Abstract

The linear production and consumption of plastics today is unsustainable. It creates large amounts of unnecessary and mismanaged waste, pollution and carbon dioxide emissions, undermining global climate targets and the Sustainable Development Goals. This Perspective provides an integrated technological, economic and legal view on how to deliver a circular carbon and plastics economy that minimizes carbon dioxide emissions. Different pathways that maximize recirculation of carbon (dioxide) between plastics waste and feedstocks are outlined, including mechanical, chemical and biological recycling, and those involving the use of biomass and carbon dioxide. Four future scenarios are described, only one of which achieves sufficient greenhouse gas savings in line with global climate targets. Such a bold system change requires 50% reduction in future plastic demand, complete phase-out of fossil-derived plastics, 95% recycling rates of retrievable plastics and use of renewable energy. It is hard to overstate the challenge of achieving this goal. We therefore present a roadmap outlining the scale and timing of the economic and legal interventions that could possibly support this. Assessing the service lifespan and recoverability of plastic products, along with considerations of sufficiency and smart design, can moreover provide design principles to guide future manufacturing, use and disposal of plastics.

Similar content being viewed by others

Main

Plastics are extraordinarily useful materials. They play key roles across the global economy in important areas such as food production and preservation, transport, insulation, clothing, healthcare and medicine. Since their discovery more than a century ago, we have mastered their mass production at a phenomenal annual rate, exceeding 460 megatonnes (Mt) in 2019 (ref. 1). Driven by their low cost, light weight, stability, longevity and high performance across various economic sectors, our consumption of plastic has greatly accelerated2. However, plastics pollution is correspondingly pervasive and only expected to get worse3,4,5, with serious consequences for the environment and human health6,7,8,9. Moreover, the greenhouse gas (GHG), and in particular carbon dioxide (CO2), emissions associated with plastics production, use and end-of-life (EoL) remain a substantial barrier to keep global warming below 1.5 °C (ref. 10).

Globally, awareness of these challenges has grown in recent years, providing scope for new research on mapping the problems and providing solutions. A growing body of academic literature has also emerged, offering important insights into the problems associated with the current economic model, including plastics life-cycle carbon emissions11,12,13, dependence on fossil resources14,15,16, inadequate recycling techniques and infrastructure17,18,19, the implications of plastic waste exports and mismanagement20,21,22,23, ecosystem pollution20,24,25 and health risks26,27. Although these studies often include mitigation strategies2,28,29,30,31, a future sustainable plastics economy requires a multidisciplinary and holistic vision of the entire life cycle, as well as an economic and legal perspective on what stimulates (or hampers) change.

In November 2020, several members of the World Trade Organization (WTO) launched an informal dialogue to explore the role of trade cooperation in reducing plastics pollution and transitioning to a more circular and environmentally sustainable global plastics economy, complementing discussions in other forums32. Moreover, following a resolution adopted unanimously at the fifth session of the United Nations Environment Assembly (UNEA) in May 2022, countries have started negotiating a legally binding international treaty on plastic pollution, addressing the full life cycle of plastics, with the ambition of completing negotiations by the end of 2024 (refs. 33,34,35). In line with the resolution, the treaty could include provisions to promote sustainable production and consumption of plastics through, among other things, product design and environmentally sound waste management (Supplementary information sections 4.2 and 4.4). If successful, the new treaty will provide legal certainty on key sustainability approaches and bring greater coherence to international law, which—at present—addresses aspects of the plastics life cycle in a fragmented manner (chemicals, wastes, pollution etc.)34,35,36,37,38,39.

In light of these continuing international discussions, this perspective aims to propose a vision for a future circular carbon and plastics economy. This circular system can only be attained if four interlinked targets, centred on consumption reduction, uptake of renewable plastics, greater recycling and elimination of burdens to the environment, are achieved at scale. Urgent adoption of key interventions is necessary to reach these four targets by 2050, a system change that, to be successful, needs to be guided by ‘smart design’.

Re-imagining a circular plastics economy

A bold system change is needed

The plastics economy remains stubbornly linear. In 2019, only 9% of global plastic waste was mechanically recycled into new products, that is, most (estimated at 320 Mt) was lost to the economy through landfilling, incineration or entered the terrestrial or marine ecosystems1. It is also estimated that the volume of plastics accumulated worldwide since the 1950s (the amount ever produced minus that incinerated) has reached 8.2 gigatonnes (Gt), of which only 2.2 Gt remains in use and 6.0 Gt is waste40. The mass of carbon trapped in these plastic wastes is approximately double the total amount stored in human and animal biomass on Earth41. Moreover, our plastic consumption contributes to climate change: the anthropogenic GHG emissions through the plastics life cycle, including the extraction of petrochemicals, production of virgin polymers and additives, manufacturing of products and common EoL options, were estimated at 1.8 GtCO2 in 2015 (ref. 42). This figure represents 3.8% of the entire current global CO2 budget, roughly the size of the combined national emissions of the three largest economies in Europe (Germany, UK and France)43.

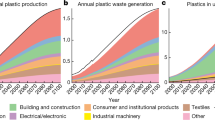

Both the increasing volumes of waste and GHG emissions emphasize the inadequacy of the current linear plastics economy (predicated on extract-make-use-waste) to respond to the demands of a growing world population and the expected rise of living standards in emerging economies. For instance, the amount of plastic waste generated could almost triple by 2060 (ref. 24) and, if not remediated, more than 50% of it could become unmanageable and end up in the oceans44. GHG emissions associated with the plastics life cycle are also predicted to rise by 2050 to 6.5 GtCO2 under business-as-usual practices using fossil energy (10–15% of the overall annual global CO2 budget in 2050)10, a 3.6-fold increase primarily driven by a net growth in plastic production and waste incineration levels42.

Against this backdrop, it is crucial to redesign the plastics economy across future sectors, regardless of their market share, place in the economy or intended use. Hence, building on the circular economy model that is already shaping law, policy and action by industry worldwide (Supplementary information section 4.1)45,46,47,48,49, we propose a future circular carbon and plastics economy centred on four targets:

-

1.

Reduce plastic demand: eliminate 50% of all plastic materials and products.

-

2.

Switch to renewable plastics: replace all fossil-fuel-based plastics with those sourced from alternative feedstocks, accelerating carbon recirculation through use of biomass and CO2.

-

3.

Maximize recycling: design plastic materials and products for circularity and ensure that 95% of plastics are recycled.

-

4.

Minimize environmental impacts: remove all sources of hazards to organisms and pollution to the environment, as well as decrease the carbon footprint throughout the plastics life cycle.

The implementation of these targets needs to be guided by smart design, as described in further detail in Supplementary information section 3.1.

The carbon and plastics life cycle

A selective focus on the individual targets set out above is unlikely to succeed. Instead, an integrated and scalable approach is essential. To accomplish this, the plastics economy as a whole needs rethinking. But where and how to start? As a useful basis for such analysis, CO2 emissions from the global plastics life cycle provide quantitative information and an effective evaluation tool. Current life-cycle emissions for plastics are dominated by the production of virgin plastics from petrochemicals (61%), followed by emissions from product manufacturing (30%) and lower emissions attributed to EoL treatments (9%)42. The four targets for future sustainability must be applied synergistically across the plastics life cycle to minimize these emissions. For instance, substituting virgin petrochemicals as a plastics feedstock and ensuring the recycling of plastic wastes should both drive down GHG emissions during the life-cycle stage42,50,51. As we shall discuss later, interventions must be carefully and simultaneously balanced to not only cut GHG emissions but also to reduce other negative social and environmental impacts throughout the entire life cycle39,44.

Proposing mechanisms for such system restructuring first requires a method to formulate global estimates for total material fluxes and life-cycle GHG emissions. One approach considers total carbon recirculation. Because carbon constitutes, on average, about 74 wt% of current commodity polymers41, tracing the carbon content of plastics serves as a useful proxy to track recirculation. Plastics feedstocks, products and wastes could be understood as mass vectors for carbon in all its oxidation states, including the most reduced in methane (CH4) and hydrocarbons, the rich structures of oxygenated bio-based raw materials and polymers, and its oxides, carbon monoxide (CO) and carbon dioxide (CO2). Some in the biogeochemical community already apply related carbon-accounting frameworks in tracing the distribution and impact of plastics in the biosphere41,52,53.

As well as understanding where and how carbon in plastics accumulates on Earth, tracking carbon is useful to monitor and improve sustainability and circularity measures; for instance, towards reducing GHG emissions, preventing environmental pollution and limiting further carbon-feedstock depletion. We propose a circular carbon and plastics life cycle that considers current, future, natural and technological pathways by which carbon raw materials are produced from feedstocks, transformed into carbon-storing assets in the form of monomers and polymers, stocked while plastics remain in use and recycled into new plastics or feedstocks (Fig. 1). Crucially, a hierarchy of recycling pathways for plastic waste is needed to organize and optimize the carbon recirculation in the system. The framework gives priority to recycling routes that preserve material integrity, value and chemical structure, and that minimize energy and material losses. This is consistent with the well-known waste-management hierarchy, which is a common principle of waste management law and policy and which generally assigns priority to waste-management options in the following order: prevention, reuse, recycling, recovery and, finally, disposal (see also Supplementary information section 4.5)54.

In the current system, which features linear flows of production and disposal (black pathway), demand for plastics is satisfied by consuming fossil resources, while the lack of perceived economic value in plastic waste leads to unsustainable rates of landfilling, incineration or, worse, environmental leakage. In this future system (grey box), a recirculation pathway hierarchy helps to maximize material recycling and carbon recirculation by prioritizing (1) reuse of products, (2) physical recycling and (3) (bio)chemical recycling (including depolymerization to monomer, pyrolysis and gasification) over (4) biodegradation and (5) energy recovery (last resort and only with carbon capture). The recycling streams replace the need for more virgin raw materials for the plastics industry (polymers, monomers or unprocessed feedstock) and avoid extraction of petrochemicals. Any remaining production of virgin polymers uses carbon from captured CO2 or indirectly from (waste) biomass. The carbon-recirculation system must be powered using only renewable energy. Acronyms refer to common polymer classes, for example: PET, poly(ethylene terephthalate); PHAs, poly(hydroxy alkanoates); PLA, poly(lactic acid); PUR, poly(urethane); TPS, thermoplastic starch.

In this circularity-oriented life cycle, plastics are used for their intended application, providing economic value through function and sustainable performance55. Once their required service life is fulfilled, which can vary from days to decades, and all options for material reuse are exhausted, retrievable wastes are collected, sorted and managed using the most appropriate recycling routes31,56,57,58,59,60 (physical, chemical or biological; see Box 1 and Fig. 1). Such selective material recirculation enables the carbon embedded in plastics to efficiently flow ‘upwards’ from waste to resources, thereby regenerating feedstocks and preventing waste accumulation, leakage and consequent pollution. Plastic wastes that cannot be either physically or (bio)chemically recycled must follow a biological degradation route in specialized facilities, including industrial composting or anaerobic digestion, which allows for the capture of the released CO2 emissions61. Only intractable or contaminated waste mixtures should be considered for energy recovery by means of incineration as a last resort, owing to the energy inefficiency of such processes and the need to capture all CO2 emissions.

In this system, all plastics are made from recycled C1 molecules, lignocellulosic biomass (second generation), waste biomass and captured CO2 (refs. 62,63,64,65). This avoids use of fossil carbon for plastic production and energy generation. C1 molecules such as CO, CO2, methanol (CH3OH) and CH4 are key building blocks that connect the downstream and upstream cycles. This future system cannot operate using only biomass as the feedstock, but carbon capture and utilization (CCU) technologies are also essential66. Estimates to reach climate targets situate the efforts to scale current carbon-removal capacity, including CCU, by a factor of 1,300 by 2050, an increase of 4.8 GtCO2 per year from 2020 values67. Captured CO2 must be catalytically transformed into chemical intermediates, for example, syngas, alkenes, naphtha, aromatics, carbonates and alcohols68,69,70. In nature, CO2 is captured and converted into biochemicals by photosynthesis. Plant metabolic pathways can be exploited, or even enhanced, to eventually produce more complex monomers, including those from lignin, carbohydrates, triglycerides and terpenes71,72. These combined synthetic and natural CO2 use pathways must offset all GHG emissions from plastic production, manufacturing, recycling and any eventual biodegradation in order for the system to reach net zero: a very tough challenge.

Evaluating carbon emissions and other metrics

Addressing the impacts and biosphere burdens of the materials, processes and energy requirements for this future circular plastics economy requires careful life-cycle assessments accompanied by notable technological breakthroughs in the coming decades. GHG emissions are essential metrics to evaluate the effect on climate change, but there will be other negative environmental trade-offs that require careful consideration and minimization. A useful metric for comparing impacts is the global planetary boundary framework73,74,75. This defines boundary limits for human activities and sets a safe operating space against nine Earth-system processes, including biosphere integrity through (in)direct land-use change, balanced nitrogen/phosphorus cycles and atmospheric aerosol loading10.

It is essential to work together to articulate clear and commonly understood international sustainability criteria76 and accelerate research, including to efficiently use and transform biomass feedstocks that avoid habitat loss, overconsumption of freshwater and fertilizers, and limits other adverse environmental impacts. Providing solutions will not be easy, but priority fields for research include methods to transform organic wastes and agricultural by-products to polymers77 or application of crops that grow rapidly in marginal lands or increase the soil organic carbon content78. By comparison, the direct use of CO2 to make monomers and polymers does not usually result in burdens on arable lands and habitats, which are great concerns in any increased-biomass-consumption model1,10. Nonetheless, CCU in polymer production may increase demand for renewable energy and green hydrogen, particularly if reduced molecules such as methanol or syngas are the primary feedstocks10. Increased renewable energy production has planetary footprints, including increases to atmospheric aerosol loading and impacts on P-cycles. Hence, the implementation of larger-scale CCU technologies and biomass uptake must be carefully balanced10. Notably, plastic recirculation by physical and (bio)chemical recycling replaces the need for extracting virgin renewable resources, avoiding notable burden shifting and, therefore, represents a promising approach to reducing GHG emissions without other negative consequences10.

Several excellent global studies have modelled and quantified the carbon footprint of the plastics life cycle, helping to visualize the consequences of implementing particular mitigation strategies. Notably, recent investigations led by Suh42, Bardow50 and Stegmann51 all show that isolated solutions cannot fix the plastics problem; it is only the interplay of four interlinked targets that effectively reduces GHG emissions towards net zero. Using these published models and datasets, we propose four different 2050 scenarios for the plastics economy, at a time when the market is expected to grow to 1.1 Gt plastic per year (Fig. 2): (1) baseline, (2) business-as-usual, (3) conservative commitments and (4) bold system change. For each scenario, estimates of the consequences for GHG emissions and recirculated carbon content are provided, capturing the possible impacts and outcomes, rather than any kind of absolute forecast. The scenarios apply the four mitigation strategies: reducing plastic consumption, increasing recycling rates, replacing fossil carbon with renewable alternatives and powering manufacturing and recycling processes with renewable electricity (Supplementary information section 1)42,50,79. It should be noted that, in these scenarios, there were many data gaps and, therefore, estimates had to be made, particularly given the diversity in global waste infrastructure (where it exists) and recycling options. Another challenge associated with estimating the effects of increased use of renewable plastics is the earlier market stage of such materials, which affects manufacturing-process efficiency with knock-on consequences for GHG emissions. In the four scenarios, the current data for the top five bio-based plastics was applied, but we acknowledge that, in the future, their properties need to be improved and that their current life-cycle GHG emissions should serve as an upper bound to drive innovation. The current scenarios do not attempt to quantify or compare other negative environmental impacts, but it is worth emphasizing the critical importance of continuing with such assessments42,80.

a, Baseline scenario (all plastic waste is discarded through a combination of landfilling and incineration). b, Business-as-usual scenario (projected growth from current levels in recycling, up to 43%, and incineration, up to 50%). c, Conservative commitments scenario (only partially deploying key interventions: 25% demand reduction, 50% substitution of fossil-based plastic and intermediate deployment of renewable energies). d, Bold system change (cut plastic demand in half, full-scale introduction of bio-based plastics and recycling technologies up to 95%, plus complete decarbonization of the energy system). In the left column, the dashed frames highlight the projected size of manufacturing and EoL in the 2050 baseline scenario. MMT, million metric tonnes.

The baseline scenario involves all plastics being both fully fossil derived and disposed of in landfill or by incineration. Because no carbon is recirculated, future demand must be satisfied by manufacturing more virgin plastics from crude oil or gas. These upstream processes result in an estimate of 4.0 GtCO2, that is, roughly 90% of all life-cycle emissions. By comparison, the business-as-usual scenario linearly tracks the range of EoL options relevant today to 2050, with rates of incineration and recycling reaching up to 50% and 43%, respectively40. The climate cost of maintaining a business-as-usual scenario is massive: the carbon footprint remains >2.5-fold higher than the level of today and surpasses 4.0 GtCO2 a year, not far from the projected baseline. This scenario reveals a key message: augmenting recycling of plastics waste alone (approximately 40% of recirculated carbon) is simply not enough to tackle the emissions crisis.

Breaking from the status quo is very challenging in complex global economies and requires coordinated action and investment. The conservative commitments scenario, which results in global GHG emissions of about 2.2 Gt per year and only moderate carbon recycling, illustrates the negative effects of such global barriers on life-cycle emissions (Fig. 2c and Supplementary information). For instance, slow changes in consumption behaviour and reorganization of power relationships could hamper a swift cut in the growth of plastics demand. The large-scale infrastructure investment needed to close the collection gap that exists in many parts of the world (about 60% of the planet either lacks or has an inadequate waste infrastructure) represents a substantial challenge to establishing a functional recycling industry. Moreover, the slow growth of recycling technologies that can preserve material quality, a difficulty in current mechanical recycling81, could perpetuate material loss. Feedstock markets, regional availability and costs to build/retrofit manufacturing and recycling infrastructure present further obstacles to a global scale-up of renewably sourced plastics production, prolonging reliance on fossil-carbon resources. Equally, the seasonal and regional intermittency of some renewable energy, its incorporation to mature energy grids and the overall system costs and complexity could slow down the deployment of decarbonized electricity82,83. Mitigation of the remaining GHG emissions from both petrochemical refining and power requires carbon capture and storage. Although the costs for such technologies remain unclear, a value of US$100 per tCO2 is the relevant order of magnitude66; compensating for the residual emissions in this scenario could add more than US$200 billion to the costs of the plastic system and would do nothing to address any other negative environmental consequences.

The bold-system-change scenario has the potential to sufficiently reduce the CO2 emissions, but it requires some very substantial changes to current practices (Fig. 2d). First, future plastic demand must be cut by 50% from expected levels, mandating the decoupling of future economic growth from plastic consumption. Second, recycling must become the dominant managed EoL option, so that it can extract the maximum material and economic value from wastes, enabling recirculated carbon to deliver 86% of new plastics demand. Third, any remaining virgin raw materials must derive from renewable resources, including biomass and CCU, which fully replace petrochemicals. Finally, the energy must be entirely renewable to access the lowest CO2 emissions. Only this scenario has the potential to reduce global emissions to about 0.2 GtCO2 in 2050 and could reach net zero if the remaining emissions were subject to carbon capture and removal technologies. Achieving such a scenario must simultaneously address any possible risks, for instance, through the adoption of global and national measures to prevent regrettable substitutions and the recirculation of hazardous chemicals.

Delivering a bold system change

At Stockholm+50 (June 2022), which took stock of the human environment, states called for a “system-wide change in the way our current economic system works to contribute to a healthy planet”84. This reflects the fact that a bold system change requires a fundamental rethinking of current economic structures and laws. The different stages of the plastics life cycle are interconnected, subject to multifaceted and complex cross-border trade flows85. A coordinated approach is therefore needed to avoid the risk of new legal and economic measures inadvertently creating new (trade) barriers, disproportionally affecting certain groups in society or disincentivizing innovation86. The following sections highlight some of the interventions required, although noting that they will require continual evaluation to guide and scale a future circular carbon and plastics economy, and acknowledging the challenges in tracking progress towards targets. The plastics life cycle is only partly regulated by international law35,36,37,38 and states across the world have adopted specific national measures in relation to the plastics sector (Supplementary information section 4.6)87. In this section, examples from the EU are provided as a useful knowledge base, as it has been actively pursuing a more circular (plastics) economy since 2015 (refs. 47,48,49) and aims for a climate-neutral continent by 2050 (refs. 88,89). This does not, however, imply that these examples are universally pertinent or may be easily implemented across all economies. Interventions for system change, particularly in the Global South, face challenges related to rapid growth and urbanization, insufficient municipal solid waste collection and management, large quantities of high-income-country waste imports, substantial data gaps impeding development of effective policy aligning social and financial incentives and scarce data on the large and important informal sector of waste management5,90,91.

Sustainable plastics through smart design

The future plastics economy should be centred on sustainable consumption and production practices, another important UN Sustainable Development Goal (SDG12)92. The transition from our current complex and interconnected economy must be upheld by principles of sufficiency rather than superfluous consumerism, while still meeting socio-ecological needs93,94.

Plastics design and manufacturing choices require a process we term ‘smart design’. Guiding this process are four questions that help focus attention across the product life cycle. What is the origin of the raw materials? What is the intended product application? What EoL option is most appropriate to recirculate the material and carbon? And what are the environmental and health impacts throughout the product life cycle? To help answer these questions, a series of smart design principles can be formulated (Box 2). These should help to guide appropriate use of resources and production methods, deliver sufficient performances, ensure sound waste management and help to minimize broader environmental impacts.

Because plastics comprise numerous different chemistries and are used across several application sectors, two other aspects of the product life cycle warrant further attention and discussion: their service lifespan and recoverability95,96. Service lifespan defines how long plastics within products remain in (re)use and varies enormously from short-lived packaging (about half a year, on average) to long-lived construction materials (approximately 35 years, on average)97. Recoverability describes the potential for plastics to be recirculated, either by reuse or recycling. It is affected by material technical characteristics, for example, composition, separation methods, product disassembly processes and polymer recyclability, as well as by the environmental impacts of any sorting, separation and treatment options. It is also influenced by economic factors, for example, waste infrastructure management, recycling business models, cost–benefits, asset devaluation and legal constraints that determine recoverability, as discussed below. To help in the (re)design process, a taxonomy for all plastic products is proposed on the basis of these distinctions and is exemplified here using some specific materials and applications (Fig. 3a).

a, Taxonomy for plastic products based on their inherent service lifespan and recoverability, with sector examples in each quadrant. b, Estimated GHG emissions for the business-as-usual and bold-system-change scenarios for four illustrative application sectors. c, Corresponding GHG savings attained by applying smart design principles in a system change.

Plastic products with long lifespans and a high (potential) recoverability must be recycled in future. This includes those materials used in construction, textile or transport sectors at present in which polymers are widely used but recycling levels are rather low. Conversely, plastics used in short-lived applications and with low recoverability show inherently linear life cycles, and so will need to be eliminated, substituted or redesigned to improve recoverability; for instance, by redesigning multilayer packaging. In applications in which recoverability is impossible and environmental dissipation is a consequence of the application, polymers must be completely biodegradable, so that carbon recirculation occurs through natural carbon cycles. These applications include plastics in agriculture (mulch films), as well as fast-moving consumer goods (personal or home-care formulations).

Figure 3b,c illustrates the potential reductions in carbon emissions, achievable by 2050, if such smart design decisions were implemented in four exemplar application sectors: recoverable packaging, complex packaging, construction and agriculture. These examples represent different quadrants in the proposed plastics taxonomy. In the bold-system-change scenario, implementation of smart design principles could help to greatly reduce GHG emissions (70–90%) compared with the business-as-usual scenario. In each sector, different interventions will be necessary to curtail emissions, examples of which include demand reduction for short-lived plastics, increased recycling of recoverable plastics and ensuring complete biodegradability for irretrievable plastics (see Supplementary information section 2). To implement smart design across all sectors, technical advances must be guided by future sustainability criteria98,99 and supported by a robust legal framework and economic incentives, as discussed next for each of the four key targets identified for a bold system change.

Reduce plastics demand

Restrictions on the production and consumption of unnecessary plastics incentivize smart design for application and thereby help to reduce overall plastic demand. These may take the form of national bans on single-use items, with early examples including the prohibition on certain plastic bags in Meghalaya (India)100, South Africa101, Eritrea102 and Bangladesh103, and—more recently—the EU Single-Use Plastics (SUP) Directive104. It has also been suggested that the new international plastics treaty could, among other things, target both the phasing out/reduction of primary plastics, of problematic and avoidable plastic products and of chemicals and polymers of concern105. This raises further questions about the most appropriate criteria for definition and the need to clearly distinguish between substances and products. An international phasing out of substances of concern in relation to plastics could draw inspiration from existing international restrictions of persistent organic pollutants106 or of ozone-depleting substances107. Furthermore, measures to reduce plastic demand could stipulate or prohibit plastic content, such as the US prohibition of microbeads in cosmetics108, the new EU ban on intentionally added microplastics109 or the ban on oxo-degradable plastics in the EU104. In the packaging sector alone, the elimination of unnecessary plastics combined with innovative product and packaging design is estimated to reduce by about 38% packaging demand in Europe by 2050 (ref. 110). A tax or fee on plastic products to reflect their social and environmental costs would also help to reduce demand by increasing the price of plastic per user. A tax on plastic products may have the added benefit of generating revenue to subsidize recycling and/or composting infrastructure, helping to make recycled materials more competitive111. Such so-called hypothecated tax revenues do not typically appeal to finance ministries, but experience suggests that they make environmental taxes more politically palatable112, provided inequitable distributive consequences are avoided or compensated for with an appropriate policy mix86.

Switch to renewably sourced plastics

So far, global climate targets are driving aspirational policy objectives for sustainable carbon cycles. However, any efforts to introduce renewable feedstocks must also carefully consider and minimize the other environmental trade-offs, as mentioned previously. This is not an easy task, as increasing use of biomass and CO2 use might result in transfer of ecological burdens from climate change to other Earth-system processes1,10. On the other hand, the petrochemicals industry also has other negative environmental effects, including particulate pollution, ecosystem threat and release of volatile organic compounds, as well as sulfur-containing and nitrogen-containing contaminant gasses.

Given the pressing need to reduce GHG emissions, the target to scale up future renewable-feedstock technologies must be guided by careful environmental-sustainability analyses. Economic and legal measures also help to drive this change, for example, in the EU, at least 20% of the carbon used in chemical and plastic products should be from renewable sources by 2030 (ref. 113). Realizing these objectives requires investment in both the infrastructure and markets for such products. States can facilitate the transition through implementing targets, for example, the Dutch Transition Agenda for Plastics plans to increase the percentage of recyclate and bio-based plastics to 41% and 15%, by 2030, respectively114; the USA has a bold goal to, in 20 years, “demonstrate and deploy cost-effective and sustainable routes to convert bio-based feedstocks into recyclable-by-design polymers that can displace more than 90% of today’s plastics”115,116; and the EU proposes to mandate the use of compostable packaging for certain applications117. States can also facilitate these objectives indirectly through exemptions, for example, the exemption for certain degradable and soluble polymers from the restriction on intentionally added microplastics under EU chemicals law109. States can further create demand for bio-based goods by implementing green public procurement criteria when exercising large-scale purchasing power in contracts for goods, services and infrastructure development118. In the EU, public authorities spend approximately €2 trillion each year on public contracts, equivalent to roughly 14% of its gross domestic product (ref. 119). Such spending power serves as an effective tool for directing markets in a sustainable direction.

Scaling renewable plastics requires cost-competitiveness, a current key barrier. States can provide financial subsidies to allow manufacturers to sell such plastics at lower cost, driving production at scale. Global growth of renewably sourced plastics could rapidly increase from about 4% to 10–20% if their adoption was subsidized and politically supported, similarly to contracts for difference used to grow low-carbon (emissions) energy120. Public–private partnerships that bring together the expertise and resources of several stakeholders can accelerate innovation and advance cost reduction for nascent bio-based industries. Further developing such partnerships is therefore flagged as critical for achieving the US biotechnology and biomanufacturing goals, including through databases, joint funding opportunity projects116 and user facilities such as the Advanced Biofuels and Bioproducts Process Development Unit (ABPDU), a scale-up facility that has already helped companies raise more than US$2 billion in private funding and transition 17 products to market. Similarly, the Circular Bio-based Europe Joint Undertaking (CBE JU) is a €2 billion public–private partnership that finances projects advancing competitive circular bio-based industries. Conversely, phasing out fossil-fuel subsidies could help to bridge the cost gap between fossil and renewably sourced plastics121,122,123. Pressure to phase out inefficient fossil-fuel subsidies will probably intensify in line with SDG12 (ref. 92) and the Glasgow Climate Pact124, and the initiatives of some countries already signal a change in this direction125. Further, a fossil-carbon-free system requires changing the investment from petrochemical plants to technologies for biomass and CCU to chemicals. This could be stimulated by including CCU in emissions-trading schemes, such as under the recently amended EU Emissions Trading System (EU ETS), which already supported innovation in CCU and other low-carbon technologies through its Innovation Fund, and where emissions allowances now no longer have to be surrendered for GHG that are captured and used where they become permanently chemically bonded in a wproduct (that is, obviating atmospheric contamination under normal use), including any normal activity occurring after the product EoL126. At present, however, the petrochemical industry continues to invest in new fossil-carbon plants, which risks petrochemical lock-in127,128.

Building and maintaining demand for renewably sourced plastics also relies on effective and accurate communication to downstream users. In the EU, for example, there is at present no systematic certification scheme or label for such products, although voluntary standards have been developed129. This gap should be addressed through clear international standards (for example, through the International Organization for Standardization) and definitions (for example, through the new plastics treaty), including for terms such as bio-based, renewable carbon, biodegradable and compostable plastics, so as to harmonize domestic measures.

Maximize recycling

Current technologies at scale for mechanical recycling are unlikely to be able to solely meet future needs for plastic waste recycling, as they are hampered by material degradation, losses and incompatibilities with mixed-waste streams, multilayers, additives and thermosets. Hence, notable technical improvements, infrastructure upgrades and worldwide expansion of matured technologies, in coordination with better waste management, are necessary. Moreover, to maximize efficient recycling, we need clear definitions, as has been discussed in the context of revising international technical guidelines on the environmentally sound management of plastic wastes under the Basel Convention (Supplementary information section 4.3)130,131. Defining what falls within/outside the definition of plastics recycling has important legal implications, both for international waste-management obligations23 and for states to meet recycling targets, such as the EU target to recycle 55% of plastic packaging waste by 2030 (ref. 132).

A variety of specific tools exist to promote recycling. These include the growing practice of extended producer responsibility (EPR) schemes specific to plastics, for example, packaging, or products containing them in, for instance, electronics or vehicles. EPR makes producers responsible physically or financially for their plastic products at EoL inclusive of collection and sorting. Many EPR schemes require fees, pricing-in environmental costs and charging producers more when selecting non-recyclable or harmful plastics. Shifting responsibilities and costs for the EoL of plastics is also intended to stimulate design change. EPR has been increasingly discussed as a means of implementing the polluter-pays principle, including within the context of the new plastics treaty133. By the end of 2024, for example, EU member states must ensure that EPR schemes are established for all packaging132. Although some producers resist, more than 100 large-scale plastic-packaging businesses support the expansion of EPR globally, pointing out the benefits for effective and economic recycling134. More than 400 EPR instruments exist around the world, some mandatory through law and some not, with varying success in inducing design changes owing to challenges such as a lack of individual rather than joint producer responsibility, free-riding and implementation gaps135,136, although criteria for a successful EPR have been developed in international forums137,138,139. Producers also increasingly make voluntary commitments through the global network of Plastics Pacts. In the UK, pact participants agreed four targets by 2025, including 70% plastic packaging effectively recycled or composted, helping to drive demand for recycling facilities, and a target of increasing to 30% the average recycled content in plastic packaging, pushing demand for recycled feedstocks140.

Other tools to increase recycling include fiscal incentives such as tax credits to promote research and development of plastics-recycling technology. In Colorado (USA), for example, a plastic recycling investment tax credit is available for expenditures made towards new plastics-recycling technology in the state141. Implementing deposit-return schemes to incentivize consumer behaviour change may be effective in enhancing consumer recycling rates and generating fewer emissions than direct recycling subsidies142. Innovative business-to-business solutions, such as digital trading platforms for recycled plastics, are showing potential to increase recycling in formal and informal economies (see Supplementary information). In developing economies, building waste-management facilities will also require supportive regulatory environments and investment to scale infrastructure projects143. Internationally, coordinating the investment for scaling recycling infrastructure with that of waste-collection systems is a continual challenge5,144.

Finally, promoting the uptake of recycled plastics as a feedstock will require coherency between different areas of law, in particular, waste, products and chemicals law (see Supplementary information section 4.7)145. In the EU, key regulatory obstacles to a circular economy have already been identified, such as different rules on how waste becomes a new material; legacy substances hampering the uptake of recycled materials; a lack of information about complex waste streams; and substances being differently classified as hazardous or not falling under products and waste law146. Greater regulatory alignment between these sectors, and across countries, will be vital to generate confidence in the quality of recycled (plastic) materials. Similarly, policy coordination including subsidies for recycling and removal of fossil-fuel subsidies (see previous section titled ‘Switch to renewably sourced plastics’) are critical for the cost competitiveness of recycling against current virgin fossil-based production.

Minimize broader environmental impacts

Eliminating pollutants will require continuous attention, as the plastics sector changes over time. Greater transparency is therefore key, from the content of waste streams to avoiding legacy pollution to identification of all additives used during manufacturing147,148. Legal measures for greater transparency include the active discussion on making certain polymers subject to registration and evaluation under EU chemicals law (REACH), as is the case in some other jurisdictions149. A comprehensive and transparent global knowledge base on the composition of plastics would benefit downstream users and allow regulators to assess and manage risks, similar to clearing-house mechanisms established in other areas150,151. Other measures could include making market access for products that contain plastics conditional on documenting environmental information (product passports)152. To be most effective, such measures should apply across the board and not only to specific products or categories.

Further, a circular plastics economy requires careful management and evaluation of its flows to eliminate pollution, involving all stakeholders. Consumer education is key, which calls for clear marking specifications about appropriate waste management and the consequences of littering, such as foreseen under the EU SUP Directive104.

A roadmap towards sustainable plastics

To inspire a shift towards a more circular carbon plastics economy and to stimulate discussion on how to achieve this, we propose an ambitious timescale for economic and legal measures, from the present until 2050 (Fig. 4 and see Supplementary information section 5 for further details). Although the roadmap proposes, sequences and tentatively suggests time periods for when their effects on the system may be felt on the basis of leading policy and academic literature, these interventions should be considered both cumulative and continuous over time. For example, a collaborative global approach to solving plastics pollution is already continuing in several multilateral forums; this includes the prospect of adopting the aforementioned plastics treaty. Moreover, some measures (for example, improving waste-management infrastructure) will be more readily achieved in economies with existing foundations for such changes, and others (for example, EPR or deposit-return schemes) may not be equally effective in all parts of the world nor across all economic sectors. As also acknowledged in the UNEA resolution for a new plastics treaty, a wide range of approaches exist to address the full life cycle of plastics, which further highlights the need for enhanced international collaboration to facilitate access to technology, capacity building and scientific and technical cooperation33. Successful system change will require global collaboration, investment and social and technical capacity building.

Timeline of interventions to prevent the projected GHG emissions of a business-as-usual pathway and their potential to curb the carbon footprint of the future plastics economy. The interventions all support the four interlinked targets to reach the life-cycle emissions of the bold-system-change scenario outlined in Fig. 2. Further scaling efforts for carbon removal to attain net zero are also shown.

Realizing the bold system change is demanding and requires integrated technical, legal and economic interventions, from the modernization of current laws to consistent implementation of economic measures across different markets and jurisdictions, and ensuring that responsibility for plastics is shared by both upstream and downstream stakeholders. Further, these technical, legal and economic frameworks must be adaptable and responsive to future breakthroughs, where possible avoiding sector lock-ins. Although the transition facing the plastics sector is very important for the chemicals industry, it is accompanied by a marked restructuring of the global energy system, which is already set to achieve 98% of the increase in global energy demand using renewables by 2025 (ref. 153). The challenge is substantial but our perspective is that re-engineering the plastics economy is achievable. Ongoing international dialogue and coordinated legal and economic actions are therefore essential to deliver change in time, and the international plastics treaty being negotiated at present has a vital role to play in empowering these efforts at a global scale.

References

Global Plastics Outlook: Economic Drivers, Environmental Impacts and Policy Options (OECD, 2022).

Schneiderman, D. K. & Hillmyer, M. A. 50th anniversary perspective: there is a great future in sustainable polymers. Macromolecules 50, 3733–3749 (2017).

Ostle, C. et al. The rise in ocean plastics evidenced from a 60-year time series. Nat. Commun. 10, 1622 (2019).

Borrelle, S. B. et al. Predicted growth in plastic waste exceeds efforts to mitigate plastic pollution. Science 369, 1515–1518 (2020).

Lau, W. W. Y. et al. Evaluating scenarios toward zero plastic pollution. Science 369, 1455–1461 (2020).

Brahney, J., Hallerud, M., Heim, E., Hahnenberger, M. & Sukumaran, S. Plastic rain in protected areas of the United States. Science 368, 1257–1260 (2020).

MacLeod, M., Arp, H. P. H., Tekman, M. B. & Jahnke, A. The global threat from plastic pollution. Science 373, 61–65 (2021).

Santos, R. G., Machovsky-Capuska, G. E. & Andrades, R. Plastic ingestion as an evolutionary trap: toward a holistic understanding. Science 373, 56–60 (2021).

Tamargo, A. et al. PET microplastics affect human gut microbiota communities during simulated gastrointestinal digestion, first evidence of plausible polymer biodegradation during human digestion. Sci. Rep. 12, 528 (2022).

Bachmann, M. et al. Towards circular plastics within planetary boundaries. Nat. Sustain. 6, 599–610 (2023). Evaluation of various pathways for a circular plastics economy in view of nine planetary boundaries beyond GHG emissions.

Carus, M., Dammer, L., Raschka, A. & Skoczinski, P. Renewable carbon: key to a sustainable and future‐oriented chemical and plastic industry: definition, strategy, measures and potential. Greenh. Gases Sci. Technol. 10, 488–505 (2020).

Pires da Mata Costa, L. et al. Capture and reuse of carbon dioxide (CO2) for a plastics circular economy: a review. Processes 9, 759 (2021).

Bauer, F. et al. Plastics and climate change—breaking carbon lock-ins through three mitigation pathways. One Earth 5, 361–376 (2022). Potential risks and consequences of carbon lock-in at each stage of the plastics life cycle and their relationship with innovations and policy to change the plastic system.

Spierling, S. et al. Bio-based plastics – a review of environmental, social and economic impact assessments. J. Clean. Prod. 185, 476–491 (2018).

Cywar, R. M., Rorrer, N. A., Hoyt, C. B., Beckham, G. T. & Chen, E. Y. X. Bio-based polymers with performance-advantaged properties. Nat. Rev. Mater. 7, 83–103 (2021).

Rosenboom, J.-G., Langer, R. & Traverso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 7, 117–137 (2022). Prospects of integrating bio-based plastics in a future circular economy, with a critical look at all the stages of the life cycle, as well as the current state of their market and policy implementation worldwide.

Law, K. L. & Narayan, R. Reducing environmental plastic pollution by designing polymer materials for managed end-of-life. Nat. Rev. Mater. 7, 104–116 (2021).

Jehanno, C. et al. Critical advances and future opportunities in upcycling commodity polymers. Nature 603, 803–814 (2022).

Mangold, H. & von Vacano, B. The frontier of plastics recycling: rethinking waste as a resource for high‐value applications. Macromol. Chem. Phys. 223, 2100488 (2022).

Jambeck, J. R. et al. Plastic waste inputs from land into the ocean. Science 347, 768–771 (2015).

Brooks, A. L., Wang, S. & Jambeck, J. R. The Chinese import ban and its impact on global plastic waste trade. Sci. Adv. 4, eaat0131 (2018).

Wang, C., Zhao, L., Lim, M. K., Chen, W.-Q. & Sutherland, J. W. Structure of the global plastic waste trade network and the impact of China’s import ban. Resour. Conserv. Recycl. 153, 104591 (2020).

van der Marel, E. R. Trading plastic waste in a global economy: soundly regulated by the Basel Convention? J. Environ. Law 34, 477–497 (2022).

Lebreton, L. C. M. et al. River plastic emissions to the world’s oceans. Nat. Commun. 8, 15611 (2017).

Horejs, C. Solutions to plastic pollution. Nat. Rev. Mater. 5, 641–641 (2020).

Rochman, C. M. et al. Classify plastic waste as hazardous. Nature 494, 169–171 (2013).

Jung, Y. S. et al. Characterization and regulation of microplastic pollution for protecting planetary and human health. Environ. Pollut. 315, 120442 (2022).

Fortman, D. J. et al. Approaches to sustainable and continually recyclable cross-linked polymers. ACS Sustain. Chem. Eng. 6, 11145–11159 (2018).

Coates, G. W. & Getzler, Y. D. Y. L. Chemical recycling to monomer for an ideal, circular polymer economy. Nat. Rev. Mater. 5, 501–516 (2020). Advances in chemical depolymerization to monomers from polymers to revalorize plastic waste.

Vollmer, I. et al. Beyond mechanical recycling: giving new life to plastic waste. Angew. Chem. Int. Ed. 59, 15402–15423 (2020).

Ellis, L. D. et al. Chemical and biological catalysis for plastics recycling and upcycling. Nat. Catal. 4, 539–556 (2021). Challenges and opportunities for catalysis development in chemical and biological recycling.

World Trade Organization (WTO), Committee on Trade and Environment. WTO Informal Dialogue on Plastics Pollution and Environmentally Sustainable Plastics Trade. WT/CTE/W/250/Rev.2 (WTO, 2021).

United Nations Environment Assembly (UNEA) of the United Nations Environment Programme. End Plastic Pollution: Towards an International Legally Binding Instrument. UNEP/PP/OEWG/1/INF/1 (UNEA, 2022).

Stöfen-O’Brien, A. The prospects of an international treaty on plastic pollution. Int. J. Mar. Coast. Law 37, 727–740 (2022).

Simon, N. et al. A binding global agreement to address the life cycle of plastics. Science 373, 43–47 (2021).

Kirk, E. A. & Popattanachai, N. Marine plastics: fragmentation, effectiveness and legitimacy in international lawmaking. Rev. Eur. Comp. Int. Environ. Law 27, 222–233 (2018).

Raubenheimer, K., McIlgorm, A. & Oral, N. Towards an improved international framework to govern the life cycle of plastics. Rev. Eur. Comp. Int. Environ. Law 27, 210–221 (2018).

United Nations Environment Assembly (UNEA) of the United Nations Environment Programme. Combating Marine Plastic Litter and Microplastics: An Assessment of the Effectiveness of Relevant International, Regional and Subregional Governance Strategies and Approaches. UNEP/EA.3/INF/5 (UNEA, 2018).

Landrigan, P. J. et al. The Minderoo-Monaco Commission on Plastics and Human Health. Ann. Glob. Health 89, 23 (2023).

Geyer, R. in Plastic Waste and Recycling: Environmental Impact, Societal Issues, Prevention, and Solutions (ed. Letcher, T. M.) 13–32 (Academic, 2020).

Stubbins, A., Law, K. L., Muñoz, S. E., Bianchi, T. S. & Zhu, L. Plastics in the Earth system. Science 373, 51–55 (2021).

Zheng, J. & Suh, S. Strategies to reduce the global carbon footprint of plastics. Nat. Clim. Change 9, 374–378 (2019). The effect of implementing decarbonized energy, reduced demand, high recycling and bio-based plastics in reducing the carbon footprint of plastics.

Friedlingstein, P. et al. Global Carbon Budget 2022. Earth Syst. Sci. Data 14, 4811–4900 (2022).

Breaking the Plastic Wave: A Comprehensive Assessment of Pathways Towards Stopping Ocean Plastic Pollution (The Pew Charitable Trusts and SYSTEMIQ, 2020).

The New Plastics Economy: Rethinking the Future of Plastics (Ellen MacArthur Foundation, 2016).

The New Plastics Economy: Catalysing Action (Ellen MacArthur Foundation, 2017).

Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: A New Circular Economy Action Plan for a Cleaner and More Competitive Europe COM(2020) 98 final (European Commission, 2020).

Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: Closing the Loop – An EU Action Plan for the Circular Economy COM(2015) 614 final (European Commission, 2015).

Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: A European Strategy for Plastics in a Circular Economy COM(2018) 28 final (European Commission, 2018).

Meys, R. et al. Achieving net-zero greenhouse gas emission plastics by a circular carbon economy. Science 374, 71–76 (2021). Life-cycle assessments of circular pathways for the plastics sector, focused on recycling, biomass and CCU, and aimed towards carbon-footprint reductions.

Stegmann, P., Daioglou, V., Londo, M., van Vuuren, D. P. & Junginger, M. Plastic futures and their CO2 emissions. Nature 612, 272–276 (2022). Cumulative projections of plastic production and emissions towards 2100 and the effects of implementing circular mitigation strategies.

Bank, M. S. & Hansson, S. V. The plastic cycle: a novel and holistic paradigm for the Anthropocene. Environ. Sci. Technol. 53, 7177–7179 (2019).

Zhu, X. The plastic cycle – an unknown branch of the carbon cycle. Front. Mar. Sci. 7, 1227 (2021).

Global Waste Management Outlook (UNEP, 2015).

Zimmerman, J. B., Anastas, P. T., Erythropel, H. C. & Leitner, W. Designing for a green chemistry future. Science 367, 397–400 (2020).

Sinha, V., Patel, M. R. & Patel, J. V. Pet waste management by chemical recycling: a review. J. Polym. Environ. 18, 8–25 (2008).

Lopez, G., Artetxe, M., Amutio, M., Bilbao, J. & Olazar, M. Thermochemical routes for the valorization of waste polyolefinic plastics to produce fuels and chemicals. A review. Renew. Sustain. Energy Rev. 73, 346–368 (2017).

Rahimi, A. & García, J. M. Chemical recycling of waste plastics for new materials production. Nat. Rev. Chem. 1, 0046 (2017).

Lopez, G. et al. Recent advances in the gasification of waste plastics. A critical overview. Renew. Sustain. Energy Rev. 82, 576–596 (2018).

Schyns, Z. O. G. & Shaver, M. P. Mechanical recycling of packaging plastics: a review. Macromol. Rapid Commun. 42, 2000415 (2021).

Ghosh, K. & Jones, B. H. Roadmap to biodegradable plastics—current state and research needs. ACS Sustain. Chem. Eng. 9, 6170–6187 (2021). Analysis of current biodegradable plastics and description of future focus areas for development.

Zhang, X., Fevre, M., Jones, G. O. & Waymouth, R. M. Catalysis as an enabling science for sustainable polymers. Chem. Rev. 118, 839–885 (2017).

Sun, Z., Fridrich, B., de Santi, A., Elangovan, S. & Barta, K. Bright side of lignin depolymerization: toward new platform chemicals. Chem. Rev. 118, 614–678 (2018). Review on the catalytic processes to obtain chemicals and monomers from lignin.

Grignard, B., Gennen, S., Jérôme, C., Kleij, A. W. & Detrembleur, C. Advances in the use of CO2 as a renewable feedstock for the synthesis of polymers. Chem. Soc. Rev. 48, 4466–4514 (2019). Catalytic pathways for the chemical conversion of CO2 into polymers.

O’Dea, R. M., Willie, J. A. & Epps, T. H. 100th anniversary of macromolecular science viewpoint: polymers from lignocellulosic biomass. Current challenges and future opportunities. ACS Macro Lett. 9, 476–493 (2020).

Hepburn, C. et al. The technological and economic prospects for CO2 utilization and removal. Nature 575, 87–97 (2019).

Smith, S. M. et al. The State of Carbon Dioxide Removal 1st edn (The State of Carbon Dioxide Removal, 2023).

Centi, G., Quadrelli, E. A. & Perathoner, S. Catalysis for CO2 conversion: a key technology for rapid introduction of renewable energy in the value chain of chemical industries. Energy Environ. Sci. 6, 1711–1731 (2013).

Sternberg, A., Jens, C. M. & Bardow, A. Life cycle assessment of CO2-based C1-chemicals. Green Chem. 19, 2244–2259 (2017).

Zhong, J. et al. State of the art and perspectives in heterogeneous catalysis of CO2 hydrogenation to methanol. Chem. Soc. Rev. 49, 1385–1413 (2020).

Kaiser, S. & Bringezu, S. Use of carbon dioxide as raw material to close the carbon cycle for the German chemical and polymer industries. J. Clean. Prod. 271, 122775 (2020).

Schirmeister, C. G. & Mülhaupt, R. Closing the carbon loop in the circular plastics economy. Macromol. Rapid Commun. 43, 2200247 (2022).

Steffen, W. et al. Planetary boundaries: guiding human development on a changing planet. Science 347, 1259855 (2015).

Tulus, V., Pérez-Ramírez, J. & Guillén-Gosálbez, G. Planetary metrics for the absolute environmental sustainability assessment of chemicals. Green Chem. 23, 9881–9893 (2021).

Rockström, J. et al. Safe and just Earth system boundaries. Nature 619, 102–111 (2023).

Raubenheimer, K. & Urho, N. Possible elements of a new global agreement to prevent plastic pollution. Nordic Council of Ministers https://www.nordicreport2020.com/ (2020).

Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: EU Policy Framework on Biobased, Biodegradable and Compostable Plastics COM(2022) 682 final (European Commission, 2022).

Brizga, J., Hubacek, K. & Feng, K. The unintended side effects of bioplastics: carbon, land, and water footprints. One Earth 3, 45–53 (2020).

Nicholson, S. R., Rorrer, N. A., Carpenter, A. C. & Beckham, G. T. Manufacturing energy and greenhouse gas emissions associated with plastics consumption. Joule 5, 673–686 (2021).

Miller, S. A. Five misperceptions surrounding the environmental impacts of single-use plastic. Environ. Sci. Technol. 54, 14143–14151 (2020).

Ragaert, K., Delva, L. & Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manage. 69, 24–58 (2017).

Stram, B. N. Key challenges to expanding renewable energy. Energy Policy 96, 728–734 (2016).

Posen, I. D., Jaramillo, P., Landis, A. E. & Griffin, W. M. Greenhouse gas mitigation for U.S. plastics production: energy first, feedstocks later. Environ. Res. Lett. 12, 034024 (2017).

Stockholm+50: A Healthy Planet for the Prosperity of All–Our Responsibility, Our Opportunity A/CONF.238/9 (United Nations, 2022).

Barrowclough, D., Birkbeck, C. D. & Christen, J. Global trade in plastics: insights from the first life-cycle trade database. UNCTAD Research Paper No. 53, UNCTAD/SER.RP/2020/12 (United Nations Conference on Trade and Development, 2020).

Chiroleu-Assouline, M. & Fodha, M. From regressive pollution taxes to progressive environmental tax reforms. Eur. Econ. Rev. 69, 126–142 (2014).

Kirk, E., Popattanachai, N., van der Marel, E. R. & Barnes, R. Research Handbook on Plastics Regulation: Law, Policy and the Environment (Edward Elgar, 2024).

Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions: The European Green Deal COM(2019) 640 final (European Commission, 2019).

The European Parliament and the Council of the European Union. Regulation (EU) 2021/1119 of the European Parliament and of the Council of 30 June 2021 establishing the framework for achieving climate neutrality and amending Regulations (EC) No 401/2009 and (EU) 2018/1999 (‘European Climate Law’) (European Commission, 2021).

Ayeleru, O. O. et al. Challenges of plastic waste generation and management in sub-Saharan Africa: a review. Waste Manage. 110, 24–42 (2020).

Velis, C. A. Circular economy and global secondary material supply chains. Waste Manag. Res. 33, 389–391 (2015).

Transforming Our World: The 2030 Agenda for Sustainable Development A/RES/70/1 (UNGA, 2015).

Bocken, N. M. P. & Short, S. W. in Handbook of the Circular Economy 250–265 (Edward Elgar, 2020).

Mederake, L. Without a debate on sufficiency, a circular plastics economy will remain an illusion. Circ. Econ. Sustain. 3, 1425–1439 (2023).

Murakami, S., Oguchi, M., Tasaki, T., Daigo, I. & Hashimoto, S. Lifespan of commodities, part I. The creation of a database and its review. J. Ind. Ecol. 14, 598–612 (2010).

Leal, J. M., Pompidou, S., Charbuillet, C. & Perry, N. Product recoverability: a review of assessment methods. Procedia CIRP 69, 710–715 (2018).

Geyer, R., Jambec, J. R. & Law, K. L. Production, use, and fate of all plastics ever made. Sci. Adv 3, e1700782 (2017).

Fagnani, D. E. et al. 100th anniversary of macromolecular science viewpoint: redefining sustainable polymers. ACS Macro Lett. 10, 41–53 (2020).

Haque, F. M. et al. Defining the macromolecules of tomorrow through synergistic sustainable polymer research. Chem. Rev. 122, 6322–6373 (2022).

The Gazette of Meghalaya. The Meghalaya Prohibition of Manufacture, Sale, Use and Throwing of Low Density Plastic Bags Act, 2001 (Act No. 4 of 2001) (Meghalaya Legislative Assembly, 2001).

Regulation Gazette. Regulation 543 under Section 24 (d) of the Environmental Conservation Act (Act No. 73 of 1989). No. 7348 Vol. 443 (South Africa Department of Environmental Affairs and Tourism, 2002).

Gazette of Eritrean Laws: Proclamations and Legal Notices. Regulations to Prohibit the Production, Sale or Distribution of Plastic Bags in Eritrea (Legal Notice No. 63/2002). Vol. 11/2002 No. 7 (The Government of Eritrea, 2002).

Bangladesh Gazette. The Bangladesh Environment Conservation Act, 1995 Act No. 1 of 1995, Sec. 6a, as amended by Sec. 5 of Act 9 of 2002 (The Government of Bangladesh, 2002).

The European Parliament and the Council of the European Union. Directive (EU) 2019/904 of the European Parliament and of the Council of 5 June 2019 on the reduction of the impact of certain plastic products on the environment. L155/1 (European Commission, 2019).

United Nations Environment Programme (UNEP). Potential options for elements towards an international legally binding instrument, based on a comprehensive approach that addresses the full life cycle of plastics as called for by United Nations Environment Assembly resolution 5/14. UNEP/PP/INC.2/4 (UNEP, 2023).

United Nations. Stockholm Convention on Persistent Organic Pollutants. Treaty Series, Vol. 2256, p. 119 (United Nations, 2001).

United Nations. Montreal Protocol on Substances that Deplete the Ozone Layer. Treaty Series, Vol. 1522, p. 3 (United Nations, 1987).

United States Congress. Microbead-Free Waters Act of 2015. Public Law 114–114 (U.S. Congress, 2015).

The European Parliament and the Council of the European Union. Commission Regulation (EU) 2023/2055 of 25 September 2023 amending Annex XVII to Regulation (EC) No 1907/2006 of the European Parliament and of the Council concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) as regards synthetic polymer microparticle. L238/67 (European Commission, 2023).

ReShaping Plastics: Pathways to a Circular, Climate Neutral Plastics System in Europe (SYSTEMIQ, 2022).

Desalegn, G. & Tangl, A. Banning vs taxing, reviewing the potential opportunities and challenges of plastic products. Sustainability 14, 7189 (2022).

Klenert, D. et al. Making carbon pricing work for citizens. Nat. Clim. Change 8, 669–677 (2018).

European Commission. Communication from the Commission to the European Parliament and the Council: Sustainable Carbon Cycles. COM(2021) 800 (European Commission, 2021).

Bergsma, G., Broeren, M., Schep, E. & Warringa, G. Mandatory percentage of recycled or bio-based plastic in the European Union (CE Delft, 2022).

The White House. Executive Order 14081: Advancing Biotechnology and Biomanufacturing Innovation for a Sustainable, Safe, and Secure American Bioeconomy (The White House, 2022).

The White House Office of Science and Technology Policy. Bold Goals for U.S. Biotechnology and Biomanufacturing. Harnessing Research and Development to Further Societal Goals (The White House, 2023).

European Commission. Art. 8 of the Proposal for a Regulation of the European Parliament and of the Council on packaging and packaging waste, amending Regulation (EU) 2019/1020 and Directive (EU) 2019/904, and repealing Directive 94/62/EC, 30 November 2022 (European Commission, 2022).

Watkins, E., Schweitzer, J.-P., Leinala, E. & Börkey, P. Policy approaches to incentivise sustainable plastic design. OECD Environment Working Papers 149. OECD Publishing https://doi.org/10.1787/233ac351-en (2019). Contextualized examples of policies designed to enhance the prospects of a sustainable plastic economy.

European Commission. Public procurement. https://single-market-economy.ec.europa.eu/single-market/public-procurement_en (European Commission, 2023).

Department for Business, Energy and Industrial Strategy, United Kingdom. Evaluation of the Contracts for Difference Scheme. Phase 1: Allocation Rounds 1 & 2. Final Report (Department for Business, Energy and Industrial Strategy, 2019).

Skovgaard, J. & van Asselt, H. The politics of fossil fuel subsidies and their reform: Implications for climate change mitigation. Wiley Interdiscip. Rev. Clim. Change 10, e581 (2019).

Döhler, N., Wellenreuther, C. & Wolf, A. Market Dynamics of Biodegradable Bio-based Plastics: Projections and Linkages to European Policies (Hamburg Institute of International Economics, 2020).

Barrowclough, D. & Birkbeck, C. Transforming the global plastics economy: the role of economic policies in the global governance of plastic pollution. Soc. Sci. 11, 26 (2022).

United Nations Framework Convention on Climate Change. Decision 1/CMA.3 Glasgow Climate Pact. Report of the Conference of the Parties serving as the meeting of the Parties to the Paris Agreement on its third session, held in Glasgow from 31 October to 13 November 2021. FCCC/PA/CMA/2021/10/Add.1 (United Nations, 2021).

World Trade Organization. Ministerial Statement on Fossil Fuel Subsidies. WT/MIN(21)/9/Rev.2 (World Trade Organization, 2022).

The European Parliament and the Council of the European Union. Directive (EU) 2023/959 of the European Parliament and of the Council of 10 May 2023 amending Directive 2003/87/EC establishing a system for greenhouse gas emission allowance trading within the Union and Decision (EU) 2015/1814 concerning the establishment and operation of a market stability reserve for the Union greenhouse gas emission trading system. L130/134 (European Commission, 2023).

The Future of Petrochemicals: Towards More Sustainable Plastics and Fertilisers (IEA, 2018). A highlight of the petrochemical sector becoming the largest driver of global oil demand and its continuous investments in the production of fossil-fuel-based plastics.

Bauer, F. & Fontenit, G. Plastic dinosaurs – digging deep into the accelerating carbon lock-in of plastics. Energy Policy 156, 112418 (2021).

European Committee for Standardization (CEN). CEN/TC 411 - Bio-based products. https://standards.cencenelec.eu/dyn/www/f?p=CEN:6 (CEN, 2021).

United Nations. Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and their Disposal. Treaty Series, Vol. 1673, p. 57 (United Nations, 1989).

United Nations Environment Programme (UNEP). Technical guidelines on the environmentally sound management of plastic wastes. UNEP/CHW.16/6/Add.3/Rev.1 (UNEP, 2023).

The European Parliament and the Council of the European Union. Directive (EU) 2018/852 of 30 May 2018 amending Directive 94/62/EC on packaging and packaging waste. L150/141 (European Commission, 2018).

Raubenheimer, K. & Urho, N. Rethinking global governance of plastics – the role of industry. Mar. Policy 113, 103802 (2020).

Extended Producer Responsibility: A Necessary Part of the Solution to Packaging Waste and Pollution (Ellen MacArthur Foundation, 2021).

Dalhammar, C. in Elgar Encyclopedia of Environmental Law Ch. VI.16 (ed. Faure, M.) (2018).

Sachs, N. Planning the funeral at the birth: extended producer responsibility in the European Union and the United States. Harv. Envtl. L. Rev. 30, 51 (2006).

Extended Producer Responsibility (OECD, 2016).

United Nations Environment Programme (UNEP). Revised Draft Practical manual on Extended Producer Responsibility. UNEP/CHW.14/5/Add.1 (UNEP, 2019).

United Nations Environment Programme (UNEP). Report of the Conference of the Parties to the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal on the work of its fourteenth meeting. UNEP/CHW.14/28 (UNEP, 2019).

WRAP and the UK Plastics Pact. A Roadmap to 2025: The UK Plastics Pact https://wrap.org.uk/resources/guide/roadmap-2025-uk-plastics-pact (WRAP, 2022).

Colorado Department of Revenue. Plastic recycling investment tax credit. https://tax.colorado.gov/sites/tax/files/Income56.pdf (1989).

Larrain, M., Billen, P. & Van Passel, S. The effect of plastic packaging recycling policy interventions as a complement to extended producer responsibility schemes: a partial equilibrium model. Waste Manage. 153, 355–366 (2022).

Gao, W., Hundertmark, T., Pais, G., Ryba, A., & Wallach, J. Addressing the challenges of plastic waste: circularity and leakage. McKinsey https://www.mckinsey.com/industries/chemicals/our-insights/addressing-the-challenges-of-plastic-waste-circularity-and-leakage#/ (2022).

Gall, M., Wiener, M., Chagas de Oliveira, C., Lang, R. W. & Hansen, E. G. Building a circular plastics economy with informal waste pickers: recyclate quality, business model, and societal impacts. Resour. Conserv. Recycl. 156, 104685 (2020).

Alaranta, J. & Turunen, T. How to reach a safe circular economy?—Perspectives on reconciling the waste, product and chemicals regulation. J. Environ. Law 33, 113–136 (2021).

European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions on the implementation of the circular economy package: options to address the interface between chemical, product and waste legislation. COM(2018) 32 final. (European Commission, 2018).

Schwarz, A. E., Lensen, S. M. C., Langeveld, E., Parker, L. A. & Urbanus, J. H. Plastics in the global environment assessed through material flow analysis, degradation and environmental transportation. Sci. Total Environ. 875, 162644 (2023).

Hahladakis, J. N., Velis, C. A., Weber, R., Iacovidou, E. & Purnell, P. An overview of chemical additives present in plastics: migration, release, fate and environmental impact during their use, disposal and recycling. J. Hazard. Mater. 344, 179–199 (2018).

European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. Chemicals Strategy for Sustainability Towards a Toxic-Free Environment. COM(2020) 667 final (European Commission, 2020).

United Nations. Cartagena Protocol on Biosafety to the Convention on Biological Diversity. Treaty Series, Vol. 2226, p. 208 (United Nations, 2000).

Basel Convention, Rotterdam Convention, and Stockholm Convention. Joint clearing house mechanism for information exchange: revised draft strategy. UNEP/CHW.13/1-UNEP/FAO/RC/COP.8/1-UNEP/POPS/COP.8/1 (Basel Convention, Rotterdam Convention, and Stockholm Convention, 2017).

European Commission. Proposal for an EU Regulation on Ecodesign for Sustainable Products. COM(2022)142 final (European Commission, 2022).

CO2 Emissions in 2022 https://www.iea.org/reports/co2-emissions-in-2022 (IEA, 2023).

Acknowledgements

The Oxford Martin School (‘Future of Plastics’, C.K.W., all authors), European Union Horizon 2020 research and innovation programme (Marie Skłodowska-Curie no. 101018516) (F.V.), EPSRC (EP/S018603/1; EP/R027129/1; EP/V038117/1) (C.K.W.) and Research England (iCAST, RED, RE-P-2020-04) (C.K.W.) are acknowledged for funding.

Author information

Authors and Affiliations

Contributions

C.K.W., C.H. and C.R. conceived the idea for the paper. F.V., E.R.v.d.M., R.W.F.K., C. McElroy and N.S. conducted the research and led the writing of the manuscript, with further contributions from all the other authors. All authors approved submission of the article for publication.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature thanks Anna Schwarz and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

This Supplementary Information file contains the following five sections: (1) Supporting Materials for Modelled Scenarios of the Plastic Industry in 2050; (2) GHG Emissions Calculations and Assumptions; (3) Supplementary Information of Economic Challenges in Section 3; (4) Supplementary Information of Legal Concepts in Section 3; and (5) Supporting Materials for Scenario Roadmaps. It includes one Supplementary Figure, 22 Supplementary Tables and Supplementary References.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vidal, F., van der Marel, E.R., Kerr, R.W.F. et al. Designing a circular carbon and plastics economy for a sustainable future. Nature 626, 45–57 (2024). https://doi.org/10.1038/s41586-023-06939-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-023-06939-z

- Springer Nature Limited

This article is cited by

-

Adverse health effects of exposure to plastic, microplastics and their additives: environmental, legal and policy implications for Israel

Israel Journal of Health Policy Research (2024)

-

Plastic recycling: A panacea or environmental pollution problem

npj Materials Sustainability (2024)

-

Oxidative degradation and upcycling of polyethylene wastes

Science China Chemistry (2024)