Abstract

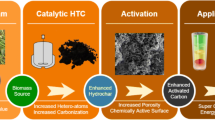

Hydrothermal carbonization (HTC) is a novel method to produce carbonaceous materials, which has been extensively concerned because of its environmentally benign and simple process. This review aims to introduce the approaches and mechanisms of carbonaceous materials prepared by hydrothermal carbonization from biomass in recent years, and discuss the applications of the functional materials transformed from carbonaceous materials. Specifically, the utilizations of various biomass raw materials, including carbohydrates, lignocellulose, and other biomass waste for the production of biochar are discussed. The significant parameter influence and mechanistic aspects of the hydrochar are critically analyzed to better understand the hydrochar formation process. More importantly, recent advances in hydrochar utilization techniques are summarized. Finally, we envision that the ideal designs of the biomass-based functional carbonaceous materials will open up a novel family of functional carbon materials with various applications towards a green and sustainable future.

Carbonaceous materials obtained from biomass via a hydrothermal route, and be used in various applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Since Kroto et al. [1] first discovered fullerene in 1985 and Novoselov [2] obtained graphene by stripping high-oriented graphite in 2004, the research of carbonaceous materials has become a worldwide upsurge. Due to the unique structure, carbonaceous materials have special properties and wide applications such as adsorption [3, 4], bioimaging [5, 6], catalysis [7, 8], and activated carbon synthesis [9,10,11]. These are promoting the development of materials science. The raw materials used to prepare carbon nanomaterials are mainly mesophase pitch. In recent years, non-asphalt materials such as biomass have become the new alternative feedstock. Biomass is a kind of energy resource with zero-carbon dioxide emissions, which complies with a requirement of green chemistry for the synthesis of carbonaceous material. Over the past couple of years, the utilization of hydrothermal technology to convert biomass into valuable carbonaceous materials has attracted much attention with the knowledge of the sustainability of natural resources.

Fundamentally, hydrothermal carbonization (HTC) is the process of converting biomass into various functional carbon materials under relatively mild hydrothermal conditions [12]. The insoluble or poorly soluble substances can be dissolved to decompose and convert to crystals under the hydrothermal conditions with a relatively high temperature and pressure environment [13]. As is known to all, the hydrothermal carbonization has several advantages, such as lower energy consumption and less emission over pyrolysis. It can provide the suitable environment for many reactions that cannot occur under normal conditions. The composition, morphology, size, and other properties of products can be adjusted by controlling reaction conditions, such as temperature, residence time, raw material concentration, and pH. This offers a variety of possibilities for carbonaceous materials.

Biomass refers to various organisms formed through photosynthesis, including animals, plants, and microorganisms. Biomass energy is the renewable resource that takes biomass as the carrier to store solar energy, which has been considered as one of the most important energy sources for human survival. After coal, oil, and natural gas, biomass energy plays an important role in the entire energy system, which is regarded as a potential energy source because of the advantages of low cost, cleanness, and environmental friendliness. Biomass waste comes from human production and consumption in the process of using biomass, which still belongs to the macroscopical category of biomass, but its energy density and availability have been significantly reduced. In 1913, Bergius and Specht [14] proposed the concept of hydrothermal carbonization for the first time to explore the formation mechanism of coal. They obtained some black residues with the O/C atom ratio of 0.1:0.2. Subsequently, Berl et al. [15] studied hydrothermal carbonization of cellulose at 250 to 310 °C in 1932. Schuhmacher et al. [16] found that the residues from hydrothermal carbonization of cellulose had the same chemical composition as that of glucose. Since then, scientists have been trying to prepare carbonaceous materials by hydrothermal carbonization from biomass or biomass waste.

It is well established that carbonaceous materials play important roles in promoting scientific and technological advancement because of their excellent structures and properties. Owing to the exceptional heat resistance, high thermal conductivity, and good chemical inertia, carbonaceous materials are widely used in metallurgy, chemical industry, machinery, electronics, aviation, and other fields. In recent years, with the shortage of fossil resources, the synthesis of carbonaceous materials from fossil resources is limited. It is imperative to find new alternative energy sources. Biomass resources are rich in carbon, which can replace fossil resources as raw materials for the preparation of various carbonaceous materials. This will be an important step towards environmental sustainability.

2 Hydrothermal carbonization of biomass

In the process of hydrothermal carbonization, water is both the solvent and catalyst to promote the hydrolysis and cracking of lignocellulosic biomass [17,18,19]. At high temperatures, water has a higher ionization constant and be used to hydrolyze organic compounds, which can be further catalyzed by acids or bases [20, 21]. During the process of hydrothermal carbonization, a decrease in pH is typically observed because of the formation of various organic acids such as acetic, formic, and lactic acids. These acids further promote hydrolysis for obtaining smaller fragments from oligomers and monomers. These series of processes can bring about a near-total disintegration of the physical structure of biomass. As the degree of reaction increases, the amount of colloidal carbon particles increases significantly. When the temperature and pressure rise to an appropriate level, about 1–5% of gas is usually produced, and most of the organic matter in the biomass feedstocks are converted to solids. The hydrothermal route for the conversion of lignocellulosic biomass into carbonaceous materials is shown in Fig. 1.

Titirici et al. [22] reported a direct synthesis of mesoporous carbons from crude plant material by hydrothermal carbonization. The conclusion showed that carbonaceous materials prepared from complex waste biomass were similar to peat or lignite in chemistry and spectroscopy. Instead of the assumption, the presence of other components in the plant had no interference in the reaction but promoted the formation of useful nanostructures. Likewise, Berge et al. [23] obtained analogous products through a hydrothermal route from municipal waste and further discussed their practicability in large-scale operations. These studies demonstrated that hydrothermal carbonization is a very promising thermo-chemical conversion technique, which can eventually transform biomass into value-added products. Among them, owing to their broad application prospects, the obtained carbonaceous materials have received considerable attention. Kang et al. [24] studied the formation of carbonaceous materials via a hydrothermal treatment of cellulose, lignin, d-xylose, and wood meal in the temperatures at 225–265 °C. They have found that the yield of hydrothermal carbon was about 45–60%, among which the yield from lignin was the highest, while that from d-xylose was the lowest. The different formation mechanisms of various hydrothermal carbons were also proposed [24]. In recent years, semi-carbonized substances could be prepared through the hydrothermal carbonization of plant or plant-based wastes such as lignocellulose under low temperature (170–350 °C). Since lignocellulose is a large classification of biomass, including lignin [25], cellulose [26], and hemicelluloses [27], the carbonaceous materials obtained from different compositions of biomass have been classified in the following sections.

2.1 Carbohydrates to hydrochar

During the hydrothermal process, the presence of hydronium ions will result in the hydrolysis of carbohydrates. In 2001, Wang et al. [28] firstly reported the synthesis of carbon microspheres by a hydrothermal method from glucose, which had controllable monodispersed particle size and high specific surface area, and the typical morphology of carbonaceous materials was a perfect sphere shape with uniform particle size. Afterwards, Mi et al. [29] successfully prepared the carbon microspheres with a regular shape, high yields, and narrow size distribution via the hydrothermal treatment of the glucose solution. They confirmed that the optimum reaction condition for preparing carbon microspheres was at 500 °C for 12 h. After determining the feasibility of preparing carbon materials from polysaccharides, the researchers shifted their attention to finding better methods to improve the structure and properties of carbonaceous materials. For instance, the carbon microspheres were prepared through a hydrothermal route from glucose by Liu et al. [30]. The particle size (0.5–0.8 μm) could be regulated by adding different amounts of oxalic acid.

Meanwhile, the other researchers found a novel route to modify the carbonaceous materials during the hydrothermal process. Compared with the modification of carbonaceous materials in the later stage, introducing functional moieties during the preparation process is much easier to control the porosities and surface functional groups, thereby improving the physical structure and chemical properties of materials. Demir-Cakan et al. [31] reported a handy hydrothermal method for the preparation of products loaded with carboxylic groups from glucose in the presence of acrylic acid. The final materials were mainly composed of amorphous carbon skeleton with high thermal and chemical stability, and the monomer introduced additional functional groups. Similarly, Zhang et al. [32] prepared the phosphorus-rich carbon microspheres (HCSs-PO4) through a hydrothermal method from glucose in the existence of phosphoric acid. Later, Zhang et al. [33] used NH4Cl as a nitrogen source to convert the carbon materials to N-doped carbon microspheres. Although the specific surface area of the N-doped carbon microspheres is lower, it exhibits a prominent increase (exceeding 3000 m2/g) after the activation of KOH.

Furthermore, with the explorations of the physical structure and chemical properties, researchers have tried to elucidate their formation mechanism for the purpose of providing a general guideline. According to Sevilla and Fuertes [34, 35], the brief formation mechanism of carbonaceous materials derived from polysaccharide can be concluded as follows: (1) the dehydration and cracking, (2) the polymerization and condensation, (3) the aromatization, and (4) the nucleation and subsequent chain propagation. Then, Falco et al. [36] further demonstrated that the chemical structure of hydrothermal carbon could be converted from polyfuran rich in oxygen-containing functional groups to aromatic carbon network by changing corresponding process parameters. Nevertheless, there are significant differences in the hydrothermal mechanisms of glucose and cellulose. The polyfuranic intermediate, which is specifically obtained from glucose, cannot be separated from cellulose-derived carbonaceous materials [36]. Later, Knežević et al. [37] confirmed the aforementioned assumption. Additionally, the carbonaceous material obtained in this process has more nanopores and a larger specific surface area. Sun and Li [38] observed that the diameter of carbon microspheres obtained by hydrothermal carbonization was affected by reaction time, temperature, and initial concentration. The formation mechanism of carbon microspheres was consistent with the LaMer model.

Fructose is an isomer of glucose, which exists in fruit juice and honey in a free state. It is also used to prepare carbonaceous materials by hydrothermal carbonization from waste fruits, contributing to waste utilization and environmental protection. Yao et al. [39] obtained colloidal carbon spheres by hydrothermal carbonization from aqueous monosaccharide solutions and found that fructose firstly formed 5-hydroxymethyl-2-furaldehyde (HMF) during the dehydration at 120–140 °C. After polymerization, the large spheres with granular surface morphology were assembled from carbon microspheres. The conclusions are in good agreement with that of Zhang et al. [40], who used fructose as a precursor to prepare the carbon spheres by a simple hydrothermal method, and then proposed a four-step formation mechanism carbon spheres. In step 1, fructose was transformed into HMF via the partial dehydration. Then, HMF monomers assembled a 3D network structure by releasing water molecules in step 2. Subsequently, the polymeric embryos formed solid primary particles by precipitation in step 3. Finally, the primary nanoparticles were aggregated by a polycondensation reaction to growing the micro-sized spheres in step 4 [40].

In addition to glucose and fructose, sucrose formed by dehydration condensation reaction from one molecule of glucose and fructose can also be used as a raw material for hydrothermal charcoal. Qi et al. [41] successfully prepared the carbon spheres with small particle size and narrow size distribution through a hydrothermal treatment from sucrose. Meanwhile, they schematically introduced a novel three-step formation mechanism of carbon spheres from sucrose. Similar to the conclusions mentioned above, the mechanism for the preparation of carbon materials from sucrose combined the formation mechanisms of that from glucose and fructose.

2.2 Lignocellulose to hydrochar

2.2.1 Cellulose

As the major component of biomass, cellulose is the polysaccharide composed of glucose and has attracted widespread attention. Currently, the preparations of carbonaceous materials by hydrothermal carbonization from cellulose have become riper. Sevilla and Fuertes [35] produced the highly functional carbonaceous materials through a hydrothermal route from cellulose at 220–250 °C and proposed that the formation of hydrochars from cellulose took place via the following steps: (1) hydrolysis of cellulose, (2) dehydration and cracking of the monomers into soluble matters, (3) further polymerization and condensation, (4) aromatization of the polymers, (5) appearance of nucleation, and (6) the subsequent chain propagation from the solution to the nuclear surface. Consequently, the formation mechanism of the carbonaceous materials by hydrothermal carbonization from cellulose fundamentally accorded with the path of the dehydration process, which was similar to the formation mechanisms of carbohydrates, such as glucose and sucrose [34, 35, 41]. Figure 2 shows the hydrothermal formation mechanism from cellulose [42].

Hydrothermal formation mechanism from cellulose [42]

On the other hand, the effect of reaction conditions on the hydrochar was also studied. Lu et al. [43] discussed the influence of reaction conditions on the formation and properties of hydrochar of cellulose. It was found that reaction time and the temperature had the greatest effects on the hydrochar, and the maximum conversion efficiency occurred in the first 8 h. Moreover, the effects of the acidic conditions on the reaction were studied by García-Bordejé et al. [44]. The hydrochloric acid greatly changed the properties of carbonaceous materials, which was conducive to hydrolysis and deoxygenation. In addition, Wu et al. [45] prepared Ni-doped spherical mesoporous carbon materials by a one-step hydrothermal treatment from cellulose with nickel acetate as Ni source. The results indicated that the mesoporous ratio increased with the increment of the Ni content.

2.2.2 Hemicelluloses

Hemicelluloses are the polysaccharides composed of different monosaccharides, which are usually used to prepare films and hydrogels, but there is still much weakness in them. The hydrothermal carbonization provides a novel route for high-value-added utilization of hemicelluloses. Falco et al. [46] advocated using the recovered hemicellulose hydrolysis products (both spruce and corncob) to prepare the precursor of functional carbon materials via a hydrothermal method. The obtained materials were interconnected microspheres, and the morphology and chemical structure were also completely characterized to extrude the similarities with glucose-derived carbon materials. Afterwards, Wang et al. [47] obtained well-shaped carbonaceous spheres with large surface area via an improved hydrothermal method from hemp stem hemicelluloses.

Furthermore, hemicelluloses can be easily hydrolyzed into xylose, which can be transformed into the other value-added product. Such a conclusion has been already drawn by Cheng et al. [48], and the carbon microspheres with controllable morphologies could be prepared via hydrothermal carbonization of xylose, which had an average size of 620 nm. Kim et al. [49] also upgraded the characteristics of hydrochar from xylan and investigated the chemical properties and suitability of the fuel products. The formation channels of hydrochars derived from d-xylose are shown in Fig. 3 [42].

Brief formation mechanism of hemicellulose (d-xylose) to hydrochar [42]

2.2.3 Lignin

As the second-largest renewable raw material, lignin can also be used as a precursor for the preparation of hydrochars. Although it is difficult to be completely hydrolyzed at typical hydrothermal carbonization temperatures, partial hydrolysis could take place at 200 °C [50]. As reported by Dinjus et al. [51], dissolved lignin could be polymerized into microspherical carbonaceous materials. Sangchoom and Mokaya [52] not only prepared the renewable carbonaceous materials through a hydrothermal route from lignin waste but also discussed the performance of materials as superior sorbents. Meanwhile, Wikberg et al. [53] investigated structural and morphological changes in Kraft lignin during the hydrothermal process. The solid yields and carbon recovery of products increased in the presence of H2SO4. Recently, Mao et al. [54] obtained spherical hydrochars from enzymatic hydrolysis lignin and explored the effects of reaction conditions on the morphology of the products. The optimal hydrothermal condition was at 270 °C for 7 h with a reaction concentration of 0.06 g/ml to obtain carbon spheres with a particle size of 3–6 μm. During the hydrothermal process, hydrolysis and cleavage of the C–O–C and C–C bonds, alkylation, condensation, and demethoxylation are the major reactions [55, 56]. The cleavage of the β–O–4 ether bonds occurs first in the reaction, while the aromatic rings have no effect during the hydrothermal process. In summary, the preparation mechanism of carbonaceous materials from lignin involves cleavage of the weak bonds, elimination of functional groups, and carbonization. Figure 4 presents a brief formation mechanism of hydrochars obtained from lignin [42]. There are two reaction pathways to form hydrochar via liquid state and solid state, and the phenolic hydrochar may exist on the surface of polyaromatic hydrochar obtained from the undissolved part of lignin.

Simple formation mechanism of lignin to hydrochar [42]

2.3 Other raw materials to hydrochar

Moreover, untreated raw materials also can be directly used to prepare carbonaceous materials. Aquatic microalgae mainly consist of proteins, carbohydrates, fats, and nucleic acids in different proportions [57]. They have promising prospects in the fields of food, medicine, genetic engineering, and liquid fuel. For example, the nitrogen-doped carbonaceous materials with high nitrogen content were obtained by Falco et al. [58] via a one-step hydrothermal method from microalgae. The resulted materials showed a typical morphology of spray-dried Spirulina platensis globular particles with an average size of several micrometers, and also had a concave bottom surface and a relatively smooth texture. Currently, Méndez et al. [59] used macroalgal wastes to prepare hydrochars through a hydrothermal route. The results showed that the products retained most vegetal structures and displayed mesoporous and macroporous nature. Besides, the available water and phosphorous content of materials increased with the degree of HTC, which was suitable for growth media components.

As a kind of agricultural waste, sugarcane bagasse can also be the raw material for the preparation of carbonaceous materials. For instance, Rattanachueskul et al. [60] successfully prepared a new magnetic material via hydrothermal carbonization of sugarcane bagasse at 230 °C. The composites exhibited the hierarchical structure, good magnetic properties, and excellent chemical stability in a wide pH range. In addition, waste fruits, cores, and shells are also potential raw materials. The hierarchical porous carbonaceous materials were successfully prepared through a hydrothermal method from waste Lentinus edodes by Tang et al. [61]. Furthermore, Wataniyakul et al. [62] prepared materials via hydrothermal carbonization of defatted rice bran and discussed the effects of temperature and time on the yield and the chemical characteristics.

In addition to plant waste, animal and human excreta can also be used as a carbon source to prepare hydrothermal carbon, reducing environmental load. For example, Lang et al. [63] used swine manure as a carbon source to prepare hydrochars by CaO assisted under a hydrothermal condition and discussed their properties. The results indicated that the pH, yield, and phosphorus content were significantly increased by the addition of CaO. Meanwhile, owing to the polar functional groups and porosity, the products had excellent hydrophilic property, which enhanced the exchange between soil and hydrochars as soil amendment. Yahav Spitzer et al. [64] presented a novel route for reuse of human excreta via hydrothermal carbonization and explored potential applications of the solid products and aqueous phase. In addition to the above, the hydrochars derived from different feedstocks by hydrothermal carbonization are shown in Table 1.

After discussing the carbonaceous materials synthesized from different biomass sources by hydrothermal carbonization, the different mechanisms and chemical compositions would affect the structure and properties of the obtained carbonaceous materials, which further influence their practical application. Afterwards, the effects of several hydrothermal parameters on the carbonaceous materials will be discussed in the following section.

3 Hydrothermal carbonization parameters

Parameters such as temperature, pressure, residence time, and substrate concentration are identified as the crucial parameters to determine the properties of products [65, 75].

3.1 Temperature

The temperature is the most vital parameter in hydrothermal carbonization reaction because it represents the main factor of the water properties leading to the ionic reaction in the subcritical region. The breakage of different chemical bonds will happen in the polymers with the rise of temperature, also the release of volatile compounds and the rearrangement reactions of residues, all of which are the primary decomposition reactions. Then, the further conversion reactions of some unstable volatile compounds are defined as the secondary reactions [76]. Two levels of decomposition mechanisms of lignocellulose by the pyrolysis process are illustrated in Fig. 5. As the temperature increases, the effectiveness of biomass conversion has an increasing trend since the temperature transfers the extra energy to destroy the biomass bonds [77].

The H/C and O/C atomic ratios can express the change of products under different temperatures. For example, Parshetti et al. [78] used empty palm fruit bunches as the carbon source to prepare carbon materials at 150 °C, 250 °C, and 350 °C, respectively. With the temperature increasing, the results of H/C and O/C atomic ratios generally decreased because of decarboxylation and volatile matter reduction [79]. Meanwhile, similar tendencies were observed from other biomass such as starch [24], municipal solid waste (MSW) [80], and sewage sludge (SS) [81].

On the other hand, the yield of the product usually decreases as the temperature increase. Hoekman et al. [82] obtained a decrease result in product yield from the mixture of Jeffrey pine and white fir as the temperature increased from 215 to 255 °C. The predominant reason might be the conversion of total organic carbon, including sugars and organic acids in solution. The research conducted by Sun et al. [83] indicated that the solid yields of the product were extremely high at temperatures below 200 °C. Meanwhile, the solid yield increased in the temperature range of 200–250 °C but decreased at 280 °C. Zhang and Wang [84] reached similar conclusions that the solid yield decreased with increasing temperature. In order to explore the effect of temperature on product distribution, a lot of researches have been carried out in recent years [85, 86].

Additionally, it is observed that temperature is also a significant parameter affecting the morphology of the obtained materials. As shown in Fig. 6, cellulose was through a hydrothermal treatment at a low temperature (160 °C), the fibers of products were still intact and arranged in the characteristic cellulose network. Upon increasing the temperature at 220 °C, spherical particles began to form, which were similar to the HTC materials obtained from glucose. However, the overall morphology is not as uniform as for simple sugars. Meanwhile, higher temperature will cause more pore structures in the obtained materials due to the release of more volatile matter from the biomass, which, in turn, increases the surface area.

Scanning electron micrographs of hydrothermal carbons obtained from cellulose at 160 °C (a, b) and 220 °C (c, d) [36]

3.2 Residence time

During the hydrothermal process, residence time also plays a significant role in the degree of reaction, the distribution, and properties of materials. The slow or conventional reaction with a residence time ranging from a few minutes to several days at moderate temperature is mainly beneficial to the production of hydrochar [87]. Compared with the temperature, the influence of residence time on solid yield is similar but relatively weak. The solid yield is high when the residence time is short, and it decreases with the extension of residence time. Because a long residence time leads to the polymerization of dissolved fragments in the liquid phase, which results in the secondary products with a polyaromatic structure [24, 88].

Furthermore, the residence time also determines the size of materials because it can result in excessive polymerization. Romero-Anaya et al. [89] prepared spherical carbons from abundant and cheap carbohydrates. As the residence time increased, the resulting carbon microspheres were more dispersible (Fig. 7). The results showed that long residence time determined the morphology of products. The residence time has a great influence on the reaction end point, specific surface area, and pore volume, due to the structural melting, elemental realignment, and shrinkage [90].

Hydrothermal carbon obtained from glucose and saccharose with different residence times. a, b For 12 h. c, d For 24 h. e, f For 48 h [89]

3.3 Substrate concentration

The high substrate concentrations are likely to reach higher product yields during the HTC reaction, whereas few studies put particular emphasis on the effects of substrate concentrations. Knežević et al. [91] proposed that a rapid polymerization reaction occurred with a high initial concentration of glucose. In a relatively short residence time, the higher substrate concentration will result in polymerization, leaving most of the reactant unhydrolyzed. Meanwhile, Sevilla and Fuertes [35] reported that less condensed products with high O/C and H/C atomic ratios appeared at a higher substrate concentration because of incomplete hydrolysis.

Moreover, insufficient polymerization of soluble products will cause a decrease in the aggregation of solid products, which can be deduced directly from the particle size of microspheres. For instance, Sevilla et al. [9] and Sevilla and Fuertes [35] suggested that the smaller microspheres would form as the substrate concentrations of cellulose increased. However, the type of raw materials may leverage the final results. The size of microspheres increased at higher substrate concentration when easily dissolved substrates were directly used, such as glucose and sucrose [35, 92]. The results reported by Romero-Anaya et al. [89] also advocated this theory. They observed an increase in the size of microsphere when the substrate concentration increased from 0.8 to 1.6 M. A higher degree of polymerization can be obtained by dehydration and condensation at a high concentration, which may further increase particle size.

4 Applications of the biomass-based functional carbonaceous materials

The most attractive feature of the conversion from biomass by hydrothermal carbonization depends on the superiority which represents a green, cost-effective, and upgradable technology. The biomass-based functional carbonaceous materials have various practical applications in the fields of catalysis, adsorption, energy storage, and so on. In the subsequent sections, the applications of carbonaceous materials derived from biomass will be introduced.

4.1 Catalysis applications

In the chemical industry, due to the high catalytic activity and selectivity, metals or metal compounds are commonly the most advanced catalyst, especially precious metals, but they tend to consume more energy [93]. The biomass-based functional materials, exhibiting environmental acceptability and good industrial application, can be powerful substitutes for some industrial chemical products. For example, carbonaceous solid acid is the typical metal-free catalyst, which is widely used in various acid-catalyzed chemical reactions, such as hydrolysis, dehydration, and esterification [94,95,96].

A new-type strong acid catalyst based on carbon was obtained by Liang and Yang [94], who used a hydrothermal method from glucose with a higher yield under the milder conditions. Afterwards, Qi et al. [97] prepared carbonaceous materials by hydrothermal carbonization of glucose, which were functionalized in situ with –SO3H or –COOH groups. The material exhibited great catalytic activity as a solid acid catalyst for the hydrolysis of cellulose. Moreover, they also obtained a similar carbonaceous microsphere via the hydrothermal route from glucose for the catalytic dehydration of fructose. The results showed that the catalytic capability is suitable for a high concentration of fructose, up to ca. 10 wt% with the yield of 5-HMF above 75.8%. After separating the product 5-HMF with ethyl acetate, it can be reused for 5 times without significant loss of activity [98]. Similarly, the carbonaceous materials with different morphologies and sizes were prepared through a hydrothermal treatment of glucose by Wen et al. [99], which were utilized as an efficient metal-free carbo-catalyst enriched with specific oxygenated groups. Carbo-catalyst containing carbonyl and hydroxyl groups could be used for nitrobenzene reduction reaction, and hydrothermal carbon enriched with carboxyl groups exhibited more superior catalytic activities than conventional solid acid in the Beckmann rearrangement reaction of cyclohexanone oxime. In a recent study, the catalyst was further obtained from hydrochars by sulfuric acid from defatted rice bran and showed higher catalytic activities on cellulose hydrolysis than the commercial sulfonated solid Amberlyst 16 WET catalyst [62].

Besides, the hydrothermal carbon materials can also be used as catalyst support. The catalyst support is the skeleton of catalyst, which can support the active component, disperse the active component, and increase the strength of the catalyst. Carbon support is the potential alternative to metal oxides because the surfaces can be upgraded by proper functionalization, and the surface areas can be increased via physical and chemical treatment [100]. For instance, Joo et al. [101] reported a simple method to prepare graphitic porous (GP) carbon by hydrothermal carbonization of non-toxic and economical carbon source (sucrose) under the relatively low temperature. The highly graphitic nature of GP carbon exerted a positive effect on the catalytic function of supported Pt catalyst, which resulted in a higher catalytic activity in methanol electro-oxidation. Moreover, Wataniyakul et al. [102] determined the suitable hydrothermal conditions for the preparation of carbonaceous material from glucose. The material was used as a catalyst carrier for sugar and cellulose conversions, which could provide a stable carbon support after sulfonation. After sulfonation, the total acidity of materials increased by 20%, which caused a decrease in catalytic activity for the hydrolysis of cellulose and the dehydration of fructose.

As mentioned above, as the substitutes for inorganic catalysts, the biomass-based carbon materials have achieved remarkable development and valuable results. They exhibited excellent catalytic activities in multifarious chemical reactions and had great advantages in green chemistry and ecological protection. However, considering the harsh reaction conditions, high production costs, and low selectivity, there are still some deficiencies in catalytic selectivity and industrial applications that need to be improved.

4.2 Energy storage applications

After the excessive consumption of fossil fuels caused a serious global energy crisis, a well-established strategy is purposed for disposing to store and use cleaner, low-cost, and renewable energy resources, such as wind, solar, and biomass [103]. Capacitor and lithium-ion batteries are popular in energy storage devices. Since the carbonaceous materials enriched many functional groups could greatly improve the pseudo-capacitance, the biomass-based functional materials are also an advantageous choice for electrode materials of capacitors. Furthermore, a great deal of electrochemical inert functional groups can enhance the wettability of electrodes, thereby improving the specific capacitance through the increase of utilization and porosity [104]. Most especially, the oxygen-containing functional groups can prevent further oxidation under a wide range of potentials, hence improving the cycle stability of the electrode material [105].

For example, Falco et al. [46] reported a hydrothermal method to prepare functional carbonaceous materials from hemicellulose hydrolysate. The materials showed a greatly high porosity (pore volume ≈ 1.0 cm3/g), mostly composing of micropores (90% of total pore volume). Therefore, the materials were further tested as electrodes for supercapacitors with potential results (300 F/g at 250 mA/g) and demonstrated the high suitability for electric double-layer supercapacitors. Moreover, Liu et al. [106] successfully prepared the carbonaceous materials (HPGC) with 3D hierarchical and interconnected honeycomb-like structure, and they used pomelo peel as the raw materials through a hydrothermal route and followed KOH activation procedure. Then, as the as-assembled symmetric supercapacitors, the materials exhibited high gravimetric/volumetric capacitance, excellent rate capability, and cycling stability.

Nowadays, carbonaceous materials are often doped with some special functional groups such as nitrogen-containing groups, boron-containing groups, and carboxyl groups. These special functional groups can improve the mechanical and electrical properties of materials, such as oxidation resistance, electrochemical efficiency, chemical reactivity, mechanical properties, and super capacitor performance.

For instance, the mesoporous carbonaceous materials doped with nitrogen via the hydrothermal soft-templating process were obtained by Hu et al. [107], who used d-fructose and dicyandiamide as a precursor. They demonstrated and clarified the effects of nitrogen doping as a mesoporous carbon electrode on supercapacitor performance. When the N-doping amount was controlled to 6.0 wt%, the compromise was achieved between the specific surface area, electrical conductivity, and redox reactions, thereby obtaining the highest electrical capacitance. Similar studies were reported by Ren et al. [108], and the N-doped carbons were obtained via hydrothermal carbonization of macroalgae, which could be utilized as electrodes for supercapacitors. The materials showed a good perspective in applications for carbon capture, oxygen reduction reaction, and supercapacitor. Among them, the supercapacitor exhibited excellent cycling stability with capacitance retention highly up to 98% at 2 A/g even after 10,000 cycles (Fig. 8).

The capacitive performance of NAC-800-based supercapacitor in 6 M KOH. a CV curves at different scan rates. b GCD curves at different current densities. c Nyquist plot and inset of the enlarged high-frequency region. d Long-term cycling stability at 2 A/g for 10,000 cycles [108]

As described above, the biomass-based functional carbonaceous materials showed various advantages in energy storage applications, due to the rich functional groups, high porosity, and easy contact of electrolyte ions. However, there are still many aspects that need us to improve and break through. Firstly, due to the insolubility of natural biomass, it is difficult to control the morphology and structure of the resulting materials based on the solution method. Secondly, the purified biomass derivatives can obtain relatively pure materials but the cost is higher. Finally, due to the volatility of certain surface functional groups, biomass-based carbonaceous materials have poorer cycle performance in supercapacitors and batteries than conventional carbon materials.

4.3 Adsorption applications

In the past few years, people have made a lot of effort to solve the environmental pollution problems, in which activated carbons play important roles in the removal of heavy metals and organic pollutants. The special adsorption of contaminants by hydrothermal carbon is attributed to the distribution of porous structures, high specific surface areas, and enhanced surface chemistry properties. The validity of adsorption also depends on other factors such as hydrophobicity, alkalinity, ion exchange capacity, and elemental composition [109, 110]. The hydrothermal carbon prepared at 180 °C without heat treatment and surface activation had a relatively limited pore structure, but the oxygen groups can not only promote adsorption but also facilitate further surface modification. However, since the single carbohydrate is usually used as the carbon source for hydrothermal carbon, the number of oxygen groups is very limited on the surface of hydrothermal carbon. The materials have no significant adsorption for heavy metal ions (including uranium and other radionuclides) and organic pollutants, which limits their further utilization in the field of adsorption applications. In order to overcome these disadvantages, the adsorption performance of hydrothermal carbon was improved through the modifications [28, 111, 112].

As mentioned above, the carbonaceous materials loaded with carboxylic groups were obtained by Demir-Cakan et al. [31] from glucose in the presence of acrylic acid. The results indicated that the material has a significant improvement in the adsorption properties of heavy metal ions such as Pb2+ (351.4 mg/g) and Cd2+ (88.8 mg/g). Similar conclusions were supported by Qi et al. [111], who used the materials as the adsorbent for the water-soluble ionic liquid (1-butyl-3-methyl-imidazolium chloride). The microspheres with low surface area (ca. 20 m2/g) exhibited adsorption capacity comparable to commercial activated carbon, which can be attributed to the presence of a high content of polar oxygenated groups, such as –OH, –C=O, and –COOH. In addition, Krstić et al. [112] prepared the precursor of activated carbon through a hydrothermal route from fructose and glucose and discussed the detailed characterization. The good removal of the heavy metal ions (~ 47–59 mg/g for Pb2+, ~ 21–27 mg/g for Cd2+, and ~ 6–10 mg/g for Zn2+) and fast (~ 10–30 min) removal of methylene blue (~ 60–200 mg/g) were also be determined. Finally, the results showed that activated carbons posed the potential to be utilized as filter materials for tailing collector.

The hydrothermal carbonaceous materials from biomass wastes can also be used as adsorbents. For example, Islam et al. [113] prepared the carbonaceous material through a hydrothermal route from factory-rejected tea, which was used as a precursor for activated carbon to remove methylene blue (487.4 mg/g) from aqueous solution. Recently, Bibaj et al. [114] prepared activated carbons via pyrolysis and hydrothermal treatment from banana peels for the removal of nickel ions. Khan et al. [115] also successfully obtained nitrogen-doped, mesoporous, and paramagnetic hydrochar (mSBHC-N) by hydrothermal carbonization from sugarcane bagasse, which were used for the removal of post-transition and transition heavy metals, such as Pb2+ and Cd2+ from aqueous environment.

Nuclear industrial wastewater is a kind of highly saline wastewater with trace amounts of radioactivity. The treatment of nuclear industrial wastewater is still a difficult problem to be solved urgently in the world. For instance, the preconcentration techniques developed for uranium are based on the physical, physics-chemical, and chemical principles, including precipitation, solvent extraction, ion exchange, and adsorption [116]. Activated carbon is widely used in the process of separation and purification for the nuclear industry due to its advantages of selective adsorption, high radiation stability, and high purity. The researchers tried to utilize the biomass-based functional carbonaceous materials as adsorbents in the treatment of nuclear industry wastewater.

Zhang et al. [117] discussed the ability of oxygen-rich carbon spheres prepared through a hydrothermal route from glucose for the adsorption of uranium (U(VI)) from aqueous solution. The results demonstrated the adsorption process of materials towards uranium was feasible, spontaneous, and effective. Complete removal (99.9%) of U(VI) from 1.0 L industry wastewater containing 15.0 mg U(VI) ions was possible with 3.0 g of materials. Afterwards, Cai et al. [118] further demonstrated that the carbon microsphere with abundant carboxyl groups had high adsorption capacity for U(VI) (163 mg/g), which were prepared by hydrothermal carbonization from glucose and further calcination. More recently, Han et al. [119] prepared the hydrothermal carbon with a huge amount of carboxyl groups via a hydrothermal method in the presence of acrylic acid, which was used for the highly efficient removal of uranium. The adsorption capacity of U(VI) on the obtained materials reached 197.7 mg/g, which was 9-fold higher than that of raw glucose-derived hydrochars.

The hydrochar applications for the adsorption of heavy metals and dyes are summarized in Table 2. On the basis of above discussion, it can be seen that the biomass-based functional carbonaceous materials show excellent performance in the field of adsorption application. However, since natural biomass is mostly a mixture, the product are heterogeneous and complex, which hinders the improvement of the adsorption performance. In addition, some pollutants may release to the environment inevitably, leading to secondary pollution. Therefore, in order to prevent secondary pollution, subsequent work should focus on the development of suitable and sustainable carbonaceous materials to reduce the release of pollutants in the adsorption process.

4.4 Other applications

In addition to catalysts, adsorption, and energy storage, the biomass-based hydrothermal carbonaceous materials can be utilized in many other fields, such as agriculture, biomedicine, and magnetic application. In agricultural production, charcoal is often added to soil as a carbon sink to improve soil productivity. As a substitute for charcoal, the biomass-based hydrothermal carbon has the advantages of choosing non-traditional carbon sources, such as animal manure [130], sludge [131], and microalgae [132]. Furthermore, photoluminescent carbon dots are novel biocompatible nanomaterials, which can be prepared from biomass, bringing great hope for the modern nanobiomedicine. Mehta et al. [133] prepared fluorescent carbon dots through a facile green hydrothermal route from apple juice. The materials were used as alternative biocompatible fluorescent probes for imaging of Mycobacterium and fungal cells. The carbon dots can also be prepared from flowers [134, 135], leaves [136, 137], and fruits [138, 139]. Recently, the biomass-based hydrothermal carbon has been used as the precursor of magnetic carbon nanocomposite because of its high surface area, controlled nanosizes, material stability, and magnetic properties [140]. Only a small part is mentioned here, there are still more possibilities for biomass-based carbonaceous materials to be explored.

5 Conclusions and outlooks

As an important component of clean energy, biomass can produce various useful chemicals, fuels, and functional materials. Hydrothermal carbonization is considered as one of the most effective methods to prepare carbonaceous materials with high-quality morphologies. Currently, there are mainly two ways to produce carbonaceous materials using hydrothermal carbonization, and this article focuses on the facile single-pot hydrothermal process. The existing approaches and technologies for the conversion of biomass into functional carbonaceous materials by hydrothermal carbonization are introduced. The different biomass raw materials in hydrothermal carbonization are firstly summarized, and the formation mechanisms of carbonaceous materials from biomass in the hydrothermal process are illuminated roughly. Subsequently, the effects of hydrothermal conditions on the products were briefly discussed. Temperature is the most vital parameter in the hydrothermal process because it is the key to cause the ionic reaction and further affects the yield and properties. The residence time also plays an important role in the degree of reaction and in the distribution and properties of products. Then, the extensive applications of biomass-based functional carbonaceous materials in catalysis, energy storage, and adsorption applications were introduced in detail. In the catalysis applications, the biomass-based functional carbonaceous materials have shown excellent activities for esterification, hydrolysis, and dehydration. They can also be used as catalyst carriers to support other nanoparticles for the catalytic reaction. In energy storage applications, the biomass-based functional carbonaceous materials are applied to electrode materials of supercapacitors or batteries because of the high specific capacitance and favorable cycle stability. In adsorption applications, the biomass-based functional carbonaceous materials exhibit great performance in removing heavy metals and organic pollutants, and even nuclides, due to rich functional groups and adjustable porosity.

Although great progress has been achieved in the conversion of the biomass into functional materials via hydrothermal carbonization, there are still some obstacles and challenges that need to be overcome. Firstly, biomass with different chemical compositions has a significant impact on the performance of the product and should be rigorously chosen as the ideal precursor for the synthesis of carbonaceous materials. The compositions such as lignocellulose, ash, moisture, and oxygen have some effects on the properties of the materials. In order to solve this problem, comprehensively comparative investigations on different raw materials are of great significance for determining the common features and formulating relevant preparation schemes. Furthermore, the relevance between the surface characteristics of materials and the composition of feedstock should also be concerned with the change of hydrothermal conditions. Therefore, the determination of hydrothermal conditions is helpful in obtaining better final products.

Secondly, for the applications of the biomass-based functional carbonaceous materials, a deep understanding of the effects of surface functional groups on their performance is critical. In recent years, heteroatom doping on the carbonaceous materials to improve the corresponding performance has received extensive attention; however, the pore blockage caused by doping often occurs. Therefore, avoidance methods will be the focus of future research. It will be helpful to fill the gaps in activation knowledge and better understand the role of heteroatoms in chemical activation. Furthermore, since hydrothermal carbonization is carried out in an aqueous solution, some substances dissolve into the liquid phase during the reaction process. Further research is still focused on the utilization and harmless treatment of the liquid-phase product. Besides, other difficulties need to be solved in commercial production such as scale-up issues, cost reduction, and efficiency increase.

Finally, as shown by numerous examples discussed herein, hydrothermal carbonization is considered as one of the most effective methods to prepare precursors for the biomass-based functional carbonaceous materials. It provides the ideal properties to make precursors more suitable for chemical activation and receives more benefits than other conventional pretreatment. The utilization of highly abundant biomass waste is a cost-effective proposal that can greatly reduce the cost of synthesis. In addition, environmental remediation can be achieved, which is an important sustainability of the environment. The biomass-based functional carbonaceous materials have achieved enormous success in many practical applications, including catalysis, energy storage, environmental remediation, biomedicine, and so on. Despite many challenges in technologies and products, the biomass-based functional carbonaceous materials can open up new avenues for development in the future.

References

Kroto HW, Heath JR, O’Brien SC, Curl RF, Smalley RE (1985) C60: buckminsterfullerene. Nature 318(6042):162–163

Novoselov KS (2004) Electric field effect in atomically thin carbon films. Science 306(5696):666–669

Liu Z, Zhang FS (2009) Removal of lead from water using biochars prepared from hydrothermal liquefaction of biomass. J Hazard Mater 167(1–3):933–939

Liu Z, Zhang FS, Wu J (2010) Characterization and application of chars produced from pinewood pyrolysis and hydrothermal treatment. Fuel 89(2):510–514

Selvi BR, Jagadeesan D, Suma BS, Nagashankar G, Arif M, Balasubramanyam K, Eswaramoorthy M, Kundu TK (2008) Intrinsically fluorescent carbon nanospheres as a nuclear targeting vector: delivery of membrane-impermeable molecule to modulate gene expression in vivo. Nano Lett 8(10):3182–3188

Guo SR, Gong JY, Jiang P, Wu M, Lu Y, Yu SH (2008) Biocompatible, luminescent silver@phenol formaldehyde resin core/shell nanospheres: large-scale synthesis and application for in vivo bioimaging. Adv Funct Mater 18(6):872–879

Titirici MM, Antonietti M, Thomas A (2006) A generalized synthesis of metal oxide hollow spheres using a hydrothermal approach. Chem Mater 18(16):3808–3812

Wang X, Hu C, Xiong Y, Liu H, Du G, He X (2011) Carbon-nanosphere-supported Pt nanoparticles for methanol and ethanol electro-oxidation in alkaline media. J Power Sources 196(4):1904–1908

Sevilla M, Fuertes AB, Mokaya R (2011) High density hydrogen storage in superactivated carbons from hydrothermally carbonized renewable organic materials. Energy Environ Sci 4(4):1400–1410

Sevilla M, Fuertes AB (2011) Sustainable porous carbons with a superior performance for CO2 capture. Energy Environ Sci 4(5):1765–1771

Sevilla M, Maciá-Agulló JA, Fuertes AB (2011) Hydrothermal carbonization of biomass as a route for the sequestration of CO2: chemical and structural properties of the carbonized products. Biomass Bioenergy 35(7):3152–3159

Hoekman SK, Broch A, Robbins C, Zielinska B, Felix L (2013) Hydrothermal carbonization (HTC) of selected woody and herbaceous biomass feedstocks. Biomass Convers Bior 3(2):113–126

Jaeckel M, Smigilski H (1990) Process for producing metallic or ceramic hollow-sphere bodies. US

Bergius F, Specht H (1913) Die Anwendung hoger durcke bei chemischen Vorgngen und eine Nachbildung des Entstehungsprozesses der Steinkohle

Berl E, Schmidt A, Koch H (1932) The development of carbon. Angew Chem 493:97–123

Schuhmacher JP, Huntjens FJ, Vankrevelen DW (1960) Chemical structure and properties of coal XXVI-studies on artificial coalification. Fuel 39(3):223–234

Hatcher PG, Clifford DJ (1997) The organic geochemistry of coal: from plant materials to coal. Org Geochem 27:251–274

Masselter S, Zemann A, Bobleter O (1995) Analysis of lignin degradation products by capillary electrophoresis. Chromatographia 40(1–2):51–57

Bobleter O (1994) Hydrothermal degradation of polymers derived from plants. Prog Polym Sci 19(5):797–841

Titirici MM, White RJ, Falco C, Sevilla M (2012) Black perspectives for a green future: hydrothermal carbons for environment protection and energy storage. Energy Environ Sci 5(5):6796–6822

Libra JA, Ro KS, Kammann C, Funke A, Berge ND, Neubauer Y, Titirici MM, Fühner C, Bens O, Kern J, Emmerich KH (2011) Hydrothermal carbonization of biomass residuals: a comparative review of the chemistry, processes and applications of wet and dry pyrolysis. Biofuels 2(1):71–106

Titirici MM, Thomas A, Yu SH, Müller JO, Antonietti M (2007) A direct synthesis of mesoporous carbons with bicontinuous pore morphology from crude plant material by hydrothermal carbonization. Chem Mater 19(17):4205–4212

Berge ND, Ro KS, Mao J, Flora JRV, Chappell MA, Bae S (2011) Hydrothermal carbonization of municipal waste streams. Environ Sci Technol 45(13):5696–5703

Kang S, Li X, Fan J, Chang J (2012) Characterization of hydrochars produced by hydrothermal carbonization of lignin, cellulose, D-xylose, and wood meal. Ind Eng Chem 51(26):9023–9031

Patra TK, Sheth PN (2015) Biomass gasification models for downdraft gasifier: a state-of-the-art review. Renew Sust Energ Rev 50:583–593

Shen D, Jin W, Hu J, Xiao R, Luo K (2015) An overview on fast pyrolysis of the main constituents in lignocellulosic biomass to valued-added chemicals: structures, pathways and interactions. Renew Sust Energ Rev 51:761–774

Titirici MM, White RJ, Brun N, Budarin VL, Su DS, del Monte F, MacLachlan MJ (2015) Sustainable carbon materials. Chem Soc Rev 44(1):250–290

Wang Q, Li H, Chen L, Huang X (2001) Monodispersed hard carbon spherules with uniform nanopores. Carbon 39(14):2211–2214

Mi Y, Hu W, Dan Y, Liu Y (2008) Synthesis of carbon micro-spheres by a glucose hydrothermal method. Mater Lett 62(8–9):1194–1196

Liu J, Tian P, Ye J, Zhou L, Gong W, Lin Y, Ning G (2009) Hydrothermal synthesis of carbon microspheres from glucose: tuning sphere size by adding oxalic acid. Chem Lett 38(10):948–949

Demir-Cakan R, Baccile N, Antonietti M, Titirici MM (2009) Carboxylate-rich carbonaceous materials via one-step hydrothermal carbonization of glucose in the presence of acrylic acid. Chem Mater 21(3):484–490

Zhang Z, Zhou Z, Cao X, Liu Y, Xiong G, Liang P (2014) Removal of uranium (VI) from aqueous solutions by new phosphorus-containing carbon spheres synthesized via one-step hydrothermal carbonization of glucose in the presence of phosphoric acid. J Radioanal Nucl Chem 299(3):1479–1487

Zhang C, Lin S, Peng J, Hong Y, Wang Z, Jin X (2017) Preparation of highly porous carbon through activation of NH4Cl induced hydrothermal microsphere derivation of glucose. RSC Adv 7(11):6486–6491

Sevilla M, Fuertes AB (2009) Chemical and structural properties of carbonaceous products obtained by hydrothermal carbonization of saccharides. Chemistry 15(16):4195–4203

Sevilla M, Fuertes AB (2009) The production of carbon materials by hydrothermal carbonization of cellulose. Carbon 47(9):2281–2289

Falco C, Baccile N, Titirici MM (2011) Morphological and structural differences between glucose, cellulose and lignocellulosic biomass derived hydrothermal carbons. Green Chem 13(11):3273–3281

Knežević D, van Swaaij W, Kersten S (2010) Hydrothermal conversion of biomass: II. Conversion of wood, pyrolysis oil, and glucose in hot compressed water. Ind Eng Chem Res 49(1):104–112

Sun X, Li Y (2004) Colloidal carbon spheres and their core/shell structures with noble-metal nanoparticles. Angew Chem Int Ed 43(5):597–601

Yao C, Shin Y, Wang LQ, Windisch CF, Samuels WD, Arey BW, Wang C, Risen WM, Exarhos GJ (2007) Hydrothermal dehydration of aqueous fructose solutions in a closed system. J Phys Chem C 111(42):15141–15145

Zhang M, Yang H, Liu Y, Sun X, Zhang D, Xue D (2012) Hydrophobic precipitation of carbonaceous spheres from fructose by a hydrothermal process. Carbon 50(6):2155–2161

Qi Y, Zhang M, Qi L, Qi Y (2016) Mechanism for the formation and growth of carbonaceous spheres from sucrose by hydrothermal carbonization. RSC Adv 6(25):20814–20823

Wang T, Zhai Y, Zhu Y, Li C, Zeng G (2018) A review of the hydrothermal carbonization of biomass waste for hydrochar formation: process conditions, fundamentals, and physicochemical properties. Renew Sust Energ Rev 90:223–247

Lu X, Pellechia PJ, Flora JRV, Berge ND (2013) Influence of reaction time and temperature on product formation and characteristics associated with the hydrothermal carbonization of cellulose. Bioresour Technol 138(2):180–190

García-Bordejé E, Pires E, Fraile JM (2017) Parametric study of the hydrothermal carbonization of cellulose and effect of acidic conditions. Carbon 123:421–432

Wu Q, Liu S, Xie C, Yu H, Liu Y, Yu S, Huang L (2018) Ni-doped mesoporous carbon obtained from hydrothermal carbonization of cellulose and their catalytic hydrogenation activity study. J Mater Sci 53(10):7900–7910

Falco C, Sieben JM, Brun N, Sevilla M, Mauelen T, Morallón E, Cazorla-Amorós D, Titirici MM (2013) Hydrothermal carbons from hemicellulose-derived aqueous hydrolysis products as electrode materials for supercapacitors. ChemSusChem 6(2):374–382

Wang Y, Yang R, Li M, Zhao Z (2015) Hydrothermal preparation of highly porous carbon spheres from hemp (Cannabis sativa L.) stem hemicellulose for use in energy-related applications. Ind Crop Prod 65:216–226

Cheng Y, Yang M, Fang C, Chen J, Bai M, Su J (2017) Controllable morphologies of carbon microspheres via green hydrothermal method using fructose and xylose. Chem Lett 46(9):1400–1402

Kim D, Lee K, Park KY (2016) Upgrading the characteristics of biochar from cellulose, lignin, and xylan for solid biofuel production from biomass by hydrothermal carbonization. J Ind Eng Chem 42:95–100

Fang Z, Sato T, Smith RL, Inomata H, Arai K, Kozinski JA (2008) Reaction chemistry and phase behavior of lignin in high-temperature and supercritical water. Bioresour Technol 99(9):3424–3430

Dinjus E, Kruse A, Troeger N (2011) Hydrothermal carbonization-1. Influence of lignin in lignocelluloses. Chem Eng Technol 34(12):2037–2043

Sangchoom W, Mokaya R (2015) Valorization of lignin waste: carbons from hydrothermal carbonization of renewable lignin as superior sorbents for CO2 and hydrogen storage. ACS Sustain Chem Eng 3(7):1658–1667

Wikberg H, Ohra-aho T, Pileidis F, Titirici MM (2015) Structural and morphological changes in Kraft lignin during hydrothermal carbonization. ACS Sustain Chem Eng 3(11):2737–2745

Mao H, Chen X, Huang R, Chen M, Yang R, Lan P, Zhou M, Zhang F, Yang Y, Zhou X (2018) Fast preparation of carbon spheres from enzymatic hydrolysis lignin: effects of hydrothermal carbonization conditions. Sci Rep 8(1):9501

Barbier J, Charon N, Dupassieux N, Loppinet-Serani A, Mahé L, Ponthus J, Courtiade M, Ducrozet A, Quoineaud AA, Cansell F (2012) Hydrothermal conversion of lignin compounds. A detailed study of fragmentation and condensation reaction pathways. Biomass Bioenergy 46:479–491

Kang S, Li X, Fan J, Chang J (2011) Classified separation of lignin hydrothermal liquefied products. Ind Eng Chem Res 50(19):11288–11296

Demirbas A, Demirbas MF (2011) Importance of algae oil as a source of biodiesel. Energy Convers Manag 52(1):163–170

Falco C, Sevilla M, White RJ, Rothe R, Titirici MM (2012) Renewable nitrogen-doped hydrothermal carbons derived from microalgae. ChemSusChem 5(9):1834–1840

Méndez A, Gascó G, Ruiz B, Fuente E (2019) Hydrochars from industrial macroalgae “Gelidium sesquipedale” biomass wastes. Bioresour Technol 275:386–393

Rattanachueskul N, Saning A, Chumaha N, Chuenchom L (2017) Magnetic carbon composites with a hierarchical structure for adsorption of tetracycline, prepared from sugarcane bagasse via hydrothermal carbonization coupled with simple heat treatment process. Bioresour Technol 226:164–172

Tang D, Luo Y, Lei W, Xiang Q, Ren W, Song W, Chen K, Sun J (2018) Hierarchical porous carbon materials derived from waste Lentinus edodes by a hybrid hydrothermal and molten salt process for supercapacitor applications. Appl Surf Sci 462:862–871

Wataniyakul P, Boonnoun P, Quitain AT, Kida T, Laosiripojana N, Shotipruk A (2018) Preparation of hydrothermal carbon acid catalyst from defatted rice bran. Ind Crop Prod 117:286–294

Lang Q, Zhang B, Liu Z, Jiao W, Xia Y, Chen Z, Li D, Ma J, Gai C (2019) Properties of hydrochars derived from swine manure by CaO assisted hydrothermal carbonization. J Environ Manag 233:440–446

Yahav Spitzer R, Mau V, Gross A (2018) Using hydrothermal carbonization for sustainable treatment and reuse of human excreta. J Clean Prod 205:955–963

Sabio E, Álvarez-Murillo A, Román S, Ledesma B (2016) Conversion of tomato-peel waste into solid fuel by hydrothermal carbonization: influence of the processing variables. Waste Manag 47:122–132

Lang Q, Guo Y, Zheng Q, Liu Z, Gai C (2018) Co-hydrothermal carbonization of lignocellulosic biomass and swine manure: hydrochar properties and heavy metal transformation behavior. Bioresour Technol 266:242–248

Nakason K, Panyapinyopol B, Kanokkantapong V, Viriya-empikul N, Kraithong W, Pavasant P (2018) Hydrothermal carbonization of unwanted biomass materials: effect of process temperature and retention time on hydrochar and liquid fraction. J Energy Inst 91(5):786–796

Shao Y, Long Y, Wang H, Liu D, Shen D, Chen T (2019) Hydrochar derived from green waste by microwave hydrothermal carbonization. Renew Energy 135:1327–1334

Liu H, Chen Y, Yang H, Gentili FG, Söderlind U, Wang X, Zhang W, Chen H (2019) Hydrothermal carbonization of natural microalgae containing a high ash content. Fuel 249:441–448

Wang Y, Cao X, Sun S, Zhang R, Shi Q, Zheng L, Sun R (2019) Carbon microspheres prepared from the hemicelluloses-rich pre-hydrolysis liquor for contaminant removal. Carbohydr Polym 213:296–303

Jiménez Toro MJ, Dou X, Ajewole I, Wang J, Chong K, Ai N, Chen T (2019) Preparation and optimization of macroalgae-derived solid acid catalysts. Waste Biomass Valori 10(4):805–816

Tong X, Chen Z, Zhuo H, Hu Y, Jing S, Liu J, Zhong L (2019) Tailoring the physicochemical properties of chitosan-derived N-doped carbon by controlling hydrothermal carbonization time for high-performance supercapacitor application. Carbohyd Polym 207:764–774

Song C, Zheng H, Shan S, Wu S, Wang H, Christie P (2019) Low-temperature hydrothermal carbonization of fresh pig manure: effects of temperature on characteristics of hydrochars. J Environ Eng 145(6):04019029

Zheng C, Ma X, Yao Z, Chen X (2019) The properties and combustion behaviors of hydrochars derived from co-hydrothermal carbonization of sewage sludge and food waste. Bioresour Technol 285:121347

Román S, Nabais JMV, Laginhas C, Ledesma B, González JF (2012) Hydrothermal carbonization as an effective way of densifying the energy content of biomass. Fuel Process Technol 103:78–83

Manon VDV, Baeyens J, Brems A, Jassense B, Dewil R (2010) Fundamentals, kinetics and endothermicity of the biomass pyrolysis reaction. Renew Energy 35(1):232–242

Akhtar J, Saidina Amin N (2012) A review on operating parameters for optimum liquid oil yield in biomass pyrolysis. Renew Sust Energ Rev 16(7):5101–5109

Parshetti GK, Hoekman SK, Balasubramanian R (2013) Chemical, structural and combustion characteristics of carbonaceous products obtained by hydrothermal carbonization of palm empty fruit bunches. Bioresour Technol 135(3):683–689

Peng C, Zhai Y, Zhu Y, Xu B, Wang T, Li C, Zeng G (2016) Production of char from sewage sludge employing hydrothermal carbonization: char properties, combustion behavior and thermal characteristics. Fuel 176:110–118

Hwang IH, Aoyama H, Matsuto T, Nakagishi T, Matsuo T (2012) Recovery of solid fuel from municipal solid waste by hydrothermal treatment using subcritical water. Waste Manag 32(3):410–416

Kim D, Lee K, Park KY (2014) Hydrothermal carbonization of anaerobically digested sludge for solid fuel production and energy recovery. Fuel 130:120–125

Hoekman SK, Broch A, Robbins C (2011) Hydrothermal carbonization (HTC) of lignocellulosic biomass. Energy Fuel 25(4):1802–1810

Sun P, Heng M, Sun S, Chen J (2010) Direct liquefaction of paulownia in hot compressed water: influence of catalysts. Energy 35(12):5421–5429

Zhang J, Wang Q (2016) Sustainable mechanisms of biochar derived from brewers’ spent grain and sewage sludge for ammonia-nitrogen capture. J Clean Prod 112:3927–3934

Yin S, Tan Z (2012) Hydrothermal liquefaction of cellulose to bio-oil under acidic, neutral and alkaline conditions. Appl Energy 92(2):234–239

Jena U, Das KC, Kastner JR (2011) Effect of operating conditions of thermochemical liquefaction on biocrude production from Spirulina platensis. Bioresour Technol 102(10):6221–6229

Chen G, Andries J, Luo Z, Spliethoff H (2003) Biomass pyrolysis/gasification for product gas production: the overall investigation of parametric effects. Energy Convers Manag 44(11):1875–1884

He C, Giannis A, Wang JY (2013) Conversion of sewage sludge to clean solid fuel using hydrothermal carbonization: hydrochar fuel characteristics and combustion behavior. Appl Energy 111:257–266

Romero-Anaya AJ, Ouzzine M, Lillo-Ródenas MA, Linares-Splano A (2014) Spherical carbons: synthesis, characterization and activation processes. Carbon 68:296–307

Yavari S, Malakahmad A, Sapari NB (2017) Sorption properties optimization of agricultural wastes-derived biochars using response surface methodology. Process Saf Environ Prot 109:509–519

Knežević D, van Swaaij WPM, Kersten SRA (2009) Hydrothermal conversion of biomass: I. glucose conversion in hot compressed water. Ind Eng Chem Res 48(10):4731–4743

Li M, Li W, Liu S (2011) Hydrothermal synthesis, characterization, and KOH activation of carbon spheres from glucose. Carbohydr Res 346(8):999–1004

Su DS, Zhang J, Frank B, Thomas A, Wang X, Paraknowitsch J, Schlögl R (2010) Metal-free heterogeneous catalysis for sustainable chemistry. ChemSusChem 3:169–180

Liang X, Yang J (2009) Synthesis of a novel carbon based strong acid catalyst through hydrothermal carbonization. Catal Lett 132(3–4):460–463

Nakajima K, Hara M (2012) Amorphous carbon with SO3H groups as a solid Brønsted acid catalyst. ACS Catal 2(7):1296–1304

Su F, Guo Y (2014) Advancements in solid acid catalysts for biodiesel production. Green Chem 16(6):2934–2957

Qi X, Lian Y, Yan L, Smith RL (2014) One-step preparation of carbonaceous solid acid catalysts by hydrothermal carbonization of glucose for cellulose hydrolysis. Catal Commun 57(4):50–54

Qi X, Liu N, Lian Y (2015) Carbonaceous microspheres prepared by hydrothermal carbonization of glucose for direct use in catalytic dehydration of fructose. RSC Adv 5(23):17526–17531

Wen G, Wang B, Wang C, Wang J, Tian Z, Schlögl R, Su DS (2016) Hydrothermal carbon enriched with oxygenated groups from biomass glucose as an efficient carbocatalyst. Angew Chem Int Ed 129(2):615–619

Furimsky E (2009) Carbons and carbon supported catalysts in hydroprocessing. Focus Catal 3:8

Joo JB, Kim YJ, Kim W, Kim P, Yi J (2008) Simple synthesis of graphitic porous carbon by hydrothermal method for use as a catalyst support in methanol electro-oxidation. Catal Commun 10(3):267–271

Wataniyakul P, Boonnoun P, Quitain AT, Sasaki M, Kida T, Laosiripojana N, Shotipruk A (2018) Preparation of hydrothermal carbon as catalyst support for conversion of biomass to 5-hydroxymethylfurfural. Catal Commun 104:41–47

Simon P, Gogotsi Y (2008) Materials for electrochemical capacitors. Nat Mater 7(11):845–854

Sevilla M, Mokaya R (2014) Energy storage applications of activated carbons: supercapacitors and hydrogen storage. Energy Environ Sci 7(4):1250–1280

Mysyk R, Raymundo-Piñero E, Anouti M, Lemordant D, Béguin F (2010) Pseudo-capacitance of nanoporous carbons in pyrrolidinium-based protic ionic liquids. Electrochem Commun 12(3):414–417

Liu J, Li H, Zhang H, Liu Q, Li R, Li B, Wang J (2018) Three-dimensional hierarchical and interconnected honeycomb-like porous carbon derived from pomelo peel for high performance supercapacitors. J Solid State Chem 257:64–71

Hu Y, Liu H, Ke Q, Wang J (2014) Effects of nitrogen doping on supercapacitor performance of a mesoporous carbon electrode produced by a hydrothermal soft-templating process. J Mater Chem A 2(30):11753–11758

Ren M, Jia Z, Tian Z, Lopez D, Cai J, Titirici MM, Jorge AB (2018) High performance N-doped carbon electrodes obtained via hydrothermal carbonization of macroalgae for supercapacitor applications. ChemElectroChem 5(18):2686–2693

Clemente JS, Beauchemin S, Mackinnon T, Martin J, Johnston CT, Joern B (2017) Initial biochar properties related to the removal of As, Se, Pb, Cd, Cu, Ni, and Zn from an acidic suspension. Chemosphere 170:216–224

Lee SJ, Park JH, Ahn YT, Chung JW (2015) Comparison of heavy metal adsorption by peat moss and peat moss-derived biochar produced under different carbonization conditions. Water Air Soil Pollut 226(2):9–19

Qi X, Li L, Tan T, Smith RL (2013) Adsorption of 1-butyl-3-methylimidazolium chloride ionic liquid by functional carbon microspheres from hydrothermal carbonization of cellulose. Environ Sci Technol 47(6):2792–2798

Krstić S, Kragović M, Pagnacco M, Dodevski V, Kaluđerović B, Momčilović M, Ristović I, Stojmenović M (2018) Hydrothermal synthesized and alkaline activated carbons prepared from glucose and fructose-detailed characterization and testing in heavy metals and methylene blue removal. Minerals 8(6):246

Islam MA, Benhouria A, Asif M, Hameed BH (2015) Methylene blue adsorption on factory-rejected tea activated carbon prepared by conjunction of hydrothermal carbonization and sodium hydroxide activation processes. J Taiwan Inst Chem Eng 52:57–64

Bibaj E, Lysigaki K, Nolan JW, Seyedsalehi M, Deliyanni EA, Mitropoulos AC, Kyzas GZ (2019) Activated carbons from banana peels for the removal of nickel ions. Int J Environ Sci Technol 16:667–680

Khan MA, Alqadami AA, Otero M, Siddiqui MR, Alothman ZA, Alsohaimi I, Rafatullah M, Hamedelniel AE (2019) Heteroatom-doped magnetic hydrochar to remove post-transition and transition metals from water: synthesis, characterization, and adsorption studies. Chemosphere 218:1089–1099

Aly MM, Hamza MF (2013) A review: Studies on uranium removal using different techniques. Overview. J Dispers Sci Technol 34(2):182–213

Zhang Z, Liu Y, Cao X, Liang P (2013) Sorption study of uranium on carbon spheres hydrothermal synthesized with glucose from aqueous solution. J Radioanal Nucl Chem 295(3):1775–1782

Cai H, Lin X, Qin Y, Luo X (2017) Hydrothermal synthesis of carbon microsphere from glucose at low temperature and its adsorption property of uranium(VI). J Radioanal Nucl Chem 311(1):1–12

Han B, Zhang E, Cheng G, Zhang L, Wang D, Wang X (2018) Hydrothermal carbon superstructures enriched with carboxyl groups for highly efficient uranium removal. Chem Eng J 338:734–744

Chen B, Chen Z, Lv S (2011) A novel magnetic biochar efficiently sorbs organic pollutants and phosphate. Bioresour Technol 102(2):716–723

Zhou X, You SJ, Wang XH, Gan Y, Zhong YJ, Ren NQ (2013) Hydrothermal synthesis of magnetic carbon microspheres for effective adsorption of Cd(II) in water. J Chem Technol Biotechnol 89(7):1051–1059

Wang MC, Sheng GD, Qiu YP (2014) A novel manganese-oxide/biochar composite for efficient removal of lead(II) from aqueous solutions. Int J Environ Sci Technol 12(5):1719–1726

Adebisi GA, Chowdhury ZZ, Abd Hamid SB, Ali E (2016) Hydrothermally treated banana empty fruit bunch fiber activated carbon for Pb(II) and Zn(II) removal. BioResources 11(4):9686–9709

Zhou N, Chen H, Xi J, Yao D, Zhou Z, Tian Y, Lu X (2017) Biochars with excellent Pb(II) adsorption property produced from fresh and dehydrated banana peels via hydrothermal carbonization. Bioresour Technol 232:204–210

Ramesh S, Sundararaju P, Banu KSP, Karthikeyan S, Doraiswamy U, Soundarapandian K (2018) Hydrothermal carbonization of arecanut husk biomass: fuel properties and sorption of metals. Environ Sci Pollut Res 26(4):3751–3761

Li Y, Tsend N, Li T, Liu H, Yang R, Gai X, Wang H, Shan S (2018) Microwave assisted hydrothermal preparation of rice straw hydrochars for adsorption of organics and heavy metals. Bioresour Technol 273:136–143

Kazak O, Eker YR, Bingol H, Tor A (2018) Preparation of chemically-activated high surface area carbon from waste vinasse and its efficiency as adsorbent material. J Mol Liq 272:189–197

Zhang X, Zhang L, Li A (2018) Eucalyptus sawdust derived biochar generated by combining the hydrothermal carbonization and low concentration KOH modification for hexavalent chromium removal. J Environ Manag 206:989–998

Shi Y, Zhang T, Ren H, Kruse A, Cui R (2018) Polyethylene imine modified hydrochar adsorption for chromium (VI) and nickel (II) removal from aqueous solution. Bioresour Technol 247:370–379

Cao X, Ro KS, Chappell M, Li Y, Mao J (2011) Chemical structures of swine-manure chars produced under different carbonization conditions investigated by advanced solid-state 13C nuclear magnetic resonance (NMR) spectroscopy. Energy Fuel 25(1):388–397

Breulmann M, van Afferden M, Müller RA, Schulz E, Fühner C (2017) Process conditions of pyrolysis and hydrothermal carbonization affect the potential of sewage sludge for soil carbon sequestration and amelioration. J Anal Appl Pyrolysis 124:256–265

Sevilla M, Gu W, Falco C, Titirici MM, Fuertes AB, Yushin G (2014) Hydrothermal synthesis of microalgae-derived microporous carbons for electrochemical capacitors. J Power Sources 267:26–32

Mehta VN, Jha S, Basu H, Singhal RK, Kailasa SK (2015) One-step hydrothermal approach to fabricate carbon dots from apple juice for imaging of mycobacterium and fungal cells. Sensors Actuators B Chem 213:434–443

Atchudan R, Edison TNJI, Aseer KR, Perumal S, Lee YR (2018) Hydrothermal conversion of Magnolia liliiflora into nitrogen-doped carbon dots as an effective turn-off fluorescence sensing, multi-colour cell imaging and fluorescent ink. Colloids Surf B: Biointerfaces 169:321–328

Ansari F, Kahrizi D (2018) Hydrothermal synthesis of highly fluorescent and non-toxic carbon dots using Stevia rebaudiana Bertoni. Cell Mol Biol 64(12):32–26

Li L, Wang X, Fu Z, Cui F (2017) One-step hydrothermal synthesis of nitrogen- and sulfur-co-doped carbon dots from ginkgo leaves and application in biology. Mater Lett 196:300–303

Thota SP, Thota SM, Bhagavatham SS, Manoj KS, Muthukumar VSS, Venketesh S, Vadlani PV, Belliraj SK (2018) Facile one-pot hydrothermal synthesis of stable and biocompatible fluorescent carbon dots from lemon grass herb. IET Nanobiotechnol 12(2):127–132

Ahmadian-Fard-Fini S, Salavati-Niasari M, Ghanbari D (2018) Hydrothermal green synthesis of magnetic Fe3O4-carbon dots by lemon and grape fruit extracts and as a photoluminescence sensor for detecting of E. coli bacteria. Spectrochim Acta A 203:481–493

He M, Zhang J, Wang H, Kong Y, Xiao Y, Xu W (2018) Material and optical properties of fluorescent carbon quantum dots fabricated from lemon juice via hydrothermal reaction. Nanoscale Res Lett 13(1):175

Siddiqui MTH, Nizamuddin S, Baloch HA, Mubarak NM, Dumbre DK, Inamuddin Asiri AM, Bhuto AW, Srinivasan M, Griffin GJ (2018) Synthesis of magnetic carbon nanocomposites by hydrothermal carbonization and pyrolysis. Environ Chem Lett 16(3):821–844

Funding

This research was funded by the Beijing Forestry University Outstanding Young Talent Cultivation Project (2019JQ03017), Fundamental Research Funds for Central Universities (2019ZY05), and Beijing Municipal Natural Science Foundation (6182031).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Y., Hu, YJ., Hao, X. et al. Hydrothermal synthesis and applications of advanced carbonaceous materials from biomass: a review. Adv Compos Hybrid Mater 3, 267–284 (2020). https://doi.org/10.1007/s42114-020-00158-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-020-00158-0