Abstract

This study is aimed to cost-effectively produce bacterial cellulose (BC) and impart it with antimicrobial activity by introducing bactericidal plant extracts into its three-dimensional matrix through an ex situ modification strategy. Briefly, the fruit wastes were utilized as the carbon source for BC production by Gluconacetobacter hansenii, followed by impregnation of bioactive extracts of Anogeissus dhofarica and Withania somnifera plants. FE-SEM and FTIR analyses showed the successful synthesis of BC-Anogeissus dhofarica (BC-A) and BC-Withania somnifera (BC-W) composites. Both BC-A and BC-W composites held 87% and 75% water of their dry weight, respectively, and each composite retained about 50% of originally absorbed water after 24 h. The bactericidal activities of BC-A and BC-W composites were investigated against Staphylococcus aureus and Escherichia coli as model Gram-positive and Gram-negative pathogens, respectively. Both BC-A and BC-W composites showed impressive antibacterial activity against S. aureus by producing a clear inhibition zone of 13 mm and 6 mm, respectively. Although no clear inhibition zone was observed against E. coli, both composites reduced its growth up to 50% of its live cell density. This is the first report of exploring the antibacterial activities of A. dhofarica and W. somnifera plant extracts and developing their composites with BC, which could be of vital importance for natural products and biopolymer researchers to develop biomedical materials.

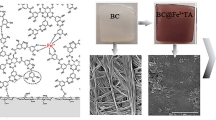

Graphical abstract

ToC. Low-cost production and ex situ impregnation of bioactive plant-extract into bacterial cellulose matrix showing antibacterial activity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Bacterial cellulose (BC), a biopolymer produced by acetic acid–producing bacteria and cell-free enzyme systems [1, 2], has received tremendous attention in the last two decades owing to its impressive physical, mechanical, and biological features. Its chemical structure is identical to plant cellulose; however, its properties such as purity, crystallinity, fibrous structure, liquid-absorbing capabilities, biocompatibility, surface chemistry, and mouldability are superior than the plant cellulose [3]. BC is produced in the form of hydrogels, membrane, pellicles, and granules through different synthesis approaches by utilizing different carbon sources such as the chemically defined media [4, 5]. However, the high price of the chemically defined medium, accounting for 30% of the total cost, leads to a high production cost of BC, which limits the commercialization of BC-based products. Therefore, extensive efforts have been devoted to the exploration of low-cost substrates such as different agro-industrial and fruit wastes as carbon sources [4, 6, 7]. Based on its effective features, BC receives applications in medical [8,9,10], textile [11, 12], food [13], environment [14], electronic and sensing devices [15,16,17], additive manufacturing [18, 19], and various other sectors [20].

Despite its excellent properties, the biomedical applications of BC are limited by lacking innate antimicrobial activity. Pure BC is non-bactericidal in nature due to the lack of active antimicrobial functional groups; therefore, its biomedical applications, such as in wound healing under infected environment, are questioned [21, 22]. This inadequacy has been suggested to be overcome through the incorporation of antimicrobial materials into the BC matrix via different strategies [23]. There has been extensive research carried out to impart antimicrobial activity to BC by making its composites with nanoparticles [24,25,26,27,28], polymers [29,30,31,32], antibiotics [33], amino acids [34], and active phytomolecules or plant extracts [35,36,37,38].

Phytomolecules from plant extracts have emerged as the prominent antimicrobial agents in the last few decades [39]. These compounds are environment-friendly and possess negligible cytotoxicity, and are generally non-immunogenic in nature. The presence of several functional groups in these compounds blesses them with antimicrobial activities. It is well-known that phytomolecules present in the extracts of different plants are rich in polyphenols, flavonoids, chalcones, nitrogen-containing moieties, alkaloids, and amines [40], which impart several biological activities to the plants. The use of plant extracts/phytomolecules in synthesizing BC-based composites is receiving immense consideration in the synthesis of green materials, with high mechanical strength [41], antimicrobial effects [42, 43], food packaging material [44], pH indicators [45], antioxidant biomaterials [46], and face masks [47]. The development of novel BC/plant extract–based composites amalgamating the therapeutic properties with cellulosic characteristics has proved to be an excellent approach for their use in wound dressing, tissue engineering scaffolds, drug delivery systems, and other biomedical applications [48].

Anogeissus spp. (Combretaceae), commonly known as axlewood tree, button tree, and chewing stick, have been traditionally used as ethnomedicine in Asia and Africa in treating various ailments like tuberculosis, fever, diabetes, diarrhea, skin diseases, wound healing, and snake and scorpion bites [49]. Anogeissus dhofarica is a commonly found plant in Oman and has a great pharmacological importance realized by the local people. It is used as an antiseptic for treating wounds [50]. The leaf extract of A. dhofarica contains several secondary metabolites such as tannins, alkaloids, ellagic acids, polyphenols, and flavonoids, which are known to possess antimicrobial activity against several clinical isolates [51]. Similarly, Withania somnifera (Solanaceae) is known for its pharmacological applications since ancient times. Several studies have reported the efficacy of W. somnifera as an antimicrobial, antioxidant, and anti-inflammatory agent [52]; antidepressant [53]; and for anticancer activities [54]. The leaf extract of W. somnifera leaves contains several secondary metabolites such as alkaloids, anthocyanin, flavonoids, and other polyphenols, which are known to have antimicrobial activities [55]. Although the potential biological activities of the extracts of A. dhofarica and W. somnifera have been evaluated either in the complete or partially purified forms, their loading into an appropriate substrate could benefit from enhancing their therapeutic value. For instance, BC as a matrix has been extensively evaluated for its drug loading and controlled release behavior [20], as well as a matrix having regenerative potential when doped with biologically active materials [36]. Moreover, the unique surface chemistry allows its chemical interaction with a range of materials, while its unique fibrous network allows the impregnation of a variety of materials. Thus, BC could serve as an ideal substrate for making bioactive materials with plant extracts.

This study was aimed to investigate and utilize the antimicrobial activity of the extracts of A. dhofarica and W. somnifera by developing their composites with BC for their potential biomedical applications. The extracts of both plants were obtained and ex situ incorporated into the BC matrix, and their in vitro antibacterial activities were evaluated against Gram-negative and Gram-positive bacterial strains.

2 Materials and methods

2.1 Materials

The leaves of A. dhofarica and W. somnifera were collected from the Dhofar region, Oman. The fruit wastes were collected from the local market of Salalah, Oman. All fruit wastes were autoclaved and blended to extract their juice. The extracted juice was filtered and heat-sterilized in an oven at 70 ℃ for 6 h. The pH of juice was adjusted to 5 (optimum pH for growth of Gluconacetobacter hansenii and BC production) through dropwise addition of 0.1 N NaOH. Other chemicals used in experiments, including glucose, peptone, acetic acid, sodium hydroxide, succinic acid, and agar were obtained from Sigma-Aldrich (USA) and used without further treatment.

2.2 Microbial cultures

G. hansenii was used as the BC-producing strain, and was cultured on MA medium as described earlier [56]. The Gram-negative Escherichia coli and Gram-positive Staphylococcus aureus strains were used as the representative bacterial strains for the determination of the antibacterial activity of BC-based composites. The E. coli and S. aureus strains were cultured in sterilized Luria–Bertani broth (2 wt.%) in a bacteriological shaking incubator at 37 °C and 200 rpm for 24 h.

2.3 BC production, harvesting, and purification

BC sheets were produced in sterilized rectangular containers by using fruit wastes as the production medium. Briefly, 1 L medium was inoculated with 5% pre-culture of G. hansenii. The containers were covered with cotton caps to allow air penetration and incubated statically at 30 °C. After 7 days, the BC sheets produced at the air-medium interface were harvested and treated with 0.3 N NaOH solution for 15 min at 103 kPa and 121 ℃ to disrupt and dissolve the bacterial cells and debris. The sterilized sheets were washed several times with distilled water until the pH became neutral and stored at 4 ℃ for further use.

2.4 Soxhlet extraction of plant bio-extracts

The collected plant leaves were shade-dried for 10 to 15 days and then mechanically grounded. The obtained powder was put in a soxhlet extractor for up to 5 h using ethanol as the solvent. Ethanol was removed using a rotary evaporator that yielded a dark greenish-brown residual mass. The residual extracts were dried, weighed, and stored at 4 °C for further use.

2.5 Minimum Inhibitory Concentration (MIC) and Minimum Bactericidal Concentration (MBC) of A. dhofarica and W. somnifera

The MIC and MBC of extracts of A. dhofarica and W. somnifera were determined following a reported protocol [57]. Briefly, twofold serial dilution of plant extracts in concentrations ranging from 25 to 0.195 mg/mL of W. somnifera and 10 to 0.078 mg/mL of A. dhofarica with adjusted cell densities of each 1 × 108 CFU/mL (0.5 McFarland’s standard) was used for determination of MIC against S. aureus. Similarly, an initial concentration of 100 mg/mL of extracts of both plants was taken according to the twofold serial dilution of the extract for determination of MIC against E. coli. The cultures of both bacterial strains without bio-extracts were used as the positive control while pure respective liquid media were used as the negative control. All samples were incubated overnight at 37 °C. The experiments were performed in replicates, and the mean values of three experiments were recorded (n = 3) with standard deviation. The visual turbidity of the tubes was observed before and after the incubation to confirm the MIC values. After the MIC determination of the plant bio-extracts, 100 μL from all tubes was seeded on LB agar plates and incubated overnight at 37 °C. The MBC endpoint was recorded at 99.9%, indicating the killing of the bacterial population by the lowest concentration by an antimicrobial agent. This was done by observing the growth on the plates before and after the incubation for the presence or absence of bacterial colonies.

2.6 Ex situ preparation of BC/bio-extract composites

The dried extracts of A. dhofarica and W. somnifera were dissolved in distilled water at 20 wt.% for developing composites with BC. The composites were ex situ prepared through immersion of BC sheets of dimension 4 cm × 3 cm in the plant extracts in a beaker followed by magnetic stirring for up to 24 h. The BC/bio-extracts sheets were taken out and placed on the filter paper to remove excess solvent. The BC composites prepared with A. dhofarica and W. somnifera were named BC-A and BC-W, respectively. The composites were freeze-dried for morphological and physiological analyses and antibacterial activity assay.

2.7 Characterization of BC/bio-extract composites

The BC-A and BC-W composites prepared under the same conditions along with pristine BC were characterized for different properties. The structural morphology of freeze-dried BC, BC-A, and BC-W was observed using field-emission scanning electron microscopy (FE-SEM, Hitachi S-4800 and EDX-350, Horiba, Tokyo, Japan). The samples were fixed onto a brass holder and coated with osmium tetroxide (OsO4) using a VD HPC-ISW osmium coater (Tokyo, Japan) before FE-SEM observation. FTIR spectra of all samples were recorded in the spectral range of 4000 to 400 cm‒1 using a PerkinElmer FTIR spectrophotometer (Spectrum GX & Autoimage, USA). The XRD patterns of the samples were recorded in the spectral range of 0 to 80° by using an X-ray diffractometer (X’Pert-APD PHILIPS, Netherlands) with radiation of CuK-α of wavelength 1.54 Å. The X-ray generator tension and current were fixed at 40 kV and 30 mA, respectively. The crystallinity of pristine BC-A and BC-W, along with pristine BC, was calculated by using the below Eq. (1):

where Acr and Aam represent the integrated areas of the crystalline and amorphous peaks, respectively, obtained after the deconvolution of experimental patterns [58].

2.8 Absorption capabilities of composites

BC and BC-based BC-A and BC-W composites were tested for their water absorption capabilities. Briefly, the samples were cut into 4 cm × 3 cm rectangular pieces and freeze-dried for water holding capacity (WHC) and water retention time (WRT) analysis. The freeze-dried samples were dipped in water for rewetting under static conditions at ambient temperature. By attaining the completely wet state (stabilized wet weight), the samples were removed and analyzed for WRT. The weights of all samples were determined at different time intervals at ambient temperature until reaching a stable weight. The samples were then kept in the oven to ensure complete water removal before calculating their WHC by using the below Eq. (2) [59]:

2.9 Antibacterial activity

The antibacterial activity of BC-A and BC-W was evaluated against Gram-negative E. coli and Gram-positive S. aureus by different methods, as detailed.

2.9.1 Disc diffusion assay

Antibacterial activity of BC and BC-based composites was evaluated by disc diffusion assay. Briefly, the composites BC-A and BC-W and negative control (pure BC) were cut into round discs of 6-mm diameter and sterilized under UV for 2 h for performing the antimicrobial assay. The ampicillin antibiotic discs were used as the positive control. For analysis, the respective bacterial strains were suspended in LB broth and diluted to the turbidity of 0.5 McFarland standards. Then, a 100 μL bacterial suspension was evenly spread over LB agar medium plates to form a culture lawn. Now, the sterile composite discs and both negative and positive controls were placed onto the culture agar plates and incubated overnight at 37 °C. The antibacterial activity was assessed by measuring the diameter of zones of inhibition formed by the composites relative to the controls.

2.9.2 Plate count method

The antibacterial activity of BC-A and BC-W relative to the controls was also evaluated through the plate count method, as reported previously [36]. Briefly, 0.25 g of each sample was added to 10-mL culture media of both E. coli and S. aureus maintained at a density of 1 × 108 to 2 × 108 CFU/mL and turbidity of 0.5 McFarland standards, screw-capped, and incubated overnight at 37 °C. The treated bacterial suspensions containing composites were serially diluted, and then 100 μL bacterial suspension from each serially diluted solution was spread on the agar plates. The plates were then incubated overnight at 37 °C, and then the numbers of colonies were counted. The antibacterial activity of BC-A and BC-W composites was determined using the below Eq. (3):

where Sp and Sm represent the number of bacterial colonies from pure BC and BC-based composites, respectively.

3 Results and discussion

3.1 Production of BC and its composites with bio-extracts

Despite its excellent features and potential for diverse and broad-spectrum applications, the widespread and commercial applications of BC have been limited by its low yield and productivity and high production cost. Herein, we attempted to cost-effectively produce BC by utilizing the fruit wastes as the potential carbon source and culture medium. We utilized orange wastes as the raw source for BC production, as illustrated in Fig. 1. It was observed that under static cultivation, a thin layer of BC was developed at the air-waste juice interface on the second day of cultivation. The thickness of the sheets increased with time, and it turned into a thick film on the 7th day of cultivation. We also utilized the same approach and produced BC from waste carrots, melon, apple, coconut, and tomatoes (data not shown here). It has already been reported that fruit juices, including orange juice, are the rich sources of fructose and glucose, which serve as the substrate for the growth of BC-producing microbial cells. The BC-producing microorganisms utilize the fruit wastes not only as food for growth and multiplication but also as a carbon source for the production of organic materials such as BC [4]. This utilization of wastes as carbon sources is not only advantageous for cost-effective production but also leads to overwhelming environmental concerns regarding the safe disposal of different food wastes. The findings of this study are in conjunction with our previously reported study where we utilized multiple wastes and cheap local resources for BC production [4]. The BC production through simple static cultivation indicates that upgrading the system to fed-batch cultivation could further enhance the yield and productivity of BC.

We further developed antimicrobial BC-based composite extracts of A. dhofarica and W. somnifera owing to the presence of several compounds like phenols, flavonoids, chalcones, alkaloids, and amines in the extract of most plants. The percentage yields of crude herbal extracts obtained through soxhlet extraction were 1.84 g (25.6%) of W. somnifera and 2.16 g (27.2%) of A. dhofarica. The initial investigation of antimicrobial activities of the extracts of both plants demonstrated excellent bioactivities against the pathogenic microorganisms. A schematic illustration of ex situ impregnation of plant extract into the BC matrix and the development of BC/plant extract composite is shown in Fig. 1. The porous morphology of BC and the presence of a number of hydrogen bonding sites allow the incorporation of plant extract in the BC matrix. It is anticipated that different chemical moieties such as alkaloids, phenols, and flavonoids containing the -OH, -NH, and -COOH (forming hydrogen bonding) groups present in the metabolites of plant extract would interact chemically with the OH groups on the surface of cellulose fibrils and form new bonds. Furthermore, these metabolites potentially penetrate into the internal matrix through physical adsorption. Both the chemical interaction and physical adsorption lead to formation of composite materials. A naked-eye observation of freeze-dried samples shows a clear change in color from white (for BC) to blackish-brown (for composite). This change in color indicates a successful impregnation of the plant extract into the BC matrix, which is further verified through FE-SEM observation (see Sect. 3.3 for details). The surface attachment of plant extract with BC and further integration into its matrix is expected to impart bactericidal features to the BC/bio-extract composites, as reported elsewhere [37, 42,43,44,45,46].

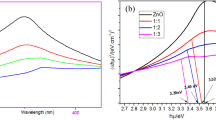

3.2 FTIR and XRD characterization of BC-based composites

FTIR analysis was carried out to confirm the purity of BC, the successful synthesis of BC-A and BC-W composites, the nature of chemical interactions between the functional groups of BC and the plant extract, and the impact of the addition of plant extract on the chemical structure of BC. The comparative spectra of pristine BC, BC-A, and BC-W are shown in Fig. 2A. The FTIR spectrum of pristine BC shows all characteristic peaks of cellulose. A broad peak for OH stretching centered at 3290 cm−1 indicates the strong hydrogen bonding in BC [60]. Similarly, the peaks for CH stretching and bending vibration appeared at 2890 cm−1 and 1453 cm−1, respectively. The peak around 1620 cm−1 could be attributed to the HOH bending vibration of the absorbed water. The typical carbon skeleton peak for COC vibration appeared in the fingerprint region around 1000 cm−1. The typical cellulose peak pattern confirms the purity of BC produced by utilizing fruit waste, showing its effectiveness as a carbon source. Further, the absence of any additional functional groups in the FTIR spectrum of BC verifies the effectiveness of the post-synthesis processing of BC via treatment with 0.3 N NaOH and washing with water. The FTIR spectra of BC-A and BC-W composites showed characteristic peaks of cellulose as well as additional peaks, however, with slight variation in peak position and intensity. The FTIR spectra of both BC-A and BC-W composites show an additional peak centered at 3350 cm−1, which could be attributed to the NH stretching of amine groups; nevertheless, this peak was overlapped with the peak for OH stretching of BC. Another additional peak appeared at 1710 cm−1 that corresponds to the aromatic COOH group, as the leaf extract of W. somnifera contains several chemical constituents such as alkaloids (withanine, somniferine, and withananine), flavonoids (catechin, kaempferol, and naringenin), terpenoids and steroids (withaferin A and withanolides), and several other carboxylic acids and phenols [55]. Similarly, the phytochemical analysis of A. dhofarica shows the presence of tannins, carboxylic acids, tannins (anogeissinin), stilbene (pterostilbene), flavonoids (quercetin and rutin), and saponins in the leaf extract [61]. The FTIR analysis shows the successful synthesis of BC-A and BC-W composites. Furthermore, the slight changes in the position and intensity of characteristic OH peak indicate an altered pattern of hydrogen bonding of BC when composited with the plant extracts.

XRD is an important tool used to investigate the structural features of pure polymers and microstructural changes engendered during the synthesis of their composites. The XRD patterns of pristine BC and the BC-A and BC-W composites are indicated in Fig. 2B. Pure BC represents semi-crystalline nature and its XRD spectrum contains two major crystalline peaks at 2θ = 14° and 22°, corresponding to the crystallographic planes of (110) and (200), respectively. In addition, the XRD spectrum of pure BC shows an amorphous halo present at 2θ = 16.6° representing the non-crystalline (amorphous) peak of BC [62]. Depending upon the nature of the reinforcement material, its impregnation into the BC matrix alters its peak pattern either by forming additional peaks or altering the peak intensity or pattern of the pristine BC. In the present study, both BC-A and BC-W show similar peak patterns to BC, indicating the non-crystalline nature of the plant extracts; however, the intensities of crystalline peaks were decreased. The decreased intensity led to reduced crystallinity of the composite. Compared to the high crystallinity of pristine BC (i.e., 59%), the BC-A and BC-W showed 53% and 50% crystallinity, respectively, as calculated from the relative integrated areas of the crystalline and amorphous regions. These results are in agreement with previous studies, which show that the addition of plant extract into the BC matrix led to altered XRD pattern and decreased its crystallinity [3, 63].

3.3 Morphology and absorbing capabilities of BC-based composites

Pure BC consists of a reticulated fibrous structure where fibrils are interconnected and form a net-shaped structure. This artistic arrangement of nanofibrils not only provides excellent mechanical and crystalline features to BC but also blesses it with high porosity. The porosity of never dried BC is reduced during the drying process due to the evaporation of adsorbed water and consequent surface shrinkage caused by the irreversible hydrogen bonding interactions [64]. During the ex situ composite synthesis, the addition of nanoparticle suspensions, polymeric solutions, or other liquids penetrates the matrix of never dried BC through these pores and interact with the OH groups through hydrogen bonding interactions. The results of structural morphology, observed through SEM, are shown in Fig. 3. As expected, the pure BC surface possesses a fibrous network structure. The nanoscale fiber diameter and number of empty spaces are clearly visible in pure BC. On the other hand, both BC-A and BC-W composites show the attachment of extract of the respective plant on the BC surface, which leads to the closure of surface pores. It is likely that the plant extract further penetrates into the BC matrix besides the attachment to the surface. The SEM micrographs also indicate that the BC-W surface was comparatively dense than the BC-A, and the porous surface was almost covered. These observations were further supported by the cross-sectional view of the pristine BC and the BC-A and BC-W composites. The cross-sectional view of the composites shows a more packed fibril arrangement than the pristine BC, indicating the impregnation of plant extracts into the BC matrix. Specifically, the cross-sectional view of BC-W shows a more packed arrangement than BC-A, which is in accordance with the surface morphologies of both composites. Altogether, the structural features of BC/bio-extract composites are in agreement with our previously developed BC-based composites with different plant extracts [65, 66].

The liquid-absorbing capability of BC has been well investigated. Owing to the hydrophilic nature and substantial porosity, BC effectively absorbs a variety of liquid materials, especially hydrophilic, and demonstrates a high liquid holding capability. It has been reported that pure BC can hold even more than 100 times of its dry weight water [59, 66]. However, the liquid holding capability of BC is entirely dependent on its structural morphology, such as fibril arrangement and porosity, which in turn vary greatly with the production process and post-synthesis processing conditions [67]. Moreover, the incorporation of different materials such as polymers, nanoparticles, and other chemicals, causes modification in the native structure of BC and thus affects its absorption capabilities to some extent. We analyzed the WHC and WRT of both pure BC and BC-A and BC-W composites, and the results are shown in Fig. 4A. The results of WHC indicated that pristine BC held 120 times more water of its dry weight, which was much higher than BC-A (87 times) and BC-W (75 times) composites. These results indicate that the addition of plant extracts into the BC matrix reduced its WHC, which could be attributed to the occupation of free spaces between the cellulose fibers and the interaction of different chemical groups in the extracts with the OH groups in BC. The high liquid holding capacity of BC is advantageous for biomedical applications, for example, to absorb the exudates at the wound site when used as the wound dressing material [33]. The WRT, on the other hand, exhibited different behavior, and BC/bio-extract composites retained the water for a comparatively longer time. It is shown that pure BC lost a high percentage (80%) of water in just 24 h, whereas the BC-A and BC-W allowed the release of only 50% water at the same time. The results of the porosity analysis of pure BC and BC-A and BC-W composites are shown in Fig. 4B, which are in accordance with the results of WHC and WRT. The porosity analysis indicates that pure BC is highly porous and has a larger pore size and volume compared to the BC/bio-extract composites, which is further in agreement with the FE-SEM observation (Fig. 3). The high porosity in pure BC led to high water absorbing capabilities. Both WHC and WRT are important features considering the pharmaceutical and medical applications of BC. For instance, a high WRT (or a slow water release rate) maintains a moist environment at the wound site for extended time, which is beneficial for wound dressing. Beside water, other liquids and drugs can also be loaded and retained in the BC matrix for its biomedical applications [59, 68, 69].

3.4 Antibacterial assessment: the bacteriostatic and bactericidal activity of BC/bio-extract composite films

Plant extracts have traditionally been used in antibacterial applications and have played a significant role in the development of antibacterial leads. Phytochemical analysis of different plant extracts revealed the presence of several secondary metabolites like flavonoids, alkaloids, steroids, terpenoids, tannins, and phenols, which have been witnessed for their impressive antibacterial activities [49, 70]. For instance, the extract of W. somnifera contains alkaloids, anthocyanin, flavonoids, and other polyphenols, which show antibacterial activities via a protein denaturing mechanism [55]. Moreover, some vital proteins (like enzymes) in different microorganisms undergo iron deprivation in the presence of these compounds, which ultimately leads to growth inhibition [71]. Similarly, the phytochemical constituents of genus Anogeissus have been extensively reviewed by Singh et al. [49], although only a few reports are available on A. dhofarica. For example, Marwah et al. quantified the total phenolic content to be 406 GAE mg/g dry weight in aqueous ethanolic extract of A. dhofarica tubers [50]. This plant also contains tannins and ellagic acids, which have been traditionally used as antiseptic and in the treatment of sores [50]. Polyphenols and tannins present in the plant extract are believed to bind to the bacterial cell wall receptors and inhibit the enzymes involved in cellular metabolism, and thus causing membrane disruption. Similarly, the flavonoids present in the plant extract bind to the cell wall receptors and make complexes, and thus inhibiting the release of autacoids and prostaglandins, which are necessary for microbial metabolism [72, 73]. The antibacterial activity of leaf extract of A. dhofarica against several clinical isolates has already been reported [51].

Considering the abovementioned reports, the antibacterial activities of both plant extracts were evaluated against E. coli and S. aureus, and the results clearly indicated substantial bactericidal effects against both pathogenic bacteria. Figure 5A depicts the MIC determination of A. dhofarica and W. somnifera extracts against S. aureus, where no visible growth was observed after the 6th tube. The MIC of A. dhofarica was found to be 0.312 mg/mL against S. aureus while W. somnifera exhibited MIC value of 0.781 mg/mL.

Although the MIC results display no visible growth up to the 6th tube, their subsequent plating gave few colonies in the 3rd plate giving MBC values (Fig. 5B). It could be concluded from these results that A. dhofarica has greater killing activity towards S. aureus with an MBC value of 5 mg/mL corresponding to the 2nd agar plate. Similarly, W. somnifera showed an MBC value of 12.5 mg/mL corresponding to the 2nd plate.

MIC results of both A. dhofarica and W. somnifera extracts against E. coli are shown in Fig. 6A. MIC of A. dhofarica was found to be 6.25 mg/mL, where no visible growth was observed after the 5th tube corresponding to the 6.25 mg/mL concentration while W. somnifera exhibited an MIC value of 25 mg/mL, where 3rd tube having the same concentration of compounds depicted no visible growth. Subsequent plating of MIC vials gave MBC values for two extracts (Fig. 6B). A. dhofarica was found to be more active with an MBC value at 12.5 mg/mL, while W. somnifera exhibited MBC at a concentration of 50 mg/mL.

The overall results of MIC and MCB for both plant extract against Gram-positive and Gram-negative bacterial species are in accordance with some previous reports. For example, the ethanolic extract of A. dhofarica was found to be active against S. aureus at a concentration of 0.250 mg/mL and against E. coli at 1 mg/mL observed through the agar dilution-streak method [50]. Similarly, Mwitari et al. reported the MIC of W. somnifera dichloromethane extract against S. aureus at 6.25 mg/mL by the paper disc technique [74] while methanolic extract of leaves was active against E. coli at MIC values of 12.5 mg/mL [75].

Despite the impressive physical, mechanical, and biological features of BC, its wide applicability for therapeutic applications has been limited by its non-bactericidal nature. Herein, we aimed to impart antibacterial features to BC by making its composites with bioactive plant extracts obtained from A. dhofarica and W. somnifera. There have already been some reports on imparting bactericidal activity to BC by combining it with different materials such as nanomaterials, polymers, peptides, and enzymes [76,77,78,79,80], which possess antimicrobial activities; however, its combination with active plant extract has been rarely reported [46, 81]. In the present study, we incorporated the extracts of two plants, A. dhofarica and W. somnifera, into the BC matrix for the first time and evaluated the antibacterial activities of the resulting composites against model pathogenic bacterial strains, E. coli and S. aureus, through disc diffusion assay and plate count technique, and the results are shown in Fig. 7A, B, respectively. In comparative antimicrobial activity testing among the two BC/bio-extract-based composites and pure BC (negative control) BC, the BC-based composite with A. dhofarica showed the highest antibacterial activity and produced an inhibition zone of 13 mm against S. aureus, while W. somnifera only produced an inhibition zone of 6 mm against S. aureus. This could be due to the greater antibacterial efficacy of A. dhofarica extract itself as evident in MIC assay of the two extracts, where MIC of A. dhofarica was found to be 0.312 mg/mL against S. aureus while W. somnifera exhibited MIC value of 0.781 mg/mL. The antibacterial activity of Anogeissus species is mostly due to the presence of phenolic compounds which possess antioxidant activity, while some species also show cytotoxic activity by lysing the cellular barrier, attack the respiratory chain, or interfere the synthesis of biological molecules such as nucleic acids, proteins, lipids, and carbohydrates [40].

A Disc diffusion assay of BC-A and BC-W against S. aureus and E. coli. Pure BC discs (white) were used as the negative control, while ampicillin discs were used as the positive control in each case. B The reduction (%) in the number of E. coli and S. aureus colonies after treatment with BC-A and BC-W composites

The inhibition zone produced by BC-A was somewhat comparable to that produced by the ampicillin (positive control), indicating its commercial potential against diseases caused by S. aureus, especially the multi-drug resistant S. aureus [77]. However, none of the composites showed any activity against E. coli. As expected, the unmodified BC did not produce any inhibition zone against either bacterial species, thus confirming its non-bactericidal nature and indicating that the inhibition zones were solely produced by the bioactive functional groups from the plant extracts. The images of the zone of inhibition produced by different BC-based composites against E. coli and S. Aureus are shown in Fig. 7A.

The plate count method further revealed that both BC-A and BC-W composites exhibited very high growth reduction and reduced the growth of S. aureus up to 99% and 97%, respectively, in only 24 h. However, both composites only showed 53% and 47% reduction, respectively, against E. coli (Fig. 7B). The results of the plate count method are in agreement with the disc diffusion analysis.

Results of both assays are in agreement with each other, where A. dhofarica exhibited greater antibacterial activity in extract comparable to MIC of 0.312 mg/mL against S. aureus, which is evident in BC-based composite activity with 100% reduction in bacterial colonies. A similar pattern was followed by W. somnifera extracts, which were found to be comparatively less active at extract level with a comparatively lower MIC value of 0.781 mg/mL against S. aureus displaying a 97% reduction in composite activity. Both BC-A and BC-W composites were less active against E. coli. The findings of the current study are supported by few earlier reports. For example, Sharma et al. reported a moderate level of antibacterial activity of BC loaded with W. somnifera against E. coli [36]. Other cellulose sheets modified with bioactive plant extract have shown bactericidal activities against S. aureus and E. coli. The BC films modified with herbal extracts of Momordica charantia and Tridax procumbens showed antibacterial activity against E. coli and S. aureus. Similarly, the M. charantia–modified BC was found to be active against S. aureus and E. coli by producing inhibition zones of 25 mm and 24 mm, respectively, while T. procumbens–modified BC films produced inhibition zones of 21 mm and 20 mm against S. aureus and E. coli, respectively [42]. The antibacterial efficacy of A. dhofarica and W. somnifera composites with BC developed in this study was profound, where 99% and 97% reduction in bacterial growth was recorded, which endorses their potential for biomedical applications, such as developing antibacterial wound dressing materials.

4 Conclusions

In the current study, we ex situ developed green antibacterial BC-based composites with bioactive natural plant extract for potential biomedical applications. The plant extract exhibited high activities at the extract level, as observed with their MIC and MBC levels. The extracts were facilely incorporated into the BC matrix through the ex situ penetration strategy, as indicated by the SEM observation and porosity analysis. Both BC-A and BC-W composites exhibited a high level of bactericidal activities against S. aureus, and a moderate level of activities against E. coli. Both composites held a substantial amount of water and retained it for an extended time, which could augment their applications in the biomedical field, especially in the development of wound dressing materials where the developed dressing could absorb the wound exudates and release the loaded drug for an extended time.

References

Ullah MW, Ul Islam M, Khan S et al (2017) Recent advancements in bioreactions of cellular and cell-free systems: a study of bacterial cellulose as a model. Korean J Chem Eng 34:1591–1599. https://doi.org/10.1007/s11814-017-0121-2

Kim Y, Ullah MW, Ul-Islam M et al (2019) Self-assembly of bio-cellulose nanofibrils through intermediate phase in a cell-free enzyme system. Biochem Eng J 142:135–144. https://doi.org/10.1016/j.bej.2018.11.017

Ul-Islam M, Khan S, Ullah MW, Park JK (2019) Comparative study of plant and bacterial cellulose pellicles regenerated from dissolved states. Int J Biol Macromol 137:247–252. https://doi.org/10.1016/j.ijbiomac.2019.06.232

Ul-Islam M, Ullah MW, Khan S, Park JK (2020) Production of bacterial cellulose from alternative cheap and waste resources: a step for cost reduction with positive environmental aspects. Korean J Chem Eng 37:925–937. https://doi.org/10.1007/s11814-020-0524-3

Lotfy VF, Basta AH, Abdel-Monem MO, Abdel-Hamed GZ (2021) Utilization of bacteria in rotten guava for production of bacterial cellulose from isolated and protein waste. Carbohydr Polym Technol Appl 2:100076. https://doi.org/10.1016/j.carpta.2021.100076

Khattak WA, Khan T, Ul-Islam M et al (2015) Production, characterization and physico-mechanical properties of bacterial cellulose from industrial wastes. J Polym Environ 23:45–53. https://doi.org/10.1007/s10924-014-0663-x

Islam MU, Ullah MW, Khan S et al (2017) Strategies for cost-effective and enhanced production of bacterial cellulose. Int J Biol Macromol 102:1166–1173. https://doi.org/10.1016/J.IJBIOMAC.2017.04.110

Ode Boni BO, Lamboni L, Bakadia BM et al (2020) Combining silk sericin and surface micropatterns in bacterial cellulose dressings to control fibrosis and enhance wound healing. Eng Sci 10:68–77. https://doi.org/10.30919/es8d906

Khan S, Ul-Islam M, Ullah MW et al (2015) Synthesis and characterization of a novel bacterial cellulose–poly(3,4-ethylenedioxythiophene)–poly(styrene sulfonate) composite for use in biomedical applications. Cellulose 22:2141–2148. https://doi.org/10.1007/s10570-015-0683-2

Khan S, Ul-Islam M, Ullah MW et al (2018) Nano-gold assisted highly conducting and biocompatible bacterial cellulose-PEDOT:PSS films for biology-device interface applications. Int J Biol Macromol 107:865–873. https://doi.org/10.1016/j.ijbiomac.2017.09.064

da Silva CJG, de Medeiros ADM, de Amorim JDP et al (2021) Bacterial cellulose biotextiles for the future of sustainable fashion: a review. Environ Chem Lett 19:2967–2980. https://doi.org/10.1007/s10311-021-01214-x

Shi Z, Shi X, Ullah MW et al (2017) Fabrication of nanocomposites and hybrid materials using microbial biotemplates. Adv Compos Hybrid Mater. https://doi.org/10.1007/s42114-017-0018-x

Cazón P, Vázquez M (2021) Bacterial cellulose as a biodegradable food packaging material: a review. Food Hydrocoll 113:106530. https://doi.org/10.1016/j.foodhyd.2020.106530

Yuan B, Li L, Murugadoss V et al (2020) Nanocellulose-based composite materials for wastewater treatment and waste-oil remediation. ES Food Agrofor. https://doi.org/10.30919/esfaf0004

Li Y, Guo J, Li M et al (2021) Recent application of cellulose gel in flexible sensing-a review. ES Food Agrofor 4:9–27. https://doi.org/10.30919/esfaf466

Vyas S, Shukla A, Shivhare SJ et al (2021) High performance conducting nanocomposites polyaniline (PANI)-CuO with enhanced antimicrobial activity for biomedical applications. ES Mater Manuf. https://doi.org/10.30919/esmm5f468

Farooq U, Ullah MW, Yang Q et al (2020) High-density phage particles immobilization in surface-modified bacterial cellulose for ultra-sensitive and selective electrochemical detection of Staphylococcus aureus. Biosens Bioelectron 157:112163. https://doi.org/10.1016/j.bios.2020.112163

Wei J, Wang B, Li Z et al (2020) A 3D-printable TEMPO-oxidized bacterial cellulose/alginate hydrogel with enhanced stability via nanoclay incorporation. Carbohydr Polym 238:116207. https://doi.org/10.1016/j.carbpol.2020.116207

McCarthy RR, Ullah MW, Booth P et al (2019) The use of bacterial polysaccharides in bioprinting. Biotechnol Adv 37:107448. https://doi.org/10.1016/j.biotechadv.2019.107448

Li S, Jasim A, Zhao W et al (2018) Fabrication of pH-electroactive bacterial cellulose/polyaniline hydrogel for the development of a controlled drug release system. ES Mater Manuf 41–49. https://doi.org/10.30919/esmm5f120

Khalid A, Khan R, Ul-Islam M et al (2017) Bacterial cellulose-zinc oxide nanocomposites as a novel dressing system for burn wounds. Carbohydr Polym 164:214–221. https://doi.org/10.1016/j.carbpol.2017.01.061

Sajjad W, He F, Ullah MW et al (2020) Fabrication of bacterial cellulose-curcumin nanocomposite as a novel dressing for partial thickness skin burn. Front Bioeng Biotechnol 8:553037. https://doi.org/10.3389/fbioe.2020.553037

Shah N, Ul-Islam M, Khattak WA, Park JK (2013) Overview of bacterial cellulose composites: a multipurpose advanced material. Carbohydr Polym 98:1585–1598. https://doi.org/10.1016/j.carbpol.2013.08.018

Jiji S, Udhayakumar S, Maharajan K et al (2020) Bacterial cellulose matrix with in situ impregnation of silver nanoparticles via catecholic redox chemistry for third degree burn wound healing. Carbohydr Polym 245:116573. https://doi.org/10.1016/J.CARBPOL.2020.116573

Almasi H, Jafarzadeh P, Mehryar L (2018) Fabrication of novel nanohybrids by impregnation of CuO nanoparticles into bacterial cellulose and chitosan nanofibers: characterization, antimicrobial and release properties. Carbohydr Polym 186:273–281. https://doi.org/10.1016/j.carbpol.2018.01.067

Islam SU, Ul-Islam M, Ahsan H et al (2021) Potential applications of bacterial cellulose and its composites for cancer treatment. Int J Biol Macromol 168:301–309. https://doi.org/10.1016/j.ijbiomac.2020.12.042

Khan SH, Pathak B, Fulekar MH (2020) A study on the influence of metal ( Fe, Bi, and Ag ) doping on structural, optical, and antimicrobial activity of ZnO nanostructures. Adv Compos Hybrid Mater 3(4):551–569. https://doi.org/10.1007/s42114-020-00174-0

Panthi G, Ranjit R, Khadka S et al (2020) Characterization and antibacterial activity of rice grain-shaped ZnS nanoparticles immobilized inside the polymer electrospun nanofibers. Adv Compos Hybrid Mater 3(1):8–15. https://doi.org/10.1007/s42114-020-00141-9

Lin WC, Lien CC, Yeh HJ et al (2013) Bacterial cellulose and bacterial cellulose-chitosan membranes for wound dressing applications. Carbohydr Polym. https://doi.org/10.1016/j.carbpol.2013.01.076

Zhang P, Chen L, Zhang Q, Hong FF (2016) Using in situ dynamic cultures to rapidly biofabricate fabric-reinforced composites of chitosan/bacterial nanocellulose for antibacterial wound dressings. Front Microbiol 7:1–15. https://doi.org/10.3389/fmicb.2016.00260

Sun K, Qin J, Wang Z et al (2020) Polyvinyl alcohol / carbon fibers composites with tunable negative permittivity behavior. Surfaces and Interfaces 21:100735. https://doi.org/10.1016/j.surfin.2020.100735

Wang Z, Li X, Wang L et al (2020) Flexible multi-walled carbon nanotubes / polydimethylsiloxane membranous composites toward high-permittivity performance. Adv Compos Hybrid Mater 3(1):1–7. https://doi.org/10.1007/s42114-020-00144-6

Lemnaru GM, Truşcă RD, Ilie CI et al (2020) Antibacterial activity of bacterial cellulose loaded with bacitracin and amoxicillin: in vitro studies. Molecules 25:4069. https://doi.org/10.3390/molecules25184069

Zywicka A, Fijałkowski K, Junka AF et al (2018) Modification of bacterial cellulose with quaternary ammonium compounds based on fatty acids and amino acids and the effect on antimicrobial activity. Biomacromol 19:1528–1538. https://doi.org/10.1021/acs.biomac.8b00183

Gupta A, Briffa SM, Swingler S et al (2020) Synthesis of silver nanoparticles using curcumin-cyclodextrins loaded into bacterial cellulose-based hydrogels for wound dressing applications. Biomacromol 21:1802–1811. https://doi.org/10.1021/acs.biomac.9b01724

Sharma C, Bhardwaj NK (2020) Fabrication of natural-origin antibacterial nanocellulose films using bio-extracts for potential use in biomedical industry. Int J Biol Macromol 145:914–925. https://doi.org/10.1016/j.ijbiomac.2019.09.182

Fatima A, Yasir S, Khan MS et al (2021) Plant extract-loaded bacterial cellulose composite membrane for potential biomedical applications. J Bioresour Bioprod 6:26–32. https://doi.org/10.1016/j.jobab.2020.11.002

Wang Y, Hu Y, Hao X et al (2020) Hydrothermal synthesis and applications of advanced carbonaceous materials from biomass : a review. Adv Compos Hybrid Mater 3:267–284. https://doi.org/10.1007/s42114-020-00158-0

Shah N, Aslam S, Ul-Islam M et al (2019) Fabrication of thermally stable graphite-based poly(acrylonitrile-co-acrylic acid) composite with impressive antimicrobial properties. Eng Sci 6:66–75. https://doi.org/10.30919/es8d758

Ullah MW, Manan S, Khattak WA et al (2020) Biotemplate-mediated green synthesis and applications of nanomaterials. Curr Pharm Des 26:5819–5836. https://doi.org/10.2174/1381612824999201105164531

Saibuatong O, Phisalaphong M (2010) Novo aloe vera–bacterial cellulose composite film from biosynthesis. Carbohydr Polym 79:455–460. https://doi.org/10.1016/j.carbpol.2009.08.039

Hungund B, Siddhan P, Basavaraj H (2016) Biosynthesis of bacterial cellulose and imparting antibacterial property through novel bio-agents biosynthesis of bacterial cellulose imparting antibacterial property through novel bio-agents. Res J Biotechnol 11:86–93

Mocanu A, Isopencu G, Busuioc C et al (2019) Bacterial cellulose films with ZnO nanoparticles and propolis extracts: synergistic antimicrobial effect. Sci Rep 9:17687. https://doi.org/10.1038/s41598-019-54118-w

Moradian S, Almasi H, Moini S (2018) Development of bacterial cellulose-based active membranes containing herbal extracts for shelf life extension of button mushrooms ( Agaricus bisporus ). J Food Process Preserv 42:e13537. https://doi.org/10.1111/jfpp.13537

Pourjavaher S, Almasi H, Meshkini S et al (2017) Development of a colorimetric pH indicator based on bacterial cellulose nanofibers and red cabbage (Brassica oleraceae) extract. Carbohydr Polym. https://doi.org/10.1016/j.carbpol.2016.09.027

Maciel GM, Lou MA (2020) Hybrid bacterial cellulose-collagen membranes production in culture media enriched with antioxidant compounds from plant extracts. Wiley Online Libr 60:2814–2826. https://doi.org/10.1002/pen.25514

Anastasia Wheni I, Vita Taufika R, Wuri A et al (2020) Antioxidant and antibacterial properties of bacterial cellulose— Indonesian plant extract composites for mask sheet. J Appl Pharm Sci 10:37–42. https://doi.org/10.7324/JAPS.2020.10705

Amalraj A, Raj KKJ, Haponiuk JT et al (2020) Preparation, characterization, and antimicrobial activity of chitosan / gum arabic / polyethylene glycol composite films incorporated with black pepper essential oil and ginger essential oil as potential packaging and wound dressing materials. Adv Compos Hybrid Mater 3(4):485–497. https://doi.org/10.1007/s42114-020-00178-w

Singh D, Baghel US, Gautam A et al (2016) The genus Anogeissus: a review on ethnopharmacology, phytochemistry and pharmacology. J Ethnopharmacol 194:30–56. https://doi.org/10.1016/j.jep.2016.08.025

Marwah RG, Fatope MO, Al MR et al (2007) Antioxidant capacity of some edible and wound healing plants in Oman. Food Chem 101:465–470. https://doi.org/10.1016/j.foodchem.2006.02.001

Dayok O, Dawang DN, Da'am CE (2018) Antimicrobial activity of leaf extract of Anogeissus leiocarpus (African Birch) on some selected clinical isolates. IOSR J Pharm Biol Sci (IOSR-JPBS 13:36–40. https://doi.org/10.9790/3008-1304063640

Rahnama M, Fakheri BA, Mashhady MA et al (2016) The antimicrobial effects of medicinal plants on pathogenic food bacteria. Int J Infect 4:2–5. https://doi.org/10.5812/iji.40238

Bhattacharya SK, Bhattacharya A, Sairam K, Ghosal S (2000) Anxiolytic-antidepressant activity of Withania somnifera glycowithanolides: an experimental study. Phytomedicine 7:463–469. https://doi.org/10.1016/S0944-7113(00)80030-6

Rai M, Jogee PS, Agarkar G, Dos SCA (2016) Anticancer activities of Withania somnifera : current research, formulations, and future perspectives. Pharm Biol 54:189–197. https://doi.org/10.3109/13880209.2015.1027778

Saleem S, Muhammad G, Hussain MA et al (2020) Withania somnifera L.: insights into the phytochemical profile, therapeutic potential, clinical trials, and future prospective. Iran J Basic Med Sci 23:1501–1526. https://doi.org/10.22038/IJBMS.2020.44254.10378

Ul-Islam M, Subhan F, Islam SU et al (2019) Development of three-dimensional bacterial cellulose/chitosan scaffolds: analysis of cell-scaffold interaction for potential application in the diagnosis of ovarian cancer. Int J Biol Macromol 137:1050–1059. https://doi.org/10.1016/j.ijbiomac.2019.07.050

Parvekar P, Palaskar J, Metgud S et al (2020) The minimum inhibitory concentration (MIC) and minimum bactericidal concentration (MBC) of silver nanoparticles against Staphylococcus aureus. Biomater Investig Dent 7:105–109. https://doi.org/10.1080/26415275.2020.1796674

Focher B, Palma MT, Canetti M et al (2001) Structural differences between non-wood plant celluloses: evidence from solid state NMR, vibrational spectroscopy and X-ray diffractometry. Ind Crops Prod 13:193–208. https://doi.org/10.1016/S0926-6690(00)00077-7

Ul-Islam M, Khan T, Park JK (2012) Water holding and release properties of bacterial cellulose obtained by in situ and ex situ modification. Carbohydr Polym 88:596–603. https://doi.org/10.1016/j.carbpol.2012.01.006

Ullah MW, Ul-Islam M, Khan S et al (2016) Structural and physico-mechanical characterization of bio-cellulose produced by a cell-free system. Carbohydr Polym 136:908–916. https://doi.org/10.1016/j.carbpol.2015.10.010

Mann A, Amupitan JO, Oyewale AO et al (2009) Chemistry of secondary metabolites and their antimicrobial activity in the drug development process: a review of the genus Anogeissus. Med Plants - Int J Phytomedicines Relat Ind 1:55. https://doi.org/10.5958/J.0975-4261.1.2.010

Castro C, Zuluaga R, Putaux JL et al (2011) Structural characterization of bacterial cellulose produced by Gluconacetobacter swingsii sp. from Colombian agroindustrial wastes. Carbohydr Polym 84:96–102. https://doi.org/10.1016/j.carbpol.2010.10.072

Phisalaphong M, Suwanmajo T, Sangtherapitikul P (2008) Novel nanoporous membranes from regenerated bacterial cellulose. J Appl Polym Sci 107:292–299. https://doi.org/10.1002/APP.27118

Ul-Islam M, Ha JH, Khan T, Park JK (2013) Effects of glucuronic acid oligomers on the production, structure and properties of bacterial cellulose. Carbohydr Polym 92:360–366. https://doi.org/10.1016/j.carbpol.2012.09.060

Ul-Islam M, Shah N, Ha JH, Park JK (2011) Effect of chitosan penetration on physico-chemical and mechanical properties of bacterial cellulose. Korean J Chem Eng 28:1736–1743. https://doi.org/10.1007/s11814-011-0042-4

Ul-Islam M, Khan T, Park JK (2012) Nanoreinforced bacterial cellulose-montmorillonite composites for biomedical applications. Carbohydr Polym 89:1189–1197. https://doi.org/10.1016/j.carbpol.2012.03.093

Ul-Islam M, Khattak WA, Kang M et al (2013) Effect of post-synthetic processing conditions on structural variations and applications of bacterial cellulose. Cellulose 20:253–263. https://doi.org/10.1007/s10570-012-9799-9

Khan S, Ul-Islam M, Ullah MW et al (2015) Engineered regenerated bacterial cellulose scaffolds for application in in vitro tissue regeneration. RSC Adv 5:84565–84573. https://doi.org/10.1039/C5RA16985B

Di Z, Shi Z, Ullah MW et al (2017) A transparent wound dressing based on bacterial cellulose whisker and poly(2-hydroxyethyl methacrylate). Int J Biol Macromol 105:638–644. https://doi.org/10.1016/j.ijbiomac.2017.07.075

Mirjalili M, Moyano E, Bonfill M et al (2009) Steroidal lactones from Withania somnifera, an ancient plant for novel medicine. Molecules 14:2373–2393. https://doi.org/10.3390/molecules14072373

Scalbert A (1991) Antimicrobial properties of tannins. Phytochemistry 30:3875–3883. https://doi.org/10.1016/0031-9422(91)83426-L

Gaspar-Pintiliescu A, Stanciuc A-M, Craciunescu O (2019) Natural composite dressings based on collagen, gelatin and plant bioactive compounds for wound healing: a review. Int J Biol Macromol 138:854–865. https://doi.org/10.1016/j.ijbiomac.2019.07.155

Cowan MM (1999) Plant products as antimicrobial agents. Clin Microbiol Rev 12:564–582. https://doi.org/10.1128/CMR.12.4.564

Mwitari PG, Ayeka PA, Ondicho J et al (2013) Antimicrobial activity and probable mechanisms of action of medicinal plants of Kenya: Withania somnifera, Warbugia ugandensis, Prunus africana and Plectrunthus barbatus. PLoS One 8:e65619. https://doi.org/10.1371/journal.pone.0065619

Alam N, Hossain M, Mottalib MA et al (2012) Methanolic extracts of Withania somnifera leaves, fruits and roots possess antioxidant properties and antibacterial activities. BMC Complement Altern Med 12:1–8. https://doi.org/10.1186/1472-6882-12-175

Khattak S, Qin XT, Wahid F et al (2021) Permeation of silver sulfadiazine into TEMPO-oxidized bacterial cellulose as an antibacterial agent. Front Bioeng Biotechnol 8:616467. https://doi.org/10.3389/fbioe.2020.616467

Mao L, Wang L, Zhang M et al (2021) In situ synthesized selenium nanoparticles-decorated bacterial cellulose/gelatin hydrogel with enhanced antibacterial, antioxidant, and anti-inflammatory capabilities for facilitating skin wound healing. Adv Healthc Mater 10:2100402. https://doi.org/10.1002/adhm.202100402

Xu Y, Liu X, Jiang Q et al (2021) Development and properties of bacterial cellulose, curcumin, and chitosan composite biodegradable films for active packaging materials. Carbohydr Polym 260:117778. https://doi.org/10.1016/j.carbpol.2021.117778

Wang Y, Liu X, Yang R, Ma Q (2021) Asymmetric wetting and antibacterial composite membrane obtained by spraying bacterial cellulose grafted with chitosan for sanitary products surface layers. Carbohydr Polym 256:117602. https://doi.org/10.1016/j.carbpol.2020.117602

Gedarawatte STG, Ravensdale JT, Al-Salami H et al (2021) Antimicrobial efficacy of nisin-loaded bacterial cellulose nanocrystals against selected meat spoilage lactic acid bacteria. Carbohydr Polym 251:117096. https://doi.org/10.1016/j.carbpol.2020.117096

Moradian S, Almasi H, Moini S (2018) Development of bacterial cellulose-based active membranes containing herbal extracts for shelf life extension of button mushrooms (Agaricus bisporus). J Food Process Preserv 42:e13537. https://doi.org/10.1111/jfpp.13537

Funding

This research was supported by The Research Council (TRC), Oman, through Block Research Funding Program (BFP/RGP/EBR/20/261), National Natural Science Foundation of China (21774039, 51973076), BRICS STI Framework Programme 3rd call 2019 (2018YFE0123700), and China Postdoctoral Science Foundation (2016M602291).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fatima, A., Yasir, S., Ul-Islam, M. et al. Ex situ development and characterization of green antibacterial bacterial cellulose-based composites for potential biomedical applications. Adv Compos Hybrid Mater 5, 307–321 (2022). https://doi.org/10.1007/s42114-021-00369-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-021-00369-z