Abstract

Bacillus subtilis UPMB13 was found to be an L-glutamic acid independent producer of extracellular polymeric substances (EPS) with bioflocculation properties. Optimum production of the bioflocculant was found to be at the early stage of cell propagation of 24–72 h of fermentation. At a limited nutrient input of 100 mL tryptic soy broth, the flocculating activities were found to be negatively correlated (p < 0.01) with growth as it continued to decline after 72 h, while cell growth proliferated further. Ample nutrient supply may prolong bioflocculant production with flocculating activities of 90 % and higher, while excess oxygen supply may promote rapid growth that can lead to poor flocculation due to the re-use of the bioflocculant as a substitute for food during starvation. Bioflocculant production occurred at best at 25-30 °C incubation temperature and at the initial pH medium of 7 to 8. The bioflocculant was proven to be extracellularly produced as the broth and the supernatant possessed the ability to flocculate the suspended kaolin particles. Bioflocculant productions by UPMB13 were hereditarily stable among succeeding progenies, hence, proving genetic competency. About 0.90 g of purified bioflocculant were collected from 1 L culture broth of UPMB13 under the optimized fermentation conditions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Flocculation is a process of agglomerating suspended particles aided by compounds known as flocculants commonly used in water treatment applications (Devesa-Rey et al. 2012). Among these flocculants, bioflocculants have been identified as the emerging alternative to the conventional chemical flocculants due to their biodegradability and environmentally benign characteristics (Muthulakshmi et al. 2013). Bioflocculants are essentially extracellular polymeric substances (EPS) synthesized mostly by bacteria as they are ubiquitous in nature.

Production of biopolymeric compounds by bacterial strains could be unpredictable even under rigorously maintained culture conditions (Bajaj and Singhal 2011a). Stressful culture conditions may induce and improve extracellular polymeric substances production by microorganisms (Yu et al. 2015). However, definition of stressful culture conditions are species dependent and may vary for different microorganisms. Salehizadeh and Yan (2014) reviewed on the production of biopolymeric flocculants by microorganisms and stressed that the major criteria influencing bioflocculant performances are culture conditions, including but not limited to culture time, initial pH and temperature, aeration rate, shaking speed and ionic dependency. Optimization of these factors was proven to enhance the yield, quality and the performances of the bioflocculants produced.

One of the most widely studied EPS produced by B. subtilis strains is the poly-γ-glutamic acid (γ-PGA) (Bajaj and Singhal 2011a). γ-PGA productions typically rely on the input of L-glutamic acid supplement in the culture media. Some exceptional cases reported on γ-PGA production in the absence of any glutamic acid additions (Zhang et al. 2012). Notably, not all γ-PGA produced were reported as potential bioflocculants.

This paper discusses the production of a novel bioflocculant by a locally isolated rhizobacterium. B. subtilis UPMB13. It aims to: (i) optimize factors which affect the growth and bioflocculant production by the strain; (ii) determine the distribution of the bioflocculant produced in different culture components; and (iii) determine genetic competency of UPMB13 in bioflocculant production. All factors will provide thorough consideration for determining the optimum culture conditions for continuous production of high performing bioflocculants by B. subtilis UPMB13 for future studies in suspended solids treatment applications.

2 Materials and Methods

2.1 Bioflocculant-Producing Bacteria

B. subtilis UPMB13, isolated from oil-palm root, obtained from the culture collection of the Soil Microbiology Laboratory, Department of Land Management, Universiti Putra Malaysia (Amir et al. 2003; Zulkeflee et al. 2012), was selected based on the morphological characteristics of mucoid and ropy colonies produced when grown on tryptic soy agar (TSA). These characteristics were used as basic identification for potential bioflocculant-producing bacteria (Wong et al. 2012). The strain was verified using Basic Local Alignment Search Tool (BLAST) program analysis based on the 16S ribosomal ribonucleic acid (rRNA) gene sequencing and through biochemical identification test (BBL Crystal Gram-Positive ID System) which proved the strain as B. subtilis at 99 % similarity.

Batch cultures of B. subtilis UPMB13 in tryptic soy broth (TSB) were prepared to produce the bioflocculants in broth form. About 50 mL seed culture of UPMB13 in TSB were prepared and incubated for 24 h on an orbital shaker (150 rpm) at room temperature. Centrifuged cells (4000 rpm for 10 min) from the seed culture were then washed three times with phosphate buffer solution (PBS) and once with sterile TSB before inoculation into a fresh 100 mL TSB and incubated again. Viscous TSB bearing the strain attained indicates bacterial growth and bioflocculant production in the culture. The culture broths were then used directly as the bioflocculant source in the flocculation assays (Aljuboori et al. 2013).

2.2 Flocculation Assay

Flocculation assays using kaolin clay as the suspended particle were conducted according to the methods described elsewhere (Zulkeflee et al. 2012). The flocculation activities were expressed in percentage clarity of the upper phase of the kaolin suspensions after treatment by the bioflocculant and by visual assessment, either present or absent of the kaolin flocs formed, stimulated by the presence of the bioflocculant.

2.3 Production Factors

2.3.1 L-Glutamic Acid Dependency

Requirement for additional L-glutamic acid supplement for bioflocculant production by UPMB13 were determined by preparing batch cultures of 100 mL TSB with treatments of L-glutamic acid (LGA) at 20 g/L (Bajaj and Singhal 2011b), L-glutamic acid and citric acid (CA) at 10 g/L (Chen et al. 2005), and solely TSB as the control treatment. All cultures with respective treatments were incubated on an orbital shaker at 130 rpm for 48 h at 25 °C.

2.3.2 Timeline of Bioflocculant Production

Optical density measurements with a spectrophotometer at 660 nm were conducted to determine the growth of UPMB13 for 5 days. Percentage flocculating activities of the bioflocculants produced by UPMB13 were measured every 6 h until 78 h, followed by 12 hourly intervals until 120 h of incubation.

2.3.3 Effect of Culture Medium Ratio on Bioflocculant Production

Batch cultures of UPMB13 in varying volume of TSB (100 mL, 250 mL and 500 mL) were prepared by inoculating 1 mL of the seed culture into each respective volume of TSB. Percentage flocculating activity measurements were done at 12 hourly intervals for 120 h.

2.3.4 Effect of Incubation Speed on Bioflocculant Production

Oxygen fluxes were introduced by means of varying incubation speed on an orbital shaker. Five speeds were selected: 100, 150, 200, 250 and 300 rpm. Percentage flocculating activities were measured every 24 h for three days to observe the effect on bioflocculant production.

2.3.5 Effect of Initial pH and Incubation Temperature on Bioflocculant Production

The initial pH of the culture media, adjusted with either HCl (1 N) or NaOH (1 N), were prepared for pH 5.0, 6.0, 7.0 and 8.0 (Su et al. 2012). Observations of the flocculating performances were done directly after 24 h to avoid further pH changes. Two ranges of incubation temperature were selected, namely 25-30 °C (Patil et al. 2009) and 37-40 °C (Bajaj and Singhal 2011b) provided by an incubator shaker. Percentage flocculating activities were measured at 24, 48, 72 and 96 h of incubation.

2.4 Determination of Bioflocculant Source among Culture Components

The source of bioflocculant produced among the culture components, broth, cell and supernatant, was determined. The cultured cells and cell-free supernatant were separated from the cultured broth by centrifugation at 4000 rpm for 10 min. The supernatant was then removed and put aside as the bioflocculant source for the cell-free supernatant. The centrifuged cells were washed with phosphate buffer solution (0.85 %) to create a cell suspension and again centrifuged before serving as the bioflocculant source for the cells.

2.5 Genetic Competence of B. subtilis UPMB13

UPMB13 genetic competence for continuous bioflocculant production was investigated. Each representative generation was prepared by sub-culturing TSA plate cultures of UPMB13, with the first generation being the one directly sub-cultured from the parent stock agar until the 10th generation. Batch cultures of 100 mL TSB of each generation were then prepared and the percentage flocculating activities were measured.

2.6 Extraction and Purification of the Bioflocculant

The culture broth of UPMB13 was first tested for flocculating activity through the kaolin assay. When the flocculating activity of the culture broth achieved 90 % and above, the culture broth was then centrifuged at 8000 x g for 10 min at 4 °C to separate the cells. The remaining supernatant was then added to 2 volumes of ice cold ethanol and left overnight at 4 °C to precipitate the bioflocculant. The precipitated bioflocculant was then collected by centrifugation at 12,000 x g for 15 min at 4 °C and re-suspended in ultra-pure water. Further impurities were separated via dialysis against ultra-pure water with minimum three times water change in 24 h at 4 °C. The resulting dialyzed suspension was then lyophilized to collect the pure bioflocculant.

2.7 Surface Morphology Imaging

The surface morphology of the freeze-dried purified bioflocculant was observed using a scanning electron microscope (SEM) Carl Zeiss EVO-MA10 (Canada). The samples attached to carbon stubs were gold-coated (Nwodo and Okoh 2012) twice and examined using the microscope at an accelerating voltage of 20.0 kV. Additionally, the surface morphology of the kaolin particles both before and after flocculation were also scanned and observed.

2.8 Data Analysis

For each experiment, a minimum of three replicates of UPMB13 cultures were prepared. Descriptive statistics for pattern and trend observations were determined with the mean and standard deviation values measured. Significant differences were analyzed through analysis of variance (ANOVA) at 0.05 confidence level. Additionally, where applicable, repeated measures ANOVA were used for data measured repeatedly in a timely basis.

3 Results and Discussion

3.1 L-Glutamic Acid Independent Production of Bioflocculants

Both L-glutamic acid and the citric acid inhibited UPMB13 growth, as the culture broths with the supplements, were observed to be clear and translucent after 48 h of incubation, suggestive of the absence of bacterial growth. In comparison, the control treatment without any added supplement were detected to be naturally viscous after 48 h of incubation (Table 1).

The upper phase of the treated kaolin suspension with the supplemented broth were observed to be clear, hence producing a measured flocculating activities of 71.7 % and 27.7 % for the LGA and the LGA + CA treatment, respectively. However, no floc formation was detected in both treatments (Table 1). In contrast, the control TSB media induced flocs formation with percentage flocculating activities measured at 81.7 % (p < 0.05). Charge de-stabilization of the kaolin particles might occur in the treated system by the LGA and LGA + CA treatments which explains the percentage flocculating activities measured, despite the absence of the bioflocculant.

Productions of γ-PGA by B. subtilis strains are usually L-glutamic acid dependent, while L-glutamic acid independent strains were described to be relatively unknown, and thus, less reported (Shih and Van 2001). Some of the L-glutamic acid independent bacteria reported to produce γ-PGA through the de novo production pathway (without supplement) includes B. subtilis TAM-4 (Ito et al. 1996), B. subtilis C1 (Shih et al. 2005) and B. subtilis C10 (Zhang et al. 2012). Among the studies on the production of γ-PGA by B. subtilis strains that were reported as bioflocculants (Yokoi et al. 1995; Yokoi et al. 1996; Wu and Ye 2007; Wang et al. 2008; Bajaj and Singhal 2011b; Bhunia et al. 2012) none were de novo producers of γ-PGA. Οther γ-PGAs produced through de novo pathways (Ito et al. 1996; Shih et al. 2005; Zhang et al. 2012) have not been reported as potential bioflocculants. In two rare cases, γ-PGA had been reported to be produced by Bacillus strains either with or without (de novo) the presence of glutamic acid (Mahmoud 2006; Xu et al. 2005). Therefore, B. subtilis UPMB13 is considered a novel de novo producer of bioflocculants as compared to other cases reported in the literature.

Production of EPS by B. subtilis strains has been reported to co-dependently rely on citric acid apart from the L-glutamic acid supplement (Bajaj and Singhal 2011a). Naturally, B. subtilis strains can utilize citric acid as an organic acid carbon source for growth. However, UPMB13 were notably different as citric acid supplement inhibited its growth. Xu et al. (2005) reported similarly for the strain B. subtilis NX-2 which could not incorporate citric acid during growth for γ-PGA production.

Hence, B. subtilis UPMB13 was concluded to be a de novo producer of bioflocculants in the absence of L-glutamic acid or citric acid supplements during growth.

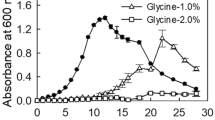

3.2 Bioflocculant Production during Growth

Time course for bioflocculant productions by B. subtilis UPMB13 are as depicted in Fig. 1. Bioflocculant presence at the early stage of UPMB13 growth was reflected by the 87.2 % flocculating activities measured and visible flocs formation observed at 24 h of incubation. The flocculating activities maintained above 80 % between 24 and 72 h (p > 0.05). This suggests that bioflocculant production by UPMB13 occurred parallel to its logarithmic growth rate. However, between 78 h and 120 h, decrements in flocculating activities were observed, although UPMB13 growth continued to proliferate. The relationship between growth of UPMB13 and bioflocculant production was analyzed using Pearson Product Moment correlation. There is a strong negative relationship (R = −0.787) between flocculating activities of the bioflocculant with growth (p < 0.01).

Okaiyeto et al. (2015) reported that the decrease in flocculating activities after 72 h of incubation could be due to deflocculating enzymes excreted by the strain during death phase. However, in this study, the growth of UPMB13 was observed to be maintained up to 120 h while flocculating activities were declining. Therefore, it was hypothesized that the limited nutrient supplied (100 mL) had led to the uptake of the bioflocculant already present in the culture by the cells as alternative food for growth, while productions of new bioflocculants were inhibited by the stressful conditions created by the scarcity of the food. This theory was proven by the results in the next section.

3.3 Effect of Culture Media Ratio on Bioflocculant Production

Consumption of the bioflocculants excreted into the culture media as substitute food source for growth was hypothesized to be the reason for the low flocculating performances observed in the later growth stage in Fig. 1. This theory was further tested by varying the ratio of culture media used to the inoculum and the results are as portrayed in Fig. 2.

Both the 250 mL and 500 mL (p > 0.05) cultures have significantly higher flocculating performances as compared to the 100 mL culture of UPMB13 (p < 0.05) after prolonged fermentations. With ample nutrients provided by the 250 mL and 500 mL culture, bioflocculant productions by UPMB13 were sustained until the 120 h as the percentage flocculating activities measured remained around 90 %. Contradictorily, the 100 mL culture experienced the normal decrease in flocculating performances with prolonged growth. Hence, it was proven that the bioflocculants already present in culture media excreted earlier were taken up by the strain to support further growth, while no new bioflocculants were produced in the stressful conditions of limited nutrients. It was reported by Kimura et al. (2004) that excreted EPS may be a source of food during starvation in the late stationary microbial growth phase.

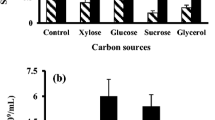

3.4 Effect of Oxygen Fluxes on Bioflocculant Production

Biopolymer yield in aerobic microbial processes depends greatly on oxygen fluxes provided through agitation and aeration during fermentations (Richard and Margaritis 2003). Figure 3 illustrates the flocculating performances of UPMB13 cultures subjected to different shaking speeds provided during incubation. Flocculating activities >80 % (p > 0.05) were recorded at the optimal incubation speeds of 100 to 200 rpm. Significantly poorer flocculation were observed for cultures agitated at speed higher than 200 rpm (p < 0.05).

Rapid bacterial growth at higher speed may result in the scarcity of food resources and leads to the re-uptake scenario of the excreted bioflocculant as alternative source for food. Excessive oxygen due to rapid agitations may also inhibit biopolymeric excretions as concentration of dissolved oxygen affects microbial nutrient absorption and enzymatic reaction for EPS productions (Su et al. 2012). Furthermore, inhibition of production could also be due to the rapid conversion of carbon source to carbon dioxide resulting from the increase in growth and respiration which led to a decrease in biopolymeric productions (Patil et al. 2010).

3.5 Effect of Initial pH on Bioflocculant Production

Optimum initial pH for bioflocculant productions by UPMB13 were at pH 7.0 to 8.0 with percentage flocculating activities measured >75 % (p > 0.05) (Fig. 4). Although the growth of UPMB13 were observed to be higher at pH 5.0 and 6.0, flocculating performances measured were significantly lower (p < 0.05). The unfavorable acidic nature of the culture media at these pH ranges might create stressful culture conditions that lower bioflocculant excretions by the strain (Ntsaluba et al. 2013).

As bioflocculant production occurs in parallel with growth, naturally the optimum pH for production would be similar to the pH that induces bacterial growth. However, for UPMB13, the initial pH of the culture media had more influence on bioflocculant production despite the level of growth. According to Prasertsan et al. (2008), the synthesis of the enzymes that are responsible for EPS excretion are pH dependent. Furthermore, it was reported that nutrient assimilation and enzymatic response of microorganisms for bioflocculant production may be affected by initial pH of the culture media (Aljuboori et al. 2013).

3.6 Effect of Incubation Temperature on Bioflocculant Production

Bioflocculant production was proven feasible in both temperature ranges with significantly different flocculating performances observed (p < 0.05). The 25-30 °C temperature range was proven optimum for both growth and bioflocculant production. In comparison, at higher temperature range of 37-40 °C, the growth and the flocculating performances of UPMB13 were observed to be inferior (Fig. 5).

While the growth of UPMB13 fluctuates in the temperature range of 25-30 °C between 24 h to 72 h, sustained bioflocculant productions were observed, reflected by the >70 % percentage flocculating activities measured throughout the assay. In contrast, the flocculating activities of UPMB13 grown at 37-40 °C decreased with time, although its growth proliferated towards the end of the test. This suggested that the available bioflocculant produced might be consumed back as food substitute that induces growth, and thus, lowered the flocculating performances.

Optimum growth temperatures for B. subtilis were reported to be at 30-37 °C with the minimum temperature of 18 °C and the maximum at 43 °C (Korsten and Cook 1996). However, for the purpose of bioflocculant production, it was concluded that the optimum temperature range for UPMB13 was 25-30 °C.

3.7 Distribution of Flocculating Abilities by Different Culture Parts

Distribution of flocculating abilities by separated culture parts reflects production source and determines the capacity of each part to be extracted and further purified (Liu and Cheng 2010). Naturally, bioflocculants productions by microorganism can be cellularly bounded or excreted extracellularly as slimes (Subramanian et al. 2009). Therefore, distribution of flocculating activities by different culture parts of UPMB13 was investigated (Fig. 6).

High flocculating activities around 89 % can be observed by both the culture broth and the cell-free supernatant (p > 0.05) with visible flocs formed. In comparison, the cells’ flocculating activities were significantly lower at only 39.4 % (p < 0.05), with no flocs formation observed. Charge destabilizations by the cation supplied may explain the percentage flocculating activities achieved by the cells apart from the residual bioflocculant activities that may adhere to the cell surfaces (Wei et al. 2008).

The results obtained proved that the bioflocculants are extracellularly produced by UPMB13 into the surrounding broth, exhibited by the cell-free supernatant similarly. Hence, the cell-free supernatant was chosen as the bioflocculant source for the extraction and characterization of the bioflocculant.

3.8 Genetic Competence for Continuous Bioflocculant Production

UPMB13 was proven to be genetically competent for continuous production of high performing bioflocculants as the ability to produce the bioflocculants persists up to its 10th generation progeny (Fig. 7).

Percentage flocculating activities measured for each generation fluctuated and were maintained above 80 % (p > 0.05) with an exception of the 10th generation, where a slight 9 % decrease can be seen compared to the highest measured performance at 86.9 % (p < 0.05). Visual assessment of flocs formation were also positive for all generations.

Continuous sub-culturing had been reported to cause loss of ropy and mucoid phenotypic expression of polysaccharides by the strain (Dierksen et al. 1997), whereby these characteristics are major contributors to bioflocculability. Furthermore, Shih and Wu (2009) reviewed that some B. subtilis strains have different genetic competency in EPS production. For instance, B. subtilis subsp. (natto) had been reported to be genetically incompetent in continuous production of γ-PGA. In other reported studies, genetic incompetency in bioflocculant production could be overcome through ion implantation (Peirui et al. 2008).

Hence, based on the results, it was proven that UPMB13 has the genetic competence in bioflocculant production even after incessant sub-culturing processes.

3.9 Microscopic Images of Purified Bioflocculant and Bioflocculation

From the optimum cultural conditions determined above, fermentation of 1 L batch cultures were prepared to extract the bioflocculant at its best measured performance based on the kaolin assays. About 0.90 g of purified bioflocculant can be collected from 1 L culture of UPMB13 in TSB.

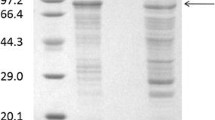

Figure 8a shows the image of the purified bioflocculant produce by UPMB13, while Fig. 8b and Fig. 8c display the microscopic images of the kaolin particles both before and after treated by the bioflocculant, respectively. The purified bioflocculant (Fig. 8a) appeared to be fibrous with smooth globular structures. These are the typical attributes of γ-PGA as observed by Yang (2011).

The un-flocculated kaolin particles (Fig. 8b) are scattered, dispersed and smaller in nature, while the flocculated kaolin particles (Fig. 8c) were observed to be clumped together and larger in comparison. According to Maximova and Dahl (2006), aggregated particles formed through induced polymeric flocculations and salt coagulations can be in the form of either loose or compact structures. Aggregates formed in a system with high salt concentrations with added polymeric bridging are loose in nature while those formed from the low coagulant concentration with added shear during bridging lead to the formation of compact aggregate structures. Therefore, referring back to Fig. 8c, it can be confirmed that the flocculated kaolin particles portrayed the properties of compact aggregated structures which were formed through the induced polymeric bridging of UPMB13 bioflocculant with applied shear and minimal cationic aid.

Similar observations were also reported by Nwodo et al. (2014), where the bioflocculated kaolin particles formed tightly weaved continuous structures with no evident spacing observed between the particles. Observations of these clumped, flocculated kaolin particles proved the binding and bridging treatment induced by the bioflocculant (Cosa et al. 2013).

4 Conclusions

Extracellular de novo synthesis (L-glutamic acid independent) of bioflocculants by B. subtilis UPMB13 were found to occur at an early logarithmic growth phase of 24–72 h of fermentation. Bioflocculant production was found to be negatively correlated with growth at a limited supply of 100 mL of tryptic soy broth media. Productions of high performing bioflocculants may be prolonged and sustained with optimal fermentation conditions of sufficient nutrients provided and suitable oxygen level supplied. Proliferation of bacterial growth occur at best at 25-30 °C and at the optimum pH of 6.0, while a pH of 7.0 was more preferable for early bioflocculant productions. Bioflocculant production through submerged fermentation of B. subtilis UPMB13 was proven feasible based on its genetic competency in continuous production of high performance bioflocculant. The results of the research can be useful in water treatment applications.

References

Aljuboori AHR, Idris A, Abdullah N, Mohamad R (2013) Production and characterization of a bioflocculant produced by Aspergillus flavus. Bioresource Technol 127:489–493. doi:10.1016/j.biortech.2012.09.016

Amir HG, Shamsuddin ZH, Halimi MS, Ramlan MF, Marziah M (2003) N2 fixation, nutrient accumulation and plant growth promotion by rhizobacteria in association with oil palm seedlings. Pakistan J Biol Sci 6:1269–1272

Bajaj I, Singhal R (2011a) Poly (glutamic acid): an emerging biopolymer of commercial interest. Bioresource Technol 102:5551–5561. doi:10.1016/j.biortech.2011.02.047

Bajaj I, Singhal R (2011b) Flocculation properties of poly(γ-glutamic acid) produced from Bacillus subtilis isolate. Food Bioprocess Tech 4:745–752. doi:10.1007/s11947-009-0186-y

Bhunia B, Mukhopadhy D, Goswami S, Mandal T, Dey A (2012) Improved production, characterization and flocculation properties of poly (γ)-glutamic acid produced from Bacillus subtilis. J Biochem Technol 3:389–394

Chen X, Chen S, Sun M, Yu Z (2005) Medium optimization by response surface methodology for poly-γ-glutamic acid production using dairy manure as the basis of a solid substrate. Appl Microbiol Biot 69:390–396. doi:10.1007/s00253-005-1989-z

Cosa S, Ugbenyen AM, Mabinya LV, Rumbold K, Okoh AI (2013) Characterization and flocculation efficiency of a bioflocculant produced by a marine Halobacillus. Environ Technol 34:2671–2679. doi:10.1080/09593330.2013.786104

Devesa-Rey R, Bustos G, Cruz J, Moldes A (2012) Evaluation of non-conventional coagulants to remove turbidity from water. Water Air Soil Poll 223:591–598. doi:10.1007/s11270-011-0884-8

Dierksen KP, Sandine WE, Trempy JE (1997) Expression of ropy and mucoid phenotypes in Lactococcus lactis. J Dairy Sci 80:1528–1536. doi:10.3168/jds.S0022-0302(97)76082-X

Ito Y, Tanaka T, Ohmachi T, Asada Y (1996) Glutamic acid independent production of poly (y-glutamic acid) by Bacillus subtilis TAM-4. Biosci Biotech Bioch 60:1239–1242. doi:10.1271/bbb.60.1239

Kimura K, Tran LSP, Uchida I, Itoh Y (2004) Characterization of Bacillus subtilis gamma-glutamyltransferase and its involvement in the degradation of capsule poly-gamma-glutamate. Microbiol 150:4115–4123. doi:10.1099/mic.0.27467-0

Korsten L, Cook N (1996) Optimizing culturing conditions for Bacillus subtilis. South Afric Avocado Grow Assoc Yearbook 19:54–58

Liu LF, Cheng W (2010) Characteristics and culture conditions of a bioflocculant produced by Penicillium sp. Biomed Environ Sci 23:213–218. doi:10.1016/S0895-3988(10)60055-4

Mahmoud DAR (2006) Isolation of polyglutamic acid flocculant producing bacteria from extreme egyptian environments. Journal of Applied Science Research 2:608–612

Maximova N, Dahl O (2006) Environmental implications of aggregation phenomena: current understanding. Curr Opin Colloid In 11:246–266. doi:10.1016/j.cocis.2006.06.001

Muthulakshmi L, Nellaiah H, Busi S (2013) Production and characterization of a novel bioflocculant from Klebsiella sp. Curr Biot 2:53–58

Ntsaluba L, Nwodo UU, Mabinya L, Okoh A (2013) Studies on bioflocculant production by a mixed culture of Methylobacterium sp. obi and Actinobacterium sp. mayor. BMC Biotechnol 13:1–7. doi:10.1186/1472-6750-13-62

Nwodo UU, Green E, Mabinya LV, Okaiyeto K, Rumbold K, Obi LC, Okoh AI (2014) Bioflocculant production by a consortium of Streptomyces and Cellulomonas species and media optimization via surface response model. Colloid Surface B 116:257–264. doi:10.1016/j.colsurfb.2014.01.008

Nwodo UU, Okoh AI (2012) Characterization and flocculation properties of biopolymeric flocculant (glycosaminoglycan) produced by Cellulomonas sp. Okoh J Appl Microbiol 114:1325–1337. doi:10.1111/jam.12095

Okaiyeto K, Nwodo UU, Mabinya LV, Okoli AS, Okoh AI (2015) Characterization of a bioflocculant (MBF-UFH) produced by Bacillus sp. AEMREG7. Int J Mol Sci 16:12986–13003. doi:10.3390/ijms160612986

Patil S, Salunkhe R, Patil C, Patil D, Salunke B (2010) Bioflocculant exopolysaccharide production by Azotobacter indicus using flower extract of Madhuca latifolia L. Appl Biochem Biotech 162:1095–1108. doi:10.1007/s12010-009-8820-8

Patil SV, Bathe GA, Patil AV, Patil RH, Salunkea BK (2009) Production of bioflocculant exopolysaccharide by Bacillus subtilis. Adv Biot 8:14–17

Peirui L, Zongwei L, Zongyi L, Guangyong Q, Yuping H (2008) Screening of bioflocculant-producing strain by ion implantation and flocculating characteristics of bioflocculants. Plasma Sci Technol 10:394. doi:10.1088/1009-0630/10/3/26

Prasertsan P, Wichienchot S, Doelle H, Kennedy JF (2008) Optimization for biopolymer production by Enterobacter cloacae WD7. Carbohyd Polym 71:468–475. doi:10.1016/j.carbpol.2007.06.017

Richard A, Margaritis A (2003) Rheology, oxygen transfer, and molecular weight characteristics of poly(glutamic acid) fermentation by Bacillus subtilis. Biotechnol Bioeng 82:299–305. doi:10.1002/bit.10568

Salehizadeh H, Yan N (2014) Recent advances in extracellular biopolymer flocculants. Biotechnol Adv 32:1506–1522. doi:10.1016/j.biotechadv.2014.10.004

Shih IL, Van YT (2001) The production of poly-(γ-glutamic acid) from microorganisms and its various applications. Bioresource Technol 79:207–225. doi:10.1016/S0960-8524(01)00074-8

Shih L, Wu JY (2009) Biosynthesis and application of poly (γ-glutamic acid). In: Bernd R (ed) Microbial production of biopolymers and polymer precursors: applications and perspectives. Horizon Scientific Press, Norfolk, pp. 101–141

Shih IL, Wu PJ, Shieh CJ (2005) Microbial production of a poly(γ-glutamic acid) derivative by Bacillus subtilis. Process Biochem 40:2827–2832. doi:10.1016/j.procbio.2004.12.009

Su X, Shen X, Ding L, Yokota A (2012) Study on the flocculability of the Arthrobacter sp., an actinomycete resuscitated from the VBNC state. World J Microb Biot 28:91–97. doi:10.1007/s11274-011-0795-2

Subramanian SB, Yan S, Tyagi RD, Surampalli RY (2009) Bioflocculants. In: Tyagi RD, Surampalli RY, Yan S, Zhang TC, Kao CM, Lohani BN (eds) Sustainable sludge management. American Society of Civil Engineers, Reston, pp. 146–167

Wang X, Zhang Y, Zhong W (2008) Poly-γ-glutamic acid production by novel isolated Bacillus subtilis zjutzy and its flocculating character. J Biotechnol 136:S43

Wei W, Fang M, Xiuli Y, Aijie W (2008) Purification and characterization of compound bioflocculant. In: The 2nd international conference on bioinformatics and biomedical engineering. Shanghai, IEEE, pp. 1127–1130. doi:10.1109/ICBBE.2008.275

Wong YS, Ong SA, Teng TT, Aminah LN, Kumaran K (2012) Production of bioflocculant by Staphylococcus cohnii sp. from palm oil mill effluent (POME). Water Air Soil Poll 223:3775–3781. doi:10.1007/s11270-012-1147-z

Wu JY, Ye HF (2007) Characterization and flocculating properties of an extracellular biopolymer produced from a Bacillus subtilis DYU1 isolate. Process Biochem 42:1114–1123. doi:10.1016/j.procbio.2007.05.006

Xu H, Jiang M, Li H, Lu D, Ouyang P (2005) Efficient production of poly(γ-glutamic acid) by newly isolated Bacillus subtilis NX-2. Process Biochem 40:519–523. doi:10.1016/j.procbio.2003.09.025

Yang X (2011) Preparation and characterization of γ-poly (glutamic acid) copolymer with glycol diglycidyl ether. Procedia Environmental Sciences 8:11–15. doi:10.1016/j.proenv.2011.10.004

Yokoi H, Arima T, Hirose J, Hayashi S, Takasaki Y (1996) Flocculation properties of poly([γ]-glutamic acid) produced by Bacillus subtilis. J Ferment Bioeng 82:84–87. doi:10.1016/0922-338X(96)89461-X

Yokoi H, Natsuda O, Hirose J, Hayashi S, Takasaki Y (1995) Characteristics of a biopolymer flocculant produced by Bacillus sp. PY-90. J Ferment Bioeng 79:378–380. doi:10.1016/0922-338X(95)94000-H

Yu W, Chen Z, Shen L, Wang Y, Li Q, Yan S, Zhong CJ, He N (2015) Proteomic profiling of Bacillus licheniformis reveals a stress response mechanism in the synthesis of extracellular polymeric flocculants. Biotechnol Bioeng 9999:1–10. doi:10.1002/bit.25838

Zhang H, Zhu J, Zhu X, Cai J, Zhang A, Hong Y, Huang J, Huang L, Xu Z (2012) High-level exogenous glutamic acid-independent production of poly-(γ-glutamic acid) with organic acid addition in a new isolated Bacillus subtilis C10. Bioresource Technol 116:241–246. doi:10.1016/j.biortech.2011.11.085

Zulkeflee Z, Aris AZ, Shamsuddin ZH, Yusoff MK (2012) Cation dependence, pH tolerance, and dosage requirement of a bioflocculant produced by Bacillus spp. UPMB13: flocculation performance optimization through kaolin assays. Sci World J. doi:10.1100/2012/495659

Acknowledgments

This research has been funded by the Spanish Ministerio de Economia y Competitividad (project CTM2015-69513-R). Dimitrios Komilis thanks Tecniospring for the financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zulkeflee, Z., Shamsuddin, Z.H., Aris, A.Z. et al. Glutamic Acid Independent Production of Bioflocculants by Bacillus subtilis UPMB13. Environ. Process. 3, 353–367 (2016). https://doi.org/10.1007/s40710-016-0161-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40710-016-0161-3

) and 37-40 °C (

) and 37-40 °C ( ) and the growth at 25-30 °C (

) and the growth at 25-30 °C ( ) and 37-40 °C (X). Flocs were present in all treatments

) and 37-40 °C (X). Flocs were present in all treatments