Abstract

An economic, eco-friendly and efficient synthesis route for Zinc oxide (ZnO) nanoparticles (NPs) using fungus Phanerochaete chrysosporium has been explored along with the single-step impregnation of these nanoparticles on cellulose fibers. The transmission electron microscopy confirmed 50 nm as an average size of ZnO NPs and showed the presence of hexagonal phases. ZnO NPs–cellulose composite was fabricated by amending sugarcane bagasse-extracted cellulose in the reaction mixture during the nanoparticle synthesis. The composite was characterized using Fourier transform infrared, X-ray diffraction patterns, Scanning electron microscopy, and Energy dispersive spectroscopy, thermogravimetric analysis, and also evaluated for its antimicrobial potential. The analyses revealed that well-dispersed hexagonal wurtzite ZnO NPs were present on the surface of the cellulose fibers. ZnO NPs–cellulose demonstrated antibacterial activity against Staphylococcus aureus and Escherichia coli, and antifungal activity against Aspergillus niger, Geotrichum candidum, and Phanerochaete chrysosporium. Thus, the study demonstrated an environmental friendly synthesis of ZnO NPs–cellulose composite using an economic and efficient method, which can be used for developing antimicrobial cellulosic fabric for numerous applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Several textile materials are used in hospitals as a shield to prevent the spread of highly infectious microbes (Livingston et al. 2020). However, most of these materials do not typically have the efficiency to prevent the transmission of microorganisms, as the surface of the material enables microorganisms to bind and expand over time (Koca et al. 2012). It therefore may contributes in the transmission of pathogens due to reckless treatment of textiles. Metal nanoparticles (NPs) based textile can minimize the risk of spreading infectious diseases through controlling microbial transfer (Morais et al. 2016). Strategic implementation of metal-based nanoparticles into the textile as an antimicrobial agent (Paladini et al. 2015) may reduce the expansion and increase of microbial contamination in biomedical textiles. Beside this, most of the antimicrobial textile and agents may cause threat to the environment, if not disposed properly. Therefore, numerous research studies have concentrated on the processing of such textiles keeping the environmental protection strategy in mind (Goswami et al. 2017). Thus, some essential aspects for the production of antimicrobial textiles need to be adopted, including the use of low-cost material, biocompatibility, and the biodegradability of the material (Shahid-ul-Islam and Mohammad 2013). In this work, all these aspects have been coved during the development of antimicrobial ZnO NPs–cellulose composite i.e. efficient antimicrobial activity, low-cost substrate, easy and economic synthesis of NPs and no known toxic byproducts during degradation.

Almost all areas of human life have been improved in the field of nanoscience, and their potential developments have progressively gained momentum in the sectors such as healthcare (Andersen and Rasmussen 2006), pharmaceutics, cosmetics (Rai and Alves dos Santos 2017), electronic products, and textile industries. In nanotechnology, the material's reactivity can be significantly improved through its higher specific surface area, antibiotic efficiency, photocatalysis, and injury healing properties that are normally not noticed in its bulk materials (Marin et al. 2015). Cellulose is extensively used in such applications as it is renewable, low-cost, recyclable (Li et al. 2018) as well as one of the most readily available natural polymers (Benabid and Zouai 2016). Along with cotton, cellulose-based fibers are also being used in the textile industry and gaining importance because of the high demand for natural fibers and several other advantages over synthetic polymers. In this context, developing a ZnO-cellulose composite may be useful for the preparation of antimicrobial fibers to be used in the bandage, sanitary pads, napkins, undergarments, etc. ZnO-cellulose composites made up of cellulose fibers homogeneously coated by ZnO nanoparticles have been suggested to be an eco-friendly material (Park et al. 2019). ZnO has large exaction binding energy (60 meV) along with a wide bandgap of 3.37 eV. Cellulose fibers serve as micro-templates for the regulated development of nano-structured ZnO, and accumulation effects may also be prevented (Zhao et al. 2018). Since cellulose behaves like a very strong polymer, ZnO-cellulose nano-composites powder has been employed in various forms, such as pellets and paper films (Jawaid and Khalil 2011). Another important point is that ZnO is not harmful to human beings due to no toxic effect on human health, so its potential application in food industries and medical sectors is rapidly increasing (Gupta et al. 2015). ZnO NPs–cellulose composites may be produced through physical, chemical, or green fabrication techniques (Qiu and Netravali 2014). Physical methods, such as inert gas polymerization, physical vapor deposition, laser, and flame hydrothermal method, electronic spraying techniques, melt mixing, etc., are expensive and involve high-throughput instruments, while the chemical methods that use chemical compounds may generate toxic byproducts that can further cause harmful effects on the environment (Fakhari et al. 2019). The green or biological synthesis of ZnO NPs nevertheless, provides a sustainable, environment-friendly, economic, and time-saving approach with their diverse biomedical applications (Mirzaei and Darroudi 2017). The biological synthesis seems to be much safer than the chemical approach. It was also reported that the obtained nanoparticles have the expected stable hexagonal structures of high purity (Król et al. 2017). These eco-friendly, as well as biocompatible properties of ZnO NPs–cellulose composites, maximize their industrial applications (Madkour 2017).

Microbial synthesis of nanomaterials depends on the ability of microorganisms to withstand heavy metal toxic potential and synthesize nanomaterials by reducing metal ions to their metal oxide form (Yusof et al. 2019). Consequently, by following the usual bio-mineralization process, zinc-tolerant microbes may efficiently produce ZnO NPs (Jain et al. 2013). Some fungal species, especially wood degrading white tor fungus e.g. Phanerochaete chrysosporium may reduce heavy metal via the extracellular secretion of different biomolecules (Ojuederie and Babalola 2017). The present study aims to demonstrate synthesis of ZnO NPs using extracellular filtrate of a non-pathogenic white-rot fungus Phanerochaete chrysosporium, and simultaneous fabrication of ZnO NPs–cellulose composite for its potential application in various industrial, environmental and medical sectors.

Materials and methods

Microorganisms

Bacterial strains Staphylococcus aureus (MTCC-96) and Escherichia coli (MTCC-443); and fungal strains Aspergillus niger (MTCC-281), Geotrichum candidum (MTCC-3993) were procured from Microbial Type Culture Collection, Chandigarh, India. Wood degrading white-rot fungus Phanerochaete chrysosporium (BKM-F-1767) was received from the Centre for Forest Mycology Research, USDA, Madison, Wisconsin, USA.

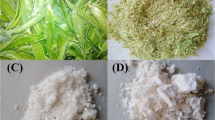

Extraction of cellulose from sugarcane bagasse

Sugarcane bagasse was ground and washed with distilled water to eliminate contaminants and impurities. This biomass was immersed in 3.5% NaCl solution for 24 h at 60 °C, then treated with 4% (w/v) NaOH for 2 h at 90 °C and washed several times. A bleaching process was carried out using 7.5 M H2O2 and 2.5 M NaOH for 24 h at 60 °C. This process was repeated three times until white pulp was obtained. HCl (1 M) was used for neutralization of the contents for 2 h at 80 °C (Alemdar and Sain 2008). The insoluble residue (cellulose) was collected by filtration, washed thoroughly three times with distilled water, and dried in an oven at 55 °C for 24 h (Lefatshe et al. 2017).

Synthesis of ZnO nanoparticles

Phanerochaete chrysosporium was inoculated in malt extract broth (150 ml) and incubated for 5–7 days, then filtered through Whatman filter paper No. 1. Zinc sulfate (ZnSO4·7H2O) solution (0.1 M) and sodium hydroxide (NaOH) solution (0.1 M) were prepared in distilled water. One hundred ml of filtrate was mixed with 100 ml of zinc sulfate solution, followed by drop-wise addition of sodium hydroxide till the appearance of white suspended nanoparticles and again it was incubated for 24 h at 27 °C. These synthesized nanoparticles were dried at 100 ºC for a further 24 h. This dried white powder was used for all the characterization and antimicrobial testing (Jain et al. 2020).

Preparation of zinc oxide nanoparticles-cellulose composites

ZnO NPs containing cellulose were fabricated by the addition of extracted cellulose fibers into P. chrysosporium filtrate (100 ml) containing zinc sulfate (0.1 M). pH 10 was maintained by addition of 0.1 M NaOH drop-by-drop. The flask containing these solutions was then kept on stirring for 24 h. Three different cellulose concentrations i.e. 1 g (1:1), 2 g (1:2), and 3 g (1:3) were used for the fabrication of ZnO NPs–cellulose composite. The composite prepared was thereafter allowed to dry in an oven at 100 °C and labeled as sample ‘A’, samples ‘B’, and sample ‘C’.

Characterization of ZnO NPs and ZnO NPs–cellulose composite

UV–Visible absorption spectra samples were measured using Shimadzu UV-2600 spectrophotometer. Fourier transform infrared (FT-IR) spectra were recorded from 4000 to 500 cm−1 using a Bruker ALPHA FT-IR spectrometer. Thermogravimetric analysis (TGA) tests were conducted on Shimadzu DTG-60H using heating point 20 °C min−1 from 30 to 600 °C in the flowing air region. The surface morphology of ZnO NPs was determined using a scanning electron microscope (SEM) (JSM-7600F; JEOL, Tokyo, Japan), while the detailed shape and size of ZnO NPs were determined using Transmission Electron Microscope (JEM-2100; JEOL, Tokyo, Japan) at an accelerating voltage of 200 kV. X-ray diffractograms (XRD) were analyzed by X-ray diffractometer (Panalytical X'pert powder).

Antibacterial activity

Agar well diffusion assay was carried out to evaluate the antibacterial activity of ZnO Nps and ZnO NPs–cellulose composite. Sterilized Luria–Bertani agar plates were inoculated by spreading 100 µl of pre-grown cultures (OD600 1) of Staphylococcus aureus or Escherichia coli. The wells (6 mm) were filled with 50 µl of the suspension having a varied concentration of ZnO NPs (from 0.1 μg L−1 to 200 μg mL−1) or ZnO NPs–cellulose composite (1:1, 1:2, 1:3). These plates were incubated for 24 h at 37 °C. The inhibition zone was measured and compared with the control (sterile distilled water).

Antifungal activity

The antifungal activity of ZnO NPs and ZnO NPs–cellulose composite was evaluated against A. niger, P. chrysosporium, and G. candidum. Varying concentrations of test samples were amended in Potato Dextrose Agar (PDA) media and poured aseptically into pre-sterilized Petri dish. The control dish contained only PDA. All the plates were inoculated with one agar disc at the center of the plate containing actively growing fungal culture from the margin of a 7 days old plate. These Petri plates were then incubated at 28 °C for 7 to 12 days. The diameter of the growing fungal colony was measured daily and compared with control. All the experiments were carried in triplicate and the mean values along with the standard deviation were represented as a result.

Results and discussion

Synthesis and characterization of ZnO nanoparticles

ZnO NPs were successfully synthesized using cell-free extracellular filtrate of 7 days old culture of P. chrysosporium. Optical characteristics of the synthesized particles indicated towards nano size of ZnO particles as the absorption bands represented a redshift with an absorbance peak at about 349 nm (Fig. 1) as recorded by UV–Vis spectrophotometer with the band gap of ZnO was about 3.55 eV. The biological synthesis of ZnO NPs has been encouraging in terms of its performance, eco-friendly methods, cost-effective, quick and mass improved productivity output (Fakhari et al. 2019). The chemical synthesis of ZnO NPs generally requires toxic chemicals, longer processing time, and requires sintering at high temperatures (Saini et al. 2019). On the other hand, the present green synthesis of NPs is rather easy, does not involve any toxic chemical, and excludes sintering. Different metallic nanoparticles have already been synthesized using white-rot fungi including P. chrysosporium (He et al. 2017). P. chrysosporium may produce different extracellular enzymes, proteins, and other compounds, which facilitate the synthesis of NPs. This fungus belongs to the Basidiomycetes and no associated pathogenicity has been reported to date. Further, the fungus has been widely used for industrial applications mainly for the production of extracellular lignocellulolytic enzymes (Liu et al. 2020). P. chrysosporium has another advantage as it may be grown on low-cost lignocellulosic waste (Sharma et al. 2010). Thus, in the present study malt extract broth was used as a production medium. Extracellular synthesis is more beneficial and preferable as compared to the intracellular approach. Other researchers have suggested that extracellular synthesis is a nitrate reductase-mediated synthesis, which is due to the reduction of metal ions to metal NPs (Yusof et al. 2019). As a result, Zn2+ gain the electron and reduced to ZnO. Consequently, this led to the formation of ZnO NPs. Lignin degrading extracellular oxidoreductase enzymes i.e. lignin peroxidase (LiP) and manganese-dependent peroxidase (MnP) are primarily produced by white-rot fungi including Cladosporium herbarum, Gloeophyllum sepiarium, and Phanerochaete chrysosporium(Yadav et al. 2010). All these enzymes along with other metabolites may act as a reducing agent during the synthesis of ZnO NPs.

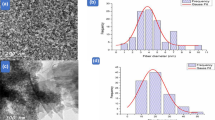

The FT-IR spectra of these particles showed the peaks in the region of 3848–3618 cm−1, which confirmed the presence of hydroxyl (O–H) groups. A characteristic peaks spectra of about 531 cm−1 and 2359 cm−1 point towards two ZnO transverse optical stretching modes (Fig. 2a). It was also revealed that the ZnO-NPs were stable by externally attached protein molecules that may prevent aggregation, as observed in peak 531 (Quadri et al. 2017). The considerable band broadening of the XRD peaks indicated that ZnO nanoparticles were present in the samples (Fig. 2b). Crystal structure, positioning, and size, full-width at half-maximum (FWHM) related data provided by XRD spectroscopy. It thus confirmed that the synthesized nanoparticles any other contamination as they did not show any X-ray diffraction peak characteristics other than zinc oxide, which matches with the JCPDS card no # 36-1451.

The TGA data for ZnO NPs revealed that the weight loss started in successive steps, along with an increase in temperature (Fig. 3a). The initial weight loss was up to 4.21% at 224 °C, while the second major loss was recorded in between 224 and 400 °C, with approximately 38.37%. There was no further decrease in weight up to 500 °C. The initial weight loss was due to the removal of water molecules adsorbed on the surface, while the subsequent weight loss might be due to the removal of hydroxyl groups (Mocanu et al. 2019).

Transmission electron microscopic (TEM) images and the Selected Area Electron Diffraction (SAED) trend are depicted for biosynthesized ZnO NPs in Fig. 3. NPs were found to be hexagonal with the particle size ranging from 5 to 200 nm (Fig. 3b). The SAED pattern confirmed that the ZnO NPs were crystalline and polydispersed (Fig. 3c). The SAED trend revealed that the d-spacing of the particles was 0.19 nm (Jain et al. 2020). The d-spacing estimated by the planes acquired by the SAED trends was further verified by the XRD analysis. SEM micrographs of the nanoparticles also confirmed the hexagonal form with the varied size of ZnO NPs (Fig. 4a).

Synthesis and characterization of ZnO NPs–cellulose composite

ZnO NPs–cellulose composite has been developed to provide a potential material for numerous applications based on recent research interests, development, and demand in the field. As bioactive materials for antibody immobilization, cellulose fiber sheets impregnated with saccharide capped-ZnO nanoparticles is being developed (Khatri et al. 2014). Active packaging materials based on carboxymethyl cellulose-chitosan-ZnO NPs nanocomposite has also been reported to increase the shelf life of bread (Noshirvani et al. 2017). The prepared ZnO NPs–cellulose composite has been characterized as reported in the present study.

The UV–Vis spectrometric spectrum of the ZnO NPs–cellulose composite with varying ratios of cellulose polymer along with pure ZnO NPs has been shown in Fig. 1. The composite spectra showed a distinguished absorption band at 352–365 nm, however, the results revealed that a sharp characteristic peak was declining as the concentration of free ZnO NPs were lower in the composite as compared to ZnO NPs suspension (Fu et al. 2015). The bandgaps for ZnO NPs–cellulose composites, 1:1, 1:2, and 1:3 were observed to be 3.52, 3.49, and 3.39 eV. This corresponding decrease in bandgap energy can be positively correlated with the increasing cellulose concentrations (Fig. 1b).

In the FT-IR spectrum of ZnO NPs–cellulose composite ratios 1:1, 1:2, and 1:3, few wide peaks were detected in the region from 3848 to 3618 cm−1, which represents the existence of hydroxyl (O–H) groups (Lefatshe et al. 2017). A peak at 2359 cm−1 was also observed in all the composites showing O=C=O stretching (Fig. 2). In the composite, an extreme peak attributed to the C–O stretching was observed in the region from 1045 to 1047 cm−1, which was absent in ZnO NPs (Lefatshe et al. 2017). XRD studies were performed to examine the crystalline property of the samples (Fig. 2b). The XRD cellulose results illustrated in the inset showed standard diffraction peaks at 2θ = 16.14°, 22.64° and 32.84° (Lefatshe et al. 2017), but such peaks were not observed in XRD graphs of ZnO NPs–cellulose composite except a peak at 22.64°. The peaks at 2θ = 31.81°, 34.46°, 36.29°, 47.57°, 56.63°, 62.89°, 66.41°, 67.98°, 69.12°, 72.60°, 76.99°, 81.41°, and 89.63°, referring to the diffraction of 100, 002, 101, 102, 110, 200, 112, 201, 004, 202 planes, indicating the existence of the hexagonal phase of zinc oxide (JCPDS: 00-036−1451) (Fu et al. 2017; Lefatshe et al. 2017) in composites. The amplitude of the crystalline cellulose peaks typically remained constant with a raise in cellulose concentrations; however, ZnO NPs peaks were reduced. Thus, XRD trends indicated that composites consist of varying amounts of cellulose and ZnO NPs. This shift in cellulose-specific peaks indicated a strong interaction between the ZnO crystals and the cellulose surface. This shift was also observed previously due to the interaction between ZnO and a polymeric matrix (Fu et al. 2017).

Thermogravimetric studies (TGAs) revealed that there was a minor weight loss (4%) in all the three formulations of ZnO NPs–cellulose composites (1:1, 1:2, and 1:3) below 100 °C due to the elimination of water molecules from the samples (Fig. 3a). These composites showed a huge weight loss between 278 and 336 °C due to the thermal degradation of cellulose leaving behind about 63% material. The initial difference between the thermal degradation of ZnO NPs–cellulose composites and ZnO NPs might be a result of the rapid disintegration of carbon skeleton bonding present in composite (Mocanu et al. 2019). At extremely high temperatures, however, ZnO NPs demonstrated superior thermal stability as compared to ZnO NPs–cellulose composites. Through the completion of the heating cycle, the overall weight loss of ZnO NPs–cellulose composites was 52.62, 65.81, and 69.28% for 1:1, 1:2, and 1:3, respectively.

Scanning electron microscope (SEM) images of the surfaces of ZnO NPs and ZnO NPs–cellulose composites are shown in Fig. 4. These micrographs confirmed the uniform coating of ZnO NPs on the cellulose fibers. The composition of ZnO NPs–cellulose composites as determined by EDX analysis revealed that the carbon signals refer to the natural polymer of the sugar cane cellulose. To consider the homogeneous distribution of the inorganic phase on the surface of the sugar cane cellulose substrate, compositional maps have been generated for atoms of interest: C as represented sugar cane cellulose and Zn for ZnO, O being typical for both (Fig. 5). As can be seen in all instances, the concentration of Zn may not demonstrate considerable gradients from one region to another, thus verifying the uniformity of inorganic particles on the surface of cellulose fibers. The extremely dispersive distribution of Zn, O, and C elements were observed with no other contaminants in all the synthesized composites despite the Au element, which was observed due to the coating on samples (Fig. 5). It was reported that the morphology of ZnO NPs was controlled by the size of cellulose fiber. However, in our study, the cellulose fiber size was not varied but the amount. This variation showed a direct effect on the antimicrobial activity of the composite as there was a difference in NPs/cellulose ratio. Different types of fibers/composites containing ZnO NPs have been developed in recent years through chemical and biological methods (Table 1). These composites have demonstrated different properties including antimicrobial, antioxidant, cytotoxic, UV protectant, and photocatalytic activity.

Antimicrobial properties of ZnO NPs and ZnO NPs–cellulose composite

Cellulose has readily modifiable hydroxyl groups thus may act as good support materials for fixing a wide range of antimicrobial agents. It is further advantageous in terms of performance stability, processing simplicity, non-cytotoxicity, and effective antimicrobial activity thus, developing durable and efficient biocompatible cellulose composites to meet the rising demand for diverse applications (Ahmad 2021).

The antibacterial property of the synthesized ZnO NPs and ZnO NPs–cellulose composites was determined against two prominent pathogenic bacteria i.e. E. coli (Gram-negative pathogen) and S. aureus (Gram-positive pathogen). ZnO NPs successfully inhibited both the bacteria at different concentrations. This inhibition was more prominent against S. aureus as compared to E. coli. S. aureus being more sensitive towards ZnO NPs was inhibited by its lowest concentration (0.1 µg/ml). Different ZnO NPs–cellulose composites showed the different pattern for S. aureus inhibition as 1:1, which contained the lowest amount of cellulose and the highest amount of NPs showed its inhibitory activity up to 0.78 µg/ml. Other composite 1:2 and 1:3 did not show any inhibitory effect at this concentration. However, both the samples were quite active in bacterial growth inhibition at higher concentrations (Fig. 6).

The growth of E. coli was inhibited by ZnO NPs and ZnO NPs–cellulose composites. E. coli could not tolerate ZnO NPs concentration beyond 6 µg/ml and inhibit by the higher concentrations to that. In all the cases it required a higher concentration of composites to inhibit its growth, while it could grow in the presence of all the concentrations of 1:3. Bacterial tolerance towards metals depends upon metal and bacterial species. The observed differences might be due to the difference in the structure and morphology of the cell membrane and cell wall of S. aureus and E. coli. Earlier the antibacterial effect of ZnO NPs on these bacteria has also demonstrated a similar pattern (Schwartz et al. 2012). Apart from plants, biodegradable bacterial cellulose produced by Gluconacetobacter xylinum has been studied for its antimicrobial potential after surface modifications by embedding ZnO NPs. However, it was observed that the composite was active only against the Bacillus subtilis, a Gram-positive bacterium (Mocanu et al. 2019). It was also observed in our study the antimicrobial effect of ZnO NPs–cellulose composite was prominent on a Gram-positive bacteria S. aureus as compared to Gram-negative E. coli.

ZnO NPs and ZnO NPs–cellulose composite demonstrated antifungal property against two pathogenic fungi A. niger and G. candidum along with a wood degrading fungus P. chrysosporium. However, none of these fungi could be inhibited by composite 1:2 and 1:3 ratios. A. niger and P. Chrysosporium were fast-growing fungi as compared to G. candidum and covered the whole plate in 7 days, while the latter one took about 14 days for the same. It was also observed that the growth of A. niger and P. chrysosporium were well inhibited by ZnO NPs and its cellulose composite, while G. candidum being less sensitive (Fig. 7). Antimicrobial properties of the composite, especially the activity against pathogenic and polymer degrading microbes further endorse the application of ZnO NPs coated textiles (Pintarić et al. 2020). ZnO NPs have also been found useful in the preservation of old documents and suggested to be used as an anti-biodeterioration agent for paper. The study further highlighted the role of cellulose-degrading fungus in the deterioration of paper mainly including Aspergillus niger. In the same lines, we have also evaluated the antifungal activity of ZnO NPs and ZnO NPs–cellulose composite against a cellulase and ligninase producing wood degrading fungus P. chrysosporium. And thus endorse the potential application of ZnO NPs against fungal deterioration of wood and paper (Fouda et al. 2019). Studies have also compared the coatings of nano-sized ZnO and micro-sized Zn salts were on the performance of linen fabric. There was no considerable change was observed in terms of physical properties, while functional efficiency and antimicrobial properties were better in nano-sized ZnO powders (Arik and Karaman Atmaca 2020).

Conclusion

Zinc oxide nanoparticles (ZnO NPs) were synthesized by extracellular filtrate of P. chrysosporium. ZnO NPs were homogeneously distributed over the cellulose exterior as hexagonal wurtzite. The process describes the synthesis of ZnO NPs–cellulose composite as a single-step synthesis instead of NPZ priming or coating, which might be advantageous in terms of time requirement, multistep handling, thus reducing the cost of production. Surface modification of cellulose increased the antimicrobial potential as ZnO NPs–cellulose composite (1:1) showed better anti S. aureus activity. Thus, ZnO NPs–cellulose composite and ZnO NPs were found to be the efficient antimicrobial agents against bacteria (E. coli and S. aureus) and fungi (A. niger, P. chrysosporium, and G. candidum). The results further highlight the importance of ZnO NPs containing cellulose fiber for its potential application in the development of antimicrobial cellulose-based fabric for diverse applications.

References

Ahmad H (2021) Celluloses as support materials for antibacterial agents: a review. Cellulose. https://doi.org/10.1007/s10570-021-03703-2

Alemdar A, Sain M (2008) Biocomposites from wheat straw nanofibers: morphology, thermal and mechanical properties. Compos Sci Technol 68:557–565. https://doi.org/10.1016/j.compscitech.2007.05.044

Andersen MM, Rasmussen B (2006) Nanotechnology development in Denmark - Environmental opportunities and risk. (Denmark. Forskningscenter Risoe. Risoe-R; No. 1550(EN))

Arik B, KaramanAtmaca OD (2020) The effects of sol–gel coatings doped with zinc salts and zinc oxide nanopowders on multifunctional performance of linen fabric. Cellulose. https://doi.org/10.1007/s10570-020-03322-3

Benabid FZ, Zouai F (2016) natural polymers: cellulose, chitin, chitosan, gelatin, starch, carrageenan, xylan and dextran. J Nat Prod 4:348–357

Dincă V, Mocanu A, Isopencu G et al (2020) Biocompatible pure ZnO nanoparticles-3D bacterial cellulose biointerfaces with antibacterial properties. Arabian J Chem 13(1):3521–3533

Elemike EE, Onwudiwe DC, Mbonu JI (2021) Facile synthesis of cellulose–ZnO-hybrid nanocomposite using Hibiscus rosa-sinensis leaf extract and their antibacterial activities. Appl Nanosci 11(4):1349–1358

Fakhari S, Jamzad M, KabiriFard H (2019) Green synthesis of zinc oxide nanoparticles: a comparison. Green Chem Lett Rev 12:19–24. https://doi.org/10.1080/17518253.2018.1547925

Fouda A, Abdel-Maksoud G, Abdel-Rahman MA et al (2019) Monitoring the effect of biosynthesized nanoparticles against biodeterioration of cellulose-based materials by Aspergillus niger. Cellulose. https://doi.org/10.1007/s10570-019-02574-y

Fu F, Li L, Liu L et al (2015) Construction of cellulose based ZnO nanocomposite films with antibacterial properties through one-step coagulation. ACS Appl Mater Interfaces 7:2597–2606

Fu F, Gu J, Xu X et al (2017) Interfacial assembly of ZnO–cellulose nanocomposite films via a solution process: a one-step biomimetic approach and excellent photocatalytic properties. Cellulose 24:147–162

Goswami L, Kim K-H, Deep A et al (2017) Engineered nano particles: nature, behavior, and effect on the environment. J Environ Manage 196:297–315. https://doi.org/10.1016/j.jenvman.2017.01.011

Gupta S, Kushwah T, Vishwakarma A, Yadav S (2015) Optimization of ZnO-NPs to investigate their safe application by assessing their effect on soil nematode caenorhabditis elegans. Nanoscale Res Lett 10:303. https://doi.org/10.1186/s11671-015-1010-4

He K, Chen G, Zeng G et al (2017) Applications of white rot fungi in bioremediation with nanoparticles and biosynthesis of metallic nanoparticles. Appl Microbiol Biotechnol 101:4853–4862

Jain N, Bhargava A, Tarafdar JC et al (2013) A biomimetic approach towards synthesis of zinc oxide nanoparticles. Appl Microbiol Biotechnol 97:859–869

Jain D, Shivani BAA et al (2020) Microbial fabrication of zinc oxide nanoparticles and evaluation of their antimicrobial and photocatalytic properties. Front Chem. https://doi.org/10.3389/fchem.2020.00778

Jawaid M, Khalil HPSA (2011) Cellulosic/synthetic fibre reinforced polymer hybrid composites: a review. Carbohydr Polym 86:1–18. https://doi.org/10.1016/j.carbpol.2011.04.043

Khatri V, Halász K, Trandafilović LV et al (2014) ZnO-modified cellulose fiber sheets for antibody immobilization. Carbohydr Polym 109:139–147

Koca O, Altoparlak U, Ayyildiz A, Kaynar H (2012) Persistence of nosocomial pathogens on various fabrics. Eurasian J Med 44:28–31. https://doi.org/10.5152/eajm.2012.06

Król A, Pomastowski P, Rafińska K et al (2017) Zinc oxide nanoparticles: synthesis, antiseptic activity and toxicity mechanism. Adv Colloid Interface Sci 249:37–52

Lefatshe K, Muiva CM, Kebaabetswe LP (2017) Extraction of nanocellulose and in-situ casting of ZnO/cellulose nanocomposite with enhanced photocatalytic and antibacterial activity. Carbohydr Polym 164:301–308. https://doi.org/10.1016/j.carbpol.2017.02.020

Li N, Chen W, Chen G et al (2018) Low-cost, sustainable, and environmentally sound cellulose absorbent with high efficiency for collecting methane bubbles from seawater. ACS Sustain Chem Eng 6:6370–6377. https://doi.org/10.1021/acssuschemeng.8b00146

Liu J, Yang J, Wang R et al (2020) Comparative characterization of extracellular enzymes secreted by Phanerochaete chrysosporium during solid-state and submerged fermentation. Int J Biol Macromol 152:288–294

Livingston E, Desai A, Berkwits M (2020) Sourcing personal protective equipment during the COVID-19 pandemic. JAMA 323:1912–1914. https://doi.org/10.1001/jama.2020.5317

Madkour HL (2017) Ecofriendly green biosynthesized of metallic nanoparticles: bio-reduction mechanism, characterization and pharmaceutical applications in biotechnology industry. Glob Drugs Ther https://doi.org/10.15761/gdt.1000144

Marin S, Vlasceanu GM, Tiplea RE et al (2015) Applications and toxicity of silver nanoparticles: a recent review. Curr Top Med Chem 15:1596–1604. https://doi.org/10.2174/1568026615666150414142209

Mirzaei H, Darroudi M (2017) Zinc oxide nanoparticles: biological synthesis and biomedical applications. Ceram Int 43:907–914. https://doi.org/10.1016/j.ceramint.2016.10.051

Mocanu A, Isopencu G, Busuioc C et al (2019) Bacterial cellulose films with ZnO nanoparticles and propolis extracts: synergistic antimicrobial effect. Sci Rep 9:17687. https://doi.org/10.1038/s41598-019-54118-w

Morais DS, Guedes RM, Lopes MA (2016) Antimicrobial approaches for textiles: from research to market. Mater (Basel, Switzerland) 9:498. https://doi.org/10.3390/ma9060498

Noorian SA, Hemmatinejad N, Navarro JA (2020) Ligand modified cellulose fabrics as support of zinc oxide nanoparticles for UV protection and antimicrobial activities. Int J Biol Macromol 154:1215–1226

Noshirvani N, Ghanbarzadeh B, Mokarram RR et al (2017) Novel active packaging based on carboxymethyl cellulose-chitosan-ZnO NPs nanocomposite for increasing the shelf life of bread. Food Packag Shelf Life 11:106–114

Ojuederie OB, Babalola OO (2017) Microbial and plant-assisted bioremediation of heavy metal polluted environments: a review. Int J Environ Res Public Health 14:1504

Paladini F, Pollini M, Sannino A, Ambrosio L (2015) Metal-based antibacterial substrates for biomedical applications. Biomacromol 16:1873–1885. https://doi.org/10.1021/acs.biomac.5b00773

Park T, Kim N, Kim D et al (2019) An Organic/inorganic nanocomposite of cellulose nanofibers and ZnO nanorods for highly sensitive, reliable, wireless, and wearable multifunctional sensor applications. ACS Appl Mater Interfaces 11:48239–48248. https://doi.org/10.1021/acsami.9b17824

Pintarić LM, Škoc MS, Bilić VL et al (2020) Synthesis, modification and characterization of antimicrobial textile surface containing ZnO nanoparticles. Polymers (Basel). https://doi.org/10.3390/POLYM12061210

Qiu K, Netravali AN (2014) A review of fabrication and applications of bacterial cellulose based nanocomposites. Polym Rev 54:598–626

Quadri TW, Olasunkanmi LO, Fayemi OE et al (2017) Zinc oxide nanocomposites of selected polymers: synthesis, characterization, and corrosion inhibition studies on mild steel in HCl solution. ACS Omega 2:8421–8437. https://doi.org/10.1021/acsomega.7b01385

Rai M, Alves dos Santos C (2017) Nanotechnology applied to pharmaceutical technology. Springer, Berlin Heidelberg

Roy S, Kim HC, Panicker PS et al (2021) Cellulose nanofiber-based nanocomposite films reinforced with zinc oxide nanorods and grapefruit seed extract. Nanomaterials 11(4):877

Saini A, Sharma JL, Sharma RK et al (2019) Zinc oxide derived from zinc (II)/acetoxime system: formation pathway and solar-driven photocatalytic and antimicrobial applications. J Sol-Gel Sci Technol 91(3):644–653

Schwartz VB, Thétiot F, Ritz S et al (2012) Antibacterial surface coatings from zinc oxide nanoparticles embedded in poly(N-isopropylacrylamide) hydrogel surface layers. Adv Funct Mater 22:2376–2386. https://doi.org/10.1002/adfm.201102980

Shahid-ul-Islam SM, Mohammad F (2013) Green chemistry approaches to develop antimicrobial textiles based on sustainable biopolymers—a review. Ind Eng Chem Res 52:5245–5260. https://doi.org/10.1021/ie303627x

Sharma RK, Chandra P, Arora DS (2010) Antioxidant properties and nutritional value of wheat straw bioprocessed by Phanerochaete chrysosporium and Daedalea flavida. J Gen Appl Microbiol 56(6):519–523

Wahid F, Duan YX, Hu XH et al (2019) A facile construction of bacterial cellulose/ZnO nanocomposite films and their photocatalytic and antibacterial properties. Int J Biol Macromol 132:692–700

Yadav RSS, Patel VK, Yadav KDS et al (2010) Lignin peroxidases of some indigenous ligninolytic fungi: secretion and enzymatic characteristics. Indian J Microbiol 50:132–138

Yusof HM, Mohamad R, Zaidan UH (2019) Microbial synthesis of zinc oxide nanoparticles and their potential application as an antimicrobial agent and a feed supplement in animal industry: a review. J Anim Sci Biotechnol 10:1–22

Zhao SW, Guo CR, Hu YZ et al (2018) The preparation and antibacterial activity of cellulose/ZnO composite: A review. Open Chem 16:9–20

Acknowledgements

JLS acknowledge financially supported by Manipal University Jaipur (Dr. Ram Das Pai Fellowship). The authors are also grateful to SAIF and CAF, Manipal University Jaipur for SEM, TGA, Uv-Vis, and FT-IR analyses.

Author information

Authors and Affiliations

Contributions

JLS conducted the experimental work and prepared draft of the manuscript, VD analyzed the data and interpreted the results, RKS conceptualized and supervised the work, and review and edited the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Sharma, J.L., Dhayal, V. & Sharma, R.K. White-rot fungus mediated green synthesis of zinc oxide nanoparticles and their impregnation on cellulose to develop environmental friendly antimicrobial fibers. 3 Biotech 11, 269 (2021). https://doi.org/10.1007/s13205-021-02840-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-021-02840-6