Abstract

Edible films for food packaging application are an alternative approach to deal with the problem of disposal of plastic packaging materials. The edible films were prepared with varying proportions (0–100%) of pectin, casein and gelatin in the ratio of 100:0:0(F1), 0:100:0(F2), 0:0:100(F3), 50:0:50(F4), 50:50:0(F5), 0:50:50(F6), 50:25:25(F7), 25:25:50(F8), 25:50:25(F9). Among all the composite films, F7 film showed the best properties. The water solubility, moisture absorption and water vapor permeability of F7 film were reported as 40.59%, 17.75% and 1.07 × 10−12 g/Pa h m, respectively, and these were ahead of the other films. Color and tensile properties of F7 film were satisfactory and showed the high tensile strength of 8.63 × 105 Pa. Surface morphology of F7 film was found smooth, uniform and without cracks through SEM analysis. However, thermal decomposition of all composite films started above 200 °C. Clove essential oil is incorporated into the selected F7 film formatting solution at 0.5, 1 and 1.5% (v/v). The film incorporated with 1.5% clove essential oil showed the highest antimicrobial property against Escherichia coli. These composite films were biodegradable and possessed moderate mechanical properties and a low water vapor transmission rate.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Packaging is a vital part of the food industry, edible films for food packaging application is an alternative approach to deal with the problem of disposal of plastic packaging materials [1]. So the application of novel packages based on natural polymers facilitates the reduction of the use of synthetic packages which contemporary pose a severe problem of environment pollution. Edible films are formed from natural polymers, of animal or vegetable origin, such as polysaccharides, proteins and lipids [2]. The protein based films not only have impressive gas and water vapor barrier property, but also better mechanical properties compared to lipids and polysaccharides films due to its high intermolecular binding potential [3].

Casein constitutes approximately 80% of the total proteins in milk and has great potential for producing protein-based edible films [4]. Edible casein films have good oxygen barrier properties, hence suitable for products prone to oxidation. Casein based films are possessed good tensile strength and moderate elasticity under normal conditions when added with glycerol [5]. These films are highly moisture sensitive, which greatly affect the mechanical properties of the films and limits their range of utilization. Gelatin also possesses a great potential to form edible films due to its abundance, biodegradability and low cost [6], good sealing strength [7], but the gelatin films have poor water vapor barrier ability [8]. Pectin is also suitable for commercial applications such as drug encapsulation, tablet coating and disposable packaging materials for food and household products due to its good tensile properties [9].

To improve the physical and barrier properties of edible films made of just one component, it is possible to change their molecular structure using chemical reactions (such as cross linking) or also by physical treatments (such as heat, ultrasound or radiation) [10]. An alternative for these treatments is to design films composed of several components to combine the advantages of each one. Various authors reported the performance of composite films prepared with mixtures of different proteins or different carbohydrates or mixtures of carbohydrates and proteins [11, 12]. Essential oils have proven to be effective natural antimicrobial agents over a wide range of microorganisms and acceptance by consumers due to their eco-friendly and biodegradable properties [13, 14]. There are many studies dealing with the antibacterial activity of oils. Some essential oils, such as mint, clove, cinnamon, garlic, ginger, rosemary or oregano are natural preservatives and flavoring substances that are not harmful when consumed in food products. The incorporation of such active agent into edible films helps to inhibit the growth of bacteria and molds [15, 16].

The protein films have impressive gas, water vapor barrier and mechanical property and polysaccharide films have excellent gas permeability. However, combine protein and polysaccharides based film will be helpful for enhancing the shelf life of the food products by preventing dehydration, oxidative rancidity, and surface browning. The casein, gelatin and pectin contain various essential properties for making a film with its desired quality. Again active edible packaging refers to the incorporation of certain active agents into packaging film or within packaging containers with the aim of maintaining and extending product shelf life [17]. The essential oils from clove are natural substances that are not harmful when consumed in medicine and food products. The previous studies showed that clove essential oil is having antifungal, antiseptic, analgesic and anaesthetic effects as well as it was show the antifungal and antimicrobial activity [18, 19].

So, the present study was focused on developing the composite edible film by combining pectin, casein and gelatin incorporated with clove essential oil to achieve the best edible film with active and enhanced properties.

Materials and Methods

Materials

Pectin, casein and gelatin, glycerol, calcium chloride, magnesium carbonate, sodium hydroxide (analytical grade) were supplied by Hi Media laboratories (India) and an active agent, clove essential oil were purchased from local market. Escherichia coli (ATCC8739) strains were collected from the Department of Food Engineering and Technology, Tezpur University, Napaam, Assam, India.

Development and Standardization of Composite Edible Film

The blend films were composed of different combination (w/w) of casein, gelatin and pectin (Fig. 1). Nine films were prepared with varying proportions (0–100%) of pectin, casein and gelatine in the proportions of 100:0:0(F1), 0:100:0(F2), 0:0:100(F3), 50:0:50(F4), 50:50:0(F5), 0:50:50(F6), 50:25:25(F7), 25:25:50(F8), 25:50:25(F9). The weight of total solid matter (5 g/100 ml) in all the film forming solutions was kept constant. A polymer solution of pectin was prepared by dissolving 5 g pectin in 100 ml distilled water at 30 °C. The solution was mechanically stirred at 800 rpm for 1 h for complete dissolution. In a separate vessel aqueous solution of casein was prepared by dispersing 5 g casein in 100 ml distilled water at room temperature (28 ± 2 °C). Sodium hydroxide was added under constant magnetic stirring until pH 7.0 is reached. Stirring was done for 30 min to completely hydrate the protein [20]. Gelatin solution was prepared by adding 5 g gelatin in 100 ml distilled water at room temperature. The pectin, casein and gelatin solutions were mixed together and stirred at 55 °C for 10 min for proper mixing, stability and keeping property of suspension. Glycerol was added (40 ml/100 g of solid matter) to the suspension as a plasticizer for decreasing the brittleness of the film [21].

Suspensions were then cooled to 40 °C and then kept under vacuum (600 mm Hg) for 24 h to release all air bubbles. Then, the suspension was poured into glass petri plates (15 mm dia.) and dried at 60 °C in a tray dryer to cast the films. Dry films were peeled intact from the casting surface. The films were then immersed in 2% w/w CaCl2 solution for 10 min and dried at 40 °C for 12 h [22]. CaCl2 was used as most effective cross linking agent which increases the strength of films. The prepared films were conditioned at 55 ± 1% RH and 20 ± 1 °C in a desiccator containing a saturated solution of Mg(NO3)2.6H2O for 72 h, or till further tests. The casted films were analyzed for its thickness, water vapor permeability, moisture absorption, solubility in water, tensile properties, color, etc. All measurements were performed in three replicates. The best film was selected on the basis of its mechanical and barrier properties.

Incorporation of Active Agent into the Developed Film

The proportions of pectin, casein and gelatin of films having the best mechanical and barrier properties were chosen for preparing the final active film. The clove essential oil added in the film forming solution at different concentrations (0.5%, 1%, 1.5%). All the film forming mixtures were blended using homogenizer at room temperature. The films were prepared by casting an amount of mixture on plastics petri plates and then films were dried at 50% relative humidity (RH) to obtain films of uniform thickness. The dried films were peeled from the casting surface. Film characteristics including antimicrobial activity were determined after all sample films are preconditioned in a constant temperature humidity chamber 50% RH for 24 h.

Assessment of Film Properties

Film Thickness

Films were measured with hand-held micrometer (Alton M820-25, China) having a sensitivity of 0.01 mm. The ten pieces of films were stacked one above the other and thickness was recorded and an average thickness was recorded [23].

Water Vapor Permeability (WVP)

WVP of developed films were estimated using dish method. Glass beakers with an average diameter of 4 cm and a depth of 5.5 cm were used to determine WVP of films. The films were cut slightly larger than the diameter of the beaker. The dried silica gel (3.5 g) was placed in each beaker to maintain the relative humidity (RH) of 0%, and it was covered with developed film and sealed from all sides. Each beaker was placed in a desiccator containing saturated potassium sulphate solution to maintain the RH of 97% at 25 °C. The desiccator was kept in an incubator at 25 °C. Beaker were weighted every 24 h for 12 days and change in the weight of the cup were recorded as a function of time. Slopes were calculated by linear regression (weight change vs. time) and the water vapor transmission rate (WVTR) was defined as the slope (g/h) divided by transfer area (m2). WVP (g m−1h−1Pa−1) was calculated as follows [23].

where P is the saturation vapor pressure of water (Pa) at the test temperature (25 °C), R1 is the RH in the desiccator, R2 is the RH in the cup and X is the film thickness (m).

Moisture Absorption

The dried films were first conditioned at 0% RH (silica gel) for 24 h. The weight (Wo) of films were taken and they were conditioned in a desiccator containing CaNO3 saturated solution at 20 °C to ensure a relative humidity of 55%. Each conditioned films were weighed at desired intervals (Wt) until the equilibrium state was reached [24]. The moisture absorption of the samples is to be calculated as follows.

Moisture absorption (%) = [(Wt− Wo)/Wo] × 100

where Wt and Wo are the weights of the sample at time t and the initial weight of the sample, respectively.

Solubility in Water

Solubility in water is defined as the percentage of the dry matter of film which is solubilized after immersing for 24 h in water [25]. Film samples were kept in a desiccator containing dry calcium sulphate till they reached constant weight. Then about 500 mg of each film were immersed in beaker containing 50 ml of distilled water at 23 °C for 24 h with periodical gentle manual agitation. The films were removed from the water and placed back in the desiccator until they reached a constant weigh to obtain the final dry weight of the film. The percentage of the total soluble matter (%TSM) of the films was calculated as follows.

Tensile Properties

Length of elongation and strain to break of the films were measured by Kieffer Dough and Gluten Extensibility Rig (A/KIE) with the help of Texture Analyzer (TA-HDPlus, Stable Microsystems, UK). The thin strips (60 × 1 mm) were cut from each film and were used to analyze textural properties. The test had a tension mode with following settings. Pre-test speed of 2 mm/s, test speed of 3 mm/s, post test speed of 10 mm/s, distance of 75 mm, trigger force of 10 g was used and the probe was attached to a 5 kg load cell [11]. Tensile strength (Pa) was calculated by dividing the maximum force at break by the length and thickness of the film and percentage change in film length were considered as elongation at break (%) of film [Eq. (2), (3)] [26].

Film Color

The color of the developed films were measured using a Hunter Lab colorimeter (Ultrascan VIS, Hunter Lab. Inc., USA) with reflectance mode, CIELab scale (L*, a* and b*), The color measurements were expressed in terms of lightness L* (L* = 0 for black and L* = 100 for white), and the chromaticity parameters a[green (−) to red (+)] and b* [blue (−) to yellow (+)]. In addition, the total color change (dE) values were calculated from the Hunter L*, a* and b* scale were measured with absorption mode and used to describe the color change during addition of active agent [Eq. (4)] [27].

where, L0, a0, b0 are the initial color measurements of films and Lt, at, bt are the color measurements of active film with reflectance mode (RSIN), CIELab scale D65 as illuminant and a 10° observer angle as a reference system.

Film Surface Characteristics

Surface morphology of the films was observed under a Scanning Electron Microscope (JEOL JSM 6390 LV, Singapore). Dried film samples were sputter coated with platinum and the images were taken at an accelerating voltage of 5 kV and magnification of 1000X and 500X [14].

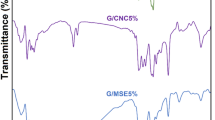

X-ray Diffraction

X ray diffraction patterns of pectin, casein, gelatin films and their composite films were analyzed using X ray diffractometer with Cu K –α radiation at a voltage of 30 kV and 15 mA. Samples were scanned between 2θ = 3°–60° with a scanning speed of 4.2°/3 min. Prior to testing, all the film samples were stored in a desiccator [28].

Thermal Properties

The thermal degradation properties of the films were determined by Thermo Gravimetric Analysis (TGA). Thermo gravimetric measurement was carried out on a thermal analyser, (TGA-60, Shimadzu). Non isothermal experiments were performed in the temperature range 25 °C–600 °C at heating rates of 10, 20 and 40 °C min−1 on each sample. The average sample size was 5 mg and the nitrogen flow rate was 30 min−1 [24].

Antimicrobial Property

Antibacterial activity test on films was carried out using the agar diffusion method [29]. The zone of inhibition assay on solid media was used for determination of the antibacterial effects of films against Escherichia coli (ATCC8739). The edible films were cut into 6 mm diameter discs and then placed on nutrient agar plates, which had been previously seeded with 0.2 ml of inoculums containing approximately 105–106 CFU/ml of tested bacteria. The plates were then incubated at 37 °C for 24 h. After that, the plates were examined for ‘zone of inhibition’ on the film discs.

Statistical Analysis

All the analyses were performed taking three replicates and data were reported as mean ± SD. One way ANOVA using ‘Data Analysis Tool’ of ‘Microsoft Excel’ was used to determine the critical difference of means, and variance among the different samples were checked at significance level P ≤ 0.05.

Results and Discussion

Effect of Different Compositions of Pectin, Casein and Gelatin on Film Properties

Film Thickness and Water Vapor Permeability

The average thickness of the prepared films was 0.195 ± 0.0023 mm. The water vapor permeability (WVP) values of the obtained films are shown in Table 1. The WVP value of pure pectin, casein and gelatin films were 1.75 × 10−12 g/Pa h m, 2.15 × 10−12 g/Pa h m and 1.46 × 1−12 g/Pa h m, respectively. The lowest WVP value of 1.07 × 10−12 g/Pa h m was observed for F7 film. The addition of pectin and gelatin caused the significant decrease in WVP values (P ≤ 0.05), resulting in better film resistance to water vapor transmission. However, pure casein (F3) film had WVP of 2.15 × 10−12 g/Pa h m, which is slightly higher than the pectin film (F1). The results for water vapor permeability indicate that the films, those containing only gelatin showed the lowest WVP values and highest tensile strength values; effects probably related to the degree of organization of the protein network, where the casein films probably presented less organization of the polymeric matrix and consequently less packing. According to Chen [30] simple, linear polymeric chains, such as those presented by various synthetic polymers, can be firmly packed, whereas molecules with voluminous chains such as proteins, are more loosely packed, presenting greater permeability. According to Mchugh, Weller, & Krochta [31], the structuring of a polymer inside the film matrix significantly affects the water vapor transference property. It might be also due to gelatinized pectin with α(1 → 4) linkages, which resulted in much tightened structures, resulting in limited mobility even after plasticizing. The tightened structures could possibly have offered greater resistance to mass transfer.

Moisture Absorption and Water Solubility

The moisture absorption and water solubility patterns of films are shown in Table 1. The film F1 showed the highest moisture absorption of 48.55%. However, moisture absorption of pectin films decreased significantly with the addition of casein and gelatin content (P ≤ 0.05). The F1 film had moisture absorption of 48.55% which reduced to 17.75% for (F7) film. The water solubility of pectin film (F1) was 48.55% which was more compared to the pectin, casein and gelatin blend film (F7). It was also observed that addition of increasing levels of casein and gelatin in the blend resulted in marked decreased in the solubility of the films in water (Table 1).

According to Gennadios, Brandenburg, Weller, & Testin [10], gelatin films have been formed as coatings to reduce oxygen, moisture and transport of oil and decrease in solubility due to a more closed matrix, owing to addition of casein and gelatin, making the blend film less accessible to water. This result is comparable with the decrease in WVP with concomitant increase in the concentration of casein and gelatin in the blend.

Tensile Properties

Tensile strength and elongation percentage was determined for comparing the mechanical performance of film. Films produced solely from casein or gelatin had significantly lowered tensile properties compared to the other blend films and pure pectin film (Table 1). The tensile strength of film increased significantly (P ≤ 0.05) with an addition of pectin to the casein and gelatin film composition and recorded the highest for F1 film and the lowest in F2 film. Casein film (F2) showed lower breakage strength, as it may absorb moisture exponentially with increased relative humidity and modifies the tensile properties of casein films [32]. However, increase in pectin in the film composition produced an inverse effect on the film elongation capacity. The tensile strength and percentage elongation for pure pectin (F1), pure casein (F2), pure gelatin (F3) and casein-gelatin-pectin (F7) film were reported as 13.53 × 105 Pa and 11.25%, 4.89 × 105 Pa and 31.05%, 3.36 × 105 Pa and 17.12%, 8.63 × 105 Pa and 21.23%, respectively.

Film Color

The nine different films produced varied in their color, mostly due to the addition of pectin, casein and gelatin in the blend. Casein left slightly an amber color in the films. Hunter color data revealed that film (F3) had the highest L* value (55.1) and lowest for the F6 film (33.81) (Table 1). The L value of F2 film was 38.71 which increased significantly to 44.80 for F7 film after addition of gelatin and pectin in casein. The concentration of casein in the final films was responsible for the difference in the color of the films. Redness (a* value) and yellowness (b* value) value of films decreased with addition of gelatin and concomitant increase in the pectin content and it was least for the pure films.

Film Surface Characteristics

The scanning electron micrographs of outer surface for selected films are shown in Fig. 2. The F7 film was found more homogeneous structures without cracks and there were no signs of phase separation between the components. This indicated that the three polymers are physically compatible with each other. The large crystal such as particles and irregularity can be observed in F8 film compared to F7 and F9 films. This crystal like particles might be due to gelatinized polysaccharide granules remaining on film [33].

Thermal Stability of Film

The curves of thermo gravimetric analysis for the selected films with the varying concentrations are shown in Fig. 3. A gradual loss of weight was observed in F7, F8 and F9 film till about 200 °C, afterwards the thermal decomposition behaviour started. The sharp weight loss was reported in the 250–350 °C regions for all the films. As the polysaccharide content in the films increased, the thermal stability also enhanced. However, pectin content in the blends helped to enhance for thermal stability of film. However, Su, Huang, Yuan, Wang, & Li [34] reported the weight loss for pure pectin in the temperature range of 300–500 °C.

Changes in Crystal Structure

Diffractograms of XRD in pectin, casein and gelatine based films can be seen in Fig. 4. The measurements were performed for films containing glycerol (40 ml/100 g) the results are very similar. Most of the diffractograms present an amorphous character with partial crystalline nature, indicating less tendency to re-crystallization, probably due to the high stability of these films, or, possible, due to increasing moisture in the films, avoiding any tendency to form semi-crystalline region.

Standardization of Film

The F7 film with a polymer blend of pectin, casein and gelatin (50:25:25) was finally selected due to its superior mechanical and barrier properties than the other blended films. The water solubility, moisture absorption and water vapor permeability of F7 film were reported as 40.59%, 17.75% and 2.81 × 10‾5 g/Pa h m, respectively, and it were ahead of the other films. Color and tensile properties of F7 film were satisfactory and showed the high breakage strength of 168.23 g. Surface morphology of F7 film was found smooth, uniform and without cracks through SEM analysis. However, thermal decomposition of this composite film started above 200 °C.

Effect of Clove Essential Oil on Film Performance

The clove essential oil was added in standardized film (F7) forming solution at different concentration (0.5, 1, and 1.5%) and film was casted. The effect of clove essential oil on film color and its antimicrobial activity against E. coli was checked.

Film Color

Color of the packaging is an important factor because they influence the consumer’s perception of acceptability. Edible casein, gelatin and pectin composite films without the incorporation of clove essential oil appeared clear and transparent and it had a slightly yellow appearance, due to the presence of casein. The addition of clove essential oil affected the appearance of the color of edible film and its transparency was reduced as shown in Table 2. As clove essential oil concentration increased, the color change (∆E) value of films were increased significantly (P < 0.05), with the highest ∆E observed at a level of 1.5% (54.68).

Antimicrobial Property of Film

The experimental inhibition areas for diffusion induced by the oil-containing films at 48 h, against E. coli are shown in Table 2. The listed inhibitory activities were estimated from area measurements of clear inhibition zones surrounding the film discs in the agar diffusion tests, respectively. Figure 5 shows typical inhibitory zones induced by different concentrations of the oil-containing films. With increasing concentration of clove essential oil the antimicrobial properties of films were enhanced. Similar results were reported for Matricaria recutita essential oil on antimicrobial properties of casein-based film against bacteria [16].

Conclusions

Pectin and casein, gelatin were successfully employed to fabricate the edible film. Nine films were prepared and among them three films showed the acceptable properties. Among the three films the F7 film prepared from pectin, casein and gelatine with the proportions of (50: 25:25) showed lower water vapor permeability, moisture absorption, water solubility and acceptable elongation capacity and breakage strength. Color value of the film was also acceptable with less yellowness and lighter film. Surface characteristics showed the uniformity of film as well as more thermal stability. Results of XRD reveal the typical broad isotropic amorphous character of these films, showing no tendency of re-crystallization, due possible to the high stability of these films or, the moisture present in them. Addition of pectin with casein and gelatin imparted an important influence on the barrier and mechanical properties of the resulted composite films. Addition of clove essential oil (1.5% v/v) to the best composite film results in reduction in microbial count with increasing zone of inhibition. For future prospects, this active film could be applied on fish fillet and their storage life may be observed.

References

Farris S, Schaich KM, Liu L, Piergiovanni L, Yam KL (2009) Development of polyion-complex hydrogels as an alternative approach for the production of bio-based polymers for food packaging applications: a review. Trends in Food Science & Technology 20:316–332

Bravin B, Peressini D, Sensidoni A (2006) Development and application of polysaccharide–lipid edible coating to extend shelf-life of dry bakery products. Journal of Food Engineering 76:280–290

Cuq B, Aymard C, CUQ JL, Guilbert S (1995) Edible packaging films based on fish myofibrillar proteins: formulation and functional properties. Journal of Food Science 60:1369–1374

Dangaran K, Tomasula PM, Qi P (2009) Structure and function of protein-based edible films and coatings. Edible films and coatings for food applications. Springer, New York, pp 25–56

Ginger MR, Grigor MR (1999) Comparative aspects of milk caseins. Comp Biochem Phys B 124:133–145

Bigi A, Cojazzi G, Panzavolta S, Roveri N, Rubini K (2002) Stabilization of gelatin films by crosslinking with genipin. Biomater 23:4827–4832

Tongnuanchan P, Benjakul S, Prodpran T, Pisuchpen S, Osako K (2016) Mechanical, thermal and heat sealing properties of fish skin gelatin film containing palm oil and basil essential oil with different surfactants. Food Hydrocoll 56:93–107

Sobral PD, Menegalli FC, Hubinger MD, Roques MA (2001) Mechanical, water vapor barrier and thermal properties of gelatin based edible films. Food Hydrocoll 15:423–432

Vandamme TF, Lenourry A, Charrueau C, Chaumeil JC (2002) The use of polysaccharides to target drugs to the colon. Carbohydrate Polymers 48:219–231

Gennadios A, Brandenburg AH, Weller CL, Testin RF (1993) Effect of pH on properties of wheat gluten and soy protein isolate films. Journal of Agriculture and Food Chemistry 41:1835–1839

Badwaik LS, Borah PK, Deka SC (2014) Antimicrobial and enzymatic antibrowning film used as coating for bamboo shoot quality improvement. Carbohydrate Polymers 103:213–220

Ryu SY, Rhim JW, Roh HJ, Kim SS (2002) Preparation and physical properties of zein-coated high-amylose corn starch film. LWT-Food Sci Technol 35:680–686

Burt S (2004) Essential oils: their antibacterial properties and potential applications in foods—a review. International Journal of Food Microbiology 94(3):223–253

Senna MM, El-Shahat HA, El-Naggar AWM (2011) Characterization of gamma irradiated plasticized starch/poly (vinyl alcohol)(PLST/PVA) blends and their application as protected edible materials. Journal of Polymer Research 18(4):763–771

Anuar H, Izzati ANF, Inani SSN, E’zzati MS, Salimah ASM, Ali FB, Manshor MR (2017) Impregnation of cinnamon essential oil Into plasticised polylactic acid biocomposite film for active food packaging. J Packag Technol Res 1(3):149–156

Sanla-Ead N, Jangchud A, Chonhenchob V, Suppakul P (2012) Antimicrobial activity of cinnamaldehyde and eugenol and their activity after incorporation into cellulose-based packaging films. Packag Technol Sci 25:7–17

Day BP, Potter L (2003) Active packaging. Food Packag Technol 5:282–300

Pinto E, Vale-Silva L, Cavaleiro C, Salgueiro L (2009) Antifungal activity of the clove essential oil from Syzygium aromaticum on Candida, Aspergillus and dermatophyte species. Journal of Medical Microbiology 58(11):1454–1462

Fu Y, Zu Y, Chen L, Shi X, Wang Z, Sun S, Efferth T (2007) Antimicrobial activity of clove and rosemary essential oils alone and in combination. Phytother Res 21(10):989–994

Chambi H, Grosso C (2006) Edible films produced with gelatin and casein cross-linked with transglutaminase. Food Research International 39:458–466

Cagri A, Ustunol Z, Ryser ET (2004) Antimicrobial edible films and coatings. J Food Protect 67:833–848

Fazilah A, Maizura M, Abd Karim A, Bhupinder K, Rajeev B (2011) Physical and mechanical properties of sago starch-alginate films incorporated with calcium chloride. Int Food Res J 18:1027–1033

Jridi M, Souissi N, Mbarek A, Chadeyron G, Kammoun M, Nasri M (2013) Comparative study of physico-mechanical and antioxidant properties of edible gelatin films from the skin of cuttlefish. International Journal of Biological Macromolecules 61:17–25

Ghanbarzadeh B, Almasi H, Entezami AA (2010) Physical properties of edible modified starch/carboxymethyl cellulose films. Innov Food Sci Emerg Tech 11:697–702

Borah PP, Das P, Badwaik LS (2017) Ultrasound treated potato peel and sweet lime pomace based biopolymer film development. Ultrasonics Sonochemistry 36:11–19

Chaichi M, Hashemi M, Badii F, Mohammadi A (2017) Preparation and characterization of a novel bionanocomposite edible film based on pectin and crystalline nanocellulose. Carbohydrate Polymers 157:167–175

Das P, Borah PP, Badwaik LS (2017) Transformation of chicken feather keratin and pomelo peel pectin into biodegradable composite film. J Polym Environ 26(5):2120–2129

Escamilla-García M, Calderon-Dominguez G, Chanona-Perez JJ, Farrera-Rebollo RR, Andraca-Adame JA, Arzate-Vazquez I, Moreno-Ruiz LA (2013) Physical and structural characterisation of zein and chitosan edible films using nanotechnology tools. International Journal of Biological Macromolecules 61:196–203

Genskowsky E, Puente LA, Pérez-Álvarez JA, Fernandez-Lopez J, Muñoz LA, Viuda-Martos M (2015) Assessment of antibacterial and antioxidant properties of chitosan edible films incorporated with maqui berry (Aristotelia chilensis). LWT Food Sci Technol 64(2):1057–1062

Chen H (1995) Functional properties and applications of edible films made of milk proteins. Journal of Dairy Science 78:2563–2583

Gennadios A, Mchugh TH, Weller CL, Krochta JM (1994) Edible coatings and films based on proteins. In: Krochta JM, Baldwin EA, Nisperos-Carriedo MO (eds) Edible coatings and films to improve food quality. CRC Press, p 201

Somanathan N (1996) Effect of environmental factors on the mechanical properties of grafted casein films: influence of humidity and biaxial orientation. Journal of Applied Polymer Science 62:1407–1414

Han XZ, Hamaker BR (2002) Partial leaching of granule-associated proteins from rice starch during alkaline extraction and subsequent gelatinization. Starch Stärke 54:454–460

Su JF, Huang Z, Yuan XY, Wang XY, Li M (2010) Structure and properties of carboxymethyl cellulose/soy protein isolate blend edible films crosslinked by Maillard reactions. Carbohydrate Polymers 79:145–153

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saikia, M., Badwaik, L.S. Characterization and Antimicrobial Property of Casein, Gelatin and Pectin Based Active Composite Films. J Package Technol Res 2, 233–242 (2018). https://doi.org/10.1007/s41783-018-0044-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41783-018-0044-3