Abstract

Plastic contamination is a major global concern as it accumulates in the environment and breaks down into harmful microplastics. The excessive dumping of plastic, especially packaging materials, in landfills, leads to capacity shortages and long-term environmental risks. Current disposal methods, such as pyrolysis, are expensive and produce ash containing heavy metals. To mitigate these issues, recycling plastics and using recycled materials instead of extracting natural resources are recommended, although the current recycling rate is low due to high costs and limited market applications. Biodegradable plastics made from natural sources offer a potential solution, particularly for non-durable applications like packaging and agricultural films. Policy-makers must instrument operative plastic waste management systems, enforce strict guidelines, and make sure comprehensive lifecycle management of plastic products. The article also examines the business aspects of bioplastic development using analytical models like Porter’s five forces and value chain analysis. Circular economy modeling is used to evaluate economic and energy considerations, highlighting the potential benefits of anaerobic digestion for energy, fertilizer, and the economy within a circular economy framework. The Driver-Pressure-State-Impact-Response technique is proposed as a policy approach. Lastly, a comparison is made between biodegradable and non-biodegradable plastics within a closed-loop supply system, considering environmental factors.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

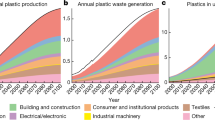

Because of its widespread use, plastic has become an actual product on the global market, affecting every aspect of daily life. In 1950, there were 2 million metric tons (MT) produced. By 2015, there were 322 million MT provided, a remarkable increase that exceeded virtually all other produced products (Geyer et al. 2017; Christopher et al. 2022). There have been 8.3 billion metric tons (MT) of plastic exported as of 2017. Regarding plastic products’ packaging, 40% of the market is dedicated to this essential section of usage, making plastic a valuable commodity. There have been noteworthy highlights in the history of plastic packaging materials. They have allowed companies to market their products effectively, design visually and physically appealing packaging, and anticipate loss from store racks, and ship products worldwide cost-effectively and efficiently. Even though plastic packaging is still used for food, beverage, and cigarette products, it contributes to 61% of the world’s beach litter (Brooks et al. 2018). When it comes to expanding plastic use’s impact on solid waste management (SWM) systems, little attention has been given to how this development would affect the flood of novel and changeable incoming items into the SW stream. China, the United States (US), Germany, Russia, Egypt, and the United Kingdom (UK) produced around 59, 38, 14.5, 6, 5.5, and 5 million tons of plastic garbage annually in 2010. According to estimates, these figures will rise as humanity as a whole rises. Each day, 159 g and 117 g of plastic garbage are produced per person in New Zealand, a country of roughly 5 million people, and Australia, a country of around 25 million (Taghavi et al. 2021a). Plastic waste management (PWM) has proven difficult, particularly in areas where the economy and population are rapidly improving. Approximately 4–12 million (MT) of plastic garbage enter the seas annually; this is despite the fact that just 9% of plastic debris has been recycled (Geyer et al. 2017; Brooks et al. 2018). At least 267 marine creatures are harmed by plastic waste (PW) worldwide, and 44% of seabird species eat plastic once it has entered the marine ecosystem (Taghavi et al. 2021b; Hou et al. 2018). To meet this problem, a broad spectrum of professionals must create new improvements and ways to discover viable solutions to the alarming forecasts. Reduce plastic consumption, eliminate microplastic (MP) leakage by changing the collection, separation, and processing of post-consumer plastics, discover affordable alternatives for throwaway items, and increase recycling rates are all included in the nine zones of relevance. A recent global study, “Breaking the Plastic Wave,” reveals that these combined efforts may reduce plastic leakage into the water by as much as 80% by 2040 (Kosloski-Oh et al. 2021). The non-degradable plastics already in the oceans and landfills and are constantly being manufactured must be addressed as well as the sustainable, degradable, and readily recyclable polymers being developed as a replacement for petroleum-based plastics. As little as 2% of all US plastic packaging is recycled in a closed-loop fashion, resulting in new goods with a similar market value (Macarthur et al. 2016). Because of their intricate construction, it is difficult to dismantle modern plastic products from recycling loops. For living creatures, both plastics and the chemicals that are released with them pose a threat to their survival (Shamsuyeva and Endres 2021). The devastating effects of disposable plastics on the planet have made international headlines. There is a constant buildup in landfills and eventual release into the environment of single-use plastic (SUP) packaging materials and other PW creating from petrochemical suppliers. The use of biodegradable polymers may help to somewhat mitigate the serious environmental problem that is PWM (Meereboer et al. 2020).

Plastic contamination occurs on two fronts: during manufacture (emissions of carbon dioxide) and disposal (contaminants and physical risks), affecting the environment and ecology. In the end, switching to polymers made from renewable sources from petroleum-based ones might cut down on pollution and energy production (Gironi and Piemonte 2011).

The industry’s rising and strong proof that the overall development of mostly plastic garbage by 2050 would surpass 25 billion MT has sparked a major change regarding financial destinations (Peng et al. 2023). There will be a 13% yearly increase in the manufacturing of bio-based, non-biodegradable plastic (N-BP), and biodegradable plastics (BPs) from 2020 to 2023 as demand rises for alternatives to petroleum-based materials. Some of the biggest names in plastic packaging hope to switch to using only recycled, biodegradable, or recyclable materials by 2025. Bio-based poly (ethylene) (Bio-PE), bio-based poly (ethylene terephthalate) (Bio-PET), poly (lactic acid) (PLA), and poly (hydroxyl alkanets) (PHAs) have shown generation capability development of roughly 22%, 10,000%, 300%, and 41%, correspondingly, between 2010 and 2017. Using bio-based plastics instead of petroleum-based plastics positively affects the environment (Meereboer et al. 2020; Gironi and Piemonte 2011; Calabrò and Grosso 2018; Folino et al. 2023a).

The dwindling supply of fossil fuels provides a strong impetus for developing bio-based products. On the other hand, biodegradable and compostable plastics are spurred on by the prospect of reducing environmental pollution or simplifying the collection of organic waste (Cazaudehore et al. 2022). Currently, bioplastics are finding use in various industries, including agriculture and horticulture, as well as the vehicle and electrical industries (Peelman et al. 2013; Barillari and Chini 2020; George et al. 2020; Razza et al. 2020). Furthermore, biodegradable polymers have long been related to biomedical applications (Narancic et al. 2020). Even though bio-plastics (Bio-P) are just 1% of the world’s plastic output, the European Commission’s “A European Technique for Plastics in a Circular Economy” acknowledges that their selection is vulnerable. Bio-P sustainability, biodegradability, and media considerations are examples of this kind of research. Research in academia has focused on combining bio-based polymers, life cycle assessment (LCA) of different bioplastics’ manufacture and end-of-life (EOL), and biodegradation under various situations, apart from the necessary biological literature (Meereboer et al. 2020; Di Bartolo et al. 2021; Dahiya et al. 2020).

Definitions, evaluating Bio-Ps’ composability and biodegradability, commercial polymers, and potential applications of Bio-Ps are all included in this paper’s overview for the reader. In this research, we look at the LCA of bioplastics, paying special attention to their EOL assessment, and the audit follows suit. In the following, the economic modeling of Bio-P trades in society is applied by both Porter’s five forces (PFF) model and value chain analysis (VCA). In addition, in light of the information gathered, we look closely at the issues that may arise from Bio-Ps and other possible configurations before drawing any judgments. Finally, the circular economy concept is presented based on biogas production from bio-plastic wastes (Bio-PW) with the application of RENERGON RSD® Real-time Simulation Engine. Likewise, for the implementation of a policy because of putting the circular economy (CE) model into action, Driver-Pressure-State-Impact-Response (DPSIR) technique is applied.

Scientometric Analysis

This summary provides a springboard for further research into the issue and the identification of research needs. After analyzing the subject matter assessment data, this article was written. Google Scholar, the Web of Science (WoS), Scopus, and Research Gate, four of the most prestigious databases, were mined for references. Scopus and WoS are the two most powerful search engines for scientific papers due to their comprehensive coverage. Scopus was selected as the scientific basis after evaluation because of its extensive list of contributors. The hunt for reliable information and outcomes remained continuous. In May of 2023, a search was conducted. “WM” and “BPs” were the primary search terms used to find this report. In addition, sustainable development objectives were attained via the utilization of the combination of the terms BP and CE. The problems and potential solutions of PWM along the way to a CE were also sought by searching for associated keywords such as recycling, bi-energy, and policy-making. Between the two primary search terms (WM and BPs), 700 articles were found in the appropriate part of the Scopus database. The references were next screened by reading their abstracts, then their titles, and finally their full texts if required. In the end, 195 citations from 700 were chosen as the most pertinent to this article’s subject. There were books, chapters in books, research papers, and review articles among these sources. The material in these sources has been thoroughly examined for relevance and usefulness. The resulting database was evaluated using the VOS viewer software. Software like VOS viewer from the field of artificial intelligence works with tools for monitoring, surveillance, and mapping of scientific information to facilitate the examination, simplification, and visualization of massive amounts of data. Its method of analysis is based on Jaccard’s similarity measurements and Pearson’s correlation, both of which use distances to illustrate the strength of a link between components in graphical representations (Van Eck and Waltman 2010; Waltman et al. 2010). Co-authorship and co-occurrence analyses were conducted. For this sort of research, keywords, countries, and authors were the three most commonly used default units of analysis. For occurrence analysis, the minimum number of occurrences of a keyword was defined as 50. As a result, of 6522 keywords, 34 meet the threshold. In fact, for each of the 34 keywords, the total strength of the co-occurrence links with the other keywords will be calculated. The keywords with the highest total strength of links will be selected. The goal of defining this threshold is to provide visually appealing and easily digestible outputs in the form of graphics. The maps’ bubble sizes show the average of the items under study, while the colors indicate the total number of distinct groups into which the data fall. Figure 1 displays the results of a scientometric analysis of the correlations between the terms “BPs,” “WM,” and “CE” in terms of (a) the occurrence of keywords, (b) countries’ activities, and (c) authors. Figure 1a shows that WM and biodegradation have emerged as one of the most important topics of research from 2014 to 2020. The strategy makes it apparent that concerns linked to PW, sustainable development, and issues related to humans, especially in 2020, are growing challenges that need to be studied in order to learn more about the biological consequences of PW on human health and, in particular, on animal life. The most frequently stated ideas, such as LCA, sustainable development objectives, CE, reuse, and recycling, were assessed in this study. For co-authorship analysis, the default units of analysis of “countries” were set with the minimum number of documents per country equal to 5. As a result, out of 90 countries, 44 met the thresholds, and the number of selected countries was 44. According to Fig. 1b, it can be seen that today some developing countries such as Malaysia, Bangladesh, Australia, Vietnam, and South Korea are assumed to be the boundaries of the research area. In addition, Italy, India, and the USA had the most research in this field. For the analysis of co-authorship, the default units of analysis were “authors,” with the minimum number of documents per author set to 4. As a result, out of 2536 authors, 24 were selected. Giving to Fig. 1c, it is evident that several research organizations, dispersed across various geographical areas, focus on PWM and BPs both individually and together. In addition, according to the figure, research groups Ali et al. Adani, and Cucina have been working in the mentioned areas in recent years, 2021–2022.

Methods of Study

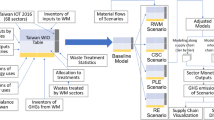

The investigation plan for the current study is shown in Fig. 2. According to the scheme, it can be seen that in the first step, the required data is gathered based on a literature review and high-credit databanks. The main framework of the article includes 14 main sections. In the first part, the global challenges of PW are mentioned. The “Methods of Study” section reviews plastic WM techniques, including landfills, gasification and pyrolysis, hydrocracking, incineration, and recycling. In addition, we have shown the four basic recycling processes (primary, secondary, tertiary, and fourth) and the plastic recycling process cycle in the next section. Developing the concept of a global CE for solid waste, LCA, replacing BPs instead of conventional plastics, and WM (recycling and composting) of Bio-Ps are among the most important parts of this review article. Then, in the final parts of this research, for the first time with the application of PFF and VCA, a business assessment is done, and it is the basis of policy-making in this field. In a parallel way, based on economic assessments, energy modeling and both fertilizer/CO2 assessments are done.

Evaluation of Business Aspects of Bio-P Development

The evaluation of business aspects related to Bio-P development involves the application of PFF model and VCA. The PFF model provides a comprehensive framework for assessing the competitive dynamics and attractiveness of the Bio-P industry. Firstly, competitive rivalry will be analyzed to determine the intensity of competition among existing Bio-P manufacturers. Factors such as market share, product differentiation, and industry growth rate will be considered. Secondly, supplier power will be examined to evaluate the influence of suppliers on the industry. The bargaining power of suppliers, availability of raw materials, and potential for forward integration will be assessed. Thirdly, buyer power will be analyzed to understand the influence of customers on the industry. Factors such as buyer concentration, price sensitivity, and switching costs will be evaluated. Fourthly, the threat of substitutes will be assessed to determine the likelihood of customers switching to alternative materials or products. Factors such as price-performance trade-offs and customer preferences will be considered. Lastly, the threat of new entrants will be examined to assess the barriers to entry for new Bio-P manufacturers. Factors such as economies of scale, capital requirements, and regulatory barriers will be analyzed.

Additionally, VCA will be conducted to identify the key activities and stakeholders involved in the Bio-P industry. This analysis will help understand the value-added processes, cost structures, and potential areas for improvement within the Bio-P production, distribution, and consumption cycle. By examining each stage of the value chain, from raw material sourcing to waste management, the study aims to identify opportunities for efficiency enhancements, cost reduction, and value creation.

Application of CE Concept

The CE concept will be applied to explore the potential benefits of utilizing anaerobic digestion as an EOL management approach for Bio-PW. Organic waste can be transformed biologically through a method called anaerobic digestion (AD), including Bio-P materials, into biogas and nutrient-rich digestate. By implementing AD, the study aims to demonstrate how the CE principles can be applied to transform Bio-PW into valuable resources.

The analysis will focus on the energy and fertilizer production capabilities of AD. The production of biogas, a renewable energy source, may offer an alternative energy source and help decrease greenhouse gas (GHG) outputs. Moreover, the digestate produced during the process can serve as a nutrient-rich fertilizer, reducing the reliance on synthetic fertilizers and promoting sustainable agricultural practices. The economic implications of implementing AD will also be assessed, considering the potential cost savings, revenue generation, and job creation opportunities associated with the utilization of Bio-PW as a resource. Furthermore, the study will explore the policy implementation aspect using the DPSIR technique. This technique provides a systematic framework for analyzing the relationships between various drivers (e.g., societal demand for sustainable waste management practices), pressures (e.g., plastic pollution and resource depletion), states (e.g., environmental and economic conditions), impacts (e.g., health and environmental consequences), and responses (e.g., policy interventions). By applying the DPSIR technique, the study aims to identify effective policy measures and strategies that can drive the adoption of AD for Bio-PWM, encouraging the shift to a sustainable, CE.

Comparison of Biodegradable and Non-BPs

To compare the environmental features of biodegradable and Non-BP materials, a closed-loop supply system analysis will be conducted. The entire life cycle of plastic materials, involving the extraction of raw materials, production, consumption, and EOL management, is taken into account in a closed-loop supply system. This investigation will make it possible to fully comprehend the effects that each type of plastic has on the ecosystem, allowing for an informed comparison. The LCA methodology will be employed to quantify and compare the ecological burdens of biodegradable and Non-BPs. The LCA will consider various environmental indicators, such as GHG emissions, energy consumption, water usage, and waste generation, to assess each material’s total ecological impact. Additionally, the closed-loop supply system analysis will examine factors such as recyclability, composability, and biodegradability, to assess the potential for material recovery and reintegration into the value chain. By considering the environmental features within a closed-loop supply system, the goal of the research is to shed light on the sustainability ramifications of plastics that are both biodegradable and not. This analysis will contribute to informed decision-making regarding the selection and use of plastic materials, promoting the adoption of more environmentally friendly alternatives.

Global PW Challenges

Worldwide PW pollution has been highlighted as a grave environmental problem, presenting threats such as vast waste creation, ocean contamination, and increasing (GHG) emissions (Liu et al. 2021; Sebastian and Louis 2022). Plastics are a widely used synthetic material that has long been subject to government regulation to ensure their safety and efficacy. It is unclear what will happen to them after their lives. As of 2015, it is predicted that 8300 MT of virgin plastics has been created, resulting in 6300 MT of waste. About 9% was recycled, 12% was burnt, and 79% was deposited in landfills or natural habitats. By 2050, there will be around 12,000 tons of PW in landfills or the environment if present garbage generation and management patterns continue (Geyer et al. 2017; Yang et al. 2022a; Ramasubramanian et al. 2023). The use of plastic in household appliances, packaging, building, healthcare, electronics, and automation has expanded along with the global population boom, putting the environment at risk. As the world’s population grows, consumption of plastic products, including home appliances, packaging, construction, medicine, electronics, and automation, has increased, endangering the environment. One explanation for this issue is to recycle plastic products. Plastic recycling involves the intermediate steps of collecting, sorting, and processing polymers. The quantity of waste in landfills is reduced, and plastic recycling reduces the quantities of waste discarded in the environment. Recycling, therefore, reduces the likelihood of disease outbreaks due to water, air, and soil pollution (Kumar and Singh 2020). PW burning contributes much to atmospheric pollutants. In the majority of situations, MSW also comprises 12% of burned plastic and emits harmful fumes. Burning PW, therefore, raises the danger of respiratory illness, heart disease, etc. Environmentalists must pay close attention to a sustainable step that will lead to a future that is greener and better for the planet as a whole. Burning plastics and the effects of plastics on water and developing solutions to develop alternative methods of PWM are essential (Verma and Vinoda 2016). Because of their decomposition, harmful plastics get out into the environment, where they eventually end up in groundwater. A lack of water may have a devastating effect on water-dependent creatures. The biodegradation of plastics is facilitated by the existence of many bacteria and pathogens in landfills buried with various plastics. Whenever PW is not correctly disposed of, wind or animals carry it into the ground, drains, and pipelines, resulting in soil contamination. These toxic deposits in the soil contaminate crops (Kehinde et al. 2020). Another environmental threat is MPs, which several studies show that they are a more significant threat than previously thought (Golmohammadi et al. 2023; Roychand and Pramanik 2020). Small pieces of plastic, known as MPs, have been found on 18 beaches on six continents, including the Portuguese towns of Faro, Sunnah, and the UK, where they were found in the most significant concentrations, and the Australian port of Douglas, where the minor concentrations were found (Gangadoo et al. 2020). The USA discharges over eight billion microbeads into aquatic habitats each day, according to global figures (Rochman et al. 2015). In the marine environment, MPs are found in sediments, at sea level, in the water column, and in wildlife, and the greatest public types of MPs are polyethylene (PE) and polypropylene (PPE) (Smith et al. 2018; Osman et al. 2023; Wong et al. 2020). The United Nations reports that MPs and their additives influence more than 200 marine species. Like macro plastic (MaPs), MPs can leach away monomers and other toxins, allowing them to be transmitted directly and indirectly, leading to contamination of living organisms (De Sá et al. 2018; Pramanik et al. 2021). Various trophic levels of marine animals, fish, crustaceans, and raptors that consume fish exhibit plastic swallowing behavior. Dissected animals have plastic particles (micro and nano plastics (NPs)) accumulated in their gastrointestinal tracts that go from the digestive system to the systemic circulation or adjacent tissues (Lusher et al. 2017). MPs may harm humans via physical and chemical mechanisms. Toxic consequences may result from the use of chemical additions in polymers. Accumulation of persistent organic pollutants (POPs) by Mps is dangerous for marine animals and subsequently humans and can affect biological systems by direct contact with POPs and other MP-related chemicals in low doses (Smith et al. 2018; Sadeghi et al. 2021a). Concerns about the environmental and biological effects of NPs have sparked an expanding corpus of studies on NPs. This work has helped to establish a distinction between nano and MPs. Many scientists assume that the decomposition process will not stop at the micro size particles but produce smaller particles. According to Andrady (2011), there is no doubt that NPs are produced during the weathering process of meso plastics and MPs (Jakubowicz et al. 2021). To date, large-scale nano plastic detection technologies have not been developed due to the small size range of NPs (less than 1 µm). In addition, because nano plastics are produced in various forms and chemical compositions, it is difficult to predict whether they will accumulate, precipitate, or dissolve and how they will collect or transport through the environment. Therefore, information on NPs is scarce due to significant challenges in sampling, segregation (Jakubowicz et al. 2021; Zhou et al. 2018).

PWM Techniques

Over 88 nations and regions have enacted legal or economic measures to enhance WM, encourage recycling, and decrease the use of specific plastic items, such as levies and restrictions on the importation of PW and SUP made of plastic. With these initiatives, the worldwide average rate of PW disposal fell from 100% in the 1980s to 55% in 2015. Up to 80% of plastic trash is not adequately handled and dumped in the environment in many countries, notably rising and developing economies like China, Sri Lanka, the Philippines, and Vietnam (Wang et al. 2021). About half of the plastic produced each year is destined for waste disposal, meaning it will be disposed of within a year after sale. The treatment of PW is, thus, a serious concern (Singh and Sharma 2016). Municipal solid waste management (MSWM) is a fundamental problem for the urbanizing world, mainly in emerging countries where economic growth and expansion have boosted MSW creation. Growing urban areas produce vast quantities of MSW that must be managed sustainably (Xu et al. 2022a). Currently, most waste is dumped into landfills, releasing methane-rich landfill gas (LFG) that significantly contributes to global warming. GHGs are a significant contributor to global warming (Yang et al. 2023; Shanmugam et al. 2020), and waste and wastewater are major contributors to this problem (Havukainen et al. 2017). For instance, Bangladesh’s current MSWM is not up to par. Despite a substantial allocation of resources, local governments are ill equipped to tackle this issue. The local government is aided in its MSWM efforts by the informal sector and non-governmental organizations (NGOs). Composting, AD, and recycling of organic and inorganic MSW are all on the rise, even if dumps that are open are still an extremely popular way to dispose of MSW. Another potential approach is treating organic solid waste (OSW) through AD to create biogas. To better manage solid waste and increase collection efficiency in developing nations, clean development mechanism initiatives may be implemented. To recover liquid fuel from MSW, pyrolysis is often used. The technologies of incineration and gasification have also garnered interest and have been shown to be relevant (Alam and Qiao 2020). Because of its high caloric content as well as organic components, MSW offers excellent potential for resource exploitation and the conversion of energy. As a result, waste-to-energy (WTE) is the most viable solution for long-term management of MSW and access to renewable energy sources, which may help slow MSW growth and lessen its negative impact on the ecosystem. Thermochemical and biochemical processes are only two examples of the many waste treatment technologies that contribute to WTE and make MSW reduction and converting energy possible. Heat treatment technology may be used to convert MSW into electrical or thermal energy, while gasification or AD can transform the chemical energy in MSW into syngas or bioenergy. In order to effectively address the social and ecological issues resulting from the overproduction of MSW and incorrect handling of it, it is necessary to implement suitable WTE procedures for WM improvement, energy supplementation, the realization of a circular economy, and waste disposal (Xu et al. 2022b; Nandhini et al. 2022; Rezvani Ghomi et al. 2021). Since the 1980s, it has been vital to dispose of PW scientifically, and several efforts have been made to develop appropriate plastic ways. Incineration and recycling are the two effective strategies used by waste solid (WS) to deal with PW. Burning plastic emits poisonous gases into the atmosphere. Burning polyvinyl chloride (PVC) also releases dangerous halogens and CO2, which cause air pollution and global warming (Alhazmi et al. 2021). PW is gathered on a WM route from either the outdoors or the municipal waste stream, disposed of in landfills, recovered for energy, recycled into valuable goods, and sold in markets (Rebeiz and Craft 1995). Figure 3 shows a schematic of PWM.

The global SWM system encountered advantages and disadvantages due to the propagation of the COVID-19 virus (Penteado and De Castro 2021, Klemeš et al. 2020; Naidoo and Fisher 2020). In answer to the rising challenges of resource use and ecological impact, greater emphasis has been given to improving the sustainability of WM systems. Minimum seven sustainable development goals (SDGs) (i.e., SDG1, 2, 3, 8, 9, 11, and 12) are connected to the SWM, as stated in a study by the United Nations Environment Program and the International Solid Waste Association. Increases in renewable energy consumption, focus on MSWM, and waste reduction via recycling and reuse were all recognized as part of the SDGs (Wilson et al. 2015). Sustainable waste management practices, such as WTE and waste-to-material (WTM), were essential to meeting these worldwide objectives. Changes occurred in several sectors during the pandemic in the solid waste industry. First, it was thought that adequately collecting and disposing of MSW and medical waste on a timely basis was a critical strategy for avoiding and managing the outbreak (Penteado and De Castro 2021, Kaza et al. 2018). Consequently, the MSW and medical waste industries may benefit from it. In addition, the COVID-19 pandemic boosted demand for PWM because of an uptick in the usage of plastic items by the public, patients, and hospital personnel (Klemeš et al. 2020; Prata et al. 2020; García-Depraect et al. 2022a; Mohana et al. 2023; Han et al. 2023). Due to COVID-19, an estimated 3.4 billion single-use PPE facemasks are discarded each day (Ajaj et al. 2023; Yek et al. 2023). Asia is the largest producer with 1.8 billion, next to Europe, Africa, Latin America, North America, and Oceania with 445, 411, 380, 244, and 22 million daily. The total amount generated is 1.6 million tons (Li et al. 2023). Authorities and health agencies continue to focus on ensuring the safety of society and eliminating the influenza epidemic. However, the actions taken to restrict COVID-19 should not be interpreted as a green light to abandon the fight against or as a government-backed endorsement of land degradation and using SUP in the marine environment. In addition, the solid waste business may be negatively impacted by the global economic slump brought on by the COVID-19 pandemic, including but not limited to increased labor costs and decreased financial investment (Laing 2020). The effects of the pandemic on the solid waste sector were very examined in the studies that looked at how trash creation and management changed (Zhou et al. 2021).

WM systems use methods like incineration, pyrolysis, and landfill dumping to minimize environmental impacts, but no foolproof system exists for unused COVID-19 vaccines. To prevent the COVID-19 virus from spreading further with the misuse of vaccines, alternatives to plastic-derived surgical facemasks, PPE, and vaccine tools should be sought. WM plants should utilize artificial intelligence, machine learning, and Internet of Things (IoT) for improved PW segregation and recycling, promoting mechanical methods and sterilization for a CE. For enhanced CE, appropriate policy design should encourage mechanical recycling of waste and then sterilization. The chemical conversion of mixed PW into useful fuels and chemicals is a unique strategy and a viable option for CE. Environmentally friendly and recyclable alternatives to traditional plastic-based products have received a lot of attention recently. These consist of both organic and synthetic polymers such as Bio-Ps, gums, cellulose, and chitosan. The present methods used, as well as potential long-term sustainable alternatives, are explored in this talk about COVID-19 vaccination regimens that aim to have a small ecological footprint (Hasija et al. 2022; Gorrasi et al. 2021).

Landfills

Landfills are increasingly scrutinized with suspicion as a last alternative for disposing of PW. Techniques for disposing of recycled plastic include recycling in construction, incinerating for energy generation, and recycling in composting or soil. However, several million tons of plastics, especially packaging plastics, still dumped in landfills, which ultimately take up large volumes and cause capacity shortages (Fazzino et al. 2021; Nanda and Berruti 2021a). In the last 30 years, China has generated an estimated three billion tons of MSW, most of which has been dumped in landfills. It is not only a waste of precious urban areas; burying recyclables underground prevents them from ever being reused. By bringing together “urban SWM” and the “material cycle,” proponents of the notion of “sustainable material management,” which includes “landfill mining,” have advanced this approach. Lately, there has been much interest in a strategy called “landfill mining,” which involves digging the wastes deposited in old landfills, recycling the waste materials, collecting the wastes with high-calorie content, and restoring the land and air (Zhou et al. 2014). Plastic landfilling is a very worrying issue because there is no way to determine if plastic is degraded, decomposed, or harmless forever. Modern waste landfills may be categorized in a variety of ways. The type of waste they get, like garbage from the municipality or dangerous materials, determines its classification. Due to difficulties in source separation, these categories are not only in practice. In the landfill model, a kind of duplication is dependent on the performance of the landfill itself. Landfills are built to keep hazardous waste out of the environment and to recycle leachate so that environmental leakage is minimized (Swift and Wiles 2002). Few worldwide studies have been conducted due to a lack of data, but understanding the physicochemical features of landfill leachate across the world and their essential elements and environmental implications may help promote sustainable MSWM. Due to poor site selection, construction, and management, landfill leachate, which includes several contaminants, may seep into the local water and soil ecosystem (Samadder et al. 2017). Even a controlled landfill that is hygienic may, over time, lose its capacity to keep pollutants out of the ecosystem because of drain blockages and geomembrane deterioration (Ma et al. 2022). Finding community support, affected by social, political, and financial incentives, and adhering to architectural and scientific norms for managing and protecting the physical environment are the two main factors that determine landfill site selection (Khan and Samadder 2014). Reliance on WM through plastic landfills varies worldwide due to differences in energy demand, network availability, support, organization, and adherence to local laws. In the European Union (EU) and the UK, trust in MSW has fallen sharply in the last 5 years. MSW is recycled in the EU at a rate of 46%; landfills get just 25% of the total waste stream. In addition, encouraging sustainable waste management has enforced EU law by implementing multiple directives and reducing landfills throughout the continent. In the case of WM technologies, Asian countries differ in the level of complexness. Seventy percent of SW redirects to energy programs in Japan. It is 1.2% in Japan and 100% in Kuwait. Throughout Asia, incineration is the most popular MSWM method in more developed nations, whereas open dumping and landfilling are more common in less developed regions (Yadav et al. 2022). While industrialized nations like Japan, Singapore, Turkey, and South Korea allot more money for the disposal of MSW, cities in underdeveloped countries spend just 4–16% of their whole municipal budget on MSWM, of which 80–90% is spent on waste collection alone (Yadav and Samadder 2018a). Plastic solid waste (PSW) accounts for 12% of the total world’s SW. Without recycling or aiming for thermally or thermal-chemical conversion (TCC), it is not economically feasible to do so, and it runs counter to the circular economy (CE) (Alhazmi et al. 2021; Al-Salem et al. 2021).

Gasification and Pyrolysis

The gasification supply process involves converting carbonaceous materials into gaseous products (for example, a mixture of H2, CO, CH4, and CO2) in which an oxidant (air, steam, and oxygen) is essential (Shah et al. 2021; Yang et al. 2021). A sub-stoichiometric oxidant enters the system and eventually, the fuel is split into CO and H2 at 550–1000 °C temperature (Li et al. 2021; Martínez-Narro et al. 2022; Teymourian et al. 2021). Gasification delivery involves several complex chemical steps, including drying of the gas phase, pyrolysis, cracking and reforming, and heterogeneous coal gasification (Lopez et al. 2018). Gasification is one of the important technologies in the next decade in terms of flexibility, strength, and economy (Dogu et al. 2021). Compared to pyrolysis, a significant advantage of gasification is due to flexibility in composition plastics and mixing plastics with other feedstocks. In addition, this process uses air, which is one of the cheapest operating options. However, it has disadvantages such as high gas flow velocity, resulting in lower power and more difficult separation, which is not economically viable. In addition, the gasification process in the presence of air as an oxidizing agent, from an environmental point of view, produces a higher amount of harmful NOx, which must be carefully monitored (Ragaert et al. 2017). PW gasification has since been used on pilot projects as well as commercial orders, not just on a research facility scale. Gasification in the United States (US) is a pilot-scale model and another is the Akzo procedure for the gasification of PVC with steam in a mingling fluidized bed. The Canadian Center for Mineral and Energy Technology (CANMET) has also created a pilot-scale PW transport plan. In addition, the plastic gasification industry carried out by the Sekunda¨rrohstoff-Verwertungszentrum (SVZ) in Germany is another model (Salaudeen et al. 2019).

Pyrolysis is an innovative way to treat MSW that can be obtained from various chemicals and fuels. In the pyrolysis process, energy is produced with low nitrogen oxides and sulfur (NOX and SOX) levels than conventional combustion. As a result, an inert atmosphere and the washing of syngases before combustion are possible. Another advantage of pyrolysis is the better quality of solid residues (Yek et al. 2023; Chen et al. 2015). In actuality, pyrolysis is the thermal breakdown of waste materials without the need of air that yields recyclable materials like coal, oil/wax, and combustible gases (Martínez-Narro et al. 2022). Thermal degradation process parameters, including the type of waste, reactor system, residence time, contact time, temperature, pressure, the existence of catalysts, and presence of hydrogen gas or hydrogen donor compounds, affect the efficiency and composition of products (Velghe et al. 2011; Xayachak et al. 2022; Suresh et al. 2021). The three major pyrolysis products are oil, gas, and coal used in refineries. This process can produce up to 80% by weight of liquid oil at an average temperature of around 500 °C (Sharuddin et al. 2016). The pyrolysis procedure is complicated and needs in height employed and investment prices. In the pyrolysis process, the ash produced contains large amounts of heavy metals that depend on the concentration in the processing stream. Therefore, the installation of an air purifier is necessary to treat most of the flue gases from pyrolysis (Dhakal et al. 2021).

Hydrocracking

Cracking is how heavy polymer molecules break down into lighter gaseous and liquid molecules. Depending on the existence or lack of a catalyst or hydrogen, cracking can happen. Hydrocracking is a method of cracking in hydrogen-containing environments (Sharuddin et al. 2016). The process of plastic hydrocracking involves utilizing batch reactors that maintain a temperature range of 230 to 380 °C and exert pressures between 3 to 10 bars. This particular procedure is capable of generating an extensive variety of gas derivatives and is proficient in breaking down all kinds of plastic substances. Various catalysts such as nickel, molybdenum, iron, alumina, zeolite, zirconia sulfate, and silica-alumina are utilized in the process (Dhakal et al. 2021). Hydrocracking produces a high-quality, extremely saturated liquid fuel that may be utilized directly as a transport fuel or furnace oil to produce energy, unlike pyrolysis and catalytic cracking. Furthermore, chlorine, bromine, and fluorine (heteroatoms) that may be involved in the PW are removed during the hydrocracking process because hydrogen is there (Munir et al. 2018). The cost of hydrogen is the biggest obstacle to implementing this process. Electrically generated hydrogen will cost approximately 2500 euros per ton (Ragaert et al. 2017). Hydrocracking technology is available in other industries, such as the petroleum industry. Although tested for waste plastic feedstock, it is only available on a pilot scale for this purpose. Therefore, several challenges such as the effects of PVC hydrocracking, high investment, and operating costs for cost-effective commercialization need to be addressed (Solis and Silveira 2020).

Incineration

Incineration plants can operate constantly for a year, with the exception of a few days for periodic maintenance. However, the use of incineration to handle PW has negative environmental implications owing to the discharge of extremely poisonous compounds that eventually contaminate the air (Luo et al. 2023). Gasification and combustion are two methods of incinerating waste (Babaremu et al. 2022).

To guarantee adequate breakdown of harmful organic compounds, the flue gases must achieve a temperature of no less than 850 °C for 2 s throughout the process. According to Gu et al. (2019), incinerating waste may decrease solid volume by up to 90%, efficiently recover energy, prevent the emission of CH4, and lessen soil and water pollution. The incinerator’s solid waste may also be disposed of in above-ground landfills or mixed with building materials because it is inert and hygienically perfect (Mayer et al. 2020). It should be highlighted that in addition to reporting greater reduction results in comparison to other MSW processing methods, incineration additionally provides a useful solution to the issue of a lack of energy supplies. In this sense, incineration offers a strategy for meeting the demand for energy and has garnered significant interest due to its greater rate of resource recovery and less need for land (He and Lin 2019). As a result, waste may be a key factor in reducing the use of fossil fuels and raising the percentage of energy from renewable sources (Escamilla-García et al. 2020). In many nations, incineration is the norm for trash disposal. To deal with MSW, Japan has 1172 incinerators. About 1770 MW are produced when MSW is burned with energy recovery (Tabata 2013; Mani 2020). Across the nation, MSW incineration generates roughly 200 kWh/t of energy (Dadario et al. 2023). The largest of Singapore’s four incineration facilities consists of four incinerator plants and has the ability to process around 1700 t/day of MSW. There are enough incineration units throughout the EU-18 to process 85% of MSW. However, the 81 million tons of MSW that remained in European waste-to-energy plants after reuse and recycling in 2013 could provide yearly power and heat for nearly 15 million people, as reported by the Confederation of European Waste-to-Energy Plants (CEWEP) (Lino and Ismail 2017).

Recycling

Most disposable plastics are disposed of as waste, which pollutes the environment. Only 9% of plastic is recycled correctly (Foolmaun et al. 2022), and the rest is buried or left in nature. Plastic recycling is an economical solution to protect the environment (Sebastian and Paul 2021) (Bigdeloo et al. 2021; Das et al. 2021). PW recycling is involved in WM as efficient and sustainable use of material resources. It should be noted that the phase of reuse, recycling, and recovery is associated with energy consumption processes and resources, while disposal can pose serious risks, so society must act rationally (Kumar and Singh 2020). Four kinds of PW recycling techniques exist (Nanda and Berruti 2021b). The American Standard Testing and Materials Association (ASTM I) has given mechanical reprocessing of waste materials with qualities and equivalents to virgin plastics the designation “primary recycling.” Primary recycling involves the re-extrusion of discarded plastics in the industry. In addition, because of the need for homogeneity, PW is not used post-consumption (Zhang et al. 2021; Hopewell et al. 2009). Injection molding and other mechanical recycling procedures are part of primary recycling, often known as non-contaminated polymer recycling. Due to high contamination, MSW is typically unsuitable for primary recycling since it cannot be cleaned or semi-cleaned to the same standards as the original items. Clean scrap is transformed into collected waste to improve its qualities above those of virgin materials. Manufacturers love this process because it turns waste plastic into a high-quality product (Singh et al. 2017). Secondary recycling is processing discarded plastics into products with less rigorous performance criteria than the original material. There are two viable techniques of secondary recycling. One way is to isolate the plastics from their pollutants and sort them into general categories, one or more recycled into goods created from virgin or primary recycled material. Re-melting the mixture without separating the polymers and impurities is another option. Granulators, shredding, and grumblers may reduce the volume of plastics-containing waste streams; separating plastics from other waste materials may be accomplished by washing, drying, and compounding. Depending on the kind and quality of waste being processed, the order and variety of procedures used in the specific treatment process may change (Kumar et al. 2011). Polymers are broken down into smaller molecules that are easier to separate from contaminants in tertiary recycling or chemical recycling (Jiang et al. 2022; Yang et al. 2022b). Feedstock recycling is a term used to describe this method of creating raw materials in petrochemical operations, or the production of monomers for new polymers and other petroleum products such as wax and paraffin are also used (Goodship 2007). This method is associated with more energy and higher cost compared to mechanical recycling and incineration (Kosloski-Oh et al. 2021). Because of the difficulty in separation that results from the product combination produced by chemical recycling at high temperatures, this process has only a limited number of industrial uses (Samak et al. 2020). Gasification, pyrolysis, hydrocracking, and catalytic cracking are only a few of the traditional refining methods that may be used to recycle chemicals (Brooks et al. 2018). Regardless of the type of plastic and its application, there are five basic steps for recycling plastic materials (Fig. 4).

Step 1: Collection of PW

The MSW is the duty of local governments worldwide. Providers of commercial or governmental MSW collection services face a lengthy process that calls for a large workforce and sophisticated equipment. Solid trash separation at home and at municipal pickup stations is the first stage in a successful recycling process. The population of industrialized nations like Japan, the USA, and Germany separates recyclables and mostly delivers them to designated drop-off points or places them at the curb for collection. Selective rubbish collection from dwellings dominates in developing nations like Brazil, which hence needs energy for transport (Lino and Ismail 2017). Critical elements having a significant influence on MSW collection include the volume of MSW, the kind of machinery, the distance MSW is carried, and the labor required (Huang et al. 2011). As an additional example, in underdeveloped nations like India, collecting and transportation expenses account for 70–85% of overall management expenses, but in rich countries like Sweden, this proportion stands between 50 and 75% (Yadav and Karmakar 2020). The need for an MSWM directed at recovering materials and energy in accordance with CE criteria is documented in more recent scientific literature. A comprehensive MSWM architecture relies on distinct collections since it enables the full enhancement of the value of MSW, including organics. Separated collection calls for ongoing dedication from the customer, as well as detailed data and educational initiatives. For nations that are still creating their MSWM frameworks, the consideration of the existing casual WM segment is considered basic for planning productive, maintainable, and flexible WM frameworks that fit the neighborhood circumstance (Calabrò and Satira 2020).

With the growth of plastic production globally, the commercial market of PW has emerged. Due to a scarcity of native raw resources for domestic manufacturing and exports, China has become the globe’s largest importer of additional raw materials such as plastics and waste since 1993 (Yoshida et al. 2005). To sustain its plastics industry, China imports between 45 and 56% of the world’s PW. The cost of using this plastic import of output is much lower than domestic PW. Exports of PW from Hong Kong, the USA, Japan, Germany, and the UK surged 817% between 1993 and 2016. Some countries account for 87% of total plastic exports, with high gross domestic product (GDP) and the development of WM systems. This is because WM costs are very high compared to developing countries like China. In 2017, the Chinese authorities prohibited the import of poor-quality and polluted PW. China’s ban will shift the production of 111 MT of PW by 2030 (Brooks et al. 2018). It has also caused Southeast Asian nations like Malaysia, Indonesia, and Thailand to import more PW. Due to limited local recycling and recycled goods manufacturing, Malaysia imports garbage. In 2017, China exported 105,000 tons of PW, up 68% from 2016 (Chen et al. 2021).

Step 2: Sorting of Plastic Waste

Even if mechanical or chemical recycling is favored, they are both cutting-edge recycling procedures. What cannot be avoided is gathering and sorting waste so that it may be used correctly as input into recycling operations. Although all associated processes must be evaluated in terms of their biological impacts, the superiority of one alternative over another must also be considered (Erkisi-Arici et al. 2021). Separation of plastic is one of the vital complex processes in the PWM system, e.g., it is hard to determine shredded bottles of PVC from shredded polyethylene terephthalate (PET) bottles, and this separation process has to be done earlier to the following process because the presence of PVC may decrease the quality of the whole batch. It is also needed to separate plastics (such as PVC, PET, and PE). In most cases, plastics are classified based on color to improve the physical appearance of the products after use (Ruj et al. 2015). Source separation is often used for preliminary sorting during the waste collection step. However, it may not be followed consistently across all areas, and the quantity of sorting may vary. Fast and precise plastic identification may be achieved via the use of several sorting procedures in the recycling sector. Therefore, manual and automatic sorting are essential (Al-Salem et al. 2009).

Direct and indirect garbage classification are automated procedures. Using magnetic sensitivity, electrical conductivity, and density, direct sorting techniques may separate heavy material using external fields like magnetism, eddy current, and gravity. In indirect sorting, sensors discover recyclables, and automated equipment or robots sort them (Gundupalli et al. 2017). It is possible to distinguish distinct kinds of recyclable plastics using an automated sorting system. By using cutting-edge technologies, these systems can automatically classify plastics depending on the kind of resin they are made of, their form, or their color (micro sorting). In plastic flake sorting systems, a granular form and this system can move a large volume of material. While flake or micro sorting systems are on the growth in the industry, macro sorting is still the most common. Macro sorting detects a plastic detection system based on the type or color of the resin or its physical properties. In the next step, these plastic bottles are removed from the conveyor with the help of ejectors (high-pressure air jets) to their respective storage bins (Wahab et al. 2006). Because of variances in dimensions, form, color, and coating, automated approaches do not always work, delaying analysis (Al-Salem et al. 2009). An automated sorting system often employs optical sorting systems, near infrared (NIR) systems, and X-ray technology. The NIR spectroscopy system uses reflected spectra of polymers excited by a light source. Within the 700–1000 nm spectrum, it may expand into the short wave IR (SWIR) area in certain situations (1000–2500 nm). A conveyor belt, lighting system, optical sensor, and separation unit with compressed air nozzles make up the NIR sensor sorting system. Conveyor-belt flakes of varying sizes serve a significant function and help detect sensors. In addition, near infrared sensors can detect many different polymers such as PP, PE, PVC, PET, and PS, and plastics are separated from materials such as paper, wood, glass, and stone. The advantages of this method can be written as follows: (1) It has no contact with the object under study, (2) it has a fast rate of sensing, (3) numerous detection and inspection, (4) and no color interference (Serranti and Bonifazi 2019). Optical sorting is limited to plastic color separation only. Near infrared is unsuitable for dark material, while middle infrared can detect them but cannot provide a quick detection. X-rays and lasers can only be used to separate PVC and PET. High-speed automated sorting cannot use spectroscopy (Bezati et al. 2011). Tracer-based sorting (TBS), a novel identification method based on a fluorescence tracer and a related detecting unit, is another new identification and sorting technology (Kusch et al. 2021). Because it may eliminate multiple phases of sorting and recycling, TBS is a significant development in the circular economy for plastics. A fluorescent tracer is a specific identification device for users based on the type of packaging or to identify the recycling path. This identification does not relate to the intrinsic properties of the material (Woidasky et al. 2020). TBS provides a reliable and effective identification technique to increase the recycling of PW by recognizing packaging and other products (Gasde et al. 2020).

Automated sorting systems make large volumes of plastics with minimal workforce intervention and high performance but require high investment in specific technologies. On the other hand, manual sorting requires planning for visual identification and manual extraction of plastic containers. However, due to high power, the production process is reduced. Due to the increase in workforce, manual sorting systems are preferred in many developing countries, and less capital is required than automated systems. Therefore, to improve the manual sorting process for recycling PW, be economically efficient and cost-effective (Jimoh et al. 2014).

Step 3: Shredding and Resizing

The next step is to reduce the size of superior fragments of PW to improve the density of materials for easy storage and transportation. The shredder is a rotating blade driven by an electric motor and has a size grid and a collection holder. The material enters the shredder through the funnel and turns into plastic flakes. The resizing also makes it easier to identify items, such as metal, that recycler cannot find when cleaning. (Siwal et al. 2021).

Step 4: Washing to Remove Impurities

Washing plastics is done after the plastic shredding step. In the washing step, most waste is washed away after consumption, but it is not valid for all the input materials used for recycling. Some regrind materials or even agglomerate are processed immediately. Consumption of hot or cold water is up to 60 °C. If cold water is used, it must use chemicals (e.g., sodium hydroxide) and mechanical energy. Wastewater is treated internally by washing. The washed plastic pieces are dried, and 0.1% by moisture’s weight is prepared for reprocessing (Worrell and Reuter 2014).

Step 5: Reprocessing

Recycled plastic pellets, powder, or scales are melted at this stage. The final products that are made using resin molding techniques such as extrusion molding, injection molding, blow molding, vacuum molding, inflation molding, and melting spin are reprocessed. The most common technique is as follows:

Extrusion

The most common technique is the extruder; homogenization and intense compression cause the plastics to melt by transferring materials. PET flakes are formed by melting with indirect heating and a temperature of 290 °C. Volatile reaction gases, such as monomers and solvents, are separated by suction. Finally, the plastics are separated from the remaining solid impurities with the help of a filter. The extruded plastic string is cut in the water bed with granular rotating cuts. Mixed plastics are recycled through penetration, injection molding, or sinter pressing. Depending on the shape, for example, industrial pallets, building fences (intrusion), flowerpots (injection molds), or large area panels (pressing techniques) are produced (Feil and Pretz 2020). Extrusion produces single-polymer plastic by stranding and pelletizing PE (Al-Salem et al. 2009).

Based on CE concepts, an algorithm for calculating the technical expertise index has been suggested to assess market technology for polymer waste collection, categorization, and recycling. The 17 countries at the beginning of 2021 have patented collection technologies, sorting and recycling of polymer waste. Studies demonstrate that barely half of the average level of skill index is produced in the worldwide market for polymer waste collecting, sorting, and recycling technologies. Three countries dominate the index of expertise: the USA, China, and the EU. We may use this market evaluation to see how well our waste management plan is working (Starodubova et al. 2021).

The Growth of a Worldwide CE for SW

The concept of a worldwide CE for solid waste was developed primarily for financial reasons. For one, recycling is more cost-effective in poor nations with low labor costs because of the time and effort required to separate valuable materials from mixed wastes. As a second point, more environmental rules and enforcement in wealthier nations make recycling waste products with environmental effects more economically viable than in less developed nations. Third, nations like China that have cheap recycling costs also tend to be industrial centers, which makes production using recycled materials a viable option. Shipping firms sometimes provide discounts on round-trip fares for returning customers after delivering completed products to industrialized nations. Moreover, the cheap cost of transportation facilitates the export of MSW from industrialized to underdeveloped nations. Finally, low quality, low-value items are produced using recycled resources from certain forms of SW. Because of the size of the consumer markets in developing nations, these products are ideal candidates for trash recycling. The global circular economy of SW recycling helps ensure the longstanding viability of the planet’s ecosystems by reviving waste materials and decreasing the need for raw resources, as well as providing economic and employment possibilities in underdeveloped nations. This global CE has positive economic and environmental effects, but it also has serious negative consequences for the environment. Due to poor environmental rules and enforcement, recycling in poor nations frequently lacks basic safeguards for health of both humans and ecosystems. Toxic resources are used in the workplace without necessary safety precautions being taken, and waste products from the mining of precious metals and minerals are often discarded without being properly processed. Transboundary transportation and dumping of hazardous wastes are prohibited under the Basel Convention (2018) and other high-level international norms, but these prohibitions have historically been difficult to enforce in both affluent and developing countries (Gu et al. 2017; Qu et al. 2019; Van Ewijk et al. 2018).

Challenges and Factors that Affect Plastic Recycling

In recent years, recycling has been one of the ways to minimize waste and a practical way to reduce the waste generation rate. Rising SW, cost issues, and the extent of SWM are significant challenges. Unless immediate action is taken to reduce waste disposal, waste generation will continue to increase, and disposal costs will be in line with population growth and living standards (Moh and Abd Manaf 2014). The widespread use of recycled plastics in secondary market plastic products still faces obstacles. Compared to virgin polymers, recycled plastics are affected by several factors that make manufacturers unsure of the performance of recycled products. Because of the sluggish pace of technological advancement and the poor quality of government procurement, widespread adoption of plastic recycling is still a long way off in the sector. A lack of understanding of plastic goods and their intrinsic qualities is common in recycling sectors. Because synthetic polymers cannot be tested, this industry area cannot compete with makers of virgin polymers. As a result, the idea of plastic recycling excellence, property evaluation, satisfying the requirements of producers and consumers, and assuring the efficiency of recycled goods in their secondary market uses has been introduced. Developing plastic recycling technologies that are quick, inexpensive, and dependable is critical for recycling facilities to assure their quality (Vilaplana and Karlsson 2008). Structured monomer units (such as bisphenol A (BPA)) or other additions (such as plasticized), or a mix of the two, are to blame for human health hazards from plastics (e.g., antimicrobial polycarbonate). Several toxic substances include BPA as a monomer building block of polycarbonate plastics and as an additive in PVC plastics and phthalates released by plastics. Over time and at extreme temperatures, BPA-coated containers for water, baby containers, and food cans enter food. When BPA is ingested or inhaled, it interferes with our bodies’ regular hormonal notification system. BPA is a hormone that mimics the “estrogen” reproductive hormones. Research shows that BPA is linked to several health issues, including the destruction of chromosomes in the ovaries and a reduction in sperm count and maturity speed. Type 2 diabetes, heart disease, overweight, and other metabolic diseases are rising, as are fast alterations in the immune response. There is evidence that BPA is linked to various health problems, including breast and prostate cancer and metabolism issues. Polycystic ovarian syndrome (PCOS), obesity, and repeated pregnancy have all been linked to BPA in women (Proshad et al. 2018). Without recognizing their dangers, toxic chemicals enter human health and the environment when we use more plastics than we should. In order to combat this problem more effectively, the government should take action and emphasis sustainable generation, utilization, and disposal of resources. Every company should be responsible for reducing the consumption of unnecessary plastics. Consumers should be informed about all accessible chemicals in their goods, which necessitates providing comprehensive information on such compounds.

Bps

BPs are divided into natural polymers or synthetic polymers, which we have discussed in this section. Natural polymers are generated from plants or biomass (Lim et al. 2021; Price et al. 2020). The raw materials for producing natural polymers are cellulose, corn, sugarcane, and bacteria. Some of the commercially used biodegradable natural polymers on the market include PLA, PHA, polyhydroxybutyrate (PHB), poly (hydroxybutyrate-co-valrate) (PHBV), and poly (hydroxyvalerate) (PHV). In recent years, PLA has been extensively adopted as “green” plastic. Many microorganisms and aggregates form a naturally thermoplastic preservation molecule known as PHAs as internal granules in excess CO2 or when phosphorus, nitrogen, or oxygen (microelement) is depleted concurrently. Polybutylene adipate-co-terephthalate (PBAT), polycaprolactone (PCL), and polybutylene succinate (PBS) are synthetic biodegradable polymers. Combining these polymers with Bio-Ps or other starches improves their performance. PLA, PHA, PHB, PHBV, and PHV are some of the commercially available biodegradable natural polymers (Filiciotto and Rothenberg 2021; Luyt and Malik 2019). Consumers commonly confuse BPs and Bio-Ps. The latter are plastics created from biomass, often derived from plants. It is easy to make the mistaken assumption that these polymers are biodegradable because of their natural source. Plastic’s chemical structure and crystallinity are important to biodegradability. Plastics made out of petroleum may also degrade. Because they are created from renewable resources, Bio-Ps may be considered environmentally friendly and sustainable (Filiciotto and Rothenberg 2021; Anastas and Eghbali 2010).

All Bio-Ps, as well as BPs (both bio and petroleum-based), are described together as “Bio-P.” Non-B and biodegradable polymers are subcategories of Bio-Ps. Bio-based PET, PE, and PP are examples of bio-based Non-B polymers (Qin et al. 2021). These Non-B polymers may be recycled with conventional polymers since their chemical composition and characteristics are comparable to those of their traditional equivalents made from petroleum resources (Fig. 5) (Lamberti et al. 2020). Ester and amide bonds in biodegradable polymers may be broken by aqueous and enzymatic hydrolysis, leading to the material’s full disintegration into CH4, CO2, and H2O without generating any poisonous or damaging molecules (Kumar et al. 2023).

The main difference between BPs and plastics that are chemically synthesized from the petrochemical industry, such as PE, polycaprolactone, polyethylene glycol, PVC, is that plastics are very resistant to biodegradation and they do not decompose naturally. It either occurs at a meager rate that can be chemically modified or combined with other chemicals to increase their degradation by abiotic and biotic factors (Steinbüchel 1992). The shift from traditional petrochemical polymers to biodegradable polymers for short-use phase applications such as disposable plastic bags is increasing worldwide. Therefore, disposable packaging materials have led to BPs such as PHA. As a result of its tensile strength, printability, scent and odor barrier, oil and grease resistance, and high-temperature stability, PHA is extensively utilized in the food packaging business (Kalia 2016). Compostable trash bags made from BPs may also be used. Improve the amount required to collect organic waste, hence minimizing landfills and enhancing the composting process and compost quality, by using these bags as organic waste collectors. Foam trays of fruits and vegetables (organic produce) and fresh meat have lately been packaged in film for prolonged shelf life, which simplifies disposal and increases the sales period, recovering spoiled food through compost without separating the packaging at the point of sale. Manufacturing of biodegradable mulch film and other forms of stiff packaging. Tires made from starchy materials minimize hysteresis and fuel consumption; diapers have smooth backplates, and papers are made from starch materials. BPs may be used in the medical field to produce stitching materials, screws, or implants, which are expensive items (Rujnić-Sokele and Pilipović 2017).

PHA

Flexible and durable petroleum-based polymers have industrial uses. Biodegradability, post-incineration toxicity, and landfill trash restrict their utilization. To generate novel biocompatible and biodegradable polymers with comparable physical and chemical characteristics to standard plastics, French microbiologist Maurice Lemoigne discovered poly (3-hydroxybutyrate) P(3HB) in 1920. P(3HB) creating intracellular granules in Gram-positive bacterium Bacillus megaterium. P(3HB) is the first and most common biopolymer belonging to PHAs. Many years later, PHA containing 3HB and 3-hydroxyvalerate (3HV) were discovered in activated sludge. It took nearly a decade when reported PHAs with 11 varieties of linear and branched repeating units of four to eight carbon atoms. PHAs are the most versatile fully biodegradable polymers with properties similar to conventional plastics. Other biodegradable polymers such as chemically synthesized plastics (e.g., polyglycollic acid (PGA) and PLA) and starch-based plastics (e.g., starch-PE) have also appeared on the scene but they lack variability in structure and extensive material properties. Appreciable number of PHAs with more than 150 monomers has been identified with molecular masses ranging from 50,000 to 1,000,000 Da. As PHAs are biodegradable and immunologically inert, they have promising future applications, particularly in medical related fields, despite their expensive production (Keshavarz and Roy 2010). PHAs were 15–17 times more costly than petroleum polymers and 4–6 times more expensive than Cargill polylactic acid in 2005. In 2009, costs were reduced to $5 per kilogram per year because of metabolic engineering, which enhanced fermentation settings. Despite only making up 33% of the market, commercial polymers remain indispensable (Dietrich et al. 2017). Bio-Ps are commercialized using one or two-step microbiological fermentation techniques. PHA is first created by microbial fermentation using a wet corn mill, sugarcane dextrose, or vegetable oil. Fermenting bacterial cells produces PHA polymer. Non-PHA components of a microbial cell are chemically or enzymatically destroyed, and the PHA polymer is recovered by solvent or aqueous methods. Aerobic fermentation infrastructure, polymer recycling technologies, and renewable raw material prices must be considered (Axelsson et al. 2012).

PLA

PLA is a compostable natural biopolymer. Wide use and annual manufacturing growth rate are equivalent to fossil-based polymers (Barletta and Cicci 2020). PLA accounted for about 25% of BP manufacture in 2018 (Cazaudehore et al. 2023). PLA is lactic acid-based aliphatic polyester. PLA is produced from starch and maize stalks. PLA breakdown depends on product and disposal circumstances. PLA polymers degrade in 1 to 2 years, half as long as fossil-based plastics (Chen and Yan 2020). There are several techniques for producing PLA as a household product and packaging. However, high impact resistance, strength, and modulus limit its application in the heat-resistant packaging industry. Therefore, by adding plasticizers, softeners, fillers, fibers, and nanoparticles or adding natural fibers, it has achieved the desired properties (Kaiser et al. 2013).

LCA of Biopolymers

LCA is a framework that can assess the environmental impact of a product’s longevity from the time it is extracted (Sadeghi et al. 2021b), from its raw materials, and the end of the life of the resulting waste that returns to the ground. Rapid progress and ongoing research have led to LCA’s acceptance as an incentive mechanism in policies that foster sustainable growth. LCA has several current uses, including product development, business strategy, marketing, and process optimization. LCA allows us to examine the effects and their root causes when applied to a product or system (Xu et al. 2019). The LCA involves collecting input and output information such as emissions, waste, and resources by assessing environmental consequences such as climate change, smog, eutrophication, acidification, and toxicity to humans and ecosystems (Yates and Barlow 2013; Dong et al. 2022). Consistent with the rise in MSW production, a greater understanding of the environmental effects of MSW has emerged worldwide. The use of the LCA methodology has expanded in the MSW management industry due to the rising awareness of the negative environmental consequences of MSW (EN ISO 14040, 2006, EN ISO 14044, 2006). After its first use in the 1990s, LCA has become a standard technique for evaluating the ecological effects of MSWM systems (Yadav and Samadder 2018b; Liikanen et al. 2018). High-income regions, especially Europe, have been the primary developers of the LCA of MSW management systems. Due to rising MSW production and urbanization, it has recently acquired favor in nations with lower per capita incomes. Recent years have seen a rise in the number of LCA studies focusing on MSW in China. Several researchers, including Tan and Khoo (2006), Banar et al. (2009), and Zhao et al. (2009), have conducted LCA studies to analyze waste management strategies for plastic and other wastes. All of these studies analyzed environmental implications by considering a variety of scenarios, including recycling, landfilling, and incineration (Aryan et al. 2019). Studies of LCAs for MSWM systems are often highly case-specific, based on the study’s purpose and local circumstances and peculiarities. However, the primary goal of LCA research is to evaluate MSW management and treatment strategies (Liikanen et al. 2017). The ISO standards control the LCA process. The LCA study determines the scope and purpose, inventory analysis, impact assessment, and interpretation of data. It is comprehensive research. The ideas, methodology, standards, and procedures for conducting an LCA study are outlined in ISO 14040 (2006) and ISO 14044 (2006) environmental management LCA. The inventory analysis data determine midpoint and endpoint indicators in the impact stage. Acidification, radiation, the climate, fossil fuels, environmental toxicity, and other midpoint indicators are examples of this. Endpoint indicators include respiratory problems, ocean levels, depletion of resources, and so forth (La Rosa 2016). It is essential to evaluate the LCA of Bio-Ps as a potential replacement for petrochemical plastics and compare these plastics’ environmental performance accurately (Bishop et al. 2021). Even though biodegradable polymers with zero or negative carbon impacts are considered in LCAs, manufacturing losses and carbon emissions throughout the process are generally disregarded (Filiciotto and Rothenberg 2021). The LCA study evaluates a bio-based polymer’s sustainability and ecological benefits over time raw materials, production, application, and end of life of biomaterials. ISO 14040 (2006) and ISO 14044 (2006) define the LCA as a four-phase process with globally recognized standards.

WM Options of BPs

There are several conventional approaches to recycling PW, including collection and incineration processes that include energy recovery, the specific burning of high-energy plastics (like those in cement kilns), and the use of plastics as reduction agents in blast furnaces or as raw materials that can be recycled. PW increases by 2 to 5% per year, producing one million tons of waste. “Waste Hierarchy” is a guideline produced by the UK government to limit the effect of waste, reduce it, reuse it, or divert material from the waste stream to decrease materials consumed. Biodegradable Bio-Ps have the potential for composting, which recovers materials and produces a valuable product such as compost. A sustainable approach to disposing of Bio-Ps, such as compost and AD, would not apply to degradable plastics (Gasde et al. 2020). It will be discussed further in the following sections. EOL management of biopolymers must be biodegradable by default, which presents a problem for researchers. Aside from landfills, where methane leaks are a potential issue, most conventional WM options differ slightly from the management of traditional biodegradable polymers.

Composting