Abstract

One of the most commonly observed distress in asphalt pavement is shrinkage cracking, which has a significant negative impact on the service life of asphalt pavement. The primary purpose of this study is to evaluate the effects of shrinkage or transverse cracking of asphalt pavement on the load transfer efficiency (LTE) by using data obtained from the portable falling weight deflectometer (PFWD) device. So, the pavements of two roads, which were different in thickness, asphalt mix design, and service life, were chosen. The deflections of about 800 different transverse cracks were then measured by the PFWD device. After the evaluation of the collected data, a new equation was proposed for the calculation of the LTE, which is expected to be more accurate than previous equations. A Finite Element (FE) model was then developed by ABAQUS to investigate the LTE of transverse cracks with high accuracy. After the comparison between the developed model and the collected data, the correctness of this model was verified. Also, the effects of some important factors, including the asphalt concrete thickness, and asphalt concrete and base course modulus on the LTE, were investigated in the FE model. The results of field data and FE analyses indicated that the LTE of transverse cracks in asphalt pavement depends on both cracks' widths and the asphalt layer's thickness. The results revealed that when the cracks' widths and the thickness of the asphalt layer increase, the LTE value decreases. Moreover, the results of the FE model analysis for the asphalt concrete and base course indicated that the effect of the asphalt concrete modulus on the LTE was negligible; however, the base course modulus had a considerable impact on the LTE. Hence, the LTE values can be estimated by using the developed model, transverse cracks' widths, and the thickness of asphalt pavement without using the PFWD device.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

One of the most important operations performed by pavement management systems (PMS) is the evaluation of the distress of road pavement and the determination of pavement quality. The obtained data are used for different purposes, such as the prediction of the distress extension and the service life of the pavement, asphalt maintenance and rehabilitation, the estimation of the required budget, and prioritizing the maintenance and repair operations [1].

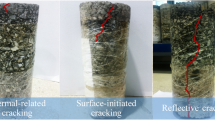

Mostly, asphalt pavement is one of the most common types of pavements for roads and highways, which is damaged due to different factors. One of the distresses observed in asphalt pavement is cracking. Several reasons are involved in creating cracks on asphalt surfaces, such as traffic loads, weather conditions, mixture properties, aging effects, and construction factors [2]. Among all types of cracks, transverse cracks are common, which can have significant negative effects on the service life of asphalt pavement. Transverse cracking is created by different factors including, thermal-stress accumulation, variations of pavements' temperatures, and daily temperature fluctuations. Transverse cracks usually originate from the asphalt's upper layer and extend toward the lower levels. These cracks can increase the roughness of asphalt and decrease the quality of road vehicle movement and the load bearing capacity of asphalt pavement. Transverse cracks can also increase water penetration into asphalt pavement layers. As a result, they reduce the service life and performance of asphalt pavement [3]. Hence, different experimental methods have been used to enhance the mechanical properties and load bearing capacity of pavements [4,5,6,7,8,9,10]. However, these methods have limitations in terms of costs and time, and new non-destructive and numerical methods are necessary to reduce pavement construction and evaluation costs.

Although some methods, such as visual surveys or coring, are usually used for the evaluation of pavements' cracks, coring is a limited, expensive, and destructive method. Also, the visual survey is not accurate due to the lack of discrimination of the full depth and the partial depth of cracks. Therefore, it is essential to use, meticulous, inexpensive, and non-destructive methods for the prediction and evaluation of cracks in asphalt layers [11]. It has been necessary to enhance the quality assurance procedures and quality control for pavement design. For this purpose, some different non-destructive methods, including the multi-channel analysis of surface waves (MASW), the falling weight deflectometer (FWD), the infrared thermography, the ground-penetrating radar (GPR) [12, 13], fuzzy networks [14], CT scan methods [15] the Texas mobile load simulator (TXMLS) [16] and plate load test (PLT) [17], have been employed to investigate the asphalt pavement structure. Nevertheless, these methods and devices are not practical due to their limitations during the pavement construction process. For instance, accessibility issues were reported for the FWD during the road construction procedure. Regarding the PLT, it usually demands a loaded truck which may be an obstacle on roads, and it has a slow process, causing a few hours of delays. These kinds of limitations encouraged the researchers to develop new pavement assessment devices which have fast measurement processes and they are easy to move and operate, one of which is the PFWD [17]. This is a portable and light device that provides the measured data quickly [18]. Some important features of this device, including low price, accessible and fast measurements, lower costs, and higher quality evaluations provided acceptable and reliable quality assurance programs for transportation agencies [19].

The prediction of asphalt pavement structural responses and mechanical performance has been investigated with the finite element (FE) method in different studies [20,21,22,23,24]. Indeed, a wide range of pavement technical problems can be solved with the Finite Element Method (FEM), and realistic predictions for asphalt pavement responses, which could meet the requirements, were provided with this method [25,26,27]. The ABAQUS software package has the capability of linear, nonlinear, static, and dynamic FEM modeling which has been used for pavement engineering in recent years. Indeed, large-scale 3D solid models have been developed for pavements considering different materials’ behavior, including hyperelasticity, linear elasticity, viscoelasticity, and elastoplasticity. Hence, the developed pavement models with these responses have been loaded in different conditions, which can save a lot of time and costs and reveal beneficial results [20].

The purpose of this study is to evaluate the effects of transverse cracking of asphalt pavements on the load transfer efficiency (LTE) of asphalt pavement by using data obtained from the PFWD device. So, the pavements of the two routes, which were different in thickness, asphalt mix design, and service life, were investigated. A FE model was then developed by ABAQUS to investigate the LTE of transverse cracks with high accuracy. The effect of different important factors, including the asphalt layer thickness, asphalt concrete, and base course modulus, were also examined on the LTE. After the comparison between the developed model and the collected data, the correctness of this model was verified.

2 Literature Review

According to the current methods for the determination of the LTE of pavements, cracks can transfer half of the loads to other sides. If an equal amount of stress and deflection is observed on both sides of the cracks, the crack system can transfer the load completely [28]. If cracks have low performance in transferring loads, different deflections can be seen on each side of the cracks, which can reduce the ratio of deflections on each side of the cracks. However, if cracks transfer a considerable amount of load, equal deflections are observed on each side of the crack. Thus, the ratio of deflection on each side is around 1 (LTE = 100) [29].

Many factors can affect the LTE, including the position of the loading plate, the temperature of pavement and variation of temperatures, traffic loads, and asphalt mix design [29,30,31].

The LTE can be calculated with Eq. 1 [29,30,31,32].

where the deflection of the unloaded edge of cracks is Wunloaded (mm), and the deflection of the loaded edge of the crack is Wloaded (mm).

Lin et al. (2006) found that transverse cracks had negative effects on the performance of pavement structures. A new parameter was also proposed called "Pavement Structure Condition (PSC)", which was directly obtained from FWD data. This parameter could determine the conditions of different transverse cracks. PSC was also beneficial to investigate the LTE of transverse cracks in semi-rigid pavements. Compared to LTE, PSC was considered a more accurate factor because it showed a higher level of sensitivity [33]. In another study, a new mechanism was suggested to evaluate the real LTE of highways and airports. Indeed, the amount of LTE is measured under wheels with non-zero speeds. The main objective was to investigate the effects of dynamic loads on rigid pavements. The results revealed that the LTE increased because of the higher velocity of dynamic loads and higher levels of damping of pavements [34].

Moreover, in another study, strain gages were utilized to evaluate the effects of cracks on the LTE values. The results showed that the peak of strain gages could be performed to investigate LTE when cracks form in rigid slabs [35]. Another method was using both coring and FWD. For this aim, the cracks were assessed by FWD on a stabilized base. Coring was then performed to determine the types of cracks by the K-nearest neighbor (KNN) method. This approach was based on the widths of cracks, and the results showed that thermal cracks had higher widths [36].

Transverse cracks were also investigated with other approaches in other studies. In a study, a new indicator called transverse crack condition index (TCCI) was calculated by the distance and width of cracks. The range of TCCI was between 0 and 100, and this indicator was reported to be a suitable parameter for the estimation of pavement conditions [37]. Furthermore, ultrasonic technology was applied for the evaluation of longitudinal cracks in flexible pavements. This is a fast and simple technology that has been used earlier for concrete and could show distress in flexible pavements [11]. Besides, Zhang et al. (2015) utilized novel statistical methods such as least squares regression and binary logistic regression to create a model for the evaluation of cracks in pavements. The results indicated that the initiation and expansion of cracks are attributed to predictor variables. So, the structure of pavement, variation of temperatures, traffic loads, and pavement mix design can play important roles in the expansion of cracks [3]. Moreover, Park et al. (2014) used Layered Viscoelastic Pavement Analysis for Critical Distress (LVECD) program to evaluate cracks in pavements. The capability of the LVECD model for the initiation, expansion, and intensity of cracks was confirmed by the comparison of the simulation and field coring results. Overall, the consistency of field observations and predictions was about 78 percent [38].

PFWD is reported to be a practical device for pavement deflection evaluation. This device is vastly utilized for concrete pavements. However, it can also be used for asphalt pavements. For example, this device was used to investigate asphalt pavement in a study [12]. One important reason for using this device is its non-destructive mechanism. Hence, the deflection of asphalt concrete in longitudinal cracks was examined. Moreover, the structural strength of asphalt pavement was examined by PFWD, and the results revealed that this could be a practical way for the asphalt pavement assessment [39]. The other application of PFWD was the prediction of the asphalt pavement master curve. Therefore, the quality of the asphalt pavement was examined [40]. More importantly, this device was used to evaluate the load transfer efficiency (LTE) in transverse and longitudinal cracks in asphalt pavements. The results showed that the behavior of these cracks is different for load transfer, and they should not be categorized in the same group for maintenance and rehabilitation [41].The surface deflections of cracked pavements were also evaluated by the data obtained from FWD in a few studies. These data were used for the simulations with the FEM [33, 42,43,44,45]

Deng and Yang (2019) investigated the semi-rigid pavement transverse cracks by FWD. Dynamic FE models were developed to model the semi-rigid pavement when FWD loads are applied. For this simulation, the loads' location and crack widths were taken into account. As a result, load transfer efficiency (LTE) indexes were calculated which were useful to distinguish between reflective and thermal cracks [23]. Besides, the deflections of asphalt pavements were evaluated by FWD. Different specifications of cracks, including crack widths, crack types, and cracks' locations, were used to develop 3D FE models. Among all these specifications, the locations and widths of cracks were believed to be influential on deflection [22]. This kind of assessment is a practical in-situ method by which the pavement performance can be predicted, or the modulus of layers can be obtained by back-calculation approaches [46].

3 Introduction of Equations for the Calculation of LTE

Some equations for the estimation of LTE are as follows:

-

The Westergaard relationship can be calculated with Eq. 2 [28]:

$$LTE=\{1- (dji - dju) / (dzi - dzu)\}\times 100,$$(2)

where dji and dju are the measured deflection on the unloaded edge and loaded edge (mm), respectively, and dzi and dzu are deflections recorded in the same position (mm) (if the joint has no capacity for LTE).

-

Sharp et al. proposed a relationship for the LTE which can be calculated with Eq. 3 [28]:where dlj and duj are the measured deflection on the unloaded edge and loaded edge (mm), respectively. dlm and dum are similar deflection (mm) in the mid-slab position for which the same measurement sensors (dlj and duj) are used.

$$LTE=({dl}_{m}-{du}_{m})/({dl}_{j}-{du}_{j}) \times 100,$$(3)

-

The LTE can be determined based on the stress and strain with Eq. 4 [29, 30]:where σunloaded and σloaded are stress on the unloaded and loaded slab (N/m2), respectively. εunloaded and εloaded are strains on the unloaded and loaded slab (m/m), respectively.

$$LTE (\sigma ) = {\sigma }_{Unloaded}/{\sigma }_{loaded}={\varepsilon }_{Unloaded}/{\varepsilon }_{loaded},$$(4)

-

The LTE can also be defined with Eq. 5 [29,30,31,32]. It should be mentioned that the parameters are similar to previous equations.where σunloaded and σloaded are stress on the unloaded and loaded slab(N/m2), respectively. εunloaded and εloaded are strains on the unloaded and loaded slab (m/m), respectively.

$$LTE (S) = {\sigma }_{Unloaded}/{\sigma }_{loaded}={\varepsilon }_{Unloaded}/{\varepsilon }_{loaded},$$(5)

4 The Specification of the PFWD Device

PFWD is used to apply a certain falling load on the pavement surface for deflection measurement in the pavement. This device consists of a few different parts, including a frame with buffers and sensors, a sliding hammer, sensors and electronic device, and a loading plate. Regarding its mechanism, the major geophone sensor is located at the center, and other geophones are located at a certain distance from the loading plate. After applying loads, the deflection of the pavement is measured. In this study, the PFWD device made by TML Construction Company is utilized. The properties of this device are shown in Table 1. Different diameters from 100 to 300 mm can be selected for the loading plate, and a 100 mm plate was used in this research.

5 Experimental Methods

5.1 Testing Procedure

The PFWD device was situated at distances of 15, 25, and 50 cm of the crack to investigate the impact of transverse cracks on LTE. Two geophones (D1 and D2) were fixed on each side of the crack's edge. Then, the loading process was performed in the distances mentioned above by the PFWD device, and geophones determined deflections. This process is depicted in Fig. 1.

After data analysis, it was concluded that the distances of 25 and 50 cm were not suitable because of large distances and low loading, and the accuracy of deflections was not high with these distances. Hence, the best distance of loading was 15 cm from the cracks. LTE can then be calculated by Eq. 5. Although these equations are theoretically correct, they may cause significant errors practically, which is illustrated in Fig. 2.

As can be seen in Fig. 2, considering the current equations for LTE calculation, D1 and D2 on each side of cracks are the primary factors for the calculation of LTE (LTE = d2/d1). As is shown in the left side of Fig. 2, for asphalt pavement without any cracks, the deflection of d3 and d4 are not equal. The reason why this measurement is not accurate is the difference caused by the radius of geophones (3.75 cm). Therefore, in this study, the positions of geophones were chosen based on Figs. 3 and 4. In these positions, the distance of geophones and the amount of deflection for each side are equal for asphalt pavement without cracks. So, Eq. 6 is proposed to calculate the LTE with the measured deflections in these distances.

The data were collected by the PFWD device and the location mentioned above for geophones. In this study, two asphalt pavements were selected to investigate the effect of transverse cracks on LTE. The LTE can be calculated with Eq. 6.

where LTE is the percent of load transfer efficiency, d2 is the deflection measured by the geophones D2 on the edge of the crack (mm), d1 is the deflection measured by the geophone D1 on the other side of asphalt without cracks (mm).

5.2 The Collection of Data

Two routes were investigated in this study, one of which was the asphalt pavement of a main road between two cities, and the other one was the asphalt pavement inside the university campus. The thickness of the studied road was about 20 cm with higher traffic loads, a 15-year life span, and more transverse cracks. Regarding the asphalt pavement of the university route, its thickness was about 7.5 cm with lower traffic loads and an 8-year life span. In this study, the deflections of transverse cracks were measured by the PFWD device. Overall, 500 spots on the main road and 300 spots on the university route were evaluated.

6 Data Analysis

After the data collection by the PFWD device, LTE was calculated by Eq. 6. The LTE of the studied road and the university route are shown in Fig. 5. Also, the comparison between the LTE of the road and the university route is demonstrated in Fig. 5.

According to Fig. 5, when the width of the crack increased, the LTE decreased. Also, regarding Fig. 5, although the thickness of the university route was lower than the studied road, its LTE was higher for cracks with the same widths. This can have two reasons, the first of which is the involvement of the base layer of the university route due to its lower thickness. Because if cracks occur in an asphalt layer with low thickness, loads can be transferred to the base layer. However, when the asphalt layer is thick, loads are mostly transferred by the asphalt layer rather than the base layer, which can cause a reduction in LTE.

The second reason can be the effects of pavement life. The asphalt pavement of the road is older than the university route, and its traffic loads are higher. So, the depths of cracks in the studied road can be higher than the university route which can decline the LTE significantly. Overall, LTE depends on many factors, including the properties of the base layer, the thickness of the asphalt layer, the compaction of base and sub-base layers, the quality of the prime coat, the pavement life, and the depth of transverse cracks. These factors require different methods of investigation. Because the width of the crack has been evaluated by common visual surveys, this study mainly focused on the relationship between the widths of the cracks and LTE.

6.1 The Determination of the Correlation Between Variables

The main purpose of this study was to examine the correlation between the width of transverse cracks and LTE. Thus, the collected data were analyzed by SPSS. For this aim, nonlinear regression models were developed for the studied road and the university route. Therefore, the function with the highest accuracy was chosen as a suitable equation for the estimation of LTE with the highest R2 values, and Eq. 7 was proposed for the estimation of the LTE of transverse cracks for the studied road.

where LTE is the percent of load transfer efficiency, and W is the width (mm) of the transverse crack.

The function with the highest accuracy was also suitable for the estimation of the LTE of transverse cracks in the university route with the highest R2 value, which is shown in Eq. 8.

where LTE is the percent of load transfer efficiency, and W is the width (mm) of the transverse crack. Therefore, LTE values for transverse cracks with different widths can be calculated by Eqs. 8 and 7.

7 The Numerical Model

In this study, a 3D FE model was developed by the finite element method in ABAQUS to investigate the LTE of transverse cracks. To verify the validity of this model, the results obtained from ABAQUS were compared with the LTE results of the studied road.

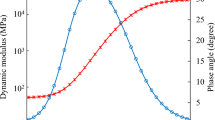

7.1 The Structure of the Model

In ABAQUS models, it is possible to define and interpret different behaviors for the materials. The numerical modeling and analysis of asphalt pavement similar to the real situation (viscoelastic and visco-plastic) demand a lot of time for runs with supercomputers. More importantly, based on some previous studies, linear elastic numerical modeling and analysis of asphalt pavements revealed reliable and acceptable results [23, 24, 44, 47, 48]. Hence, the linear elastic method was used for numerical modeling and analysis in this study which is popular for asphalt pavements.

Moreover, the damping effect and the mass inertia effect were considered for the dynamic analysis. According to the pavement materials' dynamic parameters, Rayleigh damping was utilized for the damping scheme. The damping parameters α and β were relatively constant for the various layers. α = 100 and β = 0.003 were used for the subgrade layers, and α = 0 and β = 0.005 were used for the base layers. α = 0 and β = 0.003 were used for the asphalt layers [49]. The pavement structure was comprised of asphalt concrete, base course, and subgrade. The specifications of layers in the developed model, obtained from previous studies, are shown in Table 2 [23, 24, 44, 47, 48]. The asphalt pavement structure which was used for modeling is shown in Fig. 6.

FE simulation results' accuracy depends on the model size. The suitable model size is associated with some variables. Two factors are reported to be important to achieve desired accuracy and optimum analysis time. The first factor is to choose the model dimensions to be matched with the field experiment. Secondly, applying restricted and free vertical movements on the external side can show the correctness of the selected dimensions. Therefore, if the result of these models is similar to the boundary conditions, the effects of the model dimension are omitted. After a few times trials and errors, 4 × 4 × 1.95 m (width, length, and height) were chosen as the dimensions of the model in this study.

Pavement responses during PFWD loading can be affected by contact conditions at the interface of layers. Because of the huge contact area and the effects of traffic and gravity on the compressive loading, it was expected that the pavement structure layers had complete contacts without gap-opening. Hence, both absolute and relative motions of interfaces' contacting surfaces were assumed to be small. The friction coefficient of 1.5 for the HMA and base course interface and the base course and subgrade interface was used in this study [46, 50]. Regarding the boundary conditions of FE models in previous studies, restrained bottom nodes and roller-type lateral boundaries were selected [22, 23].

The PFWD loading plate diameter was 100 mm. Regarding the meshing, the circularly loaded area was almost a square with a length of 100 mm [22, 23]. The real transient load pulse of PFWD was utilized for the model of this study to simulate the conditions of the PFWD test. Regarding the time-history graph achieved from PFWD, the applied load was 4000 N, and the loading mechanism of this study was based on Fig. 7. In this figure, the time unit is milliseconds, D0 is the deflection under the center of loading, D1 is the deflation in the uncracked pavement, and D2 is the deflection in the cracked pavement.

For the simulation of cracks in the pavement structure, a gap was created in the pavement structure [23]. Also, according to the field data collection, the position of geophones and the loading method for all models were based on Figs. 3, 4 and Sect. 5.1, respectively. In the developed models, transverse cracks were in the surface layer, and the depths of cracks were equal to the asphalt concrete thickness. The crack widths varied from 1.5 mm to 16 mm. Seven different crack widths (from 1.5 to 16 mm) were used to evaluate the impact of crack width on the deflection basin. The developed model in ABAQUS software with the loading process and cracks' locations is shown in Fig. 8.

7.2 Mesh Sensitivity Analysis

Regarding meshing, small meshes are used in the sensitive sections with high-stress concentration, and large meshes in the less important sections with less stress are used, affecting the analysis time. Also, using a mesh with the structural technic can bring about reliable and desirable results. Thus, this technic was used for the meshing of this study. In the FEM method, smaller elements can cause more accurate results. However, due to the increase in elements in the model, the analysis time will be increased. Therefore, mesh sensitivity analysis was used to find the optimum mesh size for the model. For this analysis in this study, five different mesh sizes were tested. The first number of their names shows the smallest dimension of the element, and the second number indicates the largest mesh seed for each model. Five different meshing sizes are illustrated in Fig. 9.

The analysis results for these five models were compared, and displacements for the center of loading (P) and two other points with 15 cm distance from the left (L) and right (R) sides of the center of loading are shown in Figs. 10, 11, and 12.

Analysis time for different numbers of elements is reported in Table 3.

According to Figs. 10, 11, and 12, three models of Mesh-12.5–150, Mesh-12.5–300, and Mesh-25–300 revealed similar results. As is seen in Table 3, compared to the Mesh-25–300 model, Mesh-12.5–300 and Mesh-12.5–150 had 61% and 729% more analysis time. Therefore, Mesh-25–300 meshing was used for all models in this study.

7.3 The Verification of the Numerical Model

Transverse cracks are active, and if the widths of the transverse cracks change, the edge of the cracks moves. So, for modeling these conditions in the cracked section of asphalt pavement, the interaction between the base and asphalt layer was defined as a debonding. This simulation can transfer some deformations of the base layer to the other side of the crack. Therefore, the inconsistency of asphalt and base layers near the crack can be developed in this model.

Based on coring samples, the interface of asphalt concrete and the base course is commonplace for debonding [23, 51, 52]. Also, for all cracks whose width is 1.5 mm or more, debonding length at each side of the crack for the interface of asphalt concrete and the base course was applied for the developed models. Full bonding for the other parts of the interface was also assumed for modeling.

According to the above-mentioned explanations, transverse cracks at the interface of asphalt concrete and the base course caused debonding, which is applied as debonding in the developed models. As the amount of debonding is different for each crack, the amount of debonding for each width of the crack was investigated in the FE model based on the LTE values of each crack. Hence, different FE models with different debonding were developed, and the LTE values obtained from these models were compared with the LTE values from the field data collection. After this comparison and analysis, the amount of debonding was selected from those models in which the LTE values were similar to the real field experiment values. Also, the LTE values obtained from the FE model were compared with the LTE values achieved from the regression equation, developed with field data, shown in Fig. 13.

In Fig. 14, the amount of debonding in the FE model is depicted for different crack widths. According to this figure, for instance, the amount of debonding in the FE model for a crack whose width is 10 mm should be around 30 cm to have a good correlation with the field experiments. Moreover, as is seen in Fig. 14, Eq. 9 was achieved by which the amount of debonding can be predicted for each crack width.\(f\left(x\right)=-0.008{x}^{4}+0.043{x}^{3}-8.745{x}^{2}+96.49x-128.7\) (9)where f(x) is the amount of debonding (mm), and \(x\) is the width of the crack (mm).

After the calculation of debonding for each crack width, the LTE and deflection obtained from the FE model at the loading point, cracked pavement, and uncracked pavement were compared with the field data to verify the developed model.

The time history graph for 3 mm and 6 mm cracks' widths, obtained from PFWD and the FE model, is demonstrated in Fig. 15. As is seen in this figure, the time history graph extracted from the FE model is similar to the field experiment graph. For instance, LTE values of cracks with 3 mm width were 82 and 70 for the field experiment and the developed model, respectively. Regarding cracks with 6 mm width, the former and the later values were 43 and 47, respectively, indicating the good accuracy of the simulation. Furthermore, the loading point deflection for the field experiment and the developed model was almost equal to 0.09 mm. Therefore, according to the result of LTE, maximum deflection, and the deflection pattern, the developed model had high accuracy. However, LTE values obtained from the field experiment and the developed model had a slight discrepancy attributed to the reasons below.

-

1.

In the developed model, the width of the crack is constant on its thickness, which is equal to the depth of the asphalt layer, but in the studied road, the widths of cracks are not constant in their depths, and their depths may not be equal to the depth of asphalt layer.

-

2.

In the studied road, there were very thin and small cracks around the main crack. But the impacts of these surrounding cracks were not involved in the model.

-

3.

Regarding the road, although each crack’s width was variable all over that crack, the width of each crack is assumed consistent in the model.

As the main goal of this study was to propose a new non-destructive method for the pavement assessment using the crack widths, other influential factors of the LTE had not been investigated in this study. In the visual assessment of pavements' cracks, the cracks' widths are collected, and using this data for the developed model can propose a more reliable factor for pavement maintenance and rehabilitation.

7.4 The Examination of the Effects of Asphalt Layer's Thickness on LTE

After the verification of the model with the results of field tests, the effects of the thickness of the asphalt layer on LTE were evaluated in the FE model. For this aim, six different thicknesses of the asphalt layer, including 60, 90, 120, 150, 180, and 210 mm, were modeled. Moreover, different cracks’ widths from 2 to 15 mm (W02 to W15) were used in this evaluation. LTE values of different crack widths were then calculated for each thickness. LTE values calculated by the FE model for different widths and thicknesses are shown in Fig. 16.

Regarding Fig. 16, it is concluded that when the layer's thickness increased, the LTE decreased, which is mentioned in Sect. 6. The vertical deflection contour obtained from the FE model is shown in Fig. 17. When the asphalt concrete had a higher thickness, lower loads were transferred, and less stress was transferred to the cracked pavement compared with the pavement with a lower thickness.

Also, according to Fig. 5, LTE values for different crack widths of the studied road are lower than the LTE of the university route. The thickness of the studied road was more the university route, which may be one of the causes for the lower LTE of the studied road. Finally, the developed model results were in agreement with the field test in terms of thickness.

7.5 The Asphalt Concrete and Base Course Modulus Effects on the LTE

The base course modulus effects on the LTE are demonstrated in Fig. 18. The selected range of modulus was between 50 and 500 MPa, and cracks whose widths were 2, 5, 10, and 15 mm were selected for this assessment. As can be seen in this figure, LTE values increased by raising the base course modulus, and this trend was similar to different cracks' widths. For example, for 15 mm-crack widths, increasing the base course modulus from 100 to 500 MPa, increased the LTE from 10 to 38. The vertical deflation contours in the pavement with 100 and 500 MPa base course modulus is depicted in Fig. 19.

According to this figure, the deflection in the uncracked pavement was high due to the lower modulus of the base course. When the base course modulus was low, the crack's edge in the uncracked pavement acted like a cantilever beam. As a result, when the load was applied, it had high deflection due to less stiffness. Hence, a lower load is transferred to the cracked pavement, reducing the LTE. Moreover, when the stiffness of the base course was higher, the LTE was also higher, which caused more deflection in the cracked pavement.

Besides, the deformation assessment of the loaded area showed that increasing the base course modulus can improve the load transfer. In stark contrast, when the base course modulus was lower, the major deflection was observed under the loading point due to less stiffness of the base course.

The asphalt concrete modulus effect of the LTE is illustrated in Fig. 20. The studied range was chosen between 500 and 5000 MPa to have a desirable accuracy, and cracks whose widths were 2,5, 10, and 15 mm were selected for this examination. As is seen, increasing the asphalt concrete modulus for cracks with 10- and 15-mm widths increased the LTE slightly. Indeed, when the modulus was raised from 500 to 5000 MPa, the LTE gradually increased from 10 to 19. This difference was much less for cracks with 2- and 5-mm widths which showed changing the modulus does not have noticeable effects on the LTE of smaller cracks. As it was concluded, the underneath layers have much more significant effects on the LTE of asphalt pavements, and both the thickness and modulus of these layers had noticeable impacts on the LTE.

8 Conclusion and Recommendations

The main purpose of this study was to evaluate the effects of transverse cracks on LTE by using data obtained from field tests and numerical modeling. Firstly, the PFWD device was used to measure the deflections of asphalt pavement on each side of transverse cracks in the studied road and the university route. To examine the LTE values of different crack widths, a 3D finite element model was developed in ABAQUS. The results obtained from the field tests and the FE model were then verified. After the verification of the developed model, the effects of the asphalt layer's thickness, asphalt concrete, and base course modulus were assessed by the FE model.

The main results of this study are as follows:

-

A new equation was proposed for the calculation of LTE, which is more accurate than previous equations.

-

LTE of transverse cracks depends on the widths of the cracks and the thickness of the asphalt layer. When the width of the crack or the thickness of the asphalt layer increase, LTE values decrease.

-

The comparison between the results obtained from the developed model and the field measurements showed that the maximum deflection around the loading center was almost equal in both methods, confirming the verification of the model. Besides, the LTE values achieved by these two methods were almost similar.

-

Six different thicknesses of asphalt pavement were modeled in ABAQUS. The results indicated that when the thickness of the asphalt layer increased, the LTE values decreased.

-

Increasing the modulus of the base course raised the LTE dramatically. However, rising the asphalt concrete modulus had a negligible effect on the LTE.

-

The transverse crack is active, and debonding may occur at the interface between asphalt concrete and base course with transverse cracks. The amount of this debonding depends on the cracks' widths. The FE model proposed a new model by which the amount of debonding can be calculated for different cracks' widths.

Some recommendations for future studies, which can broaden the knowledge of this subject and help pavement assessment and maintenance methods, are as follows:

-

The investigation of the fatigue cracking effects on the LTE of pavements.

-

The evaluation of LTE values in different climate conditions.

-

The determination of LTE limits as a criterion for pavement condition and quality.

References

Shahin, M.Y. (1994). Pavement management for airports, roads, and parking lots.

Yin, H. M. (2010). Opening-mode cracking in asphalt pavements: Crack initiation and saturation. Road Materials and Pavement Design, 11, 435–457.

Zhang, W., Shen, S., Basak, P., Wen, H., Wu, S., Faheem, A., & Mohammad, L. N. (2015). Development of predictive models for initiation and propagation of field transverse cracking. Transportation Research Record, 2524, 92–99.

Shamsaei, M., Aghayan, I., & Kazemi, K. A. (2017). Experimental investigation of using cross-linked polyethylene waste as aggregate in roller compacted concrete pavement. Journal of Cleaner Production, 165, 290–297.

Mammeri, A., Vaillancourt, M., & Shamsaei, M. (2023). Experimental and numerical investigation of using waste glass aggregates in asphalt pavement to mitigate urban heat islands. Clean Technologies and Environmental Policy, 2, 1–14.

Shamsaei, M., Carter, A., & Vaillancourt, M. (2022). A review on the heat transfer in asphalt pavements and urban heat island mitigation methods. Construction and Building Materials, 359, 129350.

Aghayan, I., & Khafajeh, R. (2019). 12 - Recycling of PET in asphalt concrete. In F. Pacheco-Torgal, J. Khatib, F. Colangelo, & R. Tuladhar (Eds.), Use Recycl. Plast. Eco-Efficient Concr. (pp. 269–285). New York: Woodhead Publishing.

Shamsaei, M., Khafajeh, R., & Aghayan, I. (2019). Laboratory evaluation of the mechanical properties of roller compacted concrete pavement containing ceramic and coal waste powders. Clean Technologies and Environmental Policy, 21, 707–716. https://doi.org/10.1007/s10098-018-1657-5

Shamsaei, M., Khafajeh, R., Ghasemzadeh Tehrani, H., & Aghayan, I. (2020). Experimental evaluation of ceramic waste as filler in hot mix asphalt. Clean Technologies and Environmental Policy, 22, 535–543. https://doi.org/10.1007/s10098-019-01788-9

Aghayan, I., Khafajeh, R., & Shamsaei, M. (2021). Life cycle assessment, mechanical properties, and durability of roller compacted concrete pavement containing recycled waste materials. International Journal of Pavement Research and Technology, 14, 595–606. https://doi.org/10.1007/s42947-020-0217-7

Khazanovich, L., Velasquez, R., & Nesvijski, E. G. (1940). Evaluation of top-down cracks in asphalt pavements by using a self-calibrating ultrasonic technique. Transportation Research Record, 2005, 63–68.

Tertre, A., Cascante, G., Tighe, S.L. (2010). Combining PFWD and surface wave measurements for evaluation of longitudinal joints in asphalt pavements. In: Proc. Transp. Res. Board Annu. Meet., pp. 1–18.

Solla, M., Lagüela, S., González-Jorge, H., & Arias, P. (2014). Approach to identify cracking in asphalt pavement using GPR and infrared thermographic methods: Preliminary findings. NDT&E International, 62, 55–65.

Koduru, H. K., Xiao, F., Amirkhanian, S. N., & Juang, C. H. (2010). Using fuzzy logic and expert system approaches in evaluating flexible pavement distress: Case study. Journal of Transportation Engineering, 136, 149–157.

Tomoto, T., & Moriyoshi, A. (2009). Evaluation of damage to asphalt pavements using a micro-focus CT scanner and three-dimensional crack analysis. Road Materials and Pavement Design, 10, 519–543.

Lee, N.-K., Hugo, F., & Stokoe, K. H. (1997). Detection and monitoring of cracks in asphalt pavement under Texas mobile load simulator testing. Transportation Research Record, 1570, 10–22.

Nazzal, M. D., Abu-Farsakh, M. Y., Alshibli, K., & Mohammad, L. (2016). Evaluating the light falling weight deflectometer device for in situ measurement of elastic modulus of pavement layers. Transportation Research Record, 2007, 13–22.

Dwivedi, S., & Suman, S. K. (2023). A comprehensive review on non-destructive testing using LWD and Geogauge for quick QC/QA of pavement layers. Innovative Infrastructure Solutions, 8, 101.

Lin, D.-F., Liau, C.-C., & Lin, J.-D. (2006). Factors affecting portable falling weight deflectometer measurements. Journal of Geotechnical and Geoenvironmental Engineering, 132, 804–808.

Liu, P., Xing, Q., Dong, Y., Wang, D., Oeser, M., & Yuan, S. (2017). Application of finite layer method in pavement structural analysis. Applied Sciences, 7, 611.

Sadeghi, V., & Hesami, S. (2018). Investigation of load transfer efficiency in jointed plain concrete pavements (JPCP) using FEM. International Journal of Pavement Research and Technology, 11, 245–252.

Fu, G., Zhao, Y., Wang, G., & Wei, J. (2022). Evaluation of the effects of transverse cracking on the falling weight deflectometer data of asphalt pavements. International Journal of Pavement Engineering, 23, 3198–3211.

Deng, Y., & Yang, Q. (2019). Rapid evaluation of a transverse crack on a semi-rigid pavement utilising deflection basin data. Road Materials and Pavement Design, 20, 929–942.

Park, S.-W., Park, H. M., & Hwang, J.-J. (2010). Application of genetic algorithm and finite element method for backcalculating layer moduli of flexible pavements. KSCE Journal of Civil Engineering, 14, 183–190.

Aminzadeh, M., Kazemi, H. S., & Tavakkoli, S. M. (2020). A numerical study on optimum shape of steel slit dampers. Advances in Structural Engineering, 23, 2967–2981.

Aminzadeh, M., & Tavakkoli, S. M. (2022). A parameter space approach for isogeometrical level set topology optimization. Int. J. Numer. Methods Eng., 123, 3485–3506.

Irvani, M., Ezati, H., Khafajeh, R., & Kalat Jaari, V. R. (2022). Numerically study on the seismic response of partially restrained moment connection with structural fuse T-stub for European sections. Structures., 35, 82–105. https://doi.org/10.1016/j.istruc.2021.10.078

Owusu-Anti, E.B., Meyer, A.H., Hudson, W.R. (1990). Assessing load transfer across joints and cracks in rigid pavements using the falling weight deflectometer, Center for Transportation Research, Bureau of Engineering Research.

Khazanovich, L., Gotlif, A. (2003). Evaluation of joint and crack load transfer final report, United States. Federal Highway Administration. Office of Infrastructure.

Shoukry, S. N., William, G. W., & Riad, M. Y. (2005). Evaluation of load transfer efficiency measurement. Pennsylvania State University.

Cunliffe, C. (2014). Impact of structure, material properties, temperature curling, and trafficking on load transfer efficiency.

Wadkar, A., Mehta, Y., Cleary, D., Guo, E., Musumeci, L., Zapata, A., & Kettleson, W. (2011). Load-transfer efficiencies of rigid airfield pavement joints based on stresses and deflections. Journal of Materials in Civil Engineering, 23, 1171–1180.

Lin, C., Guo, Z.Y., Fang, J.G., Yang, Y.S. (2006) Analysis and evaluation of transverse-cracked semi-rigid base asphalt pavements using FWD data. In: Pavement Mech. Perform, pp. 1–6.

Yu, X., Wu, X. (2010). Joint load transfer efficiency of rigid pavement considering dynamic effects under a single moving load. In: 2010 2nd Int. Conf. Inf. Eng. Comput. Sci., IEEE, pp. 1–4.

Cunliffe, C., Joshi, A., Mehta, Y., & Cleary, D. (2014). A study to determine the impact of cracking on load transfer efficiency of rigid airfield pavements. Journal of Testing and Evaluation, 42, 375–389.

Yang, Q., & Deng, Y. (2019). Evaluation of cracking in asphalt pavement with stabilized base course based on statistical pattern recognition. International Journal of Pavement Engineering, 20, 417–424.

Zhou, L., Ni, F., & Zhao, Y. (2010). Evaluation method for transverse cracking in asphalt pavements on freeways. Transportation Research Record, 2153, 97–105.

Park, H. J., Eslaminia, M., & Kim, Y. R. (2014). Mechanistic evaluation of cracking in in-service asphalt pavements. Materials and Structures, 47, 1339–1358.

Wei, J. G., & Wang, B. (2013). PFWD’s application in the evaluation of structural strength of field hot regeneration asphalt pavement. Advances in Materials Research, 723, 141–148.

du Tertre, A., SerhanKırlangıç, A., Cascante, G., & Tighe, S. L. (2022). A non-destructive approach for the predictive master curve of ASPHALT pavements using ultrasonic and deflection methods. International Journal of Pavement Research and Technology, 23, 1540–1551.

Khafajeh, R., Shamsaei, M., Tehrani, H. G., & Easa, S. M. (2021). Proposing Load Transfer Efficiency as Criterion for Repairing Longitudinal and Transverse Cracks of Asphalt Pavements. Journal of Transportation Engineering, Part B: Pavements, 147, 6021002. https://doi.org/10.1061/JPEODX.0000301

Uddin, W., Zhang, D., & Fernandez, F. (1994). Finite element simulation of pavement discontinuities and dynamic load response. Transportation Research Record, 2, 2.

Qiu, X., Yang, Q., & Wang, F. (2014). Diagnostic analysis of dynamic deflection for cracked asphalt pavements under FWD impulsive loading. Journal of Vibroengineering, 16, 2426–2437.

Xie, Z., Shen, J., Guo, Z., & Cong, L. (2015). Effect of distresses on deflection basins and backcalculation modulus of asphalt pavement with cement-treated base. International Journal of Pavement Research and Technology, 8, 283.

Kim, Y.R., Lee, Y.-C., Park, S., Ranjithan, S.R. (1999). Interpretation of fwd data when pavement layers are not intact.

Li, M., Wang, H., Xu, G., & Xie, P. (2017). Finite element modeling and parametric analysis of viscoelastic and nonlinear pavement responses under dynamic FWD loading. Construction and Building Materials, 141, 23–35.

Zhao, Y., Cao, D., & Chen, P. (2015). Dynamic backcalculation of asphalt pavement layer properties using spectral element method. Road Materials and Pavement Design, 16, 870–888.

Picoux, B., El Ayadi, A., & Petit, C. (2009). Dynamic response of a flexible pavement submitted by impulsive loading. Soil Dynamics and Earthquake Engineering, 29, 845–854.

Bazi, G., Gagnon, J., Sebaaly, P., & Ullidtz, P. (2020). Effects of Rayleigh damping on the subgrade’s apparent nonlinearity. Journal of Transportation Engineering, Part B: Pavements, 146, 04020042. https://doi.org/10.1061/jpeodx.0000194

Shoukry, S. N., Fahmy, M., Prucz, J., & William, G. (2007). Validation of 3DFE analysis of rigid pavement dynamic response to moving traffic and nonlinear temperature gradient effects. International Journal of Geomechanics, 7, 16–24.

Lahitou, L.A., Choi, S.-C., Won, M.C. (2008). Debonding in bonded concrete overlays over continuously reinforced concrete pavements., Texas. Dept. of Transportation. Research and Technology Implementation Office.

Perez, S. A., Balay, J. M., Tamagny, P., & Petit, C. (2007). Accelerated pavement testing and modeling of reflective cracking in pavements. Engineering Failure Analysis, 14, 1526–1537.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors would like to declare that they have no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Khafajeh, R., Shamsaei, M., Irvani, M. et al. The Development of a Finite Element Model for the Estimation of Load Transfer Efficiency in Transverse Cracks of Asphalt Pavement. Int. J. Pavement Res. Technol. (2023). https://doi.org/10.1007/s42947-023-00334-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42947-023-00334-7