Abstract

In recent decades, with the advance of industrialization, the huge amount of waste discarded by industries has generated discussions about self-sustainable solutions. One of these solutions is artificial stone, as the use of waste can be a good alternative for the production of this type of material. Therefore, the main objective of the present work was to evaluate the influence of young scales of arapaima gigas on the reinforcement of artificial stones made with quarry dust and epoxy resin, by the process of vibration, compression, and vacuum. The residue was divided into three granulometric ranges by the sieving method: Coarse and medium (quarry dust) and fine (quartzite). Data were treated through statistical analysis, using analysis of variance (ANOVA). The proportions obtained were 5, 7, and 8 (50% coarse and medium), (33% coarse, medium and fine) and (67% coarse, 17% medium, and 16% fine). The 3 developed compositions were submitted to the physical index test. The result obtained classified the composition 7 for the incorporation of arapaima scales, and the physical index, bending, and charpy impact tests were performed to characterize the developed stone. The results obtained indicate that the artificial stone with pirarucu scale had a porosity of 0.67% greater than the one without scale, indicating lack of adhesion of the scale with the residues. The mechanical strength was higher, 34.7 ± 2.7 Mpa due to the arapaima scales having a high strength. The impact energy of charpy was 28.3 ± 4.6 J/m for the scaled artificial stone and 24.1 ± 4.9 J/m for the scaleless stone.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

The search for the delicate balance between economic growth and sustainability has been one of the core issues. The underlying idea is that economies should be able to maintain sustained growth over time, but consuming fewer natural resources and avoiding the degradation of the environment [1]. The most challenging task is to use the waste from the industry in the right place. Waste comes out of the industry in many ways. Some waste causes air pollution and some waste is responsible for soil pollution [2].

Tons of ornamental stone residues are produced throughout the world every year. These residues are improperly discarded in the environment, causing serious public health problems, since they release a powder into the atmosphere. When inhaled, these substances cause respiratory complications [3].

The Brazilian ornamental stone sector assumes a privileged position in the global mineral market, producing an equivalent of 8.3 million tons in 2017 with the southeastern region of Brazil responsible for approximately 60% of this amount. Although this sector is already consolidated, its production process is still rudimentary and inefficient, and the waste is primarily disposed of in a disorderly manner [4].

Arapaima gigas, also known as pirarucu in Brazil, is considered one of the largest water fish, reaching a maximum weight close to 200 kg and length between 2 and 3 m. how many fish are covered with scales that can reach 10 cm in length, that is, aids to self-defense due to their natural habitat in rivers of the Amazon basin, which become infested by piranhas with the advance of the dry season. Arapaima scales are an example of material that evolved to provide protection from predators. They feature laminated composite structures coated with a pattern of compensated collagen layers and reinforced with nanocrystals. Collagen fibers are arranged in a cross-lamellar arrangement, resulting in a laminated composite [5,6,7].

The study of these biological materials has become increasingly attractive and reveals a range of new structures, mechanical responses, and design principles that match and often surpass synthetic materials with similar functions. The fish industry has pointed to promising prospects due to the existing demands in the markets of Asia, Africa, Latin America, and the Caribbean, this contrasts with the difficulties that the fishing sector faces, especially with regard to waste from the fish process, with highlighting the scales which are solid waste that can correspond to 1% of the total mass of the fish [7].

The quarry dust stone residue considered waste from the process of obtaining crushed stone, is called quarry fines with granulometry (<4.8 mm). It is almost always present in large quantities, they are harmful to the environment due to the dust generated, the silting produced by the drainage, and the space occupied in the quarry itself. These quarries generate a significant amount of fines mainly in the rock-crushing process. Quarry fines are accumulated in restricted areas around crushing plants, on the surface, as they are not properly used [8].

Artificial stones have demonstrated a high market value and also an increasing demand in recent times. Typically named as stone industrialized consists of 95% natural aggregates, that is, substantially a natural material. Among the advantages artificial stones are solid, impermeable, good mechanic resistant, and had liquid penetration resistant, remaining only on the surface. This is caused by resin used in the manufacturing process, that provide adhesion between the stone particles and also penetrate between the interstices, eliminating the porosity of natural stones [9].

The physical and mechanical properties of the artificial stone are the main influencing factors to its use in the construction industry. These properties are directly related to the resin content and the microstructure which can be seen in the production process [10].

Therefore, the present work main goal was to evaluate the influence of young arapaima gigas fish scales reinforcing engineered artificial stone made with waste quarry dust and epoxy resin.

Materials and Methods

The quarry dust fine particles waste was collected as tail from a pebble separation process in the Itereré quarry located in the mountain region of Serra da Bela Vista, at 17 km from the city of Campos dos Goytacazes, north of state of Rio de Janeiro, Brazil. After collection, the waste was subjected to ball milling for further reduction in particle size. By means of dry sieving, the reduced waste was then separated into three granulometric classes: (i) large, from 2 to 0.71 mm, (ii) medium, from 0.71 to 0.063 mm, and (iii) fne particles, grains with size less than 0.063 mm. The quartzite residue was supplied by the Mineral Technology Center (CETEM), located in the city of Cachoeiro, state of Espirito Santo, Brazil. Whose granulometry was below 0.063 mm. The arapaima was acquired frozen at 3 to 4 months of age, the scales were removed with pliers and placed in an oven at 60 °C until constant mass was acquired (Fig. 1).

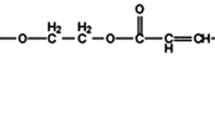

The epoxy used as binding for the waste particles was a diglycidyl ether of bisphenol A (DGEBA) resin mixed with the triethylene tetramine (TETA) supplied by Epoxyfber, Brazil. The supplier indicated the density of the epoxy as 1.15 g/cm3.

Determination of the Highest Packaging Granulometric Composition

Based on three ranges of grains obtained, 10 different mixtures with different percentages of rough, medium and fine particles were proposed. Figure 2 shows a complete ternary diagram developed in the experimental numeric-modeling grid Simplex (Simplex-Lattice Design) to obtain greater packaging, each vertex of the triangle corresponds to 100%: large (L), medium (M) and fine (F) particles. The other points in the triangle display (in parenthesis) the fractions corresponding to the mixtures. To determine the proportion of the greatest packaging of the 10 mixtures. (Tcharllis) For each composition, the test was done three times for assuring statistical validation. Each sample of waste compositional mixture was placed in a steel vessel and left vibration for 2 min under a load of 10 kg. The mixture was weighed and the apparent density was calculated.

Ternary diagram with the 10 mixtures based on the complete cubic model of the Simplex. Amounts (wt%) of Large (L), Medium (M), and Fine (F) particles [8]

The treatment of the data obtained from the vibrated density was performed, using analysis of variance (ANOVA) of the completely randomized design (DIC) (p ≤ 0.05), in order to verify the existence of statistical significance between the treatment performed. Once the statistical difference was confirmed, Tukey's means comparison test (p ≤ 0.05) was performed in order to verify which trait obtained the best results. The calculations were performed using the excel tool of the office package.

Production of Artificial Stone Plates

Thus, for the 3 compositions, artificial stone slabs with 85% by weight of the residue with 15% by weight of epoxy resin with dimension 100 × 100 × 15 mm were produced by processing under vacuum, vibration and compression.

Initially, the residue was dried in an oven at 100 °C to remove moisture, then it was weighed and placed inside the mixer, and the resin was added to complete the entire mixture. After all the mass was mixed it was deposited in the mold and connected to a vacuum system. Already under vacuum, the mold was placed on a vibrating table, to promote the spreading of the mass in the mold cavity and facilitator the removal of air bubbles that might be in the mass. After the vibration time, the mold, still under vacuum, was taken and placed in the Marcone MA 098-A hydraulic press where specimens were produced with a compression pressure of 3 MPa at 90 °C [10, 11].

Only after pressing was the mold disconnected from the vacuum system and cooled at room temperature to remove the artificial stone plate, which was then sanded and cut according to the standard for each test.

For the plates with the arapaima scales, the process was the same. The scales were placed in the middle of the plate, representing the structure of the arapaima scales and then taken to the press.

Characterization of Artificial Stone Plates

The values of density, water absorption and apparent porosity were obtained from the standard tests according to the norm ABNT NBR 15,845–2: 2015 [12]. For each condition, 15 specimens were made with dimensions of 30 × 30 × 15 mm.

Ten prismatic specimens, with dimensions of 10 × 10 × 25 mm, were three points bend tested in a model 5582 Instron machine following the recommendation for agglomerated stones as per the Brazilian NBR 15.845–6:2015 standard [13].

A total of 8 specimens for Charpy impact test were obtained by cutting each plates and sanded to suit the ASTM D256 standard [14] recommendations of 62 × 12 × 10 mm. Later a notch with 45° was made and tests were conducted in a PANTEC model XC-50 pendulum with a 22 J hammer.

Results

Table 1 presents the values obtained through the SLD method for the average density of vibrated mixtures of waste from fluorescent lamps according to Fig. 1.

As it is a parameter of the mean of the vibrated densities, the data were treated with analysis of variance considering a completely randomized design (DIC) carried out with a 95% confidence level (p ≤ 0.05), with subsequent contrasts of means by Tukey's test (Table 2).

Analyzing the results obtained in Table 2, it is possible to verify that the treatments studied present statistical difference, which means that among the 10 mixtures, at least three are differentiated. An important point to remember is that the coefficient of variation for the test was 1.91%, which represents that the results obtained are highly reliable.

To differentiate, the Tukey test was used, where it was possible to conclude that the treatments with the highest densities are at 5, 7, and 8. The Tukey test statistically proves that the addition of fine granulometry presents one of the highest densities, due to the fact that the smaller particles fill the voids between the larger ones. At the same time, it is very difficult to develop a model that can predict the behavior of mixtures involving non-spherical particles due to the high possible number of particle shapes, as well as the infinity of combinations that can arise through them. The only prediction that can be made is that as the particles become non-spherical, there will be a decrease in packing density and other related properties.

Table 2 presents the values of density, water absorption, and porosity of the artificial stone produced. It can be noted that the composition of ASQ-7 obtained the best result and was chosen for the addition of arapaima scale. It can be noted that, as expected, artificial stone is less dense.

Manufacturers of artificial stones corroborate the information above, because they report density values that are in the range between 2.4 and 2.5 g/cm3. Due to the presence of polymer in its composition, which is a lighter material; this fact makes it so that the transportation cost of this material is lower. For instance, one container has a maximum weight capacity that can be transported and the freight cost varies in terms of destination and other individual characteristics of the freight [8, 10].

When talking about water absorption, its reduction follows that of porosity, but not in a directly proportional way, since the interconnection of pores directly or through cracks can vary.

Water absorption is always lower than porosity, as not all pores are interconnected and allow the percolation of liquids. The water absorption values for ASQ-5, 7, 8, and ASQ-7 with scale are 0.14 ± 0.10%, 0.06 ± 0.02%, 0.17 ± 0.07, and 0.27 ± 0.63, which are the values within those reported in the artificial rock manufacturing industry, between 0.09% and 0.4%, considered then materials of low water absorption. The three different proportions of ASQ without fish scale have absorption below indicated by the standard of ≤ 0.2% (ASTM C503), recommended for natural marble [15].

For apparent porosity values 0.31 ± 0.23% (ASQ-5), 0.14 ± 0.05% (ASQ-7), 0.38 ± 0.14 were found and can be classified as porcelain, as their porosity values are less than 0.5%, therefore they can be used as coating materials. The ASQ-7 with scale obtained values above the expected, this may be due to unsatisfactory adhesion of the scale with the residue and resin, thus increasing porosity and water absorption. Despite this, the results are in accordance with Brazilian technical standards, according to NBR 15844, the apparent density of artificial granites must be less than 2.5 g/cm3, with a maximum absorption of 0.4% and maximum porosity of 1% (Table 3).

In the absence of a specific standard that regulates the use of artificial stones in humid environments, when framed within the limits established by the standard, it is competent to replace natural stones in the same applications.

As is known, the physical indices are closely intertwined and reflect on the improvement of characteristics such as mechanical strength, as will be observed in the mechanical tests.

Figure 3 shows the bending stress versus deformation curves of the artificial stone with crushed stone and quartzite residue, composition 7, with and without arapaima scale (ASQ-7 and ASQ-7 with scale). ASQ-7 without scale obtained a maximum tension of 30.9 ± 2.3 Mpa and ASQ-7 with scale 34.7 ± 2.7 Mpa, it is observed that despite the higher porosity of ASQ with scale in relation to the lowest index of porosity of the scaleless, the flexural strength was higher. This can be explained by the fact that the arapaima scales have a high resistance, due to the collagen in their composition and the grooves that make up their surface as they represent barriers. The calcium content is responsible for the mineralization of the scale, which leads to greater hardness, and the layers can be thought of as laminated structures formed by collagen fibers [5,6,7].

Costa et al. (2021) define that the rocks for coating must have very high strength or excellent quality when the value of the tensile strength is greater than 20/22Mpa, respectively [16]. The NBR 15,844 [17] standard stipulates the minimum flexural strength value at three points of 10 MPa for the use of rocks in coatings, while ASTM C503 determines 7 MPa [15]. ASQ-7 with and without scale have strength values to be used as a coating.

Figure 4 presents the results obtained in the Charpy impact resistance test for artificial stones with crushed stone and quartzite residue, with and without arapaima scale (ASQ-7 and ASQ-7 scale). The two basic mechanisms of energy absorption of materials are the creation of new fracture surfaces and the deformation of the material. In the impact test, the first mechanism to operate is the deformation of the material and, when the incident energy is high enough, the crack initiation and propagation occurs, acting as a second energy absorption mechanism.

It can be seen that the impact energy of charpy for ASQ-7 is 24.1 ± 4.9 J/m and ASQ-7 (scale) is 28.3 ± 4.6 J/m. The arapaima scale obtained a higher impact energy than the rock without the scale, mainly due to the fact that the fish scales are constructed in a similar way to a laminated fiber reinforced composite material. The failure mechanisms observed in impacted fish scale samples show some correspondence with the mechanisms that occur in fiber-reinforced composites. These include fiber breakage, delamination, and crack propagation in the matrix. The higher collagen content in the inner layers of fish scales (83%) is responsible for a more ductile behavior in fish scales when subjected to impact [18].

As for the macroscopic fracture, Fig. 5, all specimens were split into two parts after the impact of the Charpy hammer. The rupture of the specimen occurred in the notch as required by the standard.

Conclusion

This study investigated the technique of developing the artificial stone with residue of crushed stone and quartzite and to reinforce it, pirarucu scale was incorporated, and its physical and mechanical properties were evaluated. From the results, statistical analysis, among the 10 compositions 3 are differentiated (5, 7, and 8) and through these compositions the artificial stones were developed;

The 3 compositions, with different granulometry percentages with crushed stone and quartzite residue, had porosity results of 0.31 ± 2.3% (ASQ-5); 0.14 ± 0.05% (ASQ-7) and 0.38 ± 0.14% (ASQ-8). Water absorption 0.14 ± 0.1% (ASQ-5), 0.06 ± 0.02% (ASQ-7) and 0.17 ± 0.07% (ASQ-8). According to standards, the results of all compositions were low porosity and water absorption, which could be used for coating.

ASQ-7 obtained the best results and was chosen for the incorporation of the pirarucu scale. The result of porosity 0.67 ± 0.14% and for water absorption 0.27 ± 0.63% (ASQ-7 scale), even the result being lower than ASQ-7 to ASQ-7 (scale), was in accordance with the standard and can be used with coating, only in an area with little use of water. The result of bending and charpy impact was superior to ASQ-7 without scale, 34.7 ± 2.7 Mpa and 28.4 ± 4.6 J/m.

This study is characterized as authentic, in the matter of pirarucu scales, with the first encouraging results, and in the future, it may serve several segments of architecture and/or civil construction. Once commercialized, the artificial stones developed would generate a new economic cycle that ranges from waste collection to cutting, including the use of waste, creating new stakeholders in addition to adding socioeconomic value.

References

Alcay A, Montañés A, Simón-Fernández M (2021) Waste generation and the economic cycle in European countries. Has the Great Recession decoupled waste and economic development. Sci Total Env https://doi.org/10.1016/j.scitotenv.2021.148585

Kumar S, Dwivedi VK, Dwivedi SP (2021) Waste material produced from industry and its utilization in development of green composite material: a review. Mat Today Proc 43:490–496. https://doi.org/10.1016/j.matpr.2020.12.021

Valensca S, Barros A, Marciano JEA, Ferreira HC, Menezes RR, Neves GA (2016) Addition of quartzite residues on mortars: analysis of the alkali aggregate reaction and the mechanical behavior. Const Build Mat 118:344–351. https://doi.org/10.1016/j.conbuildmat.2016.05.079

Silva MCA, Leão VA, Reis EL (2021) Incorporation of quartzite fines in the production of red ceramics. J Clean Prod 288:125098. https://doi.org/10.1016/j.jclepro.2020.125098

Bezerra WBA, Monteiro SN, Oliveira MS, Santos da Luz F, Garcia Filho FC, Cruz LC, Ulisses Oliveira Costa DUO (2020) Processing and characterization of Arapaima gigas scales and their reinforced epoxy composites. Jmr&t 9(3):3005–3012. https://doi.org/10.1016/j.jmrt.2020.01.051

Torres FG, Malásquez M, Troncoso OP (2015) Impact and fracture analysis of fish scales from Arapaima gigas. Mater Sci Eng C 51:153–157. https://doi.org/10.1016/j.msec.2015.02.034

Yang W, Quan H, Meyers MA, Ritchie RO (2019) Arapaima fish scale: one of the toughest flexible biological materials. Matter 1557–1566. https://doi.org/10.1016/j.matt.2019.09.014

Gomes MAPM, Carvalho EAS, Demartini TJC, Carvalho EA, Colorado HA, Vieira MF (2020) Mechanical and physical investigation of an artificial stone produced with granite waste and epoxy resin. J. Compos. Mater. https://doi.org/10.1177/0021998320968137

Silva FS, Ribeiro CE, Rodriguez RJS (2018) Physical and mechanical characterization of artificial stone with marble calcite waste and epoxy resin. Mater. Res. 21(1):1–6. https://doi.org/10.1590/1980-5373-MR-2016-0377

Demartini TJC, Rodriguez RJS, Silva FS (2018) Physical and mechanical evaluation of artificial marble produced with dolomitic marble waste processed by diamond–plated bladed gangsaws J Mater Res Technol 7(3):308–313. https://doi.org/10.1016/j.jmrt.2018.02.001

Ribeiro CEG, Rodriguez RJ, Carvalho EA (2017) Microstructure and mechanical properties of artificial marble. Constr Build Mater 149:149–155. https://doi.org/10.1016/j.conbuildmat.52017.05.119

Associação Brasileira de Normas Técnicas (2015) Rochas para revestimento—Parte 2: Determinação da densidade aparente, da porosidade aparente e da absorção de água—NBR 15.845-2. Rio de Janeiro

Associação Brasileira de Normas Técnicas (2015). Rochas para revestimento—Parte 6: Determinação do módulo de ruptura (flexão por carregamento em três pontos)—NBR 15.845-6. Rio de Janeiro

American Society for Testing and Materials (2018) Standard test methods for determining the izod pendulum impact resistance of plastics—ASTM D256

American Society for Testing and Materials (2016) Standard specification for marble dimension stone—ASTM C503

Costa FP, Fernandes JV, Melo LRL, Rodrigues AM, Menezes RR, Neves GA (2021) The potential for natural stones from northeastern Brazil to be used in civil construction. Minerals 11(5):440

Associação Brasileira de Normas Técnicas (2015) Rocks for cladding—requirements for granite—NBR 15.844, Rio de Janeiro

Nascimento LFC, Monteiro SN, Louro LHL, Santos da Luz F, Santos JL, Braga FO, Marçal RLSB (2018) Charpy impact test of epoxy composites reinforced with untreated and mercerized mallow fibers. JMR&T 7(4):520–527

Acknowledgements

The authors thank the Brazilian agency FAPERJ for financing this research and for providing scholarships. They also thank UENF and coach Renan da Silva Guimarães for their support.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Carvalho, E.A.S. et al. (2023). Izod Impact Characterization of Engineered Artificial Stone Reinforced by Arapaima Gigas Fish Scales. In: Zhang, M., et al. Characterization of Minerals, Metals, and Materials 2023. TMS 2023. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-22576-5_45

Download citation

DOI: https://doi.org/10.1007/978-3-031-22576-5_45

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-22575-8

Online ISBN: 978-3-031-22576-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)