Abstract

This paper reviews the previous studies on mechanically stabilized earth (MSE) wall, soil nail (SN) wall, and hybrid earth retaining structures (HERS) to provide a critical appraisal and state-of-the-art review followed by way forward regarding recommendations on the analysis, design, and practice. The first part of the paper deals with the brief review of the deterministic and reliability analyses of the MSE and SN walls. The second part presents the review of the literature related to the HERS, which consists of MSE over SN wall and shored MSE and narrow MSE walls. Even though the HERS are alternative to the MSE and SN walls and are especially effective in hilly terrains, they are not yet that popular owing to the lack of well-established design guidelines and construction procedures. A limited number of studies have been available in the literature on the HERS from the deterministic and probabilistic perspectives and are not available in the main-stream publications. Due to uncertainties of the material parameters of the soil and geo-synthetics, realistic and accurate prediction of the behavior of the reinforced earth retaining structures is very necessary and accordingly the studies reported on reliability studies are reviewed and presented. In the current design practice, the HERS are conservatively designed using guidelines developed for the MSE and SN walls. Therefore, there is a need to develop comprehensive analysis and design procedures for the safe and economical design of HERS.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Population growth and ever-growing urbanization have forced the engineering community to improve infrastructure facilities worldwide. It is necessary to widen the existing roadways and construct new ones to accommodate the increasing traffic volumes. A limited right-of-way (ROW) available in the case of existing roadways and scarcity of the land and existing site conditions available for the construction of new roadways have complicated the construction of earth retaining structures. Ever since the conceptualization of reinforced earth by Vidal [1], reinforced earth structures have become an integral part of the transportation infrastructure facilities. Over the past four decades, mechanically stabilized earth (MSE) walls have been used to minimize the required ROW for embankments and used in the construction of new roads. In the case of unstable natural slopes, soil nail (SN) walls have been used to provide the required stability against the lateral movement of the soil. These retaining structures involve the passive inclusion of reinforcement or nails to improve the overall stability.

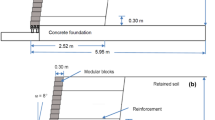

The earth retaining structures involving the MSE and SN walls are termed hybrid earth retaining structures (HERS). The HERS result in substantial reduction in the earth volume apart from maintaining and improving the overall inherent stability. The main advantages of the HERS are: (i) widening of existing embankments without disrupting the traffic, (ii) restoration of the collapsed mountain embankments, and (iii) stabilization of the natural slopes prone to instability and landslides. Combinations of the MSE and SN walls can be categorized into two types viz.: hybrid MSE/SN wall and shored mechanically stabilized earth (SMSE) wall. The hybrid MSE/SN wall is the construction of MSE wall above the SN wall which is mainly used in cut/fill situations with the SN wall in the cut section and the MSE wall in the fill section. In the case of SMSE wall, the MSE wall is constructed adjacent to the existing stable SN wall. These walls are used extensively in the widening and construction of the roads in mountainous terrains without disturbing the existing traffic. In the hilly terrains, a special type of HERS i.e., the narrow MSE (NMSE) walls are constructed where the minimum reinforcement length for the MSE walls cannot be achieved as specified in standards and guidelines [2,3,4,5,6,7]. The complete design of any geotechnical structure must ensure adequate safety for all the possible limit states using both the deterministic and probabilistic approaches.

The MSE and SN walls are the most popular reinforced earth retaining structures in geotechnical engineering due to the well-established design procedures. Despite having several advantages, the HERS are not yet popular in practice due to the lack of proper design guidelines and procedures. The stability and serviceability of the HERS have to be evaluated using numerical methods [8]. There are a few successful case histories regarding the use of HERS in practice [9,10,11,12,13,14,15,16,17,18,19,20,21]. The stability and serviceability analyses of the earth retaining structures include large number of uncertain input parameters. It is not possible to evaluate the absolute safety of the structure in the presence of such uncertainties. The deterministic analysis ignores the effect of these uncertainties in the performance assessment of the reinforced earth retaining structures. The effect of uncertainties is offset in the design of retaining structures using a safety factor as specified in the codal provisions. However, the design procedure should be able to incorporate the uncertainties associated with the input parameters for the realistic evaluation of the stability and serviceability of the retaining structures. The probabilistic approaches provide a framework to consider the uncertainties inherent in the system. A few researchers have studied HERS using deterministic and probabilistic approaches; however, these studies are not well documented and presented in a systematic manner. A typical example of the hybrid MSE/SN wall comprising the MSE wall over the SN wall is shown in Fig. 1.

This paper critically reviews the different studies available related to the analysis and design of the MSE and SN walls and HERS. The review includes the deterministic studies of the global stability and maximum lateral facing displacement of the above-mentioned retaining structures and a few slopes. A brief review of the available literature related to the probabilistic studies, load and resistance factor design (LRFD), and calibration of the load and resistance factors is also presented. Based on the review, an attempt has been made to provide some specific recommendations on the design of HERS using both the deterministic and probabilistic procedures and to streamline the need for future research and way forward.

Mechanically Stabilized Earth Walls

Modern concepts of the MSE walls were conceptualized and popularized by Vidal [1]. Initially, these walls were constructed using galvanized steel strips to provide resistance against lateral earth pressure. The first MSE wall was built in France in 1970 [22, 23] and later geo-synthetics have also been used as reinforcements in the MSE walls. The MSE walls have become extremely popular in the place of conventional retaining walls, and they have many advantages, such as (i) reduced bearing loads due to the use of relatively lightweight facia, (ii) improved flexibility in the system that helps accommodate moderate deformations, (iii) lesser requirement of skilled labor, (iv) economic viability, and (v) reduced construction time. The construction of these walls follows a bottom-up sequential approach, where the first layer of soil and reinforcements is laid down with the corresponding facing elements. This process is then repeated until the required height of the MSE wall is achieved. There are many guidelines developed in several countries for the design of MSE walls [2,3,4,5,6, 24,25,26,27,28,29]. The design methodologies have been largely based on lateral earth pressure theories in the case of reinforced earth retaining structures and for the reinforced slopes, the concepts of slope stability analysis are used. The most common design methods developed for the design of MSE walls, and their suitability assessment were discussed by Anderson et al. [30]. The general design philosophy involves the evaluation of external, internal and global stability followed by the checks for the serviceability criteria. The well-established design guidelines are available for the internal and external stability of the MSE walls. Most often, global stability is evaluated based on the conventional limit equilibrium method (LEM) [31]. The serviceability criteria are assessed in terms of the lateral facing displacement and overall settlement of the backfill.

Deterministic Analysis—A State-of-the-Art Review

The available design methods of MSE walls can be categorized into force-equilibrium and deformation-based approaches. The LEM and earth pressure method come under the force-equilibrium approach, whereas the finite element method (FEM) and the K-stiffness method fall under the deformation-based approaches. The major limitations of the LEM are its inability to evaluate the displacement [32,33,34,35]. In recent decades, the numerical analyses have replaced the conventional LEM in modeling and analyses of the behavior of earth retaining structures due to its many advantages. The strength reduction method (SRM) incorporated in the FEM or finite difference method (FDM) overcomes the disadvantages of the LEM and also simulates the construction sequences realistically [36,37,38,39,40,41]. The FEM [42,43,44,45,46,47,48] and FDM [49, 50] have been used frequently to analyze the behavior of the MSE walls. They yielded satisfactory results for the prediction of different responses in the field and laboratory studies [50,51,52,53,54,55,56,57].

The different design codes available for the design of reinforced earth structures are mainly focused on ultimate limit states and offer only semi-empirical guidelines for the serviceability limit states. However, they fail to address the lack of procedure to evaluate the limit states such as excessive deformations [58]. A large number of MSE walls have been failed due to the excessive lateral facing displacement [59]. It has been recommended that the MSE walls must be designed based on the displacement consideration instead of the force equilibrium concepts. Many researchers have developed the guidelines for evaluating the horizontal displacement of the MSE wall and a few of them are adopted in the design codes [60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76]. However, these design codes focus mainly on the height of the wall, type of reinforcement and surcharge. Several of the MSE walls have failed due to the excessive deformations because of the other factors involved in the instability of the walls [77,78,79,80]. Further studies are needed in this regard to develop the most up-to-date comprehensive design guidelines to evaluate the lateral facing displacement accounting for all the factors affecting the response of the wall.

The horizontal displacement is a sum of three components i.e., facing, internal and global displacements. The facing displacement can be calculated analytically based on the linear interpolation of the maximum strain (Δ) in the respective reinforcements [27, 28, 64, 81]. The simple analytical equation proposed by Giroud [64] to evaluate the horizontal displacement (δx) of any layer is expressed as

where L is the reinforcement length.

A semi-empirical equation was proposed by Wu [69] for calculating the lateral displacement (δ) of the wrapped geo-synthetic reinforced soil (GRS) wall of heights less than 6.1 m. Wu [69] expressed δ as a function of reinforcement strain design limit (Δd) as

where H is the height of the GRS wall.

Lee [70] developed a face deflection model and expressed the normalized maximum facing deflection with respect to the Young’s modulus of the geo-synthetics in compression (Ecomp). The Ecomp was expressed in terms of the reinforcement stiffness (J), vertical spacing between the reinforcement layers (sv), and Young’s modulus of the soil (Es) as

Jewell and Milligan [65] developed the analytical upper-bound model considering the internal deformation of the GRS wall. The soil domain is divided into three zones and defined by the friction angle (ϕ) and dilatancy angle (ψ) of the soil as shown in Fig. 1. Zone 1 corresponds to uniform mobilization of reinforcement strain, and Zone 3 corresponds to zero reinforcement strain. Zone 2 is the transition zone between Zones 1 and 3. Wu et al. [75] modified the analytical model proposed by Jewell and Milligan [65] to incorporate the interface friction between the different components and the facing rigidity of the GRS wall.

Christopher et al. [24] developed the empirical fourth-order polynomial model for evaluating the maximum lateral facing displacement which was later adopted in the design guidelines [2]. The equation is derived considering several parameters, such as height (H), reinforcement length (L), surcharge (q), and reinforcement type (i.e., inextensible or extensible). Christopher [67] proposed the empirically developed chart to evaluate the maximum displacement based on the slenderness ratio (L/H).

Adams et al. [82] proposed a method to calculate the maximum lateral displacement of the MSE walls where the vertical settlement of the GRS abutment must be known a priori. However, the complications involved in the evaluation of the lateral displacement make the results least certain. The methods discussed above are based either on approximate empirical equations or charts to calculate the lateral displacement. However, it has been assumed that the lateral displacements are within the permissible limits, provided the sufficient safety is ensured for the external and internal instability of the wall. It should be noted that the lateral displacements are governed by several parameters, such as thickness, stiffness, inclination and material type of the facing [83,84,85,86,87], spacing, layout and stiffness of reinforcement [88,89,90,91,92,93], backfill properties [94], state of compaction [42, 95,96,97,98,99] and foundation material, and toe restraint and interface [100,101,102]. The above-mentioned parameters may influence the horizontal displacement of the MSE walls individually or jointly. The combined effects of different parameters on the lateral displacement of the MSE walls have also been studied [48, 103, 104].

Khosrojerdi et al. [105] presented a review of the available methods for evaluating the horizontal displacement of the GRS walls and abutments. A summary of literature highlighting the evaluation of maximum lateral facing displacement of the MSE wall (ym) with the different variables involved is presented in Table 1. The table reveals that there are various individual variables that affect the maximum horizontal displacement of MSE walls. However, only a few studies have examined the combined impact of these variables on horizontal displacement. Furthermore, the predictive equations proposed by some researchers for assessing horizontal displacement are restricted in their applicability due to the limited selection and range of variables, such as geometry, soil and reinforcement properties, that were considered during their development. Recent developments in the evaluation of the maximum horizontal displacements of the MSE walls can be seen in the studies by Pramanik et al. [106], Morsy et al. [107] and Khosrojerdi et al. [108].

Several standards suggest a minimum ratio of reinforcement length (L) to wall height (H) between 0.6 and 0.7. According to Chew and Mitchell [68], reducing the reinforcement length from 0.7 to 0.5H resulted in a 50% increase in the lateral displacement, as numerically predicted. The required minimum reinforcement length may depend on several factors, including wall height, soil properties, type of geo-synthetic material, and expected loads. It may be possible to use reinforcement lengths as low as 50% of the wall height, instead of the 70% required by many agencies worldwide. For instance, Hong Kong guidelines suggest 0.5H as the minimum reinforcement length, while Brazilian guidelines recommend a minimum of 0.8H [1]. The Federal Highway Administration (FHWA) guidelines [2] recommend a minimum ratio of 0.7 and acknowledge that longer reinforcement lengths are necessary for structures subject to surcharge loads, while shorter lengths may be used in special conditions [3]. The American Association of State Highway and Transportation Officials (AASHTO) specifications [6] require a minimum reinforcement length of approximately 70% of the wall height and not less than 2.4 m [4]. The National Concrete Masonry Association (NCMA) design manual [3] requires a minimum reinforcement length of 0.6H, which is an empirical constraint to prevent wall construction in limited spaces [5]. According to British Standard [28, 29], walls with normal retaining function require a maximum reinforcement length of 0.7H and 3 m.

The L/H ratio influences both the failure modes and the design approach to be employed. For L/H ratios below 0.25, the external failure mode dominates, and the wall must be designed as a cement stabilized wall. Walls with L/H ratios between 0.25 and 0.7 exhibit a compound failure mode, with the failure surface partially formed through the reinforced soil and partly through the interface between the MSE and stabilized wall facing. For walls with L/H ratios greater than 0.7, the internal failure mode predominates.

Reliability Analysis—A State-of-the-Art Review

The FS used for different geotechnical systems depends on experience and engineering judgment [118]. The conventional approach suffers from many drawbacks such as the choice of different safety factors for different performance requirements. Chalermyanont and Benson [119] highlighted that the conventional design of the MSE walls using the FS approach results in under- or over-estimation of the safety of the system. They emphasized the importance of using the reliability analysis for the design of MSE walls. The reliability analysis accounts for the uncertainties involved in the geotechnical problems in a more rational way. The inherent uncertainties in the soil, reinforcement, and interaction parameters involved in the MSE walls must be considered for their reliable design. Phoon and Kulhawy [120, 121], Phoon and Tang [122] and Tang and Phoon [123] discussed the different types of uncertainties in geotechnical engineering and reported the associated inherent variabilities. These studies carried out an extensive literature review to estimate the typical coefficient of variation (COV) and scale of fluctuation for the common geotechnical parameters.

The reliability analyses have been used for the design of retaining walls since 1960s [124]. Several researchers have carried out the reliability analysis of the MSE walls considering different limit states, such as internal stability, external stability and serviceability, wherein the safety of the walls was expressed in terms of the reliability index and/or the probability of failure [117, 125,126,127,128,129,130]. These studies have considered the available explicit performance functions for the internal and external stability assessment of the wall. However, in the absence of such explicit performance functions, response surface method (RSM) can be used to approximate the performance function. The accuracy of the approximated performance function depends on the order of the polynomial, choice and number of random variables and their associated variabilities and design of experiments.

The applications of the RSM for various geotechnical problems including the slopes and retaining structures were discussed and presented by many researchers [109, 114,115,116,117, 131,132,133,134]. The performance functions for the response quantities of interest of the MSE walls, such as maximum lateral facing displacement [109, 114,115,116,117], and reinforcement and connection strains [115], have been developed using the RSM. The main objective of the reliability analysis is to evaluate the probability of failure and/or the reliability index of the system. The Monte Carlo simulation [114, 117, 133], first-order second moment method [117, 125, 126], point estimate method [128], and first-order reliability method [109, 116, 117, 135,136,137,138] are used to carry out the reliability analysis of the MSE walls. The response surface equations developed for the horizontal displacement hold good only for the particular type of facing material considered and also limited to the scope of the variables in consideration. The proposed equations cannot be extrapolated outside the range of parameters that were considered during their development.

The Load and Resistance Factored Design (LRFD) has become popular in geotechnical engineering in recent times and is seen as an alternative to the conventional Working or Allowable Stress Design (WSD or ASD). The LRFD includes the variability in both the loading and resistance-related variables and the uncertainties are quantified using the probabilistic approaches. A proper selection of the load and resistance factors ensures robust and reliable designs. The LRFD uses the load and resistance factors derived using the rigorous reliability analyses. The application of the load and resistance factors in the design of the MSE walls was discussed by a few researchers [2, 135,136,137,138,139,140]. A several studies are also reported on the calibration of the load and resistance factors using probabilistic analyses considering the internal and external stability of the MSE walls [130, 135,136,137,138,139, 141,142,143]. However, there is no study reported on the calibration of load and resistance factors considering the horizontal displacement and global stability limit states of the MSE wall. The criteria based on the target reliability indices or probabilities of failure are employed in the calibration process. The choice of these target values depends on the importance of the structure, stability requirements and the consequences of the failure of the structure.

The stability of the MSE wall depends not only on the individual or component reliability levels of the limit states but also on the system reliability levels. The engineered systems can be grouped under three categories viz., series, parallel, and hybrid. Several studies have modeled the MSE walls as series systems in which the structure fails if any one of the performance criteria is not satisfied [139, 144,145,146,147]. Basha and Babu [139] proposed a system reliability-based LRFD approach for the analysis of MSE walls considering the external stability under seismic loading. System reliability-based LRFD approach considering both the serviceability and stability criteria is deemed necessary for the complete satisfactory design of the MSE walls.

A State-of-the-Art Review on Soil Nail Walls

The SN walls are used in the cut situations, underground excavations, transportation infrastructure especially for stabilizing the slopes, uphill widening of hill roads, tunnel portals, landslide mitigation and for the repair, and rehabilitation of MSE walls [20, 148,149,150,151,152,153,154,155,156,157]. The SN walls develop their reinforcing action by mobilizing the resisting force through the soil nail interactions as the soil deforms during and/or after the construction of the facility. The nails generate tensile forces through friction during the deformation of the soil along its length, thereby preventing the slope failure [158]. In recent decades, there is a huge demand for stabilization of cut slopes in the transportation infrastructure especially in the hilly terrains [158,159,160]. The complex interactions between the individual components of the SN wall (soil, nail and facing) dictate its performance. The soil nailing is widely used because of their low construction cost, simple installation procedure, ease, and the speed of construction [161, 162]. The SN walls are constructed using a top-down approach, where the slope is excavated, and the top nails are installed first. The same process is then repeated until the bottom of the wall is reached.

Deterministic Analysis

Duncan and Wright [163] presented a thorough review of different techniques of LEM used for the stability analysis of slopes. In the case of slopes reinforced with soil nails, the resistance offered by the soil nails should also be considered in the LEM. In general, the tensile stresses are generated in the nails; however, in certain situations, the nails experience bending and shear stresses. The advantages and disadvantages of considering the bending and shear stiffnesses of the nails in addition to the axial stiffness are discussed by Singh and Babu [164]. Several researchers have considered different types of failure surfaces including: (i) planar [165], (ii) bilinear with a two-wedge slipping mass [166, 167], (iii) parabolic [168], (iv) log spiral [167, 169] and (v) circular [170] to incorporate the effect of nail–soil interaction in the stability analysis. Basset and Last [171] stated that the locus of maximum tension could be considered as the potential slip surface based on the theoretical analysis. This fact was further validated by Schlosser and Unterreiner [172] through prototype-scale experiments. Based on the studies by Bonab and Razavi [173], it is concluded that the failure surface is circular for cohesive soils and is bilinear or trilinear for granular soils depending on the non-associated or associated flow rule.

The SN walls undergo lateral deformation and vertical settlement during and after the construction with the maximum values observed at the top of the wall. The wall displacements are influenced by the designed margin of safety, properties of the soil, facing thickness and its inclination and type, wall height, length of the nail (l) to height of the wall (h) ratio [i.e., l/h], l, slope angle, backslope inclination, nail inclination, connection type, pull-out capacity, spacing, layout, nail head type, nail diameter, interface, surcharge, etc. [172,173,174,175,176,177,178,179,180,181,182,183,184]. It is generally assumed that the vertical displacement is equal to the maximum horizontal displacement [185]. For vertical soil nail walls of height, h and with typical nail length-to-wall height ratios and negligible surcharge loadings, the observed maximum horizontal displacements vary between 0.1 and 0.4% of h depending on the soil/rock type [5, 7, 29, 185,186,187,188,189]. The permissible limits and variables that affect the FS and studies highlighting the evaluation of maximum lateral displacement of the SN wall (yn) with its corresponding influencing parameters are presented in Tables 2 and 3, respectively.

Numerical analyses using the FEM and FDM considering the SN wall system as two-dimensional (2D) system have been performed to understand the behavior of slopes reinforced with nails [31, 199,200,201,202,203,204,205,206,207]. These studies have also evaluated the lateral movement of the slope. Several researchers have brought out the important aspects of the interactions involved in the SN wall system based on the FE analyses using Plaxis and Abaqus [158, 162, 192, 193, 199, 208]. A few researchers have also attempted to optimize the design of SN walls with respect to different geometric parameters, such as nail spacing, length, diameter, inclination, etc. [161, 168, 209]. The factor of safety of the SN wall is evaluated using the SRM in the FE analysis [161, 210,211,212,213]. A few studies have also developed the regression models for the lateral displacement and global stability using the numerically designed experiments considering the geotechnical parameters, nail length patterns and limiting conditions [191,192,193, 214].

Over the years, several laboratory and field studies have been conducted to analyze the behavior of SN walls [215,216,217,218,219,220]. The centrifuge modeling has been widely used for the performance assessment of the reinforced slopes [174, 221, 222]. There is a good agreement between the measured values and those predicted using the 2D numerical analyses [158, 162, 212, 223, 224]. In the past studies, various design aspects were proposed for the design of SN walls [209, 225,226,227,228,229]. A brief appraisal of the design approaches of the SN walls is given by Babu and Singh [230] and Patra and Basudhar [231]. There is a lack of information regarding the collective impact of various parameters on both the factor of safety (FS) and lateral displacement of SN walls. The proposed equations are only applicable within the range of parameters that were considered, and it is not recommended to extend the use of these equations beyond that range.

Reliability Analysis

The existing simplified empirical model [7, 185] under-predicts the lateral displacement of the SN walls built in clayey media and over-predicts for those built in sandy media. The lateral displacement of the SN wall should therefore be assessed probabilistically to quantify the variability in the predictions of the empirical model. A brief review of the available literature on the reliability analysis of the SN walls is presented in this section. The reliability-based design of the SN walls has been extensively adopted in recent times considering the ultimate limit states of internal stability [190, 232,233,234] and external stability [190, 193,194,195, 234,235,236]. However, a very few studies have been reported considering the serviceability limit states [193, 197, 198, 234, 237]. It is to be noted that there is a considerable interdependence between the lateral displacement and global stability limit states of the SN wall [234].

A few researchers have adapted the first-order reliability method [194] and Monte Carlo simulation technique [190, 195] for evaluating the reliability index or probability of failure associated with the SN walls. A limited studies on the system reliability analysis of the SN walls is also attempted in the literature [190, 197, 216, 238]. The calibration of load and resistance factors required in the LRFD of the SN walls for different limit states has also been accomplished by a few researchers [185, 195, 238,239,240,241,242]. Therefore, further studies on the reliability analysis of the SN walls are required considering different serviceability limit states so that easy-to-use reliability-based design guidelines can be formulated.

Hybrid Earth Retaining Structures

In this section, a brief review of the literature on the HERS viz. the hybrid MSE/SN wall and the SMSE and NMSE walls is presented.

Hybrid MSE/SN Walls—A Review

The MSE/SN wall is a highly feasible solution in engineering practice and provides a more economical solution in the cut/fill situations compared to the conventional MSE walls [17]. It is also a viable option where the construction space is limited or road must remain open during the entire construction duration and it restricts the movement likely to be induced by the shallow landslides in the hilly areas [10, 243]. The natural slope is excavated using the top-down construction approach with the nails installed at the desired locations and then the MSE wall is built using the bottom-top construction approach.

Traditional limit equilibrium (LE) approaches do not provide information on the lateral displacement; therefore, they are not used as standalone techniques for the design of MSE/SN walls [8]. The LEM considers the MSE wall as an equivalent surcharge load, arising as a combination of the vertical surcharge and shear forces from the lateral earth pressure acting on the MSE wall [185]. However, the realistic assessment of the behavior of MSE/SN wall requires proper modeling of all the component materials as a single composite system incorporating the respective interactions and evaluating the effect of one retaining structure over the other. Wei [244] used the FE simulations to develop the equivalent surcharge loads to represent the MSE walls in the form of load coefficients for the design of the soil nailed segment of the MSE/SN walls. This approach can be considered as an equivalent technique wherein the direct effect of the MSE wall is omitted in the analysis of the MSE/SN wall. The MSE wall portion can be modeled completely using the continuum-based numerical methods for accurate performance assessment of the MSE/SN walls.

Numerical methods have the added capability to estimate the FS and lateral displacement and also they evaluate the failure mechanisms and deformation modes of the MSE/SN walls. The FE analysis using Plaxis has been used successfully in the modeling of MSE/SN walls [8, 245,246,247]. The efficiency of the FE analysis for the modeling of MSE/SN walls is highlighted with respect to the LE and empirical methods [248]. Design charts and procedures were developed by Alhabshi [245] considering different responses of interest to evaluate the relationship between the lateral displacement and FS against the global instability of the wall. It was concluded that an optimum nail length exists beyond which no benefits are gained from extending the nails’ length. The FE models showed that the critical failure surface of the hybrid walls consists of two continuous portions, first one passing internally through the soil nails and thereafter extending behind the reinforcements in the MSE wall section [8, 244, 247]. In most of the earlier studies, the Mohr–Coulomb material model is used to model the behavior of the soil [8, 244, 245] and it proved to yield the satisfactory results when compared with the experimental and field studies. The behavior of the soil was also modeled using a few advanced constitutive models, such as Modified Cam Clay and Plaxis Cap [245] and hardening soil [8] models. Rabi [8] has suggested the use of FE analysis for the estimation of global FS and failure surface, and the LE approaches for the internal and facing stability analyses. Eldiasty et al. [248] discussed the advantages of hybrid walls over the monotype walls in the expansion of roads. It is advocated that the traditional LE methods are not suitable for analyzing the MSE/SN walls due to the prior assumption of the location and shape of the failure surfaces [244, 247].

Shored MSE and Narrow MSE Walls—A Review

The SMSE and NMSE walls are creative applications of the conventional MSE walls [249]. The NMSE walls are those MSE walls constructed using shorter reinforcements than those recommended by the design guidelines, preferably less than 0.7H or 0.6H. The SMSE walls are those MSE walls built adjacent to the flexible or rigid stable medium which may be rock or a soil nail wall which acts as a shoring for the MSE walls. The existing stable medium promotes the usage of shorter reinforcements in the narrow available space and thereby reduces the mobilization of the reinforcement loads. These walls are specially constructed as part of the transportation infrastructure in the mountainous steep terrains where the limited ROW is available, and they do not affect the traffic flow. The combined system results in the reduction of the earthwork and in addition increases the global stability of the sloped terrain [13, 20]. The well monitored case histories have proved successful implementation and satisfactory performance of the SMSE and NMSE walls [9, 13, 15, 16, 20, 250,251,252,253]. Most of these studies have used the extensible reinforcements with a few exceptions wherein the inextensible reinforcements are used. The combined advantages of the SMSE, NMSE and MSE/SN walls have also been utilized successfully for the landslide mitigation [17, 243, 254].

In the absence of well-established design guidelines in codes, many researchers have carried out analytical, numerical and experimental studies to understand the behavior of SMSE and NMSE walls. The LEM is extensively used for evaluating the potential critical failure surfaces along with the FEM, FDM and experimental studies. The commonly used numerical (FE and FD) programs for the analysis and design of SMSE and NMSE walls are Plaxis [15, 16, 255,256,257,258,259] and Flac [14, 17, 260,261,262,263]. The numerical analysis proved to be accurate in capturing the realistic responses of the NMSE walls [255, 264]. Different material models for the soils are also used in the numerical analyses including a few of the advanced models (e.g., HS model) [256, 259, 264, 265]. The MC model for the soil is reported to be sufficient to accurately capture the behavior of the NMSE and SMSE walls [15, 16, 254, 261,262,263,264, 266, 267]. Parametric studies are also carried out by Abdelrahman et al. [257] to examine the influence of different factors, such as aspect ratio of the wall, elastic axial stiffness of the reinforcement, angle of internal friction, reinforcement spacing and wall height on the lateral displacement and global stability of the wall. The results from these studies indicated that there is a reduction in the lateral and vertical earth pressure for the NMSE walls compared to the conventional MSE walls due to the arching effect and boundary constraints. The easy-to-use charts were also proposed by Leshchinsky et al. [261] and Kniss et al. [264] and to predict the reduced stresses.

The pull-out failure is governed by the lower reinforcement layers extending into the resisting zone. A few studies have suggested using the increased FS against the reinforcement pull-out i.e., 1.5–2.0 for the aspect ratios less than or equal to 0.4 [266, 267]. A few analytical models were proposed to predict the lateral displacement of the SMSE wall with a wrap-around facing [265, 268]. It is noted that the external stability is not ensured by extending the top reinforcement layers into the stable medium [269]. The LEM was adopted to study the failure surface and stability analysis of the wall and arrived at the optimum layout of the reinforcements needed for the satisfactory performance [12, 15, 16]. Leshchinsky et al. [261] postulated a procedure for determining the required tensile strength of the geosynthetics considering its limited length in the case of NMSE walls. It was observed that the friction angle of the reinforced fill and its geometrical extent influence the coefficient of earth pressure acting on the face of the restrained wall [268].

The effect of different parameters, such as the vertical spacing and stiffness of the reinforcement, ratio of nail length to total height of wall, inclinations of the MSE and SN wall facings on the developed tensile stresses in the reinforcements of the MSE wall, is examined by Abbas et al. [259]. Further, a comparison is made among the available design methods of the MSE wall. The significance of evaluating the global stability of the hybrid MSE walls is demonstrated using the case history [253]. Ren et al. [258] compared the deformation characteristics of the SMSE walls between the reduced and full-scale tests using numerical analysis. A series of load displacement/settlement tests on the small-scale model of the NMSE walls is carried out considering the static loads to investigate the performance of the walls in terms of lateral displacement, settlement, distribution of lateral earth pressure, and mobilization of tensile stress at each reinforcement layer [270]. The influence of surcharge and wall deformation modes on the earth pressure of the NMSE walls was numerically investigated by Rajeev et al. [271]. The load deformation response of the NMSE walls under static loading is investigated by Kakrasul et al. [272,273,274]. Full-scale tests were also performed by Luo et al. [275] to study the overall behavior of the NMSE walls.

It has been observed from the numerical, scaled-down experimental, and centrifuge and field studies that a zero-pressure zone is formed at the MSE/stable wall interface representing the formation of a trench. It is also noted that the walls with a very low L/H ratio are susceptible to overturning failure and the walls with L/H ratios of 0.6–0.7 are governed by the lateral sliding failure [255, 256, 260, 264, 266, 267, 276, 277]. The NMSE walls experienced failure for the L/H ratio of 0.25 as the zero-pressure zone reaches the bottom of the wall which forces the MSE wall to sink [256]. A bilinear failure surface originating from the toe of the MSE wall to the stable wall is observed for the walls having aspect ratios ranging from 0.26 to 0.7 with inclination between 48° and 57° [263, 265, 269, 277,278,279]. The failure surface thereafter intersects the shoring wall following the soil wall interface and progresses toward the ground surface. The trench formation triggers the external failure by pulling away the MSE wall from the stable wall. The inclination of the failure surface for the NMSE wall is 10–20% lesser than the actual Rankine failure surface [278,279,280]. The vertical stress on the rear end of the reinforcement was found to be less than that calculated analytically. This reduction is reported due to the arching effect induced by the presence of stiffer soil/rock behind the MSE wall. For more satisfactory performance evaluation of the NMSE walls, further studies are needed with respect to effectiveness of the soil arching and the influence of various parameters on the development of soil arching. The findings from these types of studies will help formulate the extensive design guidelines for the efficient and economical designs of the HERS.

The MSE/SN wall is vulnerable to differential settlement which would result in increased lateral displacement and vertical settlement [281]. A numerical study by Sadat et al. [281] also showed that the friction angle of the backfill soil, surcharge, L/H ratio and tensile stiffness of the reinforcement have a noticeable influence on the lateral and vertical movements of the wall. Application of the MSE wall design procedures to the SMSE walls leads to conservative designs, because the MSE wall design procedures do not consider the reduced lateral earth pressure due to the existence of the stable shoring wall [261, 267, 268]. Moreover, the existing literature has mentioned about the reduction in the earth pressure in the hybrid walls, however, a very few studies have focused on the lateral displacement and global stability of the walls.

It has been suggested that the stability of the NMSE wall could be improved by extending the top reinforcements over the stable wall or attaching all the reinforcements to the stable medium using rigid facing elements of the SN wall. This eventually arrests the deformation and improves the shear strength properties of the soil, thereby eliminating the development of zero pressure zone [14, 266,267,268,269,270, 272, 280, 282]. It was also observed that the displacement can be controlled even for the L/H ratio of 0.3 by the above recommendations or by bending the reinforcements upwards at the rear end. The internal stability is achieved by dissipating the residual reinforcement tensile stresses. The factors, such as the slope gradient, backslope inclination, reinforcement stiffness, angle of internal friction of backfill and reinforcement length, govern the development of nail tensile force during and after the construction of the slope upon allowing the traffic [15, 16]. From these studies, it is concluded that the NMSE walls experience a very little deformation due to the increase in the wall stiffness. It is recommended to use L/H ratio of 0.3 or a minimum reinforcement length of 1.5 m for satisfactory performance of these walls [264, 266, 267]. It is also suggested to consider the noncircular slip surfaces for evaluating the global stability of the NMSE walls [264].

A few authors have also examined the connection between the nails in the existing stable medium and the reinforcements of the MSE wall. The connections considered were: sandwich connection in which the reinforcements and nails overlap [19, 262], anchors attached between the reinforcements and nails to fasten the nails with the reinforcements [250, 258, 261, 262, 266, 267], a fastening system [283], PRO’LINK [12] and yoke [13]. These connections improved the stability of the SN wall by full utilization of the resisting force developed by the reinforcements of the MSE wall. Freitag et al. [14] have also found that the connection provided the additional friction between the nails and the reinforcements which ensured the internal stability of the MSE wall system.

There are hardly any reliability studies attempted on the HERS in the literature. Yang et al. [279] performed the reliability analysis of the NMSE walls considering only the external stability (i.e., overturning and sliding). However, the reliability studies on the MSE/SN and SMSE walls have not been reported in the literature. Yang et al. [279] carried out only the component level reliability analysis of the NMSE walls. A comprehensive reliability analysis requires estimates of the system reliability of the HERS which considers the different components and/or the different limit states of the system. The system reliability studies on the HERS are very much needed to formulate the reliability-based design guidelines. The reliability studies, in general, are computationally costly and require a proper understanding of the probabilistic methods. Calibration of the load and resistance factors for the different limit states of the HERS based on a target probability of failure is also essential and accordingly the further studies can be taken up to develop the LRFD guidelines. The calibrated load and resistance factors ensure the consistent reliabilities for the HERS and at the same time they will not defy the current design practice.

Concluding Remarks and Recommendations

A comprehensive review of the state-of-the-art on the previous publications, reports, and existing design guidelines on the MSE wall [2,3,4,5,6, 25,26,27,28], SN wall [5, 7, 29, 185,186,187,188,189] and HERS [264, 267, 280] is presented in this paper. The following concluding remarks and recommendations are made keeping in view the future framework for further studies:

-

The HERS are viable options to expand the right-of-way compared to the conventional MSE and SN walls especially in the hilly terrains having space constraints. These hybrid walls are also useful for slope stabilization and shallow landslide mitigation. Despite the significant cost reduction, improved flexibility and other engineering advantages, the HERS are not widely used in practice. This under-utilization of the HERS is attributed to the lack of well-established design procedures. Hence, further studies are needed to develop the proper design guidelines so that the HERS can be adopted in the practice of transportation geotechnics.

-

The behavior of the MSE and SN walls in terms of serviceability and ultimate limit states is addressed by many researchers over the years. The allowable stress design and LRFD guidelines are available in the literature for the design of MSE and SN walls. Moreover, the guidelines available in the literature for the design of SMSE and NMSE walls are based on deterministic framework. In the case of hybrid MSE/SN walls, the guidelines are not available yet even from the deterministic framework. Therefore, the systematic further studies are needed to establish the guidelines within the framework of deterministic analysis.

-

The conventional limit equilibrium method cannot be used as a stand-alone analysis method for the performance assessment of the HERS. The field conditions are very well simulated using the numerical methods, provided the interfaces, constitutive models, boundary conditions, geometry, and other parameters are precisely considered in the analysis. The advances in the numerical methods have significantly improved the analysis procedures of the HERS. This also helps to avoid the oversimplified consideration of the MSE wall as an equivalent surcharge acting over/side of the SN wall (MSE/SN or SMSE). A few studies in the literature have discussed the failure mechanisms involved and the reduction in earth pressure due to the arching and boundary constraints. However, there are no studies on the displacement characteristics, deformation modes involved and the overall global stability of the HERS. The numerical analysis captures the arching mechanism and accurately predicts the reduced earth pressure by modeling the HERS as a single composite system. These analyses are also capable of capturing the impact of the interaction between the components of the MSE and SN walls on the overall performance of the HERS. This facilitates the proper evaluation of the lateral displacement and global stability of the wall in a rational way.

-

Many researchers have performed the numerical investigations and developed the response surfaces for different limit states of the MSE and SN walls. The lateral displacements of the MSE and SN walls are generally evaluated based on the developed predictive equations and empirical charts. Similarly, several researchers have performed the experimental (field and laboratory), analytical and numerical studies to analyze the behavior of HERS. Most of these research studies have focused on the evaluation of the responses rather than developing easy-to-use predictive equations for the different responses of the HERS. At present, the design guidelines available for the MSE and SN walls are being used in the design of HERS and are reported to be conservative in general. Therefore, there is a need to develop the rational set of design guidelines for the HERS considering the overall system behavior.

-

Earlier studies have focused on the reliability analyses of the individual MSE and SN walls and in some cases the system reliability analysis has also been performed. The reliability analyses of the MSE and SN walls for different limit states, such as internal, external and serviceability, have been documented in the literature. These reliability analyses have been performed on the developed performance function or on the available explicit functions using the Monte Carlo simulation, first-order second moment method, point estimate method and first-order reliability method. The responses of the HERS depend very much on the uncertainties associated with the soil properties and type of geo-synthetics used in the construction.

-

The reliability analysis of the HERS is not yet attempted, except for the one study which has considered only the external stability limit state of the NMSE wall. Moreover, the reliability studies on the HERS for the lateral displacement and overall global stability limit states have not been performed. Many studies are available pertaining to the calibration of the load and resistance factors for the individual MSE and SN walls considering different limit states. There is hardly any mention in the published literature regarding the system reliability analysis and calibration of the load and resistance factors for the HERS. The reliability of a hybrid wall system is a function of the reliability of its individual limit states. The system reliability assessment of the HERS therefore needs to account for multiple limit states, perhaps correlated, limit states. Therefore, the reliability studies are very much needed to develop the system reliability guidelines for the design of HERS in the probabilistic framework.

Availability of data and materials

The authors confirm that the data supporting the findings of this study are available within the article.

References

Vidal H (1969) The principle of reinforced earth. Highway Research Record No.: 282.NCR-HRB, Washington, D.C.

Berg RR, Christopher BR, Samtani NC (2009) Design of mechanically stabilised earth walls and reinforced soil slopes, Volumes I and II, Geotechnical Engineering Circular No. 11, Report No. FHWA-NHI-10-024, Federal Highway Administration, Washington, DC

NCMA (2009) Design Manual for Segmental Retaining Walls. In: Bernardi M (eds) National Concrete Masonry Association, Herndon

WSDOT (2006) Geotechnical Design Manual, M 46-03, Chapter 15: Abutments, retaining walls, and reinforced slopes. Washington State Department of Transportation, Olympia, Washington

Geoguide 7 (2008) Guide to soil nail design and construction. The Government of the Hong Kong Special Administrative Region

AASHTO (2020) LRFD Bridge Design Specifications. American Association of State Highway and Transportation Officials, Washington, DC

IRC:SP:102 (2014) Guidelines for design and construction of reinforced soil walls. Indian Roads Congress

Rabi M (2016) Performance of hybrid MSE/soil nail walls using numerical analysis and limit equilibrium approaches. HBRC J 12:63–70

Bastick MJ (1990) Reinforced earth narrow walls and abutments correlation of measured performance with design. In: Proceedings of Performance of Reinforced Soil, British Geotechnical Society, Glasgow, pp 59–63

Turner JP, Jensen WG, Wolosick J, Falk M (1999) Soil nail and MSE wall for stabilization of the elbow fill slide, Snake River Canyon, Wyoming. In: Proceedings of 50th annual highway geology symposium, Roanoke, pp 232–246

Alexiew D (2004) Solving landslide problems by combined and geosynthetic reinforced systems. In: Proceedings of 9th international symposium on landslides, Rio de Janeiro, pp 1713–1717

Ziai F, Paris A (2004) Review and design approach of a retaining structure built against and connected to a nailed embankment. In: Proceedings of 3rd European geosynthetics conference, Munich, pp 1–4

Bergmann T, Smith ACS (2007) Design and construction of a composite nailed and mechanically stabilized embankment structure across a talus slope. In: Proceedings of 5th international symposium on earth reinforcement, Fukuoka, pp 701–706

Freitag N, Smith ACS, Maritz LHJ (2007) An innovative connection between a nailed slope and an MSE structure: application at Sishen mine, RSA. In: Proceedings of 5th international symposium on earth reinforcement, Fukuoka, pp 141–146

Fan CC, Hsieh CC (2009) Design of a hybrid reinforced earth embankment for roadways in mountainous regions. In: Proceedings of GeoHunan international conference, Hunan, pp 133–144

Fan CC, Hsieh CC (2011) The mechanical behaviour and design concerns for a hybrid reinforced earth embankment built in limited width adjacent to a slope. Comput Geotech 38:233–247

Wood TA, Jayawickrama PW, Lawson WD (2009) Instrumentation and monitoring of an MSE/soil nail hybrid retaining wall. In: Proceedings of international foundation congress and equipment expo, Florida, pp 177–184

Fan CC, Hsiao CF (2011) Field performance of a hybrid reinforced earth embankment built adjacent to a slope with narrow fill space. J Geo-Eng 6:47–62

Tavakolian R, Grien M (2011) Narrow shored reinforced earth wall with friction based reinforcing strip connection, as an innovative solution to expand urban highways. In: Proceedings of geo-frontiers, Texas, pp 3469–3476

Durgunoglu HT, Sahin A, Akcakal O (2013) A case study on the use of flexible earth retaining structure in instable slopes. In: Proceedings of 7th international conference on case histories in geotechnical engineering, USA, pp 1–5

Kerfontain S, Sankey J, Freitag N, Lucas E (2016) A fully geosynthetic shored reinforced earth wall. In: Proceedings of 3rd Pan-American conference on geosynthetics, Miami, pp 1–11

Leflaive E (1988) Durability of geotext: the French experience. Geotext Geomembr 7:23–31

Puig J, Blivet JC, Pasquet P (1977) Remblai Armé avec un Textile Synthétiqu. In: Proceedings of the international conference on the use of fabrics in geotechnics, Paris, pp 85–90 (French)

Christopher BR, Gill SA, Giroud JP, Juran I, Mitchell JK, Schlosser F, Dunnicliff J (1990) Reinforced soil structures vol. 1: design and construction guidelines. Federal Highway Administration, USA, Report No.: FHWA-RD-89-043

NGG (2005) Nordic guidelines for reinforced soils and fills. Nordic Geosynthetic Group, Nordic Industrial Fund

PWRC (2000) Design and construction manual of geosynthetics reinforced soil, (revised version). Public Works Research Center, Tsukuba

CFEM (2006) Canadian Foundation Engineering Manual. Canadian Geotechnical Society, Richmond

BS 8006-1 (2010) Code of practice for strengthened/reinforced soils and other fills. British Standards Institution, London

BS 8006-2 (2010) Code of practice for strengthened/reinforced soils Part 2: Soil nail design. British Standards Institution, London

Anderson PL, Gladstone RA, Sankey JE (2012) State of the practice of MSE wall design for highway structures. In: Proceedings of geo-congress, California, pp 443–463

Villalobos SA, Villalobos FA (2021) Effect of nail spacing on the global stability of soil nailed walls using limit equilibrium and finite element methods. Transp Geotech 26:100454

Claybourn AF, Wu JTH (1993) Geosynthetic-reinforced soil wall design. Geotext Geomembr 12:707–724

Rowe RK, Ho SK (1993) A review of the behavior of reinforced soil walls. In: Proceedings of international symposium on earth reinforcement practice, Balkema, pp 801–830

Krahn J (2003) The 2001 R.M. Hardy Lecture: the limits of limit equilibrium analyses. Can Geotech J 40:643–660

Allen TM, Bathurst RJ (2013) Comparison of working stress and limit equilibrium behavior of reinforced soil walls. In: Proceedings of geo-congress, San Diego, pp 2–15

Zienkiewicz OC, Humpheson C, Lewis RW (1975) Associated and non-associated visco-plasticity and plasticity in soil mechanics. Géotechnique 25:671–689

Matsui T, San KC (1992) Finite element slope stability analysis by shear strength reduction technique. Soils Found 32:59–70

Ugai K, Leshchinsky D (1995) Three-dimensional limit equilibrium and finite element analyses: a comparison of results. Soils Found 35:1–7

Griffiths DV, Lane PA (1999) Slope stability analysis by finite elements. Géotechnique 49:387–403

Dawson EM, Roth WH, Drescher A (1999) Slope stability analysis by strength reduction. Géotechnique 49:835–840

Cheng YM, Lansivaara T, Wei WB (2007) Two-dimensional slope stability analysis by limit equilibrium and strength reduction methods. Comput Geotech 34:137–150

Mirmoradi S, Ehrlich M (2014) Modeling of the compaction-induced stresses in numerical analyses of GRS walls. Int J Comput Methods 11:1342002

Mirmoradi S, Ehrlich M (2015) Numerical evaluation of the behavior of GRS walls with segmental block facing under working stress conditions. J Geotech Geoenviron Eng 141:04014109

Mirmoradi S, Ehrlich M (2018) Numerical evaluation of compaction-induced stress for the analysis of RS walls under working conditions. Geotext Geomembr 46:354–365

Djabri M, Benmebarek S (2016) FEM analysis of back-to-back geosynthetic-reinforced soil retaining walls. Int J Geosynth Ground Eng 3:1–8

Cristelo N, Felix C, Lopes ML, Dias M (2016) Monitoring and numerical modelling of an instrumented mechanically stabilized earth wall. Geosynth Int 23:48–61

Capilleri PP, Ferraiolo F, Motta E, Scotto M, Todaro M (2019) Static and dynamic analysis of two mechanically stabilized earth walls. Geosynth Int 26:26–41

Mirmoradi SH, Ehrlich M, Chinchay P, Dieguez C (2019) Evaluation of the combined effect of facing inclination and uniform surcharge on GRS walls. Geotext Geomembr 47:685–691

Abdelouhab A, Dias D, Freitag N (2011) Numerical analysis of the behaviour of mechanically stabilized earth walls reinforced with different types of strips. Geotext Geomembr 29:116–129

Yu Y, Bathurst RJ, Allen TM, Nelson R (2016) Physical and numerical modelling of a geogrid-reinforced incremental concrete panel retaining wall. Can Geotech J 53:1–19

Ling HI, Leshchinsky D (2003) Finite element parametric study of the behavior of segmental block reinforced-soil retaining walls. Geosynth Int 10:77–104

Hatami K, Bathurst RJ (2005) Development and verification of a numerical model for the analysis of geosynthetic-reinforced soil segmental walls under working stress conditions. Can Geotech J 42:1066–1085

Guler E, Hamderi M, Demirkan MM (2007) Numerical analysis of reinforced soil retaining wall structures with cohesive and granular backfills. Geosynth Int 14:330–345

Huang B, Bathurst RJ, Hatami V (2009) Numerical study of reinforced soil segmental walls using three different constitutive soil models. J Geotech Geoenviron Eng 135:1486–1498

Damians IP, Bathurst RJ, Josa A, Lloret A (2015) Numerical analysis of an instrumented steel-reinforced soil wall. Int J Geomech 15:04014037

Baral P, Bergado DT, Duangkhae S (2016) The use of polymeric and metallic geogrid on a full-scale MSE wall/embankment on hard foundation: a comparison of field data with simulation. Int J Geo-Eng 7:7–20

Ling HI, Xu L, Leshchinsky D, Collin JG, Rimoldi P (2016) Centrifugal modeling of reinforced soil retaining walls considering staged construction. In: Proceedings of Geo-Chicago, Chicago, pp 95–105

Scotland I (2016) Analysis of horizontal deformations to allow the optimisation of geogrid reinforced structures. Dissertation, Loughborough University, England

Koerner RM, Koerner GR (2018) An extended data base and recommendations regarding 320 failed geosynthetic reinforced mechanically stabilized earth (MSE) walls. Geotext Geomembr 46:904–912

Hermann LR, Al-Yassin Z (1978) Numerical analysis of reinforced soil systems. In: Proceedings of symposium on earth reinforcement, USA, pp 428–457

Gourc JP, Ratel A, Delmas P (1986) Design of fabric retaining walls: the displacements method. In: Proceedings of 3rd international conference on geotextiles and geomembranes, Vienna

Gourc JP, Gotteland P, Delmas P (1988) Design of geosynthetic retaining walls: Displacements method and two blocks method. Comparison and charts. In: Proceedings of international geotechnical symposium on theory and practice of earth reinforcement, Fukuoka, pp 517–522

Adib ME. Internal lateral earth pressure in earth walls (1988) Dissertation, University of California, Berkeley

Giroud JP (1989) Geotextile engineering workshop-Design examples. Federal Highway Administration, Washington, D.C., USA, Report No.: FHWA-HI-89-002

Jewell RA, Milligan GW (1989) Deformation calculation for reinforced soil walls. In: Proceedings of 12th International conference on soil mechanics and foundation engineering, Rio de Janeiro, pp 1259–1262

O’Rourke TD, Jones CJFP (1990) Overview of earth retention systems: 1970–1990. In: Proceedings of design and performance of earth retaining structures, pp 22–51

Christopher BR (1993) Deformation response and wall stiffness in relation to reinforced soil wall design. Dissertation, Purdue University, Indiana

Chew SH, Mitchell JK (1994) Deformation evaluation procedure for reinforced soil walls. In: Proceedings of 5th international conference on geotext, geomembr and related products, Singapore, pp 171–176

Wu JTH (1994) Design and construction of low cost retaining walls: The next generation in technology. Colorado Transportation Institute, Denver, Report No.: CTI-UCD-1-94

Lee WF (2000) Internal stability analyses of geosynthetic reinforced retaining walls. Dissertation, University of Washington, USA

Bathurst RJ, Allen TM, Walters DL (2002) Short-term strain and deformation behaviour of geosynthetic walls at working stress conditions. Geosynth Int 9:451–482

Allen TM, Bathurst RJ, Holtz RD, Walters DL, Lee WF (2003) A new working stress method for prediction of reinforcement loads in geosynthetic walls. Can Geotech J 40:976–994

Al Hattamleh O, Muhunthan B (2006) Numerical procedures for deformation calculations in the reinforced soil walls. Geotext Geomembr 24:52–57

Correia AAS, Pinto MIM, Lopes MLC (2011) Design brick faced retaining walls reinforced with Geotext: face deformation. J Geotech Geoenviron Eng 138:629–632

Wu JTH, Pham TQ, Adams MT (2013) Composite behaviour of geosynthetic reinforced soil mass. McLean, Virginia, Report No.: FHWA-HRT-10-077

Liu H, Yang G (2015) Analytical method for the lateral displacements of steel reinforced soil walls on stiff foundations with incremental panel facings. Géotechnique 65:728–739

Scarborough JA (2005) A tale of two walls: Case histories of failed MSE walls. In: Proceedings of geo-frontiers, Texas, pp 1–12

Mahmood T (2009) Failure analysis of a mechanically stabilized earth (MSE) wall using finite element program Plaxis. Dissertation, University of Texas, Arlington

Hossain MS, Kibria G, Khan MS, Hossain J, Taufiq T (2012) Effects of backfill on excessive movement of MSE wall. J Perform Constr Facil 26:793–802

Kibria G, Hossain MDS, Khan MS (2014) Influence of soil reinforcement on horizontal displacement of MSE wall. Int J Geomech 14:130–141

EBGEO (2010) Recommendation for design and analysis of earth structures using geosynthetics, EBGEO. German Geotechnical Society, Ernst and Sohn Berlin

Adams MT, Lillis CP, Wu JTH, Ketchart K (2002) Vegas mini pier experiment and postulate of zero volume change. In: Proceedings of 7th international conference on geosynthetics, Netherlands, pp 389–394

Tatsuoka F (1993) Keynote Lecture: roles of facing rigidity in soil reinforcing. In: Proceedings of international symposium on earth reinforcement practice. Fukuoka, pp 831–870

Ho SK, Rowe RK (1996) Effect of wall geometry on the behaviour of reinforced soil walls. Geotext Geomembr 14:521–541

Leshchinsky D, Vulova C (2001) Numerical investigation of the effects of geosynthetic spacing on failure mechanisms in MSE block walls. Geosynth Int 8:343–365

Liu H (2012) Long-term lateral displacement of geosynthetic-reinforced soil segmental retaining walls. Geotext Geomembr 32:18–27

Rahmouni O, Mabrouki A, Benmeddour D, Mellas M (2016) A numerical investigation into the behavior of geosynthetic-reinforced soil segmental retaining walls. Int J Geotech Eng 10:435–444

Helwany SMB, Reardon G, Wu JTH (1999) Effects of backfill on the performance of GRS retaining walls. Geotext Geomembr 17:1–16

Hatami K, Bathurst RJ, Pietro PD (2001) Static response of reinforced-soil retaining walls with non-uniform reinforcement. Int J Geomech 1:477–506

Holtz RD, Lee WF (2001) Internal stability analysis of geosynthetic reinforced retaining walls. Washington State Dept. of Transportation, Olympia, Final Research Report No.: WA-RD 532.1

Yoo C (2004) Performance of a 6-year-old geosynthetic-reinforced segmental retaining wall. Geotext Geomembr 22:377–399

Kim YS, Won MS (2006) Deformation behaviors of geosynthetic reinforced soil walls on shallow weak ground. In: Proceedings of soil stress-strain behavior: measurement, modeling and analysis, Rome, pp 819–830

Bilgin Ö, Mansour E (2014) Effect of reinforcement type on the design reinforcement length of mechanically stabilized earth walls. Eng Struct 59:663–673

Bilgin Ö, Kim H (2010) Effect of soil properties and reinforcement length on mechanically stabilised earth wall deformations. In: Proceedings of earth retention conference, Washington, pp 556–563

Hatami K, Witthoeft AF, Jenkins LM (2008) Influence of inadequate compaction near the facing on the construction response of wrapped-face MSE walls. Transp Res Rec 2045:85–94

Ehrlich M, Mirmoradi SH, Saramago RP (2012) Evaluation of the effects of compaction on the behavior of geosynthetic-reinforced soil walls. Geotext Geomembr 34:108–115

Zheng YW, Fox PJ, McCartney JS (2018) Numerical simulation of deformation and failure behavior of geosynthetic reinforced soil bridge abutments. J Geotech Geoenviron Eng 144:04018037

Nascimento G, Ehrlich M, Mirmoradi SH (2020) Numerical- simulation of compaction-induced stress for the analysis of RS walls under surcharge loading. Geotextile Geomembr 48:532–538

Ehrlich M, Mirmoradi SH, Tortureli M (2021) Numerical evaluation of backfill compaction behind the face of reinforced soil walls. Proc Inst Civ Eng Geotech Eng 176:74–85

Schmertmann GR, Chew SH, Mitchell JK (1989) Finite element modeling of reinforced soil wall behaviour. University of California, Berkeley, Geotechnical Engineering Report No.: UCB/GT/89-01

Kazimierowicz-Frankowska K (2005) A case study of a geosynthetic reinforced wall with wrap-around facing. Geotext Geomembr 23:107–115

Huang B, Bathurst RJ, Hatami K, Allen TM (2010) Influence of toe restraint on reinforced soil segmental walls. Can Geotech J 47:885–904

Mirmoradi SH, Ehrlich M, Dieguez C (2016) Evaluation of the combined effect of toe resistance and facing inclination on the behavior of GRS walls. Geotext Geomembr 44:287–294

Mirmoradi SH, Ehrlich M, Magalhães LFO (2021) Numerical evaluation of the effect of foundation on the behaviour of reinforced soil walls. Geotext Geomembr 49:619–628

Khosrojerdi M, Xiao M, Qiu T, Nicks J (2016) Evaluation of prediction methods for lateral deformation of GRS walls and abutments. J Geotech Geoenviron Eng 143:06016022

Pramanik R, Mukherjee S, Babu GLS (2022) Deterministic and probabilistic prediction of maximum wall facing displacement of geosynthetic-reinforced soil segmental walls using multivariate adaptive regression splines. Transp Geotech 36:100816

Morsy AM, Zornberg JG, Christipher BR, Leshchinsky D (2020) Lateral displacements in geosynthetic-reinforced soil structures with segmental-block facing systems. In: Proceedings of 4th Pan American conference on geosynthetics, USA

Khosrojerdi M, Xiao M, Qiu T, Nicks J (2020) Prediction equations for estimating maximum lateral displacement and settlement of geosynthetic reinforced soil abutments. Comput Geotech 125:103622

Sayed S, Dodagoudar GR, Rajagopal K (2010) Finite element reliability analysis of reinforced retaining walls. Geomech Geoeng 5:187–197

Wu JTH, Pham TQ (2010) An analytical model for evaluation of compaction-induced stresses in a reinforced soil mass. Int J Geotech Eng 4:549–556

Adams M, Nicks J, Stabile T, Wu JTH, Schlatter W, Hartmann J (2011a) Geosynthetic reinforced soil integrated bridge system interim implementation guide. Federal Highway Administration, Washington, DC, Report No.: FHWA-HRT-11-026

Adams M, Nicks J, Stabile T, Wu JTH, Schlatter W, Hartmann J (2011b) Geosynthetic reinforced soil integrated bridge system synthesis report. Federal Highway Administration, McLean, VA, Report No.: FHWA-HRT-11-027

Allen TM, Bathurst RJ (2015) An improved simplified method for prediction of loads in reinforced soil walls. J Geotech Geoenviron Eng 141:1–14

Lin BH, Yu Y, Bathurst RJ, Liu CN (2016) Deterministic and probabilistic prediction of facing deformations of geosynthetic-reinforced MSE walls using a response surface approach. Geotext Geomembr 44:813–823

Yu Y, Bathurst RJ (2017) Probabilistic assessment of reinforced soil wall performance using response surface method. Geosynth Int 24:524–542

Hamrouni A, Das D, Sbartai B (2018) Reliability analysis of a mechanically stabilized earth wall using the response surface methodology optimized by a genetic algorithm. Geomech Eng 15:937–945

Toufigh V, Pahlavani H (2018) Probabilistic-based analysis of MSE walls using the latin hypercube sampling method. Int J Geomech 18:04018109

Duncan JM (2000) Factors of safety and reliability in geotechnical engineering. J Geotech Geoenviron Eng 126:307–316

Chalermyanont T, Benson C (2004) Reliability-based design for internal stability of mechanically stabilized earth walls. J Geotech Geoenviron Eng 130:163–173

Phoon KK, Kulhawy FH (1999) Characterization of geotechnical variability. Can Geotech J 36:612–624

Phoon KK, Kulhawy FH (1999) Evaluation of geotechnical property variability. Can Geotech J 36:625–639

Phoon KK, Tang C (2019) Characterisation of geotechnical model uncertainty. Georisk Assess Manage Risk Eng Syst Geohazards 13:101–130

Tang C, Phoon KK (2021) Model uncertainties in foundation design, 1st edn. CRC Press Taylor and Francis Group, Boca Raton

Meyerhoff GG (1970) Safety factors in soil mechanics. Can Geotech J 7:349–355

Basheer IA, Najjar YM (1994) Reliability based design of reinforced earth retaining walls. Transp Res Rec 1526:64–78

Basma AA, Barakat SA, Omar MT (2003) Reliability based risk index for the design of reinforced earth structures. Geotech Geol Eng 21:225–242

Chalermyanont T, Benson C (2005) Reliability-based design for external stability of mechanically stabilized earth (MSE) walls. Int J Geomech 5:196–205

Sayed S, Dodagoudar GR, Rajagopal K (2008) Reliability analysis of reinforced soil walls under static and seismic forces. Geosynth Int 15:246–257

Wang L, Powers M, Gong W (2017) Reliability analysis of geosynthetic reinforced soil walls. In: Proceedings of geo-risk, Denver, pp 91–100

Bathurst RJ, Lin P, Allen TM (2019) Reliability based design of internal limit states for mechanically stabilized earth walls using geosynthetic reinforcement. Can Geotech J 56:774–788

Wong FS (1985) Slope reliability and response surface method. J Geotech Eng 111:32–53

Xu B, Low BK (2006) Probabilistic stability analyses of embankments based on finite-element method. J Geotech Geoenviron Eng 132:1444–1454

Bathurst RJ, Yu Y (2018) Probabilistic prediction of reinforcement loads for steel MSE walls using response surface method. Int J Geomech 18:1–13

Wu YC, Liu CN, Lin BH (2020) Reliability based design for deformation targeted segment mechanically stabilized earth wall. J GeoEngin 15:1–11

Kim D, Salgado R (2012a) Resistance factors for MSE wall sliding and overturning checks. In: Proceedings of GeoCongres, California, pp 25–29

Kim D, Salgado R (2012) Load and resistance factors for external stability checks of mechanically stabilized earth walls. J Geotech Geoenviron Eng 138:241–251

Kim D, Salgado R (2012) Load and resistance factors for internal stability checks of mechanically stabilized earth walls. J Geotech Geoenviron Eng 138:910–921

Basha BM, Sivakumar Babu GL (2013) Reliability based LRFD approach for external stability of reinforced soil walls. Indian Geotech J 43:292–302

Basha BM, Babu GLS (2013b) System reliability-based load resistance factor design (LRFD) for external seismic stability of reinforced soil walls. In: Proceedings of ASCE geotechnical special publication, California

Lin P, Bathurst RJ (2018) Reliability-based internal limit states analysis and design of soil nails using different load and resistance models. J Geotech Geoenviron Eng 144:04018022

Bathurst RJ, Allen TM, Nowak AS (2008) Calibration concepts for load and resistance factor design (LRFD) of reinforced soil walls. Can Geotech J 45:1377–1392

Bathurst RJ, Huang B, Allen TM (2012) LRFD calibration of the ultimate pullout limit state for geogrid reinforced soil retaining walls. Int J Geomech 12:399–413

Bathurst RJ, Allen TM, Miyata Y, Javankhoshdel S, Bozorgzadeh N (2019) Performance-based analysis and design for internal stability of MSE walls. Georisk Assess Manage Risk Eng Syst Geohazards 13:214–223

Chalermyanont T, Benson C (2005b) Method to estimate the system probability of failure of mechanically stabilized earth (MSE) walls. In: Proceedings of sessions of the geo-frontiers congress, Texas, pp 1–15

Zevgolisa IE, Bourdeaub PL (2010) System reliability analysis of the external stability of reinforced soil structures. Georisk Assess Manage Risk Eng Syst Geohazards 4:148–156

Zevgolis IE, Bourdeau PL (2017) Reliability and redundancy of the internal stability of reinforced soil walls. Comput Geotech 84:152–163

Mahapatra S, Basha BM, Manna B (2021) System reliability framework for design of MSE walls for vertical expansion of MSW landfills. J Hazard Toxic Radioact Waste 25:04020060

Rabcewicz LV (1964) The new Austrian tunnelling method, Part 1. Water Power 16:453–457

Rabcewicz LV (1964) The new Austrian tunnelling method, Part 2. Water Power 16:511–516

Bruce DA, Jewell RA (1987) Soil nailing: application and practice—Part 2. Gr Eng 20:21–33

Bruce DA, Jewell RA (1986) Soil nailing: application and practice—Part 1. Gr Eng 19:10–15

Watkins AT, Powell GE (1992) Soil nailing to existing slopes as landslip preventive works. In: Proceedings of Hong Kong Engineer, vol 20, pp 20–46

Babu GLS, Rao RS, Dasaka SM (2007) Stabilisation of vertical cut supporting a retaining wall using soil nailing: a case study. Gr Improv 11:157–163

Koerner RM (2015) In-situ stabilization of soil slopes using nailed or anchored geosynthetics. Int J Geosynth Gr Eng 1:1–9

Babu GLS, Jaladurgam R (2015) Rehabilitation of distressed retaining walls using soil nails. In: Proc Inst Civ Eng Gr Improv, pp 22–32

Birchmier M, Lobato C (2014) An innovative case study on the use of launched nails for landslide repair. In: Proceedings of biennial rocky mountain geo-conference, Lakewood, pp 139–147

Rout SK, De M, Mandal AK, Das B (2019) Soil nailing for failed slope stabilization on hilly terrain. In: Proceedings of geotechnics for transportation infrastructure, Singapore, pp 625–638

Zhou YD, Cheuk CY, Tham LG (2009) Numerical modeling of soil nails in loose fill slope under surcharge loading. Comput Geotech 36:837–850

Nowatzki E, Samtani N (2004) Design, construction, and performance of an 18-meter soil nail wall in Tucson, AZ. In: Proceedings of geosupport conference, USA, pp 741–752

Seo HJ, Lee IM, Lee SW (2014) Optimization of soil nailing design considering three failure modes. KSCE J Civ Eng 18:488–496

Cheuk CY, Ng CWW, Sun HW (2005) Numerical experiments of soil nails in loose fill slopes subjected to rainfall infiltration effects. Comput Geotech 32:290–303

Kim Y, Lee S, Jeong S, Kim J (2013) The effect of pressure-grouted soil nails on the stability of weathered soil slopes. Comput Geotech 49:253–263

Duncan M, Wright SG (2005) Soil strength and slope stability. Wiley, Hoboken

Singh VP, Babu GLS (2010) 2D Numerical simulations of soil nail walls. Geotech Geol Eng 28:299–309

Sheahan TC, Ho CL (2003) Simplified trial wedge method for soil nailed wall analysis. J Geotech Geoenviron Eng 2:117–124

Stocker M, Korber G, Gassler G, Gudehus G (1979) Soil nailing. In: Proceedings of international conference on soil reinforcement, Paris, pp 469–474

Kim JS, Park CL, Kim JY, Lee SD, Lee SR (1996) A large-scale experimental study of soil-nailed structures. In: Proceedings of international symposium on earth reinforcement, Balkema, pp 775–781

Shen CK, Bang S, Herrmann LR (1981) Ground movement analysis of an earth support system. J Geotech Geoenviron Eng-ASCE 107(12):1609–1624

Juran I, Baudrand G, Farrag K, Elias V (1990) Kinematical limit analysis for design of soil-nailed structures. J Geotech Eng 116:54–72

Plumelle C, Schlosser F (1990) A French national research project on soil nailing: CLOUTERRE. In: Proceedings of international reinforced soil conference glasgow