Abstract

Natural stones are exposed to various physical, chemical and environmental interactions during service life. It is quite important to determine physico-mechanical properties of natural stones for specific applications. This paper presents an experimental study conducted to explore effect of acid and sulfate shocks on some physico-mechanical properties and color of natural stones. For this purpose, five different building stones used as marble (Malatya Beige, Ağrı Onyx, Adıyaman Crystal Emperador, Diyarbakır Black Pearl, Elazığ Rosso Levanto) were supplied from eastern region of Turkey. Point load strength, Schmidt hardness rebound, unit weight, porosity, water absorption and color measurements were conducted on provided natural stones. Additionally, mineralogical properties of natural stones were investigated with XRD and XRF analyses. Then, these natural stones were exposed to chemical shocks with 5% H2SO4 and Na2SO4 solutions for 0, 10, 20 and 30 cycles. Changes in Schmidt hardness, point load strength, porosity, dry weight and color after chemical shock cycles were investigated. Experimental results showed that Diyarbakır Black Pearl (DBP) and Malatya Beige natural stones might be used in aggressive H2SO4 and Na2SO4 environments for structural and ornamental purposes. After 30 cycles of H2SO4 and Na2SO4 shock, minimum decrease in point load values was obtained from DBP samples with 5.97% and 9.15%, respectively. Similarly, decrease in Schmidt harness values of DBP was minimum. Among natural stones exposed to H2SO4 and Na2SO4 shocks, AO sample that had the greatest strength loss was 17.36% and 9.68%, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Natural stones have been used as construction material for hundreds of years worldwide, and they are subject to various climates, seasonal and atmospheric effects. These external effects can cause deterioration of marbles partially or completely. Marbles deteriorate more severely in urban environments. Weathering of marbles exposed to aggressive environments is a field of study in constant development. Predicting response of marbles to environmental weathering is a key factor for assessing a constructions life span [1,2,3,4,5,6,7]. Marketability of marbles is affected by many factors such as atmospheric pollution, natural geochemical and physical processes-slow dissolution by rain water, salt deposition, recrystallization, freeze-thawing cycles, spalling, climatic factors, air pollution, industrial pollutant, chemical contaminants, solar radiation, (notably acid rain), bio-deterioration and thermal effects. These effects cause changes in color, stains, efflorescence, material loss, porosity and loosening of rock cohesion. As a result, color change caused from chemical reactions during exposure to external effect has a priority for evaluation of decay. Weathering may cause chemical changes as oxidation or rain, producing a change in color of stones [6,7,8,9,10,11,12,13,14,15].

Accelerated durability tests and decay processes are conducted in order to avoid such decay. These tests provide valuable knowledge about degree of degradation, including surface properties such as changes of color and roughness [6, 8, 16, 17]. The commercial value of ornamental stones depends on color [18]. The degradation of stones is related to both internal parameters of rock such as porosity, texture and structure, as well as human and natural atmospheric factors [19,20,21,22,23,24]. Environmental effects such as acidic and alkaline solutions can deteriorate durability characteristics of natural building stones. The physical deterioration of marbles exposed to acidic environment is more severe than basic environment. Decay of natural stones exposed to acidic environments is also more prominent due to presence of hydrogen ions that accelerate corrosion [10, 25]. Acid conditions lead to both physical and chemical changes in marbles. The changes on marble surfaces can be observed up to a few millimeters deep. Acid solutions such as carbonic acid (CO2H2O), sulfuric acid (H2SO4), sulfurous acid (SO2H2O) and nitric acid (HNO3) are main environmental effects that significantly destroy natural stones [9]. Sarıısık and Sarıısık (2011) investigated changes in unit weight by exposing natural stones having different water absorption and porosity to acidic environments. It was reported that as acid concentration increased, weight loss of natural stones having high porosity increased [10].

Another environmental factor affecting natural stones used for structural and ornamental purposes is salt crystallization [26]. The use of salt to de-icing in cold regions has increased salt damage that accelerates degradation of natural stones [27]. Especially porous rocks are more affected by salt crystallization due to their high water absorption ratios [6]. Sarıisik et al. (2010) investigated effect of sulfated water compounds on natural stones by exposing them to different sodium sulfate concentrations (Na2SO410H2O) under laboratory conditions. For this purpose, they determined changes in their physico-mechanical properties by exposing two different natural stone samples to 5.0%, 1.0%, 0.5% and 0.2% sulfate decahydrate solution (Na2SO410H2O). The salts that penetrate into natural stone cause voids in microstructure to grow over time and new cracks to form [28]. In Sarıisik and Sarıisik (2010), natural stones are exposed to various environmental factors throughout their lifetime and lose their initial strength over time. They stated that porosity, which is the most important factor affecting the magnitude of this loss, should be discussed in detail [29].

It is important to determine behavior under different environmental conditions for long-term durability of historical artifacts and monuments built with natural stones [8]. Turkey possesses considerable natural stone reserves and high market potential with different color and texture qualities up to 650 types. The general purpose of this research is to evaluate effects of acidic and basic atmospheres on physico-mechanical and surface (color) of different stones. Thus, H2SO4 and Na2SO4 were used to create acidic (pH: 2.0–2.2) and basic (pH: 12.0–12.2) atmospheres under laboratory conditions. The samples were subjected to 5% H2SO4 and 5% Na2SO4 solutions for 0, 10, 20 and 30 cycles. The changes in Schmidt hardness rebound, point load strength, porosity, dry weight and color were investigated. As a result of experimental study, it was revealed that Diyarbakır Black Pearl (DBP) exhibited most resistant behavior against chemical shocks in terms of change in Schmidt hardness, point load strength, porosity and dry weight properties.

Materials and methods

Materials

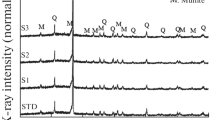

This study investigates effects of sulfate and acid conditions on five natural stones, which are obtained from eastern of Turkey. The sample codes, commercial names and origins are given in Table 1. In order to determine physical properties (unit weight, water absorption, Mohs hardness) of natural stones, five samples were used for each rock with dimensions of 50 × 50 × 50 mm. For point load strength test, a total of 240 samples (30 × 40 × 40 mm), 48 for each natural stone, were used. Unit volume weight and porosity of natural stones are made to TS EN 1936, and water absorption TS EN 13,755 standards [30, 31]. Mohs hardness, which is resistance of a mineral to scratching, is determined according to TS 6809 [32]. The physical properties, XRD and XRF analysis of samples are given in Tables 2, 3 and 4.

Chemical shock cycles

Chemical shock cycles were performed with procedures suggested by TS EN 14,066, with minor modification [33]. The samples were immersed in solutions with different pH values instead of distilled water. The samples were kept in oven at 105 °C for 18 h and then immersed in two different chemical solutions for 6 h at room temperature. The pH values of 5% H2SO4 and 5% Na2SO4 chemical solutions were kept constant in range of 2–2.20 and 10–10.20, respectively. The chemical solutions were renewed so that pH values remained within this ranges. After every 10 cycles, point load strength, porosity, weight loss, Schmidt hammer hardness and color changes were determined and their arithmetic averages were calculated.

Experimental tests

Point load test

Point load test is an accepted test procedure used to determine mechanical properties of natural stones. This index can also be used to indirectly predict other mechanical properties of natural stones. The block point load test was carried out in accordance with ISRM procedures [34]. The 40 × 40 × 30 mm samples were used for tests. Tests were carried out at the end of 0, 10, 20, 30 cycles.

Porosity

Porosity was determined in accordance with TS EN 1936 standard [30]. Samples were kept in distilled water for 48 h. The saturated samples were weighed in air and water, dried in oven for 24 h at 105 °C. Afterward, the weights of samples were re-measured. The porosity is calculated using Eq. (1)

where

n: porosity,

msat: weight of saturated samples,

mdry: weight of dry samples,

msub: weight of saturated samples in submerged in water.

Percentage change by weight

The samples were washed with distilled water so that no particles remained on them and then kept in an oven at 105 ± 5 °C for 24 h until their mass stabilized. After drying process, samples were cooled at room temperature. Initial weights of samples were determined (m1). Samples were shocked in 5% H2SO4 and 5% Na2SO4 solutions for 0, 10, 20, 30 cycles, and then, samples were dried for 24 h in an oven and cooled to room temperature, and final weight was determined (m2). Change in dry weight is calculated by Eq. (2).

ΔW = Change in dry weight, (%).

m1 = Initial weight of samples.

m2 = Final weight of samples.

Schmidt hardness

Schmidt hardness test has been increasingly used because of its simplicity, rapidity, non-destructiveness and portability [35]. Schmidt hardness was determined in accordance with ISRM (1978) at the end of 0, 10, 20 and 30 cycles [36]. Schmidt hammers are divided into 2 as L and N types when classified according to their impact energies. The impact energy of L type hammers is 0.735 Nm, and impact energy of N type Schmidt hammer is 2.207 Nm. However, when hardness testing is performed on core samples in laboratory, L type hammer is used instead of N type hammer. In this study, L type Schmidt hammer was used in experiments.

Color changes

The color change was assessed using Konica-Minolta color reader. In CIELAB system, color is quantified according to three chromatic coordinates: “a” parameter is red-green axis (a < 0 green; a > 0 red); “b” parameter is yellow-blue axis (b < 0 blue; b > 0 yellow) and L parameter represents lightness or luminosity (L = 100 white; L = 0 dark) [37]. The CIELAB coordinate system is given in Fig. 1 [15]. The total color differences (∆E) are defining total color changes and determined in Eq. (3) [38].

Result and discussion

Porosity, dry weight, Schmidt hardness and point load strength of samples after chemical shocks of 0, 10, 20 and 30 cycles are given as a whole in Table 5. Moreover, changes in these parameters after 30 cycles are also presented by percentage in Table 6. Then, findings are interpreted graphically in related title.

Color changes

After chemical shocks, color modifications occurred in all samples. At 30 cycles, color and lightness values of samples are given in Table 7. The total color differences after chemical shocks of samples are given in Table 8 and trends are given in Fig. 2.

At the end of chemical shocks, color change was observed in all samples. H2SO4 shock led to more noticeable changes compared to Na2SO4. At 30 cycles, dark color samples (ERL, DBP and ACE) exhibited more evident color changes compared to MB and AO samples. The L, a, b are different in all samples. The most prominent color changes in terms of L occurred in ERL and DBP sample after chemical shocks. The glossiness of ERL and DBP showed higher increase compared to other samples. The color changes due to chemical shocks in case of lightness (L) are different in all samples. The remarkable differences occurred in ERL and DBP samples.

All samples have large redness. H2SO4 shock has positive effect on redness, except for ACE samples. Na2SO4 shock has negative effect on AO, ACE and ERL samples. In MB and DBP samples, Na2SO4 shock led to increase in redness. Except from DBP, all of samples had large yellowness. H2SO4 shock led to decrease in yellowness in ERL, AO, DBP samples. Na2SO4 led to increase in yellowness except for AO samples. When total color changes after H2SO4 and Na2SO4 cycles are examined, it is seen that the biggest change is in ERL (66.74%) and AO (50.64%), while the lowest change is in MB (17.39%) and ACE (16.39%) samples, respectively. Change in visual appearance of samples after chemical shocks of 30 cycles is also given in Table 9. When samples are examined, it is clearly seen that there was a significant decrease in surface glossiness of all samples. The glossiness of samples was not uniformly affected by chemical solutions after 30 cycles. In light-colored sample group (such as MB, AO and ACE), it was observed that a noticeable yellowing in color occurred after H2SO4 shock. In dark-colored sample group (such as ERL and DBP), there was lightening in color after chemical solutions.

Change in Schmidt hardness

Schmidt hardness changes of samples after chemical shocks are given in Figs. 3 and 4.

There was not significant decrease in Schmidt hardness values of DBP and MB samples. After H2SO4 and Na2SO4 shock cycles, there is a decrease of 4.33–2.5% in DBP sample and 6.68–3.23% in MB sample, respectively. However, there was a noticeable decrease in Schmidt hardness values of ERL, AO and ACE samples after immersion in H2SO4 and Na2SO4 solutions. After H2SO4 and Na2SO4 shock cycles, there is a decrease of 17.36–9.68% in AO sample, 14.11–7.07% in ACE sample, and 11.02–5.63% in ERL sample, respectively. This decrease may be associated with increase in porosity of ERL, AO and ACE samples. Additionally, water absorption by weight and by volume of ERL, AO and ACE samples is higher and point load strength values are low. Similarly, Taghipour et al. (2015) investigated durability of limestones obtained from Dariyan and Ilam formations against acid solutions and stated that Dariyan limestone showed lower Schmidt hammer rebound values than Ilam limestone due to lower strength properties and durability [39]. Figure 5 shows decrease in Schmidt hardness by percentage.

Change in porosity

The porosity values of samples after chemical shocks of 0, 10, 20 and 30 cycles are given in Figs. 6 and 7.

When porosity changes are examined, there are changes depending on pH value of chemical and cycle’s number. However, Na2SO4 shock does not lead to serious changes in porosity. There is a significant increase in porosity of samples (especially ERL, AO and ACE) immersed in H2SO4 solution. Transition of chemical solutions into samples caused expansion of pores and existing of new pores. As a result of experimental and statistical studies on similar rock types, it was observed that the strength decreased as porosity increased [40]. In this study, it was determined that porosity increased and point load strength decreased as pH value decreased.

Change in dry weight

Increase in porosity and water absorption capacity of samples is most important parameters affecting decay rate and weight loss. Dry weight losses by percentage of samples at the end of 30 cycles are shown in Fig. 8. Chemical shocks led to a decrease in dry weight of all samples. The dry weight was not uniformly affected by chemical shocks. Samples exposed to H2SO4 shock exhibited higher decrease in dry weight than Na2SO4. After H2SO4 and Na2SO4 shock, minimum dry weight loss occurred in DBP samples with 0.86% and 0.03%, respectively. Similarly, DBP samples are more durable than others in terms of Schmidt hammer hardness and point load test values. ERL, AO and ACE samples exposed to chemical shock showed higher decrease in dry weight. After H2SO4 and Na2SO4 shock cycles, there is a decrease of 2.05–0.14% in AO sample, 1.78–0.38% in ACE sample, and 1.51–0.27% in ERL sample, respectively. This may be because ERL, AO and ACE samples have higher porosity and water absorption capacity.

Change in point load strength

The point load strength values of samples after chemical shocks are given in Figs. 9 and 10.

There was decrease in point load values of all samples in both H2SO4 and Na2SO4 solutions. Decrease in point load values of samples immersed in H2SO4 solution was more than ones immersed in Na2SO4. Similarly, Sharma et al. (2007) revealed that physico-mechanical properties of sample were adversely affected by an acidic and alkaline watery environment. The reduction recorded in physico-mechanical properties was lower in an alkaline environment, compared to an acidic environment. In acidic environment, greater decrease in strength is due to fact that a higher concentration of hydrogen ions accelerates rate of abrasion [10, 25]. After 30 cycles, minimum decrease in point load values was obtained from DBP samples with 5.97% and 9.15%, respectively. Similarly, decrease in Schmidt harness values of DBP was minimum. It is known that there is a general relation between rock strength and porosity [40,41,42]. Smaller porosity results in greater rock strength [43]. DBP was most resistant after chemical shocks in terms of change in Schmidt hardness, point load strength, porosity and dry weight properties. However, ERL, AO and ACE samples were weaker against H2SO4 and Na2SO4 conditions. Decrease in point load strength by percentage at the end of 30 cycles is shown in Fig. 11. After H2SO4 and Na2SO4 shock cycles, there is a decrease of 24.72–15.96% in AO sample, 20.69–15.02% in ACE sample, and 18.45–12.22% in ERL sample, respectively. Both point load and Schmidt hardness values are inversely related to porosity. It was observed that point load and Schmidt hardness values decreased with increasing porosity.

Conclusion

Natural stones are exposed to various atmospheric effects during their service life, and their strength properties decrease over time. This paper presents an experimental study conducted to explore some physico-mechanical properties of five different samples after exposed to Na2SO4 and H2SO4 shocks up to 30 cycles. The following conclusions are drawn from this study:

-

H2SO4 shock led to more noticeable color changes compared to Na2SO4. The glossiness of ERL and DBP showed higher increase compared to other samples. H2SO4 shock has positive effect on redness, except for ACE samples. H2SO4 shock led to decrease in yellowness in ERL, AO, DBP samples. In dark-colored sample group (such as ERL and DBP), there was lightening in color after chemical solutions. When total color changes (ΔE) are examined, the greatest change after H2SO4 cycle is seen in ERL sample with 66.74%, while the greatest change after Na2SO4 cycle is in AO sample with 50.64%.

-

There was not significant decrease in Schmidt hardness values of DBP and MB samples. After H2SO4 and Na2SO4 shock cycles, a percent loss was obtained in DBP sample of 4.33–2.5% and in MB sample of 6.68–3.23%, respectively.

-

There are changes in porosity values depending on pH value of chemical and number of cycles. However, it was observed that Na2SO4 shock did not cause serious changes in porosity.

-

There were parallel decreases in weight losses due to increase in porosity and water absorption capacity of samples. Considering percent weight losses, the greatest loss after H2SO4 cycle is seen in AO sample with 2.5%, while the greatest loss after Na2SO4 cycle is in ACE sample with 0.38%.

-

Point load strength test is one of the most important methods used to determine indirectly compressive and tensile strength values of rocks. In this study, point load strength was performed as a mechanical parameter. There was decrease in point load strength of all samples in both H2SO4 and Na2SO4 solutions. After 30 cycles, minimum decrease in point load strength was obtained from DBP samples with 5.97% and 9.15%, respectively.

DBP and MB samples may be preferred in Na2SO4 and H2SO4 environments when used for structural and ornamental purposes. However, ERL, AO and ACE samples are not suitable for such aggressive environments because of its high porosity and water absorption capacity. Additionally, it will be beneficial to investigate effect of different acidic and alkaline environments (acid rain related attack and dissolution, salt crystallization, and freeze–thaw cycles, etc.) on physico-mechanical properties of samples obtained from different rock types with different porosity and water absorption capacity.

References

Barone G, Mazzoleni P, Pappalardo G, Raneri S (2015) Microtextural and microstructural influence on the changes of physical and mechanical proprieties related to salts crystallization weathering in natural building stones. The example of Sabucina stone (Sicily). Constr Build Mater 95:355–365. https://doi.org/10.1016/j.conbuildmat.2015.07.131

Scrivano S, Gaggero L, Gisbert Aguilar J (2018) Micro-porosity and mineropetrographic features influences on decay: experimental data from four dimension stones. Constr Build Mater 173:342–349. https://doi.org/10.1016/j.conbuildmat.2018.04.041

Navarro R, Pereira D, Gimeno A, Del Barrio S (2018) Influence of natural carbonation process in serpentinites used as construction and building materials. Constr Build Mater 170:537–546. https://doi.org/10.1016/j.conbuildmat.2018.03.100

Jian-bin L, Zhong-jian Z, Biao L (2019) Microscopic & macroscopic characterizations of Beijing marble as a building material for UNESCO heritage sites: new insights into physico-mechanical property estimation and weathering resistance. Constr Build Mater 225:510–525. https://doi.org/10.1016/j.conbuildmat.2019.07.094

Cardenes V, Mateos FJ, Fernandez-Lorenzo S (2014) Analysis of the correlations between freeze-thaw and salt crystallization tests. Environ Earth Sci 71:1113–1134. https://doi.org/10.1007/s12665-013-2516-7

Vazquez P, Luque A, Alonso FJ, Grossi CM (2013) Surface changes on crystalline stones due to salt crystallization. Environ Earth Sci 69:1237–1248. https://doi.org/10.1007/s12665-012-2003-6

Careddu N, Marras G (2013) The effects of solar UV radiation on the gloss values of polished stone surfaces. Constr Build Mater 49:828–834. https://doi.org/10.1016/j.conbuildmat.2013.09.010

Cardell C, Benavente D, Rodriguez-Gordill J (2008) Weathering of limestone building material by mixed sulfate solutions. Characterization of stone microstructure, reaction products and decay forms. Mater Charac 59:1371–1385. https://doi.org/10.1016/j.matchar.2007.12.003

Ross M, McGee ES, Ross DR (1989) Chemical and mineralogical effects of acid deposition on Shelburne Marble and Salem Limestone test samples placed at four NAPAP weather-monitoring sites. Am Mineral 74:367–383

Sarıısık A, Sarıısık G (2011) Environmental interaction properties of marble used in the restoration of historical monuments (Dalyan-Kaunos). Ekoloji 20(79):12–20. https://doi.org/10.5053/ekoloji.2011.792

Vazquez P, Carrizo L, Thomachot-Schneider C, Francisco SG, Alonso J (2016) Influence of surface finish and composition on the deterioration of building stones exposed to acid atmospheres. Constr Build Mater 106:392–403. https://doi.org/10.1016/j.conbuildmat.2015.12.125

Grossi CM, Alonso FJ, Esbert RM, Rojo A (2007) Effect of laser cleaning on granite color. Color Res Appl 32(2):152–159. https://doi.org/10.1002/col.20299

Royer-Carfagni GF (1999) On the thermal degradation of marble. Int J Rock Mech Min Sci 36:119–126. https://doi.org/10.1016/S0148-9062(98)00169-7

Ozguven A, Ozcelik Y (2014) Effects of high temperature on physico-mechanical properties of Turkish natural building stones. Eng Geol 83:127–136. https://doi.org/10.1016/j.enggeo.2014.10.006

Eren-Sarici D (2016) Thermal deterioration of marbles: gloss, color changes. Constr Build Mater 102:416–421. https://doi.org/10.1016/j.conbuildmat.2015.10.200

Török A, Rozgonyi N (2004) Morphology and mineralogy of weathering crusts on highly porous oolitic limestones, a case study from Budapest. Environ Geol 46(3–4):333–349. https://doi.org/10.1007/s00254-004-1036-x

Ausset P, Del Monte M, Lefevre RA (1999) Embryonic sulphated black crusts on carbonate rocks in atmospheric simulation chamber and in the field: role of carbonaceous fly-ash. Atmos Environ 33:1525–1534. https://doi.org/10.1016/S1352-2310(98)00399-9

Gökay MK, Gundogdu IB (2008) Color identification of some Turkish marbles. Constr Build Mater 22(7):1342–1349. https://doi.org/10.1016/j.conbuildmat.2007.04.016

Massey SW (1999) The effects of ozone and NOx on the deterioration of calcareous stone. Sci Total Environ 227(2–3):109–121. https://doi.org/10.1016/S0048-9697(98)00409-4

Müller U (2008) The mineralogical composition of sandstone and its effect on sulphur dioxide deposition. Mater Constr 58:81–95. https://doi.org/10.3989/mc.2008.v58.i289-290.86

Lipfert FW (1989) Atmospheric damage to calcareous stones: comparison and reconciliation of recent experimental findings. Atmos Environ 23(2):415–429. https://doi.org/10.1016/0004-6981(89)90587-8

Sweevers H, Van Grieken R (1992) Analytical study of the deterioration of sandstone, marble and granite. Atmos Environ Part B Urban Atmos 26(2):159–163. https://doi.org/10.1016/0957-1272(92)90019-O

Grossi CM, Murray M, Butlin RN (1995) Response of porous building stones to acid deposition. Water Air Soil Pollut 85(4):2713–2718. https://doi.org/10.1007/BF01186244

Bonazza A, Messina P, Sabbioni C, Grossi CM, Brimblecombe P (2009) Mapping the impact of climate change on surface recession of carbonate buildings in Europe. Sci Total Environ 407(6):2039–2050. https://doi.org/10.1016/j.scitotenv.2008.10.067

Sharma PK, Khandelwal M, Singh TN (2007) Variation on physico-mechanical properties of Kota stone under different watery environments. Build Environ 42:4117–4123. https://doi.org/10.1016/j.buildenv.2006.11.032

Alves C, Figueiredo C, Mauricio A, Braga MAS, Aires-Barros L (2011) Limestone under salt decay test: assessment of pore network-dependent durability predictors. Environ Earth Sci 63:1511–1527. https://doi.org/10.1007/s12665-011-0915-1

Lubelli B, De Rooij MR (2009) NaCI crystallization in restoration plasters. Constr Build Mater 23:1736–1742. https://doi.org/10.1016/j.conbuildmat.2008.09.010

Sarıısık A, Sarıısık G, Senturk A (2010) Characterization of physical and mechanical properties of natural stones affected by ground water under different ambient conditions. Ekoloji 19(77):88–96. https://doi.org/10.5053/ekoloji.2010.7713

Sariisik A, Sariisik G (2010) Quality control of Turkish calcareous natural stone using the merkont system. J Test Eval 38(5):575–587. https://doi.org/10.1520/JTE102774

TS EN 1936 (2010) Natural stone test methods- Determination of real density and apparent density and of total and open porosity. Turkish Standardization Institute, Ankara (in Turkish)

TS EN 13755 (2009) Natural stone test methods - Determination of water absorption at atmospheric pressure. Turkish Standardization Institute, Ankara (in Turkish)

TS 6809 (2012) Determination of scratch hardness according to Mohs Scale. Turkish Standards Institution (TSE), Ankara (in Turkish)

TS EN 14066 (2015) Natural stone test methods - Determination of resistance to ageing by thermal shock, Turkish Standards Institution (TSE), Ankara (in Turkish)

ISRM (1985) Suggested method for determining point load strength. Int J Rock Mech Min Sci Geomech Abstr 22:51–60. https://doi.org/10.1016/0148-9062(85)92327-7

Kahraman S, Fener M, Gunaydin O (2002) Predicting the schmidt hammer values of in-situ intact rock from core sample values. Int J Rock Mech Min Sci 39:395–399. https://doi.org/10.1016/S1365-1609(02)00028-X

ISRM (1978) Suggested methods for determining hardness and abrasiveness of rocks. Int J Rock Mech Min Sci Geomech Abstr 15:89–97. https://doi.org/10.1016/0148-9062(78)91509-7

Sousa LMO, Gonçalves BMM (2013) Differences in the quality of polishing between sound and weathered granites. Environ Earth Sci 69:1347–1359. https://doi.org/10.1007/s12665-012-2035-y

Ozguven A, Ozcelik Y (2013) Investigation of some property changes of natural building stones exposed to fire and heat. Constr Build Mater 38:813–821. https://doi.org/10.1016/j.conbuildmat.2012.09.072

Taghipour M, Nikudel MR, Farhadian MB (2015) Engineering properties and durability of limestones used in Persepolis complex, Iran, against acid solutions. Bull Eng Geol Environ. https://doi.org/10.1007/s10064-015-0821-y

Farrokhrouz M, Asef MR (2017) Experimental investigation for predicting compressive strength of sandstone. J Nat Gas Sci Eng 43:222–229. https://doi.org/10.1016/j.jngse.2017.03.023

Atapour H, Mortazavi A (2018) The influence of mean grain size on unconfined compressive strength of weakly consolidated reservoir sandstones. J Petr Sci Eng 171:63–70. https://doi.org/10.1016/j.petrol.2018.07.029

Özdemir E, Eren Sarici D (2018) Combined effect of loading rate and water content on mechanical behavior of natural stones. J Min Sci 54:931–937. https://doi.org/10.1134/S1062739118065072

Kahraman S, Gunaydin O, Fener M (2005) The effect of porosity on the relation between uniaxial compressive strength and point load index. Int J Rock Mech Min Sci 42:584–589. https://doi.org/10.1016/j.ijrmms.2005.02.004

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no confict of interest.

Rights and permissions

About this article

Cite this article

Özdemir, E., Kantarcı, F. & Eren Sarıcı, D. Effects of acid–base solutions on some Turkish natural building stones: physico-mechanical and color changes. Innov. Infrastruct. Solut. 7, 103 (2022). https://doi.org/10.1007/s41062-021-00698-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-021-00698-4