Abstract

A novel and efficient method is presented for identifying the location and severity of damage in structural elements using vibration modes and circular natural frequency. This method is based on sensitivity analysis of the structure and allows for model updating of a given structural finite element construct using the iterative process of the Levenberg–Marquardt algorithm. The proposed approach is superior in its capability of locating and estimating the severity of structural damage in the presence of noise or incomplete response. The efficiency and performance of the proposed method are assessed through numerical case studies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Inverse problems are of particular interest in various scientific and engineering disciplines such as structural health monitoring, seismology, non-destructive evaluation (NDE), medical diagnosis and geophysics/submarine detection. In recent years, many studies have been conducted to develop effective approaches for damage detection in structural components. A significant progress has been achieved in obtaining numerical solutions of these problems during the past years (Kaveh et al. 2014; Kaveh et al. 2019a, b; Kaveh and Zolghadr 2017a, b; Kaveh and Dadras 2018; Kaveh and Mahdavi 2016; Saberi and Kaveh 2015).

Several numerical treatments of inverse problems are categorized as nonlinear. The efforts made over the last decades to overcome these nonlinear mathematical challenges can be categorized into two categories: qualitative methods and iterative algorithms.

Qualitative methods are characterized by an inverse scattering solution. These methods detect the obstacle (damage) from far- and/or near-field measurements of the scattered field which avoids the incorrect model assumption (Cakoni and Colton 2005). These qualitative methods may be classified as topological sensitivity (TS) (Bonnet and Guzina 2004; Gallego and Rus 2004; Guzina and Bonnet 2004), factorization method (FM) (Kirsch 2002), linear sampling method (LSM) (Dehghan Manshadi et al. 2014, 2018; Dehghan Manshadi and Khaji 2014; Khaji and Dehghan Manshadi 2015), the probe method (Potthast 2006) and point source method (Potthast 2001) which seek to determine the geometric properties (i.e., shape and location) of the scattered.

Iterative algorithms deal with the minimization of the error between the responses of a real damaged structure and hypothetical damaged structure. Some of these methods update the structural model during an iterative process (Perera and Fang 2010; Rao et al. 2004; Seyedpoor 2012). The other approaches are based on sensitivity analysis. These methods minimize the objective function to update the finite element model of the structure (Bakir et al. 2007; Li et al. 2016; Teughels and De Roeck 2005; Wu and Li 2006).

In recent years, many optimization techniques have been developed and used in various structural engineering problems, such as designing structures (Akin and Saka 2015; Esfandiari et al. 2018a, b; Esfandiary et al. 2016; Kaveh and Sabzi 2011). For detecting damages in these structures, optimization methods can be implemented using various response parameters. Some researchers used static response parameters such as displacement (Buda and Caddemi 2007; Chou and Ghaboussi 2001) and strain (Wang et al. 2010). Some others used dynamic response parameters such as frequency (Kaveh and Zolghadr 2012, 2015; Khiem and Tran 2014; Lee 2009; Morassi and Rollo 2001; Tabrizian et al. 2013), mode shape (Homaei et al. 2014; Ismail et al. 2006), a combination of frequency and mode shape (Ge and Lui 2005; Kang et al. 2012; Teughels and De Roeck 2005; Yu and Xu 2011), and modal curvatures (Quaranta et al. 2016) and acceleration (Li and Law 2010).

The main objective of this paper is to present a novel and efficient method for damage detection using the Levenberg–Marquardt algorithm. The method uses dynamic response parameters including frequency and mode shape. The formulation of the forward problem is presented first followed by model updating. The damage detection process using the Levenberg–Marquardt algorithm is elaborated followed by results of numerical case studies. The results from this study confirmed the effectiveness of the proposed model in finding damages in variety of structures, which in turn lays the foundation for damage detection in retrofitted beams (Esfandiari et al. 2018a, b, c; Urgessa and Esfandiari 2018).

Forward problem

The well-known dynamic equation of motion for a linear elastic system can be expressed as

where M, C and K are the mass, damping and stiffness matrices of the structure, respectively (Chopra 2017). \(\ddot{\user2{u}}\), \(\dot{\user2{u}}\) and \({\varvec{u}}\) are the acceleration, velocity and displacement response vectors of the structure, respectively. P(t) is a vector of applied external forces. Free vibration of un-damped system can be obtained by omitting the damping matrix and applied external forces from Eq. (1):

in which 0 is a zero vector. The solution of Eq. (2) can be obtained by solving an eigenvalue problem as shown in Eq. (3).

where \(\omega_{\,i}\) is the natural circular frequency of the ith mode and \({\varvec{\phi}}_{\,\,i}\) is the vibration eigenvector of the ith mode. By assuming that the mass parameter remains unchanged as damage occurs, the eigenvalue equation can be expressed as follows in Eq. (4):

where Kd is the global stiffness matrix of the damaged structure, \(\omega_{i}^{{\text{d}}}\) is the ith circular frequency of the damaged structure and \({\varvec{\phi}}_{i}^{{\text{d}}}\) is the corresponding mode shape. In this paper, damage is defined as perturbation in the stiffness parameter of the structure. Hence, the global stiffness matrix Kd can be defined as

Substituting Eq. (5) into Eq. (4) yields:

Model updating

In recent decades, finite element model updating approaches have been widely used for damage detection. In an iterative process, the unknown model parameters (including physical and material properties) are adjusted until the difference between a measured data and an updated finite element model are minimized.

Objective function based on vibration data

Identification of the intensity and position of damage using model updating is similar to detection of unknown parameters in an optimization problem. Hence, the objective function for model updating is defined as minimizing the residual between the dynamic response of a healthy structure and an updated structure. Minimizing the objective function is defined as a nonlinear least square minimization problem that is determined from the sum of squared errors as shown in Eqs. (7) and (8).

where g is the residual matrix function, Rd is the response vector of existing damaged structure, Rup is the response vector of updated model, \({\varvec{X}} = \{ x_{1} ,x_{2} ,...,x_{ne} \}^{{\text{T}}}\) indicates the updated damage vector which consists of updated parameter for all structural elements and the subscript ne is the number of the structural elements. It should be noted that in order to obtain a unique solution, the number of residuals, m, should be greater than the number of updated damage vector, ne.

In this paper, the proposed residual function is based on both natural circular frequency and the corresponding mode shape. It can be expressed as follows

where \(\omega_{j}^{{{\text{up}}}}\) is the jth updated natural circular frequency, \(\omega_{j}^{{\text{d}}}\) is the jth circular frequency of the damaged structure, \({{\varvec{\Phi}}}_{ij}^{{{\text{up}}}}\) is the updated modal displacement of the ith receiver of the jth mode shape, \({{\varvec{\Phi}}}_{ij}^{{\text{d}}}\) is the damaged modal displacement of the ith receiver of the jth mode shape, nr is the number of receivers, nm is the number of mode shapes and the subscript r defined as j × i. Substituting Eq. (9) into Eq. (7) yields:

Updating parameter

The updating parameter is the unknown dimensionless damage severity of the model. In this paper, the damage of the structural elements is modeled as a reduction in Young’s modulus. Thus, the dimensionless updating parameter, for each element, can be defined as

where \(E_{e}^{{{\text{up}}}}\) and \(E_{e}^{{}}\) denote the updated modulus of elasticity and its initial value of the ith element, respectively. It is noted that xe ∈ [0, 1] where xe = 0 and xe = 1 denote healthy and completely damaged states, respectively. Based on Eq. (11), the updated stiffness matrix of the eth element in damaged state, Ked, can be defined by Eq. (12).

where the Ke is the initial stiffness matrix of the eth element.

Damage detection using the Levenberg–Marquardt algorithm

Levenberg–Marquardt algorithm

The Gauss–Newton (GN) method is generally used to solve the nonlinear least squares function shown in Eq. (10), which relies on an iterative sensitivity-based optimization approach. The gradient and Hessian matrices of the objective function are defined by Eqs. (14) and (15), respectively.

where J is the Jacobian matrix containing the first partial derivatives of the residuals gr with respect to X, H denotes the Hessian matrix, the superscript k indicates the iteration number at which the Jacobian and Hessian matrix are computed and Xk+1 is the updated vector of the parameter. The Hessian matrix was improved by Marquardt (1963) in the Levenberg–Marquardt algorithm as shown in Eq. (16).

where λ is a damping parameter adjusted by the algorithm. The basic strategy behind choosing the damping term depends on the error rate in the updating process. If the error goes down following an update, the algorithm will take a small λ (usually by a constant coefficient) to reduce the influence of gradient descent. On the other hand, if the error goes up, λ is increased by the same factor. Using the Levenberg–Marquardt algorithm, Eq. (15) can be rewritten as shown in Eq. (17):

The updating process using the Levenberg–Marquardt algorithm starts out by updating the function and Jacobian values (if necessary) using Eq. (16) and then evaluating the error at the new parameter vector. If the error increases as a result of the update, then retract the step and increase λ in Eq. (16) by a significant constant factor followed by trying the updating process again. If the error has decreased as a result of the update, then accept the step and decrease λ by the same factor.

In the updating process, the Hessian matrix may be severely ill-conditioned. In order to overcome this issue, the Singular Value Decomposition (SVD) method is employed to decompose the Hessian matrix (H) as H = USVT. In this regard, U and V are unitary matrices, VT denotes the transpose of V, and S implies a diagonal matrix whose components are \(S_{ii} = \sigma_{i}\). According to the SVD method, the pseudo-inverse of the Hessian matrix (H) can be calculated as \({\varvec{H}} + = {\varvec{VS}} + {\varvec{U}}^{\user2{*}}\), \(S_{ii}^{ + } = {1 \mathord{\left/ {\vphantom {1 {\sigma_{i} }}} \right. \kern-\nulldelimiterspace} {\sigma_{i} }}\).

The model updating for damage detection is inhibited by challenges associated with structural complexity, large search spaces and the presence of too many variables, amongst other types of constraints. Levenberg–Marquardt algorithm is considered for this study because it is faster to converge than either the gradient descent or the GN. Moreover, it is able to handle models with multiple free parameters and most of the time, it can find an optimal solution despite the initial guess.

Sensitivity matrix

As mentioned earlier, the sensitivity or the Jacobian matrix is defined as the first-order derivative of residual function with respect to vector of updating parameters. The sensitivity matrix can be obtained by forward difference method as shown in Eq. (18).

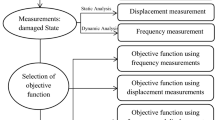

where gr is the rth component of the residual vector and Xe is the eth component of the updating vector. The flowchart of the method presented is shown in Fig. 1.

Numerical case studies

In this section, the numerical results obtained from the Levenberg–Marquardt (LM) algorithm in conjunction with the finite element method (FEM) is illustrated. In all numerical examples, the damaged structural elements are simulated by using a reduction in the Young’s modulus of the material. All case studies are numerical and where measurement sensor is used in the text, it refers to the place that dynamic responses that used in the algorithm are generated numerically in that place. In these example, the influence of data noise on the quality of the image reconstruction is investigated by considering noisy simulated data of the form uε = ucomp(1 + ηχ) in which χ is a uniformly distributed random number between − 1 and 1.

Thirty one-bar planar truss

In the first case study, a thirty one-bar planar truss shown in Fig. 2 was considered for assessing the efficiency of the proposed method. The truss was previously studied by Seyedpoor (2012). The material properties are assumed to be: Young’s modulus E = 70 GPa and mass density ρ = 2770 kg/m3; and cross-sectional area of the members is 40 cm2. Similar to Seyedpoor (2012), it is assumed that the first five mode shapes of the structure are available. Four different damage cases given in Table 1 are considered. The first three damage cases are similar to Seyedpoor (2012). The measurement sensors are located at nodes numbered 4, 6, 7, 10 and 11. The fourth damage case consists of all damages in previous scenarios at the same time. This scenario was selected to show the efficiency and superiority of the algorithm for detecting several simultaneous damages.

Figure 3a–d shows the damage severity with respect to element number for damage cases 1–4, respectively. The results of the LM algorithm are compared with the proposed method reported by Seyedpoor (2012). In fact, the damage detection process in Seyedpoor (2012) is a two-stage method and the responses were recorded in all degrees of freedom. In the first stage, the potentially flawed elements were detected based on modal strain energy and the second stage includes searching in reduced space using particle swarm optimization (PSO). The LM algorithm used in this current study has advantages when compared to Seyedpoor (2012). The proposed LM method was able to detect damaged elements during the one-step process. On the other hand, damaged elements were identified using five sensors (corresponding to the degrees of freedom) accurately. The convergence history of the LM algorithm for various cases is shown in Fig. 4. This figure demonstrates that the convergence speed and accuracy of proposed method is very high.

25-Bar truss bridge

The second case study is statically determinate 25-bar truss bridge shown in Fig. 5 (Esfandiari et al. 2009). The truss was previously studied by Kaveh and Maniat (2015). Cross-sectional area of the members for all elements is 10 cm2. The Young’s modulus E and mass density ρ are 200 GPa and 7780 kg/m3, respectively.

Figure 6a–c shows the damage severity with respect to element number for damage cases 1–3, respectively. The convergence history of the LM algorithm for various cases is shown in Fig. 7. As can be seen from the figures, the proposed LM method was able to detect damaged elements during the one-step process and the convergence speed and accuracy of proposed method was very high.

Two-story two-bay unbraced frame

The two-bay, two-story steel frame shown in Fig. 8 was selected from Tabrizian et al. (2013) as the third case study. The material properties of the frame are as follows: Young’s modulus, Poisson’s ratio and mass density are 207 GPa, 0.30 and 7780 kg/m3, respectively. The cross-sectional area and the moment of inertia of all columns and beams are 0.025 m2, 6.386 × 10–4 m4, 0.0123 m2 and 2.218 × 10–4 m4, respectively. Similar to Tabrizian et al. (2013), three different damage cases given in Table 2 are considered. The measurement sensors are located at nodes numbered 5, 11, 13 and 17. Only the first five mode shapes of the structure are considered. Figure 9 represents the damage states reported by Tabrizian et al. (2013). In Tabrizian et al. (2013), 20 first modes are considered in damage detection for the first and second cases, and 45 first modes for the third case, while the method presented in this study enables us to detect the damaged elements using 5 measurement sensors. The number of sensors used to measure the mode shapes may be limited in the experiments and engineering applications due to cost and other mitigating factors. Therefore, to overcome this drawback, the proposed method in this research can be practical and inexpensive.

Cantilever beam

A 100-element cantilever beam with uniform cross section, which was previously studied by Homaei et al. (2014), was considered as the fourth case study as shown in Fig. 10. The responses of the beam measured by 25 sensors located at select nodes and 10 vibration modes of the beam were available. Damage scenarios for this beam are presented in Table 3. The first damage case is similar to Homaei et al. (2014). In Homaei et al. (2014), damaged elements are identified by the measured first two mode shapes. Figure 11a, b demonstrates that the proposed method in this study provides accurate identification of damaged elements with a limited number of measurement sensors. It is worth mentioning that the proposed method can achieve the actual sizes and locations of damages comparing to the method reported in Homaei et al. (2014).

Bridge girder with non-prismatic section

The last case study is a three-span continuous steel bridge girder shown in Fig. 12. The bridge has a length of 58.7 m. The finite element model of the bridge includes 100 elements. Two damage case scenarios were induced as shown in Table 4. In the second scenario, six damaged elements were considered, the measurement sensors are located at select nodes. Damage identification results are shown in Fig. 13a, b, respectively. As shown in this figure, the locations and extents of the damaged elements are detected correctly for the two scenarios.

Conclusions

A practical method for detecting the locations and extents of multiple damage in the four different types of structural systems has been presented. This method is based on sensitivity analysis of the structure and provides updating the structural finite element model using the iterative process of Levenberg–Marquardt algorithm. The updating parameter, which is the unknown dimensionless damage severity of the model, is considered as a reduction in Young’s modulus. The method uses dynamic response parameters including frequency and mode shape. The objective function for model updating is defined as minimizing the residual between the dynamic response of a healthy structure and an updated structure. For this purpose, the model uses the nonlinear least square minimization problem that is determined from the sum of squared errors. In order to assess the performance of the proposed method for structural damage detection, the numerical results of the presented method are compared with those available in the literature, including the accuracy and convergence speed of the algorithm. To make a comprehensive assessment, different types of structure including two planar truss, a two-bay unbraced frame, a cantilever beam and a non-prismatic bridge girder were analyzed. According to the high cost of measurement sensors in engineering applications, the number and optimal placement of sensors can play an important role in cost reduction. As such, results of the numerical examples have demonstrated that the proposed method can provide accurate identification of damaged elements with a limited number of measurement sensors and incomplete data.

References

Akin, A., & Saka, M. P. (2015). Harmony search algorithm based optimum detailed design of reinforced concrete plane frames subject to ACI 318-05 provisions. Computers & Structures,147, 79–95. https://doi.org/10.1016/j.compstruc.2014.10.003.

Bakir, P. G., Reynders, E., & De Roeck, G. (2007). Sensitivity-based finite element model updating using constrained optimization with a trust region algorithm. Journal of Sound and Vibration,305(1), 211–225. https://doi.org/10.1016/j.jsv.2007.03.044.

Bonnet, M., & Guzina, B. B. (2004). Sounding of finite solid bodies by way of topological derivative. International Journal for Numerical Methods in Engineering,61(13), 2344–2373. https://doi.org/10.1002/nme.1153.

Buda, G., & Caddemi, S. (2007). Identification of concentrated damages in Euler–Bernoulli beams under static loads. Journal of Engineering Mechanics,133(8), 942–956. https://doi.org/10.1061/(ASCE)0733-9399(2007)133:8(942).

Cakoni, F., & Colton, D. (2005). Qualitative methods in inverse scattering theory: An introduction. Berlin: Springer.

Chopra, A. K. (2017). Dynamics of structures: Theory and applications to earthquake engineering. Englewood Cliffs, NJ: Prentice Hall.

Chou, J.-H., & Ghaboussi, J. (2001). Genetic algorithm in structural damage detection. Computers & Structures,79(14), 1335–1353. https://doi.org/10.1016/S0045-7949(01)00027-X.

Dehghan Manshadi, S. H., Dehghan Manshadi, S. M., Amiri, H. R., et al. (2018). Flaw identification for Laplace equation using the linear sampling method. Mathematics and Mechanics of Solids,23(8), 1225–1236.

Dehghan Manshadi, S. H., & Khaji, N. (2014). Cavity detection in a heat conductor using linear sampling method. Heat and Mass Transfer,50(7), 973–984.

Dehghan Manshadi, S. H., Khaji, N., & Rahimian, M. (2014). Cavity/inclusion detection in plane linear elastic bodies using linear sampling method. Journal of Nondestructive Evaluation,33(1), 93–103.

Esfandiari, A., Bakhtiari-Nejad, F., Rahai, A., et al. (2009). Structural model updating using frequency response function and quasi-linear sensitivity equation. Journal of Sound and Vibration,326(3), 557–573. https://doi.org/10.1016/j.jsv.2009.07.001.

Esfandiari, M. J., Bondarabadi, H. R., Sheikholarefin, S., et al. (2018a). Numerical investigation of parameters influencing debonding of FRP sheets in shear-strengthened beams. European Journal of Environmental and Civil Engineering,22(2), 246–266. https://doi.org/10.1080/19648189.2016.1186117.

Esfandiari, M. J., Urgessa, G. S., Sheikholarefin, S., et al. (2018b). Optimization of reinforced concrete frames subjected to historical time-history loadings using DMPSO algorithm. Structural and Multidisciplinary Optimization. https://doi.org/10.1007/s00158-018-2027-y.

Esfandiari, M. J., Urgessa, G. S., Sheikholarefin, S., et al. (2018c). Optimum design of 3D reinforced concrete frames using DMPSO algorithm. Advances in Engineering Software,115, 149–160. https://doi.org/10.1016/j.advengsoft.2017.09.007.

Esfandiary, M. J., Sheikholarefin, S., Bondarabadi, R., et al. (2016). A combination of particle swarm optimization and multi-criterion decision-making for optimum design of reinforced concrete frames. Iran University of Science & Technology,6(2), 245–268.

Gallego, R., & Rus, G. (2004). Identification of cracks and cavities using the topological sensitivity boundary integral equation. Computational Mechanics,33(2), 154–163.

Ge, M., & Lui, E. M. (2005). Structural damage identification using system dynamic properties. Computers & Structures,83(27), 2185–2196. https://doi.org/10.1016/j.compstruc.2005.05.002.

Guzina, B. B., & Bonnet, M. (2004). Topological derivative for the inverse scattering of elastic waves. Quarterly Journal of Mechanics and Applied Mathematics,57(2), 161–179. https://doi.org/10.1093/qjmam/57.2.161.

Homaei, F., Shojaee, S., & Amiri, G. G. (2014). A direct damage detection method using multiple damage localization index based on mode shapes criterion. Structural Engineering and Mechanics,49(2), 183–202.

Ismail, Z., Abdul Razak, H., & Abdul Rahman, A. G. (2006). Determination of damage location in RC beams using mode shape derivatives. Engineering Structures,28(11), 1566–1573. https://doi.org/10.1016/j.engstruct.2006.02.010.

Kang, F., Li, J., & Xu, Q. (2012). Damage detection based on improved particle swarm optimization using vibration data. Applied Soft Computing,12(8), 2329–2335. https://doi.org/10.1016/j.asoc.2012.03.050.

Kaveh, A., & Dadras, A. (2018). Structural damage identification using an enhanced thermal exchange optimization algorithm. Engineering Optimization,50(3), 430–451. https://doi.org/10.1080/0305215X.2017.1318872.

Kaveh, A., Hoseini Vaez, S. R., & Hosseini, P. (2019b). Enhanced vibrating particles system algorithm for damage identification of truss structures. Scientia Iranica,26(1), 246–256. https://doi.org/10.24200/sci.2017.4265.

Kaveh, A., Hosseini Vaez, S. R., Hosseini, P., et al. (2019a). A new two-phase method for damage detection in skeletal structures. Iranian Journal of Science and Technology, Transactions of Civil Engineering,43(S1), 49–65. https://doi.org/10.1007/s40996-018-0190-4.

Kaveh, A., Kalateh-Ahani, M., & Fahimi-Farzam, M. (2014). Damage-based optimization of large-scale steel structures. Earthquakes and Structures,7(6), 1119–1139. https://doi.org/10.12989/eas.2014.7.6.1119.

Kaveh, A., & Mahdavi, V. R. (2016). Damage identification of truss structures using CBO and ECBO algorithms. Asian Journal of Civil Engineering, 17(1), 75–89.

Kaveh, A., & Maniat, M. (2015). Damage detection based on MCSS and PSO using modal data. Smart Structures and Systems,15(5), 1253–1270. https://doi.org/10.12989/SSS.2015.15.5.1253.

Kaveh, A., & Sabzi, O. (2011). A comparative study of two meta-heuristic algorithms for optimum design of reinforced concrete frames. International Journal of Civil Engineering,9(3), 193–206.

Kaveh, A., & Zolghadr, A. (2012). An improved charged system search for structural damage identification in beams and frames using changes in natural frequencies. International Journal of Optimization in Civil Engineering, 2(3), 321–339.

Kaveh, A., & Zolghadr, A. (2015). An improved CSS for damage detection of truss structures using changes in natural frequencies and mode shapes. Advances in Engineering Software,80, 93–100. https://doi.org/10.1016/j.advengsoft.2014.09.010.

Kaveh, A., & Zolghadr, A. (2017a). Cyclical parthenogenesis algorithm for guided modal strain energy based structural damage detection. Applied Soft Computing,57, 250–264. https://doi.org/10.1016/j.asoc.2017.04.010.

Kaveh, A., & Zolghadr, A. (2017b). Guided modal strain energy-based approach for structural damage identification using tug-of-war optimization algorithm. Journal of Computing in Civil Engineering,31(4), 04017016. https://doi.org/10.1061/(ASCE)CP.1943-5487.0000665.

Khaji, N., & Dehghan Manshadi, S. H. (2015). Time domain linear sampling method for qualitative identification of buried cavities from elastodynamic over-determined boundary data. Computers & Structures,153, 36–48. https://doi.org/10.1016/j.compstruc.2015.02.011.

Khiem, N. T., & Tran, H. T. (2014). A procedure for multiple crack identification in beam-like structures from natural vibration mode. Journal of Vibration and Control,20(9), 1417–1427.

Kirsch, A. (2002). The MUSIC-algorithm and the factorization method in inverse scattering theory for inhomogeneous media. Inverse Problems,18(4), 1025.

Lee, J. (2009). Identification of multiple cracks in a beam using natural frequencies. Journal of Sound and Vibration,320(3), 482–490.

Li, H., Lu, Z., & Liu, J. (2016). Structural damage identification based on residual force vector and response sensitivity analysis. Journal of Vibration and Control,22(11), 2759–2770.

Li, X. Y., & Law, S. S. (2010). Adaptive Tikhonov regularization for damage detection based on nonlinear model updating. Mechanical Systems and Signal Processing,24(6), 1646–1664.

Marquardt, D. W. (1963). An algorithm for least-squares estimation of nonlinear parameters. Journal of the Society for Industrial and Applied Mathematics,11(2), 431–441.

Morassi, A., & Rollo, M. (2001). Identification of two cracks in a simply supported beam from minimal frequency measurements. Journal of Vibration and Control,7(5), 729–739.

Perera, R., & Fang, S. E. (2010). Multi-objective damage identification using particle swarm optimization techniques. In N. Nedjah et al. (Ed.), Multi-objective swarm intelligent systems (pp. 179–207). Berlin, Heidelberg: Springer.

Potthast, R. (2001). Point sources and multipoles in inverse scattering theory. Boca Raton: Chapman and Hall/CRC.

Potthast, R. (2006). A survey on sampling and probe methods for inverse problems. Inverse Problems,22(2), R1.

Quaranta, G., Carboni, B., & Lacarbonara, W. (2016). Damage detection by modal curvatures: Numerical issues. Journal of Vibration and Control,22(7), 1913–1927.

Rao, M. A., Srinivas, J., & Murthy, B. S. N. (2004). Damage detection in vibrating bodies using genetic algorithms. Computers & Structures,82(11–12), 963–968.

Saberi, M., & Kaveh, A. (2015). Damage detection of space structures using charged system search algorithm and residual force method. Iranian Journal of Science and Technology Transactions of Civil Engineering,39(C2), 215–229. https://doi.org/10.22099/ijstc.2015.3131.

Seyedpoor, S. M. (2012). A two stage method for structural damage detection using a modal strain energy based index and particle swarm optimization. International Journal of Non-Linear Mechanics,47(1), 1–8.

Tabrizian, Z., Afshari, E., Amiri, G. G., et al. (2013). A new damage detection method: Big Bang-Big Crunch (BB-BC) algorithm. Shock and Vibration,20(4), 633–648.

Teughels, A., & De Roeck, G. (2005). Damage detection and parameter identification by finite element model updating. Revue européenne de génie civil,9(1–2), 109–158.

Urgessa, G. S., & Esfandiari, M. (2018). Review of polymer coatings used for blast strengthening of reinforced concrete and masonry structures. In International congress on polymers in concrete (ICPIC 2018), 29 April 2018 (pp. 713–719). Cham: Springer. https://doi.org/10.1007/978-3-319-78175-4_91.

Wang, Y., Liu, J., Shi, F., et al. (2010). A method to identify damage of roof truss under static load using genetic algorithm. In International conference on artificial intelligence and computational intelligence, 2010 (pp. 9–15). Springer.

Wu, J. R., & Li, Q. S. (2006). Structural parameter identification and damage detection for a steel structure using a two-stage finite element model updating method. Journal of Constructional Steel Research,62(3), 231–239.

Yu, L., & Xu, P. (2011). Structural health monitoring based on continuous ACO method. Microelectronics Reliability,51(2), 270–278.

Funding

This research project has been financially supported by the Research Council of Islamic Azad University, Yazd Branch.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest in preparing this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Amiri, H.R., Esfandiari, M.J., Dehghan Manshadi, S.H. et al. A novel sensitivity-based method for damage detection of a structural element. Asian J Civ Eng 21, 1079–1093 (2020). https://doi.org/10.1007/s42107-020-00263-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42107-020-00263-x