehr, Applications of nanostructured semiconductor photocatalysts for the decontamination of assorted pollutants from wastewater. Inorgan. Chem. Commun. 2023, 111357 (2023)

M. Zhu, X. Zhang, H. Feng, J. Dai, J. Li, Q. Che, Q. Gu, T. Zhu, D. Li, Penicisulfuranols A–F, alkaloids from the mangrove endophytic fungus Penicillium janthinellum HDN13-309. J. Nat. Prod. 80, 71–75 (2017)

H. Maleki-Ghaleh, M. Shakeri, Z. Dargahi, M. Kavanlouei, H.K. Garabagh, E. Moradpur-Tari, A. Yourdkhani, A. Fallah, A. Zarrabi, B. Koç, Characterization and optical properties of mechanochemically synthesized molybdenum-doped rutile nanoparticles and their electronic structure studies by density functional theory. Mater. Today Chem. 24, 100820 (2022)

N.U.M. Nor, E. Mazalan, C. Risko, M. Crocker, N.A.S. Amin, Unveiling the structural, electronic, and optical effects of carbon-doping on multi-layer anatase TiO2 (1 0 1) and the impact on photocatalysis. Appl. Surf. Sci. 586, 152641 (2022)

C. Feng, Z. Chen, W. Li, F. Zhang, X. Li, L. Xu, M. Sun, First-principle calculation of the electronic structures and optical properties of the metallic and nonmetallic elements-doped ZnO on the basis of photocatalysis. Physica B 555, 53–60 (2019)

M. Kapilashrami, Y. Zhang, Y.-S. Liu, A. Hagfeldt, J. Guo, Probing the optical property and electronic structure of TiO2 nanomaterials for renewable energy applications. Chem. Rev. 114, 9662–9707 (2014)

S. Xu, E.A. Carter, Theoretical insights into heterogeneous (photo) electrochemical CO2 reduction. Chem. Rev. 119, 6631–6669 (2018)

H. Yang, F. Teng, W. Gu, Z. Liu, Y. Zhao, A. Zhang, Z. Liu, Y. Teng, A simple post-synthesis conversion approach to Zn (OH) F and the effects of fluorine and hydroxyl on the photodegradation properties of dye wastewater. J. Hazard. Mater. 333, 250–258 (2017)

Z. Zhang, L. Wang, W. Liu, Z. Yan, Y. Zhu, S. Zhou, S. Guan, Photogenerated-hole-induced rapid elimination of solid tumors by the supramolecular porphyrin photocatalyst. Natl. Sci. Rev. 8, naa155 (2021)

I. Okeke, C. Okeke, Molecular docking and analysis of in silico generated ligands against SARS-CoV-2 spike and replicase proteins (2022). https://doi.org/10.21203/rs.3.rs-2069911/v1.

C.O.L. Mbuya, C.G. Okoye-Chine, K. Ramutsindela, L.L. Jewell, M. Scurrell, Microwave modification of iron supported on beta silicon carbide catalysts for Fischer–Tropsch synthesis. React. Chem. Eng. 7, 1307–1314 (2022)

R. Gandhi, A. Moses, S.S. Baral, Fundamental study of the photocatalytic reduction of CO2: a short review of thermodynamics, kinetics and mechanisms. Chem. Process. Eng. 43, 223–228 (2022)

T. Mavrič, Synthesis and characterization of metal/semiconductor nanocomposites for photocatalysis (Univerza v Novi Gorici, Fakulteta za podiplomski študij, 2017)

H. Liang, H. Zhang, P. Zhao, X. Zhao, H. Sun, Z. Geng, D. She, Synthesis of a novel three-dimensional porous carbon material and its highly selective Cr(VI) removal in wastewater. J. Clean. Prod. 306, 127204 (2021)

J.R. Bolton, Solar fuels: the production of energy-rich compounds by the photochemical conversion and storage of solar energy. Science 202, 705–711 (1978)

J.-M. Lehn, R. Ziessel, Photochemical generation of carbon monoxide and hydrogen by reduction of carbon dioxide and water under visible light irradiation. Proc. Natl. Acad. Sci. 79, 701–704 (1982)

X. Tan, Y. Jiang, Y. Chen, A. Tong, J. Li, Y. Sun, Roles of different components of complex inclusion in pitting of 321 stainless steel: induction effect of CaS and inhibition effect of TiN. Corros. Sci. 209, 110692 (2022)

G. Yasin, S. Ibraheem, S. Ali, M. Arif, S. Ibrahim, R. Iqbal, A. Kumar, M. Tabish, M. Mushtaq, A. Saad, Defects-engineered tailoring of tri-doped interlinked metal-free bifunctional catalyst with lower Gibbs free energy of OER/HER intermediates for overall water splitting. Mater. Today Chem. 23, 100634 (2022)

X. Li, J. Yu, M. Jaroniec, X. Chen, Cocatalysts for selective photoreduction of CO2 into solar fuels. Chem. Rev. 119, 3962–4179 (2019)

K. Nakata, A. Fujishima, TiO2 photocatalysis: design and applications. J. Photochem. Photobiol. C 13, 169–189 (2012)

A.L. Linsebigler, G. Lu, J.T. Yates Jr., Photocatalysis on TiO2 surfaces: principles, mechanisms, and selected results. Chem. Rev. 95, 735–758 (1995)

A. Dhakshinamoorthy, S. Navalon, A. Corma, H. Garcia, Photocatalytic CO2 reduction by TiO2 and related titanium containing solids. Energy Environ. Sci. 5, 9217–9233 (2012)

V.P. Indrakanti, J.D. Kubicki, H.H. Schobert, Photoinduced activation of CO2 on Ti-based heterogeneous catalysts: current state, chemical physics-based insights and outlook. Energy Environ. Sci. 2, 745–758 (2009)

T. Inoue, A. Fujishima, S. Konishi, K. Honda, Photoelectrocatalytic reduction of carbon dioxide in aqueous suspensions of semiconductor powders. Nature 277, 637–638 (1979)

J. Nunez, P. Jana, J.M. Coronado, D.P. Serrano, Effect of copper on the performance of ZnO and ZnO1−xNx oxides as CO2 photoreduction catalysts. Catal. Today 209, 21–27 (2013)

G. Xi, S. Ouyang, J. Ye, General synthesis of hybrid TiO2 mesoporous “French fries” toward improved photocatalytic conversion of CO2 into hydrocarbon fuel: a case of TiO2/ZnO. Chem. A Eur. J. 17, 9057–9061 (2011)

G. Guan, T. Kida, A. Yoshida, Reduction of carbon dioxide with water under concentrated sunlight using photocatalyst combined with Fe-based catalyst. Appl. Catal. B 41, 387–396 (2003)

G. Mahmodi, S. Sharifnia, F. Rahimpour, S. Hosseini, Photocatalytic conversion of CO2 and CH4 using ZnO coated mesh: effect of operational parameters and optimization. Sol. Energy Mater. Sol. Cells 111, 31–40 (2013)

H. Inoue, H. Moriwaki, K. Maeda, H. Yoneyama, Photoreduction of carbon dioxide using chalcogenide semiconductor microcrystals. J. Photochem. Photobiol. A 86, 191–196 (1995)

H. Fujiwara, H. Hosokawa, K. Murakoshi, Y. Wada, S. Yanagida, Surface characteristics of ZnS nanocrystallites relating to their photocatalysis for CO2 reduction1. Langmuir 14, 5154–5159 (1998)

K. Kočí, M. Reli, O. Kozák, Z. Lacný, D. Plachá, P. Praus, L. Obalová, Influence of reactor geometry on the yield of CO2 photocatalytic reduction. Catal. Today 176, 212–214 (2011)

H. Zhou, J. Guo, P. Li, T. Fan, D. Zhang, J. Ye, Leaf-architectured 3D hierarchical artificial photosynthetic system of perovskite titanates towards CO2 photoreduction into hydrocarbon fuels. Sci. Rep. 3, 1667 (2013)

B. Aurian-Blajeni, M. Halmann, J. Manassen, Photoreduction of carbon dioxide and water into formaldehyde and methanol on semiconductor materials. Sol. Energy 25, 165–170 (1980)

D. Sui, X. Yin, H. Dong, S. Qin, J. Chen, W. Jiang, Photocatalytically reducing CO2 to methyl formate in methanol over Ag loaded SrTiO3 nanocrystal catalysts. Catal. Lett. 142, 1202–1210 (2012)

W.-H. Lee, C.-H. Liao, M.-F. Tsai, C.-W. Huang, J.C. Wu, A novel twin reactor for CO2 photoreduction to mimic artificial photosynthesis. Appl. Catal. B 132, 445–451 (2013)

S. Yamamura, H. Kojima, J. Iyoda, W. Kawai, Formation of ethyl alcohol in the photocatalytic reduction of carbon dioxide by SiC and ZnSe/metal powders. J. Electroanal. Chem. Interfacial Electrochem. 225, 287–290 (1987)

H. Li, Y. Lei, Y. Huang, Y. Fang, Y. Xu, L. Zhu, X. Li, Photocatalytic reduction of carbon dioxide to methanol by Cu2O/SiC nanocrystallite under visible light irradiation. J. Nat. Gas Chem. 20, 145–150 (2011)

T.-C. Yang, F.-C. Chang, C.-Y. Peng, H.P. Wang, Y.-L. Wei, Photocatalytic reduction of CO2 with SiC recovered from silicon sludge wastes. Environ. Technol. 36, 2987–2990 (2015)

Y. Li, W.-N. Wang, Z. Zhan, M.-H. Woo, C.-Y. Wu, P. Biswas, Photocatalytic reduction of CO2 with H2O on mesoporous silica supported Cu/TiO2 catalysts. Appl. Catal. B 100, 386–392 (2010)

I.-H. Tseng, W.-C. Chang, J.C. Wu, Photoreduction of CO2 using sol–gel derived titania and titania-supported copper catalysts. Appl. Catal. B 37, 37–48 (2002)

Y. Bessekhouad, D. Robert, J.-V. Weber, Photocatalytic activity of Cu2O/TiO2, Bi2O3/TiO2 and ZnMn2O4/TiO2 heterojunctions. Catal. Today 101, 315–321 (2005)

D. Robert, Photosensitization of TiO2 by MxOy and MxSy nanoparticles for heterogeneous photocatalysis applications. Catal. Today 122, 20–26 (2007)

H. Fujiwara, H. Hosokawa, K. Murakoshi, Y. Wada, S. Yanagida, T. Okada, H. Kobayashi, Effect of surface structures on photocatalytic CO2 reduction using quantized CdS nanocrystallites. J. Phys. Chem. B 101, 8270–8278 (1997)

B.-J. Liu, T. Torimoto, H. Yoneyama, Photocatalytic reduction of CO2 using surface-modified CdS photocatalysts in organic solvents. J. Photochem. Photobiol. A 113, 93–97 (1998)

X. Li, J. Chen, H. Li, J. Li, Y. Xu, Y. Liu, J. Zhou, Photoreduction of CO2 to methanol over Bi2S3/CdS photocatalyst under visible light irradiation. J. Nat. Gas Chem. 20, 413–417 (2011)

P. Praus, O. Kozák, K. Kočí, A. Panáček, R. Dvorský, CdS nanoparticles deposited on montmorillonite: preparation, characterization and application for photoreduction of carbon dioxide. J. Colloid Interface Sci. 360, 574–579 (2011)

Y.S. Chaudhary, T.W. Woolerton, C.S. Allen, J.H. Warner, E. Pierce, S.W. Ragsdale, F.A. Armstrong, Visible light-driven CO2 reduction by enzyme coupled CdS nanocrystals. Chem. Commun. 48, 58–60 (2012)

X. Li, H. Liu, D. Luo, J. Li, Y. Huang, H. Li, Y. Fang, Y. Xu, L. Zhu, Adsorption of CO2 on heterostructure CdS (Bi2S3)/TiO2 nanotube photocatalysts and their photocatalytic activities in the reduction of CO2 to methanol under visible light irradiation. Chem. Eng. J. 180, 151–158 (2012)

E.E. Barton, D.M. Rampulla, A.B. Bocarsly, Selective solar-driven reduction of CO2 to methanol using a catalyzed p-GaP based photoelectrochemical cell. J. Am. Chem. Soc. 130, 6342–6344 (2008)

K. Sekizawa, K. Maeda, K. Domen, K. Koike, O. Ishitani, Artificial Z-scheme constructed with a supramolecular metal complex and semiconductor for the photocatalytic reduction of CO2. J. Am. Chem. Soc. 135, 4596–4599 (2013)

M. Hara, J. Nunoshige, T. Takata, J.N. Kondo, K. Domen, Unusual enhancement of H2 evolution by Ru on TaON photocatalyst under visible light irradiation. Chem. Commun. 2003, 3000–3001 (2003)

E.S. Kim, N. Nishimura, G. Magesh, J.Y. Kim, J.-W. Jang, H. Jun, J. Kubota, K. Domen, J.S. Lee, Fabrication of CaFe2O4/TaON heterojunction photoanode for photoelectrochemical water oxidation. J. Am. Chem. Soc. 135, 5375–5383 (2013)

K. Maeda, M. Higashi, D. Lu, R. Abe, K. Domen, Efficient nonsacrificial water splitting through two-step photoexcitation by visible light using a modified oxynitride as a hydrogen evolution photocatalyst. J. Am. Chem. Soc. 132, 5858–5868 (2010)

J. Mao, T. Peng, X. Zhang, K. Li, L. Ye, L. Zan, Effect of graphitic carbon nitride microstructures on the activity and selectivity of photocatalytic CO2 reduction under visible light. Catal. Sci. Technol. 3, 1253–1260 (2013)

J. Yu, S. Wang, B. Cheng, Z. Lin, F. Huang, Noble metal-free Ni (OH) 2–gC3N4 composite photocatalyst with enhanced visible-light photocatalytic H2-production activity. Catal. Sci. Technol. 3, 1782–1789 (2013)

J. Zhang, X. Chen, K. Takanabe, K. Maeda, K. Domen, J.D. Epping, X. Fu, M. Antonietti, X. Wang, Synthesis of a carbon nitride structure for visible-light catalysis by copolymerization. Angew. Chem. Int. Ed. 49, 441–444 (2010)

A. Kudo, K. Ueda, H. Kato, I. Mikami, Photocatalytic O2 evolution under visible light irradiation on BiVO4 in aqueous AgNO3 solution. Catal. Lett. 53, 229–230 (1998)

A. Kudo, K. Omori, H. Kato, A novel aqueous process for preparation of crystal form-controlled and highly crystalline BiVO4 powder from layered vanadates at room temperature and its photocatalytic and photophysical properties. J. Am. Chem. Soc. 121, 11459–11467 (1999)

S. Tokunaga, H. Kato, A. Kudo, Selective preparation of monoclinic and tetragonal BiVO4 with scheelite structure and their photocatalytic properties. Chem. Mater. 13, 4624–4628 (2001)

H. Jiang, H. Dai, X. Meng, K. Ji, L. Zhang, J. Deng, Porous olive-like BiVO4: alcoho-hydrothermal preparation and excellent visible-light-driven photocatalytic performance for the degradation of phenol. Appl. Catal. B 105, 326–334 (2011)

H. Jiang, X. Meng, H. Dai, J. Deng, Y. Liu, L. Zhang, Z. Zhao, R. Zhang, High-performance porous spherical or octapod-like single-crystalline BiVO4 photocatalysts for the removal of phenol and methylene blue under visible-light illumination. J. Hazard. Mater. 217, 92–99 (2012)

W.-J. Chun, A. Ishikawa, H. Fujisawa, T. Takata, J.N. Kondo, M. Hara, M. Kawai, Y. Matsumoto, K. Domen, Conduction and valence band positions of Ta2O5, TaON, and Ta3N5 by UPS and electrochemical methods. J. Phys. Chem. B 107, 1798–1803 (2003)

M. Higashi, K. Domen, R. Abe, Fabrication of efficient TaON and Ta3N5 photoanodes for water splitting under visible light irradiation. Energy Environ. Sci. 4, 4138–4147 (2011)

Y. Li, T. Takata, D. Cha, K. Takanabe, T. Minegishi, J. Kubota, K. Domen, Vertically aligned Ta3N5 nanorod arrays for solar-driven photoelectrochemical water splitting. Adv. Mater. 25, 125–131 (2013)

S.S.K. Ma, T. Hisatomi, K. Maeda, Y. Moriya, K. Domen, Enhanced water oxidation on Ta3N5 photocatalysts by modification with alkaline metal salts. J. Am. Chem. Soc. 134, 19993–19996 (2012)

X. Yang, C. Cao, L. Erickson, K. Hohn, R. Maghirang, K. Klabunde, Synthesis of visible-light-active TiO2-based photocatalysts by carbon and nitrogen doping. J. Catal. 260, 128–133 (2008)

D. Jiang, Y. Xu, D. Wu, Y. Sun, Isocyanate-modified TiO2 visible-light-activated photocatalyst. Appl. Catal. B 88, 165–172 (2009)

K. Villa, A. Black, X. Domenech, J. Peral, Nitrogen doped TiO2 for hydrogen production under visible light irradiation. Sol. Energy 86, 558–566 (2012)

S. Qin, S.L. Chan, S. Gu, Y. Bai, Z. Ren, X. Lin, Z. Chen, W. Jia, Y. Jin, Y. Guo, Camrelizumab plus rivoceranib versus sorafenib as first-line therapy for unresectable hepatocellular carcinoma (CARES-310): a randomised, open-label, international phase 3 study. The Lancet 402, 1133–1146 (2023)

Y. Zou, S. Wang, An investigation of active sites for electrochemical CO2 reduction reactions: from in situ characterization to rational design. Adv. Sci. 8, 2003579 (2021)

M. Dunwell, W. Luc, Y. Yan, F. Jiao, B. Xu, Understanding surface-mediated electrochemical reactions: CO2 reduction and beyond. ACS Catal. 8, 8121–8129 (2018)

A.J. Morris, G.J. Meyer, E. Fujita, Molecular approaches to the photocatalytic reduction of carbon dioxide for solar fuels. Acc. Chem. Res. 42, 1983–1994 (2009)

Z. Yu, K. Zheng, X. Li, P. Xia, J. Xu, J. Sun, N. Zhou, F. Pan, Effect of Ti6Al4V reinforcement particles on the mechanical, wear, and corrosion properties of AZ91D magnesium matrix composites. J. Market. Res. 26, 7395–7411 (2023)

I. Willner, R. Maidan, D. Mandler, H. Duerr, G. Doerr, K. Zengerle, Photosensitized reduction of carbon dioxide to methane and hydrogen evolution in the presence of ruthenium and osmium colloids: strategies to design selectivity of products distribution. J. Am. Chem. Soc. 109, 6080–6086 (1987)

A. Yahaya, M. Gondal, A. Hameed, Selective laser enhanced photocatalytic conversion of CO2 into methanol. Chem. Phys. Lett. 400, 206–212 (2004)

W.A. Thompson, E. Sanchez Fernandez, M.M. Maroto-Valer, Review and analysis of CO2 photoreduction kinetics. ACS Sustain. Chem. Eng. 8, 4677–4692 (2020)

M. Tahir, N.S. Amin, Photocatalytic CO2 reduction with H2O vapors using montmorillonite/TiO2 supported microchannel monolith photoreactor. Chem. Eng. J. 230, 314–327 (2013)

L.-L. Tan, W.-J. Ong, S.-P. Chai, A.R. Mohamed, Photocatalytic reduction of CO2 with H2O over graphene oxide-supported oxygen-rich TiO2 hybrid photocatalyst under visible light irradiation: process and kinetic studies. Chem. Eng. J. 308, 248–255 (2017)

A. Khalilzadeh, A. Shariati, Photoreduction of CO2 over heterogeneous modified TiO2 nanoparticles under visible light irradiation: synthesis, process and kinetic study. Sol. Energy 164, 251–261 (2018)

S. Delavari, N.A.S. Amin, Photocatalytic conversion of CO2 and CH4 over immobilized titania nanoparticles coated on mesh: optimization and kinetic study. Appl. Energy 162, 1171–1185 (2016)

M. Tahir, N.S. Amin, Indium-doped TiO2 nanoparticles for photocatalytic CO2 reduction with H2O vapors to CH4. Appl. Catal. B 162, 98–109 (2015)

J.C. Wu, H.-M. Lin, C.-L. Lai, Photo reduction of CO2 to methanol using optical-fiber photoreactor. Appl. Catal. A 296, 194–200 (2005)

Y. Ku, W.-H. Lee, W.-Y. Wang, Photocatalytic reduction of carbonate in aqueous solution by UV/TiO2 process. J. Mol. Catal. A: Chem. 212, 191–196 (2004)

S. Jain, G. Dangi, J. Vardia, S.C. Ameta, Photocatalytic reduction of some alkali carbonates in the presence of methylene blue. Int. J. Energy Res. 23, 71–77 (1999)

J. Ran, M. Jaroniec, S.Z. Qiao, Cocatalysts in semiconductor-based photocatalytic CO2 reduction: achievements, challenges, and opportunities. Adv. Mater. 30, 1704649 (2018)

J. Ângelo, L. Andrade, L.M. Madeira, A. Mendes, An overview of photocatalysis phenomena applied to NOx abatement. J. Environ. Manag. 129, 522–539 (2013)

H. Chen, C.E. Nanayakkara, V.H. Grassian, Titanium dioxide photocatalysis in atmospheric chemistry. Chem. Rev. 112, 5919–5948 (2012)

S. Nahar, M. Zain, A.A.H. Kadhum, H.A. Hasan, M.R. Hasan, Advances in photocatalytic CO2 reduction with water: a review. Materials 10, 629 (2017)

J.M. Luo, C.F. Lam, Travel anxiety, risk attitude and travel intentions towards “travel bubble” destinations in Hong Kong: effect of the fear of COVID-19. Int. J. Environ. Res. Public Health 17, 7859 (2020)

M. Cheng, P. He, L. Lei, X. Tan, X. Wang, Y. Sun, J. Li, Y. Jiang, Comparative studies on microstructure evolution and corrosion resistance of 304 and a newly developed high Mn and N austenitic stainless steel welded joints. Corros. Sci. 183, 109338 (2021)

W. Fan, Q. Zhang, Y. Wang, Semiconductor-based nanocomposites for photocatalytic H2 production and CO2 conversion. Phys. Chem. Chem. Phys. 15, 2632–2649 (2013)

S. Shen, J. Shi, P. Guo, L. Guo, Visible-light-driven photocatalytic water splitting on nanostructured semiconducting materials. Int. J. Nanotechnol. 8, 523–591 (2011)

P. Rajesh, F.H. Shajin, B.N. Kommula, An efficient integration and control approach to increase the conversion efficiency of high-current low-voltage DC/DC converter. Energy Syst. 13, 939–958 (2022)

J. Yu, J. Jin, B. Cheng, M. Jaroniec, A noble metal-free reduced graphene oxide–CdS nanorod composite for the enhanced visible-light photocatalytic reduction of CO2 to solar fuel. J. Mater. Chem. A 2, 3407–3416 (2014)

J. Lin, Z. Pan, X. Wang, Photochemical reduction of CO2 by graphitic carbon nitride polymers. ACS Sustain. Chem. Eng. 2, 353–358 (2014)

J. Yu, K. Wang, W. Xiao, B. Cheng, Photocatalytic reduction of CO2 into hydrocarbon solar fuels over gC3N4–Pt nanocomposite photocatalysts. Phys. Chem. Chem. Phys. 16, 11492–11501 (2014)

Y. Liu, Z. Wang, B. Huang, Y. Dai, X. Qin, X. Zhang, Microstructure modulation of semiconductor photocatalysts for CO2 reduction. Curr. Org. Chem. 18, 620–628 (2014)

Y.P. Xie, G. Liu, L. Yin, H.-M. Cheng, Crystal facet-dependent photocatalytic oxidation and reduction reactivity of monoclinic WO3 for solar energy conversion. J. Mater. Chem. 22, 6746–6751 (2012)

Y. Matsumoto, Energy positions of oxide semiconductors and photocatalysis with iron complex oxides. J. Solid State Chem. 126, 227–234 (1996)

L. Jia, J. Li, W. Fang, Enhanced visible-light active C and Fe co-doped LaCoO3 for reduction of carbon dioxide. Catal. Commun. 11, 87–90 (2009)

Y. Liu, B. Huang, Y. Dai, X. Zhang, X. Qin, M. Jiang, M.-H. Whangbo, Selective ethanol formation from photocatalytic reduction of carbon dioxide in water with BiVO4 photocatalyst. Catal. Commun. 11, 210–213 (2009)

J. Mao, T. Peng, X. Zhang, K. Li, L. Zan, Selective methanol production from photocatalytic reduction of CO2 on BiVO4 under visible light irradiation. Catal. Commun. 28, 38–41 (2012)

Y. Zhou, Z. Tian, Z. Zhao, Q. Liu, J. Kou, X. Chen, J. Gao, S. Yan, Z. Zou, High-yield synthesis of ultrathin and uniform Bi2WO6 square nanoplates benefitting from photocatalytic reduction of CO2 into renewable hydrocarbon fuel under visible light. ACS Appl. Mater. Interfaces 3, 3594–3601 (2011)

H. Cheng, B. Huang, Y. Liu, Z. Wang, X. Qin, X. Zhang, Y. Dai, An anion exchange approach to Bi2 WO6 hollow microspheres with efficient visible light photocatalytic reduction of CO2 to methanol. Chem. Commun. 48, 9729–9731 (2012)

P. Li, Y. Zhou, W. Tu, Q. Liu, S. Yan, Z. Zou, Direct growth of Fe2V4O13 nanoribbons on a stainless-steel mesh for visible-light photoreduction of CO2 into renewable hydrocarbon fuel and degradation of gaseous isopropyl alcohol. ChemPlusChem 78, 274–278 (2013)

Z.-Y. Wang, H.-C. Chou, J.C. Wu, D.P. Tsai, G. Mul, CO2 photoreduction using NiO/InTaO4 in optical-fiber reactor for renewable energy. Appl. Catal. A 380, 172–177 (2010)

P.-W. Pan, Y.-W. Chen, Photocatalytic reduction of carbon dioxide on NiO/InTaO4 under visible light irradiation. Catal. Commun. 8, 1546–1549 (2007)

H.-C. Chen, H.-C. Chou, J.C. Wu, H.-Y. Lin, Sol–gel prepared InTaO4 and its photocatalytic characteristics. J. Mater. Res. 23, 1364–1370 (2008)

C.-W. Tsai, H.M. Chen, R.-S. Liu, K. Asakura, T.-S. Chan, Ni@ NiO core–shell structure-modified nitrogen-doped InTaO4 for solar-driven highly efficient CO2 reduction to methanol. J. Phys. Chem. C 115, 10180–10186 (2011)

W. Shi, M. Laabs, M. Reinmoeller, L. Kong, S.V. Vassilev, S. Guhl, J. Bai, B. Meyer, W. Li, The fusion mechanism of complex minerals mixture and prediction model for flow temperature of coal ash for gasification. Fuel 305, 121448 (2021)

S. Li, Y. Wu, H. Zheng, H. Li, Y. Zheng, J. Nan, J. Ma, D. Nagarajan, J.-S. Chang, Antibiotics degradation by advanced oxidation process (AOPs): recent advances in ecotoxicity and antibiotic-resistance genes induction of degradation products. Chemosphere 311, 136977 (2023)

N. Serpone, A. Emeline, Semiconductor Photocatalysis—Past, Present, and Future Outlook (ACS Publications, London, 2012), pp.673–677

J.-X. Wang, Y. Zhao, M.-S. Chen, H. Zhang, J.-G. Cui, J.-L. Li, Heme-oxygenase-1 as a target for phthalate-induced cardiomyocytes ferroptosis. Environ. Pollut. 317, 120717 (2023)

L.G. Devi, R. Kavitha, A review on non metal ion doped titania for the photocatalytic degradation of organic pollutants under UV/solar light: role of photogenerated charge carrier dynamics in enhancing the activity. Appl. Catal. B 140, 559–587 (2013)

R. Huang, J. Wu, M. Zhang, B. Liu, Z. Zheng, D. Luo, Strategies to enhance photocatalytic activity of graphite carbon nitride-based photocatalysts. Mater. Des. 210, 110040 (2021)

F.A. Qaraah, S.A. Mahyoub, Q.A. Drmosh, A. Qaraah, F. Xin, One-step fabrication of unique 3D/2D S, O-doped g-C3N4 S-scheme isotype heterojunction for boosting CO2 photoreduction. Mater. Today Sustain. 23, 100437 (2023)

N. Serpone, Is the Band Gap of Pristine TiO2 Narrowed by Anion-and Cation-Doping of Titanium Dioxide in Second-Generation Photocatalysts? (ACS Publications, London, 2006), pp. 24287–24293.

S.B. Patil, P.S. Basavarajappa, N. Ganganagappa, M. Jyothi, A. Raghu, K.R. Reddy, Recent advances in non-metals-doped TiO2 nanostructured photocatalysts for visible-light driven hydrogen production, CO2 reduction and air purification. Int. J. Hydrog. Energy 44, 13022–13039 (2019)

N. Shehzad, M. Tahir, K. Johari, T. Murugesan, M. Hussain, A critical review on TiO2 based photocatalytic CO2 reduction system: strategies to improve efficiency. J. CO2 Util. 26, 98–122 (2018).

Y. Yan, Y. Yu, S. Huang, Y. Yang, X. Yang, S. Yin, Y. Cao, Adjustment and matching of energy band of TiO2-based photocatalysts by metal ions (Pd, Cu, Mn) for photoreduction of CO2 into CH4. J. Phys. Chem. C 121, 1089–1098 (2017)

Y. Sohn, W. Huang, F. Taghipour, Recent progress and perspectives in the photocatalytic CO2 reduction of Ti-oxide-based nanomaterials. Appl. Surf. Sci. 396, 1696–1711 (2017)

J. Jiao, Y. Wei, K. Chi, Z. Zhao, A. Duan, J. Liu, G. Jiang, Y. Wang, X. Wang, C. Han, Platinum nanoparticles supported on TiO2 photonic crystals as highly active photocatalyst for the reduction of CO2 in the presence of water. Energ. Technol. 5, 877–883 (2017)

M. Tahir, B. Tahir, N.A.S. Amin, H. Alias, Selective photocatalytic reduction of CO2 by H2O/H2 to CH4 and CH3OH over Cu-promoted In2O3/TiO2 nanocatalyst. Appl. Surf. Sci. 389, 46–55 (2016)