Abstract

Microbial l-asparaginases have received significant attention due to their potential for applications in cancer treatment and for preparation of acrylamide-free baked and fried food. Eleven fungal-type strains were obtained from Iranian Biological Resource and screened for production of l-asparaginase using dye-based plate assay on modified Czapek Dox medium. The efficiency of three different dye indicators including phenol red, bromothymol blue and cresol red was evaluated. Production mode was also evaluated by the agar well diffusion method. A comparative study was carried out to evaluate l-asparaginase production in submerged condition by enzymatic assay using Nessler’s reagent. Optimization of the enzyme production by the selected superior strain was performed using one factor at a time method for temperature, inoculum and different carbon and nitrogen sources. Five-type strains showed positive l-asparaginase activity in preliminary screening. Phenol red and bromothymol blue showed better differentiable zone of hydrolysis and consistent results in comparison with cresol red. The results also indicated that l-asparaginase production mode is extracellular. l-asparaginase production by Fereydounia khargensis IBRC-M 30116T which showed the highest zone of color change was then optimized. The optimum enzyme activity of 61.3 U. mL−1 was obtained with 9% inoculum, at a temperature of 30 °C and at the presence of ammonium chloride as nitrogen source and with glycerol as the carbon sources. The study revealed that, apart from bacteria, yeast and yeast-like microorganisms could be considered as novel and appropriate sources for production of the high yield of l-asparaginase.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

l-asparaginase is a hydrolase that primarily catalyzes the conversion of l-asparagine to l-aspartic and ammonia (Qeshmi et al. 2018). l-asparaginase has received considerable attention as a primary component in the treatment of a variety of lymphoproliferative disorders and lymphomas particularly acute lymphoblastic leukemia (ALL) (Doriya and Kumar 2016; Qeshmi et al. 2018). Normal cells can synthesize l-asparagine with the help of asparagine synthetase, whereas certain sensitive malignant cells cannot synthesize it by itself and require an external source of l-asparagine for growth (Doriya and Kumar 2016). As a result, the enzyme activity can inhibit the growth of tumor cells by consuming the l-asparagine and restrict the protein synthesis leading to apoptosis and G1 cell-cycle arrest (Vimal and Kumar 2017a; Ashok et al. 2019). l-asparaginase contributes to 40% of the total enzyme demands worldwide and one-third of the global requirements as anti-leukemic and anti-lymphoma agents (Qeshmi et al. 2018; Chand et al. 2020). The market size of the enzyme in the healthcare sector expected to reach from $5.0 billion in 2016 to $6.3 billion by 2021 with 4.7% annual growth rate (Chand et al. 2020). In addition to medicine and pharmaceuticals, the enzyme received remarkable attention in the food industry due to the ability to reduce the formation of acrylamide in the fried and baked food and hence, to decrease the risk of carcinogenicity (Vala and Dave 2016). l-asparaginase is also used for the development of biosensor technology to analyze asparagine levels and/or to determine the ammonium ions levels either in leukemia or the food industry (Batool et al. 2016; Chand et al. 2020).

Asparaginase activity is widely observed in plants, animal tissues and microorganisms including bacteria, archaea, algae and fungi (Doriya and Kumar 2016; Vimal and Kumar 2017a; Brumano et al. 2019). The microbial enzymes production is preferred over plant and animal sources because their production process is more economically feasible and process modification, optimization, extraction and purification is easier in microbial strains (Trivedi and Padalia 2016; Vimal and Kumar 2017a, Brumano et al. 2019). The production of this enzyme is mainly carried out by submerged fermentation (Vimal and Kumar 2017a, b; Cachumba et al. 2016). Currently, all available commercial l-asparaginase drugs in the market derived from bacterial sources such as Escherichia coli and Erwinia chrysanthemi (Vala and Dave 2016; Ashok et al. 2019). However, clinical usage of bacterial l-asparaginase has led to unpleasant side effects such as normal cell toxicity, patient hypersensitivity, development of allergic reactions and immunogenic complications. Besides, the rapid clearance of the enzyme from the bloodstream which requires multiple administrations makes the treatment very costly (Vala and Dave 2016, El-Naggar et al. 2018). Considering the higher similarity of fungi to humans which could decrease the chance of immunological reactions, l-asparaginase production by fungi seems more promising. Furthermore, the possibility of extracellular production of the enzyme in fungal strains could facilitate the purification process and eventually reduces the final production cost (Vala and Dave 2016). Understanding these limitations, this study aims to investigate the alternative unexplored microbial sources for the extracellular production of l-asparaginase that can offer better production yields and avoid undesired side effects to meet the market requirements.

2 Materials and Methods

2.1 Microorganisms

Eleven yeast and yeast-like-type strains used in the present study were isolated by Iranian researchers from various environmental sources and the cultures were obtained from Microorganisms Bank, Iranian Biological Resource Center (IBRC), ACECR, Tehran, Iran (Table 1).

2.2 Preliminary Screening of l-Asparaginase Production Using Semi-quantitative Assay

Screening of l-asparaginase production was carried out by rapid plate assay. Modified Czapek Dox (MCD) agar medium (glucose 2 g, l-asparagine 10 g, KH2PO4 1.52 g, KCl 0.52 g, MgSO4.7H2O 0.52 g, agar 20 g, distilled water 1000 mL) was used (Thirunavukkarasu et al. 2011). The medium was separately supplemented with 0.009% phenol red (PR), 0.009% cresol red (CR) and 0.008% bromothymol blue (BTB) as pH indicators, respectively (Mihooliya et al. 2017). The initial pH of each medium was adjusted at 6.2. Uninoculated plates were set as control (Mahajan et al. 2013). In order to inoculate the plates for the semi-quantitative assay, the fungi were cultured in 5 mL YPG broth for 48 h, the cultures were centrifuged at 10 000 × g for 10 min, and the cells were resuspended in 500-µL sterile distilled water that contained agar and tween 80 to avoid spreading of the inoculum (Nasr et al. 2018a, b, c). All plates were point-inoculated in the center with 5 μL of the cell suspension and incubated at 25 °C for 5 d. The diameter of zone of color change was measured as zone of hydrolysis (Vimal and Kumar 2017b; Ashok et al. 2019).

2.3 Plate assay for l-glutaminase Activity

l-Glutaminase activity of the l-asparaginase producing fungal strains was detected by supplementing MCD agar medium with l-glutamine as sole nitrogen source. The test strains were inoculated and observed for color change in presence of PR and BTB dyes as an indicator after 5 d incubation (Doriya and Kumar 2016).

2.4 Inoculum Preparation

In order to inoculate the production medium, the fungi were cultured in tubes containing 3 mL MCD broth and incubated on a rotary shaking incubator at 150 rpm and 25 °C for 72 h. Then, the culture broth was centrifuged at 10 000× g for 15 min and the supernatant were discarded. The harvested pellet was resuspended in MCD broth and used to reach the culture absorbance of 0.1 at 600 nm (A600 nm) in the production flask.

2.5 l-asparaginase Production by Submerged Fermentation

Five fungal strains which showed positive results during primary screening were further tested for production of l-asparaginase. The 100-mL flasks containing 20 mL broth medium were incubated on a rotary shaker incubator at 150 rpm and 25 °C. After 4-day incubation, the broth was centrifuged with cooling centrifuge at 10,000×g for 15 min at 4 °C and the clear supernatant served as crude enzyme.

2.6 Evaluation of Enzyme Production Mode

The modified agar well diffusion method was employed to measure the l-asparaginase activity of the crude enzyme. Modified Czapek Dox (MCD) agar medium supplemented with 0.009% PR or 0.008% BTB was punched for 8-mm-diameter wells. Wells were filled with 100 μL of the filtrated crude enzyme (0.2 µm Cellulose Acetate Membrane Filters; Sartorius). and sterile distilled water was used as negative control. The crude enzyme was incubated at 25 °C for 72 h. A clear zone formation of color change around the well indicated as the extracellular l-asparaginase activity.

2.7 Quantitative Assay for l-asparaginase Production

l-Asparaginase activity assay was quantified in the five isolates that produced the five highest zone of color change according to the method of Wriston and Yellin (1973), Imada et al. (1973) using nesslerization to measure the amount of liberated ammonia. The reaction mixture containing 0.5 mL of 0.4 M asparagine, 0.5 mL of 0.05 M Tris–HCl buffer (pH 8.6) and 0.5 mL of a proper dilution from the crude enzyme was incubated at 37 °C for 30 min. The reaction was terminated by the addition of 0.5 mL of 1.5 M trichloroacetic acid (TCA). The negative control was run by adding the inactive crude enzyme after incubation. To remove the precipitated protein, the reaction contents were centrifuged at 10,000×g for 5 min and the filtrate was collected. For quantification of liberated ammonia, 0.1 mL filtrate was diluted with 3.75 mL distilled water and 0.2 mL Nessler’s reagent was added to the mixture. The color reaction was allowed to proceed for 10 min before measuring the absorbance at 450 nm using UV-1800 spectrophotometer (Shimadzu, Schweiz GmbH). The amount of liberated ammonia by the test sample was calculated by comparing the absorbance with a standard curve prepared from solutions of ammonium sulfate (0–0.9 mM) as the ammonia source. One unit (U) of l-asparaginase was defined as the amount of enzyme which generates 1 μmole of ammonia in 1 min at 37 °C and pH 8.6.

2.8 Optimization of Fermentation Parameters

The optimization of l-asparaginase production process for F. khargensis IBRC-M 30116T was carried out based on one factor at a time method by varying only a single factor and keeping the remaining factors constant. Fifty milliliters MCD broth in a 250-mL flask was used as the initial production medium. The selected parameters including inoculum concentration (1, 3, 6, 9% v/v), incubation temperature (at 15, 20, 25, 30, 35 and 37 °C), different carbon sources (by adding 1% w/v of each one of the glucose, sucrose, citric acid and glycerol into the production medium) different inorganic nitrogen sources (by adding 1% w/v of each one of the ammonium chloride and sodium nitrate) and organic nitrogen sources (by adding 1% w/v of each one of yeast extract, proline and asparagine) were evaluated, respectively. Samples were withdrawn after 4 days and the cell density (A600 nm) and enzyme activity was determined.

2.9 Statistical Analysis

All the above-mentioned experiments were conducted in triplicate and the experimental results presented as means of ± S.E.M (standard error mean) of three independent trials. The data were analyzed by one-way analysis of variance and Tukey test with 95% confidence level using Minitab 17 software. P values less than 0.05 were considered as significant.

3 Results

A total of 11 yeast and yeast-like-type strains were investigated for l-asparaginase production (Table 1). The screening was carried out by plate assay method using MCD agar medium which separately supplemented with phenol red, cresol red and bromothymol blue as pH indicators. Five-type strains out of eleven showed positive results for the production of l-asparaginase enzyme (Table 2). The medium containing BTB and PR as pH indicators showed better contrast in comparison to CR (Fig. 1). Growth of F. khargensis and A. mangrovei resulted in the largest zone of color change on the dye containing media. The slight amount of l-glutaminase production was observed in both A. mangrovei IBRC-M 30265T and F. khargensis IBRC-M 30116T.

The extracellular production mode was detected based on agar well diffusion method in all the positive enzyme producer strains except S. orientalis IBRC-M 30204T. Since low activity was observed for crude enzyme obtained from S.orientalis in quantitative asparaginase assay, this negative result may be due to low enzyme activity or low enzyme production. The diameter of the zone of hydrolysis by extracellular enzyme was ranging from 20 to 30 mm. The highest extracellular l-asparaginase activity was obtained from F. khargensis IBRC-M 30116T, and the enzyme production of this type strain was 13.6 ± 5.7 U/mL.

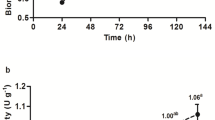

The highest level of l-asparaginase production of F. khargensis IBRC-M 30116T was observed with 9% inoculum (Fig. 2a). The reduction in inoculum concentration led to decrease in enzyme production level in this strain. A steady increase in l-asparaginase production was observed with increasing in temperature from 20 °C and reached the maximum at 30 °C. Further increase in temperature resulted in decline in production of the enzyme (Fig. 2b). The influence of different carbon sources on the production of l-asparaginase was recorded for F. khargensis IBRC-M 30116T. The optimum growth and l-asparaginase production was observed while using glycerol as a carbon source, whereas the lower amount of enzyme production was observed with sucrose followed by glucose and citric acid (Fig. 2c). Among the nitrogen sources tested, ammonium chloride was found to significantly enhance l-asparaginase production when the strain was grown at 30 °C. Among the organics nitrogen sources, asparagine was the proper choice that increases the enzyme production to 51.9 ± 4.9 U/mL (Fig. 2d).

4 Discussion

Different type of microorganisms such as archaea, bacteria, actinomycetes, yeast and fungi have been found to produce l-asparaginase in significant quantities. l-asparaginase production using microbial systems has attracted significant attention due to its cost-effective and ecofriendly nature and ease of production in industrial scale using submerge or solid-state fermentation (Krishnapura et al. 2016). Apart from bacteria, fungi could be considered as a proper potential source for l-asparaginase production owing to two main reasons: first, less chance of immunological reactions expected for fungal strains as they are more closely related to human beings and second, extracellular production of l-asparaginase will lead to easier purification process and reducing production cost (Vala and Dave 2016). Overall 45% of tested yeast and yeast-like-type strains were found positive for l-asparaginase production. In this study, the species F. khargensis, A. mangrovei, C. iranica, G. fimbriata, S. orientalis are reported for the first time as l-asparaginase producing fungi.

The plate assay method was chosen as a semi-quantitative, simple and rapid screening procedure for l-asparaginase production. The method is suitable for preliminary large-scale screening due to the fact that it is easy and l-asparaginase production can be visualized directly from the plates without performing time-consuming assays (Rani et al. 2012). Previously, multiple studies were carried out with the objective to improve the plate assay method using different pH indicator dyes for the screening of asparaginase producer strains; however, the results are not always compatible (Mahajan et al. 2013; Mihooliya et al. 2017; Vaishali and Bhupendra 2017).

In the present study, PR, BTB and CR were used as pH indicator dyes for the screening of l-asparaginase producing microorganisms. PR shows a yellow color at pH range of 6.8–8.2 and turns red at the pH level above 8 (Merck). CR is a maroon to dark red crystals and soluble in water. It shows a yellow color at pH 7.2 and turns to a dark red or maroon when pH increases to 8.2 (Mihooliya et al. 2017). BTB gives a transient green color at the pH range of 6.0–7.6 and it turns to blue at the pH level above 7.6 (Mahajan et al. 2013), thus, is more sensitive to alkalifying agents. The hydrolytic action of l-asparaginase on l-asparagine causes an increase in pH from acidic to basic (in the range of 7.0–9.0; data not shown) due to the release of ammonia. This formation of ammonia is responsible for the development of a zone of hydrolysis in plates supplemented with different pH indicator dyes. In this study, plates containing Modified Czapek Dox agar medium were supplemented with 0.008% bromothymol blue were observed to produce sharp and clear hydrolysis zone which might be attribute to the lower turning point of BTB in alkaline zone. However, the plates with phenol red were observed to produce a zone of hydrolysis with the lower intensity. In contrast, cresol red has the lowest efficiency among the tested pH indicator dyes. These results seem to contradict Mihooliya et al. 2017 that claimed CR is better than PR and BTB relating to the sensitivity and consistency of the results. In addition to l-asparaginase production, a quantitative assessment for the production of glutaminase was also done. Glutaminase activity was present in two-type strains which show better results in the preliminary screening. However, the glutaminase activity was not significant in comparison with l-asparaginase activity. The concomitant presence of the activity of glutaminase is not ideal for clinical application due to the toxic side effects that are generally attributed to the glutaminase activity (Ashok et al. 2019).

Many factors such as type and concentration of carbon and nitrogen sources, pH, aeration, temperature, fermentation time, and, mainly, the microbial sources, have great influence on the efficiency of industrial production process aiming to reach higher production yield and economic viability (Trivedi and Padalia 2016). Therefore, fermentation process and fermentation media have been continuously updated to obtain the highest production level of the selected enzyme (Talluri et al. 2019). There are few reports on media and optimization process for production of l-asparaginase by yeast strains. Four significant parameters (inoculum concentration, temperature, carbon source; nitrogen source) were evaluated using classical One Factor at a Time (OFAT) optimization method to increase the level of l-asparaginase production in the F. khargensis IBRC-M 30116T. In this method, optimization process was done by varying a single factor only and keeping the remaining factors constant enzyme (Talluri et al. 2019). In the first step, the optimal level of inoculum was studied by varying the concentration 1–9%. Enzyme production increased with increasing inoculum size and it seems lower level of an inoculum may not be sufficient for initiating the growth of the producer strain, whereas, much higher level of inoculum may cause competitive inhibition (Nandal et al. 2013). Positive effect of increasing inoculum size on l-asparaginase production by the yeast Leucosporidium scottii has been reported by Moguel (2018). One of the most significant factors for l-asparaginase production is the incubation temperature which affects the microbial growth, enzyme secretion, and rate of the chemical reaction, which finally affects the rate of enzymatic activity (El-Hadi et al. 2019). To determine the optimum temperature for l-asparaginase production, the type strain was cultured in a modified Czapek Dox broth medium supplied with l-asparagine at different temperatures ranging from 20 to 37 °C for an incubation period of 4 days. A steady escalation in the enzyme activity with increasing in temperature from 20 °C observed, and the maximum activity obtained (35.5 ± 1.5 U/mL) at 30 °C (Fig. 2b). Further increase in the temperature resulted in significant reduction in enzyme activity. This may be due to the heat accumulation in the medium and subsequent denaturation of the enzyme. Selection of the appropriate substrate based on nutritional value, availability and cost plays an important role in enzyme production in industrial scale (Ghosh et al. 2013). In the next step, different carbon sources (glucose, sucrose, citric acid and glycerol) and then, different nitrogen sources (yeast extract, proline and asparagine, ammonium chloride, sodium nitrate) at a final concentration of 1% w/v were used. The highest level of enzyme activity obtained was 49.9 ± 1.6 U/mL when glycerol was used as a carbon source. On the other hand, citric acid recorded the lowest value in l-asparaginase production (15.4 ± 1.0 U/mL). Sucrose, glycerol and citric acid have been reported as positive factors on l-asparaginase production by L. scottii (Moguel 2018). Improving the production of l-asparaginase is highly affected by the nitrogen sources either the organic form or inorganic form. In this study, ammonium chloride in the medium provides the highest level of l-asparaginase production (61.3 ± 0.2 U/mL). However, the researchers don’t share the same opinion regarding the proper choice of suitable nitrogen sources. Some researchers such as Venil and Lakshmanaperumalsamy (2008), El-Naggar et al. (2018) reported that the addition of organic nitrogen sources in production medium will induce maximum l-asparaginase production and inorganic nitrogen supplements reduce l-asparaginase production significantly while others such as El-Hadi et al. (2017) contradict this notion. Finally, the results of this study indicated that the yeast-like F. khargensis IBRC-M 30116T possessed an activity level of 13.6 U/mL before obtaining optimal conditions, and after reaching optimal conditions this increased to 61.3 U/mL, which represents a 4.5-fold increase.

5 Conclusion

l-asparaginase is one of the most potential industrial enzymes that usually produce by bacterial sources. However, recognition of several adverse side effects linked with bacterial asparaginase requests a universal search for l-asparaginase from new sources. Asparaginase production has been reported from the various yeasts and yeast-like genera including Saccharomyces sp., Candida sp., Pichia sp., Rhodotorula sp., Hansenula sp., and Spobolomyces sp. (Batool et al. 2016). However, to the best of our knowledge, this is the first report which describes an unexploited source for production of l-asparaginase enzyme by type species of Fereydounia genus. Nevertheless, further studies are required to characterize this microbial enzyme and to fully optimize the production process using statistical design of experiment approaches and also to use latest recombinant technologies which could improve the efficiency of large-scale production of the enzyme for commercial purposes in the future.

Availability of Data and Material

The data that support the finding of this study are openly available in NCBI.

References

Alimadadi N, Soudi MR, Wang SA, Wang QM, Talebpour Z, Bai FY (2016) Starmerella orientalis f.a., sp. nov., an ascomycetous yeast species isolated from flowers. IJSEM 66(3):1476–1481. https://doi.org/10.1099/ijsem.0.000905

Ashok A, Doriya K, Rao JV, Qureshi A, Tiwari AK, Kumar DS (2019) Microbes producing l-asparaginase free of glutaminase and urease isolated from extreme locations of antarctic soil and moss. Sci Rep 9:1423. https://doi.org/10.1038/s41598-018-38094-1

Batool T, Makky EA, Jalal M, Yusoff MM (2016) A comprehensive review on l-asparaginase and its applications. Appl Biochem Biotechnol 178(5):900–923. https://doi.org/10.1007/s12010-015-1917-3

Brumano LP, Santos da Silva FV, Costa-Silva TL, Apolinário AC, Madalena Santos JHP, Kleingesinds EK, Monteiro G, Rangel-Yagui CO, Benyahia B, Junior AP (2019) Development of l-asparaginase biobetters: current research status and review of the desirable quality profiles. Front Bioeng Biotechnol 6:212. https://doi.org/10.3389/fbioe.2018.00212

Cachumba JJ, Antunes FA, Peres GF, Brumano LP, Santos JC, Da Silva SS (2016) Current applications and different approaches for microbial l-asparaginase production. Braz J Microbiol 1(1):77–85. https://doi.org/10.1016/j.bjm.2016.10.004

Chand S, Mahajan RV, Prasad JP, Sahoo DK, Mihooliya KN, Dhar MS, Sharma G (2020) A comprehensive review on microbial l-asparaginase: bioprocessing, characterization and industrial applications. Biotechnol Appl Biochem. https://doi.org/10.1002/bab.1888

Doriya K, Kumar DS (2016) Isolation and screening of L-asparaginase free of glutaminase and urease from fungal sp. 3 Biotech 6:239. https://doi.org/10.1007/s13205-016-0544-1

El-Hadi AA, El-Refai HA, Shafei MS, Zaki R (2017) Statistical optimization of l-asparaginase production by using Fusarium solani. Egypt Pharmaceut J 16(1):16–23. https://doi.org/10.4103/1687-4315.205825

El-Hadi AA, Ahmed HM, Hamzawy RA (2019) Optimization and characterization of L-asparaginase production by a novel isolated Streptomyces spp. strain. Egypt Pharmaceut J 18(2):111–122. https://doi.org/10.4103/epj.epj_23_18

El-Naggar NA, Deraz SF, El-Ewasy SM, Suddek GM (2018) Purification, characterization and immunogenicity assessment of glutaminase free l-asparaginase from Streptomyces brollosae NEAE-115. BMC Pharmacol Toxicol 19(1):51. https://doi.org/10.1186/s40360-018-0242-1

Ghosh S, Murthy S, Govindasamy S, Chandrasekaran M (2013) Optimization of l-asparaginase production by Serratia marcescens (NCIM 2919) under solid state fermentation using coconut oil cake. Sustain Chem Process 1:9. https://doi.org/10.1186/2043-7129-1-9

Imada A, Igarasi S, Nakahama K, Isono M (1973) Asparaginase and glutaminase activities of micro-organisms. J Gen Microbiol 76(1):85–99. https://doi.org/10.1099/00221287-76-1-85

Krishnapura PR, Belur PB, Subramanya S (2016) A critical review on properties and applications of microbial l-asparaginases. Crit Rev Microbiol 42(5):720–737. https://doi.org/10.3109/1040841X.2015.1022505

Mahajan RV, Saran S, Saxena RK, Srivastava AK (2013) A rapid, efficient and sensitive plate assay for detection and screening of l-asparaginase-producing microorganisms. FEMS Microbiol Lett 341(2):122–126. https://doi.org/10.1111/1574-6968.12100

Mihooliya KN, Nandal J, Swami L, Verma H, Chopra L (2017) A new pH indicator dye-based method for rapid and efficient screening of l-asparaginase producing microorganisms. Enzyme Microb Technol 107:72–81. https://doi.org/10.1016/j.enzmictec.2017.08.004

Moguel IS (2018) Production of l-asparaginase of pharmaceutical interest from yeasts isolated from the Antarctic continent. Dissertation, University of Sao Paulo, Faculty of Pharmacetical Sciences

Nandal P, Ravella SR, Kuhad RC (2013) Laccase production by Coriolopsis caperata RCK2011: optimization under solid state fermentation by Taguchi DOE methodology. Sci Rep 3:1386. https://doi.org/10.1038/srep01386

Nasr S, Soudi MR, Zamanzadeh Nasrabadi SM, Moshtaghi Nikou M, Salmanian AH, Nguyen HDT (2014a) Basidioascus persicus: a new yeast-like species of the Geminibasidiales isolated from Iran soil. IJSEM 64:3046–3052. https://doi.org/10.1099/ijs.0.062380-0

Nasr S, Soudi MR, Shahzadeh Fazeli SA, Nguyen HDT, Lutz M, Piątek M (2014b) Expanding evolutionary diversity in the Ustilaginomycotina: fereydouniaceae fam. nov. and Fereydounia gen. nov., the first urocystidalean yeast lineage. Mycol Prog 13:1012. https://doi.org/10.1007/s11557-014-1012-0

Nasr S, Nguyen HDT, Soudi MR, Shahzadeh Fazeli SA, Sipiczki M (2016) Wickerhamomyces orientalis f. a., sp. nov.:anascomycetous yeast species belonging to the Wickerhamomyces clade. IJSEM 66(7):2534–2539. https://doi.org/10.1099/ijsem.0.001096

Nasr S, Mohammadimehr M, Geranpayeh Vaghei M, Amoozegar MA, Shahzadeh Fazeli SA, Yurkov A (2017) Jaminaea pallidilutea sp. nov. (Microstromatales), a basidiomycetous yeast isolated from plant material of mangrove forests in Iran. IJSEM 67(11):4405–4408. https://doi.org/10.1099/ijsem.0.002302

Nasr S, Mohammadimehr M, Geranpayeh Vaghei M, Amoozegar MA, Shahzadeh Fazeli SA (2018a) Aureobasidium mangrovei sp. nov., an ascomycetous species recovered from Hara protected forests in Persian Gulf, Iran. Antonie Van Leeuwenhoek 111(9):1697–1705. https://doi.org/10.1007/s10482-018-1059-z

Nasr S, Bien S, Soudi MR, Alimadadi N, Shahzadeh Fazeli SA, Damm U (2018b) Novel Collophorina and Coniochaeta species from Euphorbia polycaulis, an endemic plant in Iran. Mycol Prog 17:755–771. https://doi.org/10.1007/s11557-018-1382-9

Nasr S, Lutz M, Amoozegar MA, Eparvier V, Stien D, Shahzadeh Fazeli SA, Yurkov A (2018c) Graphiola fimbriata: the first species of Graphiolaceae (Exobasidiales, Basidiomycota) described only based on its yeast stage. Mycol Prog 18:359–368. https://doi.org/10.1007/s11557-018-1450-1

Nouri H, Moghimi H, Geranpayeh Vaghei M, Nasr S (2017) Blastobotrys persicus sp. nov., an ascomycetous yeast species isolated from cave soil. Antonie Van Leeuwenhoek 111:517–524. https://doi.org/10.1007/s10482-017-0972-x

Qeshmi FI, Homaei A, Fernandes P, Javadpour S (2018) Marine microbial l-asparaginase: biochemistry, molecular approaches and applications in tumor therapy and in food industry. Microbiol Res 208:99–112. https://doi.org/10.1016/j.micres.2018.01.011

Rani SA, Sundaram L, Vasantha PB (2012) Isolation and screening of l-asparaginase producing fungi from soil samples. Int J Pharm Pharm Sci 4(1):279–282

Talluri VP, Lanka SS, Saladi VR (2019) Statistical optimization of process parameters by central composite design (CCD) for an enhanced production of l-asparaginase by Myroides gitamensis BSH-3, a novel species. Avicenna J Med Biotechnol 11(1):59–66

Thirunavukkarasu N, Suryanarayanan TS, Murali TS, Ravishankar JP, Gummadi SN (2011) l-asparaginase from marine derived fungal endophytes of seaweeds. Mycosphere 2:147–155

Trivedi R, Padalia U (2016) l-Asparaginase as an anti-carcinogenic agent. IJESC 6:2824–2826

Vaishali P, Bhupendra NT (2017) A rapid and efficient dye based plate assay technique for screening of l-asparaginase producing fungal strains. J. Microb Biochem Technol 9(4):162–168. https://doi.org/10.4172/1948-5948.1000361

Vala KA, Dave BP (2016) l-Asparaginases from fungi: a mini review. J Bacteriol Mycol 3(1):181–182

Venil CK, Lakshmanaperumalsamy P (2008) Solid state fermentation for production of l-asparaginase in rice bran by Serratia marcescens SB08. Int J Microbiol 7:30. https://doi.org/10.5580/1d06

Vimal A, Kumar A (2017a) Biotechnological production and practical application of L asparaginase enzyme. Biotechnol Genet Eng Rev 33(1):40–61. https://doi.org/10.1080/02648725.2017.1357294

Vimal A, Kumar A (2017b) In vitro screening and in silico validation revealed key microbes for higher production of significant therapeutic enzyme l-asparaginase. Enzyme Microb Technol 98:9–17. https://doi.org/10.1016/j.enzmictec.2016.12.001

Wriston J, Yellin T (1973) l-asparaginase: a review. Adv Enzymol Relat Areas Mol Biol 39:185–248. https://doi.org/10.1002/9780470122846.ch3

Acknowledgements

The authors gratefully acknowledge financial support from the Iranian Biological Resource Centre (IBRC), ACECR.

Funding

This study was funded by Iranian Biological Resource Centre (IBRC), ACECR, Iran.

Author information

Authors and Affiliations

Contributions

All authors have contributed sufficiently in the planning, execution, or analysis of this study to be included as authors.

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Consent to Participate

The authors declare that they voluntarily agree to participate in this research study.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Fazeli, N., Alimadadi, N. & Nasr, S. Screening and Optimization of Process Parameters for the Production of l-asparaginase by Indigenous Fungal-Type Strains. Iran J Sci Technol Trans Sci 45, 409–416 (2021). https://doi.org/10.1007/s40995-020-01056-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40995-020-01056-2