Abstract

Cardoon plants are cultivated mostly for the added value of their flowers, used in the cheese industry as a coagulant, but the stalks, branches and leaves are a by-product with no added value. In the present work, totally biosourced particleboards were produced using cardoon particles, bound with an adhesive based on a cardoon leaf extract and citric acid. For that, the highly polyphenolic extract was obtained from the underutilized leaves of the plant. Extraction was performed with water in alkali conditions. The extract was combined with citric acid as crosslinking agent. The effects of the content of cardoon leaf extract and citric acid (0–50% on weight, dry basis) and the pressing temperature were evaluated by Automatic Bonding Evaluation System (ABES). The chemical curing reaction of cardoon leaf extract alone and with citric acid was evaluated by FTIR-ATR. The best formulations were used to produce the bio-adhesive and the cardoon-based particleboards.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nowadays, the search for alternative lignocellulosic forestry or food industry by-products that may be an alternative to timber wood in the production of particleboards is increasing (Santos et al. 2021). The use of fast-growing crops with low carbon footprint is the most promising route to reduce the environmental impact of the growing demand for wood-based products.

On the other hand, the use of particleboards as an alternative to plastics in food packaging is also an emerging topic. For that purpose, the industry demands materials that are recyclable, nontoxic, low density, and, if possible, with antifungal properties. Cardoon (Cynara cardunculus L.) is native to the Mediterranean basin and belongs to Asteraceae Dumortier family. In Portugal, cardoon plants are cultivated mostly for the value of the flowers, used in the cheese industry (Barracosa et al. 2019). The stalks, branches, and leaves are a by-product with no added value. The aqueous extracts from its flowers have been used for centuries as coagulant, due to high content of aspartic proteases and high milk-clotting activity (Monteiro et al. 2020).

Recent works show that cardoon particles can be combined with starch-based binder for producing low-density particleboards appropriate for interior furniture (Monteiro et al. 2020).

Beyond the potential of cardoon stalks as raw materials in the particleboard industry, the antibacterial activity of cultivated cardoon leaf extracts towards different Gram-positive and negative bacterial species of agriculture has also been demonstrated, showing a potential interest to be incorporated in the food packaging design (Scavo et al. 2019).

Citric acid is one of the most common food additives in the world. It is used to boost acidity, enhance flavour, and preserve ingredients. Some studies have shown that citric acid is a good crosslinking agent, in the formulation of bio-based adhesives mainly with carbohydrates such as starch (Huang et al. 2020) or sucrose (Umemura et al. 2012), or in combination with tannins (Zhongyuan et al. 2016).

In the formulation of bio-adhesives, the use of raw materials without nutritional value is always an important advantage, due to the increase in global demand for food. The use of extracts of high polyphenolic content, with citric acid as a hardener, could be a good route to produce low toxicity adhesives with applicability in the design of food packaging solutions.

The possibility of obtaining an extract from a lignocellulosic by-product in the same industrial process will be an added advantage.

The aim of this work was the valorisation of a lignocellulosic by-product from the cheese industry, cardoon, in the development of a new material with applicability in food packaging. Cardoon stalks were used as the main raw material, in the form of particles and the cardoon leaf extracts as a binder, permitting to formulate a new bio-adhesive.

Materials and Methods

Raw Material

Cardoon stalks and leaves were supplied by Casa da Ínsua (Viseu, Portugal). Both by-products were air-dried till equilibrium moisture content, ground in a in a cutting mill (Retsch, Haan Germany), sieved by a vibratory sieve shaker (Retsch, Haan Germany), and the fraction of particle size between 1 and 4 mm was selected. Later, the materials were oven-dried at 60 °C until equilibrium moisture content.

Extraction

The cardoon leaves’ (CL) extraction process was performed by alkali extraction in a 2 L glass reactor, with water solid/liquid ratio that was fixed at 1/10 (w/w), and 1% of Na2SO3 and 1% NaOH respect dry material were used as extraction agents, and the selected temperature was 95 °C. The material and water were mixed at room temperature and heated, and, once the selected temperature was attained, the alkali was added, and contact time begun to run. After 30 min, the suspension was vacuum filtered; the solid residue was washed with water until a nearly colourless filtrate was obtained. The obtained extract was concentrated in a rotary evaporator (BÜCHI, Flawil, Switzerland).

The extraction yield is calculated by measuring the difference between the initial dry material weight and the ends waste dry material weight (Eq. 1):

Fourier Transform Infrared Spectroscopy (FTIR) Assay

FTIR spectra were recorded on a VERTEX 70 FTIR spectrometer (BRUKER, Billerica, MA, USA) in transmittance mode and equipped with a high sensitivity DLaTGS detector at room temperature.

Samples were measured in ATR mode, with an A225/Q PLATINUM ATR diamond crystal with a single reflection accessory. The spectra were recorded from 4000 to 400 cm−1 with a resolution of 4 cm−1. All spectra were recorded and processed with OPUS 7.0 software.

Automated Bonding Evaluation System (ABES) Assay

An ABES instrument (Adhesive Evaluation Systems, Corvallis, Oregon, USA) was used to evaluate the maximum shear strength of the wood-adhesive-wood system at defined temperature and time conditions (Costa et al. 2014).

Wood veneer samples (Fagus sylvatica L., thickness 0.7 mm) were stored in a conditioned chamber for 1 week at 20 °C and 53% relative humidity before testing. Probes were cut into 117 mm × 20 mm strips using a pneumatically driven sample cutting device for ABES sample preparation (supplied by Adhesive Evaluation Systems, Corvallis, Oregon, USA).

Two peeled wood veneer strips were glued along the fibre direction with a 100 mm2 overlap using 20 μg of adhesive. Analyses were conducted at 120 and 160 °C over 30, 60, 90, 120, 150, and 180 s time frames. Measurements were repeated five times for each data point.

Adhesive Preparation

Adhesives studied were prepared as follows:

The EXCL previously concentrated using a rotatory evaporator, with (35.0 ± 0.5) % of solid content, was mixed with the different percentages of citric acid by mechanical stirring for 5 min. Table 1 shows the ratio of EXCL and citric acid studied.

After citric acid addition to EXCL, the solid content of all the adhesives was adjusted to 35.0 ± 0.5 by adding distilled water.

Particleboard Manufacture and Testing

Particleboards were produced with the selected dried cardoon stalk particles (1–4 mm).

All particleboards were blended with the bio-adhesive based on the cardoon leaf extract (EXCL) and citric acid (10% mass of resin solids/mass of dry wood), in a laboratory glue blender.

One layer 210 mm × 210 mm × 15 and 8 mm particleboards were pressed at a specific pressure of 4 MPa and 160 °C press temperature for 20 min.

The glued mat was pressed to produce a board with a target density between 550 and 600 kg m−3.

Particleboards were evaluated by physical and mechanical tests according to European standards: density (EN 323: 1993), moisture content (EN 322: 1993), internal bond strength (EN 319: 1993), and bending strength (EN 310: 1993). Board classification was done according to (EN 312: 2010).

Results and Discussion

The extraction yield obtained for the cardoon leaves was 28.3 ± 0.4%, which is consistent with other lignocellulosic materials like chestnut shell (Santos et al. 2017), using similar extraction conditions.

For the evaluation of the extraction process, FTIR-ATR analysis of the cardoon leaves and the cardoon leaf extract, both dried at 50 °C till equilibrium moisture contents were done, and the spectra are showed in Fig. 1.

The main differences between the CL and EXCL spectra were in the band at 1054 cm−1 due to the C–O–C aromatic ethers and symmetric stretch (pyranose ring) vibration; the band at 1105 cm−1 due to the C–O–C stretching (cellulose and hemicellulose) vibration; the band at 1060 cm−1 that involves C-O stretching vibrations of C–OH/C–O–C (cellulose); the band at 1320 cm−1 of the C–O–C aromatic ethers and asymmetric stretching vibrations; the band at 1370 cm−1 due to CH deformation vibration (cellulose and hemicellulose); and the band at 1423 cm−1 due to C = C and C-H bond O–H in plane deformation (lignin and hemicellulose) (Hospodarova et al. 2018; Vázquez et al. 2008). These bands present in the CL spectrum disappeared or were greatly reduced in the spectrum of the EXCL extract.

The EXCL spectrum showed the typical polyphenol bands at 1600–1500 (1557) cm−1 and around 1400 (1403) cm−1, due to the C = C stretching vibrations of the phenolic aromatic ring and the bending C-H vibrations of the CH2 groups (Escobar-Avello et al. 2021); these bands increased in intensity in relation to the spectra of the original CL, showing the selectivity of the extraction process to obtain the polyphenol soluble fraction.

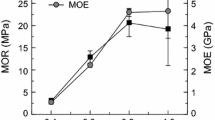

The curing of an adhesive can be evaluated in terms of the shear strength of wood-adhesive joints, using an ABES equipment. This method quantifies how fast the bond strength develops under controlled hot-pressing conditions. The effects of pressing time (30–180 s) and temperature (120–160 °C) on the mechanical cure were analysed (Fig. 2).

The EXCL extract was used as adhesive alone, in the form of aqueous solutions (self-condensation reaction) and mixed with different percentages of citric acid (20–33-43–50%) by mechanical stirring. The effect of citric acid content and press temperature (120–160 °C) on adhesive performance was evaluated by ABES, which permitted to determine the maximum shear strength of the wood-adhesive-wood system at defined temperature and time conditions. The methodology used was the same described in previous works (Santos et al. 2018).

The results showed that at 120 °C, the performance of the adhesive due to the EXCL and the citric acid reaction was maintained up to 43% (on adhesive solid weight, dry basis) of citric acid, but when the percentage of citric acid increased to 50%, the performance of the adhesive decreased.

However, when the test temperature was increased to 160 °C, this effect was sufficient to activate the reaction between citric acid and EXCL, and the addition of citric acid improves the adhesive behaviour in all the values tested.

Based on the results obtained, the use of more than 33% (on adhesive weight, dry basis) of citric acid did not imply an improvement in the adhesive properties under the pressing conditions studied.

FTIR-ATR technique was also used to evaluate the chemical reactivity of the EXCL extract, for which the extract solution (30%) alone and with 33% citric acid were reacted at 120 °C for 300 s. The objective was to evaluate the chemical reactivity of the extract, alone (self-condensation), and with the citric acid. Figure 3 shows the FTIR-ATR spectra for the extract cured alone and with citric acid.

The spectra in Fig. 3 show the interaction between the citric acid and the polyphenols present in the EXCL extract curing reaction. The most relevant changes appear in the band at 1742 cm−1 which is related to axial stretching of carbonyl groups (C = O) in carboxylic acid groups.

This band shifts to 1711 cm−1 in the spectrum of the mixture of EXCL extract and citric acid, showing the formation of methylene ester bonds. Also, it can be observed the presence of the band at 1216 cm−1, indicating the stretching vibration of the C-O bond of -O-(C = O)-. In addition, the band at 1118 cm−1 corresponds to stretches of C-O bonds (Teixeira et al. 2020).

To evaluate the potential of the combination of cardoon stalks with the bio-adhesive based on EXCL extract and citric acid, particleboards were made based only on cardoon by-products.

Table 2 shows the influence of the citric acid percentage used in the bio-adhesives formulation on the particleboard properties.

For the internal bond strength values of the cardoon-based particleboards, the results were in agreement with the essays performed by ABES (Fig. 2).

The bending strength was not determined for the particleboard with 15 mm of thickness since it was not possible to comply the test methods described in EN 310. For this board thickness, the specimen length should be 350 mm, and our panels were produced with 210 × 210 × 15 mm.

The average values of bending strength for the particleboards prepared in this study are presented in Table 2. A slight increase in bending strength was observed with the increase of the citric acid used in the formulation. However, the difference in density might explain these results, since in the bending test; the faces density has a great impact. Although these results do not comply with the requirements of EN 312 for general purpose boards for use in dry conditions (Type P1), it is important to notice that the particleboards were produced with homogeneous density, in comparison with standard particleboards that are generally produced with three layers, being the face layers more dense than the core layer. Nevertheless, the bending strength values of the particleboards prepared from cardoon stalks, using the bio-adhesive based on EXCL and citric acid, were similar to those obtained by other authors for particleboards produced using insect rearing residue and rice husks with starch/citric acid mixture as a natural binder (Huang et al. 2020) and for particleboards made from rice husks using soy protein-derived bio-binder (Chalapud et al. 2020).

The increase in the percentage of citric acid added above 50% of the EXCL mass did not produce a considerable variation in the properties of the particleboard. This work shows that it is possible to produce a new biomaterial from an underused by-product, such as cardoon leaves and stalks, using only citric acid as a crosslinking agent (Fig. 4).

These results have potential applicability in the development of new low or no toxicity products with a very low environmental impact, for use in food packaging.

Conclusion

Citric acid demonstrated to be a good crosslinking agent to be used combined with cardoon leaf extract in the bio-adhesive formulation. The viability of cardoon leaf extract, to be used as bio-adhesive, was demonstrated. The possibility of the use of the same agricultural or forestry industry by-product as raw material and as a component of the bio-adhesive is a very interesting route to produce sustainable packaging products without using any toxic or high environmental impact petroleum-based product. The low toxicity of particleboard components (raw material and binders) will make it a very easy material to reuse, recycle or compost.

This work shows that it is technically feasible the valorisation of a food industry by-product, like are the cardoon stalks and leaves and could be the starting point for the future development of new food-packaging products with low environmental impact.

Data availability

All data generated or analysed during this study are included in this published article.

References

Barracosa P, Barracosa M, Pires E (2019) Cardoon as a sustainable crop for biomass and bioactive compounds production. Chem Biodivers. https://doi.org/10.1002/cbdv.201900498

Chalapud MC, Herdt M, Nicolao ES, Ruseckaite RA, Ciannamea EM, Stefani PM (2020) Biobased particleboards based on rice husk and soy proteins: effect of the impregnation with tung oil on the physical and mechanical behavior. Constr Build Mater 230:116996. https://doi.org/10.1016/j.conbuildmat.2019.116996

Costa NA, Pereira J, Ferra J, Cruz P, Martins J, Magalhães FD, Mendes A, Carvalho LH (2014) Evaluation of bonding performance of amino polymers using ABES. J Adhes 90(1):80–88. https://doi.org/10.1080/00218464.2013.784693

Escobar-Avello D, Avendaño-Godoy J, Santos J, Lozano-Castellón J, Mardones C, von Baer D, Luengo J, Lamuela-Raventós RM, Vallverdú-Queralt A, Gómez-Gaete C (2021) Encapsulation of phenolic compounds from a grape cane pilot-plant extract in hydroxypropyl beta-cyclodextrin and maltodextrin by spray drying. Antioxidants 10(7):1130. https://doi.org/10.3390/antiox10071130

Hospodarova V, Singovszka E, Stevulova N (2018) Characterization of cellulosic fibers by FTIR spectroscopy for their further implementation to building materials. Am J Anal Chem 09(06):303–310. https://doi.org/10.4236/ajac.2018.96023

Huang HK, Hsu CH, Hsu PK, Cho YM, Chou TH, Cheng YS (2020) Preparation and evaluation of particleboard from insect rearing residue and rice husks using starch/citric acid mixture as a natural binder. Biomass Convers Biorefinery.https://doi.org/10.1007/s13399-020-00994-6

Monteiro S, Nunes L, Martins J, Magalhães FD, Carvalho L (2020) Low-density cardoon (Cynara cardunculus L.) particleboards bound with potato starch-based adhesive. Polymers 12(8):1799. https://doi.org/10.3390/polym12081799

Santos J, Antorrena G, Freire MS, Pizzi A, González-Álvarez J (2017) Environmentally friendly wood adhesives based on chestnut (Castanea sativa) shell tannins. Eur J Wood Wood Prod 75(1):89–100. https://doi.org/10.1007/s00107-016-1054-x

Santos J, Delgado N, Fuentes J, Fuentealba C, Vega-Lara J, García DE (2018) Exterior grade plywood adhesives based on pine bark polyphenols and hexamine. Ind Crop Prod 122. https://doi.org/10.1016/j.indcrop.2018.05.082

Santos J, Pereira J, Ferreira N, Paiva N, Ferra J, Magalhães FD, Martins JM, Dulyanska Y, Carvalho LH (2021) Valorisation of non-timber by-products from maritime pine (PinusPinaster, Ait) for particleboard production. Ind Crop Prod. https://doi.org/10.1016/j.indcrop.2021.113581

Scavo A, Pandino G, Restuccia C, Parafati L, Cirvilleri G, Mauromicale G (2019) Antimicrobial activity of cultivated cardoon (Cynara cardunculus L. Var. Altilis DC.) leaf extracts against bacterial species of agricultural and food interest. Ind Crop Prod 129:206–211. https://doi.org/10.1016/j.indcrop.2018.12.005

Teixeira DE, Pereira DC, Nakamura APD, Brum SS (2020) Adhesivity of bio-based anhydrous citric acid, tannin-citric acid and ricinoleic acid in the properties of formaldehyde-free medium density particleboard (Mdp). Drvna Industrija. https://doi.org/10.5552/drvind.2020.1917

Umemura K, Ueda T, Munawar SS, Kawai S (2012) Application of citric acid as natural adhesive for wood. J Appl Polym Sci. https://doi.org/10.1002/app.34708

Vázquez G, Fontenla E, Santos J, Freire MS, González-Álvarez J, Antorrena G (2008) Antioxidant activity and phenolic content of chestnut (Castanea sativa) shell and eucalyptus (Eucalyptus globulus) bark extracts. Ind Crop Prod 28(3):279–285. https://doi.org/10.1016/j.indcrop.2008.03.003

Zhongyuan Z, Umemura K, Kanayama K (2016) Effects of the addition of citric acid on tannin-sucrose adhesive and physical properties of the particleboard. BioResources. https://doi.org/10.15376/biores.11.1.1319-1333

Acknowledgements

The authors wish to thank EuroResinas – Indústrias Químicas and project INNOSURF under PT2020 for the support with data, equipment, and materials. We would also like to show our gratitude to Dr. Paulo Barracosa, for his assistance in the conceptual design of this work.

Funding

This work was financially supported by the following: Base Funding, UIDB/00511/2020 of the Laboratory for Process Engineering, Environment, Biotechnology and Energy (LEPABE), funded by national funds through the FCT/MCTES (PIDDAC), and Project INNOSURF (SI I&DT, projects in co-promotion, POCI-01–0247-FEDER-33768) in the scope of Portugal 2020, co-funded by FEDER (Fundo Europeu de Desenvolvimento Regional) under the framework of POCI (Programa Operacional Competitividade e Internacionalização).

Author information

Authors and Affiliations

Contributions

J. Santos: Term; Conceptualization; Methodology; Investigation; Writing, original draft preparation; Reviewing and editing. J. Pereira: Investigation, Validation. J. Ferra: Resources, Reviewing and editing, Funding acquisition. F. D. Magalhães: Resources, Reviewing and editing, Supervision, Funding acquisition. J. M. Martins: Resources, Reviewing and editing, Conceptualization, Supervision, Funding acquisition. L. H. Carvalho: Resources, Reviewing and editing, Conceptualization, Supervision, Funding acquisition.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of the Topical Collection on Natural Fibers: Materials of the Future

Rights and permissions

About this article

Cite this article

Santos, J., Pereira, J., Ferra, J. et al. New Cardoon (Cynara cardunculus L.) Particleboards Using Cardoon Leaf Extract and Citric Acid as Bio-adhesive. Mater Circ Econ 3, 14 (2021). https://doi.org/10.1007/s42824-021-00027-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42824-021-00027-1