Abstract

In order to address the challenges to repair uncontrollable cracks and to enhance the life span of civil engineering structures in a sustainable manner the technique of self-healing of cracks by introducing bacterial concrete has been developed, researched and implemented by many researchers. The present paper focuses on the overview of self-healing concrete (SHC) and conducting laboratory investigation of the prep bacteria, feeding material and water. The study experimentally investigates its compressive strength and explores an alternate mathematical approach to predict its mechanical characteristics. An attempt is made to predict the compressive strength of self-healing concrete with varying proportions of calcium lactate using an artificial neural network (ANN) and adaptive neuro-fuzzy interface system (ANFIS). It has been discovered that using bacteria improves the compressive strength of normal concrete and aids in the self-healing property of concrete. The best prediction models that can learn, compute, and solve problems with non-linear data are the artificial neural network (ANN) and adaptive neuro-fuzzy inference system (ANFIS). The study finally compares the compressive strength values obtained from experimental work, ANN and ANFIS models and determines the best suitable model out of both ANN and ANFIS for the considered dataset in the study. The study concludes that the ANN design model produces the most accurate results with a regression value of 0.9865 and a mean square error of 3.07 in comparison to the regression value of 0.9725 and a mean square error of 3.16 obtained from the ANFIS model.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Many advances in the field of the construction industry have been carried out to improve the properties of concrete by introducing supplementary cementitious materials or additives to enhance the property of concrete and reduce carbon emissions due to the overuse of cement. The ease of production process, accessibility to raw materials, and compression strength qualities make concrete a good choice for construction. However, the material yields low tensile strength (10–15% of compressive strength), low ductility, and a low strength-to-weight ratio and is susceptible to cracking [1]. The uncontrollable cracks in concrete are primarily developed due to its weakness in tension, shrinkage, fatigue loading and the weather [2]. The likelihood of cracking in concrete can be caused in several ways by its tensile properties. The well-known property of concrete is that it is a brittle material and is subjected to cracks due to excess load on structures. At any stage of the service life of concrete, it experiences cracking as shown in Fig. 1 and this happens when the concrete is in a plastic state or a hardened state due to thermal stresses, plastic shrinkage, settlement, drying shrinkage, weathering, and various loading conditions, or a combination of various factors [3]. Moreover, external exposure to environmental conditions and loadings (cyclic or static) such as freeze–thaw cycling, chemical attack, carbonation, abrasion and erosion, chemical reactions, moisture and temperature variations and corrosion of reinforcement cause the micro-size cracks to develop into macro-size fractures [4]. The micro-cracks cause permeability in concrete by which undissolved particles of unwanted fluids and gases flow through the cracks. This lowers the durability of concrete. As a result, the reinforcing steel is exposed to oxygen and moisture, increasing the risk of structural failure and steel corrosion. Corrosion of steel reinforcement in concrete due to oxygen and moisture exposure can compromise the protective oxide layer, leading to steel corrosion, cracking, reduced load-bearing capacity and decreased durability, ultimately affecting the structure's service life and stability. The urge to stop this kind of degeneration led to the development of numerous techniques of upkeep and repair. One such idea is self-healing concrete, which began with the research conducted by Siddiqui [5]. Autogenous self-healing in concrete is driven by factors such as hydration of cement, calcium hydroxide conversion to calcium carbonate, self-induced swelling of C–S–H gel, and self-sealing through water seepage. These processes fill small cracks, enhance concrete's resistance to further cracking, and improve its overall integrity naturally [6, 7]. The cracks can be fixed naturally by adding different healing agents or components to the concrete. The most likely solution to the problem of concrete fractures seems to be self-healing technology. The microbial method is thought to be the one that will be commercialized in the upcoming years in many ways. The main benefit of microbial self-healing technology [8, 9] as an eco-friendly solution is that it can fix cracks in places where it is impossible to access them by using bacteria's metabolic processes. This enhances the useful life of the concrete structure while significantly lowering the expense of fracture identification and the difficulties of repair. Concrete is a highly alkaline substance, and bacteria can survive in an alkaline environment. The other components of concrete, such as sand and gravel, are bound by calcium carbonate precipitation, and the microcracks in the concrete are filled. Increased concrete durability may result from microorganism engagement in calcite precipitation. Bacillus species can precipitate CaCO3 in an environment with high levels of carbonate and ammonium by converting urea to these two compounds. Concrete itself can seal cracks that are less than 0.2 mm in width [10]. However, concrete cannot repair itself if fissures are larger than 0.2 mm, which allows harmful materials (moisture, chemical substances, corrosive agents and biological agents) to pass through. In self-healing concrete, when cracks occur, dormant or inactive bacteria become activated and start functioning [11]. During the self-healing process, calcium carbonate precipitates into the cracks and fills them through the metabolic activities of bacteria. Bacteria resume their sleep phase once the calcium carbonate fills in all of the crevices. The bacteria get activated and plug the fractures if any developed in the future by consuming nutrients, including calcium-based compounds and producing calcium carbonate within the cracks. This precipitation fills and seals the damaged area, promoting self-healing. The process is triggered by the presence of water and nutrients in the crack environment, enhancing the concrete's durability and reducing the need for external repairs. Microbiologically induced calcium carbonate precipitation (MICP), is a process that bacteria use as a long-lasting healing agent [12]. The bacteria involved in the procedure known as induced microbial-induced calcium carbonate precipitation (MICP) carries a negative charge on its cell wall as depicted in Fig. 2a. The bacteria then attract cations, including Ca2+, from their surroundings to deposit onto their cell surface, as illustrated in Fig. 2b. The Ca2+ ions then interact with CO32− to form calcium carbonate, which precipitates at the cell surface and serves as a starting point for further mineralization. Figure 2c shows the resulting precipitation of calcium carbonate on the bacterial cell wall. Equations 1 and 2 elaborate on the chemical reactions during the entire self-healing process with the help of bacteria as discussed by [13,14,15,16]. The process is also illustrated in Fig. 3.

Bacteria-based self-healing concrete [10]

The impact of nutrients on the strength and healing capacity of bio concrete was studied by [17] using the bacillus subtilis category of bacteria. A nutrient named calcium lactate is utilized as a feeding material for bacteria. The concentration of the microorganism is kept constant with 105 cells and the proportion of C6H10CaO6 is varied. Variations are done concerning the weight of cement as 0.5%, 1%, 1.5%, 2%, and 25%. Though the Bacillus subtilis species has proven [18] to produce good compressive strength the process of healing in its healing capacity needs further investigation. From past studies [19,20,21,22] it has been observed that the bacillus subtilis bacteria survive in extreme pH conditions 10 and above, internal dryness and lack of nutrients. The prime reason to select Bacillus subtilis is its high resistance capacity towards the pH level of concrete as not many species of bacteria can resist the alkaline pH of 13 which is produced when cement is mixed with water. These bacteria can survive up to 200yrs and can stay dry stay up to 50yrs. Suitable choice of food for bacteria is also important for the bacteria to effectively perform the self-healing mechanism.

The findings of the testing of the mixtures suggested that calcium lactate, which serves as a food source for bacteria, has an adverse impact on strength if it is not ingested and transformed into CaCO3. The study by Shen [23] reviewed the evaluation of the compressive strength of self-healing concrete with the effect of food on bacteria. Along with the materials, the conditions under which bacteria is mixed in concrete play a significant role in understanding the self-healing mechanism of bacteria [24]. Some studies [25, 26] employed various characterization techniques to understand the self-healing process in concrete using microbial agents. Researchers [27, 28] have also conducted flexural, non-destructive tests and nanoindentation tests to evaluate the effectiveness of healing in concrete. Hence the first objective of the present study focuses on incorporating bacillus subtilis bacteria into a cement concrete matrix along with calcium lactate as a food source for it to survive and study its impact on compressive strength properties. The present study intends to perform a mix design of concrete and identify the optimum mix through compressive strength with four different categories as listed below:

-

1.

Cement concrete

-

2.

Cement concrete (with bacteria alone)-bacteria concentration is fixed taken as 105 cells/ml

-

3.

Cement concrete (with calcium lactate alone-20 gm, 40 gm, 60 gm)

-

4.

Cement concrete (with calcium lactate-20 gm, 40gm and 60 gm and bacteria-concentration is fixed as 105 cells/ml)

It is a universal fact that the major ingredients of concrete usually are cement, coarse aggregate, cement and water. The strength and standard of concrete directly depend on the standards of material introduced in the concrete matrix. Hence, certain tests have to be conducted on concrete to determine its strength and standard of concrete. Majorly conducted test is a compressive test. Compression test on concrete indicates the durability of concrete. The concrete should attain the designed characteristic strength for better durability of structure this characteristic strength of concrete is achieved on the 28th day of curing. To know the characteristic behaviour of concrete one has to wait for 28 days. Testing of cubes needs many specimens and each specimen needs a certain quantity of materials. To obtain one single result of compression casting, testing, trials and curing have to be carried out manually which may cost money and time intensive. The cost and time-intensive methods can be replaced with advanced techniques such as artificial intelligence.

Fields like information technology, medicine, automobile, mechanical and other engineering and non-engineering specializations are adopting artificial intelligence (AI) techniques to replace manual work. AI techniques are also relevant to the civil engineering field and deal with complicated problems and complex materials. AI involves many branches such as machine learning and deep learning. Artificial neural network (ANN) is part of deep learning which has the potential to get trained, learn, compute, solve and generate desired outputs. Accompanying the mathematical equations, maximum utilization of soft computing techniques such as ANN and ANFIS in the branch of civil engineering have been reported by many researchers in the last few years [29]. For instance, a fuzzy inference system model was introduced by [30, 31] and has proven that an artificial neural network is a renowned technique for approximating the compressive test results of a rock. Another study by [32] utilized an adaptive neuro-fuzzy system (ANFIS), ANN and multiple regression analysis for forecasting the uniaxial compressive strength and proposed that the ANFIS model is a reliable predictive model for further research.

Identifying the self-healing capacity and strength parameters of self-healing concrete using experimental techniques is being carried out for a limited duration but in practice, the self-healing of mortar of concrete is required after certain years of construction of the structure when cracks start emerging in the structural components. Therefore, the approximate prediction of strength and self-healing characteristics of self-healing concrete is required. Machine learning techniques serve as the best methods for prediction. Artificial intelligence methods in the form of artificial neural networks are one promising strategy for forecasting the effectiveness of concrete self-healing (ANN). The investigations carried out by Adeli [33] proved that ANN acts as a trustable tool which can model and predict complicated problems. It contains computational devices which are a replica of biological learning in a human brain.

The human biological neural network (BNN) passes information with the help of dendrites, nuclei and axons to give out proper decisions by humans as depicted in Fig. 4. Similarly in ANN with the help of weighing information is carried from one node to another node in a sequential manner which gives out accurate output prediction values.

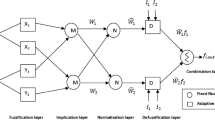

As per [34], ANN techniques are capable of applicability in various tasks and problems, such as classification, interpretation, diagnosis, modelling, and control. The method is the best solution for problems that are extremely complicated for solving mathematical models rather than traditional procedures. In the year 1989, the first research paper was published on the applications of ANN in civil engineering, thereafter many studies have been reported on the commendable ability of ANN to model and solve complex problems in different civil engineering areas. Many research papers project that ANN techniques are being successfully implemented to investigate the concrete’s drying shrinkage [35], strain and dynamic modulus of elasticity [36], deflection analysis [37], cement-based material properties [38], slab behaviour [39], compressive and shear strength [40] in situ concrete strength [41]. Many researchers have trained the ANN model using the back-propagation (BP) algorithm. BP is a local search algorithm used in combination with gradient descent to update the weights and biases of the neural network and minimize the performance function [42]. According to [43], training ANN by BP has been a successful approach that can provide solutions for several engineering applications. ANN and ANFIS models are the few best methods which provide an approximate prediction of concrete parameters [44, 45]. Prediction using ANN is carried out using various software methods out of which MATLAB is one of its best to produce accurate results with comparative prediction data. Based on the nature of the problem, the ANN components need to be defined as an initial set of weights and display how weights should be changed during training to enhance performance [46]. ANN involves three layers namely the input layer which includes input nodes with input values, the hidden layer which consists of bias and weights used to compute the given inputs to produce target value and the output layer which produces the output computed by the hidden layer as discussed in Fig. 5. The output layer exploits these features to determine the output pattern [47]. Afterwards, the actual output is compared to the historical outputs to calculate the output error [48, 49]. This procedure is repeated until the error reaches a defined level such as the mean square error (MSE) [50, 51]. However, for training an ANN model, an experimental database requires an appropriate number of datasets [52].

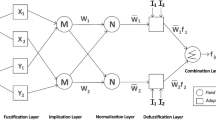

An artificial neural network (ANN) and a fuzzy interface system (FIS) are combined to form the hybridized neural network known as ANFIS. In the FIS structure, there are five layers of perceptron or neurons [53,54,55] namely the fuzzifying Layer in which the nodes are called adaptive nodes. Each node works based on MF such as trapezoidal and triangular membership function, implication Layer where the node output from layer 1 shows the strength of rules. Next is the normalizing Layer where nodes represent the strength of rules and normalize it. The fourth layer is the De fuzzifying Layer in which the participation of each rule in giving output is measured. Last later is the combining layer in which the total output layer, a single node adds all the rules as detailed in Fig. 6. Such estimation capacity is expected where various membership functions (MFs) [56,57,58] have been examined concerning the datasets. Hence based on the past application of artificial intelligence in the field of civil engineering, the present study aims to develop ANN and ANFIS models to forecast the compressive strength of self-healing concrete depending on the input parameters namely curing period, weight of cement, coarse aggregate, fine aggregate, water cement ratio (w/c ratio), bacteria concentration and calcium lactate. The study also compares the compressive strength values obtained from experimental work, ANN and ANFIS models. The study aims to develop the best suitable model from the amount of error between the values through root mean square error (RMSE). The best model was developed using 300 datasets using Sugeno FIS. Grid partition and sub-clustering methods were applied to generate the model. Out of 30 combinations, hybrid-linear provides more accuracy than hybrid-constant, backdrop-linear and backdrop-constant methods. The paper concludes that the hybrid constant is one of the best combinations for predicting the compressive strength of high-strength concrete.

2 Experimental study

In this study, self-healing concrete is made using cement, coarse aggregate, fine aggregate, bacillus bacteria, calcium lactate and water. A mix proportion of 1: 1.62:2.89:0.5 ratio of cement, coarse aggregate (C.A), fine aggregate (F.A), and w/c ratio was used along with varying percentages of bacteria and calcium lactate. In the initial stage mixes of conventional concrete and concrete with only bacterial concentration of 105 cell/ml are tested. Later in the second stage mixes of concrete with the addition of only calcium lactate at three different weights of 20 gms, 40 gms and 60 gms are prepared for testing. In the final stage mixes of concrete with the addition of bacteria at a concentration of 105 cell/ml and calcium lactate at three different weights of 20 gms, 40 gms and 60 gms are prepared. The details of mixed proportions and their designations are as tabulated in Table 1.

In the lab, compressive tests on cube specimens are conducted on the batches of the above-mentioned material mixes as per IS 10262-200 [59, 60]. The mould used for casting has a cube size of 150 mm × 150 mm × 150 mm. After casting the specimens are demoulded after 24 h and left for water curing for a period of 7, 14, 21, 28 days. Upon curing, the specimens are allowed to air dry for 24 h at room temperature. Later the tests are conducted by placing them in a compression testing machine. The load was applied gradually at a rate of 140 kg/cm2 till the cubes.

The tests are conducted on conventional concrete and self-healing concrete with varying calcium lactate at respective curing periods and the results are analyzed with the help of artificial intelligence techniques namely ANN and ANFIS. The average compressive strengths obtained from the lab are used to train the developed model to accurately predict the compressive strength without any future experimental testing. In the next section, the developed models are discussed to achieve the desired compressive strength results.

3 ANN model

An ANN model is generally developed to predict the compressive strength of the self-healing concrete by using a multilayer feed-forward neural network using a backpropagation algorithm. The steps followed to develop the model are illustrated in Fig. 7. The backpropagation approach is utilized in this ANN model, where the input data are supplied to the input layer and transmitted through the network till the output is formed. This input experimental compressive strength values pass through the activation function by initializing the weights. This is known as a learning or training technique. The network calculates its outputs, weights and mathematical function model threshold. Afterwards, the output error is calculated by comparing the actual output to the historical outputs. If the error values are greater than zero, the obtained error is propagated back through the network and the individual weights are updated. This is known as the backward pass and the technique is carried out until the error becomes less than or equal to zero. Once the defined level is achieved the final compressive strength values are predicted as per the inputs provided.

In the present study, the compressive strength of self-healing concrete was controlled by proportioning cement, coarse and fine aggregate, bacterial concentration and calcium lactate properly with a constant water-cement ratio of 0.5. The training has been carried out by feeding, five parameters namely days, the total weight of (cement, coarse and fine aggregate quantity), bacterial concentration and calcium lactate are used as the input nodes and the compressive strength was used as the target node as depicted in Fig. 8.

A total of 96 datasets are used to develop a neural network. Among the 100% data set,70% is used for training and the rest was used for testing the dataset. The data division is random. The input data of ANN is shown in Table 2. The training method used was Levenberg- Marquardt.

For modelling, the mix proportioning and strength data of eight distinct mixes with varying curing durations are used. Three specimens are evaluated for each mix type and curing period, yielding a data set of 96 compressive strength values. The number of hidden layers used determines the quality of the ANN’s training pattern.

The developed neural network as shown in Fig. 9 is simulated with the input parameters whose output values had to be predicted. The compressive strength of the bacterial concrete is predicted for the 7th day, 14th day, 21st day and 28th day curing periods.

4 ANFIS model

The ANFIS model is used to validate the findings generated by the ANN model. Figure 10 depicts how training is carried out. This ANFIS model employs learning techniques via a specific method that consists of a forward pass with the least square error. Later levels employ the gradient descent algorithm in conjunction with Backpropagation. By picking the triangular function, the experimental compressive strength values are sent through the membership function. The network estimates its real outputs as well as the mistakes. The actual output is then compared to the historical outputs to determine the output inaccuracy. If the error values are more than zero, the error is propagated back via the network. Once the defined level is achieved the final compressive strength values are predicted as per the inputs provided.

Training of ANFIS was carried out by feeding, five parameters such as days, the total weight of (cement, coarse aggregate, fine aggregate), w/c ratio, bacterial concentration and calcium lactate quantity were used as the input vectors and compressive strength was used as the target value. The membership function used was a triangular function for input and the membership function was constant for output. The dataset used for the development of both ANN and ANFIS remains the same in the present study.

A total of 96 datasets were used to design ANFIS. Among the 100% data set,70% is used for training and the rest was used for testing the dataset. The data division was done randomly and the number of MFs used was 4 for single input parameters. The grid partitioning method was used to generate fuzzy rules using the MATLAB application as depicted in Fig. 11. The input data of ANFIS is shown in Table 3.

The developed ANFIS was simulated with the input parameter whose output values have to be predicted as elaborated in Fig. 12. In the present work, the quantity of material used in the concrete matrix and the day of strength required were fed as the input values. Prediction of compressive strength of Bacterial concrete has been conducted for the 7th day, 14th day, 21st day and 28th day.

5 Results and discussion

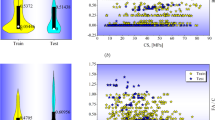

The average compressive strength of the self-healing concrete obtained at various curing periods is illustrated in Fig. 13. The ranges of compressive strengths given in Table 4 for various curing periods satisfied the requirement of self-healing concrete.

It is observed from Fig. 13 that at CLC-20 gms of calcium lactate per litre of water there is a good increase in compressive strength on the 28th day when compared to CLC-40 gm of calcium lactate and CLC-60gms of calcium lactate. Thus, the optimum proportion of calcium lactate found is CLC-20 gms of water. The compressive strength of conventional concrete is 34.37 MPa and the compressive strength of bacterial concrete with the optimum proportion of calcium lactate of.

CLC-20gms was found to be 52.91 MPa for a curing period of 28 days. Hence, there is an increase in compressive strength of bacterial concrete with 20gm calcium lactate by 18% when compared to conventional concrete after 28 days of curing. The highest compressive strength was achieved for bacterial concentration, BC-20 gms mix with the addition of bacteria at 105 cells/ml and CLC-20 gms of calcium lactate after curing for a period of 28 days. In contrast, the lowest compressive strength was achieved for a mix of CLC-60 gms mix with the addition of exclusively calcium lactate without any bacteria for a curing period of 7 days. The experimental results show that BC-20 gms optimized the gain in compressive strength. The addition of bacteria along with an optimum food quantity has enhanced the micro filling of the voids present in the concrete matrix thereby producing a dense concrete structure. Furthermore, the reaction of calcium lactate, which serves as a food source for bacteria, has increased the compressive strength of the concrete by improving the pore structure of the binder paste and strengthening the intermittent bond between the binder paste and the aggregate. The addition of calcium lactate has a favourable effect on producing faster production of calcium carbonate which in turn helps in the sealing of the void spaces present in the concrete.

From the laboratory results obtained a database is developed which is both the training and validation for the ANN and ANFIS models as given in Table 5. The frequency histograms of the parameters and the relationship between compressive strength and the parameters of the mortars are depicted in Fig. 14. This figure effectively demonstrates the complex and nonlinear behaviour of the mortar mixes, which is why deterministic methods are unable to provide a reliable analytical formula for predicting compressive strength. Although the database used in this research is from the experimental results, Fig. 15 indicates which parameter value ranges still need further investigation and experimentation. Knowing about these data gaps reveals areas of high uncertainty about the reliability of the proposed numerical model. This issue will be discussed further in the results and discussion section, as will the authors' plans for future research. Each set consisted of five input parameters, curing period(days), the quantity of (cement, FA and CA (kg/m3)), w/c ratio, the concentration of bacteria (cells/ml) and calcium lactate (gms). The output was only one component, which is the compressive strength.

5.1 Results of ANN model

To avoid overfitting the network, approximately 70% of the database was used for training and was stopped when the network prediction closely matched the experimental results, as shown in Fig. 15. This stabilized at an epoch value of 14 as depicted in Fig. 16. Thirty per cent of the total data was used for testing. It is shown the test and validation of the MSE/Epoch results with the predicted output concerning the experimental results of the compressive strength and the maximum error was found to be 4.66. The mean compressive strength of experimental and predicted values was found to be 32.9 MPa and 32.7 MPa respectively whose difference was found to be only 0.2 MPa. This showed a very strong correlation between the two results.

In the current study evaluation of the accuracy and performance of the ANN model was done through methods including mean squared error (MSE) and coefficient of determination R2. All these methods were considered after a detailed literature review as mentioned in [61]. It is revealed from these results that ANN provides excellent prediction accuracy and lower prediction error as compared to any other models. The MSE obtained was 3.07 for the outputs generated by the model after training. The MSE obtained was 0.08 for predicated values by model. The coefficient of determination R2 obtained was 0.9865 as achieved in Fig. 17a, b. The model developed can predict the compressive strength of bacterial concrete. It is noticed that the correlation coefficient obtained by ANN (R = 98.4% during training and R = 98.7% during testing). The root mean square error (RMSE) values obtained were (RMSE = 1.751 for training and RMSE = 0.283 for testing). Similarly, the maximum average error (MAE) values obtained were (MAE = 1.240 for training and MAE = 0.20 for testing). Thus, indicating that ANN has the potential to predict the compressive strength of self-healing concrete. The study carries out the comparison of experimental compressive strength to the predicted compressive strength using ANN for every mix proportion as highlighted in Fig. 18.

The second model, ANFIS, was created in MATLAB using 70% of the database for training and the remaining 30% for testing and predicting the compressive strength of bacterial concrete. The ANFIS model was tuned, and after 100 epochs, the errors between the target and output values were found to be the smallest. The model's generated coefficient of determination R2 value is 0.9725, and the mean square error between experimental and output values is 3.16. Figure 19 depicts the predicted output based on the experimental compressive strength results, with the maximum error found to be 5.82. The mean compressive strength of the experimental and predicted values was found to be 32.9 MPa and 32.4 MPa, respectively, with a difference of 0.5 MPa. This demonstrated a very strong correlation between the two outcomes. Figure 20 depicts the results of a CA comparison between target values and output values for the training and testing datasets. The R-value of the correlation coefficient between the predicted and measured compressive strength values of bacterial concrete using ANFIS during the training and testing processes for all data sets is obtained as (R = 96.3% during training and R = 97.5% during testing). The root mean square error (RMSE) values obtained were (RMSE = 1.778 for training and RMSE = 2.416 for testing). Similarly, the maximum average error (MAE) values obtained were (MAE = 1.257 for training and MAE = 1.711 for testing). Hence, indicating that the ANFIS model can learn, train and predict the values for desired inputs. In the past, the compressive strength results of cement mortars using the ANFIS technique proved to be highly efficient as compared to the ANN technique [62]. The research conducted by [63] showed the accurate accuracy of ANN and ANFIS models in predicting the concrete properties with the help of ground-granulated blast furnace slag. Similar conclusions were drawn in the field of determining the compressive strength of concrete [64], manufactured sand concrete [65] and hydraulic impact hammers [66] depicting the efficiency of the ANFIS model as compared to that obtained by ANN models. Figure 21 shows the comparison of experimental compressive strength to the predicted compressive strength using ANFIS for each mix proportion. On comparing the potential of both the models ANN is found to be more effective than ANFIS with a greater regression value (0.9865 > 0.9725). Based on the regression graphs as plotted in Fig. 22 the following equations are generated by ANN and ANFIS models giving the relation between the actual and predicted values of the compressive strength based on the trained dataset of bacterial concrete. The Equation of ANN as obtained is given by 3 whereas the obtained equation of the ANFIS model is given by 4.

Comparing the performance of the ANN and ANFIS models for predicting the compressive strength of bacterial concrete, we observe notable differences in their respective evaluation metrics. During training, the ANN exhibits a high correlation coefficient (R = 98.4%) and achieves a relatively low RMSE (1.751) and MAE (1.240). Conversely, the ANFIS model demonstrates a slightly lower correlation coefficient (R = 96.3%) during training, with a higher RMSE (1.778) and MAE (1.257) compared to the ANN. In the testing phase, both models maintain strong correlation coefficients, with the ANN showing an R-value of 98.7% and the ANFIS with an R-value of 97.5%. However, the ANN significantly outperforms the ANFIS in terms of RMSE (0.283 for ANN and 2.416 for ANFIS) and MAE (0.20 for ANN and 1.711 for ANFIS), indicating superior accuracy and precision in the ANN's predictions during testing. Additionally, the mean squared error (MSE) for testing is considerably higher in the ANFIS (5.82) compared to the ANN (0.08), implying that the ANN model's predictions better align with the actual data during testing.

In conclusion, the ANN model exhibits higher accuracy and generalization performance for predicting the compressive strength of bacterial concrete, as evidenced by its superior correlation coefficient, and lower RMSE, MAE, and MSE values compared to the ANFIS. The ANN's ability to provide more precise and reliable predictions during both training and testing phases makes it a more favourable choice for predicting the compressive strength of bacterial concrete. Figure 23 gives a comparison graph between ANN-predicted values and ANFIS-predicted values with experimental compressive strength values.

6 Conclusion

The present research aims to employ artificial intelligence in the form of ANN and ANFIS techniques to evaluate the compressive strength of self-healing concrete. The study details the steps required to model and train the input parameters in generating the compressive strength of self-healing concrete and prediction of its strength using AI techniques namely ANN and ANFIS. The major conclusions drawn from the study are as follows:

-

1.

It is observed that 20 gm of calcium lactate per litre of water, shows an appreciable increase in compressive strength on the 28th day when compared to 40 gm of calcium lactate and 60 gm of calcium lactate. Thus, the optimum proportion of calcium lactate found is 20 g/l of water.

-

2.

The compressive strength of conventional concrete is 34.37 N/mm2 and the compressive strength of bacterial concrete with the optimum proportion of calcium lactate of 20 gm is found to be 52.91 N/mm2 on the 28th day. Hence, there is an increase in compressive strength of bacterial concrete with 20 gm calcium lactate by 18% when compared to conventional concrete after 28 days of curing.

-

3.

The models adopted to predict compressive strength give good and satisfactory results proving that ANN and ANFIS both developed models have the potential to predict the compressive strength of self-healing concrete. The first model ANN designed using MATLAB gives accurate results with a regression value of 0.9865 and mean square error of 3.07 between experimental values and output values. Hence, indicating that the ANN model can learn, train and predicate the values for desired inputs. The MSE of 0.08 is found between experimental values of bacterial concrete with calcium lactate and predicated values by ANN. Thus, indicating that ANN has the potential to predicate the compressive strength of self-healing concrete.

-

4.

Second model ANFIS designed using MATLAB gives a regression value of 0.9725 and a mean square error of 3.16 between experimental values and output values. Hence, indicating that the ANFIS model can learn, train and predicate the values for desired inputs. The MSE of 0.28 is found between experimental values of bacterial concrete with calcium lactate and predicated values by ANFIS. Thus, indicating that ANFIS is capable to predicate the compressive strength of self-healing concrete.

-

5.

On comparing the potential of both the model ANN is found to be more effective than ANFIS with a greater regression value (0.9865 > 0.9725).

-

6.

Both models have successfully predicted the values obtained by Laboratory manual test results proving the ANN and ANFIS models to be a more feasible method to obtain compressive strength of self-healing concrete. Application of both models to obtain the compressive strength will reduce the material cost and will offer modification in mix design if the concrete does not meet the desired strength, strength can be obtained with a change in the quantities of materials. Both models can be used to determine the future strength of self-healing concrete.

Change history

12 October 2023

A Correction to this paper has been published: https://doi.org/10.1007/s41024-023-00353-8

References

Yoo DY, Banthia N, Yoon YS (2015) Effectiveness of shrinkage-reducing admixture in reducing autogenous shrinkage stress of ultra-high-performance fibre-reinforced concrete. Cem Concr Compos 64:27–36

Zhao K, Ma X, Zhang H, Dong Z (2022) Performance zoning method of asphalt pavement in cold regions based on climate indexes: a case study of Inner Mongolia, China. Constr Build Mater 361:129650

Sidiq A, Gravina R, Giustozzi F (2019) Is concrete healing efficient? A review. Constr Build Mater 205:257–273

Li F, Yuan Y, Li CQ (2011) Corrosion propagation of prestressing steel strands in concrete subject to chloride attack. Constr Build Mater 25(10):3878–3885

Muhammad S, Siddiqui HA, Abro MI, Usmani A, Mallick MAA (2021) Bacillus subtilis as a self-healing agent in cement mortar: combined and the separate effect of bacteria and calcium lactate on self-healing behavior in cement mortar. Mehran Univ Res J Eng Technol 40(2):426–434

Edvardsen C (1999) Water permeability and autogenous healing of cracks in concrete. In: Innovation in concrete structures: design and construction. Thomas Telford Publishing, pp 473–487

Danish A, Mosaberpanah MA, Salim MU (2020) Past and present techniques of self-healing in cementitious materials: a critical review on efficiency of implemented treatments. J Market Res 9(3):6883–6899

Monica R, Nandhini V (2016) Experimental study on bacteria based self-healing concrete. Adv Nat Appl Sci 10(3):38–43

Hearn N (1998) Self-sealing, autogenous healing and continued hydration: what is the difference? Mater Struct 31(8):563–567

Ramm W, Biscoping M (1998) Autogenous healing and reinforcement corrosion of water-penetrated separation cracks in reinforced concrete. Nucl Eng Des 179(2):191–200

Chahal N, Siddique R, Rajor A (2012) Influence of bacteria on the compressive strength, water absorption and rapid chloride permeability of fly ash concrete. Constr Build Mater 28(1):351–356

Jonkers HM et al (2010) Application of bacteria as self-healing agent for the development of sustainable concrete. Ecol Eng 36(2):230–235

Khaliq W, Ehsan MB (2016) Crack healing in concrete using various bio influenced self-healing techniques. Constr Build Mater 102:349–357

Qian C, Zheng T, Zhang X, Su Y (2021) Application of microbial self-healing concrete: case study. Constr Build Mater 290:123226

Vijay K, Murmu M, Deo SV (2017) Bacteria based self-healing concrete—a review. Constr Build Mater 152:1008–1014

Vijay K, Murmu M (2019) Effect of calcium lactate on compressive strength and self-healing of cracks in microbial concrete. Front Struct Civ Eng 13(3):515–525

Mondal S, Ghosh AD (2018) Investigation into the optimal bacterial concentration for compressive strength enhancement of microbial concrete. Constr Build Mater 183:202–214

Monishaa M, Nishanthi S (2017) Experimental study on strength of self-healing concrete. SSRG Int J Civ Eng (ICRTCETM-2017) Special Issue 2017:476–484.

Abdulkareem M, Ayeronfe F, Abd Majid MZ, Sam ARM, Kim JHJ (2019) Evaluation of effects of multi-varied atmospheric curing conditions on compressive strength of bacterial (bacillus subtilis) cement mortar. Constr Build Mater 218:1–7

Nielsen SD, Paegle I, Borisov SM, Kjeldsen KU, Røy H, Skibsted J, Koren K (2019) Optical sensing of pH and O2 in the evaluation of bioactive self-healing cement. ACS Omega 4(23):20237–20243

González Á, Parraguez A, Corvalán L, Correa N, Castro J, Stuckrath C, González M (2020) Evaluation of Portland and Pozzolanic cement on the self-healing of mortars with calcium lactate and bacteria. Constr Build Mater 257:119558

Wang J-Y, Belie ND, Verstraete W (2012) Diatomaceous earth as a protective vehicle for bacteria applied for self-healing concrete. J Ind Microbiol Biotechnol 39(4):567–577

Shen LA, Yu W, Li L, Zhang T, Abshir IY, Luo P, Liu Z (2021) Microorganism, carriers, and immobilization methods of the microbial self-healing cement-based composites: a review. Materials 14(17):5116

Williams SL, Kirisits MJ, Ferron RD (2017) Influence of concrete-related environmental stressors on biomineralizing bacteria used in self-healing concrete. Constr Build Mater 139:611–618

Luo M, Qian C-X, Li R-Y (2015) Factors affecting crack repairing capacity of bacteria-based self-healing concrete. Constr Build Mater 87:1–7

Wang JY et al (2014) Self-healing concrete by use of microencapsulated bacterial spores. Cem Concr Res 56:139–152

Xu J, Yao Wu (2014) Multiscale mechanical quantification of self-healing concrete incorporating non-ureolytic bacteria-based healing agent. Cem Concr Res 64:1–10

Durga CSS, Ruben N, Chand MSR, Venkatesh C (2020) Performance studies on rate of self-healing in bio concrete. Mater Today Proc 27:158–162

Jahed Armaghani D, Shoib RSNSBR, Faizi K, Rashid ASA (2017) Developing a hybrid PSO–ANN model for estimating the ultimate bearing capacity of rock-socketed piles. Neural Comput Appl 28:391–405

Yagiz S, Sezer EA, Gokceoglu C (2012) Artificial neural networks and nonlinear regression techniques to assess the influence of slake durability cycles on the prediction of uniaxial compressive strength and modulus of elasticity for carbonate rocks. Int J Numer Anal Methods Geomech 36(14):1636–1650

Ceryan N, Okkan U, Kesimal A (2013) Prediction of unconfined compressive strength of carbonate rocks using artificial neural networks. Environ Earth Sci 68(3):807–819

Jahed Armaghani D, Tonnizam Mohamad E, Hajihassani M, Yagiz S, Motaghedi H (2016) Application of several non-linear prediction tools for estimating uniaxial compressive strength of granitic rocks and comparison of their performances. Eng Comput 32(2):189–206

Adeli H (2001) Neural networks in civil engineering: 1989–2000. Comput Aided Civ Infrastruct Eng 16(2):126–142

Kartam N, Flood I, Garrett JH (1997) Artificial neural networks for civil engineers: fundamentals and applications. ASCE

Bal L, Buyle-Bodin F (2013) Artificial neural network for predicting drying shrinkage of concrete. Constr Build Mater 38:248–254

Duan Z-H, Kou S-C, Poon C-S (2013) Using artificial neural networks for predicting the elastic modulus of recycled aggregate concrete. Constr Build Mater 44:524–532

Elbahy YI, Nehdi M, Youssef MA (2010) Artificial neural network model for deflection analysis of superelastic shape memory alloy reinforced concrete beams. Can J Civ Eng 37(6):855–865

El-Chabib H, Nehdi M (2005) Neural network modelling of properties of cement-based materials demystified. Adv Cem Res 17(3):91–102

Hegazy T, Tully S, Marzouk H (1998) A neural network approach for predicting the structural behavior of concrete slabs. Can J Civ Eng 25(4):668–677

Hossain KMA, Gladson LR, Anwar MS (2017) Modeling shear strength of medium-to ultra-high-strength steel fiber-reinforced concrete beams using artificial neural network. Neural Comput Appl 28:1119–1130

Lee S-C (2003) Prediction of concrete strength using artificial neural networks. Eng Struct 25(7):849–857

Mashhadban H, Kutanaei SS, Sayarinejad MA (2016) Prediction and modeling of mechanical properties in fiber reinforced self-compacting concrete using particle swarm optimization algorithm and artificial neural network. Constr Build Mater 119:277–287

Nehdi ML, Soliman AM (2012) Artificial intelligence model for early-age autogenous shrinkage of concrete. ACI Mater J 2012;109(3)

Yeh I-C (1998) Modeling of strength of high-performance concrete using artificial neural networks. Cem Concr Res 28(12):1797–1808

Yeh I-C (2007) Modeling slump flow of concrete using second-order regressions and artificial neural networks. Cem Concr Compos 29(6):474–480

Chandwani V, Agrawal V, Nagar R (2015) Modeling slump of ready-mix concrete using genetic algorithms assisted training of artificial neural networks. Expert Syst Appl 42(2):885–893

Huang H-X, Li J-C, Xiao C-L (2015) A proposed iteration optimization approach integrating backpropagation neural network with genetic algorithm. Expert Syst Appl 42(1):146–155

Specht DF (1991) A general regression neural network. IEEE Trans Neural Netw 2(6):568–576

Monjezi M, Dehghani H (2008) Evaluation of effect of blasting pattern parameters on back break using neural networks. Int J Rock Mech Min Sci 45(8):1446–1453

Bounds DG, Lloyd PJ, Mathew BG, Waddell G (1988) A multilayer perceptron network for the diagnosis of low back pain. In: ICNN, no 2, pp 481–489

Rafiai H, Jafari A (2011) Artificial neural networks as a basis for new generation of rock failure criteria. Int J Rock Mech Min Sci 48(7):1153–1159

Simpson PK (1990) Artificial neural system-foundation, paradigm, application and implementation. Pergamon Press, New York

Kubat M (1992) "Neural networks and fuzzy systems: a dynamical systems approach to machine intelligence by Bart Kosko. Prentice Hall, Englewood Cliffs

Dreyfus G (2005) Neural networks: methodology and applications. Springer, Berlin

Jahed Armaghani D, Hajihassani M, Sohaei H, Tonnizam Mohamad E, Marto A, Motaghedi H, Moghaddam MR (2015) Neuro-fuzzy technique to predict air-overpressure induced by blasting. Arab J Geosci 8(12):10937–10950

Momeni E et al (2018) Prediction of bearing capacity of thin-walled foundation: a simulation approach. Eng Comput 34(2):319–327

Ali OAM, Ali AY, Sumait BS (2015) Comparison between the effects of different types of membership functions on fuzzy logic controller performance. Int J 76:76–83

Dinesh S, Shanmugapriyan R, Namitha Sheen ST (2017) A review on bacteria-based self-healing concrete. Imperial J Interdiscip Res 3(1):2454–1362

Standard, Indian (2000) Plain and reinforced concrete-code of practice. Bureau of Indian Standards, New Delhi

IS 10262-2009 (2009) Code of practice for concrete mix proportioning. Bureau of Indian Standards, New Delhi

Amor N, Noman MT, Petru M (2021) Prediction of functional properties of nano TiO2 coated cotton composites by artificial neural network. Sci Rep 11(1):1–11

Armaghani DJ, Asteris PG (2021) A comparative study of ANN and ANFIS models for the prediction of cement-based mortar materials compressive strength. Neural Comput Appl 33(9):4501–4532

Boğa AR, Öztürk M, Topcu IB (2013) Using ANN and ANFIS to predict the mechanical and chloride permeability properties of concrete containing GGBFS and CNI. Compos Part B Eng 45(1):688–696

Keshavarz Z, Torkian H (2018) Application of ANN and ANFIS models in determining compressive strength of concrete. J Soft Comput Civ Eng 2(1):62–70

Ly HB, Pham BT, Dao DV, Le VM, Le LM, Le TT (2019) Improvement of ANFIS model for prediction of compressive strength of manufactured sand concrete. Appl Sci 9(18):3841

Iphar M (2012) ANN and ANFIS performance prediction models for hydraulic impact hammers. Tunn Undergr Space Technol 27(1):23–29

Acknowledgements

The authors gratefully acknowledge the research and testing facilities provided by the National Institute of Technology, Warangal, Telangana.

Author information

Authors and Affiliations

Contributions

K. Shanthi sri: Conceptualization, Methodology, Investigation, Resources R. Ramesh Nayaka : Formal analysis, Visualization, Writing- Original draft preparation. M.V.N.Siva Kumar- Reviewing and Editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. The authors confirm that they have read, understand, and agreed to the submission guidelines, policies, and submission declaration of the journal.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sri, K.S., Nayaka, R.R. & Kumar, M.V.N.S. Mechanical properties of sustainable self-healing concrete and its performance evaluation using ANN and ANFIS models. J Build Rehabil 8, 99 (2023). https://doi.org/10.1007/s41024-023-00345-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41024-023-00345-8