Abstract

Stone columns are considered as one of the influential soil-stabilising methods that can increase the strength and workability of soft soil foundations considerably. In order to enhance stone columns workability, in this experimental study, some laboratory tests were carried out on different columns. They consist of various gravel shapes and particles distributions and columns reinforced by steel fibre reinforcements as well. Some additional tests were also conducted on columns covered by an ordinary gravel mattress reinforced by geotextile. In addition, stone columns with diameters of 63 and 92 mm were tested with a length-to-diameter ratio of 5. The test results were compared with different shapes of geotextiles, such as routine (full-length sleeve) and ring shapes, as the encasing material. It has been observed that using the mattress, geotextile and steel-fibre reinforcements enhances the load-carrying capacity of them that provide a basis for reasonable predictions on their settlement behaviour.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The formation of stone columns in soft soil leads to improvements in load-carrying capacity and stiffness, coupled with a reduction in consolidation settlement. Efforts have been made by numerous researchers to investigate various aspects of stone columns. They have investigated stone columns workability in different soil samples such as clay samples [1,2,3,4], soft clay foundations [5], layered soil [6] and also behaviour of sand confined with single and multiple geocells [7]. Moreover, numerical investigations were conducted on stone columns as well [8,9,10].

Inadequate lateral support in soft soils results in a significant reduction in the stone columns effectiveness. This deficiency of the lateral confinement mainly happens to shallow depths which cause bulging failure of the upper part of the columns. This is explained by Huges and Withers [11] for the first time. In these cases, the column encapsulating in different forms of geotextile results in the improvement of stone column behaviour. Therefore, various studies have been conducted on the behaviour of encapsulated stone columns through experimental tests, theoretical and numerical analyses and field applications as well. Some of them are explained here.

Experimental investigations have been made by small-scale laboratory tests, mostly concentrating on the analysis of load-settlement behaviour [12,13,14,15]. Since one of the principal constraints of stone columns is their failure during loading, various failure mechanisms have also been analysed in other investigations such as bulging failure, shear failure and punching failure like the ones presented by Ali et al. [16, 17] or Chen et al. [18]. For these experimental studies, the sleeves were mainly made with geotextiles by a sewn overlap of the fabric (e.g. Murugesan and Rajagopal [19, 20] or by a glued overlap of the fabric (e.g. Gniel and Bouazza [21]). In addition to small-scale tests in laboratory, Yoo and Lee [22] have studied the performance of encased stone columns in soft ground with full-scale load tests in the field.

Other experimental analyses are based on triaxial compression tests of encased samples, such as Sivakumar et al. [23] who used stone columns to reinforce clay samples with diameter and depth of 300 and 400 mm, respectively, in a large triaxial cell under a confining pressure of 50 kPa. Along with it, Wu and Hong [24] performed triaxial compression tests on reinforced and non-reinforced columns largely to evaluate the influence of the encasement on the radial strains of the sample and on the deviator stress. Najjar et al. [25] also adopted the same procedure to examine normally consolidated kaolin samples reinforced with single sand columns. Moreover, using a centrifuge, some tests have also been conducted by Kim and Lee [26].

1-g tests are also considered by some researchers as a more simulating procedure in comparison with other methods. For instance, Cimentada et al. [27] performed 1-g consolidation tests on a unit cell that was included of kaolin reinforced with single ordinary gravel columns with diameters of 84.7 and 63.5 mm. The gravel columns were prepared by freezing at a dry density of 16.5 kN/m3. The most important findings that were achieved through these tests were the rate of pore pressure dissipation, the vertical strain reduction due to the presence of column of approximately 25–35% and the load transfer to the column related to the stiffness ratio between the column and soil resulting in incremental stress concentration factors in the range 2.5–9.2.

Ghazavi and Afshar [28] also conducted several 1-g tests on single and groups of stone columns. They used ordinary and encased columns with diameters of 60, 80 and 100 mm, respectively. In order to encase, two non-woven geotextiles were used with the secant stiffness of 35 and 16.36 kN/m. They claimed that using geotextile encasement improves the load-carrying capacity of stone columns.

In this paper, in order to complement the understanding of stone columns behaviour in a more rewarding way, a study based on 1-g compression test is performed. This test is on columns with various gravels such as mixed gravels with steel fibres, different distributions and particle shapes. Stone columns with a gravel mattress on top and encased by ordinary and ringy geotextile were also tested. The ringy form is simulating annular forms of the encasement. This study focuses on the improvement of the column strength by analysing different responses in laboratory tests.

Experimental Study

Loading Device and Sensors

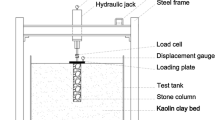

For testing single stone columns, a steel structure was manufactured that included a hydraulic jack (attached by a loading plate with a diameter of 180 mm). It had the total power of 30 kN that was fixed on a horizontal beam of the steel frame, and its displacement rate was controlled by a particular valve. Columns were constructed in the centre of the box for each test. The box size (1.20 × 1.20 × 0.90 m) was chosen so that its boundaries did not cause any confinement against column deformations (Fig. 1).

Two different sensors that had been calibrated before testing were used; displacement sensor with the capacity of 300 mm and accuracy of 1 mm was fixed on the loading plate such that it was kept vertical. Force sensor with an S-shaped load cell with a total range of 30 kN was attached to the loading plate from one side and to a hydraulic jack from the other side. Measured loads were shown on a monitor with an accuracy of 1 N.

Physical Models

A load was continuously applied on the top of each stone column to reach 50 mm of settlement at a rate of 2 mm/min. In this study, 26 tests were conducted on different single stone columns with diameters of 63 and 92 mm and lengths of 315 and 460 mm, respectively (Table 1). The lengths were determined based on a length-to-diameter ratio of 5. Chosen scale was one-tenth of real stone columns size in the field.

In order for the results to be more accurate, each test has been repeated twice under the same conditions. In some cases when the results were not adequate enough and were not close to each other, a third test was performed, and the average of the obtained results in the two tests with the closest agreement was taken into account. For instance, Fig. 2 indicates the results of G1 tests with the column diameter of 92 mm. There was an agreement between this pair of tests.

The different configurations, types of stone columns and their abbreviations in this study are as follows: OSC (ordinary stone column), ESC (encased stone column), RESC (ringed encased stone column), SFRC (steel fibre-reinforced stone columns), OGM (ordinary gravel mattress) and HRGM (horizontal-reinforced gravel mattress).

Materials

Soils

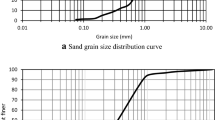

A natural low plasticity clay (CL) was excavated from the depth of 2 m below ground level. The site is located in city of Arak in Markazi province, Iran. Figure 3 shows the clay particle distribution. The majority of columns were constructed by gravel that its particle sizes were between 2 and 10 mm (G1:Cu = 1.57, Cc = 0.94). The features of the clay and gravel type G1 are given in Table 2.

Most of laboratory studies on stone columns were made on clays with less than 15 kPa undrained shear strength. In this study, the clay had an undrained shear strength of 13 kPa at a moisture content of 21%. To estimate the moisture content, multiple specimens were taken from the test box after each test. The results showed a maximum variation of 1% in clay moisture content. To have the same clay conditions in all tests such as amount of the undrained shear strength, a series of unconfined compressive strength tests (UCS) were conducted on clay samples specimens with a diameter of 38 mm and a height of 76 mm that were randomly taken from the top to the bottom of stone columns in depth. This strategy helps to check the strength anisotropy through the length of stone columns.

To study the effect of different particles shapes, three types of gravel were employed. Moreover, their particle distributions are illustrated in Fig. 4.

-

G2—sub-angular gravel (Cu = 1.31, Cc = 0.95).

-

G3—flaky gravel (BS 812: Part 105 [29]) (Cu = 1.39, Cc = 0.95).

-

G4—mixture of G1 and G2 (Cu = 2.41, Cc = 0.78).

Geotextile

The non-woven polypropylene geotextile used in this experimental program was 1 mm thick with an ultimate tensile strength of 9 kN/m and secant stiffness of 16.36 kN/m at 55% strain. Cylindrical shape was prepared by 15 mm which was overlapping to the edges of a rectangular geotextile while a special polypropylene glue stuck the edges properly (Fig. 5).

The strength of stuck area was checked by some tensile tests and the results were acceptable. Figure 6 illustrates the load–strain behaviour of geotextile specimens with and without a seam.

Steel Fibre

Steel fibre reinforcement, which was used in some tests in this study, had Fy = 2400 kg/cm2, a thickness of 1 mm and a length of 50 mm (Fig. 7).

Material Preparation

Soft Clay Bed

To reach a uniform moisture of 21%, which was determined from Table 3, additional water was added to the clay, and the mixture was kept in plastic boxes that maintained the mixture isolated from vaporisation for 5 days. To fill the main box of the test, a protocol was assumed and followed in all tests to provide a similar test tendency. Some weighted amount of clay was moved to the test box, and uniform compaction was performed with an 11-kg tamper (Fig. 8a) to achieve a layer with the thickness of 60 mm. Each layer had a bulk unit weight of 19 kN/m3 without any significant air voids remaining. Layers were made continuously to fill the large box. The final surface of the clay bed was horizontally cut to have a suitable surface for the tests. To validate the test results, some unconfined compression tests were conducted on specimens taken from different depths of the test box after each test to ensure that the undrained shear strength was 13 kPa; moisture changes were controlled to ensure that it was kept less than 1%.

Stone Columns

The stone columns were constructed by a replacement method at the centre of the test box. Two open-ended stainless steel pipes with outer diameters of 63 and 92 mm and a wall thickness of 2 mm were prepared. By using a handy jack (Fig. 8b), each of the pipes was slightly pushed into the clay while both the inner and outer sides of the pipes were greased in order to reduce friction. Subsequently, the clay within the pipe was scooped out through a helical auger with a 50 mm diameter in four stages to minimise the suction effect. After the excavation, pipes were slowly removed without any major soil movement around the top level of the stone columns. A weighted amount of gravel, enough for the columns, was charged gradually; compaction was provided with a 2-kg cylindrical tamper (Fig. 8c) to achieve a 50 mm thickness and a bulk unit weight of 15.5 kN/m3 (Dash and Bora [5] have assumed that 15.3 kN/m3 to be the bulk unit weight). The care was taken that no significant lateral bulging occurred during compaction.

Analyses of Experiments

In this part, the influences of some parameters on the load-carrying capacity of stone columns are investigated, and the load-settlement behaviour of stone columns for each section is presented.

Effect of Stone Column

To investigate the effect of the stone column on load-carrying capacity of the soft clay, the load-settlement behaviour of clay bed and OSCs with both diameters of 63 and 92 mm was determined which is illustrated in Fig. 9. It shows that using stone columns resulted in the increasing of load-carrying capacity of the soft clay. In addition, by increasing the diameter of stone columns, the bearing capacities of OSCs increased.

Effect of Gravel Mattress

Dash and Bora [5] used a gravel mattress with equal column diameters and mattress thicknesses (optimal state) that caused the increasing of load-carrying capacity of the columns. In this section, some tests were performed on stone columns with D = 63 mm covered by a gravel mattress with H = 63 mm in three forms (Fig. 10):

-

Ordinary gravel mattress (OGM).

-

Gravel mattress with a layer of geotextile in the middle (HRGM1).

-

Gravel mattress with a layer of geotextile under it (HRGM2).

The load-settlement behaviour of columns with different states of the gravel mattress is shown in Fig. 11. Test results of the OGM were compared with an OSC by the same diameter. An increase of approximately 33% was observed in load-carrying capacity because of the transmission of bulging failures to deeper points of the stone column.

As shown in Fig. 11, using a geotextile to reinforce the gravel mattress in two forms, HRGM1 and HRGM2, resulted in rises of 5.7 and 20% in the load-carrying capacity in comparison with the OGM, respectively. In addition, HRGM1 and HRGM2 showed increases of 40.7 and 59% of the load-carrying capacity compared with OSC. This improvement might be a result of the uniform distribution of the load on stone columns by the gravel mattress.

Comparison Between OGM with ESC and RESC

Ringed encased stone columns (RESC) was used to provide the possibility of investigating the performance of these annular shapes of reinforcement. To clarify the point, these forms of encasement with geotextile have been shown in Fig. 12.

The load-carrying capacity of OSCs, ESC and RESC and the percentages of their changes for a settlement of 50 mm can be observed in Table 4. As illustrated in Table 4, using a routine form of geotextile (ESC) caused an increase of 14.6 and 30.1% of the load-carrying capacity of stone columns with diameters of 63 and 92 mm, respectively. These amounts were 4.4 and 22.3% when ringy geotextiles (RESC) were used.

As shown in Fig. 13, the load-carrying capacity of columns with OGM is the maximum amount in comparison with the other forms and shows increases of 16.2, 27.5 and 33.1% for ESC, RESC and OSC, respectively.

Reinforced Stone Columns with Steel Fibre

From this section on, stone columns with a diameter of 92 mm were used. As shown in Fig. 14, steel fibre reinforcement was used in three ways (the same amount of steel fibre was used for each form): uniformly mixed with gravel (SFRC1), vertically placed around the column (SFRC2) and horizontally placed in four layers that divided columns into the same five parts (SFRC3). For all tests, the amount of fibre was 2% of the gravel weight.

The load-settlement behaviour of columns for different forms of SFRC has been illustrated in Fig. 15. The maximum load-carrying capacity is obtained from SFRC3 that indicates an increase of approximately 14.4% on the total load-carrying capacity of columns in comparison with OSCs. This is the result of provided tensile strength due to fibres present, which affect layers of stone columns. However, in SFRC1, steel fibre prevented particles from locking in their situation. Therefore, a decrease in its load-carrying capacity is observed compared with OSCs. Furthermore, steel fibres in SFRC2 do not provide a uniformly consistent cover; therefore, its result was the same as OSC.

Comparison Between SFRC3 and RESC with ESC

The test results on steel fibre-reinforced columns (SFRC3) are compared with OSC, ESC and RESC. Figure 16 shows that the load-carrying capacity of steel fibre-reinforced columns is approximately 14 and 7% less than that of ESC and RESC, respectively. These results might be due to the confinement that is provided by the geotextile, which decreased the amount of bulging failure; in contrast, steel fibre does not lead to bulge which is considered as the failure factor in tests on single stone columns.

Stone Columns with Different Types of Gravel

For all of the previously mentioned tests in this paper, gravel 1 (G1) was used. To investigate the effect of different particle shapes (Fig. 17) and distributions of particles (Fig. 4), three different gravels were used to make columns with the 92 mm diameter.

To investigate the effect of particle shape on the load-carrying capacity of columns, G2 (sub-angular shape) and G3 (flaky shape) were tested with the same particle distribution. Accordingly, Fig. 18 shows that G3 has provided a higher load-carrying capacity by approximately 7% due to the better interlocking of flaky shaped grains.

Additionally, the load-settlement behaviour of columns with different particle distributions is shown in Fig. 19. As illustrated, G1 and G2 with different particle distributions showed the same load-carrying capacity; the difference between these two with G4 is less than 4% because of the higher Cu of G4. Additionally, a comparison between Figs. 18 and 19 implies the idea that particle shapes were more efficient than particle distributions in increasing the load-carrying capacity of stone columns. Generally, change in stone columns gravel does not make any considerable changes in the load-carrying capacity in comparison with the other forms.

Load Ratio

Load ratio (LR) is defined as the ultimate load obtained from reinforced soil divided by the ultimate load obtained from soft soil without the stone column. This parameter helps to determine the efficiency of stone columns on improving the ultimate load-carrying capacity of the soft clay. As seen in Table 5, the minimum LR is 1.13 for OSCs, and the maximum LR is 1.84 for HRGM2.

Deformation and Failure Mode

After the tests, in order to check the deformed shape of stone columns, soft clay around the columns was cut softly. As shown in Fig. 20, the bulging failure usually occurred at the top of the column to the depth of 2D and its shape was axisymmetric.

Conclusions

In this research, some laboratory tests were conducted on different stone columns to investigate the effects of using a gravel mattress, steel fibre reinforcement, geotextile encasement and also varying gravel particle distributions and shapes on the load-carrying capacity of columns. By considering the project conditions and the amount of load-carrying capacity that was needed for each project, the best-suited procedure can be adopted.

Regarding, well-known results of using different forms of stone columns (notable increase in the load-carrying capacity of the soft soil), the following conclusions can be drawn:

-

1.

Due to encapsulation, using a routine form of geotextile (ESC) caused an increase of 14.6 and 30.1% of the load-carrying capacity of stone columns with diameters of 63 and 92 mm, respectively in comparison with ordinary stone columns (OSC). These amounts were 4.4 and 22.3% when ringy geotextiles (RESC) were used. Consequently, ESC worked better than RESC in the case of providing better confinement.

-

2.

Placing the horizontal steel fibre-reinforcing layers within the columns can increase 14.4% of the load-carrying capacity of ordinary stone columns.

-

3.

Stone columns with a gravel mattress on top can carry a greater load. Additionally, a gravel mattress reinforced by a geotextile layer (at the bottom of the mattress) had higher bearing capacities. This rise has been 59% more than the load-carrying capacity of OSCs.

-

4.

The different types of gravels (shapes of particles and their distribution) do not have any special effects on the load-carrying capacity compared with other states.

-

5.

It seems necessary to study the scale effects of models in experiments in order to generalise the results of small-scale to the real-scale tests. However, to study scale effects of model geometry and reinforcing material stiffness, some selected results of experimental can be compared with numerical results. After validating the numerical results, real size columns can be designed and their data can be extracted.

Abbreviations

- OSC:

-

Ordinary stone column

- RESC:

-

Ringed encased stone column

- OGM:

-

Ordinary gravel mattress

- ESC:

-

Encased stone column

- SFRC:

-

Steel fibre-reinforced stone columns

- HRGM:

-

Horizontal-reinforced gravel mattress

References

Bergado D, Singh N, Sim S, Panichayatum B, Sampaco C, Balasubramaniam A (1990) Improvement of soft Bangkok clay using vertical geotextile band drains compared with granular piles. Geotext Geomembr 9(3):203–231

Black J, Sivakumar V, McKinley JD (2007) Performance of clay samples reinforced with vertical granular columns. Can Geotech J 44(1):89–95. https://doi.org/10.1139/t06-081

Miranda M, Da Costa A (2016) Laboratory analysis of encased stone columns. Geotext Geomembr 44(3):269–277

Hasan M, Samadhiya NK (2018) Soft soils improvement by granular piles reinforced with horizontal geogrid strips. Int J Geotech Eng 12(1):101–108. https://doi.org/10.1080/19386362.2016.1252139

Dash SK, Bora MC (2013) Improved performance of soft clay foundations using stone columns and geocell-sand mattress. Geotext Geomembr 41:26–35

Mohanty P, Samanta M (2015) Experimental and numerical studies on response of the stone column in layered soil. Int J Geosynth Gr Eng 1:1–14

Rajagopal K, Krishnaswamy NR, Latha GM (1999) Behaviour of sand confined with single and multiple geocells. Geotext Geomembr 17:171–181

Muzammil SP, Varghese RM, Joseph J (2018) Numerical simulation of the response of geosynthetic encased stone columns under oil storage tank. Int J Geosynth Gr Eng 4:4

Ng KS, Tan SA (2015) Stress transfer mechanism in 2D and 3D unit cell models for stone column improved ground. Int J Geosynth Gr Eng 1:1–9

Hasan M, Samadhiya NK (2016) Experimental and numerical analysis of geosynthetic-reinforced floating granular piles in soft clays. Int J Geosynth Gr Eng 2:22:1–3

Huges JMO, Withers NJ (1974) Reinforcing of cohesive soils with stone columns. Gr Eng 7(3):42e49

Fattah MY, Shlash KT, Al-Waily MJM (2011) Stress concentration ratio of model stone columns in soft clays. Geotech Test J ASTM 34(1):1–11

Shahu JT, Reddy YR (2011) Clayey soil reinforced with stone column group: model tests and analyses. J Geotech Geoenviron Eng ASCE 137(12):1265–1274

Stuedlein AW, Holtz RD (2012) Analysis of footing load tests of aggregate piers in clay. J Geotech Geoenviron Eng ASCE 138(9):1091–1103

Hong Y-S, Wu C-S, Yu Y-S (2016) Model tests on geotextile-encased granular columns under 1-g and undrained conditions. Geotext Geomembr 44(1):13–27

Ali K, Shahu JT, Sharma KG (2012) Model tests on geosynthetic-reinforced stone columns: a comparative study. Geosynth Int 19(4):292–305

Ali K, Shahu JT, Sharma KG (2014) Model tests on single and groups of stone columns with different geosynthetic reinforcement arrangement. Geosynth Int 21(2):103–118

Chen JF, Li LY, Xue JF, Feng SZ (2015) Failure mechanism of geosynthetic encased stone columns in soft soils under embankment. Geotext Geomembr 43(5):424–431

Murugesan S, Rajagopal K (2007) Model tests on geosynthetic-encased stone columns. Geosynth Int 14(6):346–354

Murugesan S, Rajagopal K (2010) Studies on the behaviour of single and group of geosynthetic encased stone columns. J Geotech Geoenviron Eng ASCE 136(1):129–139

Gniel J, Bouazza A (2009) Improvement of soft soils using geogrid encased stone columns. Geotext Geomembr 27(3):167–175

Yoo C, Lee D (2012) Performance of geogrid-encased stone columns in soft ground: full-scale load tests. Geosynth Int 19(6):480–490

Sivakumar V, Jeludine DKNM, Bell A, Glyn DT, Mackinnon P (2011) The pressure distribution along stone columns in soft clay under consolidation and foundation loading. Geotechnique 61(7):613–620

Wu CS, Hong YS (2009) Laboratory tests on geosynthetic encapsulated sand columns. Geotext Geomembr 27:107–120

Najjar SS, Sadek S, Maakaroun T (2010) Effect of sand columns on the undrained load response of soft clays. J Geotech Geoenviron Eng ASCE 136(9):1263–1277

Kim BI, Lee SH (2005) Comparison of bearing capacity characteristics of sand and gravel compaction pile treated ground. KSCE J Civ Eng 9(3):197–203

Cimentada A, Da Costa A, Canizal J, Sagaseta C (2011) Laboratory study on radial consolidation and deformation in clay reinforced with stone columns. Can Geotech J 48:36–52

Ghazavi M, Afshar JN (2013) Bearing capacity of geosynthetic encased stone columns. Geotext Geomembr 38:26–36

BSI (1989) EN 812, Part 105 Flakiness index. Methods for determination of particle shape. BSI, London

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hamidi, M., Lajevardi, S.H. Experimental Study on the Load-Carrying Capacity of Single Stone Columns. Int. J. of Geosynth. and Ground Eng. 4, 26 (2018). https://doi.org/10.1007/s40891-018-0142-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40891-018-0142-x